Enhanced Magnetic Properties and Thermal Conductivity of FeSiCr Soft Magnetic Composite with Al2O3 Insulation Layer Prepared by Sol-Gel Process

Abstract

1. Introduction

2. Experimental Methods

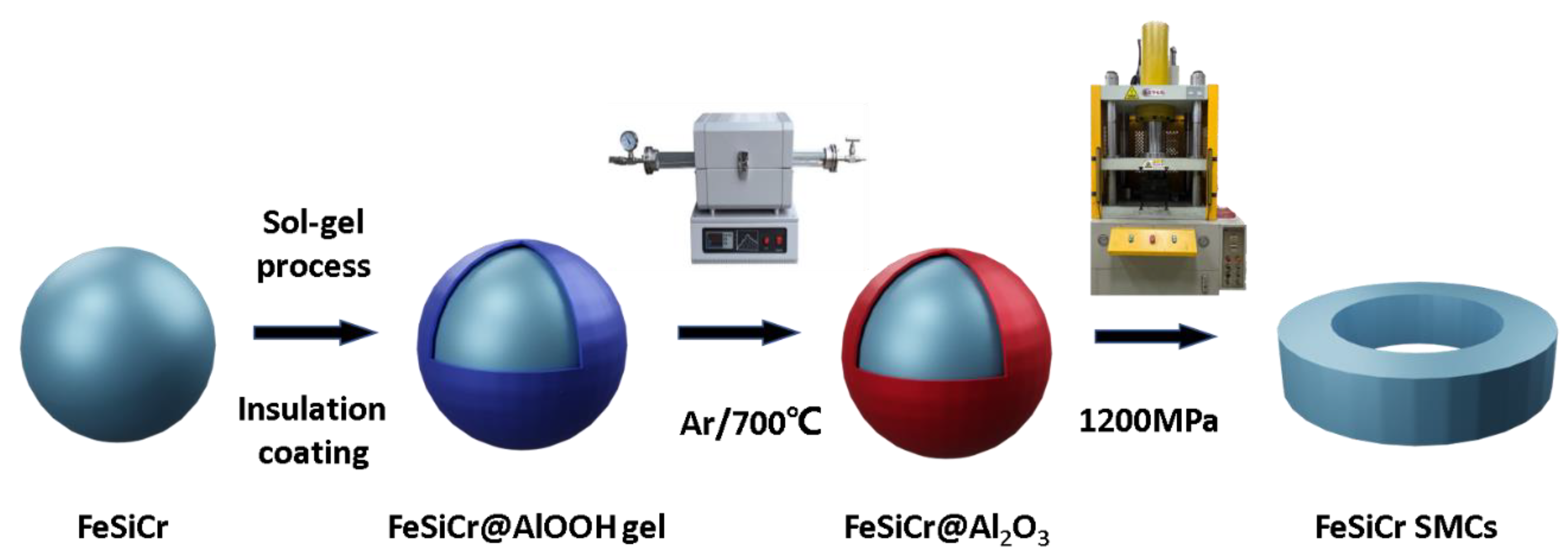

2.1. SMC Preparation

2.2. Characterizations

3. Results and Discussion

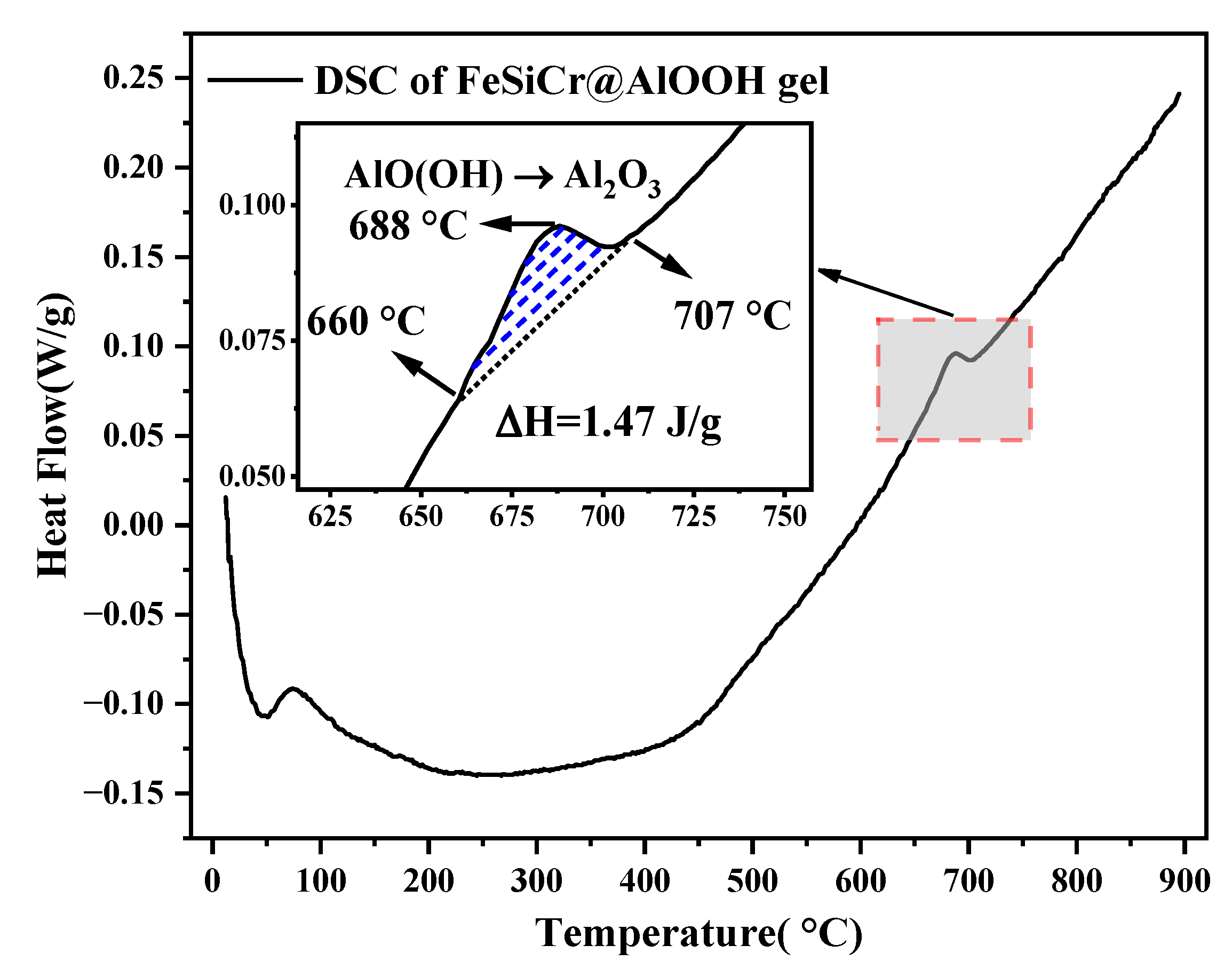

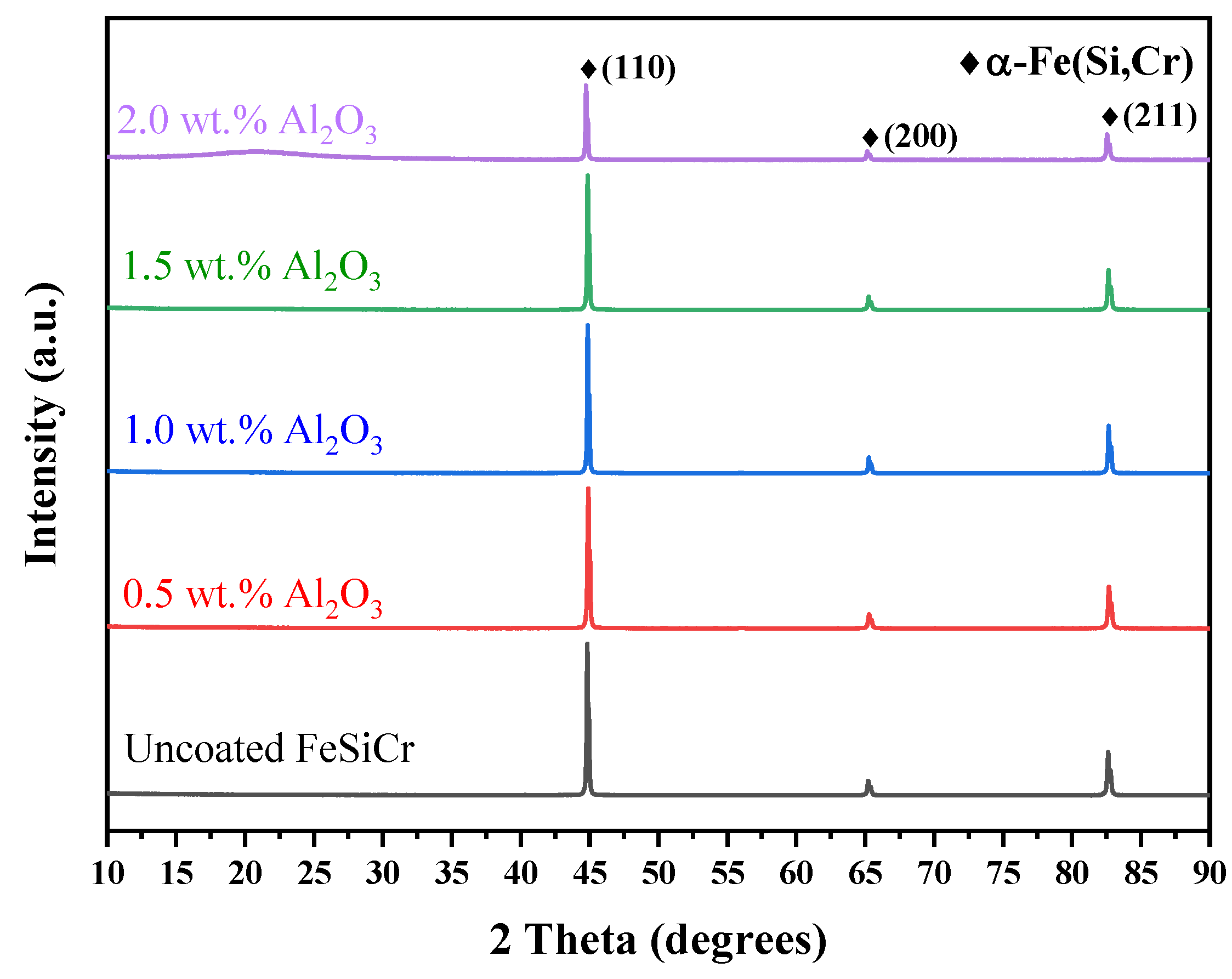

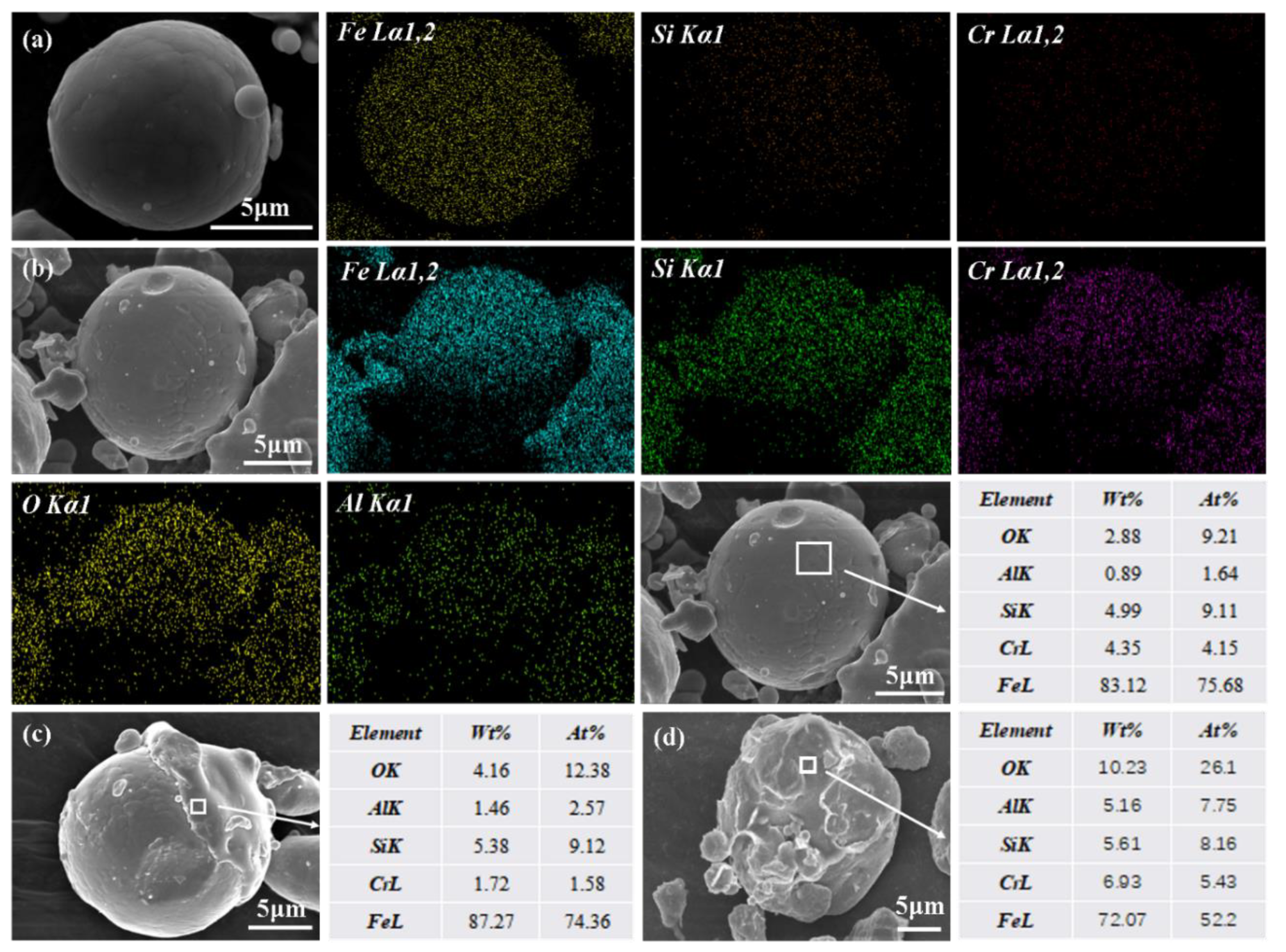

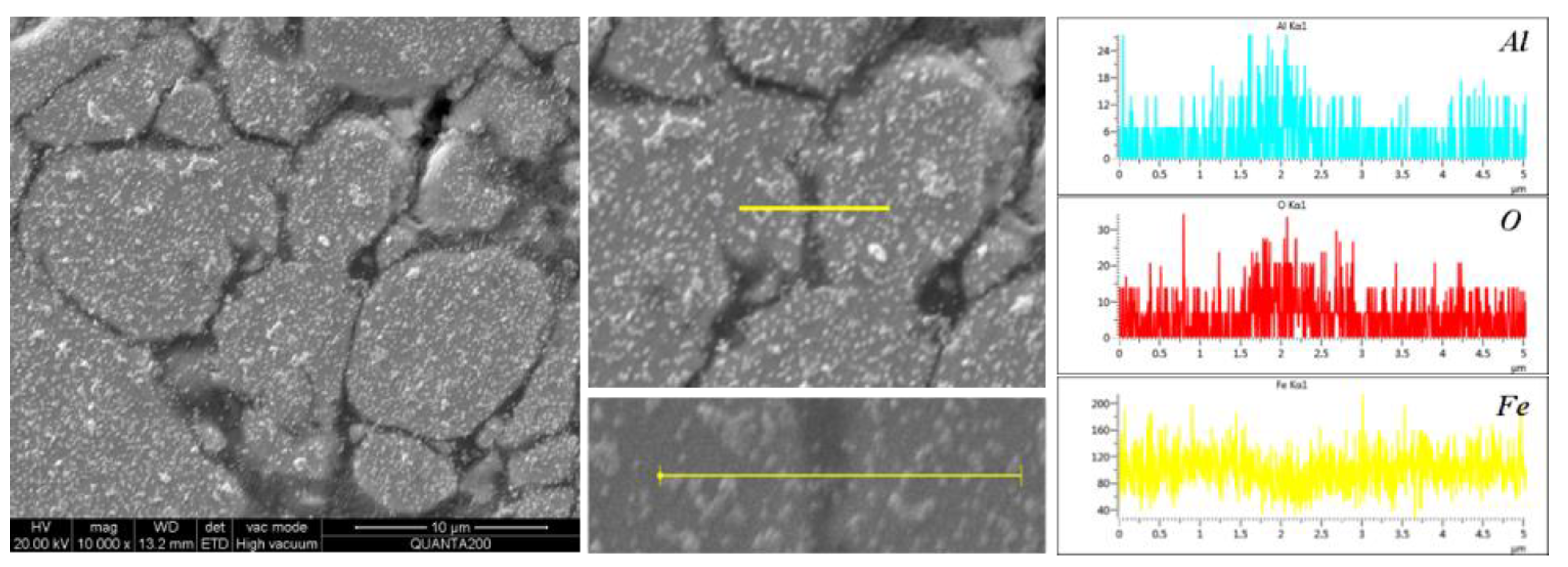

3.1. Structure Analysis

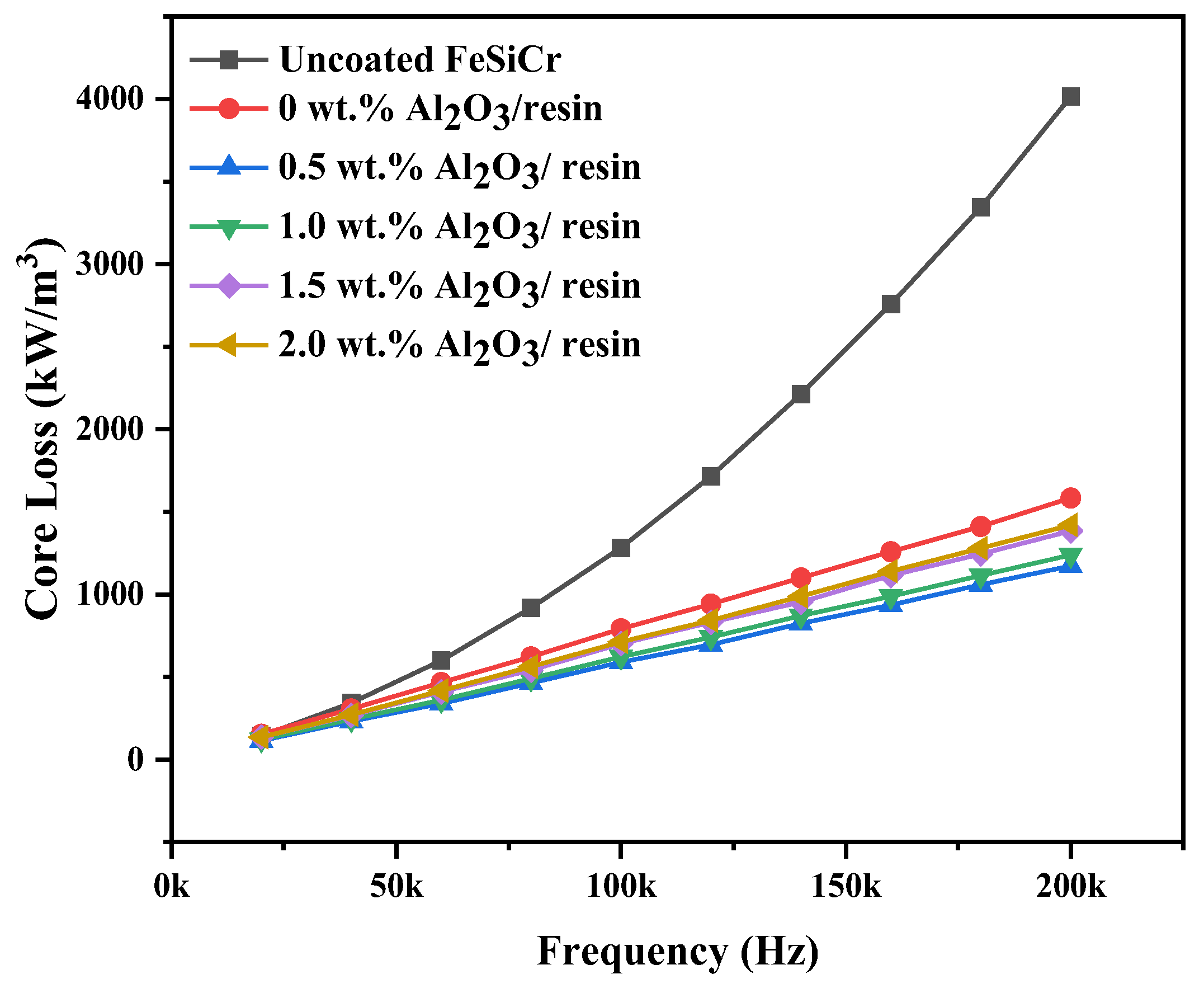

