Effect of Warm Crossing Rolling on the Microstructure, Texture and Annealing Behavior of High-Purity Tantalum

Abstract

:1. Introduction

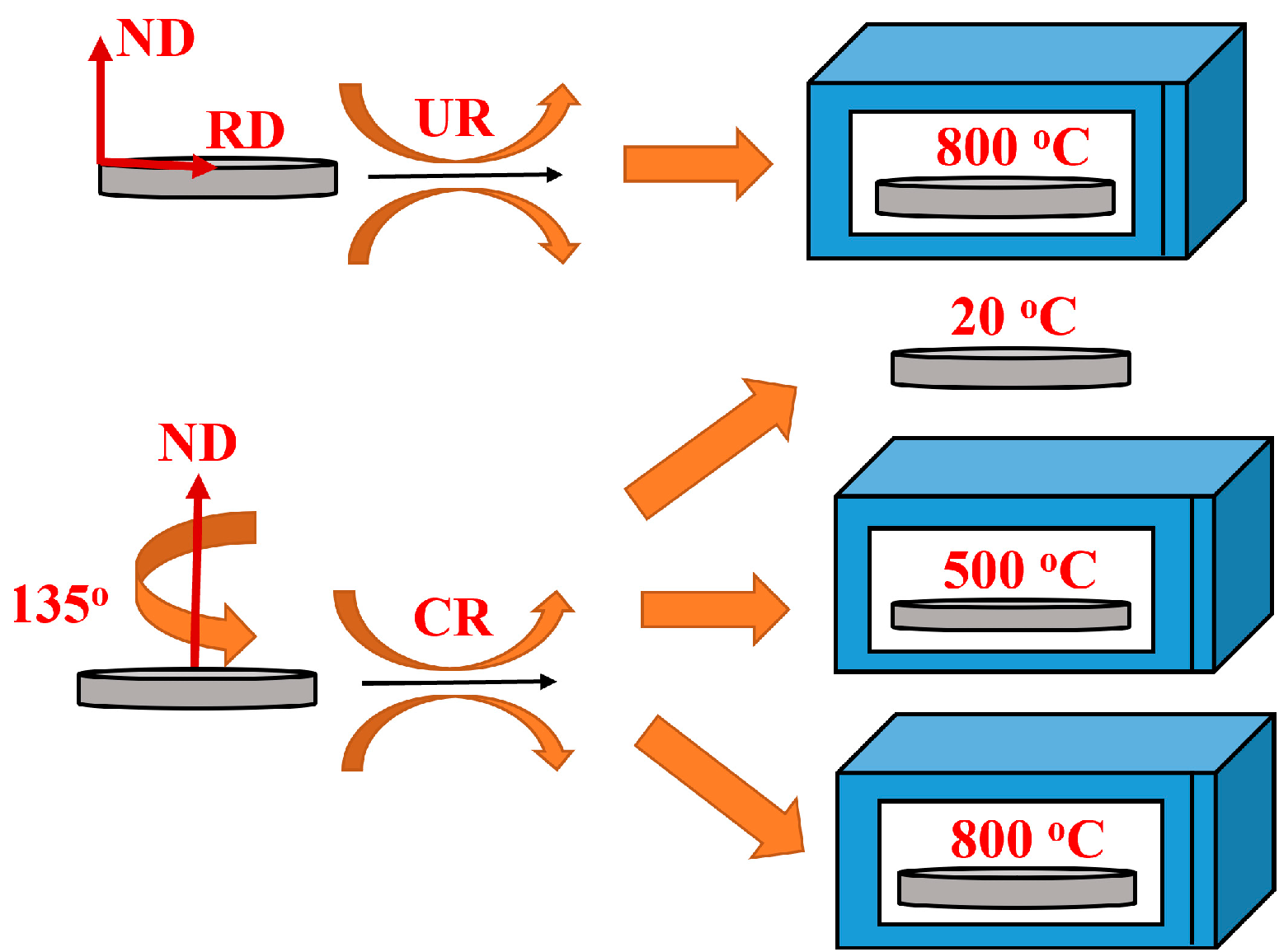

2. Experimental Section

2.1. Experimental Materials and Rolling Methods

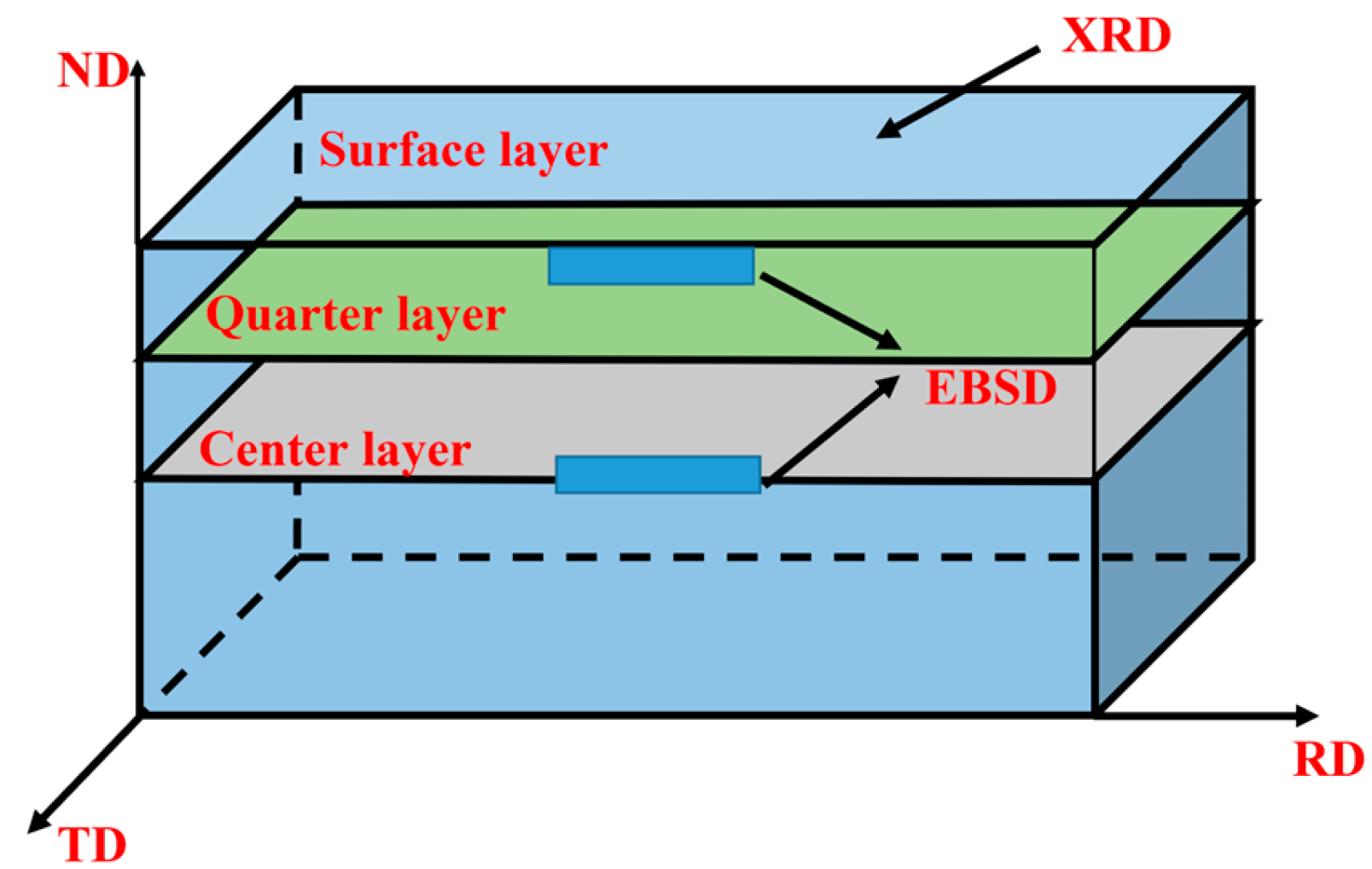

2.2. Characterization Methods

3. Results

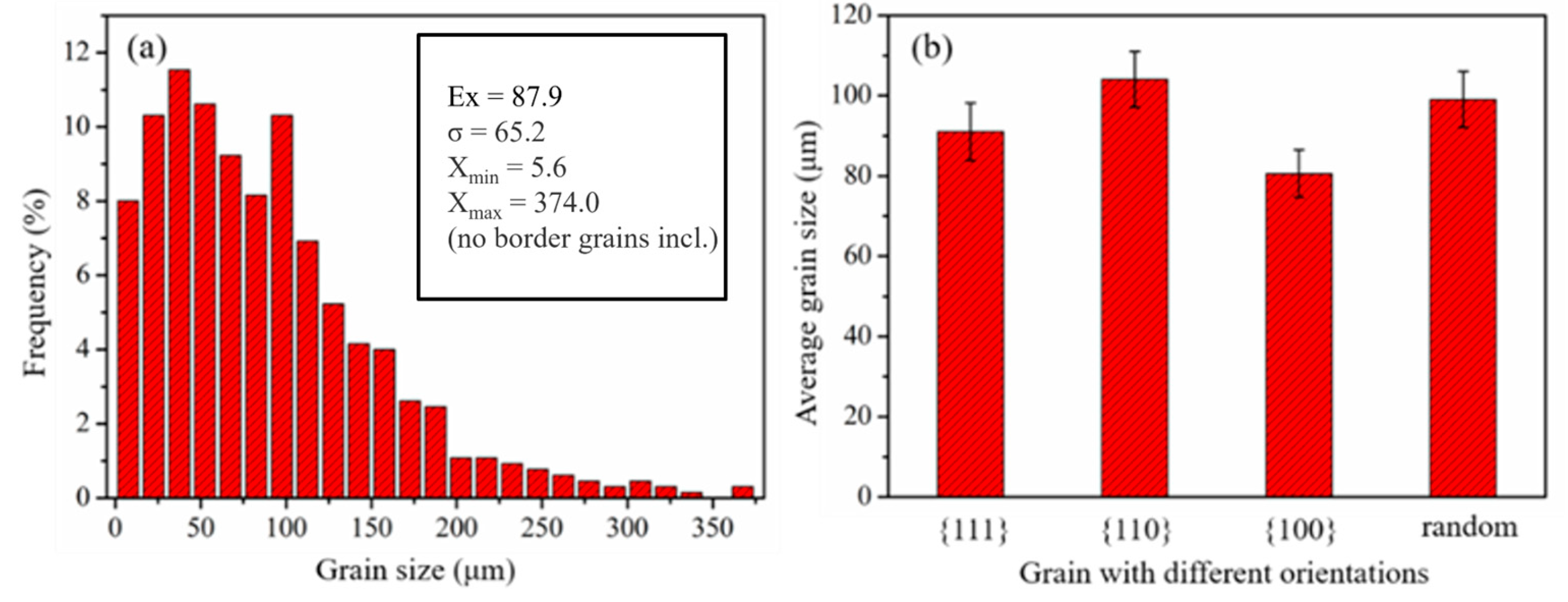

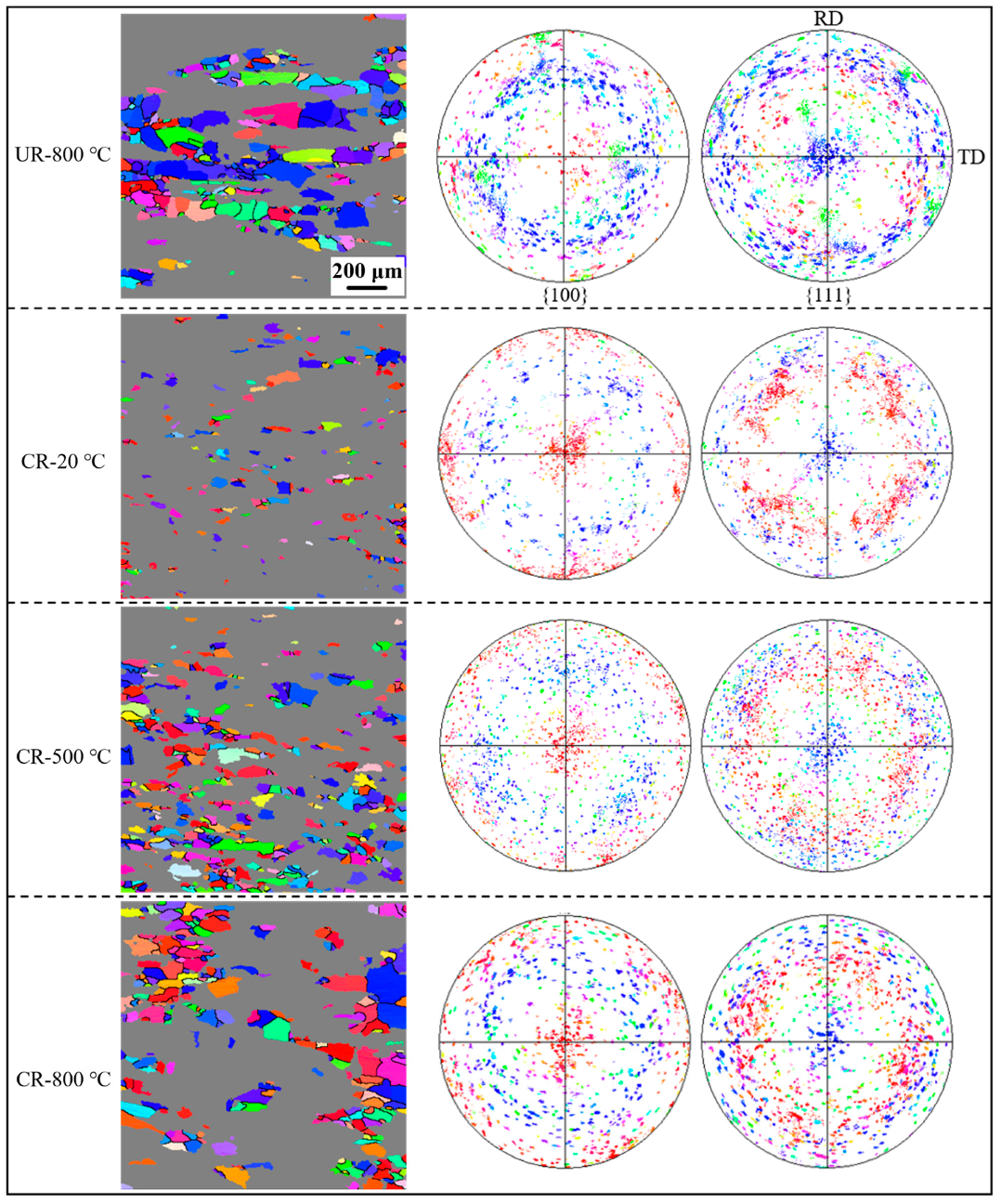

3.1. Initial Texture and Grain Size Distribution

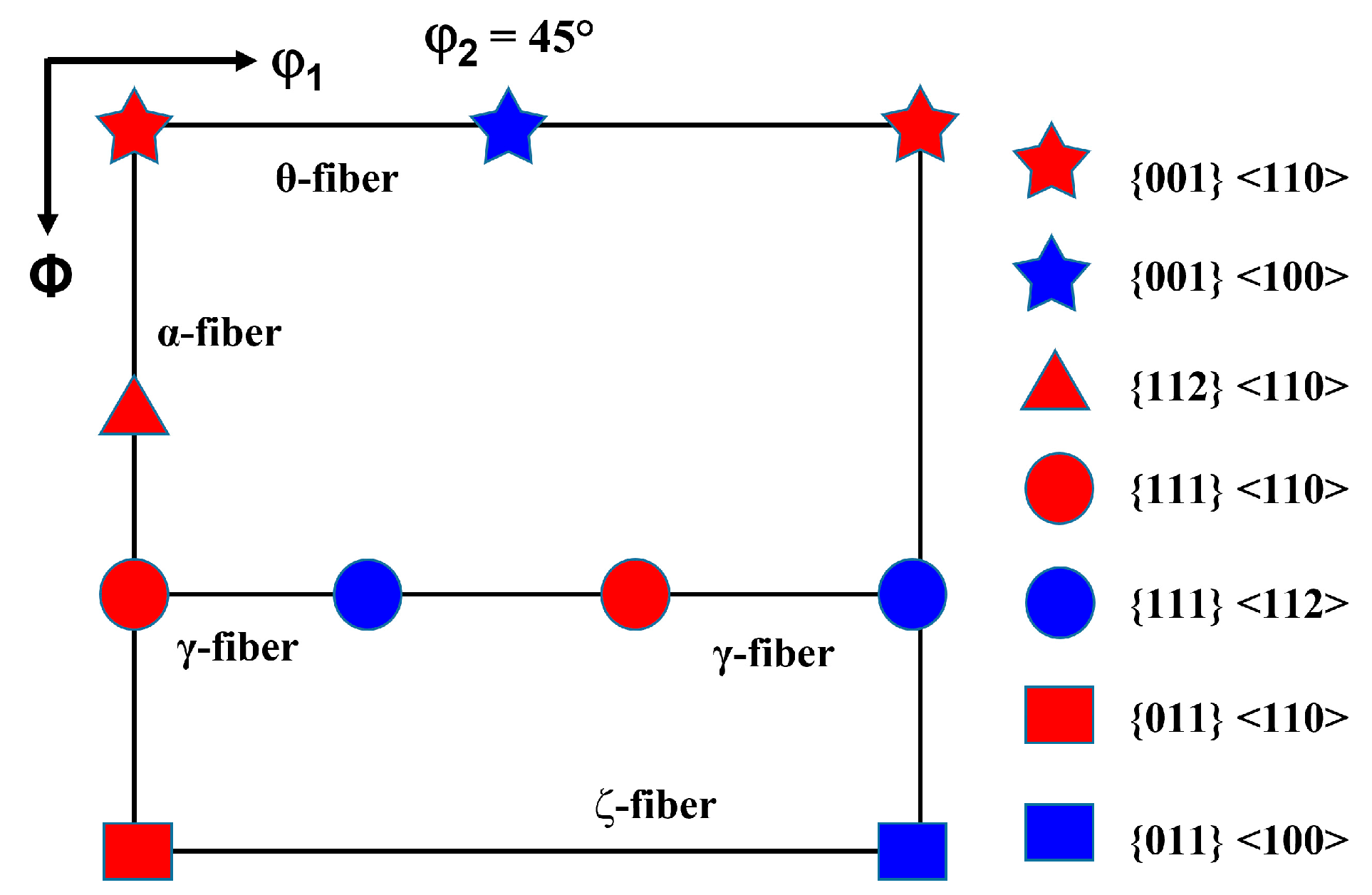

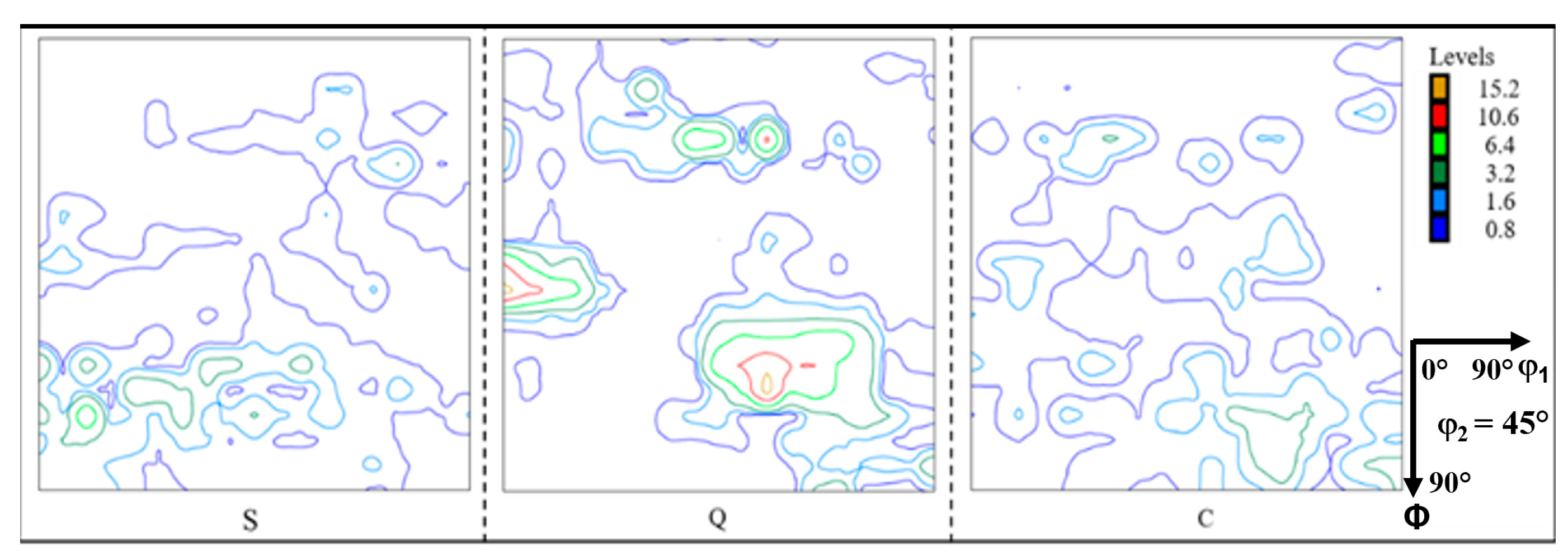

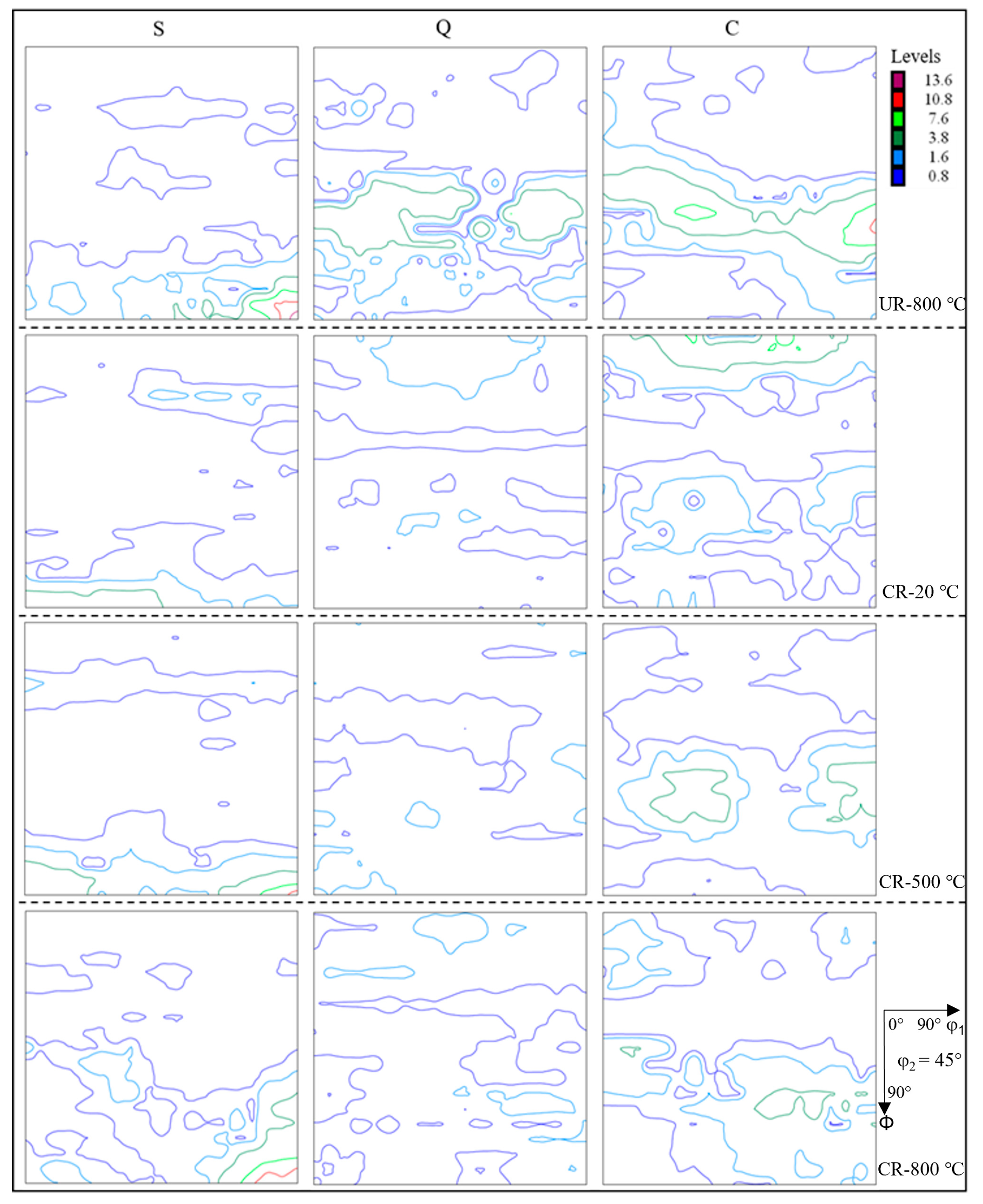

3.2. Deformation Texture

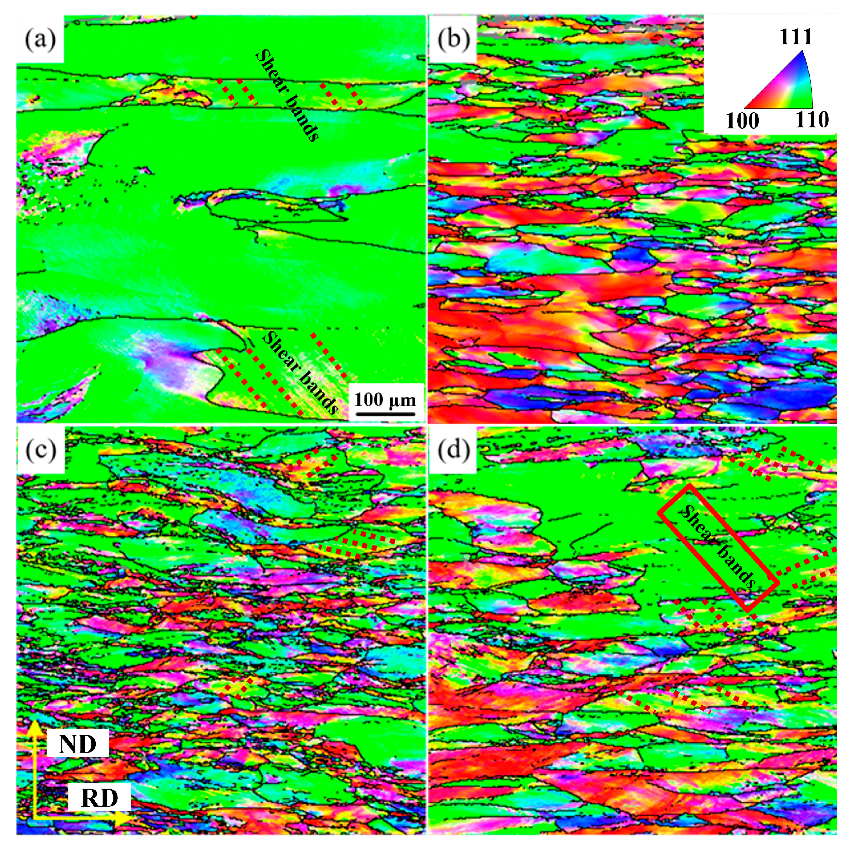

