Preparation and Characterization of Low-Carbon Cementitious Materials Based on Soda-Residue-Activated Ground Granulated Blast-Furnace Slag: A Case Study on Cemented Paste Backfills

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Test Methods

3. Results and Discussion

3.1. XRD Analysis

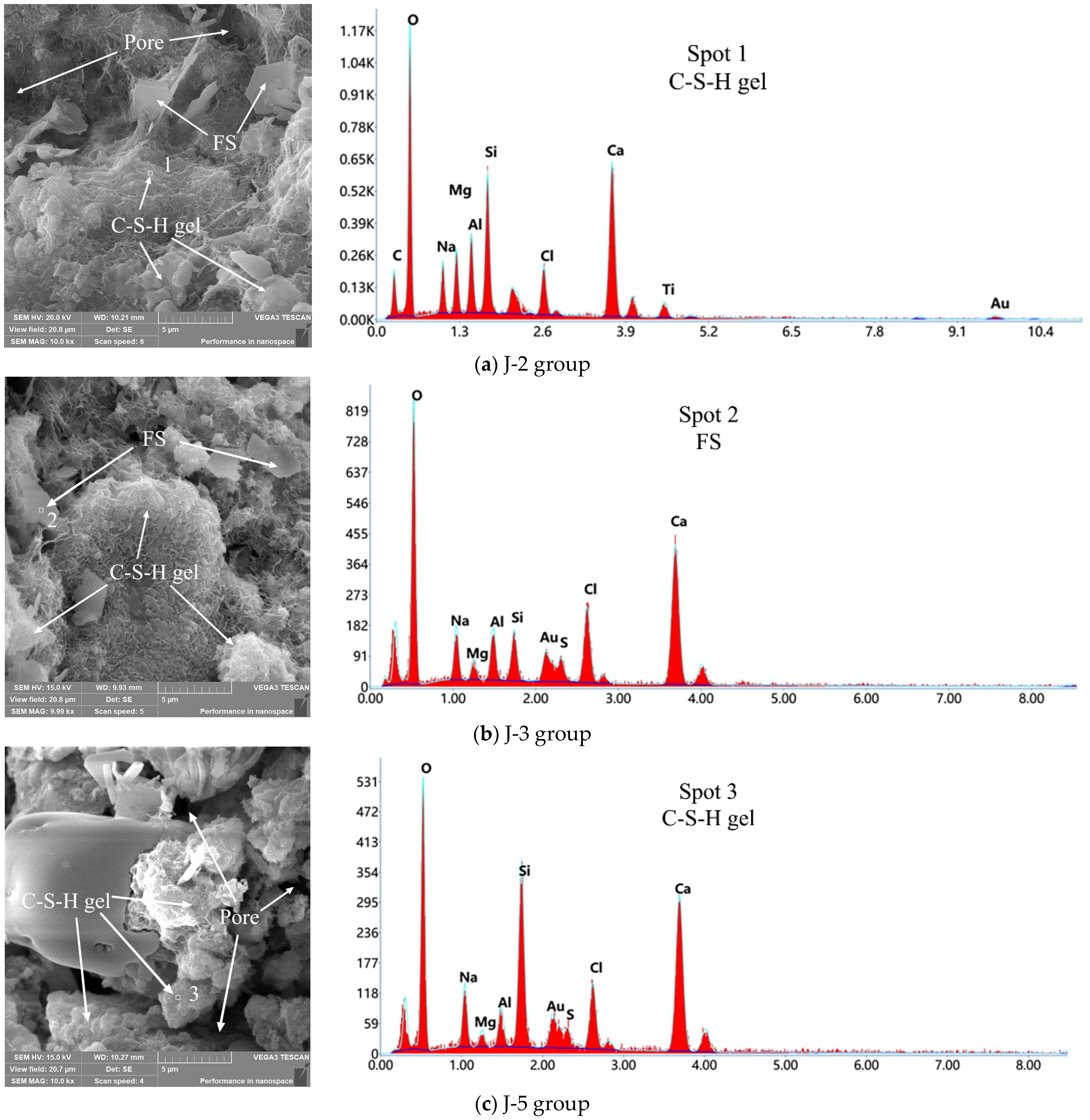

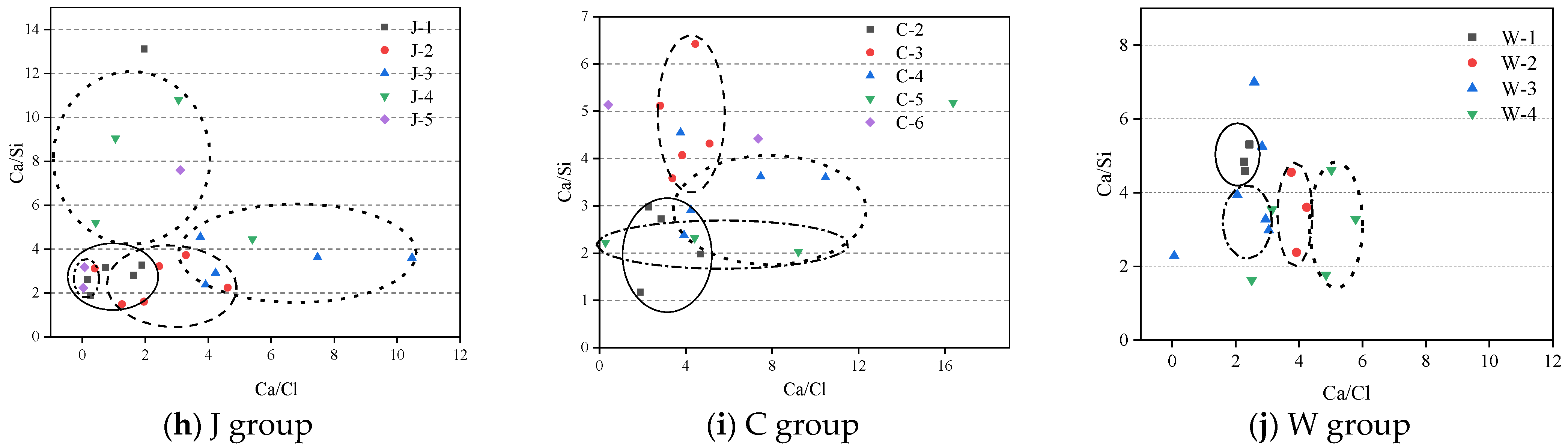

3.2. SEM Analysis

3.3. FTIR Analysis

3.4. TG-DTG Analysis

3.5. Discussion

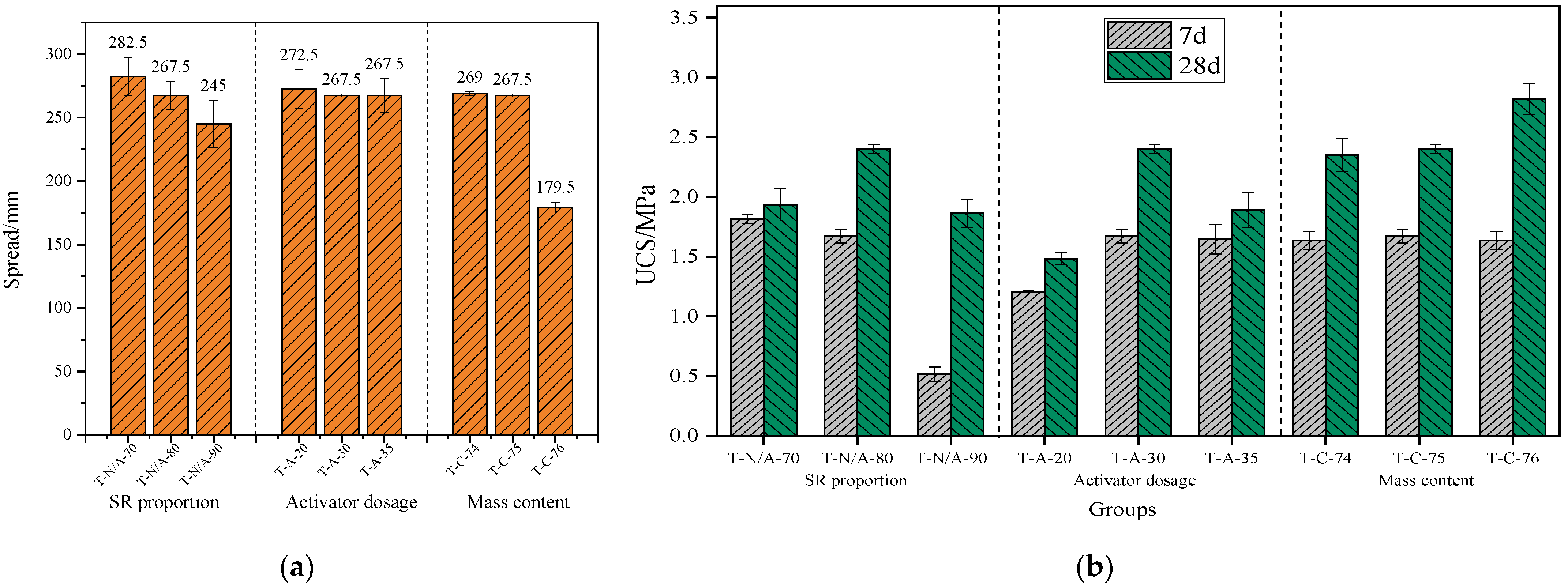

4. A Case-Study Preparation of CPB

Results and Discussion

5. Conclusions

- Under the synergistic effect of NaOH-SR, the hydration products of GGBS were mainly C-S-H gel, C-A-S-H gel, and hydrated calcium chloroaluminate [3CaO·Al2O3·CaCl2·10H2O, FS]. With the increase in SR proportion, the hydration reaction weakens, the generated quantity of C-S-H gel reduces, and the generated FS content increases. When the SR proportion is 80%, the reaction of hydration of GGBS is much more adequate with the synergistic effect of NaOH and SR.

- When the activator dosage is lower than 20%, more unreacted GGBS particles are found. When the activator dosage was more than 35%, excess OH− inhibits the generation of C-S-H gel, and there were more SR particles and NaCl crystals that had not reacted. The reaction of hydration of GGBS is relatively adequate when the activator dosage is between 20% and 35%.