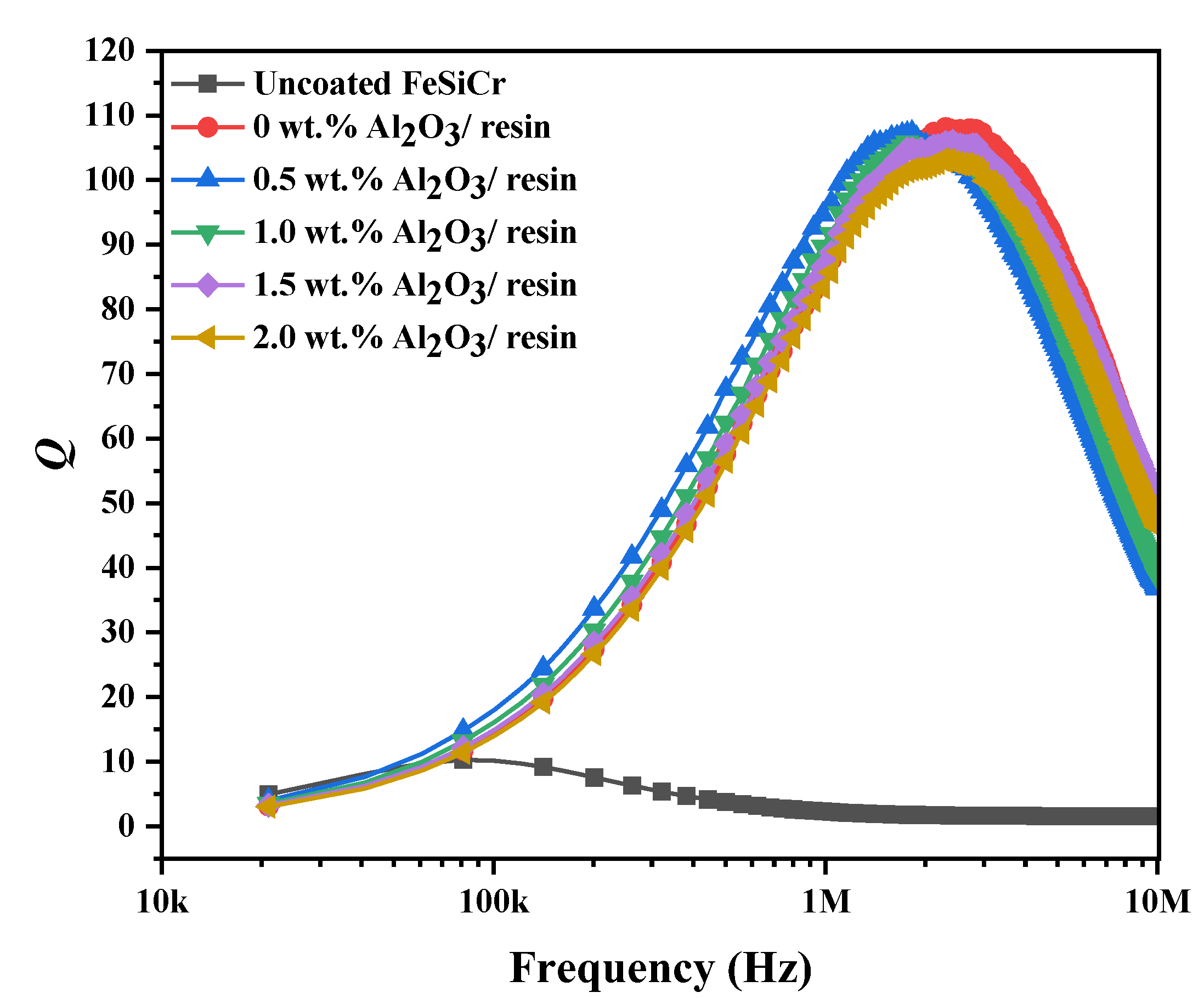

3.2. Magnetic Performance

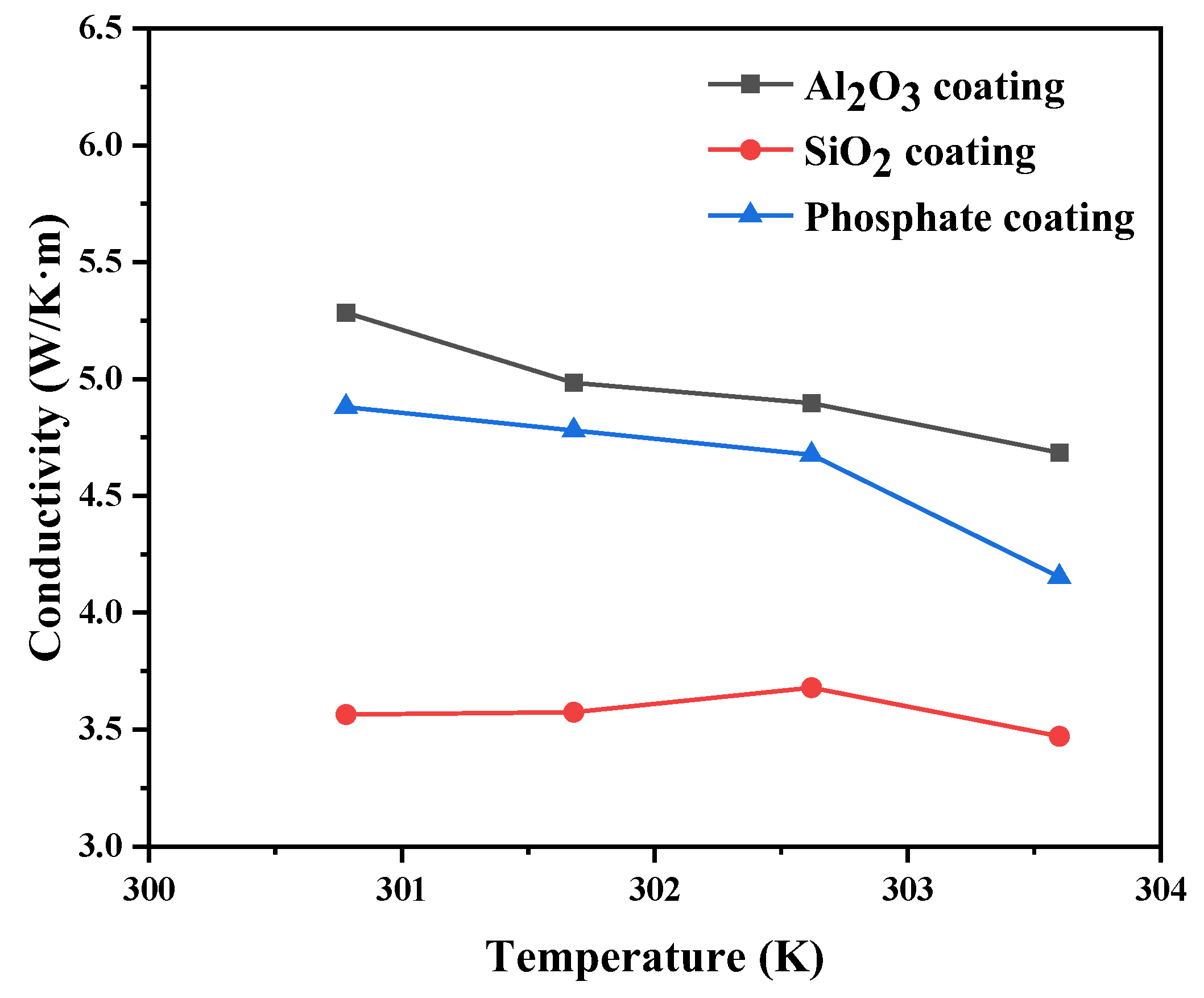

3.3. Thermal Conductivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, eaao0195. [Google Scholar] [CrossRef] [PubMed]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Sunday, K.J.; Taheri, M.L. Soft magnetic composites: Recent advancements in the technology. Met. Powder Rep. 2017, 72, 425–429. [Google Scholar] [CrossRef]

- Périgo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 31301. [Google Scholar] [CrossRef]