3.3. Deformation Microstructure

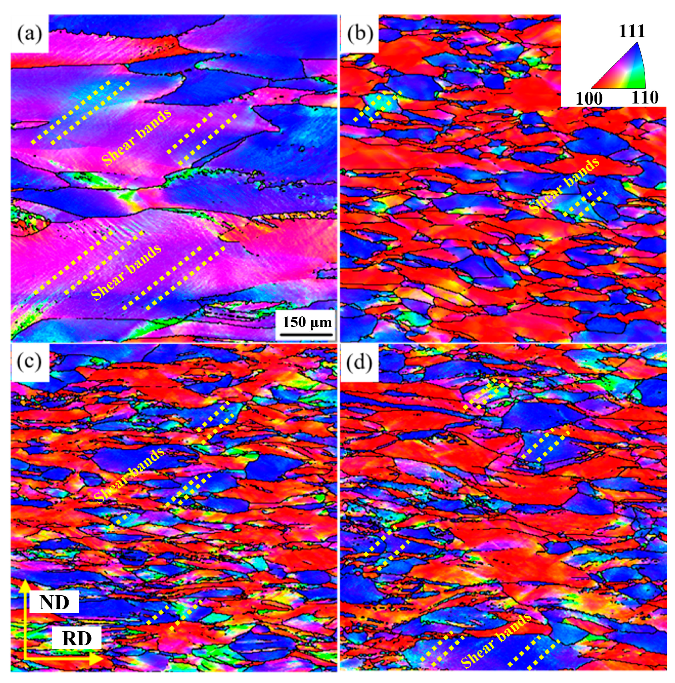

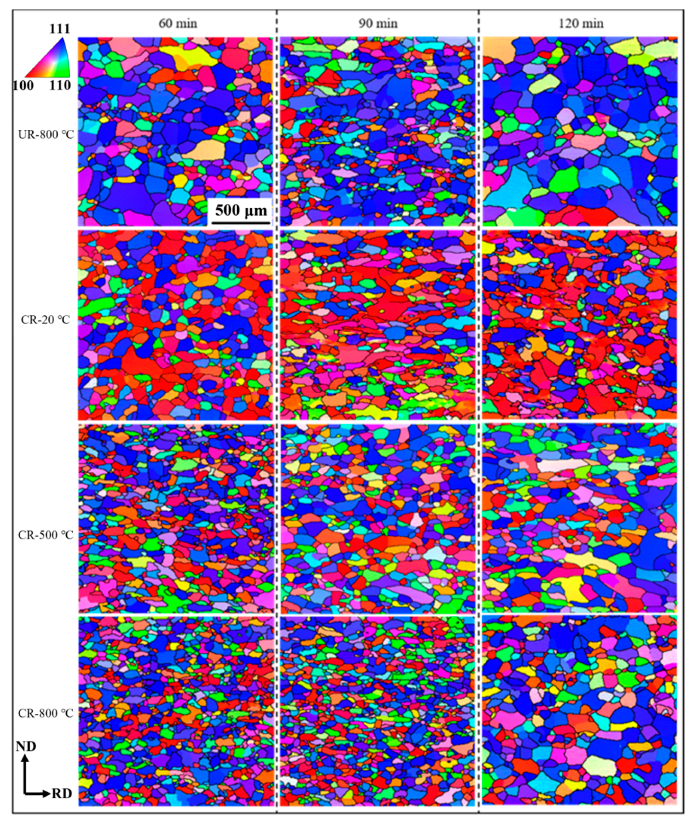

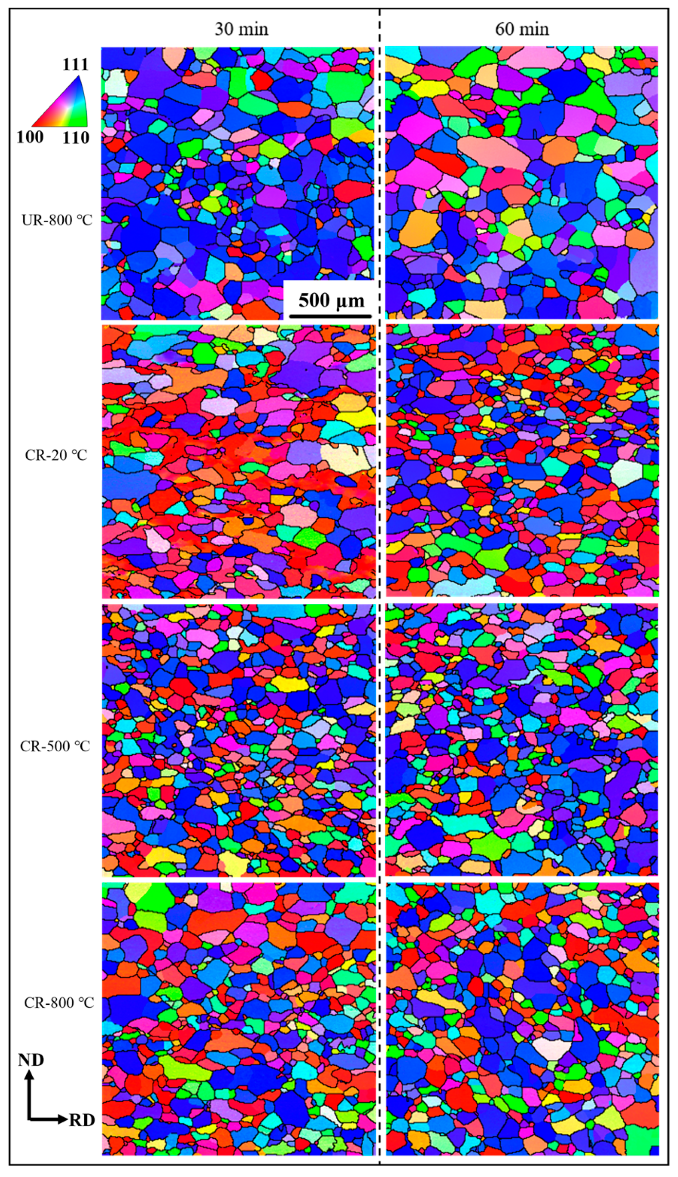

3.4. Microstructure after Annealing

4. Discussion

4.1. Effect of Deformation Temperature on Microstructure

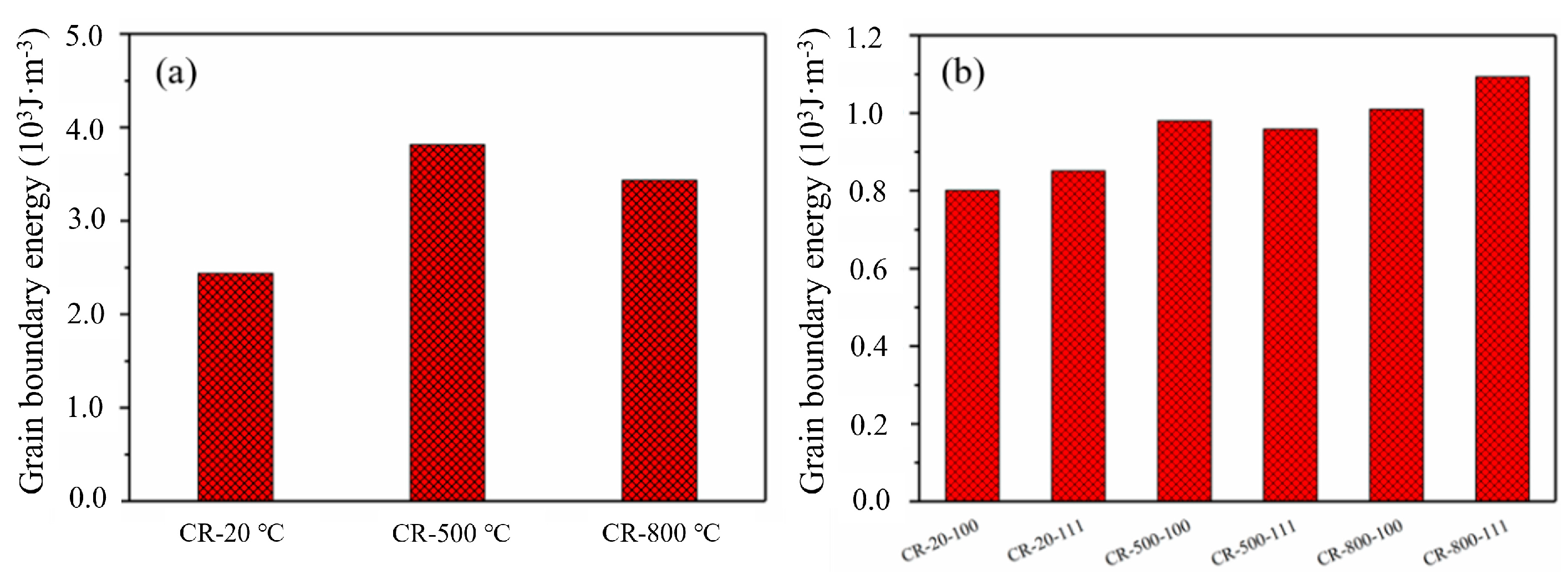

4.2. Distribution of Grain Boundary Energy

4.3. Recrystallized Microstructure Homogeneity

5. Conclusions

- (1)

- A strong shear texture (ζ fiber texture) is exhibited on the surface layer of the WCR sample due to the strong friction between the sample surface and the roll. The center layer of the WCR sample is subjected to