Additive Manufacturing of Aluminum Alloys for Aeronautic Applications: Advantages and Problems

Abstract

:1. Introduction

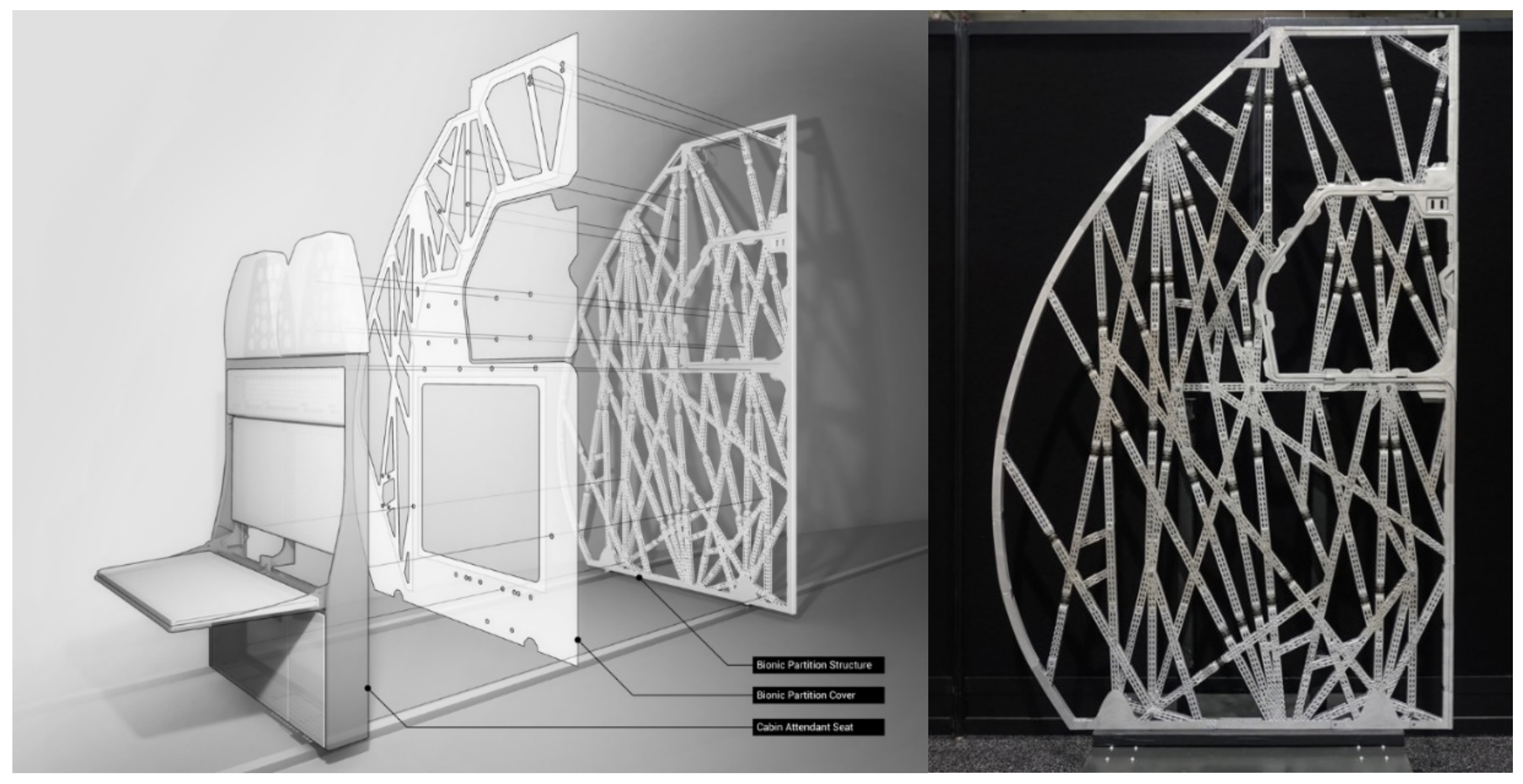

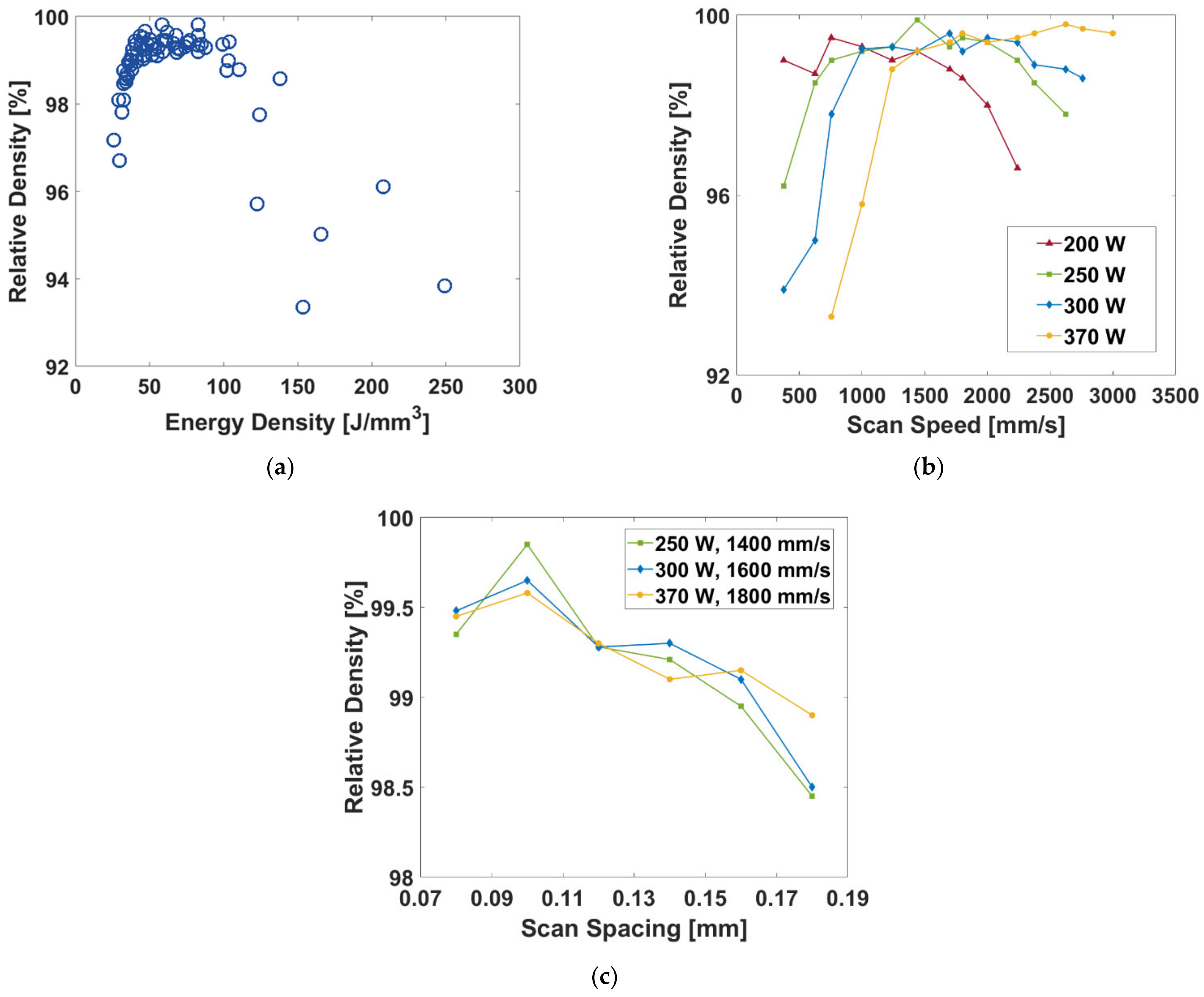

2. Applications of AM Parts Made of Al Alloys

3. Defects

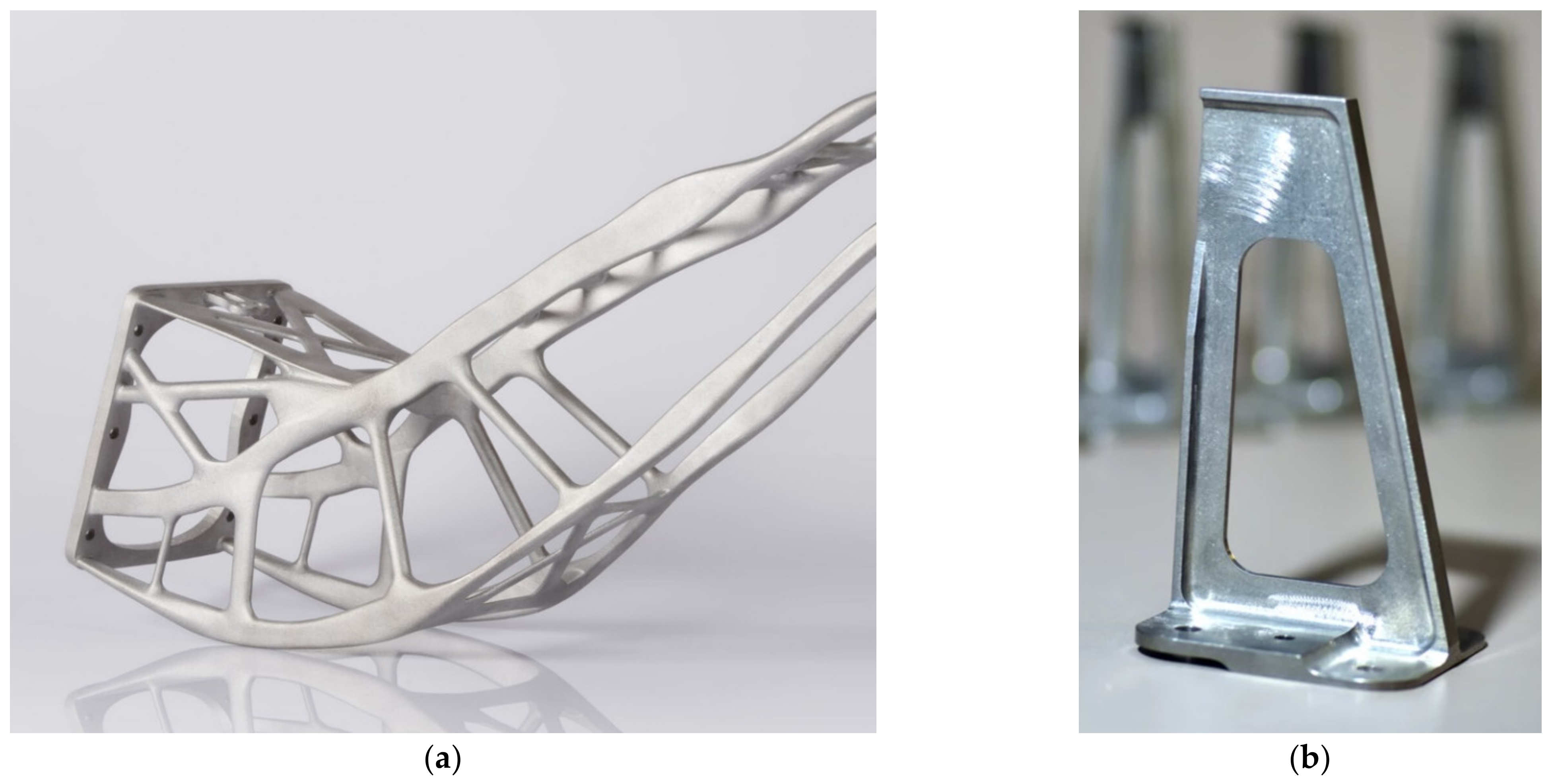

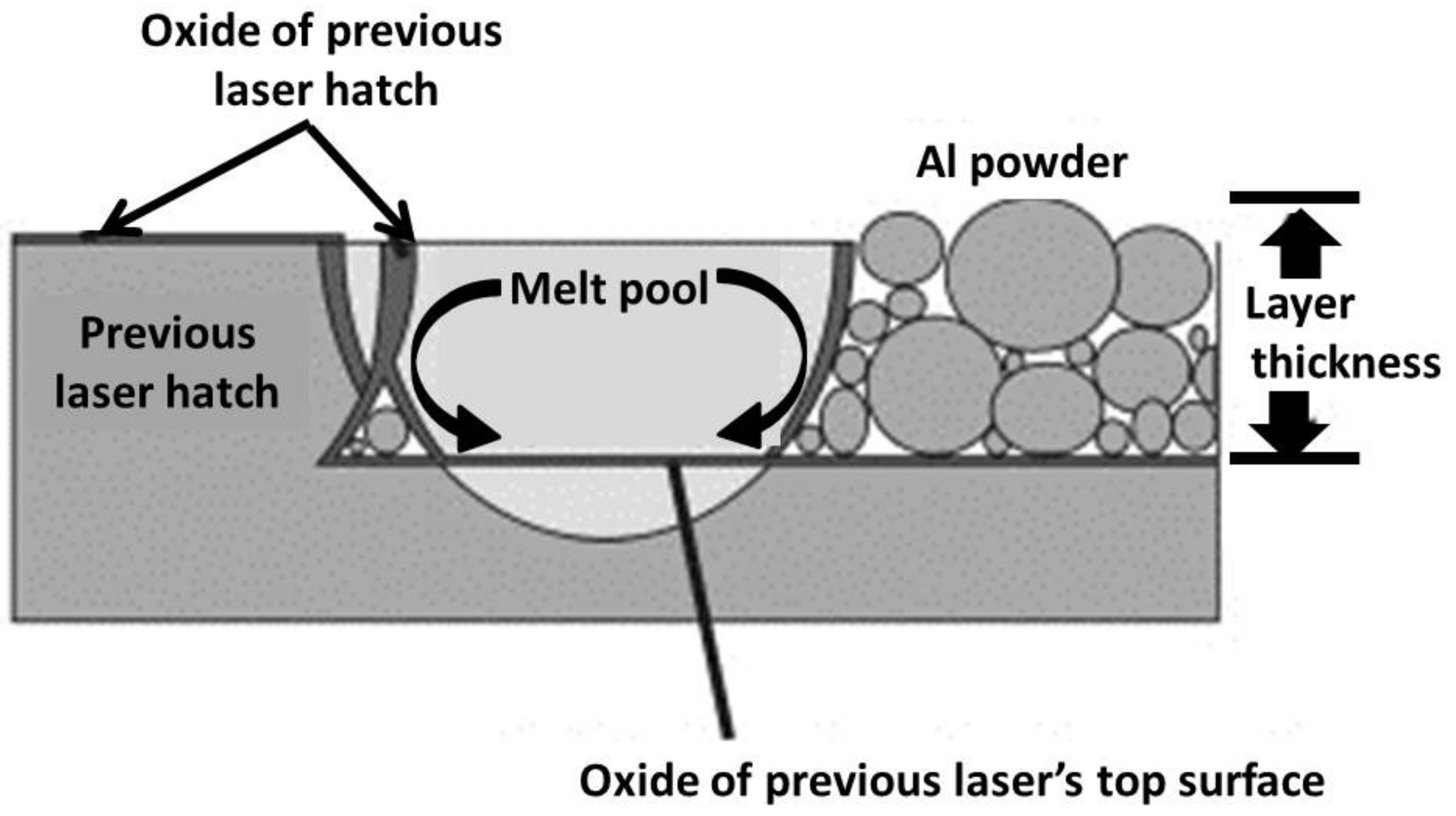

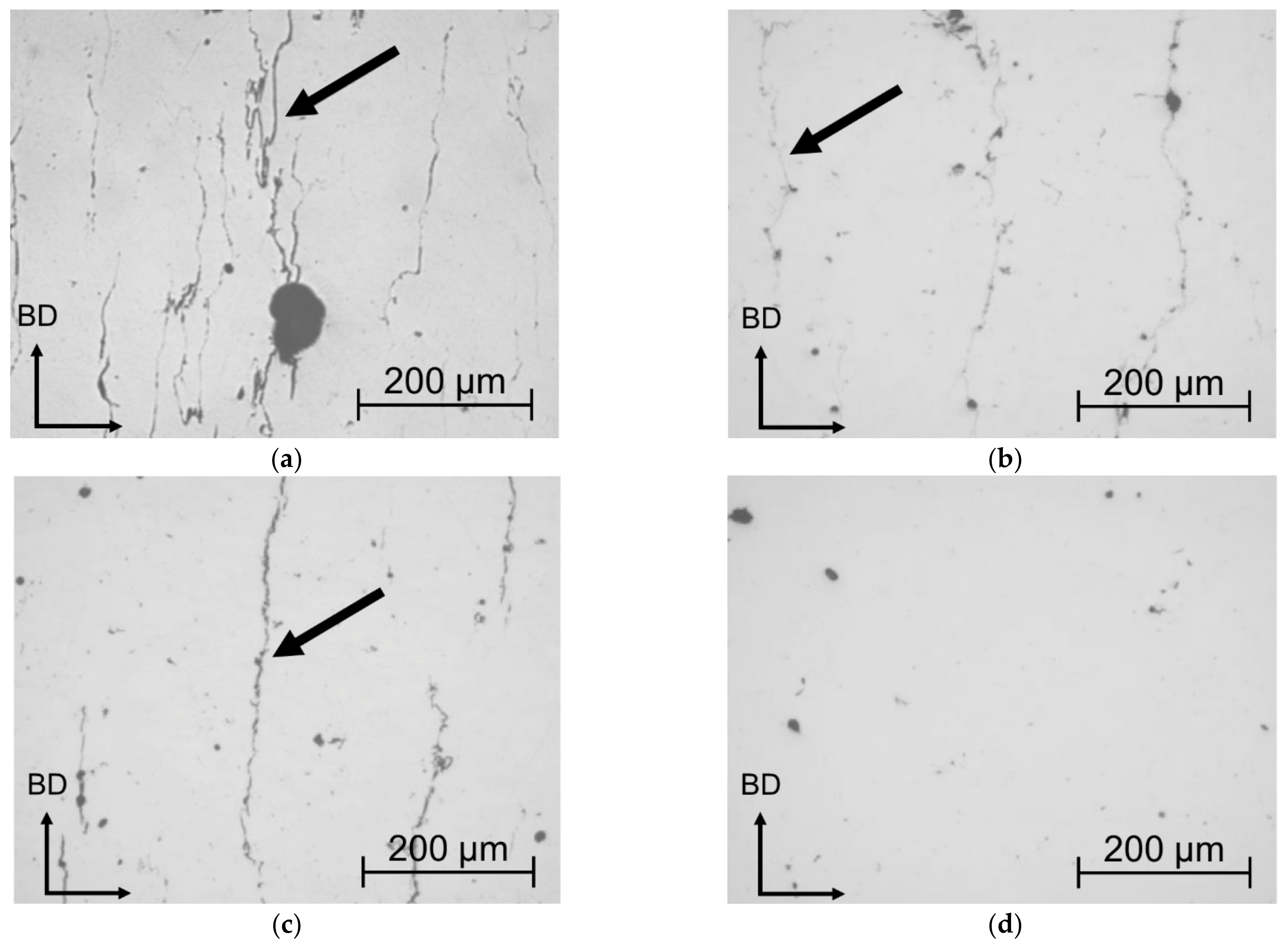

3.1. Porosity

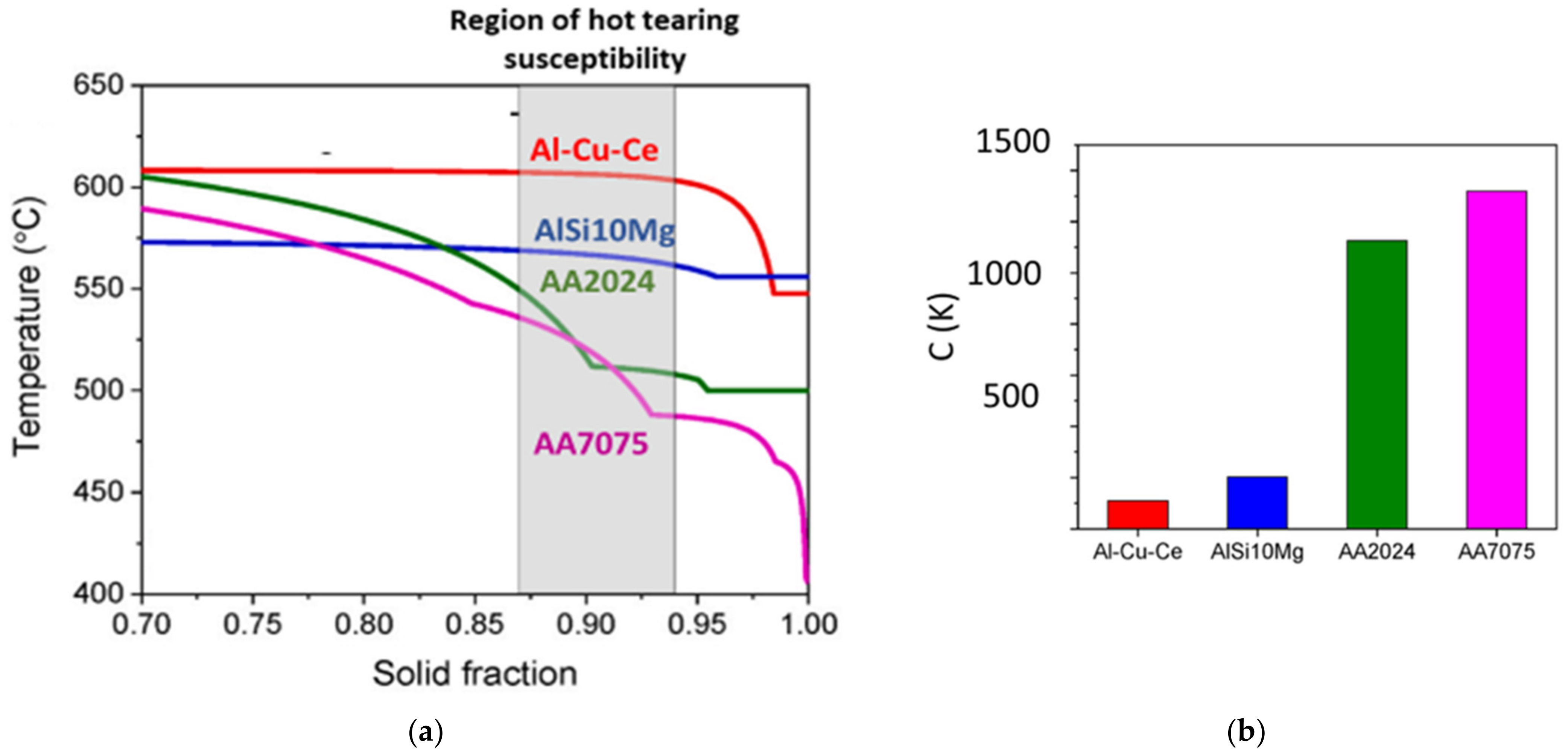

3.2. Hot Cracking

3.3. Anisotropy

3.4. Poor Surface Morphology

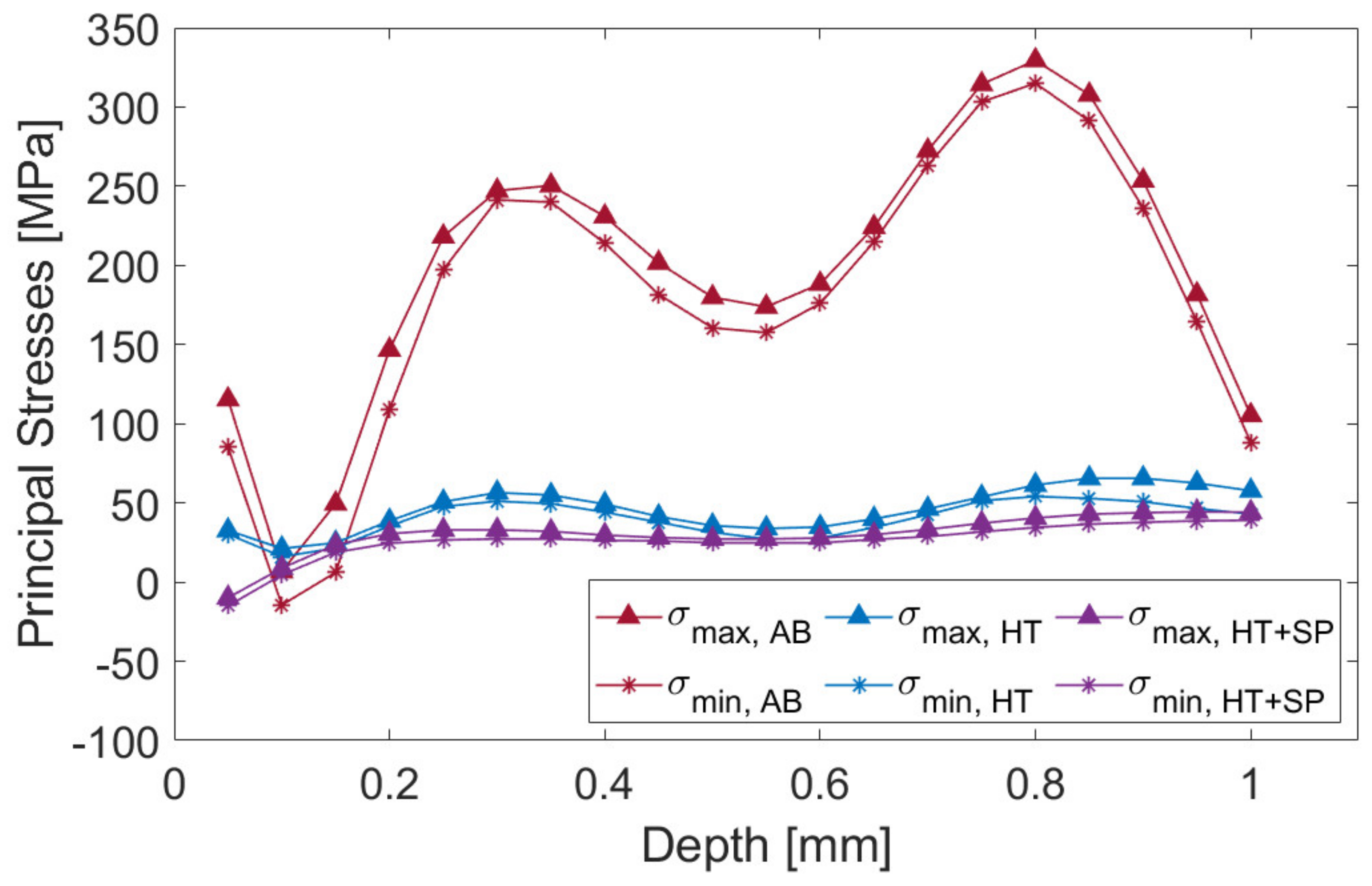

3.5. Residual Stresses

4. Microstructure and Mechanical Properties

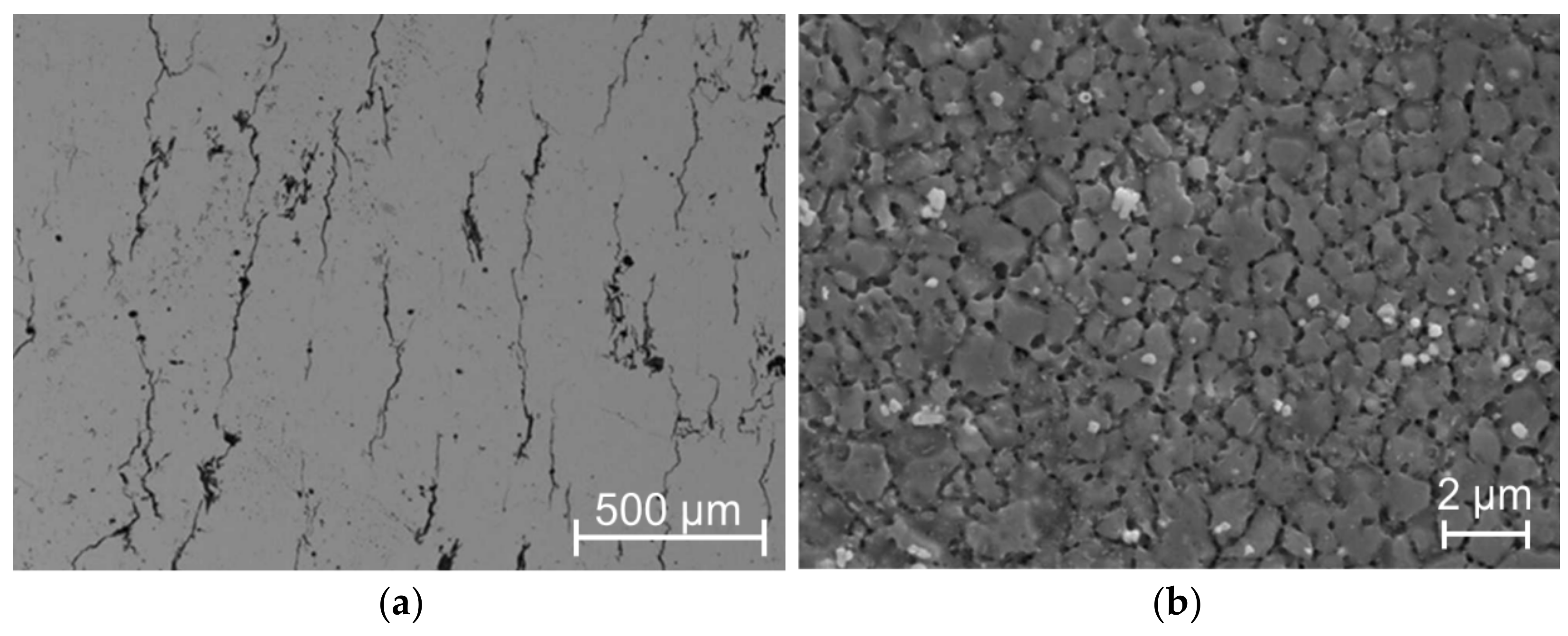

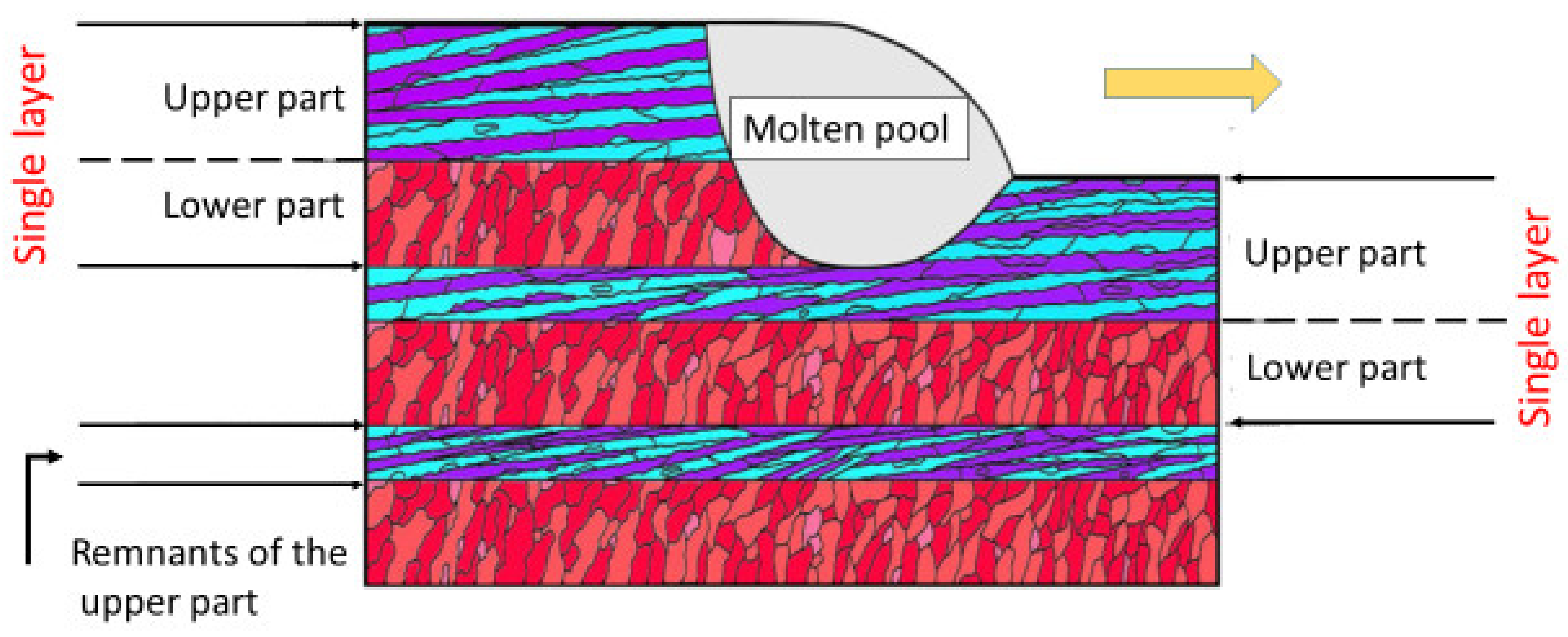

4.1. Hierarchical Structure

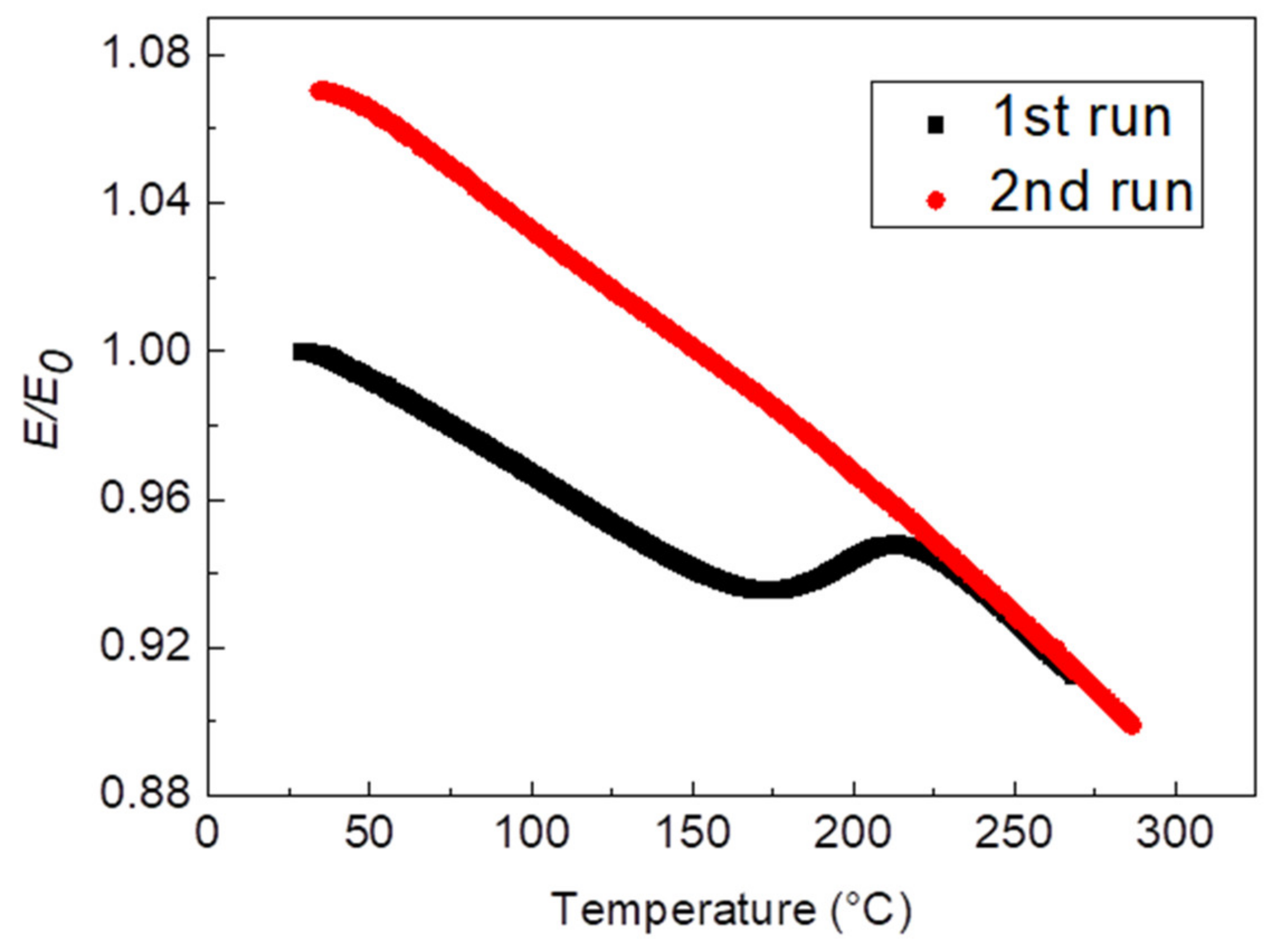

4.2. Grain Morphology and Precipitation Strengthening

4.3. Printing Conditions

5. Tailoring of Alloy Composition

6. Postprocess Treatments

6.1. Aging Treatments

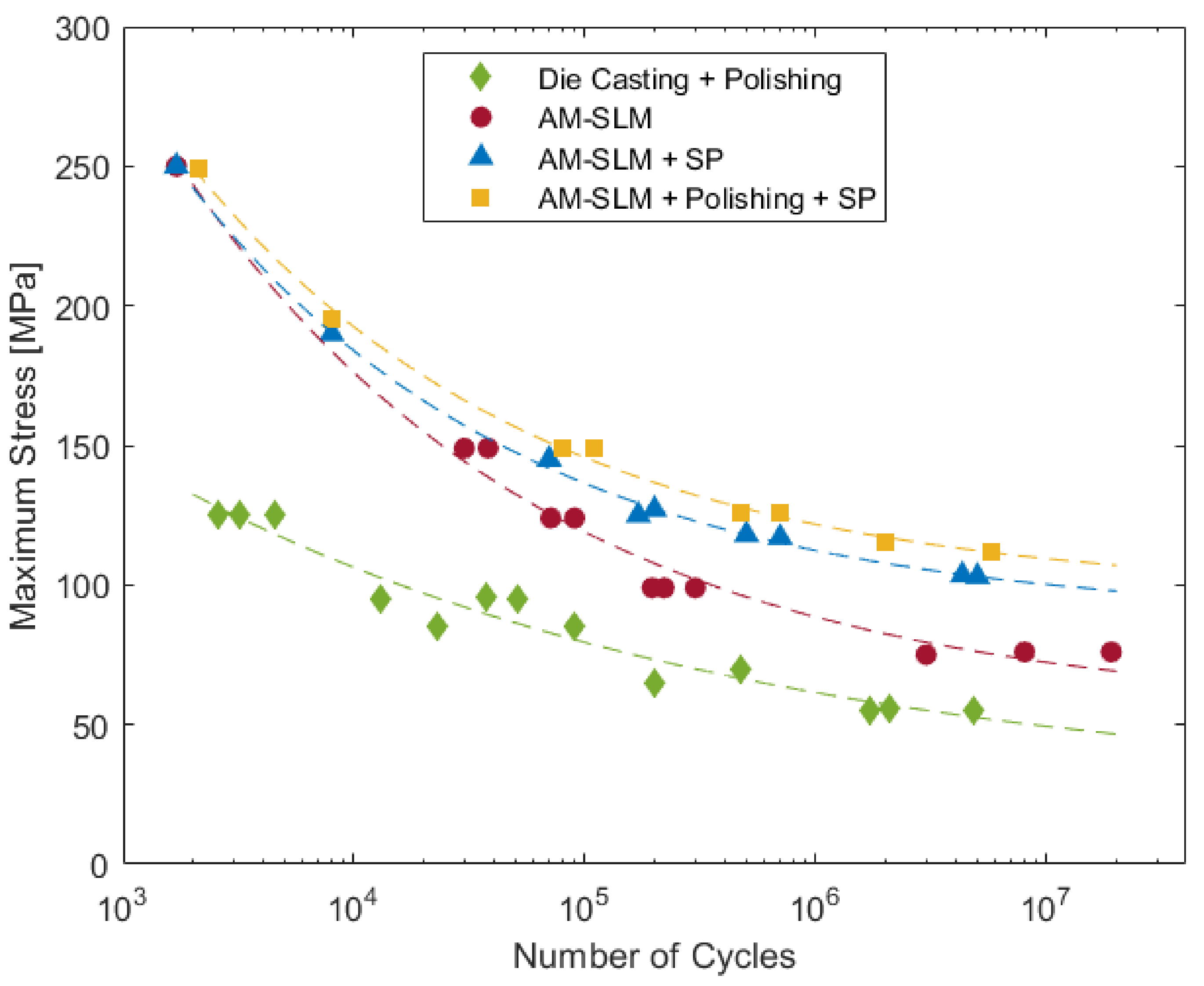

6.2. Reduction in Porosity and Improvement of Surface Quality

6.3. Relieve of Residual Stresses

7. Conclusions

- (i)

- A major part of the literature papers are focused on specific aspects of the AM process of Al alloys; however, defects in printed components depend in many ways on material composition and process parameters, and it is a challenging task to find the optimal trade-off of all the factors affecting the final macro- and microstructure. Therefore, more efforts should be made to investigate the process of a single material in a whole by combining experimental work and simulation, with particular attention to the contributions which could be given today by artificial intelligence.

- (ii)

- The development of models and deep learning systems able to predict with accuracy the final characteristics of printed products will be very useful to reduce long and expensive experimental trails and accelerate the application of AM on a larger industrial scale.

- (iii)

- Since AM has characteristics completely different from conventional manufacturing methods, the design and development of new alloys, in particular high-strength Al alloys, with compositions specifically tailored for this technology, is a critical issue, and relevant advancements are expected from future research.

