Influence of Cryogenic Temperatures on the Mechanical Properties and Microstructure of 2195-T8 Alloy

Abstract

1. Introduction

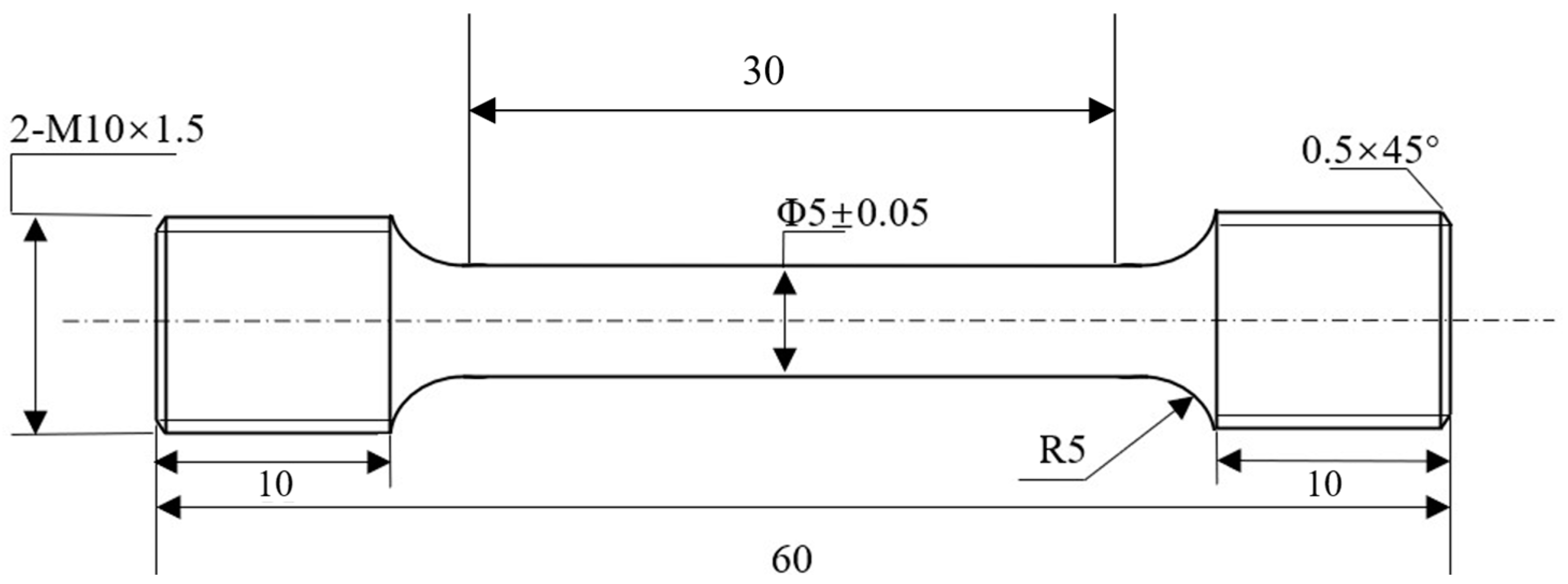

2. Materials and Methods

3. Results and Discussion

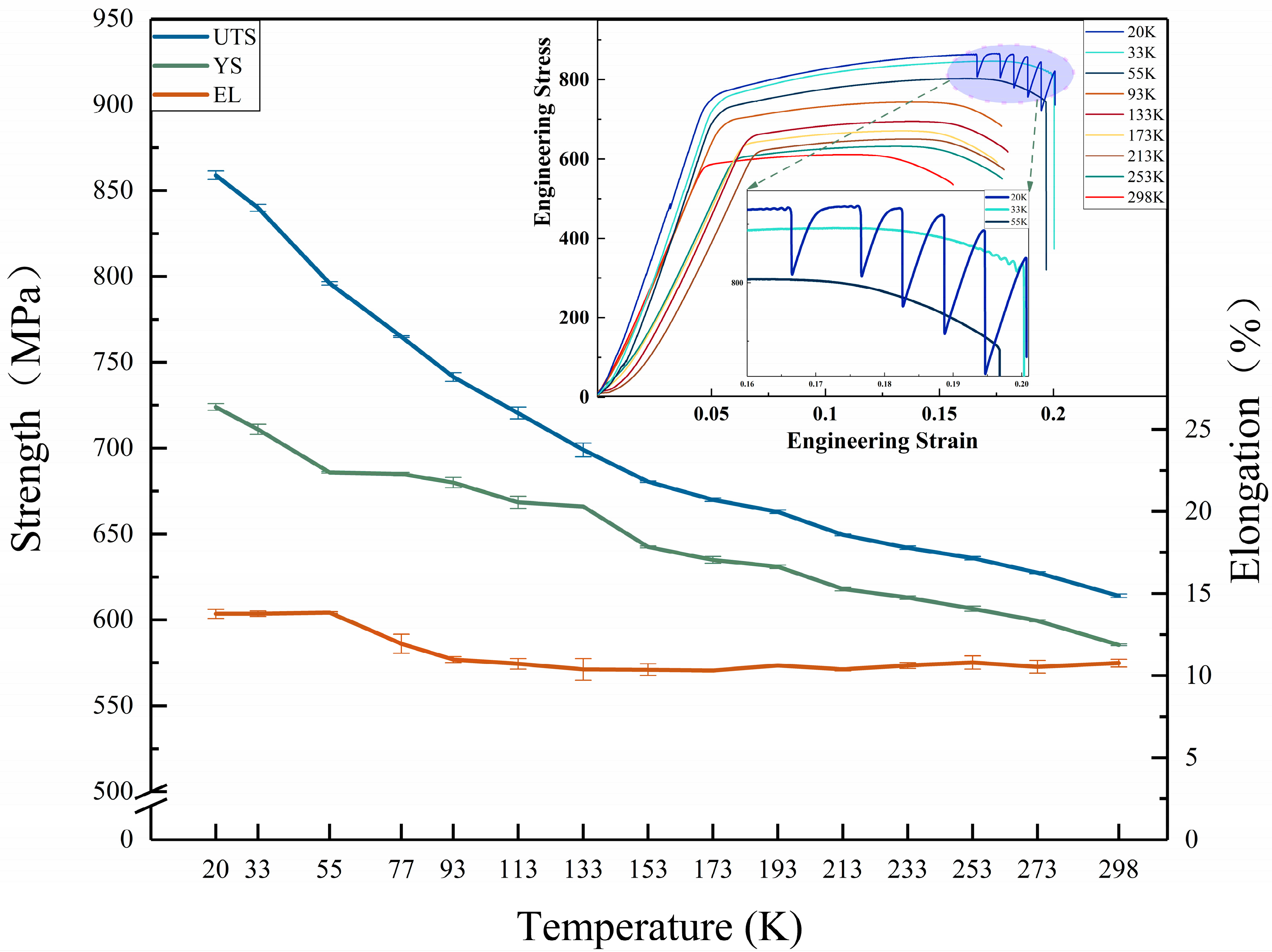

3.1. Mechanical Properties

3.2. Microstructures after the Tensile Test

3.2.1. Fracture Surfaces Analyses

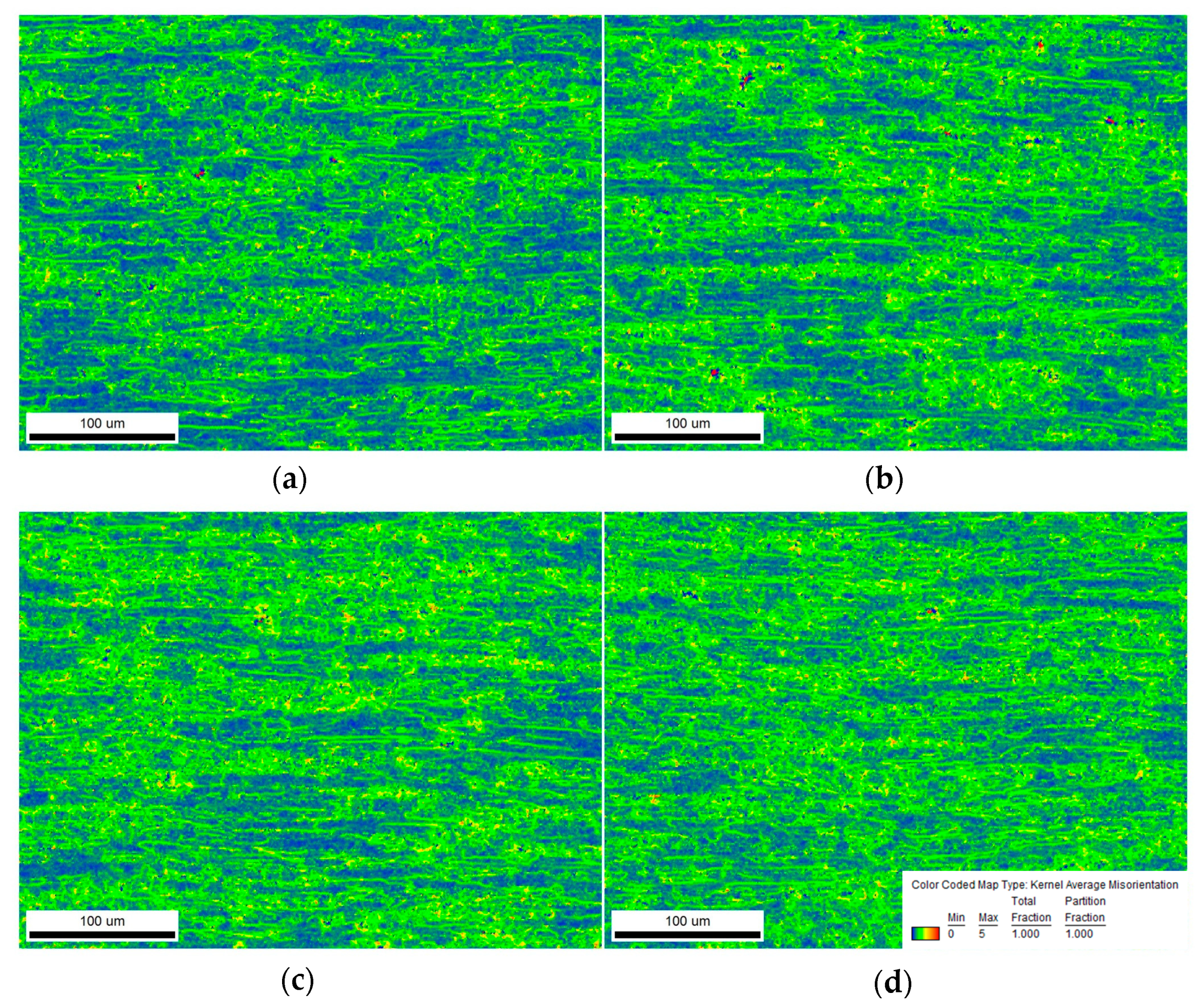

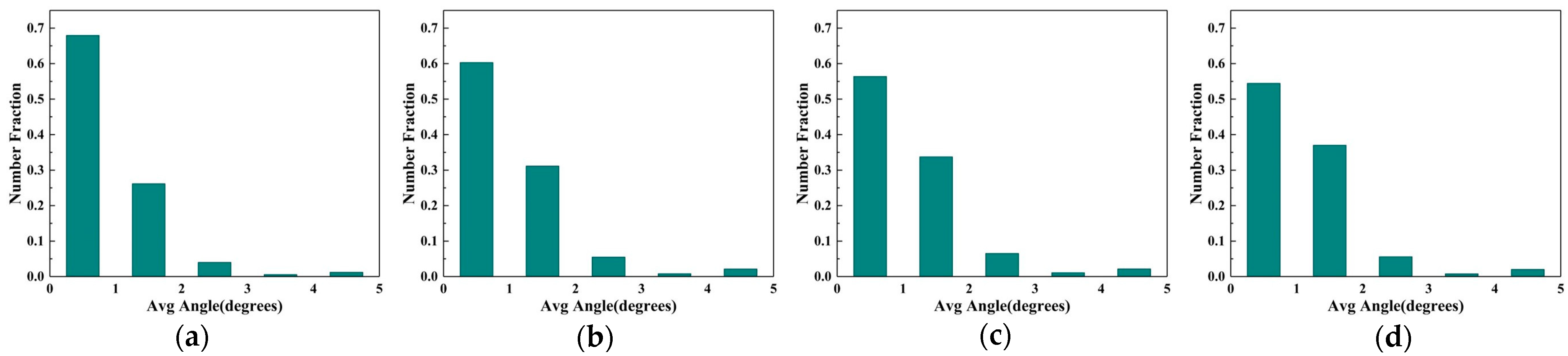

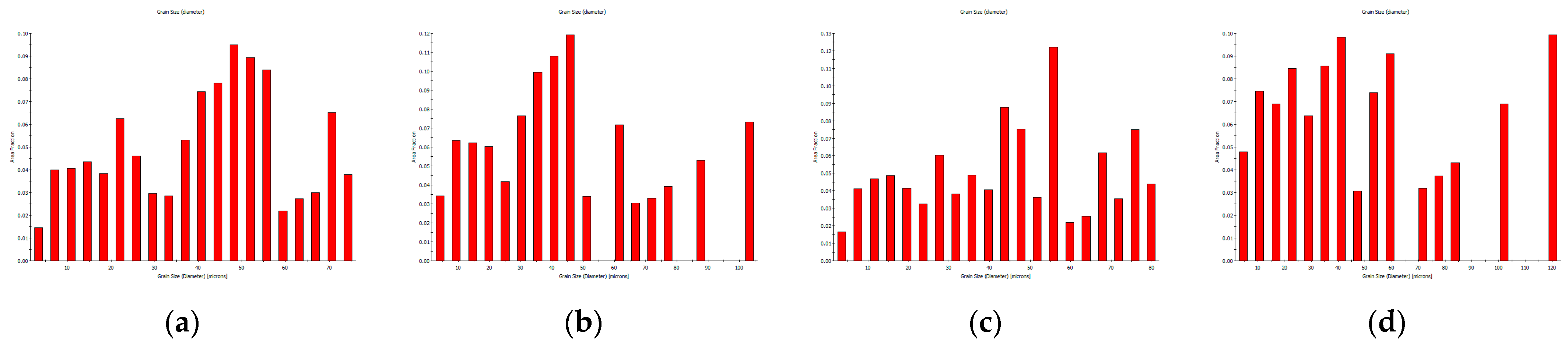