plane strain, resulting in the formation of γ and θ fiber textures with an alternating distribution. The randomly distributed texture occurs in the WCR sample with a quarter thickness, which is associated with the shear strength lower than the surface layer and grains not completely in the plane strain state;

- (2)

- The percentage of LAGBs within the deformed grains is significantly reduced in the CR-500 °C and CR-800 °C samples compared with the CR-20 °C and UR-800 °C samples. WCR can improve the rate of dislocation motion, causing small Peierls stress to be overcome;

- (3)

- The dynamic recovery is promoted in WCR samples, resulting in further rearrangement of dislocations and reduction in the dislocation density. The sub-grains produced by dynamic recovery are thermodynamically unstable and can act as nuclei for subsequent recrystallization, inducing high grain boundary energy within WCR samples;

- (4)

- Small differences in the average size of grains with different orientations are observed during recrystallization in the WCR samples. The CR-800 °C sample enjoys the smallest average grain size of 40.9 μm after annealing at 1050 °C for 60 min. Future experiments can optimize the rolling temperature during warm cross rolling and use lubricants to achieve a uniform microstructure of the sample along the thickness direction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, H.; Liu, S.; Deng, C.; Wu, X.; Cao, L.; Liu, Q. Quantitative analysis: How annealing temperature influences recrystallization texture and grain shape in tantalum. Int. J. Refract. Met. Hard Mat. 2018, 72, 244–252. [Google Scholar] [CrossRef]

- Cardonne, S.M.; Kumar, P.; Michaluk, C.A.; Schwartz, H.D. Tantalum and its alloys. Int. J. Refract. Met. Hard Mat. 1995, 13, 187–194. [Google Scholar] [CrossRef]

- Lin, N.; Liu, S.; Liu, Y.; Fan, H.; Zhu, J.; Deng, C.; Liu, Q. Effects of asymmetrical rolling on through-thickness microstructure and texture of