A Review on the Corrosion and Fatigue Failure of Gas Turbines

Abstract

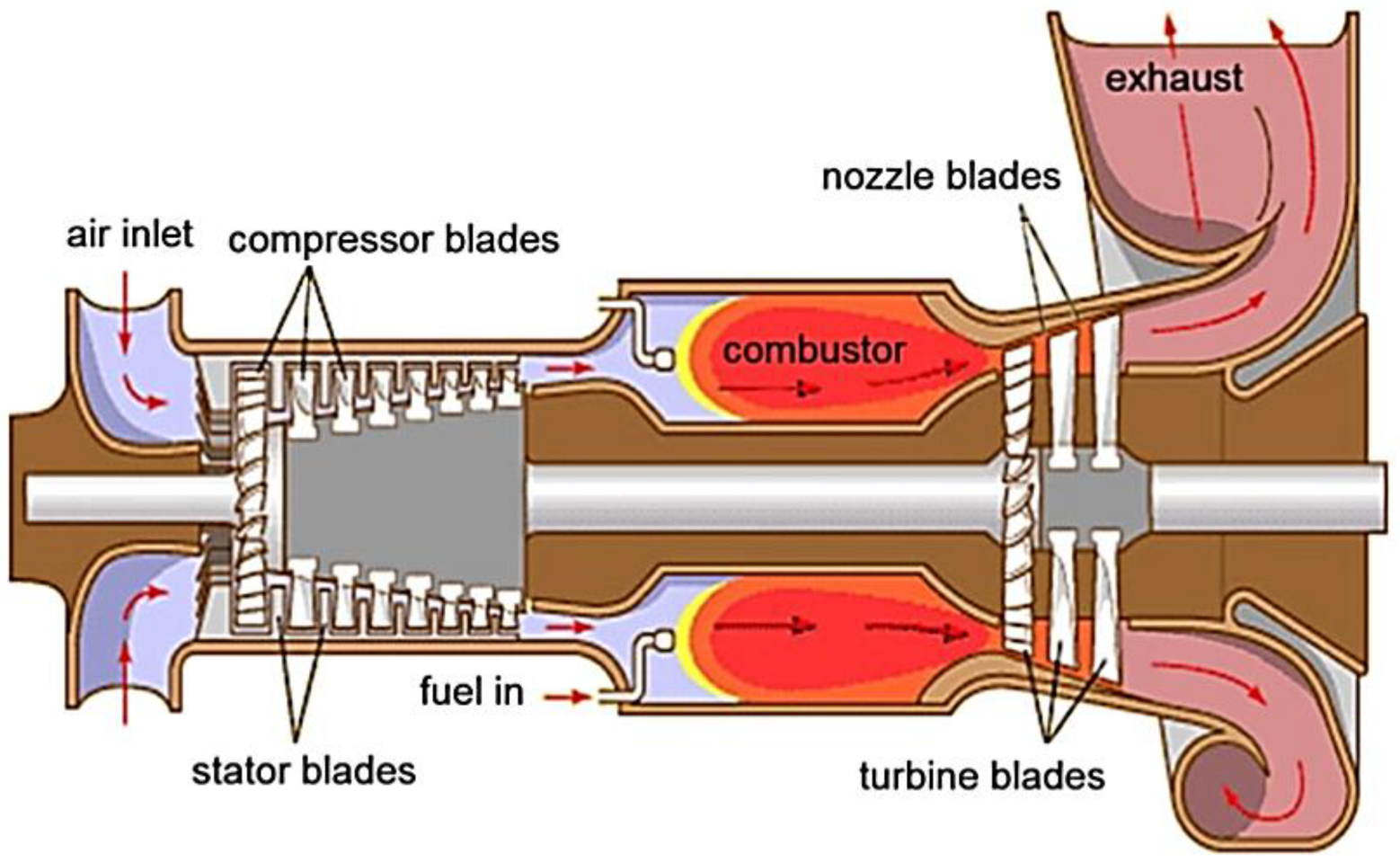

:1. Introduction

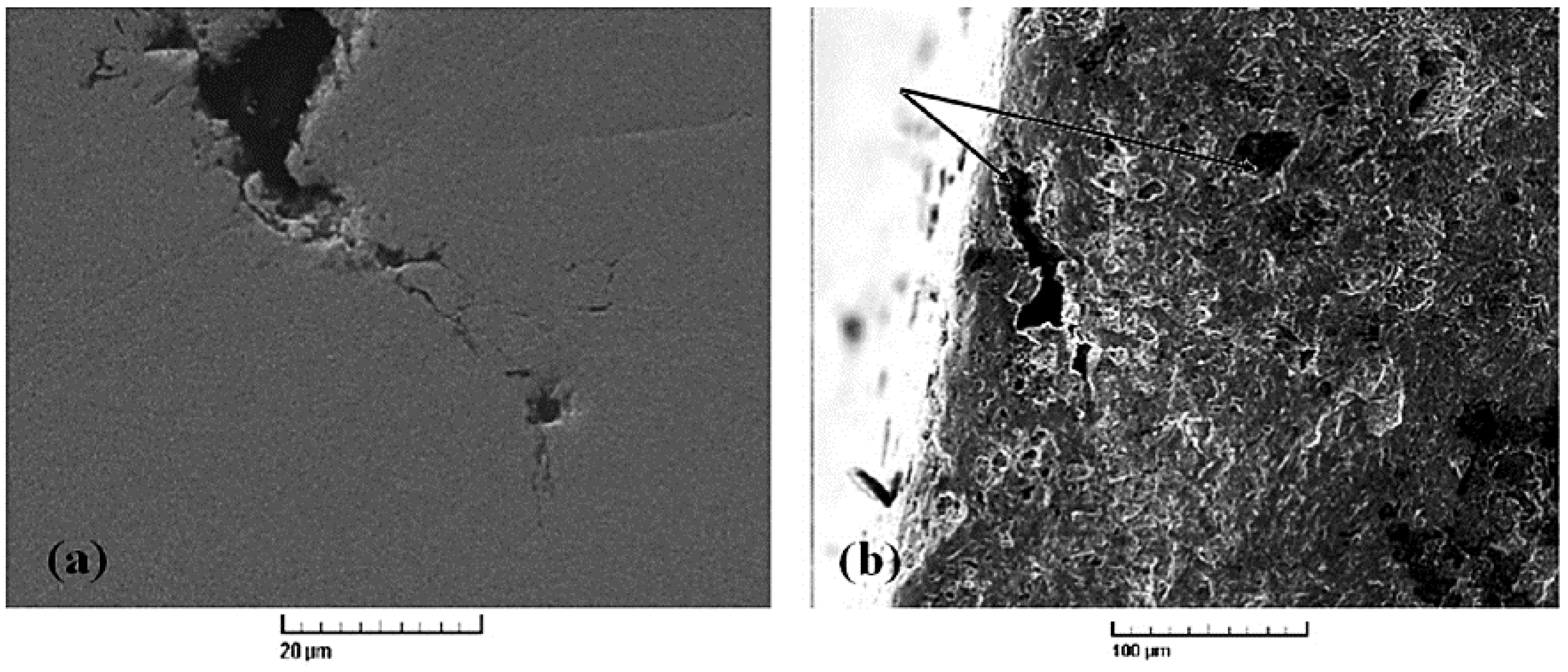

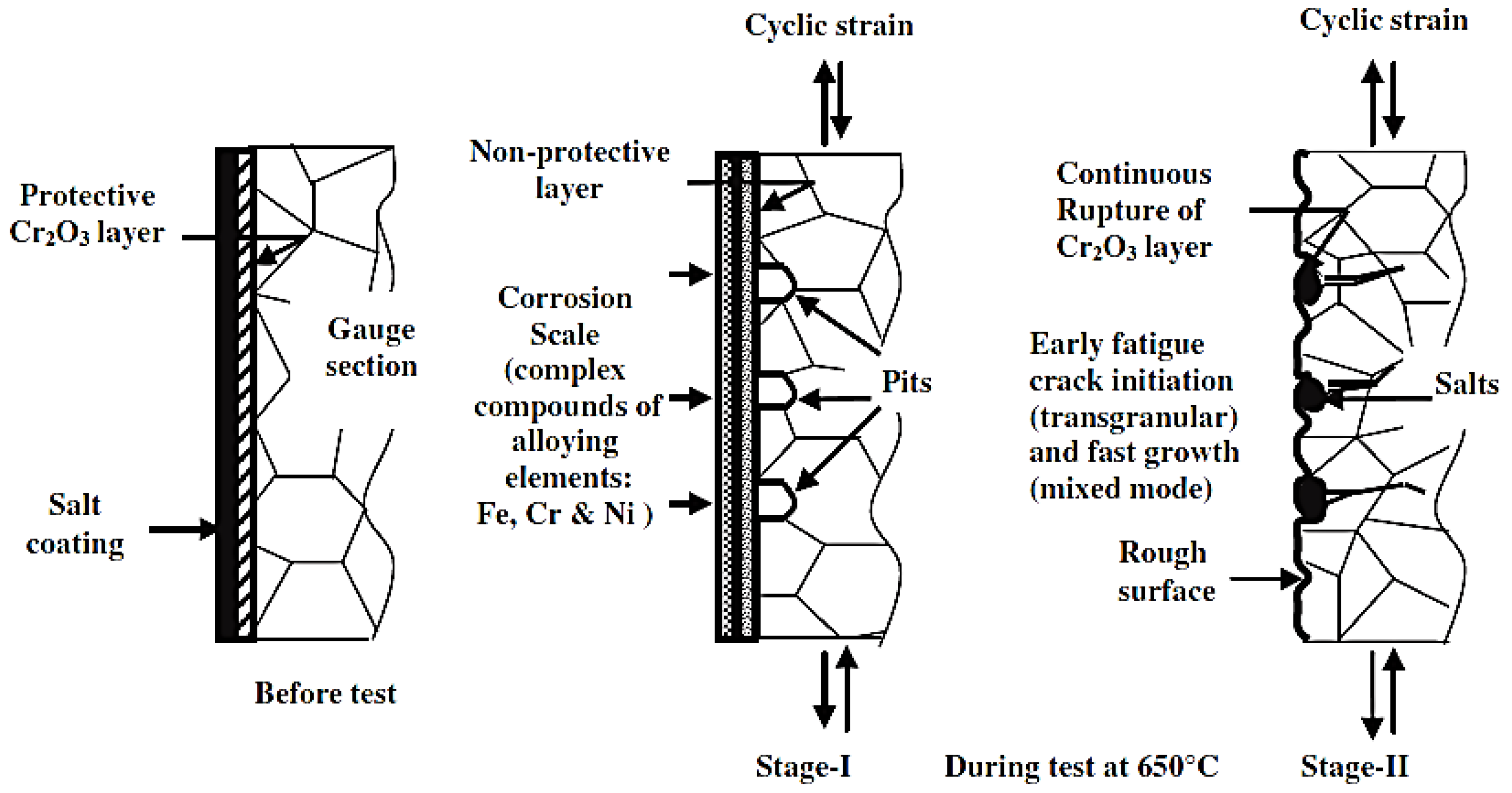

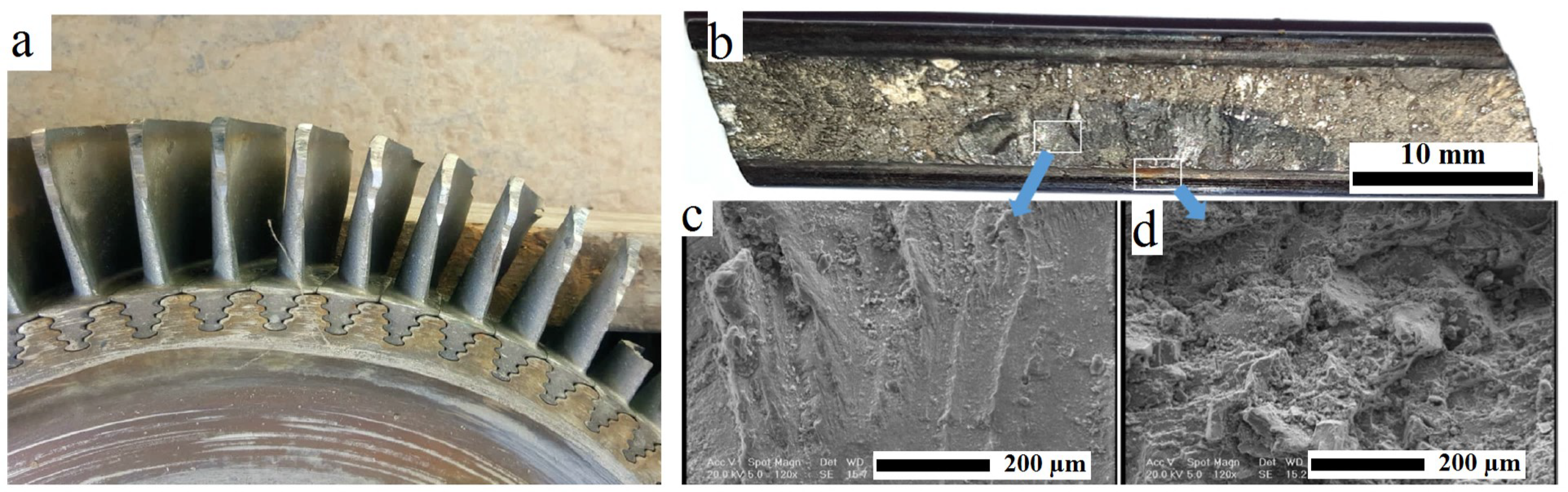

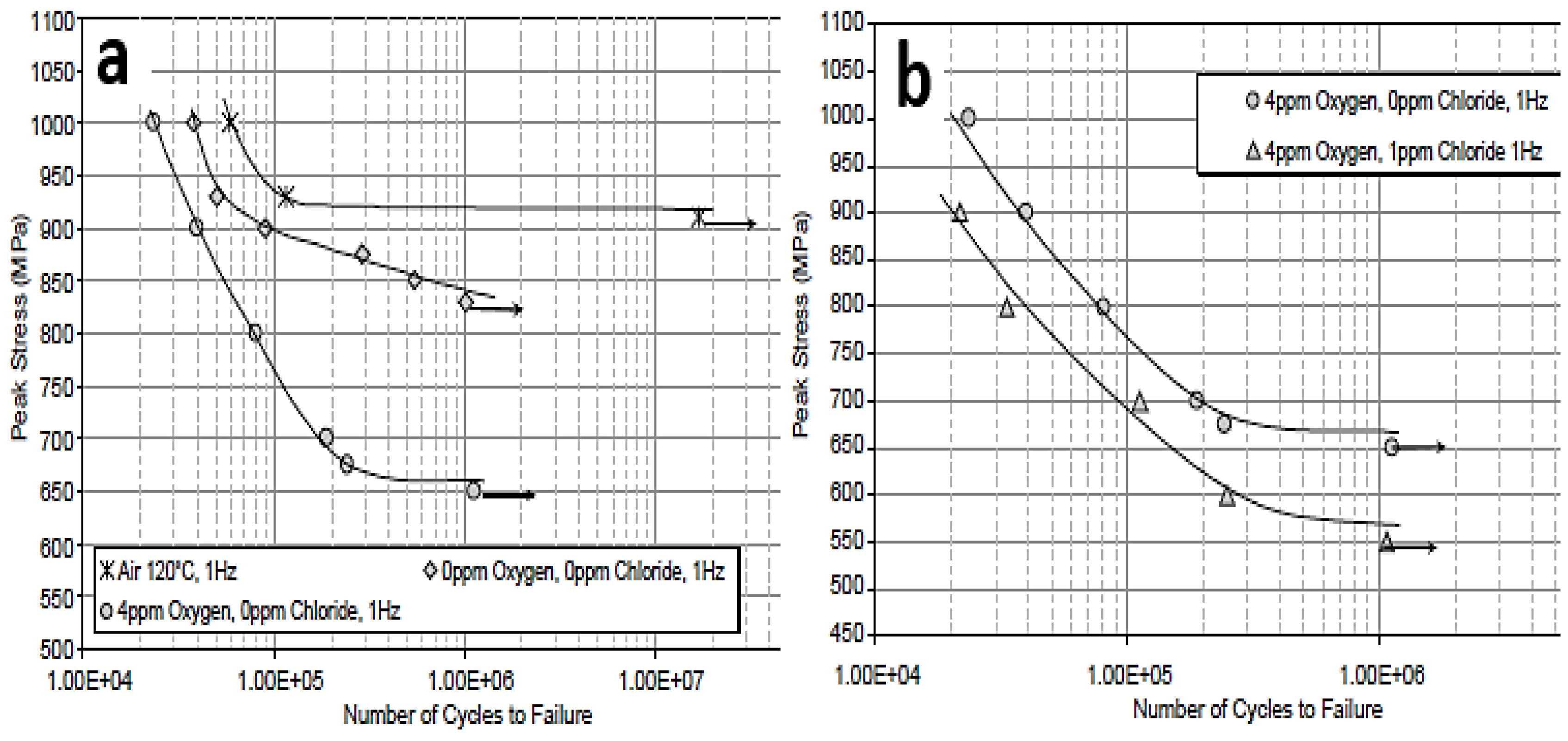

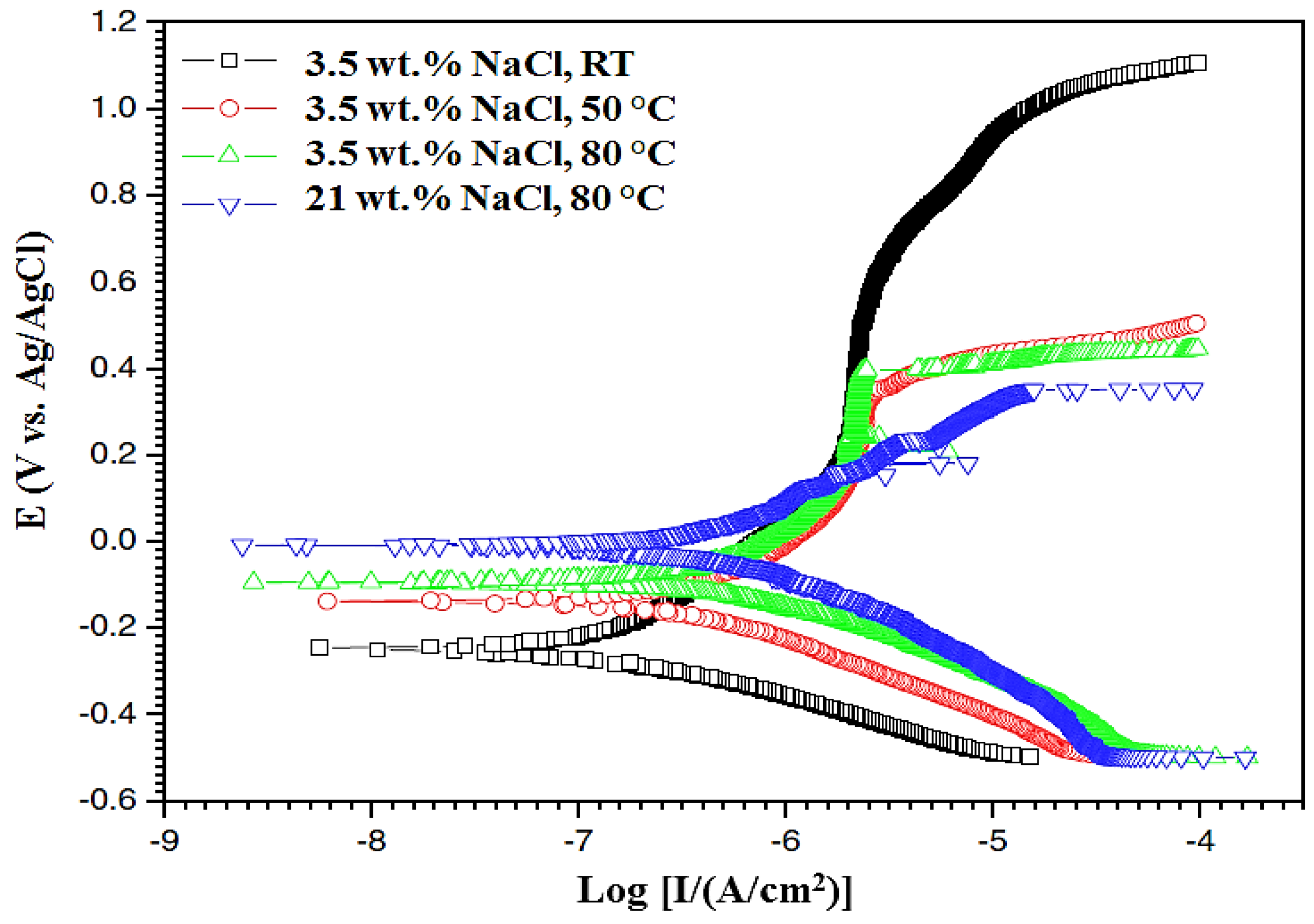

2. Corrosion Fatigue

3. Hot Corrosion Fatigue

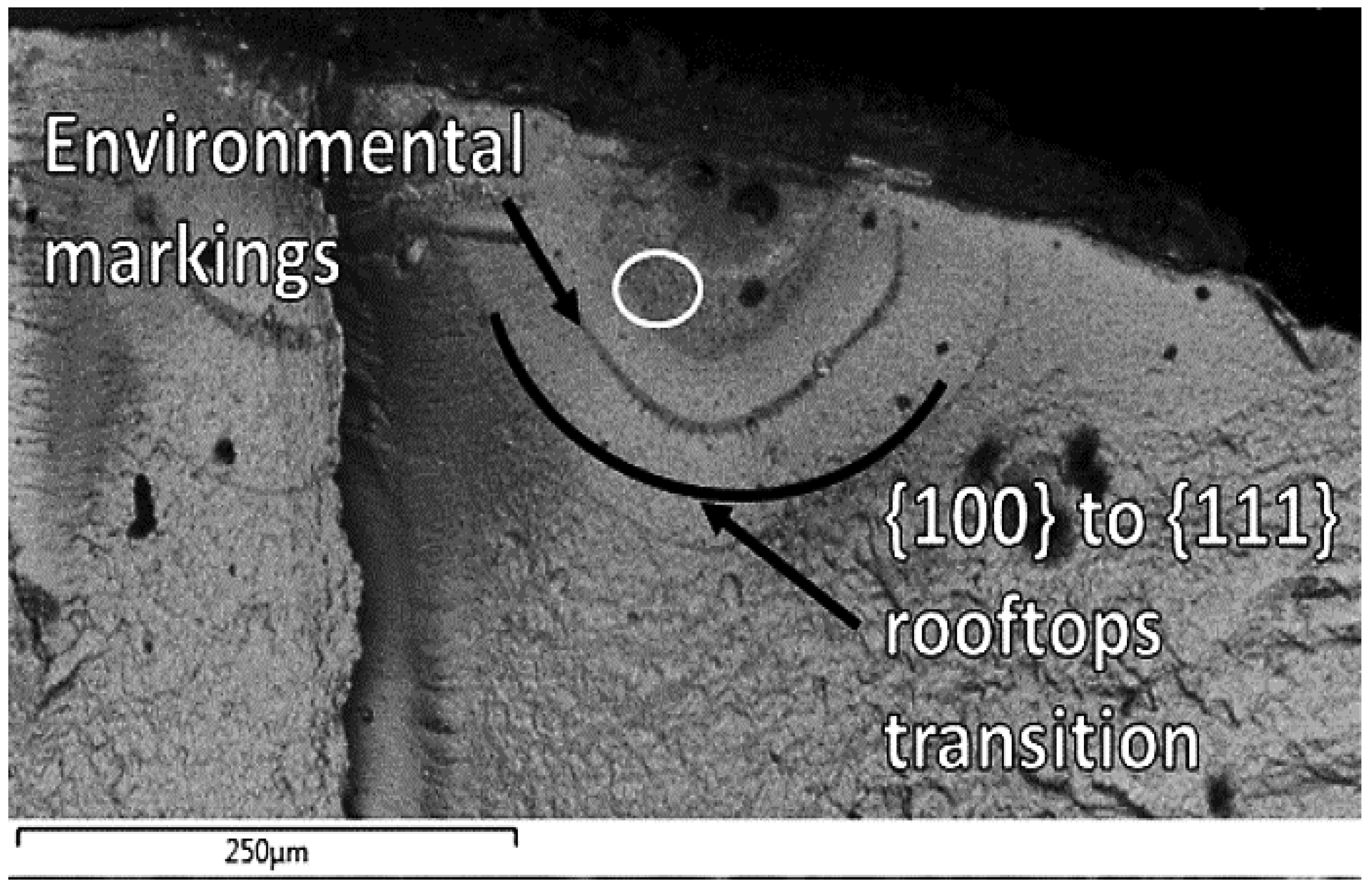

4. Thermomechanical Fatigue

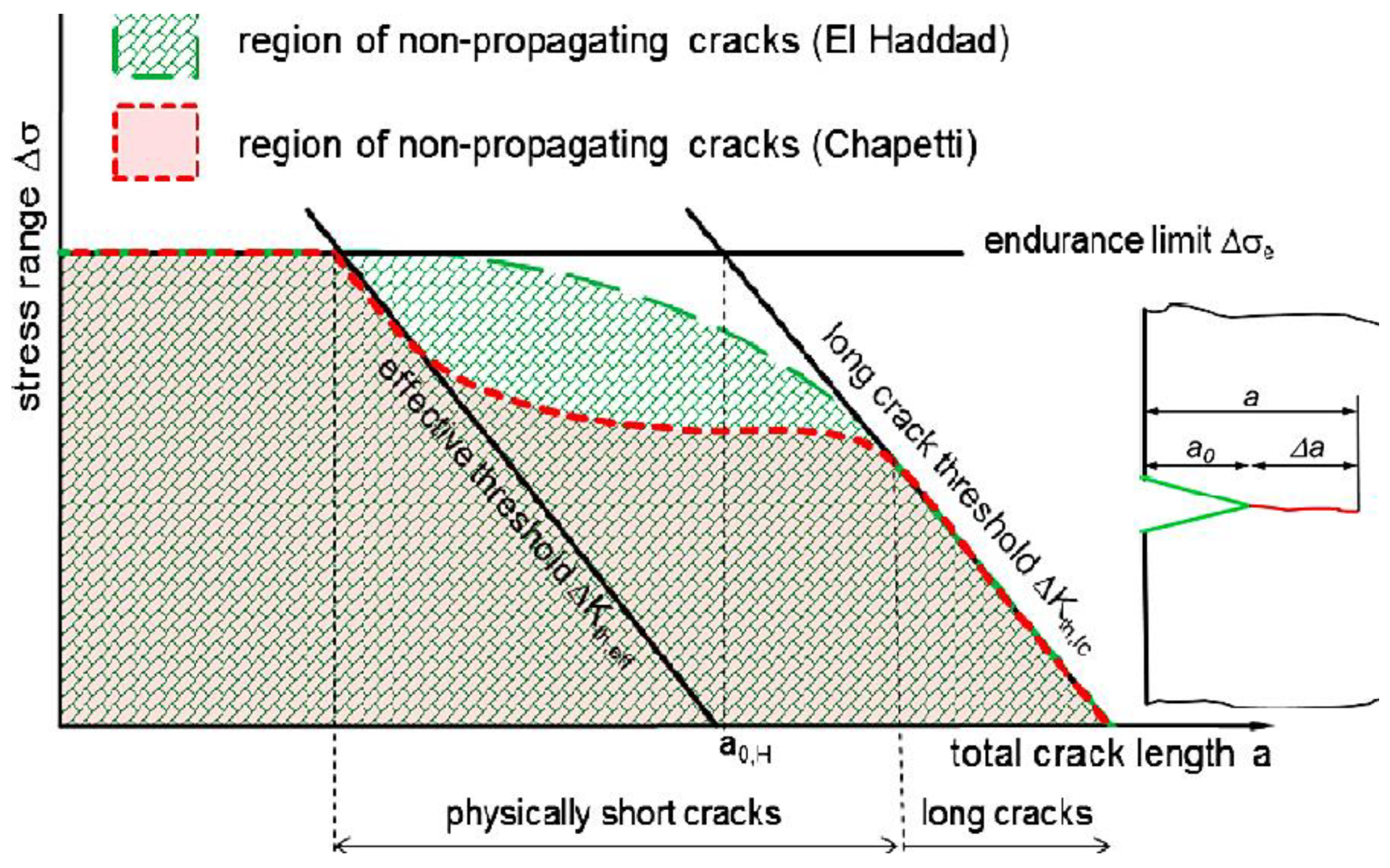

5. Mechanism and Modeling of Fatigue Cracking

| Reaction 1 | |

| Reaction 2 | |

| Reaction 3 |

6. Role of Different Parameters in Corrosion Fatigue

6.1. Environmental Parameters

6.2. Loading Conditions

6.3. Material Characteristics

7. Surface Treatment for Improving the Fatigue and Corrosion Fatigue Strength

8. Recommendations and Future Prospects

9. Conclusions