- The GGBS synergistically reactivated by NaOH-SR is used as cementing materials, and iron tailings are used as aggregates to prepare the CPB. When the mass content is 75%, the SR proportion is 80%, and the activator dosage is 30%, the fluidity of the CPB prepared is 267.5 mm and a UCS of 2.4 MPa at 28 days. In this proportion of cemented filling material, both performance and cost aspects meet the requirements of the CPB.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dener, M.; Karatas, M.; Mohabbi, M. High temperature resistance of self compacting alkali activated slag/portland cement composite using lightweight aggregate. Constr. Build. Mater. 2021, 290, 123250. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Z.; Zhuang, S.; He, W. Hydration properties and microstructure characteristics of alkali–activated steel slag. Constr. Build. Mater. 2020, 241, 118141. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M. Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Jiang, D.; Li, X.; Lv, Y.; Li, C.; Jiang, W.; Liu, Z.; Xu, J.; Zhou, Y.; Dan, J. Autogenous shrinkage and hydration property of alkali activated slag pastes containing superabsorbent polymer. Cem. Concr. Res. 2021, 149, 106581. [Google Scholar] [CrossRef]

- Shariati, M.; Shariati, A.; Trung, N.T.; Shoaei, P.; Ameri, F.; Bahrami, N.; Zamanabadi, S.N. Alkali-activated slag (AAS) paste: Correlation between durability and microstructural characteristics. Constr. Build. Mater. 2021, 267, 120886. [Google Scholar] [CrossRef]

- Le, T.-T.; Park, S.-S.; Lee, J.-C.; Lee, D.-E. Strength characteristics of spent coffee grounds and oyster shells cemented with GGBS-based alkaline-activated materials. Constr. Build. Mater. 2021, 267, 120986. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L. 29Si and 27Al NMR study of alkali-activated slag. Cem. Concr. Res. 2003, 33, 769–774. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L. Hydration products of alkali activated slag cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Ben Haha, M.; Le Saout, G.; Winnefeld, F.; Lothenbach, B. Influence of activator type on hydration kinetics, hydrate assemblage and microstructural development of alkali activated blast-furnace slags. Cem. Concr. Res. 2011, 41, 301–310. [Google Scholar] [CrossRef]