3.2.2. EBSD Analyses

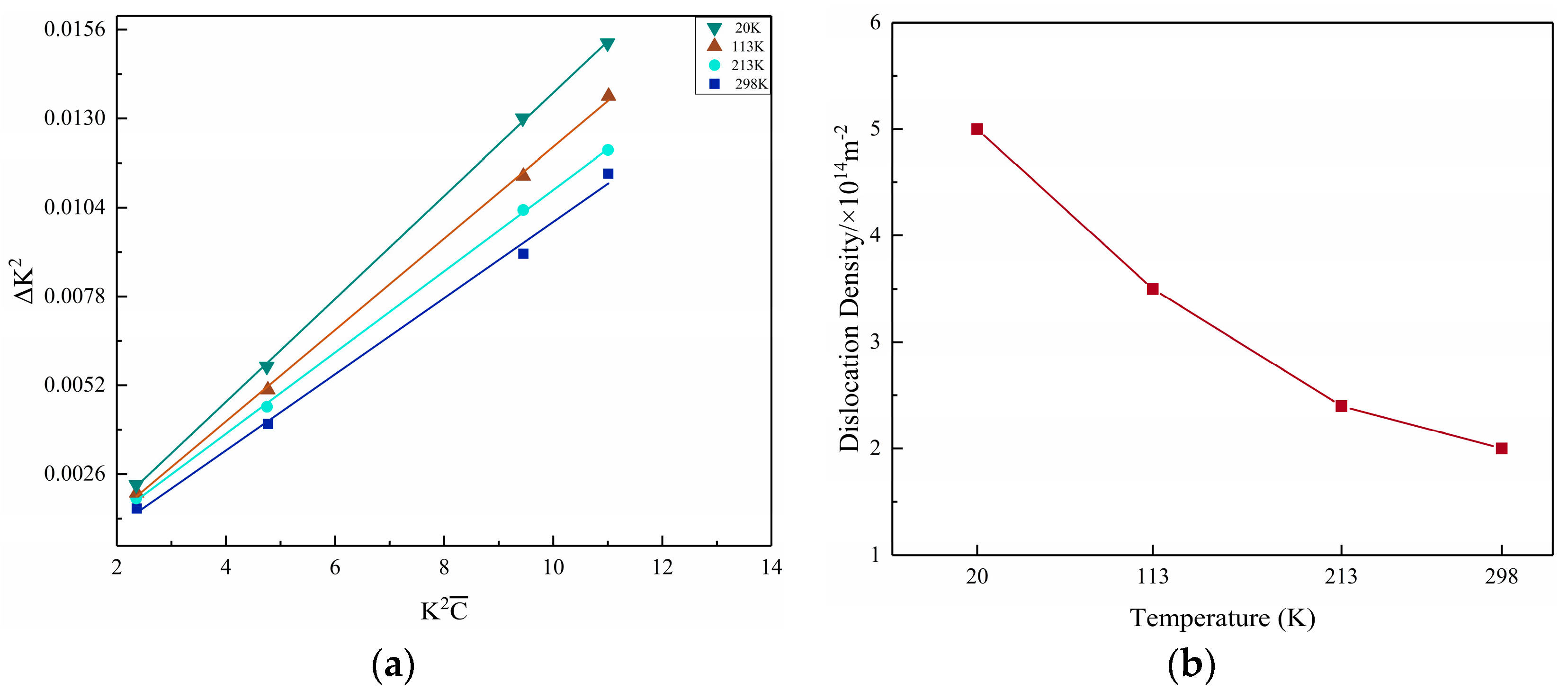

3.2.3. Dislocation Density Measurements

3.2.4. Dislocation Structures

4. Conclusions

- (1)

- As the temperature decreases, the strength of the 2195-T8 alloy gradually increases; the lower the temperature, the more significant the increase in strength. However, elongation hardly changes.

- (2)

- Dislocation cross-slipping becomes more difficult as the temperature decreases. The increase