- In most cases, failure in turbines is due to the interrelation of more than one failure mechanism. The combination of complex alternating stresses and working in harsh environments causes unexpected corrosion fatigue failure of the turbine components much earlier than the designed lifetime.

- The low-pressure blades are more prone to corrosion fatigue because of easy con-densation of steam containing Cl and S on the low-pressure last-stage blades, which accelerates the localized pitting corrosion. Moreover, the presence of high chloride salts ingested from the air and sulphur contaminants of fuels causes the hot corrosion of turbine components at elevated temperatures.

- The anodic dissolution of metal at the crack tip and hydrogen embrittlement are the two main mechanisms involved in the crack growth, depending on the metallurgical, mechanical and environmental variations.

- The corrosion pits are the preferred sites for crack initiation. The pit dimensions can affect the amount of threshold stress intensity factor (∆kth) below which fatigue cracks cannot propagate. Moreover, the exposure of the crack tip to the corrosive environment and hydrogen for a long time per cycle as well as time-dependent oxidation at elevated temperatures make the low frequency loading more harmful.

- Microstructure is another factor influencing fatigue and corrosion fatigue behavior. For example, fatigue cracks in duplex stainless steel grow preferentially in the ferrite phase and are significantly affected by hydrogen embrittlement, whereas the ductile austenite phase delays the crack propagation. Furthermore, adding Al, Ti, Nb and Ta to increase the volume fraction of the phase γ″ and applying heat treatment improve the fatigue behavior of Ni-based superalloys.