- Chen, W.; Li, B.; Wang, J.; Thom, N. Effects of alkali dosage and silicate modulus on autogenous shrinkage of alkali-activated slag cement paste. Cem. Concr. Res. 2021, 141, 106322. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Chen, B. Strength evolutions of varying water content-dredged sludge stabilized with alkali-activated ground granulated blast-furnace slag. Constr. Build. Mater. 2021, 275, 122111. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, B.; Guo, S.; Long, G.; Xie, Y. Properties and characterization of green one-part geopolymer activated by composite activators. J. Clean. Prod. 2019, 220, 188–199. [Google Scholar] [CrossRef]

- Rashad, A.M.; Bai, Y.; Basheer, P.A.M.; Milestone, N.B.; Collier, N.C. Hydration and properties of sodium sulfate activated slag. Cem. Concr. Compos. 2013, 37, 20–29. [Google Scholar] [CrossRef]

- Jin, F.; Al-Tabbaa, A. Strength and drying shrinkage of slag paste activated by sodium carbonate and reactive MgO. Constr. Build. Mater. 2015, 81, 58–65. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Binding mechanism and properties of alkali-activated fly ash/slag mortars. Constr. Build. Mater. 2013, 40, 291–298. [Google Scholar] [CrossRef]

- Abdalqader, A.F.; Jin, F.; Al-Tabbaa, A. Development of greener alkali-activated cement: Utilisation of sodium carbonate for activating slag and fly ash mixtures. J. Clean. Prod. 2016, 113, 66–75. [Google Scholar] [CrossRef]

- Zhao, D. Reactive MgO-modified slag-based binders for cemented paste backfill and potential heavy-metal leaching behavior. Constr. Build. Mater. 2021, 298, 123894. [Google Scholar] [CrossRef]

- Xu, D.; Ni, W.; Wang, Q.; Xu, C.; Li, K. Ammonia-soda residue and metallurgical slags from iron and steel industries as cementitious materials for clinker-free concretes. J. Clean. Prod. 2021, 307, 127262. [Google Scholar] [CrossRef]

- Li, W.; Yi, Y. Use of carbide slag from acetylene industry for activation of ground granulated blast-furnace slag. Constr. Build. Mater. 2020, 238, 117713. [Google Scholar] [CrossRef]

- He, J.; Shi, X.-K.; Li, Z.-X.; Zhang, L.; Feng, X.-Y.; Zhou, L.-R. Strength properties of dredged soil at high water content treated with soda residue, carbide slag, and ground granulated blast furnace slag. Constr. Build. Mater. 2020, 242, 118126. [Google Scholar] [CrossRef]

- Sun, R.; Fang, C.; Zhang, H.; Ling, Y.; Feng, J.; Qi, H.; Ge, Z. Chemo-mechanical properties of alkali-activated slag/fly ash paste incorporating white mud. Constr. Build. Mater. 2021, 291, 123312. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, Z.; Bai, Y.; Zhao, G.; Sang, Z.; Zhao, Q. Development and characterization of a new multi-strength level binder system using soda residue-carbide slag as composite activator. Constr. Build. Mater. 2021, 291, 123367. [Google Scholar] [CrossRef]

- Feng, Y.; Qi, W.; Zhao, Q.; Huang, Y.; Ren, Q.; Qi, W.; Kong, F. Synthesis and characterization of cemented paste backfill: Reuse of multiple solid wastes. J. Clean. Prod. 2023, 383, 135376. [Google Scholar] [CrossRef]

- Zhan, X.; Wang, L.; Wang, L.; Wang, X.; Gong, J.; Yang, L.; Bai, J. Enhanced geopolymeric co-disposal efficiency of heavy metals from MSWI fly ash and electrolytic manganese residue using complex alkaline and calcining pre-treatment. Waste Manag. 2019, 98, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Wang, S.; Xu, Z.; Zhang, Z.; Zhang, C.; Bai, Y.; Zhao, Q. Mechanical performance and microstructure improvement of soda residue–carbide slag–ground granulated blast furnace slag binder by optimizing its preparation process and curing method. Constr. Build. Mater. 2021, 302, 124403. [Google Scholar] [CrossRef]