- (iv)

- It is of fundamental importance to identify inoculants that are more effective in promoting a microstructure consisting of equiaxed grains with small size and random orientation.

- (v)

- The integration of AM with MRO aircraft operations through the just-in-time production of components requires relatively simple machinery; thus, complex postprocess treatments represent a drawback. In addition to the production of printed components of better quality, a target of future research should be the reduction of postprocess treatments, as well as their simplification and integration.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AM | Additive Manufacturing |

| TO | Topology Optimization |

| CAD | Computer-Aided Design |

| MRO | Maintenance, Repair, and Overhaul |

| L-PBF | Laser Powder Bed Fusion |

| DED | Direct Energy Deposition |

| WAAM | Wire Arc Additive Manufacturing |

| SLM | Selective Laser Melting |

| DMLS | Direct Metal Laser Sintering |

| CET | Columnar to Equiaxed Transition |

| G | Thermal gradient |

| R | Growth rate |

| EBM | Electron Beam Melting |

| SMS | Solidification Microstructure Selection |

| GND | Geometrical Necessary Dislocations |

| E | Dynamic modulus |

| YS | Yield Stress |

| UTS | Ultimate Tensile Strength |

| SP | Shot Peening |

| HIP | Hot Isostatic Pressing |

References

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for aeronautic applications: State of art and perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef] [Green Version]

- Debnath, B.; Shakur, M.S.; Tanjum, F.; Rahman, M.A.; Adnan, Z.H. Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review. Logistics 2022, 6, 28. [Google Scholar] [CrossRef]

- Bendsøe, M.; Sigmund, O. Topology Optimization: Theory, Method and Applications; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Fetisov, K.V.; Maksimov, P.V. Topology Optimization and Laser Additive Manufacturing in Design Process of Efficiency Lightweight Aerospace Parts. J. Phys. Conf. Ser. 2018, 1015, 052006. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Karalekas, D.; Tzetzis, D. Architected Materials for Additive Manufacturing: A Comprehensive Review. Materials 2022, 15, 5919. [Google Scholar] [CrossRef] [PubMed]