- Since fatigue and corrosion usually start from the surface damage, the surface state is of significant importance. Mechanical treatment of surfaces and/or application of a suitable coating are effective strategies to increase fatigue endurance limit.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kulor, F.; Markus, E.D.; Kanzumba, K. Design and control challenges of hybrid, dual nozzle gas turbine power generating plant: A critical review. Energy Rep. 2021, 7, 324–335. [Google Scholar] [CrossRef]

- Mangra, A.C. Design and Numerical Analysis of a Micro Gas Turbine Combustion Chamber. Eng. Technol. Appl. Sci. Res. 2020, 10, 6422–6426. [Google Scholar] [CrossRef]

- Wei, D.; Lei, L.; Yinghou, J.; Songtao, W.; Xingchen, L.; Sunden, B. Heat transfer in the trailing region of gas turbines—A state-of-the-art review. Appl. Therm. Eng. 2021, 199, 117614. [CrossRef]

- Ajiwibowo, M.W.; Darmawan, A.; Aziz, M. A conceptual chemical looping combustion power system design in a power-to-gas energy storage scenario. Int. J. Hydrogen Energy 2018, 44, 9636–9642. [Google Scholar] [CrossRef]

- Öberg, S.; Odenberger, M.; Johnsson, F. Exploring the competitiveness of hydrogen-fueled gas turbines in future energy systems. Int. J. Hydrogen Energy 2021, 47, 624–644. [Google Scholar] [CrossRef]

- Gupta, K.; Rehman, A.; Sarviya, R. Bio-fuels for the gas turbine: A review. Renew. Sustain. Energy Rev. 2010, 14, 2946–2955. [Google Scholar] [CrossRef]

- Sirignano, W.A.; Liu, F. Performance Increases for Gas-Turbine Engines Through Combustion Inside the Turbine. J. Propuls. Power 1999, 15, 111–118. [Google Scholar] [CrossRef]

- Poullikkas, A. An overview of current and future sustainable gas turbine technologies. Renew. Sustain. Energy Rev. 2005, 9, 409–443. [Google Scholar] [CrossRef]

- Shirzadi, A.; Jackson, S. Structural Alloys for Power Plants, Operational Challenges and High-Temperature Materials; Woodhead Publishing Series in Energy: Cambridge, UK, 2014; pp. 3–21. [Google Scholar]

- Cheddie, D.F. Thermo-economic optimization of an indirectly coupled solid oxide fuel cell/gas turbine hybrid power plant. Int. J. Hydrogen Energy 2011, 36, 1702–1709. [Google Scholar] [CrossRef]

- Park, Y.; Choi, M.; Kim, K.; Li, X.; Jung, C.; Na, S.; Choi, G. Prediction of operating characteristics for industrial gas turbine combustor using an optimized artificial neural network. Energy 2020, 213, 118769. [Google Scholar] [CrossRef]

- Salehnasab, B.; Poursaeidi, E.; Mortazavi, S.; Farokhian, G. Hot corrosion failure in the first stage nozzle of a gas turbine engine. Eng. Fail. Anal. 2016, 60, 316–325. [Google Scholar] [CrossRef]

- Bontempo, R.; Manna, M. Work and efficiency optimization of advanced gas turbine cycles. Energy Convers. Manag. 2019, 195, 1255–1279. [Google Scholar] [CrossRef]

- Shayegh, S.; Moreno-cruz, J.; Caldeira, K. Optimal gas turbine inlet temperature for cyclic operation. IOP Conf. Ser. J. Phys. Conf. Ser. 2018, 1111, 012046. [Google Scholar]

- Salim, B.; Orfi, J.; Alaqel, S.S. Effect of Turbine and Compressor Inlet Temperatures and Air Bleeding on the Comparative Performance of Simple and Combined Gas Turbine Unit. Eur. J. Eng. Technol. Res. 2020, 5, 39–45. [Google Scholar]

- Mirhosseini, A.M.; Nazari, S.A.; Pour, A.M.; Haghighi, S.E.; Zareh, M. Failure analysis of first stage nozzle in a heavy-duty gas turbine. Eng. Fail. Anal. 2019, 109, 104303. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Puspitasari, P.; Andoko, A.; Kurniawan, P. Failure analysis of a gas turbine blade: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012156. [Google Scholar] [CrossRef]

- Kanesund, J.; Brodin, H.; Johansson, S. Hot corrosion influence on deformation and damage mechanisms in turbine blades made of IN-792 during service. Eng. Fail. Anal. 2018, 96, 118–129. [Google Scholar] [CrossRef]

- Carter, T.J. Common failures in gas turbine blades. Eng. Fail. Anal. 2005, 12, 237–247. [Google Scholar] [CrossRef]

- Gurrappa, I.; Rao, A.S. Thermal barrier coatings for enhanced efficiency of gas turbine engines. Surf. Coat. Technol. 2006, 201, 3016–3029. [Google Scholar] [CrossRef]

- DeMasi-Marcin, J.T.; Gupta, D.K. Protective coatings in the gas turbine engine. Surf. Coat. Technol. 1994, 68, 1–9. [Google Scholar] [CrossRef]

- Salehnasab, B.; Poursaeidi, E. Mechanism and modeling of fatigue crack initiation and propagation in the directionally solidified CM186 LC blade of a gas turbine engine. Eng. Fract. Mech. 2020, 225, 106842. [Google Scholar] [CrossRef]

- Nowell, D.; Duó, P.; Stewart, I. Prediction of fatigue performance in gas turbine blades after foreign object damage. Int. J. Fatigue 2003, 25, 963–969. [Google Scholar] [CrossRef]

- Hou, J.; Wicks, B.J.; Antoniou, R.A. An investigation of fatigue failures of turbine blades in a gas turbine engine by mechanical analysis. Eng. Fail. Anal. 2002, 9, 201–211. [Google Scholar] [CrossRef]

- Li, K.-S.; Wang, J.; Fan, Z.-C.; Cheng, L.-Y.; Yao, S.-L.; Wang, R.-Z.; Zhang, X.-C.; Tu, S.-T. A life prediction method and damage assessment for creep-fatigue combined with high-low cyclic loading. Int. J. Fatigue 2022, 161, 106923. [Google Scholar] [CrossRef]

- Mazur, Z.; Ramirez, A.L.; Islas, J.A.J.; Amezcua, A.C. Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Eng. Fail. Anal. 2005, 12, 474–486. [Google Scholar] [CrossRef]

- Shlyannikov, V.; Yarullin, R.; Zakharov, A. Fatigue of Steam Turbine Blades with Damage on the Leading Edge. Procedia Mater. Sci. 2014, 3, 1792–1797. [Google Scholar] [CrossRef] [Green Version]

- Gu, S.; An, D.; Qiu, G.; Wang, R.; Liu, Y. Failure Analysis of Compressor IGV in 9F Gas Turbine Generator Unit. J. Fail. Anal. Prev. 2022, 22, 1393–1399. [Google Scholar] [CrossRef]

- Katinić, M.; Kozak, D.; Gelo, I.; Damjanović, D. Corrosion fatigue failure of steam turbine moving blades: A case study. Eng. Fail. Anal. 2019, 106, 104136. [Google Scholar] [CrossRef]

- Liu, X.; Luo, Y.; Wang, Z. A review on fatigue damage mechanism in hydro turbines. Renew. Sustain. Energy Rev. 2016, 54, 1–14. [Google Scholar] [CrossRef]

- Rajabinezhad, M.; Bahrami, A.; Mousavinia, M.; Seyedi, S.J.; Taheri, P. Corrosion-Fatigue Failure of Gas-Turbine Blades in an Oil and Gas Production Plant. Materials 2020, 13, 900. [Google Scholar] [CrossRef] [Green Version]

- Plesiutschnig, E.; Fritzl, P.; Enzinger, N.; Sommitsch, C. Fracture analysis of a low pressure steam turbine blade. Case Stud. Eng. Fail. Anal. 2016, 5, 39–50. [Google Scholar] [CrossRef] [Green Version]

- Kanesund, J.; Brodin, H.; Johansson, S. High temperature corrosion influence on deformation and damage mechanisms in turbine blades made of IN-792 during service. Eng. Fail. Anal. 2020, 110, 104388. [Google Scholar] [CrossRef]

- Hata, S.; Nagai, N.; Yasui, T.; Tsukamoto, H. Investigation of Corrosion Fatigue Phenomena in Transient Zone and Preventive Coating and Blade Design against Fouling and Corrosive Environment for Mechanical Drive Turbines. Int. J. Fluid Mach. Syst. 2008, 1, 121–139. [Google Scholar] [CrossRef] [Green Version]

- Mukhopadhyay, N.; Chowdhury, S.; Das, G.; Chattoraj, I.; Das, S.; Bhattacharya, D. An investigation of the failure of low pressure steam turbine blades. Eng. Fail. Anal. 1998, 5, 181–193. [Google Scholar] [CrossRef]

- Sriraman, M.R.; Pidaparti, R.M. Crack Initiation Life of Materials Under Combined Pitting Corrosion and Cyclic Loading. J. Mater. Eng. Perform. 2009, 19, 7–12. [Google Scholar] [CrossRef]

- Rokhlin, S.I.; Kim, J.Y.; Nagy, H.; Zoofan, B. Effect of pitting corrosion on fatigue crack initiation and fatigue life. Eng. Fract. Mech. 1999, 43, 425–444. [Google Scholar] [CrossRef]

- Igwemezie, V.; Mehmanparast, A. Waveform and frequency effects on corrosion-fatigue crack growth behaviour in modern marine steels. Int. J. Fatigue 2020, 134, 105484. [Google Scholar] [CrossRef]

- Olugbade, T.O.; Ojo, O.T.; Omiyale, B.O.; Olutomilola, E.O.; Olorunfemi, B.J. A review on the corrosion fatigue strength of surface-modified stainless steels. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 421. [Google Scholar] [CrossRef]

- EL May, M.; Saintier, N.; Devos, O.; Rozinoer, A. Effect of Corrosion on the Low-cycle Fatigue Strength of Steels used in Frequent Start-up Power Generation Steam Turbine. Procedia Eng. 2015, 133, 528–534. [Google Scholar] [CrossRef] [Green Version]

- Rivaz, A.; Anijdan, S.M.; Moazami-Goudarzi, M. Failure analysis and damage causes of a steam turbine blade of 410 martensitic stainless steel after 165,000 h of working. Eng. Fail. Anal. 2020, 113, 104557. [Google Scholar] [CrossRef]

- Thellaputta, G.R.; Chandra, P.S.; Rao, C. Machinability of Nickel Based Superalloys: A Review. Mater. Today Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Child, D.J.; Meldrum, J.; Onwuarolu, P. Corrosion-fatigue testing of Ni-based superalloy RR1000. Mater. Sci. Technol. 2016, 33, 1040–1047. [Google Scholar] [CrossRef]

- Masuyama, F. Low-alloyed steel grades for boilers in ultra-supercritical power plants. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants; Elsevier: Amsterdam, The Netherlands, 2017; pp. 53–76. [Google Scholar]

- Kumari, S.; Satyanarayana, D.; Srinivas, M. Failure analysis of gas turbine rotor blades. Eng. Fail. Anal. 2014, 45, 234–244. [Google Scholar] [CrossRef]

- Rao, A.R.; Dutta, B. Vibration analysis for detecting failure of compressor blade. Eng. Fail. Anal. 2012, 25, 211–218. [Google Scholar]

- Kargarnejad, S.; Djavanroodi, F. Failure assessment of Nimonic 80A gas turbine blade. Eng. Fail. Anal. 2012, 26, 211–219. [Google Scholar] [CrossRef]

- Katinić, M.; Kozak, D. Steam turbine moving blade failure caused by corrosion fatigue–case history. Procedia Struct. Integr. 2018, 13, 2040–2047. [Google Scholar] [CrossRef]