- Mollah, M.Y.A.; Yu, W.; Schennach, R.; Cocke, D.L. A Fourier transform infrared spectroscopic investigation of the early hydration of Portland cement and the influence of sodium lignosulfonate. Cem. Concr. Res. 2000, 30, 267–273. [Google Scholar] [CrossRef]

- Yu, P.; Kirkpatrick, R.J.; Poe, B.; McMillan, P.F.; Cong, X. Structure of Calcium Silicate Hydrate (C-S-H): Near-, Mid-, and Far-Infrared Spectroscopy. J. Am. Ceram. Soc. 2004, 82, 742–748. [Google Scholar] [CrossRef]

- Petlovanyi, M.V.; Zubko, S.A.; Popovych, V.V.; Sai, K.S. Physicochemical mechanism of structure formation and strengthening in the backfill massif when filling underground cavities. Vopr. Khimii I Khimicheskoi Tekhnologii 2020, 6, 142–150. [Google Scholar] [CrossRef]

- Tian, Z.; Ye, H. Electrical resistivity of partially-saturated alkali-activated slag containing sodium nitrite admixture. Cem. Concr. Compos. 2021, 120, 104053. [Google Scholar] [CrossRef]

- Reig, F. FTIR quantitative analysis of calcium carbonate (calcite) and silica (quartz) mixtures using the constant ratio method. Application to geological samples. Talanta 2002, 58, 811–821. [Google Scholar] [CrossRef]

- García Lodeiro, I.; Macphee, D.E.; Palomo, A.; Fernández-Jiménez, A. Effect of alkalis on fresh C–S–H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Gu, Y.-M.; Fang, Y.-H.; You, D.; Gong, Y.-F.; Zhu, C.-H. Properties and microstructure of alkali-activated slag cement cured at below- and about-normal temperature. Constr. Build. Mater. 2015, 79, 1–8. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, D.; Zhao, X. Effect of Soda Residue Addition and Its Chemical Composition on Physical Properties and Hydration Products of Soda Residue-Activated Slag Cementitious Materials. Materials 2020, 13, 1789. [Google Scholar] [CrossRef] [PubMed]

- Ubbrìaco, P.; Calabrese, D. Hydration Behaviour of Mixtures of Cement and Fly Ash with High Sulphate and Chloride Content. J. Therm. Anal. Calorim. 2000, 61, 615–623. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, Z.-G.; Huang, X.; Bai, X.-H. Effect of Friedel’s salt on strength enhancement of stabilized chloride saline soil. J. Cent. South Univ. 2017, 24, 937–946. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, H.; He, X.; Yang, W.; Deng, X. Utilization of carbide slag-granulated blast furnace slag system by wet grinding as low carbon cementitious materials. Constr. Build. Mater. 2020, 249, 118763. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Gao, X.; Yu, Q.L.; Brouwers, H.J.H. Reaction kinetics, gel character and strength of ambient temperature cured alkali activated slag–fly ash blends. Constr. Build. Mater. 2015, 80, 105–115. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Yao, G.; Zhu, X.; Hu, S.; Qiu, J.; Chen, P.; Lyu, X. Characterization of the mechanical properties and microcosmic mechanism of Portland cement prepared with soda residue. Constr. Build. Mater. 2020, 241, 117994. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Mamaikin, O. Assessment of an expediency of binder material mechanical activation in cemented rockfill. J. Eng. Appl. Sci. 2019, 14, 3492–3503. [Google Scholar]

- Xue, G.; Yilmaz, E.; Song, W.; Cao, S. Compressive Strength Characteristics of Cemented Tailings Backfill with Alkali-Activated Slag. Appl. Sci. 2018, 8, 1573. [Google Scholar] [CrossRef]