- Guan, W.W.; Shi, X.Y.; Xu, T.T.; Wan, K.; Zhang, B.W.; Liu, W.; Su, H.L.; Zou, Z.Q.; Du, Y.W. Synthesis of well-insulated Fe–Si–Al soft magnetic composites via a silane-assisted organic/inorganic composite coating route. J. Phys. Chem. Solids 2021, 150, 109841. [Google Scholar] [CrossRef]

- Li, W.; Cai, H.; Kang, Y.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Jiang, Y.; Che, S. High permeability and low loss bioinspired soft magnetic composites with nacre-like structure for high frequency applications. Acta Mater. 2019, 167, 267–274. [Google Scholar] [CrossRef]

- Li, W.; Li, W.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Li, J.; Zhang, L.; Fan, L.; Wakiya, N.; et al. Magnetic and Mechanical Properties of Iron-Based Soft Magnetic Composites Coated with Silane Synergized by Bi2O3. J. Electron. Mater. 2021, 50, 2425–2435. [Google Scholar] [CrossRef]

- Yao, Z.; Peng, Y.; Xia, C.; Yi, X.; Mao, S.; Zhang, M. The effect of calcination temperature on microstructure and properties of FeNiMo@Al2O3 soft magnetic composites prepared by sol-gel method. J. Alloy. Compd. 2020, 827, 154345. [Google Scholar] [CrossRef]