- Kwon, H.; Lee, D.; Lee, Y. Failure analysis of blades and vanes of a compressor for a gas turbine engine. Eng. Fail. Anal. 2021, 124, 105386. [Google Scholar] [CrossRef]

- Brooking, L.; Gray, S.; Sumner, J.; Nicholls, J.; Simms, N. Interaction of hot corrosion fatigue and load dwell periods on a nickel-base single crystal superalloy. Int. J. Fatigue 2018, 117, 13–20. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, B.; Hu, D.; Jiang, K.; Liu, H.; Mao, J.; Jing, F.; Hao, X. Thermomechanical fatigue experiment and failure analysis on a nickel-based superalloy turbine blade. Eng. Fail. Anal. 2019, 102, 35–45. [Google Scholar] [CrossRef]

- Lesiuk, J.F. Fatigue failure analysis of last stage blade in a low pressure steam turbine. Eng. Fail. Anal. 1998, 6, 93–100. [Google Scholar]

- Wei, Y.; Li, Y.; Lai, J.; Zhao, Q.; Yang, L.; Lin, Q.; Wang, X.; Pan, Z.; Lin, Z. Analysis on corrosion fatigue cracking mechanism of 17-4PH blade of low pressure rotor of steam turbine. Eng. Fail. Anal. 2020, 118, 104925. [Google Scholar] [CrossRef]

- Elmekawy, A.M.N.; Ali, M.E.H. Computational modeling of non-equilibrium condensing steam flows in low-pressure steam turbines. Results Eng. 2019, 5, 100065. [Google Scholar] [CrossRef]

- Jaffee, R.I. Titanium Steam Turbine Blading. In Proceedings of the Electric Power Research Institute (EPRI) Workshop on Titanium Steam Turbine Blading, Palo Alto, CA, USA, 9–10 November 1988; pp. 1–25. [Google Scholar]

- Perkins, K.; Bache, M. Corrosion fatigue of a 12%Cr low pressure turbine blade steel in simulated service environments. Int. J. Fatigue 2005, 27, 1499–1508. [Google Scholar] [CrossRef]

- Lourenço, N.; Graça, M.; Franco, L.; Silva, O. Fatigue failure of a compressor blade. Eng. Fail. Anal. 2008, 15, 1150–1154. [Google Scholar] [CrossRef]

- Schönbauer, B.M.; Stanzl-Tschegg, S.E.; Perlega, A.; Salzman, R.N.; Rieger, N.F.; Zhou, S.; Turnbull, A.; Gandy, D. Fatigue life estimation of pitted 12% Cr steam turbine blade steel in different environments and at different stress ratios. Int. J. Fatigue 2014, 65, 33–43. [Google Scholar] [CrossRef]

- Almaraz, G.M.D.; Tapia, M.G.; Zuñiga, I.F.; Almaraz, G.M.D.; Tapia, T.G.; Zuñiga, I.F. Ultrasonic fatigue endurance of Inconel 718 after the heat treatments: Solution annealing and double aging. Procedia Struct. Integr. 2022, 39, 281–289. [Google Scholar] [CrossRef]

- Mokaberi, A.; Derakhshandeh-Haghighi, R.; Abbaszadeh, Y. Fatigue fracture analysis of gas turbine compressor blades. Eng. Fail. Anal. 2015, 58, 1–7. [Google Scholar] [CrossRef]

- Ziegler, D.; Puccinelli, M.; Bergallo, B.; Picasso, A. Case Studies in Engineering Failure Analysis Investigation of turbine blade failure in a thermal power. Biochem. Pharmacol. 2013, 1, 192–199. [Google Scholar]

- Adnyana, D.N. Corrosion Fatigue of a Low-Pressure Steam Turbine Blade. J. Fail. Anal. Prev. 2018, 18, 162–173. [Google Scholar] [CrossRef]

- Adedipe, O.; Brennan, F.; Kolios, A. Review of corrosion fatigue in offshore structures: Present status and challenges in the offshore wind sector. Renew. Sustain. Energy Rev. 2016, 61, 141–154. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure, and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Dawood, M.N.; Salim, A.M. A Review on Characterization, Classifications, and Applications of Super Alloys. J. Univ. Babylon Eng. Sci. 2021, 29, 53–62. [Google Scholar]

- Ebara, R. Corrosion fatigue phenomena learned from failure analysis. Eng. Fail. Anal. 2006, 13, 516–525. [Google Scholar] [CrossRef]

- Encinas-Oropesa, A.; Drew, G.; Hardy, M.; Leggett, A.; Nicholls, J.; Simms, N. Effects of Oxidation and Hot Corrosion in a Nickel Disc Alloy. In Proceedings of the Eleventh International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008. [Google Scholar]

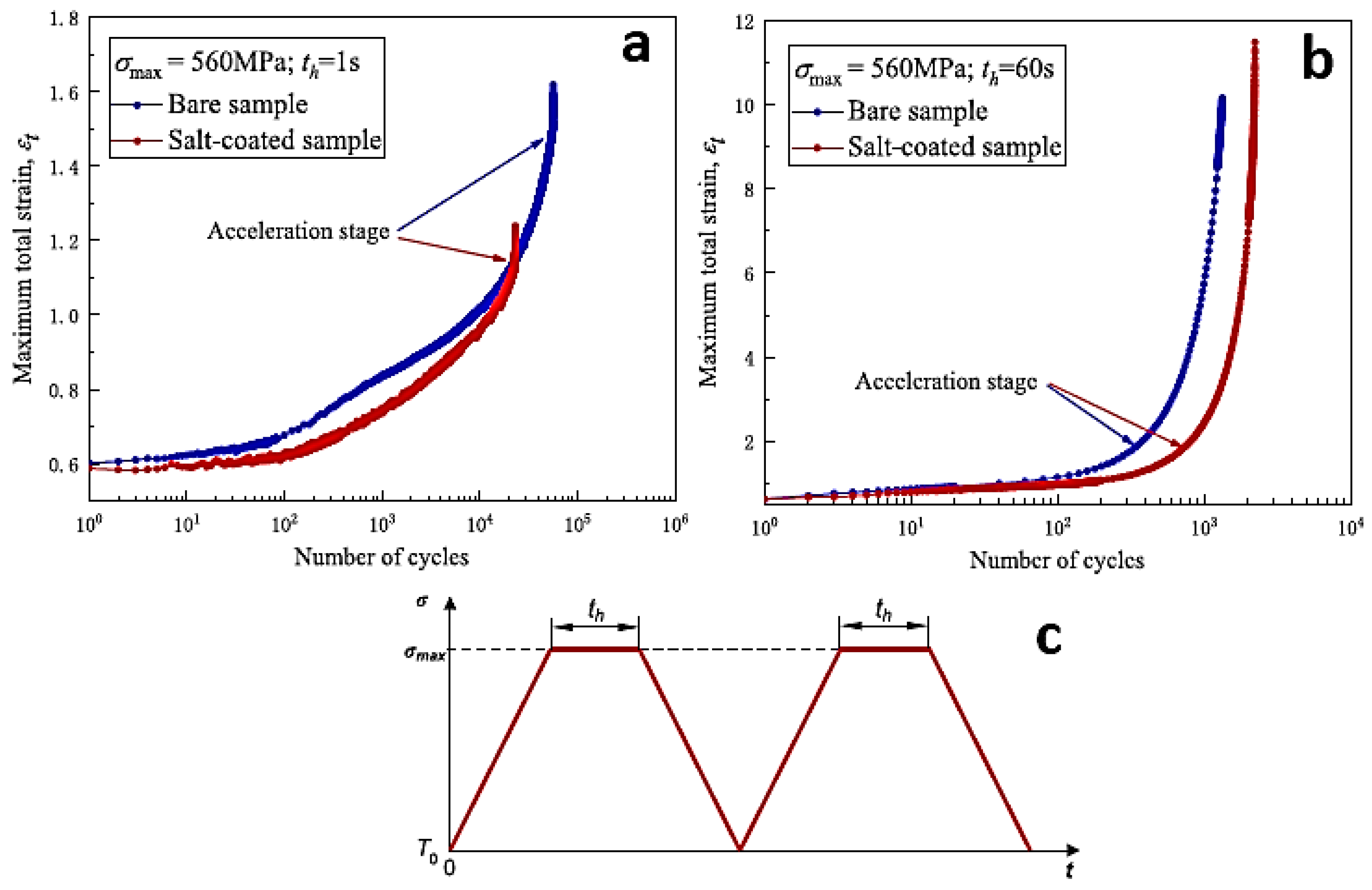

- Zhao, G.; Qi, H.; Li, S.; Yang, X.; Shi, D. Effects of tensile load hold time on the fatigue and corrosion-fatigue behavior of turbine blade materials. Int. J. Fatigue 2021, 152, 106448. [Google Scholar] [CrossRef]

- Abedini, M.; Jahangiri, M.R.; Karimi, P. Oxidation and Hot Corrosion Behaviors of Service-Exposed and Heat-Treated Gas Turbine Vanes Made of IN939 Alloy. Oxid. Met. 2018, 90, 469–484. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H. Hot corrosion behavior of super alloys. Mater. Today Proc. 2020, 26, 1131–1135. [Google Scholar] [CrossRef]

- Montero, X.; Ishida, A.; Meißner, T.; Murakami, H.; Galetz, M. Effect of surface treatment and crystal orientation on hot corrosion of a Ni-based single-crystal superalloy. Corros. Sci. 2020, 166, 108472. [Google Scholar] [CrossRef]

- Hendery, M.; Whittaker, M.; Cockings, B.; Mignanelli, P. The effect of salt composition on the stress-free and corrosion-fatigue performance of a fine-grained nickel-based superalloy. Corros. Sci. 2022, 198, 110113. [Google Scholar] [CrossRef]

- Khajavi, M.; Shariat, M. Failure of first stage gas turbine blades. Eng. Fail. Anal. 2004, 11, 589–597. [Google Scholar] [CrossRef]

- Cockings, H.; Cockings, B.; Harrison, W.; Dowd, M.; Perkins, K.; Whittaker, M.; Gibson, G. The effect of near-surface plastic deformation on the hot corrosion and high temperature corrosion-fatigue response of a nickel-based superalloy. J. Alloys Compd. 2020, 832, 154889. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, H.; Wen, Z.; Zhang, H.; Yue, Z. Low Cycle Fatigue Failure Analysis of a Ni-Based Single Crystal Superalloys at 850 °C. Adv. Eng. Mater. 2018, 21, 1800647. [Google Scholar] [CrossRef]

- Pippan, R. Dislocation emission and fatigue crack growth threshold. Acta Met. Mater. 1991, 39, 255–262. [Google Scholar] [CrossRef]