- Wang, S.; Song, X.; Wei, M.; Liu, W.; Wang, X.; Ke, Y.; Tao, T. Strength characteristics and microstructure evolution of cemented tailings backfill with rice straw ash as an alternative binder. Constr. Build. Mater. 2021, 297, 123780. [Google Scholar] [CrossRef]

| Material | CaO | Al2O3 | SiO2 | MgO | SO3 | Na2O | Fe2O3 | K2O | TiO2 | P2O5 | Cl | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GGBS | 31.30 | 17.60 | 35.20 | 8.00 | 3.00 | 0.71 | 0.80 | 0.57 | 2.32 | - | - | 0.50 |

| SR | 40.30 | 2.09 | 9.02 | 10.00 | 6.41 | 3.58 | 0.59 | 0.31 | - | - | 27.40 | 0.30 |

| Influence Factor | Specimen No. | W/C | Mix Proportion of Binders by Weight (%) | SR/Activator (%) | Cure Time | ||

|---|---|---|---|---|---|---|---|

| GGBS | SR | SH | |||||

| SR/(SR + SH) | J-1 | 0.5 | 70 | 21 | 9 | 70 | 28 d |

| J-2 | 70 | 22.5 | 7.5 | 75 | |||

| J-3 | 70 | 24 | 6 | 80 | |||

| J-4 | 70 | 25.5 | 4.5 | 85 | |||

| J-5 | 70 | 27 | 3 | 90 | |||

| SR + SH | C-1 | 0.5 | 85 | 12 | 3 | 80 | 28 d |

| C-2 | 80 | 16 | 4 | ||||

| C-3 | 75 | 20 | 5 | ||||

| C-4 | 70 | 24 | 6 | ||||

| C-5 | 65 | 28 | 7 | ||||

| C-6 | 60 | 32 | 8 | ||||

| W/B | W-1 | 0.4 | 70 | 24 | 6 | 80 | 28 d |

| W-2 | 0.5 | 70 | 24 | 6 | |||

| W-3 | 0.6 | 70 | 24 | 6 | |||

| W-4 | 0.7 | 70 | 24 | 6 | |||

| Trial Mix | Mass Content (%) | Activator Dosage (%) | SH (%) | SR (%) | Temp. (°C) | Mixing Water | |

|---|---|---|---|---|---|---|---|

| Impact of Mass content | T-C-76 | 76 | - | - | - | - | - |

| T-C-75 | 75 | 30 | 20 | 80 | 20 | tap water | |

| T-C-74 | 74 | - | - | - | - | - | |

| Impact of Activator dosage | T-A-20 | - | 20 | - | - | - | - |

| T-A-30 | 75 | 30 | 20 | 80 | 20 | tap water | |

| T-A-35 | - | 35 | - | - | - | - | |

| Impact of SR proportion | T-N/A-70 | - | - | 30 | 70 | - | - |

| T-N/A-80 | 75 | 30 | 20 | 80 | 20 | tap water | |

| T-N/A-90 | - | - | 10 | 90 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Q.; Qi, W.; Zhao, Q.; Jia, Y.; Feng, Y.; Han, Y.; Duan, G.; Pang, H. Preparation and Characterization of Low-Carbon Cementitious Materials Based on Soda-Residue-Activated Ground Granulated Blast-Furnace Slag: A Case Study on Cemented Paste Backfills. Metals 2023, 13, 694. https://doi.org/10.3390/met13040694

Ren Q, Qi W, Zhao Q, Jia Y, Feng Y, Han Y, Duan G, Pang H. Preparation and Characterization of Low-Carbon Cementitious Materials Based on Soda-Residue-Activated Ground Granulated Blast-Furnace Slag: A Case Study on Cemented Paste Backfills. Metals. 2023; 13(4):694. https://doi.org/10.3390/met13040694

Chicago/Turabian StyleRen, Qiangsheng, Wenyue Qi, Qingxin Zhao, Yali Jia, Yabin Feng, Yongji Han, Ge Duan, and Haotian Pang. 2023. "Preparation and Characterization of Low-Carbon Cementitious Materials Based on Soda-Residue-Activated Ground Granulated Blast-Furnace Slag: A Case Study on Cemented Paste Backfills" Metals 13, no. 4: 694. https://doi.org/10.3390/met13040694

APA StyleRen, Q., Qi, W., Zhao, Q., Jia, Y., Feng, Y., Han, Y., Duan, G., & Pang, H. (2023). Preparation and Characterization of Low-Carbon Cementitious Materials Based on Soda-Residue-Activated Ground Granulated Blast-Furnace Slag: A Case Study on Cemented Paste Backfills. Metals, 13(4), 694. https://doi.org/10.3390/met13040694