- Costanza, G.; Gusmano, G.; Montanari, R.; Tata, M.E. Optimisation of TiH2, and SiC content in Al foams. Metall. Ital. 2005, 97, 41–47. [Google Scholar]

- Costanza, G.; Gusmano, G.; Montanari, R.; Tata, M.E.; Ucciardello, N. Effect of powder mix composition on Al foam morphology. J. Mater. Des. Appl. 2008, 222, 131–140. [Google Scholar] [CrossRef]

- Lapi, G.; Montanari, R.; Tata, M.E.; Barbieri, G.; Balijepalli, S.K.; Kaciulis, S. Investigation of Skin-Core Joints in Aluminium Foam Sandwich Panels by EDS and XPS. Surf. Interface Anal. 2016, 48, 479–482. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive Manufacturing: Technology, Applications and Research Needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Singamneni, S.; Yifan, L.V.; Hewitt, A.; Chalk, R.; Thomas, W.; Jordison, D. Additive Manufacturing for the Aircraft Industry: A Review. J. Aeronaut. Aerosp. Eng. 2019, 8, 215. [Google Scholar] [CrossRef] [Green Version]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef] [Green Version]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive Manufacturing in the Spare Parts Supply Chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Additive Manufacturing Reduces Tooling Cost and Lead Time to Produce Composite Aerospace Parts-Global Print Monitor. Available online: http://globalprintmonitor.de/en/3d/3d-printing-news/aerospace/17617-additive-manufacturing-reducestooling-cost-and-lead-time-to-produce-composite-aerospace-parts (accessed on 13 March 2022).

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Seifi, M.; Gorelik, M.; Waller, J.; Hrabe, N.; Shamsaei, N.; Daniewicz, S.; Lewandowski, J.J. Progress towards metal additive manufacturing standardization to support qualification and certification. JOM 2017, 69, 439–455. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.H.; Fatemi, A.; Phan, N. Critical assessment of the fatigue performance of additively manufactured Ti–6Al–4V and perspective for future research. Int. J. Fatigue 2016, 85, 130–143. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Sharifimehr, S.; Shamsaei, N.; Phan, N. Torsional fatigue behavior of wrought and additive manufactured Ti-6Al-4V by powder bed fusion including surface finish effect. Int. J. Fatigue 2017, 99, 187–201. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I.; du Plessis, A.; MacDonald, E. Fundamentals of Laser Powder Bed Fusion of Metals, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal Additive Manufacturing in the Commercial Aviation Industry: A Review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Gibbons, G.; Das, A.; Howes, P.D. A review of Laser Powder Bed Fusion Additive Manufacturing of aluminium alloys: Microstructure and properties. Addit. Manuf. 2021, 46, 102155. [Google Scholar] [CrossRef]

- Madhavadas, V.; Srivastava, D.; Chadha, U.; Aravind Raj, S.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. A Review on Metal Additive Manufacturing for Intricately Shaped Aerospace Components. CIRP J. Manuf. Sci. Technol. 2022, 39, 18–36. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar] [CrossRef]

- Make Parts Fast. Available online: https://www.makepartsfast.com/additive-manufacturing-enables-bionic-aircraft-designs/ (accessed on 17 January 2023).

- AdditiveManufacturing. Available online: https://additivemanufacturing.com/2017/04/10/norsk-titanium-to-deliver-the-worlds-first-faa-approved-3d-printed-structural-titanium-components-to-boeing/ (accessed on 17 January 2023).

- Airbus. Available online: https://www.airbus.com/en/newsroom/press-releases/2017-09-first-titanium-3d-printed-part-installed-into-serial-production (accessed on 17 January 2023).

- GKN Aerospace. Available online: https://www.gknaerospace.com/en/our-technology/2017/gkn-aerospace-engine-systems-journey-to-introduce-additive-manufacturing/ (accessed on 17 January 2023).

- EOS. Available online: https://www.eos.info/en/all-3d-printing-applications/aerospace-3d-printing/aircraft (accessed on 17 January 2023).

- Autodesk. Available online: https://adsknews.autodesk.com/stories/how-this-light-weight-airplane-seat-can-save-airlines-200000000-and-dramatically-reduce-carbon-emissions (accessed on 17 January 2023).

- Arch Daily. Available online: https://www.archdaily.com/780661/the-livings-parametric-3d-printed-airplane-partition-is-designed-to-mimic-bone-structure (accessed on 17 January 2023).