in strength at cryogenic temperatures happens because more areas are involved in the deformation and because the deformation is more uniform. As the temperature decreases, the fracture mode gradually changes, and ductile fracture characteristics gradually disappear.

- (3)

- As the temperature decreases, the dislocation density follows the same trend as the material strength, and the increase in dislocation density is an important reason for the increase in material strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lin, Y.; Zheng, Z.; Li, S.; Kong, X.; Han, Y. Microstructures and properties of 2099 Al–Li alloy. Mater. Charact. 2013, 84, 88–99. [Google Scholar] [CrossRef]

- Giummarra, C.; Thomas, B.; Rioja, R.J. New aluminum lithium alloys for aerospace applications. In Proceedings of the Light Metals Technology Conference, Saint-Sauveur, QC, Canada, 24–26 September 2007. [Google Scholar]

- Kablov, E.N.; Antipov, V.V.; Oglodkova, J.S.; Oglodkov, M.S. Development and application prospects of aluminum–lithium alloys in aircraft and space technology. Metallurgist 2021, 65, 72–81. [Google Scholar] [CrossRef]

- Sova, B.J.; Sankaran, K.K.; Babel, H.; Farahmand, B.; Cho, A. Aging Optimization of Aluminum-Lithium Alloy L277 for Application to Cryotank Structures. In Proceedings of the AeroMat, Dayton, OH, USA, 1 January 2003; Available online: https://ntrs.nasa.gov/citations/20030068241 (accessed on 4 April 2023).