- Li, J.; Ni, J.; Zhu, S.; Feng, S. Evolution of magnetic loss with annealing temperature in FeSiAl/carbonyl iron soft magnetic composite. Mater. Technol. 2022, 37, 2313–2317. [Google Scholar] [CrossRef]

- Guo, R.; Wang, S.; Yu, Z.; Sun, K.; Jiang, X.; Wu, G.; Wu, C.; Lan, Z. FeSiCr@NiZn SMCs with ultra-low core losses, high resistivity for high frequency applications. J. Alloy. Compd. 2020, 830, 154736. [Google Scholar] [CrossRef]

- Nie, W.; Yu, T.; Wang, Z.; Wei, X. High-performance core-shell-type FeSiCr@MnZn soft magnetic composites for high-frequency applications. J. Alloy. Compd. 2021, 864, 158215. [Google Scholar] [CrossRef]

- Wang, F.; Dong, Y.; Chang, L.; Pan, Y.; Chi, Q.; Gong, M.; Li, J.; He, A.; Wang, X. High performance of Fe-based soft magnetic composites coated with novel nano-CaCO3/epoxy nanocomposites insulating layer. J. Solid State Chem. 2021, 304, 122634. [Google Scholar] [CrossRef]

- Dong, B.; Qin, W.; Su, Y.; Wang, X. Magnetic properties of FeSiCr@MgO soft magnetic composites prepared by magnesium acetate pyrolysis for high-frequency applications. J. Magn. Magn. Mater. 2021, 539, 168350. [Google Scholar] [CrossRef]