- EOS. Available online: https://www.eos.info/en/innovations/all-3d-printing-applications/aerospace/aerospace-case-studies/ruag-aerospace-3d-printed-satellite-components (accessed on 17 January 2023).

- Additive Manufacturing Media. Available online: https://www.additivemanufacturing.media/articles/what-is-the-role-for-additive-manufacturing-in-aircraft-structural-components (accessed on 17 January 2023).

- EOS. Available online: https://www.eos.info/01_parts-and-applications/case_studies_applications_parts/_case_studies_pdf/en_cases/cs_m_aerospace_sogeti_en.pdf (accessed on 17 January 2023).

- Hettesheimer, T.; Hirzel, S.; Roß, H.B. Energy savings through additive manufacturing: An analysis of selective laser sintering for automotive and aircraft components. Energy Effic. 2018, 11, 1227–1245. [Google Scholar] [CrossRef]

- nTopology. Available online: https://ntopology.com/case-studies/cobra-aero/ (accessed on 17 January 2023).

- Muhammad, M.; Nezhadfar, P.D.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. A comparative investigation on the microstructure and mechanical properties of additively manufactured aluminum alloys. Int. J. Fatigue 2021, 146, 106165. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of aluminium alloys: Additive manufacturing of aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Lightweight Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Waller, D.; Polizzi, A.; Iten, J. Feasibility study of additively manufactured Al-6061 RAM2 parts for aerospace applications. In Proceedings of the AIAA 2019-0409, Session: Materials and Design for Additive Manufacturing, San Diego, CA, USA, 7–11 January 2019. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Maskery, I.; Ashcroft, I.; Tuck, C. Selective laser melting of aluminum alloys. MRS Bull. 2017, 42, 311–319. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E.; Manfredi, D.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review. Materials 2019, 12, 1007. [Google Scholar] [CrossRef] [Green Version]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Buchbinder, D.; Schleifenbaum, H.; Heidrich, S.; Meiners, W.; Bültmann, J. High Power Selective Laser Melting (HP SLM) of Aluminum Parts. Phys. Procedia 2011, 12, 271–278. [Google Scholar] [CrossRef]

- Hamidi Nasab, M.; Romano, S.; Gastaldi, D.; Beretta, S.; Vedani, M. Combined effect of surface anomalies and volumetric defects on fatigue assessment of AlSi7Mg fabricated via laser powder bed fusion. Addit. Manuf. 2020, 34, 100918. [Google Scholar] [CrossRef]

- Bauer, D.M.; Dietrich, K.; Walter, M.; Forêt, P.; Palm, F.; Witt, G. Effect of process gas and powder quality on aluminum alloys processed by laser based powder bed melting process. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016; pp. 419–425. [Google Scholar]

- Anwar, A.B.; Pham, Q.C. Selective laser melting of AlSi10Mg: Effects of scan direction, part placement and inert gas flow velocity on tensile strength. J. Mater. Process. Technol. 2017, 240, 388–396. [Google Scholar] [CrossRef]

- Galy, C.; Le Guen, E.; Lacoste, E.; Arvieu, C. Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences. Addit. Manuf. 2018, 22, 165–175. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Microstructures and mechanical properties of A356 (AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting. Mater. Des. 2016, 89, 1294–1301. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef] [Green Version]

- Damon, J.; Dietrich, S.; Vollert, F.; Gibmeier, J.; Schulze, V. Process Dependent Porosity and the Influence of Shot Peening on Porosity Morphology Regarding Selective Laser Melted AlSi10Mg Parts. Addit. Manuf. 2018, 20, 77–89. [Google Scholar] [CrossRef]

- Cerri, E.; Ghio, E.; Bolelli, G. Defect-Correlated Vickers Microhardness of Al-Si-Mg Alloy Manufactured by Laser Powder Bed Fusion with Post-process Heat Treatments. J. Mater. Eng. Perform. 2021, 31, 8047–8067. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Breese, P.P.; Lutz, B.S.; Pantano, M.; Nalam, Y.; Bela, K.; Kamps, T.; Volpp, J.; Kaplan, A.F.H. Porosity in Wire Arc Additive Manufacturing of Aluminium Alloys. Addit. Manuf. 2021, 41, 101993. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Tonelli, L.; Liverani, E.; Valli, G.; Fortunato, A.; Ceschini, L. Effects of Powders and Process Parameters on Density and Hardness of A357 Aluminum Alloy Fabricated by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2020, 106, 371–383. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal Post-Processing of AlSi10Mg Parts Produced by Selective Laser Melting Using Recycled Powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- Stopyra, W.; Gruber, K.; Smolina, I.; Kurzynowski, T.; Kuźnicka, B. Laser Powder Bed Fusion of AA7075 Alloy: Influence of Process Parameters on Porosity and Hot Cracking. Addit. Manuf. 2020, 35, 101270. [Google Scholar] [CrossRef]

- Muñiz-Lerma, J.A.; Nommeots-Nomm, A.; Waters, K.E.; Brochu, M. A Comprehensive Approach to Powder Feedstock Characterization for Powder Bed Fusion Additive Manufacturing: A Case Study on AlSi7Mg. Materials 2018, 11, 2386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baitimerov, R.; Lykov, P.; Zherebtsov, D.; Radionova, L.; Shultc, A.; Prashanth, K.G. Influence of Powder Characteristics on Processability of AlSi12 Alloy Fabricated by Selective Laser Melting. Materials 2018, 11, 742. [Google Scholar] [CrossRef] [Green Version]

- Balbaa, M.A.; Ghasemi, A.; Fereiduni, E.; Elbestawi, M.A.; Jadhav, S.D.; Kruth, J.-P. Role of Powder Particle Size on Laser Powder Bed Fusion Processability of AlSi10mg Alloy. Addit. Manuf. 2021, 37, 101630. [Google Scholar] [CrossRef]

- Riener, K.; Albrecht, N.; Ziegelmeier, S.; Ramakrishnan, R.; Haferkamp, L.; Spierings, A.B.; Leichtfried, G.J. Influence of Particle Size Distribution and Morphology on the Properties of the Powder Feedstock as Well as of AlSi10Mg Parts Produced by Laser Powder Bed Fusion (LPBF). Addit. Manuf. 2020, 34, 101286. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and Reduction of Hydrogen Porosity during Selective Laser Melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Li, X.P.; O’Donnell, K.M.; Sercombe, T.B. Selective Laser Melting of Al-12Si Alloy: Enhanced Densification via Powder Drying. Addit. Manuf. 2016, 10, 10–14. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-Structured Aluminium Products with Controllable Texture by Selective Laser Melting of Pre-Alloyed AlSi10Mg Powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Montero-Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.-P.; Van Humbeeck, J. Changing the Alloy Composition of Al7075 for Better Processability by Selective Laser Melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Kaufmann, N.; Imran, M.; Wischeropp, T.M.; Emmelmann, C.; Siddique, S.; Walther, F. Influence of Process Parameters on the Quality of Aluminium Alloy EN AW 7075 Using Selective Laser Melting (SLM). Phys. Procedia 2016, 83, 918–926. [Google Scholar] [CrossRef] [Green Version]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Griffiths, S.; Croteau, J.R.; Rossell, M.D.; Erni, R.; De Luca, A.; Vo, N.Q.; Dunand, D.C.; Leinenbach, C. Coarsening- and Creep Resistance of Precipitation-Strengthened Al–Mg–Zr Alloys Processed by Selective Laser Melting. Acta Mater. 2020, 188, 192–202. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of Zirconium Addition on Crack, Microstructure and Mechanical Behavior of Selective Laser Melted Al-Cu-Mg Alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc-and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Zhou, L.; Hyer, H.; Park, S.; Pan, H.; Bai, Y.; Rice, K.P.; Sohn, Y. Microstructure and Mechanical Properties of Zr-Modified Aluminum Alloy 5083 Manufactured by Laser Powder Bed Fusion. Addit. Manuf. 2019, 28, 485–496. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure and Tensile Property of a Novel AlZnMgScZr Alloy Additively Manufactured by Gas Atomization and Laser Powder Bed Fusion. Scr. Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Bi, J.; Zhenglong, L.; Chen, Y.; Chen, X.; Tian, Z.; Liang, J.; Zhang, X.; Qin, X. Microstructure and Mechanical Properties of a Novel Sc and Zr Modified 7075 Aluminum Alloy Prepared by Selective Laser Melting. Mater. Sci. Eng. A 2019, 768, 138478. [Google Scholar] [CrossRef]

- Hu, Z.; Nie, X.; Qi, Y.; Zhang, H.; Zhu, H. Cracking Criterion for High Strength Al–Cu Alloys Fabricated by Selective Laser Melting. Addit. Manuf. 2021, 37, 101709. [Google Scholar] [CrossRef]

- Cao, Y.; Wei, H.L.; Yang, T.; Liu, T.T.; Liao, W.H. Printability Assessment with Porosity and Solidification Cracking Susceptibilities for a High Strength Aluminum Alloy during Laser Powder Bed Fusion. Addit. Manuf. 2021, 46, 102103. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective Laser Melting of High Strength Al–Cu–Mg Alloys: Processing, Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, H.; Xiaojia, N.; Hu, Z.; Zhu, H.; Zeng, X. A High Strength Al–Li Alloy Produced by Laser Powder Bed Fusion: Densification, Microstructure, and Mechanical Properties. Addit. Manuf. 2020, 35, 101346. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Prashanth, K.G.; Mendes, R.G.; Rümmeli, M.H.; Gemming, T.; Eckert, J.; Scudino, S. Microstructure and Mechanical Properties of a Heat-Treatable Al-3.5Cu-1.5Mg-1Si Alloy Produced by Selective Laser Melting. Mater. Sci. Eng. A 2018, 711, 562–570. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Effect of Zr Content on Formability, Microstructure and Mechanical Properties of Selective Laser Melted Zr Modified Al-4.24Cu-1.97Mg-0.56Mn Alloys. J. Alloys Compd. 2018, 764, 977–986. [Google Scholar] [CrossRef]

- Rasch, M.; Heberle, J.; Dechet, M.A.; Bartels, D.; Gotterbarm, M.R.; Klein, L.; Gorunov, A.; Schmidt, J.; Körner, C.; Peukert, W.; et al. Grain Structure Evolution of Al–Cu Alloys in Powder Bed Fusion with Laser Beam for Excellent Mechanical Properties. Materials 2020, 13, 82. [Google Scholar] [CrossRef] [Green Version]

- Rosenthal, D. Mathematical theory of heat distribution during welding and cutting. Weld. J. 1941, 20, 220–234. [Google Scholar]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Atzeni, E. From Powders to Dense Metal Parts: Characterization of a Commercial AlSiMg Alloy Processed through Direct Metal Laser Sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef] [Green Version]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Elambasseril, J.; Brandt, M. Effect of energy per layer on the anisotropy of selective laser melted AlSi12 aluminium alloy. Addit. Manuf. 2018, 22, 426–439. [Google Scholar] [CrossRef]

- Nezhadfar, P.D.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. Structural Integrity of Additively Manufactured Aluminum Alloys: Effects of Build Orientation on Microstructure, Porosity, and Fatigue Behavior. Addit. Manuf. 2021, 47, 102292. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Gu, X.; Dai, N.; Qin, P.; Zhang, L.-C. Distinction of Corrosion Resistance of Selective Laser Melted Al-12Si Alloy on Different Planes. J. Alloys Compd. 2018, 747, 648–658. [Google Scholar] [CrossRef]

- Tonelli, L.; Laghi, V.; Palermo, M.; Trombetti, T.; Ceschini, L. AA5083 (Al–Mg) Plates Produced by Wire-and-Arc Additive Manufacturing: Effect of Specimen Orientation on Microstructure and Tensile Properties. Prog. Addit. Manuf. 2021, 6, 479–494. [Google Scholar] [CrossRef]

- Qin, Z.; Kang, N.; El Mansori, M.; Wang, Z.; Wang, H.; Lin, X.; Chen, J.; Huang, W. Anisotropic High Cycle Fatigue Property of Sc and Zr-Modified Al-Mg Alloy Fabricated by Laser Powder Bed Fusion. Addit. Manuf. 2022, 49, 102514. [Google Scholar] [CrossRef]