- Wang, D.; Huang, S.; Yi, Y.; He, H.; Li, C. Effects of cryogenic deformation on the microstructure and mechanical properties of high-strength aluminum alloys. Mater. Charact. 2022, 187, 111831. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, W.; Wang, C.; Zhu, C.; Yi, Y. Cryogenic deformation behavior and microstructural characteristics of 2195 alloy. Metals 2021, 11, 1406. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Yi, Y.; Zhu, C. Effect of pretreatment and cryogenic temperatures on mechanical properties and microstructure of Al-Cu-Li alloy. Materials 2021, 14, 4873. [Google Scholar] [CrossRef] [PubMed]

- Glazer, J. Mechanical behavior of aluminum-lithium alloys at cryogenic temperatures. Metall. Mater. Trans. A 1986, 18, 1695–1701. [Google Scholar] [CrossRef]

- Wang, C.; Yi, Y.; Huang, S.; Dong, F.; He, H.; Huang, K.; Jia, Y. Experimental and Theoretical Investigation on the Forming Limit of 2024-O Aluminum Alloy Sheet at Cryogenic Temperatures. Met. Mater. Int. 2021, 27, 5199–5211. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, H.; Tong, M.; Jiang, F.; Zhang, M. Effect of cryogenic environment on tensile property and microstructure evolution of an Al-Mg-Sc alloy. Mater. Charact. 2023, 195, 112550. [Google Scholar] [CrossRef]

- Nayan, N.; Murty, S.; Jha, A.K.; Pant, B.; Sharma, S.C.; George, K.M.; Sastry, G.V.S. Mechanical properties of aluminium–copper–lithium alloy AA2195 at cryogenic temperatures. Mater. Des. 2014, 58, 445–450. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Huang, Y.; Brough, I.; Harris, C. Electron backscatter diffraction of grain and subgrain structures—Resolution considerations. J. Microsc. 1999, 195, 212–216. [Google Scholar] [CrossRef]

- Masumura, T.; Inami, K.; Matsuda, K.; Tsuchiyama, T.; Nanba, S.; Kitahara, A. Quantitative evaluation of dislocation density in as-quenched martensite with tetragonality by X-ray line profile analysis in a medium-carbon steel. Acta Mater. 2022, 234, 118052. [Google Scholar] [CrossRef]

- Lan, J.; Shen, X.; Liu, J.; Hua, L. Strengthening mechanisms of 2A14 aluminum alloy with cold deformation prior to artificial aging. Mater. Sci. Eng. A 2019, 745, 517–535. [Google Scholar] [CrossRef]

- Zhong, Z.Y.; Brokmeier, H.G.; Gan, W.M.; Maawad, E.; Schwebke, B.; Schell, N. Dislocation density evolution of AA 7020-T6 investigated by in-situ synchrotron diffraction under tensile load. Mater. Charact. 2015, 108, 124–131. [Google Scholar] [CrossRef]

- Xie, B.; Huang, L.; Xu, J.; Su, H.; Zhang, H.; Xu, Y.; Li, J.; Wang, Y. Effect of the aging process and pre-deformation on the precipitated phase and mechanical properties of 2195 Al–Li alloy. Mater. Sci. Eng. A 2022, 832, 142394. [Google Scholar] [CrossRef]

- Feng, B.; Xiong, B.Q. Effect of Annealing Temperature on the Microstructure of 2195 Al–Li Alloy Sheet. MSF 2021, 1026, 49–58. [Google Scholar] [CrossRef]

- Härtel, M.; Illgen, C.; Frint, P.; Wagner, M.F.X. On the PLC effect in a particle reinforced AA2017 alloy. Metals 2018, 8, 88. [Google Scholar] [CrossRef]

- Kulkarni, S.S.; Starke, E.A., Jr.; Kuhlmann-Wilsdorf, D. Some observations on deformation banding and correlated microstructures of two aluminum alloys compressed at different temperatures and strain rates. Acta Mater. 1998, 46, 5283–5301. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Q.; Chen, X.; Chen, Z.; Jiang, Z.; Wu, X.; Fan, J. Three types of Portevin–Le Chatelier effects: Experiment and modelling. Acta Mater. 2007, 55, 2219–2228. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Q.; Wu, X.; Fan, J. Spatiotemporal aspects of the Portevin–Le Chatelier effect in annealed and solution-treated aluminum alloys. Scr. Mater. 2006, 54, 2041–2045. [Google Scholar] [CrossRef]