- Zhang, Y.; Shi, H.-J.; Gu, J.; Li, C.; Kadau, K.; Luesebrink, O. Crystallographic analysis for fatigue small crack growth behaviors of a nickel-based single crystal by in situ SEM observation. Theor. Appl. Fract. Mech. 2013, 69, 80–89. [Google Scholar] [CrossRef]

- Li, S.; Yang, X.; Qi, H.; Song, J.; Shi, D. Low-temperature hot corrosion effects on the low-cycle fatigue lifetime and cracking behaviors of a powder metallurgy Ni-based superalloy. Int. J. Fatigue 2018, 116, 334–343. [Google Scholar] [CrossRef]

- Cockings, H.L.; Perkins, K.M.; Dowd, M. Influence of environmental factors on the corrosion-fatigue response of a nickel-based superalloy. Mater. Sci. Technol. 2016, 33, 1048–1055. [Google Scholar] [CrossRef]

- Brooking, L.; Gray, S.; Sumner, J.; Nicholls, J.; Marchant, G.; Simms, N. Effect of stress state and simultaneous hot corrosion on the crack propagation and fatigue life of single crystal superalloy CMSX-4. Int. J. Fatigue 2018, 116, 106–117. [Google Scholar] [CrossRef]

- Sahu, J.; Kumar, B.R.; Das, S.; Paulose, N.; Mannan, S. Isothermal high temperature low cycle fatigue behavior of Nimonic-263: Influence of type I and type II hot corrosion. Mater. Sci. Eng. A 2014, 622, 131–138. [Google Scholar] [CrossRef]

- Mahobia, G.; Paulose, N.; Mannan, S.; Sudhakar, R.; Chattopadhyay, K.; Srinivas, N.S.; Singh, V. Effect of hot corrosion on low cycle fatigue behavior of superalloy IN718. Int. J. Fatigue 2014, 59, 272–281. [Google Scholar] [CrossRef]

- Gabb, T.P.; Telesman, J.; Hazel, B.; Mourer, D.P. The Effects of Hot Corrosion Pits on the Fatigue Resistance of a Disk Superalloy. J. Mater. Eng. Perform. 2009, 19, 77–89. [Google Scholar] [CrossRef] [Green Version]

- Mousavinia, M.; Bahrami, A.; Rafiaei, S.; Rajabinezhad, M.; Taghian, M.; Seyedi, S. Root cause analysis of failure of bolts in the low pressure section of a gas turbine in an oil and gas production plant. Eng. Fail. Anal. 2020, 115, 104675. [Google Scholar] [CrossRef]

- Qian, C.; Cui, H. Study on thermomechanical behavior and fatigue life prediction method of nickel base superalloy GH4169. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Nagabandi, K.; Pujari, A.K.; Iyer, D.S. Thermo-mechanical assessment of gas turbine combustor tile using locally varying thermal barrier coating thickness. Appl. Therm. Eng. 2020, 179, 115657. [Google Scholar] [CrossRef]

- Jacobsson, L.; Persson, C.; Melin, S. Thermo-mechanical fatigue crack propagation experiments in Inconel 718. Int. J. Fatigue 2009, 31, 1318–1326. [Google Scholar] [CrossRef]

- Jacobsson, L.; Persson, C.; Melin, S. Experimental methods for thermomechanical fatigue in gas turbine materials. In Proceedings of the 15th European Conference of Fracture, Stockholm, Sweden, 11–13 August 2004. [Google Scholar]

- Mishra, R.K.; Vaishakhi, N.; Bhatt, R.R. Thermo-mechanical Fatigue Failure of a Low-Pressure Turbine Blade in a Turbofan Engine. J. Fail. Anal. Prev. 2018, 18, 233–240. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.; Dong, T.; Pei, Y.; Gong, S.; Li, S. The mechanism of thermal corrosion fatigue (TCF) on nickel-based single crystal superalloy and the corresponding structure shape effect. Corros. Sci. 2020, 179, 109142. [Google Scholar] [CrossRef]

- Segersäll, M.; Leidermark, D.; Moverare, J.J. Influence of crystal orientation on the thermomechanical fatigue behaviour in a single-crystal superalloy. Mater. Sci. Eng. A 2015, 623, 68–77. [Google Scholar] [CrossRef] [Green Version]

- Pang, H.T.; Reed, P.A.S. Fatigue crack initiation and short crack growth in nickel-base turbine disc alloys—The effects of microstructure and operating parameters. Int. J. Fatigue 2003, 25, 1089–1099. [Google Scholar] [CrossRef]

- Tan, Y.; Bull, D.; Jiang, R.; Evangelou, A.; Chaudhuri, S.; Octaviani, S.; Pierron, F.; Gao, N.; Toda, H.; Sinclair, I.; et al. Data rich imaging approaches assessing fatigue crack initiation and early propagation in a DS superalloy at room temperature. Mater. Sci. Eng. A 2020, 805, 140592. [Google Scholar] [CrossRef]

- El May, M.; Saintier, N.; Palin-Luc, T.; Devos, O.; Brucelle, O. Modelling of corrosion fatigue crack initiation on martensitic stainless steel in high cycle fatigue regime. Corros. Sci. 2018, 133, 397–405. [Google Scholar] [CrossRef]

- El May, M.; Palin-Luc, T.; Saintier, N.; Devos, O. Effect of corrosion on the high cycle fatigue strength of martensitic stainless steel X12CrNiMoV12-3. Int. J. Fatigue 2013, 47, 330–339. [Google Scholar] [CrossRef] [Green Version]

- Kovacs, S.; Beck, T.; Singheiser, L. Influence of mean stresses on fatigue life and damage of a turbine blade steel in the VHCF-regime. Int. J. Fatigue 2013, 49, 90–99. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Y.; Zhang, T.; Wang, Y. Study on the mechanism of high-cycle corrosion fatigue crack initiation in X80 steel. Corros. Sci. 2012, 57, 99–103. [Google Scholar] [CrossRef]

- El May, M.; Saintier, N.; Palin-Luc, T.; Devos, O. Non-local high cycle fatigue strength criterion for metallic materials with corrosion defects. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1017–1025. [Google Scholar] [CrossRef] [Green Version]

- Co, N.E.C.; Burns, J.T. Effects of macro-scale corrosion damage feature on fatigue crack initiation and fatigue behavior. Int. J. Fatigue 2017, 103, 234–247. [Google Scholar] [CrossRef]

- Ebara, R. Corrosion fatigue crack initiation in 12% chromium stainless steel. Mater. Sci. Eng. A 2007, 468, 109–113. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Lai, J.; Wei, Y.; Luo, J. Corrosion fatigue life prediction of crude oil storage tank via improved equivalent initial flaw size. Theor. Appl. Fract. Mech. 2021, 114, 103023. [Google Scholar] [CrossRef]

- Larrosa, N.O.; Akid, R.; Ainsworth, R.A. Corrosion-fatigue: A review of damage tolerance models. Int. Mater. Rev. 2017, 63, 283–308. [Google Scholar] [CrossRef] [Green Version]

- Li, S.-X.; Akid, R. Corrosion fatigue life prediction of a steel shaft material in seawater. Eng. Fail. Anal. 2013, 34, 324–334. [Google Scholar] [CrossRef]

- Yang, Z.; Lie, S.; Gho, W. Fatigue crack growth analysis of a square hollow section T-joint. J. Constr. Steel Res. 2006, 63, 1184–1193. [Google Scholar] [CrossRef]

- Poursaeidi, E.; Bakhtiari, H. Fatigue crack growth simulation in a first stage of compressor blade. Eng. Fail. Anal. 2014, 45, 314–325. [Google Scholar] [CrossRef]

- Döker, H. Fatigue crack growth threshold: Implications, determination and data evaluation. Int. J. Fatigue 1997, 19, 145–149. [Google Scholar] [CrossRef]

- Bang, D.; Ince, A. A short and long crack growth model based on 2-parameter driving force and crack growth thresholds. Int. J. Fatigue 2020, 141, 105870. [Google Scholar] [CrossRef]

- Padula, S.A., II; Shyam, A.; Ritchie, R.O.; Milligan, W.W. High frequency fatigue crack propagation behavior of a nickel-base turbine disk alloy. Int. J. Fatigue 1999, 21, 725–731. [Google Scholar] [CrossRef]

- Xiaojing, C.; Ri, X.; Mingchen, H.; Jinquan, X. A threshold formula for fatigue crack growth with mean stress intensity factors. Int. J. Mech. Sci. 2018, 135, 639–645. [Google Scholar]

- Maierhofer, J.; Pippan, R.; Gänser, H.-P. Modified NASGRO equation for physically short cracks. Int. J. Fatigue 2014, 59, 200–207. [Google Scholar] [CrossRef] [Green Version]

- Barlow, K.; Chandra, R. Fatigue crack propagation simulation in an aircraft engine fan blade attachment. Int. J. Fatigue 2005, 27, 1661–1668. [Google Scholar] [CrossRef]

- Semenov, A.; Semenov, S.; Nazarenko, A.; Getsov, L. Computer simulation of fatigue, creep and thermal-fatigue cracks properties in gas-turbine blades. Mater. Tehnol./Mater. Technol. 2012, 46, 197–203. [Google Scholar]

- Li, Z.; Li, S.; Xu, G.; Shi, D.; Liu, C.; Yang, X. The framework of hot corrosion fatigue life estimation of a PM superalloy using notch fatigue methodology combined with pit evaluation. Int. J. Fatigue 2021, 153, 106483. [Google Scholar] [CrossRef]

- Maierhofer, J.; Gänser, H.P.; Pippan, R. Modified Kitagawa-Takahashi diagram accounting for finite notch depths. Int. J. Fatigue 2015, 70, 503–509. [Google Scholar] [CrossRef] [Green Version]

- Peters, J.; Boyce, B.; Chen, X.; McNaney, J.; Hutchinson, J.; Ritchie, R. On the application of the Kitagawa–Takahashi diagram to foreign-object damage and high-cycle fatigue. Eng. Fract. Mech. 2002, 69, 1425–1446. [Google Scholar] [CrossRef]

- Chan, K.S.; Enright, M.P.; Moody, J.P. Development of a Probabilistic Methodology for Predicting Hot Corrosion Fatigue Crack Growth Life of Gas Turbine Engine Disks. J. Eng. Gas Turbines Power 2013, 136, 022505. [Google Scholar] [CrossRef]

- Jirandehi, A.P.; Chakherlou, T. A fatigue crack initiation and growth life estimation method in single-bolted connections. J. Strain Anal. Eng. Des. 2019, 54, 79–94. [Google Scholar] [CrossRef]