- Majeed, A.; Ahmed, A.; Salam, A.; Sheikh, M.Z. Surface Quality Improvement by Parameters Analysis, Optimization and Heat Treatment of AlSi10Mg Parts Manufactured by SLM Additive Manufacturing. Int. J. Lightweight Mater. Manuf. 2019, 2, 288–295. [Google Scholar] [CrossRef]

- Mohammadi, M.; Asgari, H. Achieving Low Surface Roughness AlSi10Mg_200C Parts Using Direct Metal Laser Sintering. Addit. Manuf. 2018, 20, 23–32. [Google Scholar] [CrossRef]

- Poncelet, O.; Marteleur, M.; van der Rest, C.; Rigo, O.; Adrien, J.; Dancette, S.; Jacques, P.J.; Simar, A. Critical Assessment of the Impact of Process Parameters on Vertical Roughness and Hardness of Thin Walls of AlSi10Mg Processed by Laser Powder Bed Fusion. Addit. Manuf. 2021, 38, 101801. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of Process Parameters on Surface Roughness of Aluminum Parts Produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef] [Green Version]

- Hönnige, J.R.; Colegrove, P.A.; Ganguly, S.; Eimer, E.; Kabra, S.; Williams, S. Control of Residual Stress and Distortion in Aluminium Wire + Arc Additive Manufacture with Rolling. Addit. Manuf. 2018, 22, 775–783. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Jiang, X.; Zhu, Y.; Ding, Z.; Zhu, X.; Sun, J.; Yan, B. Investigation of Performance and Residual Stress Generation of AlSi10Mg Processed by Selective Laser Melting. Adv. Mater. Sci. Eng. 2018, 2018, 7814039. [Google Scholar] [CrossRef] [Green Version]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Yasa, E.; Badrossamay, M.; Verheecke, W.; Kruth, J. Process Optimization and Microstructural Analysis for Selective Laser Melting of AlSi10Mg. In Proceedings of the 22nd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2011, Austin, TX, USA, 8–10 August 2011. [Google Scholar]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on Reducing Distortion by Preheating during Manufacture of Aluminum Components Using Selective Laser Melting. J. Laser Appl. 2014, 26, 012004. [Google Scholar] [CrossRef]

- Oyama, K.; Diplas, S.; M’hamdi, M.; Gunnæs, A.E.; Azar, A.S. Heat Source Management in Wire-Arc Additive Manufacturing Process for Al-Mg and Al-Si Alloys. Addit. Manuf. 2019, 26, 180–192. [Google Scholar] [CrossRef]

- Liu, Y.J.; Liu, Z.; Jiang, Y.; Wang, G.W.; Yang, Y.; Zhang, L.C. Gradient in Microstructure and Mechanical Property of Selective Laser Melted AlSi10Mg. J. Alloys Compd. 2018, 735, 1414–1421. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, C.; Zhou, X.; Shen, Z.; Liu, W. Microstructure of Selective Laser Melted AlSi10Mg Alloy. Mater. Des. 2019, 168, 107677. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shalchi Amirkhiz, B.; Odeshi, A.G.; Li, J.; Mohammadi, M. Role of Hierarchical Microstructure of Additively Manufactured AlSi10Mg on Dynamic Loading Behavior. Addit. Manuf. 2019, 28, 1–13. [Google Scholar] [CrossRef]

- Tonelli, L. Revealing the Hierarchical Microstructure of Innovative Additively Manufactured Metal Parts with Conventional Light Microscopy. Metallogr. Microstruct. Anal. 2021, 10, 278–282. [Google Scholar] [CrossRef]

- Xiong, Z.H.; Liu, S.L.; Li, S.F.; Shi, Y.; Yang, Y.F.; Misra, R.D.K. Role of Melt Pool Boundary Condition in Determining the Mechanical Properties of Selective Laser Melting AlSi10Mg Alloy. Mater. Sci. Eng. A 2019, 740–741, 148–156. [Google Scholar] [CrossRef]

- Cabibbo, M.; Montanari, R.; Pola, A.; Tocci, M.; Varone, A. Mechanical Spectroscopy Study of As-Cast and Additive Manufactured AlSi10Mg. J. Alloys Compd. 2022, 914, 165361. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, Precipitates and Hardness of Selectively Laser Melted AlSi10Mg Alloy before and after Heat Treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. Contribution of Mg2Si Precipitates to the Strength of Direct Metal Laser Sintered AlSi10Mg. Mater. Sci. Eng. A 2019, 739, 295–300. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and Strength of Selectively Laser Melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef] [Green Version]

- Hadadzadeh, A.; Amirkhiz, B.S.; Langelier, B.; Li, J.; Mohammadi, M. Microstructural Consistency in the Additive Manufactured Metallic Materials: A Study on the Laser Powder Bed Fusion of AlSi10Mg. Addit. Manuf. 2021, 46, 102166. [Google Scholar] [CrossRef]

- Fite, J.; Eswarappa Prameela, S.; Slotwinski, J.A.; Weihs, T.P. Evolution of the Microstructure and Mechanical Properties of Additively Manufactured AlSi10Mg during Room Temperature Holds and Low Temperature Aging. Addit. Manuf. 2020, 36, 101429. [Google Scholar] [CrossRef]

- Ghio, E.; Cerri, E. Additive Manufacturing of AlSi10Mg and Ti6Al4V Lightweight Alloys via Laser Powder Bed Fusion: A Review of Heat Treatments Effects. Materials 2022, 15, 2047. [Google Scholar] [CrossRef]

- Kurz, W.; Bezençon, C.; Gäumann, M. Columnar to Equiaxed Transition in Solidification Processing. Sci. Technol. Adv. Mater. 2001, 2, 185–191. [Google Scholar] [CrossRef]

- Montiel, D.; Liu, L.; Xiao, L.; Zhou, Y.; Provatas, N. Microstructure Analysis of AZ31 Magnesium Alloy Welds Using Phase-Field Models. Acta Mater. 2012, 60, 5925–5932. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to Equiaxed Transition in Al-Mg(-Sc)-Zr Alloys Produced by Selective Laser Melting. Scr. Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Rao, H.; Giet, S.; Yang, K.; Wu, X.; Davies, C.H.J. The Influence of Processing Parameters on Aluminium Alloy A357 Manufactured by Selective Laser Melting. Mater. Des. 2016, 109, 334–346. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Chen, X.; Qiu, C. Complete Columnar-to-Equiaxed Transition and Significant Grain Refinement in an Aluminium Alloy by Adding Nb Particles through Laser Powder Bed Fusion. Addit. Manuf. 2022, 51, 102615. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.P. Selective Laser Melting of Nano-TiB2 Decorated AlSi10Mg Alloy with High Fracture Strength and Ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Dumitraschkewitz, P.; Pogatscher, S.; Wegener, K. Microstructure Characterization of SLM-Processed Al-Mg-Sc-Zr Alloy in the Heat Treated and HIPed Condition. Addit. Manuf. 2018, 20, 173–181. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Columnar to Equiaxed Transition during Direct Metal Laser Sintering of AlSi10Mg Alloy: Effect of Building Direction. Addit. Manuf. 2018, 23, 121–131. [Google Scholar] [CrossRef]

- Maizza, G.; Pero, R.; Richetta, M.; Montanari, R. Continuous Dynamic Recrystallization (CDRX) Model for Aluminum Alloys. J. Mater. Sci. 2018, 53, 4563–4573. [Google Scholar] [CrossRef]

- Tedde, G.M.; Di Schino, A.; Donnini, R.; Montanari, R.; Richetta, M.; Santo, L.; Testani, C.; Varone, A. An Innovative Industrial Process for Forging 7050 Al Alloy. Mater. Sci. Forum 2019, 941, 1047–1052. [Google Scholar] [CrossRef]

- Angella, G.; Di Schino, A.; Donnini, R.; Richetta, M.; Testani, C.; Varone, A. AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties. Metals 2019, 9, 64. [Google Scholar] [CrossRef] [Green Version]

- Di Schino, A.; Montanari, R.; Testani, C.; Varone, A. Dislocation Breakaway Damping in AA7050 Alloy. Metals 2020, 10, 1682. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of Arc Mode in Cold Metal Transfer Process on Porosity of Additively Manufactured Al-6.3%Cu Alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Bai, J.Y.; Yang, C.L.; Lin, S.B.; Dong, B.L.; Fan, C.L. Mechanical Properties of 2219-Al Components Produced by Additive Manufacturing with TIG. Int. J. Adv. Manuf. Technol. 2016, 86, 479–485. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Bai, J.; Zhai, Y.; Ma, P. The Strengthening Effect of Inter-Layer Cold Working and Post-Deposition Heat Treatment on the Additively Manufactured Al–6.3Cu Alloy. Mater. Sci. Eng. A 2016, 651, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Sun, R.; Li, L.; Zhu, Y.; Guo, W.; Peng, P.; Cong, B.; Sun, J.; Che, Z.; Li, B.; Guo, C.; et al. Microstructure, Residual Stress and Tensile Properties Control of Wire-Arc Additive Manufactured 2319 Aluminum Alloy with Laser Shock Peening. J. Alloys Compd. 2018, 747, 255–265. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X. Optimisation of Interpass Temperature and Heat Input for Wire and Arc Additive Manufacturing 5A06 Aluminium Alloy. Sci. Technol. Weld. Join. 2017, 22, 472–483. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Geometric Limitation and Tensile Properties of Wire and Arc Additive Manufacturing 5A06 Aluminum Alloy Parts. J. Mater. Eng. Perform. 2017, 26, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Gu, J.; Wang, X.; Bai, J.; Ding, J.; Williams, S.; Zhai, Y.; Liu, K. Deformation Microstructures and Strengthening Mechanisms for the Wire+arc Additively Manufactured Al-Mg4.5Mn Alloy with Inter-Layer Rolling. Mater. Sci. Eng. A 2018, 712, 292–301. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire Arc Additive Manufacturing of Al-6Mg Alloy Using Variable Polarity Cold Metal Transfer Arc as Power Source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Dong, B.; Cai, X.; Lin, S.; Li, X.; Fan, C.; Yang, C.; Sun, H. Wire Arc Additive Manufacturing of Al-Zn-Mg-Cu Alloy: Microstructures and Mechanical Properties. Addit. Manuf. 2020, 36, 101447. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, X.; Kang, N.; Tang, Y.; Huang, W.; Wang, Z. The Heterogeneous Band Microstructure and Mechanical Performance in a Wire + Arc Additively Manufactured 2219 Al Alloy. Addit. Manuf. 2022, 49, 102486. [Google Scholar] [CrossRef]

- Tiryakioḡlu, M.; Campbell, J. Ductility, Structural Quality, and Fracture Toughness of A-Cu-Mg-Ag (A201) Alloy Castings. Mater. Sci. Technol. 2009, 25, 784–789. [Google Scholar] [CrossRef]

- Kuo, Y.S. Mechanical Properties and Porosity Content of A201 Aluminum Alloy Castings in Different Cooling Rate Sand Molds. Adv. Mater. Res. 2011, 154–155, 787–793. [Google Scholar] [CrossRef]

- Roscher, M.; Balachandran, S.; Mayweg, D.; Jägle, E. Development of Al-Ti-Based Alloys for Laser Powder Bed Fusion. Addit. Manuf. 2021, 47, 102315. [Google Scholar] [CrossRef]

- Aeromet. Available online: https://www.aeromet.co.uk/a20x (accessed on 13 January 2023).