- Pustovalov, V.V. Serrated deformation of metals and alloys at low temperatures (Review). Low Temp. Phys. 2008, 34, 683–723. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Fernández, R.; Saliwan-Neumann, R.; González-Doncel, G.; Bruno, G. Dislocation structures after creep in an Al-3.85% Mg alloy studied using EBSD-KAM technique. Mater. Lett. 2023, 337, 133978. [Google Scholar] [CrossRef]

- Shen, R.R.; Efsing, P. Overcoming the drawbacks of plastic strain estimation based on KAM. Ultramicroscopy 2018, 184, 156–163. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Roven, H.J.; Jia, Z. Mechanical properties and surface characteristics of an AA6060 alloy strained in tension at cryogenic and room temperature. Mater. Sci. Eng. A 2015, 648, 350–358. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Zhu, C.; Yi, Y. Multi slip activation enabled excellent low-temperature strength-ductility synergy in Al–Cu–Li alloy. Vacuum 2022, 204, 111328. [Google Scholar] [CrossRef]

- Decreus, B.; Deschamps, A.; Donnadieu, P.; Ehrström, J.C. On the role of microstructure in governing fracture behavior of an aluminum–copper–lithium alloy. Mater. Sci. Eng. A 2013, 586, 418–427. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Li, Y.Z.; Huang, M.X. The respective hardening contributions of dislocations and twins to the flow stress of a twinning-induced plasticity steel. Scr. Mater. 2016, 112, 28–31. [Google Scholar] [CrossRef]

- Serquis, A.; Zhu, Y.T.; Peterson, E.J.; Coulter, J.Y.; Peterson, D.E.; Mueller, F.M. Effect of lattice strain and defects on the superconductivity of MgB2. Appl. Phys. Lett. 2001, 79, 4399–4401. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Bakshi, S.D.; Sinha, D.; Chowdhury, S.G. Anisotropic broadening of XRD peaks of α′-Fe: Williamson-Hall and Warren-Averbach analysis using full width at half maximum (FWHM) and integral breadth (IB). Mater. Charact. 2018, 142, 144–153. [Google Scholar] [CrossRef]

- Ungár, T.; Borbély, A. The effect of dislocation contrast on x-ray line broadening: A new approach to line profile analysis. Appl. Phys. Lett. 1996, 69, 3173–3175. [Google Scholar] [CrossRef]

- Ungár, T.; Ott, S.; Sanders, P.G.; Borbély, A.; Weertman, J.R. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 1998, 46, 3693–3699. [Google Scholar] [CrossRef]

- Masumura, T.; Takaki, S.; Tsuchiyama, T. Proposal of the parameters CH00 and Q required in the modified Williamson-Hall method Modified Williamson-Hall Ch00 q. Zair./J. Soc. Mater. Sci. Jpn. 2020, 69, 290–292. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Wen, K.; Lin, B.; Li, X.; Li, Y.; Li, Z.; Zhang, Y.; Xiong, B. Influence of Cryogenic Temperatures on the Mechanical Properties and Microstructure of 2195-T8 Alloy. Metals 2023, 13, 740. https://doi.org/10.3390/met13040740

Wang T, Wen K, Lin B, Li X, Li Y, Li Z, Zhang Y, Xiong B. Influence of Cryogenic Temperatures on the Mechanical Properties and Microstructure of 2195-T8 Alloy. Metals. 2023; 13(4):740. https://doi.org/10.3390/met13040740

Chicago/Turabian StyleWang, Tao, Kai Wen, Ben Lin, Xiwu Li, Yanan Li, Zhihui Li, Yongan Zhang, and Baiqing Xiong. 2023. "Influence of Cryogenic Temperatures on the Mechanical Properties and Microstructure of 2195-T8 Alloy" Metals 13, no. 4: 740. https://doi.org/10.3390/met13040740

APA StyleWang, T., Wen, K., Lin, B., Li, X., Li, Y., Li, Z., Zhang, Y., & Xiong, B. (2023). Influence of Cryogenic Temperatures on the Mechanical Properties and Microstructure of 2195-T8 Alloy. Metals, 13(4), 740. https://doi.org/10.3390/met13040740