- Hsiang, H.-I.; Chuang, K.-H.; Lee, W.-H. FeSiCr Alloy Powder to Carbonyl Iron Powder Mixing Ratio Effects on the Magnetic Properties of the Iron-Based Alloy Powder Cores Prepared Using Screen Printing. Materials 2021, 14, 1034. [Google Scholar] [CrossRef]

- Gong, M.; Dong, Y.; Huang, J.; Chang, L.; Pan, Y.; Wang, F.; He, A.; Li, J.; Liu, X.; Wang, X. The enhanced magnetic properties of FeSiCr powder cores composited with carbonyl iron powder. J. Mater. Sci. Mater. Electron. 2021, 32, 8829–8836. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, S.; Zhang, G.; Dong, B.; Meng, L.; Li, Z.; Dong, Y.; Cao, X. The phosphating effect on the properties of FeSiCr alloy powder. J. Magn. Magn. Mater. 2022, 552, 168741. [Google Scholar] [CrossRef]

- Xia, C.; Peng, Y.; Yi, Y.; Deng, H.; Zhu, Y.; Hu, G. The magnetic properties and microstructure of phosphated amorphous FeSiCr/silane soft magnetic composite. J. Magn. Magn. Mater. 2019, 474, 424–433. [Google Scholar] [CrossRef]

- Yaghtin, M.; Taghvaei, A.H.; Hashemi, B.; Janghorban, K. Structural and magnetic properties of Fe-Al2O3 soft magnetic composites prepared by sol-gel method. Int. J. Mater. Res. 2013, 105, 474–479. [Google Scholar] [CrossRef]

- Liu, D.; Wu, C.; Yan, M.; Wang, J. Correlating the microstructure, growth mechanism and magnetic properties of FeSiAl soft magnetic composites fabricated via HNO3 oxidation. Acta Mater. 2018, 146, 294–303. [Google Scholar] [CrossRef]

- Monier-Vinard, E.; Bissuel, V.; Laraqi, N.; Daniel, O.; Signing, D. Experimental characterization of DELPHI Compact Thermal Model for Surface-Mounted Soft Magnetic Composite Inductor. In Proceedings of the 2015 21st International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Paris, France, 30 September–2 October 2015. [Google Scholar]

- Ouyang, Y.; Hou, G.; Bai, L.; Li, B.; Yuan, F. Constructing continuous networks by branched alumina for enhanced thermal conductivity of polymer composites. Compos. Sci. Technol. 2018, 165, 307–313. [Google Scholar] [CrossRef]

- Yu, L.; Lirui, S.; Qingyu, W.; Haitao, Q.; Chuncheng, H.; Qingquan, L. Effect of branched alumina on thermal conductivity of epoxy resin. J. Ind. Eng. Chem. 2022, 120, 209–215. [Google Scholar]

- Pinheiro, A.; da Costa, Z.; Bell, M.; Anjos, V.; Dantas, N.; Reis, S. Thermal characterization of iron phosphate glasses for nuclear waste disposal. Opt. Mater. 2011, 33, 1975–1979. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Joshi, G.; Saxena, N.; Mangal, R. Temperature dependence of effective thermal conductivity and effective thermal diffusivity of Ni-Zn ferrites. Acta Mater. 2003, 51, 2569–2576. [Google Scholar] [CrossRef]

- Li, K.; Cheng, D.; Yu, H.; Liu, Z. Process optimization and magnetic properties of soft magnetic composite cores based on phosphated and mixed resin coated Fe powders. J. Magn. Magn. Mater. 2020, 501, 166455. [Google Scholar] [CrossRef]

- Hu, B.; Jia, E.; Du, B.; Yin, Y. A new sol-gel route to prepare dense Al2O3 thin films. Ceram. Int. 2016, 42, 16867–16871. [Google Scholar] [CrossRef]

- Paulik, F.; Paulik, J.; Naumann, R.; Köhnke, K.; Petzold, D. Mechanism and kinetics of the dehydration of hydrargillites. Part I. Thermochim. Acta 1983, 64, 1–14. [Google Scholar] [CrossRef]

- Padmaja, P.; Anilkumar, G.; Mukundan, P.; Aruldhas, G.; Warrier, K. Characterisation of stoichiometric sol–gel mullite by fourier transform infrared spectroscopy. Int. J. Inorg. Mater. 2001, 3, 693–698. [Google Scholar] [CrossRef]

- Pu, H.; Jiang, F.; Yang, Z. Studies on preparation and chemical stability of reduced iron particles encapsulated with polysiloxane nano-films. Mater. Lett. 2006, 60, 94–97. [Google Scholar] [CrossRef]

- Shen, S.-C.; Ng, W.K.; Zhong, Z.-Y.; Dong, Y.-C.; Chia, L.; Tan, R.B.H. Solid-Based Hydrothermal Synthesis and Characterization of Alumina Nanofibers with Controllable Aspect Ratios. J. Am. Ceram. Soc. 2009, 92, 1311–1316. [Google Scholar] [CrossRef]

- Peng, Y.; Yi, Y.; Li, L.; Yi, J.; Nie, J.; Bao, C. Iron-based soft magnetic composites with Al2O3 insulation coating produced using sol–gel method. Mater. Des. 2016, 109, 390–395. [Google Scholar] [CrossRef]