- Rungta, R.; Begley, J.A.; Staehle, R.W. Effect of Steam Impurities on Corrosion Fatigue Crack Growth Rates of a Turbine Disc Steel. Corrosion 1981, 37, 682–690. [Google Scholar] [CrossRef]

- Schönbauer, B.M.; Stanzl-Tschegg, S.E.; Perlega, A.; Salzman, R.N.; Rieger, N.F.; Turnbull, A.; Zhou, S.; Lukaszewicz, M.; Gandy, D. The influence of corrosion pits on the fatigue life of 17-4PH steam turbine blade steel. Eng. Fract. Mech. 2015, 147, 158–175. [Google Scholar] [CrossRef]

- Zhou, S.; Turnbull, A. Influence of pitting on the fatigue life of a turbine blade steel. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 1083–1093. [Google Scholar] [CrossRef]

- Sadananda, K.; Vasudevan, A. Analysis of pit to crack transition under corrosion fatigue & the safe-life approach using the modified Kitagawa-Takahashi diagram. Int. J. Fatigue 2020, 134, 105471. [Google Scholar]

- Cerit, M.; Genel, K.; Eksi, S. Numerical investigation on stress concentration of corrosion pit. Eng. Fail. Anal. 2009, 16, 2467–2472. [Google Scholar] [CrossRef]

- Shipilov, S.A. Mechanisms for corrosion fatigue crack propagation. J. Chin. Soc. Corros. Prot. 2004, 24, 321–333. [Google Scholar] [CrossRef]

- De Seranno, T.; Lambrechts, E.; Verliefde, A.; Depover, T.; Verbeken, K. Mechanistic interpretation on acidic stress-corrosion cracking of NiCrMoV steam turbine steel. Mater. Sci. Eng. A 2020, 802, 140433. [Google Scholar] [CrossRef]

- Michailidis, N.; Stergioudi, F.; Maliaris, G.; Tsouknidas, A. Influence of galvanization on the corrosion fatigue performance of high-strength steel. Surf. Coat. Technol. 2014, 259, 456–464. [Google Scholar] [CrossRef]

- Suresh, S.; Ritchie, R.O. Mechanistic dissimilarities between environmentally influenced fatigue-crack propagation at near-threshold and higher growth rates in lower strength steels. Met. Sci. 1982, 16, 529–538. [Google Scholar] [CrossRef] [Green Version]

- Maktouf, W.; Saï, K. An investigation of premature fatigue failures of gas turbine blade. Eng. Fail. Anal. 2015, 47, 89–101. [Google Scholar] [CrossRef]

- Luer, K.; DuPont, J.; Marder, A.; Skelonis, C. Materials at High Temperatures Corrosion fatigue of alloy 625 weld claddings in combustion environments Corrosion fatigue of alloy 625 weld claddings in combustion environments. Mater. High Temp. 2001, 18, 11–19. [Google Scholar] [CrossRef]

- Chen, T.; Nutter, J.; Hawk, J.; Liu, X. Corrosion fatigue crack growth behavior of oil-grade nickel-base alloy 718. Part 1: Effect of corrosive environment. Corros. Sci. 2014, 89, 146–153. [Google Scholar] [CrossRef]

- Barsom, J. Corrosion-fatigue crack propagation below KIscc. Eng. Fract. Mech. 1971, 3, 15–25. [Google Scholar] [CrossRef]

- Ghonem, H.; Wen, Y.; Zheng, D.; Thompson, M.; Linsey, G. Effects of temperature and frequency on fatigue crack growth in Ti-β21S monolithic laminate. Mater. Sci. Eng. A 1993, 161, 45–53. [Google Scholar] [CrossRef]

- Pradhan, A.; Vishwakarma, M.; Dwivedi, S.K. A review: The impact of hydrogen embrittlement on the fatigue strength of high strength steel. Mater. Today Proc. 2020, 26, 3015–3019. [Google Scholar] [CrossRef]

- Cunningham, B.M.D.; Evangelou, A.; You, C.; Morris, A.; Wise, J.; Reed, P.A.S.; Hamilton, A.R. Fatigue crack initiation and growth behavior in a notch with periodic overloads in the low-cycle fatigue regime of FV566 ex-service steam turbine blade material. Fatigue Fract. Eng. Mater. Struct. 2021, 45, 546–564. [Google Scholar] [CrossRef]

- Ebara, R. The influence of metallurgical factors on corrosion fatigue strength of stainless steels. Procedia Struct. Integr. 2016, 2, 517–524. [Google Scholar] [CrossRef] [Green Version]

- Makhlouf, K.; Sidhom, H.; Triguia, I.; Braham, C. Corrosion fatigue crack propagation of a duplex stainless steel X6 Cr Ni Mo Cu 25-6 in air and in artificial sea water. Int. J. Fatigue 2003, 25, 167–179. [Google Scholar] [CrossRef]

- Marrow, T.J.; King, J.E. Microstructural and environmental effects on fatigue crack propagation in duplex stainless steels. Fatigue Fract. Eng. Mater. Struct. 1994, 17, 761–771. [Google Scholar] [CrossRef]

- Pradhan, K.K.; Matawale, C.R. Heat treatment analysis of SS304 for gas turbine application. Mater. Today Proc. 2020, 33, 5734–5739. [Google Scholar] [CrossRef]

- Akita, M.; Uematsu, Y.; Kakiuchi, T.; Nakajima, M.; Tsuchiyama, T.; Bai, Y.; Isono, K. Effect of sensitization on corrosion fatigue behavior of type 304 stainless steel annealed in nitrogen gas. Mater. Sci. Eng. A 2015, 640, 33–41. [Google Scholar] [CrossRef]

- Sui, S.; Zhong, C.; Chen, J.; Gasser, A.; Huang, W.; Schleifenbaum, J.H. Influence of solution heat treatment on microstructure and tensile properties of Inconel 718 formed by high-deposition-rate laser metal deposition. J. Alloys Compd. 2018, 740, 389–399. [Google Scholar] [CrossRef]

- Li, W.J.; Liu, Y.; Wang, Y.; Han, C.; Tang, H.P. Hot corrosion behavior of Ni-16Cr-xAl based alloys in mixture of Na 2SO 4-NaCl at 600 °C. Trans. Nonferrous Met. Soc. China 2011, 21, 2617–2625. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Fu, Q.; Akiyama, E.; Song, X.; Shen, S.; Li, Q. Hydrogen embrittlement of high strength steam turbine last stage blade steels: Comparison between PH17-4 steel and PH13-8Mo steel. Mater. Sci. Eng. A 2018, 742, 353–363. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Kvasnytska, Y.H.; Ivaskevych, L.M.; Kvasnytska, K.H.; Balitskii, O.A. Hydrogen and Corrosion Resistance of Nickel Superalloys for Gas Turbines, Engines Cooled Blades. Energies 2023, 16, 1154. [Google Scholar] [CrossRef]

- Wee, S.; Do, J.; Kim, K.; Lee, C.; Seok, C.; Choi, B.-G.; Choi, Y.; Kim, W. Review on Mechanical Thermal Properties of Superalloys and Thermal Barrier Coating Used in Gas Turbines. Appl. Sci. 2020, 10, 5476. [Google Scholar] [CrossRef]

- Pourazizi, R.; Mohtadi-Bonab, M.; Szpunar, J. Role of texture and inclusions on the failure of an API X70 pipeline steel at different service environments. Mater. Charact. 2020, 164, 110330. [Google Scholar] [CrossRef]

- Mohtadi-Bonab, M.; Mousavi, H.; Pourazizi, R.; Szpunar, J. Finite element modeling of HIC propagation in pipeline steel with regard to experimental observations. Int. J. Hydrogen Energy 2020, 45, 23122–23133. [Google Scholar] [CrossRef]

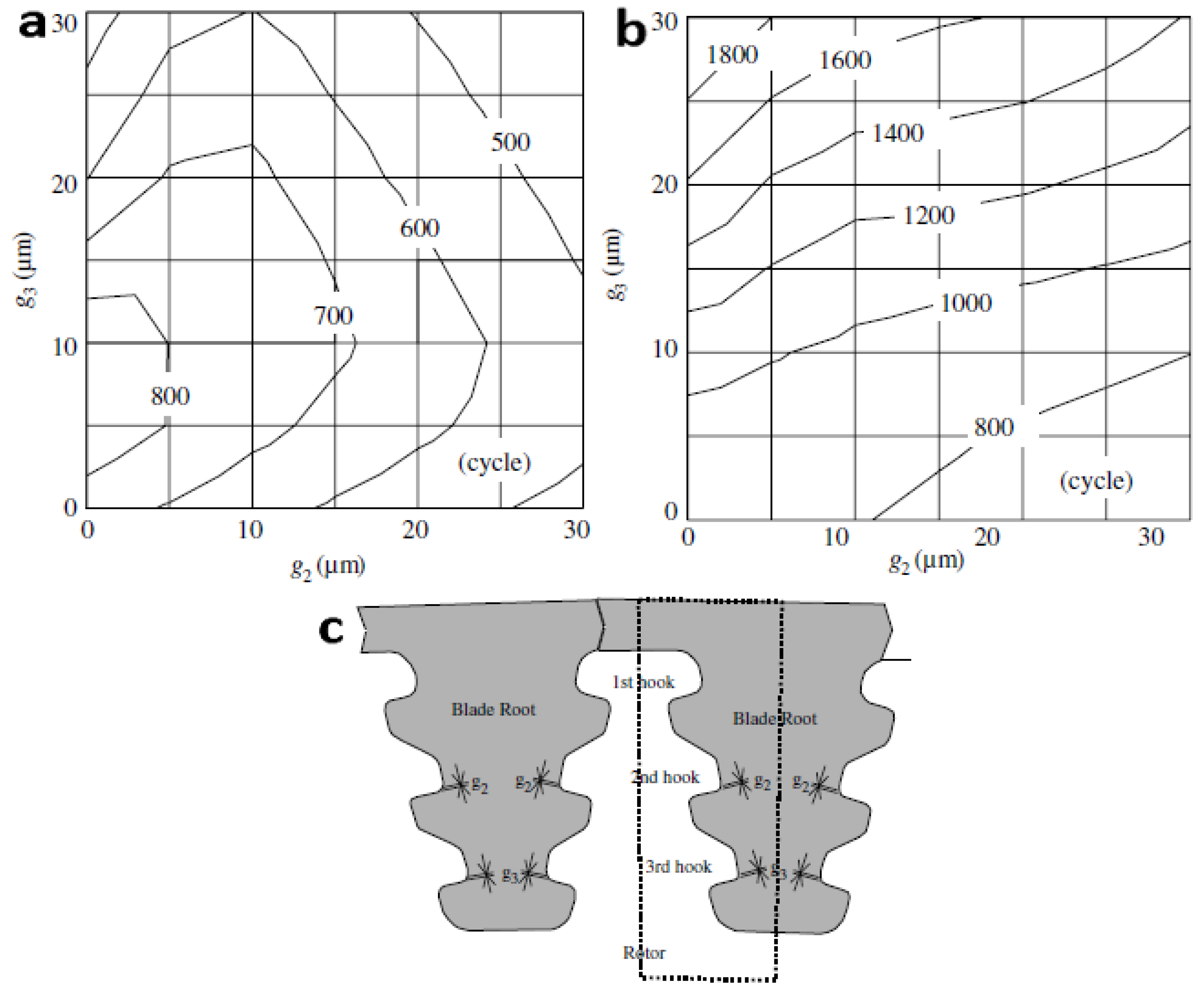

- Morita, A.; Kagawa, H.; Sugawara, M.; Kondo, Y.; Kubo, S. Evaluation of corrosion fatigue crack propagation life at low-pressure steam turbine rotor groove. Eng. Fract. Mech. 2006, 73, 1615–1628. [Google Scholar] [CrossRef]