- Bermingham, M.; StJohn, D.; Easton, M.; Yuan, L.; Dargusch, M. Revealing the Mechanisms of Grain Nucleation and Formation During Additive Manufacturing. JOM 2020, 72, 1065–1073. [Google Scholar] [CrossRef]

- Carluccio, D.; Bermingham, M.J.; Zhang, Y.; StJohn, D.H.; Yang, K.; Rometsch, P.A.; Wu, X.; Dargusch, M.S. Grain Refinement of Laser Remelted Al-7Si and 6061 Aluminium Alloys with Tibor® and Scandium Additions. J. Manuf. Process. 2018, 35, 715–720. [Google Scholar] [CrossRef]

- Ghoncheh, M.H.; Sanjari, M.; Zoeram, A.S.; Cyr, E.; Amirkhiz, B.S.; Lloyd, A.; Haghshenas, M.; Mohammadi, M. On the Microstructure and Solidification Behavior of New Generation Additively Manufactured Al-Cu-Mg-Ag-Ti-B Alloys. Addit. Manuf. 2021, 37, 101724. [Google Scholar] [CrossRef]

- Bassani, P.; Biffi, C.A.; Casati, R.; Zanatta Alarcon, A.; Tuissi, A.; Vedani, M. Properties of Aluminium Alloys Produced by Selective Laser Melting. Key Eng. Mater. 2016, 710, 83–88. [Google Scholar] [CrossRef]

- Tocci, M.; Varone, A.; Montanari, R.; Pola, A. Study of High Temperature Properties of AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion. Mater. Sci. Forum 2021, 1016, 1485–1491. [Google Scholar] [CrossRef]

- Fava, A.; Montanari, R.; Varone, A. Mechanical spectroscopy investigation of point defect-driven phenomena in a Cr martensitic steel. Metals 2018, 8, 870. [Google Scholar] [CrossRef] [Green Version]

- Montanari, R.; Varone, A. Synergic Role of Self-interstitials and Vacancies in Indium Melting. Metals 2015, 5, 1061–1072. [Google Scholar] [CrossRef]

- Balijepalli, S.K.; Donnini, R.; Kaciulis, S.; Lucci, M.; Montanari, R.; Ucciardello, N.; Varone, A. Modulo elastico della fase S in un acciaio 316 L kolsterizzato. La Metall. Ital. 2013, 105, 42–47. [Google Scholar]

- Balijepalli, S.K.; Donnini, R.; Kaciulis, S.; Montanari, R.; Varone, A. Young’s modulus profile in kolsterized AISI 316 L steel. Mater. Sci. Forum 2013, 762, 183–188. [Google Scholar] [CrossRef]

- Montanari, R.; Varone, A. Mechanical spectroscopy investigation of liquid Pb-Bi alloys. Solid State Phenom. 2012, 184, 434–439. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Baxter, C.; Amirkhiz, B.S.; Mohammadi, M. Strengthening Mechanisms in Direct Metal Laser Sintered AlSi10Mg: Comparison between Virgin and Recycled Powders. Addit. Manuf. 2018, 23, 108–120. [Google Scholar] [CrossRef]

- Mohammadpour, P.; Plotkowski, A.; Phillion, A.B. Revisiting Solidification Microstructure Selection Maps in the Frame of Additive Manufacturing. Addit. Manuf. 2020, 31, 100936. [Google Scholar] [CrossRef]

- Li, S.; Zhang, L.-J.; Ning, J.; Wang, X.; Zhang, G.-F.; Zhang, J.-X.; Na, S.-J.; Fatemeh, B. Comparative Study on the Microstructures and Properties of Wire+arc Additively Manufactured 5356 Aluminium Alloy with Argon and Nitrogen as the Shielding Gas. Addit. Manuf. 2020, 34, 101206. [Google Scholar] [CrossRef]

- Bian, H.; Aoyagi, K.; Zhao, Y.; Maeda, C.; Mouri, T.; Chiba, A. Microstructure Refinement for Superior Ductility of Al–Si Alloy by Electron Beam Melting. Addit. Manuf. 2020, 32, 100982. [Google Scholar] [CrossRef]

- Aversa, A.; Lorusso, M.; Trevisan, F.; Ambrosio, E.P.; Calignano, F.; Manfredi, D.; Biamino, S.; Fino, P.; Lombardi, M.; Pavese, M. Effect of Process and Post-Process Conditions on the Mechanical Properties of an A357 Alloy Produced via Laser Powder Bed Fusion. Metals 2017, 7, 68. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt Pool Temperature and Cooling Rates in Laser Powder Bed Fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive Manufactured AlSi10Mg Samples Using Selective Laser Melting (SLM): Microstructure, High Cycle Fatigue, and Fracture Behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Ghasemi, A.; Fereiduni, E.; Balbaa, M.; Jadhav, S.D.; Elbestawi, M.; Habibi, S. Influence of Alloying Elements on Laser Powder Bed Fusion Processability of Aluminum: A New Insight into the Oxidation Tendency. Addit. Manuf. 2021, 46, 102145. [Google Scholar] [CrossRef]

- Mauduit, A. Study of the Suitability of Aluminum Alloys for Additive Manufacturing by Laser Powder Bed Fusion. UPB Sci. Bull. Ser. B Chem. Mater. Sci. 2017, 79, 219–238. [Google Scholar]

- Karg, M.; Ahuja, B.; Kuryntsev, S.; Gorunov, A.; Schmidt, M. Processability of High Strength Aluminium-Copper Alloys AW-2022 and 2024 by Laser Beam Melting in Powder Bed. In Proceedings of the 25th Annual International Solid Freeform Fabrication (SFF) Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Sun, S.; Zheng, L.; Liu, Y.; Liu, J.; Zhang, H. Characterization of Al–Fe–V–Si Heat-Resistant Aluminum Alloy Components Fabricated by Selective Laser Melting. J. Mater. Res. 2015, 30, 1661–1669. [Google Scholar] [CrossRef]

- Jia, Q.; Rometsch, P.; Kürnsteiner, P.; Chao, Q.; Huang, A.; Weyland, M.; Bourgeois, L.; Wu, X. Selective laser melting of a high strength Al-Mn-Sc alloy: Alloy design and strengthening mechanisms. Acta Mater. 2019, 171, 108–118. [Google Scholar] [CrossRef]

- Zhang, H.; Gu, D.; Yang, J.; Dai, D.; Zhao, T.; Hong, C.; Gasser, A.; Poprawe, R. Selective Laser Melting of Rare Earth Element Sc Modified Aluminum Alloy: Thermodynamics of Precipitation Behavior and Its Influence on Mechanical Properties. Addit. Manuf. 2018, 23, 1–12. [Google Scholar] [CrossRef]

- Agrawal, P.; Gupta, S.; Thapliyal, S.; Shukla, S.; Haridas, R.S.; Mishra, R.S. Additively manufactured novel Al-Cu-Sc-Zr alloy: Microstructure and mechanical propertiez. Addit. Manuf. 2021, 37, 101623. [Google Scholar] [CrossRef]

- Glerum, J.A.; Kenel, C.; Sun, T.; Dunand, D.C. Synthesis of Precipitation-Strengthened Al-Sc, Al-Zr and Al-Sc-Zr Alloys via Selective Laser Melting of Elemental Powder Blends. Addit. Manuf. 2020, 36, 101461. [Google Scholar] [CrossRef]

- Opprecht, M.; Garandet, J.-P.; Roux, G.; Flament, C.; Soulier, M. A Solution to the Hot Cracking Problem for Aluminium Alloys Manufactured by Laser Beam Melting. Acta Mater. 2020, 197, 40–53. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Wang, K.; Zhan, Q.; Xiao, X. Grain Refinement and Crack Inhibition of Selective Laser Melted AA2024 Aluminum Alloy via Inoculation with TiC–TiH2. Mater. Sci. Eng. A 2021, 813, 141171. [Google Scholar] [CrossRef]

- Mair, P.; Goettgens, V.S.; Rainer, T.; Weinberger, N.; Letofsky-Papst, I.; Mitsche, S.; Leichtfried, G. Laser Powder Bed Fusion of Nano-CaB6 Decorated 2024 Aluminum Alloy. J. Alloys Compd. 2021, 863, 158714. [Google Scholar] [CrossRef]

- Zhou, L.; Hyer, H.; Chang, J.; Mehta, A.; Huynh, T.; Yang, Y.; Sohn, Y. Microstructure, Mechanical Performance, and Corrosion Behavior of Additively Manufactured Aluminum Alloy 5083 with 0.7 and 1.0 Wt% Zr Addition. Mater. Sci. Eng. A 2021, 823, 141679. [Google Scholar] [CrossRef]

- Tan, Q.; Zhang, J.; Sun, Q.; Fan, Z.; Li, G.; Yin, Y.; Liu, Y.; Zhang, M.-X. Inoculation Treatment of an Additively Manufactured 2024 Aluminium Alloy with Titanium Nanoparticles. Acta Mater. 2020, 196, 1–16. [Google Scholar] [CrossRef]

- Otani, Y.; Sasaki, S. Effects of the Addition of Silicon to 7075 Aluminum Alloy on Microstructure, Mechanical Properties, and Selective Laser Melting Processability. Mater. Sci. Eng. A 2020, 777, 139079. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Su, Y.; Wang, H.; Enz, J.; Ebel, T.; Yan, M. Selective Laser Melting Additive Manufacturing of 7xxx Series Al-Zn-Mg-Cu Alloy: Cracking Elimination by Co-Incorporation of Si and TiB2. Addit. Manuf. 2020, 36, 101458. [Google Scholar] [CrossRef]

- Qi, Y.; Hu, Z.; Zhang, H.; Nie, X.; Zhang, C.; Zhu, H. High Strength Al–Li Alloy Development for Laser Powder Bed Fusion. Addit. Manuf. 2021, 47, 102249. [Google Scholar] [CrossRef]

- Belelli, F.; Casati, R.; Vedani, M. Development of Al-Cu-Mg and Al-Mg-Si-Zr Alloys with Improved L-PBF Processability. In Proceedings of the 151st Annual Meeting and Exhibition of The Minerals, Metals and Materials Society, TMS 2022, Anaheim, CA, USA, 27 February–3 March 2022; pp. 289–297. [Google Scholar] [CrossRef]

- Belelli, F.; Casati, R.; Vedani, M. Effect of Cu Content on Hot-Crack Resistance of Al-Cu-Mg Alloys Produced by Laser Powder Bed Fusion. Philos. Mag. Lett. 2022, 102, 111–119. [Google Scholar] [CrossRef]

- Casati, R.; Coduri, M.; Riccio, M.; Rizzi, A.; Vedani, M. Development of a High Strength Al–Zn–Si–Mg–Cu Alloy for Selective Laser Melting. J. Alloys Compd. 2019, 801, 243–253. [Google Scholar] [CrossRef]

- Marola, S.; Gianoglio, D.; Bosio, F.; Aversa, A.; Lorusso, M.; Manfredi, D.; Lombardi, M.; Battezzati, L. Alloying AlSi10Mg and Cu Powders in Laser Single Scan Tracks, Melt Spinning, and Laser Powder Bed Fusion. J. Alloys Compd. 2020, 821, 153538. [Google Scholar] [CrossRef]

- Belelli, F.; Casati, R.; Vedani, M.; Volpp, J. Design and Characterization of Al–Mg–Si–Zr Alloys with Improved Laser Powder Bed Fusion Processability. Metall. Mater. Trans. A 2022, 53, 331–343. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Kang, N.; Hu, Y.; Chen, J.; Huang, W. Strength-Ductility Synergy of Selective Laser Melted Al-Mg-Sc-Zr Alloy with a Heterogeneous Grain Structure. Addit. Manuf. 2020, 34, 101260. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, J.; Song, B.; Zhang, L.; Han, C.; Cai, C.; Zhou, K.; Shi, Y. A Novel Crack-Free Ti-Modified Al-Cu-Mg Alloy Designed for Selective Laser Melting. Addit. Manuf. 2021, 38, 101829. [Google Scholar] [CrossRef]

- Goebel, J.; Ghidini, T.; Graham, A.J. Stress-Corrosion Cracking Characterisation of the Advanced Aerospace Al–Li 2099-T86 Alloy. Mater. Sci. Eng. A 2016, 673, 16–23. [Google Scholar] [CrossRef]

- Chen, R.; Wang, H.; He, B.; Tu, Y.; Tang, H. Effect of Thermal Cycling on Microstructure and Mechanical Properties of 2A97 Al–Li Alloy Fabricated by Direct Laser Deposition. Vacuum 2021, 190, 110299. [Google Scholar] [CrossRef]

- Yürekli, B.; Schade, L.; Ullsperger, T.; Seyfarth, B.; Kohl, H.; Matthäus, G.; Liu, D.; Rettenmayr, M.; Nolte, S. Additive Manufacturing of Binary Al-Li Alloys. Procedia CIRP 2020, 94, 69–73. [Google Scholar] [CrossRef]