- Liu, D.; Wu, C.; Yan, M. Investigation on sol–gel Al2O3 and hybrid phosphate-alumina insulation coatings for FeSiAl soft magnetic composites. J. Mater. Sci. 2015, 50, 6559–6566. [Google Scholar] [CrossRef]

- Lefèvre, G. In situ Fourier-transform infrared spectroscopy studies of inorganic ions adsorption on metal oxides and hydroxides. Adv. Colloid Interface Sci. 2004, 107, 109–123. [Google Scholar] [CrossRef] [PubMed]

- Sunday, K.J.; Taheri, M.L. NiZnCu-ferrite coated iron powder for soft magnetic composite applications. J. Magn. Magn. Mater. 2018, 463, 1–6. [Google Scholar] [CrossRef]

- Olekšáková, D.; Kollár, P.; Jakubčin, M.; Füzer, J.; Tkáč, M.; Slovenský, P.; Bureš, R.; Fáberová, M. Energy loss separation in NiFeMo compacts with smoothed powders according to Landgraf’s and Bertotti’s theories. J. Mater. Sci. 2021, 56, 12835–12844. [Google Scholar] [CrossRef]

- Olekšáková, D.; Kollár, P.; Neslušan, M.; Jakubčin, M.; Füzer, J.; Bureš, R.; Fáberová, M. Impact of the Surface Irregularities of NiFeMo Compacted Powder Particles on Irreversible Magnetization Processes. Materials 2022, 15, 8937. [Google Scholar] [CrossRef]

- Kollár, P.; Birčáková, Z.; Füzer, J.; Bureš, R.; Fáberová, M. Power loss separation in Fe-based composite materials. J. Magn. Magn. Mater. 2013, 327, 146–150. [Google Scholar] [CrossRef]

- Talaat, A.; Suraj, M.; Byerly, K.; Wang, A.; Wang, Y.; Lee, J.; Ohodnicki, P. Review on soft magnetic metal and inorganic oxide nanocomposites for power applications. J. Alloy. Compd. 2021, 870, 159500. [Google Scholar] [CrossRef]

- Hsiang, H.-I. Progress in materials and processes of multilayer power inductors. J. Mater. Sci. Mater. Electron. 2020, 31, 16089–16110. [Google Scholar] [CrossRef]

- Monier-Vinard, E.; Bissuel, V.; Dia, C.T.; Daniel, O.; Laraqi, N. Investigation of Delphi Compact Thermal Model Style for Modeling Surface-Mounted Soft Magnetic Composite Inductor. In Proceedings of the 19th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Berlin, Germany, 25–27 September 2013. [Google Scholar]

| Sample(Powder Treatment) | Density(g/cm3) | Resistivity ρ(Ω·cm) | Permeability(μe/200 kHz) | Ps@50 mT/mW/cm3 | |

|---|---|---|---|---|---|

| 100 kHz | 200 kHz | ||||

| Uncoated FeSiCr | 6.31 ± 0.03 | 58 ± 9 | 55.5 ± 1.6 | 1283 ± 8 | 4015 ± 26 |

| 0% Al2O3-resin | 6.23 ± 0.03 | (2.8 ± 0.1) × 105 | 39.9 ± 1.2 | 783 ± 3 | 1584 ± 11 |

| 0.5% Al2O3-resin | 6.19 ± 0.02 | (8.3 ± 0.5) × 105 | 39.3 ± 1.3 | 589 ± 3 | 1173 ± 8 |

| 1.0% Al2O3-resin | 6.10 ± 0.02 | (2.1 ± 0.2) × 106 | 37.8 ± 1.1 | 620 ± 5 | 1239 ± 10 |

| 1.5% Al2O3-resin | 5.98 ± 0.02 | (1.9 ± 0.1) × 107 | 34.2 ± 0.9 | 701 ± 2 | 1385 ± 5 |

| 2.0% Al2O3-resin | 5.97 ± 0.02 | (7.8 ± 0.2) × 107 | 33.7 ± 0.9 | 712 ± 5 | 1420 ± 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Q.; Yu, H.; Yuan, H.; Han, G.; Chen, X.; Liu, Z. Enhanced Magnetic Properties and Thermal Conductivity of FeSiCr Soft Magnetic Composite with Al2O3 Insulation Layer Prepared by Sol-Gel Process. Metals 2023, 13, 813. https://doi.org/10.3390/met13040813

Xie Q, Yu H, Yuan H, Han G, Chen X, Liu Z. Enhanced Magnetic Properties and Thermal Conductivity of FeSiCr Soft Magnetic Composite with Al2O3 Insulation Layer Prepared by Sol-Gel Process. Metals. 2023; 13(4):813. https://doi.org/10.3390/met13040813

Chicago/Turabian StyleXie, Qintian, Hongya Yu, Han Yuan, Guangze Han, Xi Chen, and Zhongwu Liu. 2023. "Enhanced Magnetic Properties and Thermal Conductivity of FeSiCr Soft Magnetic Composite with Al2O3 Insulation Layer Prepared by Sol-Gel Process" Metals 13, no. 4: 813. https://doi.org/10.3390/met13040813

APA StyleXie, Q., Yu, H., Yuan, H., Han, G., Chen, X., & Liu, Z. (2023). Enhanced Magnetic Properties and Thermal Conductivity of FeSiCr Soft Magnetic Composite with Al2O3 Insulation Layer Prepared by Sol-Gel Process. Metals, 13(4), 813. https://doi.org/10.3390/met13040813