- Gibson, G.J.; Perkins, K.M.; Gray, S.; Leggett, A.J. Influence of shot peening on high-temperature corrosion and corrosion-fatigue of nickel based superalloy 720 Li. Mater. High Temp. 2016, 33, 225–233. [Google Scholar] [CrossRef] [Green Version]

- Preve´y, P.S.; Jayaraman, N.; Ravindranath, R. Fatigue Life Extension of Steam Turbine Alloys Using Low Plasticity Burnishing (LPB). In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; Volume 7, pp. 2277–2287. [Google Scholar]

- Preve, P.S. Case Studies of Fatigue Life Improvement Using Low Plasticity Burnishing in Gas Turbine Engine. J. Eng. Gas Turbine Power 2006, 128, 865–872. [Google Scholar] [CrossRef] [Green Version]

- Preve, P.S. The influence of surface enhancement by low plasticity burnishing on the corrosion fatigue performance of AA7075-T6. Int. J. Fatigue 2004, 26, 975–982. [Google Scholar] [CrossRef]

- Wang, C.; Luo, K.; Bu, X.; Su, Y.; Cai, J.; Zhang, Q.; Lu, J. Laser shock peening-induced surface gradient stress distribution and extension mechanism in corrosion fatigue life of AISI 420 stainless steel. Corros. Sci. 2020, 177, 109027. [Google Scholar] [CrossRef]

- Yan, X.; Yin, S.; Chen, C.; Jenkins, R.; Lupoi, R.; Bolot, R.; Ma, W.; Kuang, M.; Liao, H.; Lu, J.; et al. Fatigue strength improvement of selective laser melted Ti6Al4V using ultrasonic surface mechanical attrition. Mater. Res. Lett. 2019, 7, 327–333. [Google Scholar] [CrossRef]

- Peters, B.M.; Leyens, C.; Schulz, U.; Kaysser, W.A. EB-PVD Thermal Barrier Coatings for Aeroengines and Gas Turbines. Adv. Eng. Mater. 2001, 3, 193–204. [Google Scholar] [CrossRef]

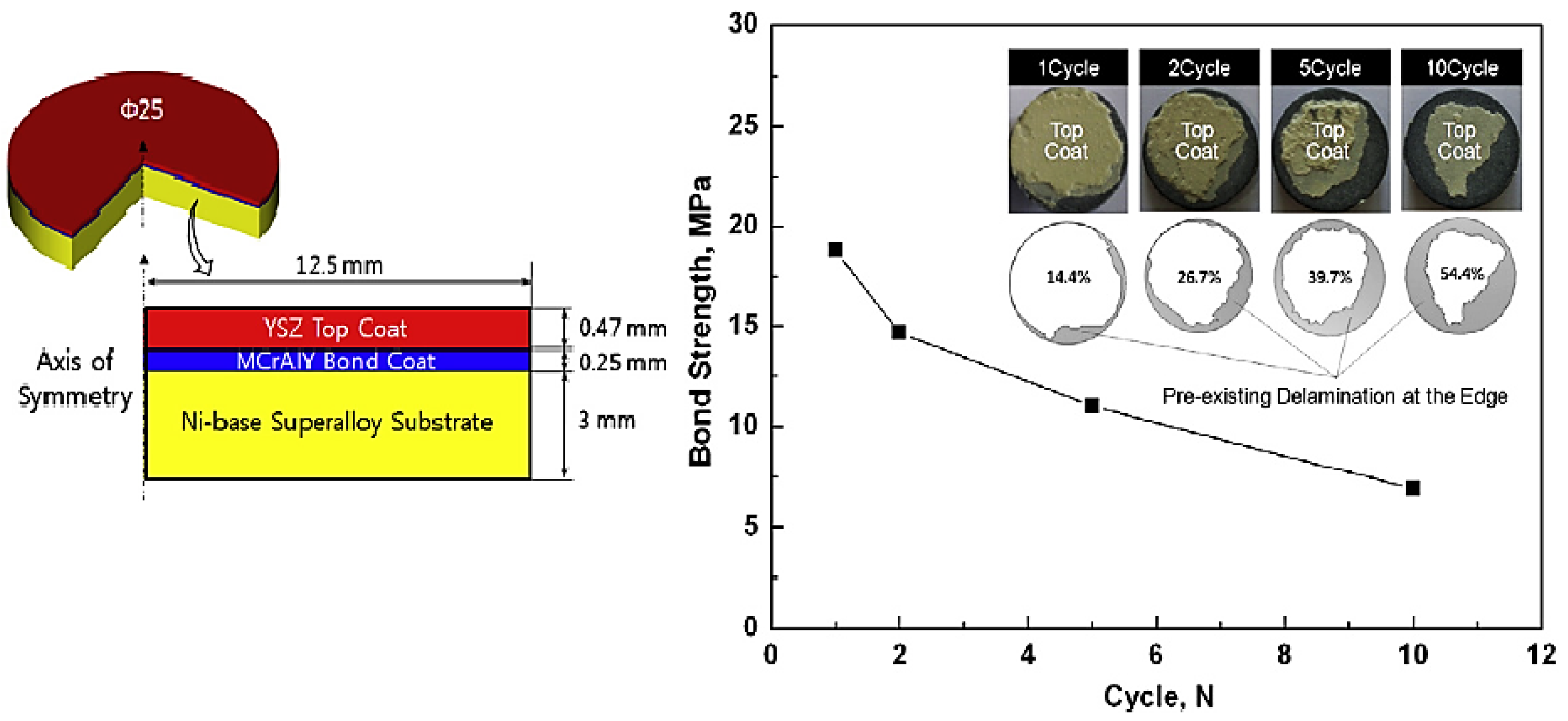

- Shin, I.-H.; Koo, J.-M.; Seok, C.-S.; Yang, S.-H.; Lee, T.-W.; Kim, B.-S. Estimation of spallation life of thermal barrier coating of gas turbine blade by thermal fatigue test. Surf. Coat. Technol. 2011, 205, S157–S160. [Google Scholar] [CrossRef]

- Xu, H.; Guo, H.; Liu, F.; Gong, S. Development of gradient thermal barrier coatings and their hot-fatigue behavior. Surf. Coat. Technol. 2000, 130, 133–139. [Google Scholar] [CrossRef]

- Smialek, J.L.; Nesbitt, J.A.; Gabb, T.P.; Garg, A.; Miller, R.A. Hot corrosion and low cycle fatigue of a Cr2AlC-coated superalloy. Mater. Sci. Eng. A 2018, 711, 119–129. [Google Scholar] [CrossRef]

- Igwemezie, V.; Mehmanparast, A.; Kolios, A. Materials selection for XL wind turbine support structures: A corrosion-fatigue perspective. Mar. Struct. 2018, 61, 381–397. [Google Scholar] [CrossRef]

| Material Type | Working Conditions | Type of Damage | Consequences | Ref |

|---|---|---|---|---|

| Ni-based superalloy | High temperature, high pressure | Corrosion fatigue, oxidation | Corrosion pits, formation of carbide along grain boundaries, ϒ’-particle coarsening | [46] |

| It is not mentioned | Frequency of 500 Hz | Fatigue, oxidation | Fracture of blade at root of the airfoil due to high cycle fatigue, corrosion pitting on the leading edge of the blade | [47] |

| Nimonic 80A superalloy | First-stage blade of a 3 MW combustion turbine with a gas inlet temperature of 770 °C | Creep failure, oxidation | ϒ’-particle coarsening, delamination of the coating and cracks at the interface of the bond coat and the base metal in the blade airfoil hot zones | [48] |

| Nimonic 105 superalloy | Working in hot and humid climate in Persian Gulf region | Hot corrosion, thermal fatigue | Pitting corrosion on the surface of blade airfoil, intergranular cracks and fracture surface at the failure area on the trailing edge. | [12] |

| Stainless steel | 90 °C, low pressure | Corrosion fatigue | Decrease in the fatigue strength under corrosion | [41] |

| Steel | Working at phase transition zone of the turbine | Corrosion fatigue | Failure of steam turbine rotor blades | [49] |

| Ti-6Al-4 V alloy | Rotor blade | Pitting corrosion, fatigue cracking | Failure of rotor blade | [50] |

| Single-crystal superalloy CMSX-4 | High temperature, in the presence of corrosive salt species | Hot corrosion fatigue | Corrosion embrittlement, crack-tip oxidation | [51] |

| Ni-based superalloy IN792 | Operating with 30 starts and stops in an industrial environment | Creep, hot corrosion, thermal mechanical fatigue | Precipitation of TiN and AlN near the crack due to corrosion/nitridation, formation of a ϒ’ depletion zone in front of crack, failure after 21,000 h | [34] |

| Ni-based superalloy K444 | High temperature, low pressure | Thermomechanical fatigue, oxidation | Initiation of crack at the trailing edge of blade | [52] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fathyunes, L.; Mohtadi-Bonab, M.A. A Review on the Corrosion and Fatigue Failure of Gas Turbines. Metals 2023, 13, 701. https://doi.org/10.3390/met13040701

Fathyunes L, Mohtadi-Bonab MA. A Review on the Corrosion and Fatigue Failure of Gas Turbines. Metals. 2023; 13(4):701. https://doi.org/10.3390/met13040701

Chicago/Turabian StyleFathyunes, Leila, and M. A. Mohtadi-Bonab. 2023. "A Review on the Corrosion and Fatigue Failure of Gas Turbines" Metals 13, no. 4: 701. https://doi.org/10.3390/met13040701

APA StyleFathyunes, L., & Mohtadi-Bonab, M. A. (2023). A Review on the Corrosion and Fatigue Failure of Gas Turbines. Metals, 13(4), 701. https://doi.org/10.3390/met13040701