- Li, L.; Meng, X.; Huang, S.; Wang, H.; Li, P.; Zhou, J. Investigating the Effect of the Scanning Speed on the Characteristics of Al-Li Alloy Fabricated by Selective Laser Melting. J. Manuf. Process. 2022, 75, 719–728. [Google Scholar] [CrossRef]

- Bahl, S.; Sisco, K.; Yang, Y.; Theska, F.; Primig, S.; Allard, L.F.; Michi, R.A.; Fancher, C.; Stump, B.; Dehoff, R.; et al. Al-Cu-Ce(-Zr) Alloys with an Exceptional Combination of Additive Processability and Mechanical Properties. Addit. Manuf. 2021, 48, 102404. [Google Scholar] [CrossRef]

- Czerwinski, F. Cerium in Aluminum Alloys. J. Mater. Sci. 2020, 55, 24–72. [Google Scholar] [CrossRef]

- Czerwinski, F. Thermal Stability of Aluminum Alloys. Materials 2020, 13, 3441. [Google Scholar] [CrossRef]

- Czerwinski, F. Critical Assessment 40: A Search for the Eutectic System of High-Temperature Cast Aluminium Alloys. Mater. Sci. Technol. 2021, 37, 683–692. [Google Scholar] [CrossRef]

- Czerwinski, F. Thermal Stability of Aluminum–Cerium Binary Alloys Containing the Al–Al11Ce3 Eutectic. Mater. Sci. Eng. A 2021, 809, 140973. [Google Scholar] [CrossRef]

- Ng, D.S.; Dunand, D.C. Aging- and creep-resistance of a cast hypoeutectic Al-6.9Ce- 9.3Mg (wt%) alloy. Mater. Sci. Eng. A 2020, 786, 139398. [Google Scholar] [CrossRef]

- Plotkowski, A.; Sisco, K.; Bahl, S.; Shyam, A.; Yang, Y.; Allard, L.; Nandwana, P.; Rossy, A.M.; Dehoff, R.R. Microstructure and Properties of a High Temperature Al–Ce–Mn Alloy Produced by Additive Manufacturing. Acta Mater. 2020, 196, 595–608. [Google Scholar] [CrossRef]

- Manca, D.R.; Churyumov, A.Y.; Pozdniakov, A.V.; Prosviryakov, A.S.; Ryabov, D.K.; Krokhin, A.Y.; Korolev, V.A.; Daubarayte, D.K. Microstructure and Properties of Novel Heat Resistant Al–Ce–Cu Alloy for Additive Manufacturing. Met. Mater. Int. 2019, 25, 633–640. [Google Scholar] [CrossRef]

- Yang, Y.; Bahl, S.; Sisco, K.; Lance, M.; Shin, D.; Shyam, A.; Plotkowski, A.; Dehoff, R.R. Primary Solidification of Ternary Compounds in Al-Rich Al–Ce–Mn Alloys. J. Alloys Compd. 2020, 844, 156048. [Google Scholar] [CrossRef]

- Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Mehta, A.; Song, S.; Bai, Y. Laser powder bed fusion of Al-10 wt% Ce alloys: Microstructure and tensile property. J. Mater. Sci. 2020, 55, 14611–14625. [Google Scholar] [CrossRef]

- Dantzig, J.A.; Rappaz, M. Solidification: Revised & Expanded; EPFL Press: Lausanne, Switzerland, 2016. [Google Scholar]

- Tiwary, C.S.; Pandey, P.; Sarkar, S.; Das, R.; Samal, S.; Biswas, K.; Chattopadhyay, K. Five Decades of Research on the Development of Eutectic as Engineering Materials. Prog. Mater. Sci. 2022, 123, 100793. [Google Scholar] [CrossRef]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Criteria for Developing Castable, Creep-Resistant Aluminum-Based Alloys—A Review. Int. J. Mater. Res. 2006, 97, 246–265. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shahabi, H.S.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of High Strength Al85Nd8Ni5Co2 Alloy by Selective Laser Melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Thapliyal, S.; Shukla, S.; Zhou, L.; Hyer, H.; Agrawal, P.; Agrawal, P.; Komarasamy, M.; Sohn, Y.; Mishra, R.S. Design of Heterogeneous Structured Al Alloys with Wide Processing Window for Laser-Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2021, 42, 102002. [Google Scholar] [CrossRef]

- Aversa, A.; Bosio, F.; Marola, S.; Lorusso, M.; Manfredi, D.; Battezzati, L.; Fino, P.; Lombardi, M. Laser single scan tracks of new aluminium alloys compositions. In Proceedings of the Euro PM 2018 Congress and Exhibition, Bilbao, Spain, 14–18 October 2020. [Google Scholar]

- Belelli, F.; Casati, R.; Larini, F.; Riccio, M.; Vedani, M. Investigation on Two Ti–B-Reinforced Al Alloys for Laser Powder Bed Fusion. Mater. Sci. Eng. A 2021, 808, 140944. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of Heat Treatment on AlSi10Mg Alloy Fabricated by Selective Laser Melting: Microstructure Evolution, Mechanical Properties and Fracture Mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Yu, Y.; Kenevisi, M.S.; Yan, W.; Lin, F. Modeling Precipitation Process of Al-Cu Alloy in Electron Beam Selective Melting with a 3D Cellular Automaton Model. Addit. Manuf. 2020, 36, 101423. [Google Scholar] [CrossRef]

- Paoletti, C.; Cerri, E.; Ghio, E.; Santecchia, E.; Cabibbo, M.; Spigarelli, S. Effect of Low-Temperature Annealing on Creep Properties of AlSi10Mg Alloy Produced by Additive Manufacturing: Experiments and Modeling. Metals 2021, 11, 179. [Google Scholar] [CrossRef]

- Hu, Z.; Qi, Y.; Gao, S.; Nie, X.; Zhang, H.; Zhu, H.; Zeng, X. Aging Responses of an Al-Cu Alloy Fabricated by Selective Laser Melting. Addit. Manuf. 2021, 37, 101635. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Zhang, K.; Huang, A.; Davies, C.H.J.; Wu, X. Multiple Precipitation Pathways in an Al-7Si-0. 6Mg Alloy Fabricated by Selective Laser Melting. Scr. Mater. 2019, 160, 66–69. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, Porosity and Fatigue Performance of AlSi10Mg Parts Produced by Selective Laser Melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

- Nicoletto, G. Influence of rough as-built surfaces on smooth and notched fatigue behavior of L-PBF AlSi10Mg. Addit. Manuf. 2020, 34, 101251. [Google Scholar] [CrossRef]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the Effect of Shot-Peening on Fatigue Resistance of AlSi10Mg Specimens Fabricated by Additive Manufacturing Using Selective Laser Melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

- Uzan, N.E.; Shneck, R.; Yeheskel, O.; Frage, N. Fatigue of AlSi10Mg Specimens Fabricated by Additive Manufacturing Selective Laser Melting (AM-SLM). Mater. Sci. Eng. A 2017, 704, 229–237. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective Laser Melting of AlSi10Mg: Influence of Post-Processing on the Microstructural and Tensile Properties Development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef] [Green Version]

- Giovagnoli, M.; Tocci, M.; Fortini, A.; Merlin, M.; Ferroni, M.; Migliori, A.; Pola, A. Effect of Different Heat-Treatment Routes on the Impact Properties of an Additively Manufactured AlSi10Mg Alloy. Mater. Sci. Eng. A 2021, 802, 140671. [Google Scholar] [CrossRef]

- Di Egidio, G.; Ceschini, L.; Morri, A.; Martini, C.; Merlin, M. A Novel T6 Rapid Heat Treatment for AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion: Comparison with T5 and Conventional T6 Heat Treatments. Metall. Mater. Trans. B 2022, 53, 284–303. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Leuders, S.; Sprauel, J.M.; Grün, F.; Pfeifer, T.; Jantschner, O. Fatigue Strength Estimation Methodology of Additively Manufactured Metallic Bulk Material. Addit. Manuf. 2021, 39, 101688. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Academic Press: London, UK, 2019. [Google Scholar]

| Material | Condition | Process | Tensile Axis Orientation | Yield Stress Anisotropy (%) | Elongation Anisotropy (%) | Yield Stress (MPa) | Elongation (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Al12Si | As-built | SLM | Z XY | −1.7 | 50 | 274.8 ± 8 270.1 ± 10 | 2.2 ± 0.3 4.4 ± 0.7 | [86] |

| Al12Si | HT | SLM | Z XY | 2.0 | 20.8 | 150.3 ± 17 153.4 ± 5 | 4.2 ± 0.3 5.3 ± 0.7 | [86] |

| AlSi10Mg | As-built | SLM | Z XY | 4.0 | 16.7 | 240 250 | 1 1.2 | [53] |

| AlSi10Mg | As-built | SLM | Z XY | - | 37.5 | - - | 3.47 ± 0.6 5.55 ± 0.4 | [87] |

| Al–Si–Mg | As-built | DMLS | Z XY | 4.9 | 33.9 | 231 ± 3 243 ± 7 | 4.1 ± 0.2 6.2 ± 0.3 | [88] |

| Element | Mg | Sc | Zr | Mn | Si | Fe | Zn | Cu | Ti | O | V | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | (min) | 4.00 | 0.60 | 0.20 | 0.30 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| (max) | 4.90 | 0.80 | 0.50 | 0.80 | 0.40 | 0.40 | 0.25 | 0.10 | 0.15 | 0.05 | 0.05 | |

| Treatment | GND Density (m−3) | Main Precipitates | Volume Fraction (%) | YS (MPa) | UTS (MPa) |

|---|---|---|---|---|---|

| As-built | 7.2 × 1013 | 155.5 ± 1.5 | 317.3 ± 1.2 | ||

| Solution + Natural Aging | 3.3 × 1013 | θ″ θ′ | 217.2 ± 20.4 | 412.7 ± 15.6 | |

| Solution + Artificial Aging (426 K, 10 h) | 5.5 × 1013 | θ″ θ′ | 282.1 ± 15.1 | 458.0 ± 10.7 | |

| Solution + Artificial Aging (426 K, 24 h) | 4.8 × 1013 | θ″ θ′ | 3.67 0.53 | 345.4 ± 15.5 | 470.6 ± 6.5 |

| Solution + Artificial Aging (426 K, 48 h) | 4.3 × 1013 | θ″ θ′ | 4.29 1.49 | 383.3 ± 10.8 | 476.2 ± 6.4 |

| Solution + Artificial Aging (446 K, 2 h) | 4.4 × 1013 | θ″ θ′ | 1.51 0.10 | 262.8 ± 5.7 | 437.3 ± 22.1 |

| Solution + Artificial Aging (446 K, 6 h) | 3.7 × 1013 | Mixed θ″/θ′ | 3.27 | 352.5 ± 10.5 | 453.3 ± 5.0 |

| Solution + Artificial Aging (446 K, 10 h) | 4.1 × 1013 | Mixed θ″/θ′ | 3.35 | 344.7 ± 14.4 | 441.5 ± 8.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montanari, R.; Palombi, A.; Richetta, M.; Varone, A. Additive Manufacturing of Aluminum Alloys for Aeronautic Applications: Advantages and Problems. Metals 2023, 13, 716. https://doi.org/10.3390/met13040716

Montanari R, Palombi A, Richetta M, Varone A. Additive Manufacturing of Aluminum Alloys for Aeronautic Applications: Advantages and Problems. Metals. 2023; 13(4):716. https://doi.org/10.3390/met13040716

Chicago/Turabian StyleMontanari, Roberto, Alessandra Palombi, Maria Richetta, and Alessandra Varone. 2023. "Additive Manufacturing of Aluminum Alloys for Aeronautic Applications: Advantages and Problems" Metals 13, no. 4: 716. https://doi.org/10.3390/met13040716

APA StyleMontanari, R., Palombi, A., Richetta, M., & Varone, A. (2023). Additive Manufacturing of Aluminum Alloys for Aeronautic Applications: Advantages and Problems. Metals, 13(4), 716. https://doi.org/10.3390/met13040716