body-centered cubic (BCC) tantalum. Int. J. Refract. Met. Hard Mat. 2019, 78, 51–60. [Google Scholar] [CrossRef]

- Michaluk, C.A. Correlating discrete orientation and grain size to the sputter deposition properties of tantalum. J. Electron. Mater. 2002, 31, 2–9. [Google Scholar] [CrossRef]

- Sandim, H.R.Z.; Martins, J.P.; Pinto, A.L.; Padilha, A.F. Recrystallization of oligocrystalline tantalum deformed by cold rolling. Mater. Sci. Eng. A 2005, 392, 209–221. [Google Scholar] [CrossRef]

- Wright, S.I.; Gray, G.T.; Rollett, A.D. Textural and microstructural gradient effects on the mechanical behavior of a tantalum plate. Metall. Mater. Trans. A 1994, 25, 1025–1031. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, S.; Yuan, X.; Liu, Q. Comparing the Through-Thickness Gradient of the Deformed and Recrystallized Microstructure in Tantalum with Unidirectional and Clock Rolling. Materials 2019, 12, 169. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, S.; Long, D.; Orlov, D.; Liu, Q. Pass number dependence of through-thickness microstructure homogeneity in tantalum sheets under the change of strain path. Mater. Charact. 2020, 160, 110076. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, S.; Yang, S.; Long, D.; Liu, Y.; Yuan, X.; Orlov, D. Strain dependence of deformation and recrystallization microstructure homogeneity in clock-rolled tantalum sheets. Mater. Charact. 2020, 161, 110165. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, S.; Yang, S.; Liu, Y.; Chapuis, A. Beneficial clock-rolling cycles on the microstructure uniformity of {111} grains in tantalum sheets. Prog. Nat. Sci. Mater. 2020, 30, 124–127. [Google Scholar] [CrossRef]

- Xiang, K.Y.; Lei, X.C.; Ding, L.P.; Jia, Z.; Yang, X.; Liu, Q. Optimizing mechanical property of spray formed Al-Zn-Mg-Cu alloy by combination of homogenization and warm-rolling. Mater. Sci. Eng. A 2022, 75, 1509–1524. [Google Scholar] [CrossRef]

- Saha, J.; Ummethala, G.; Malladi, S.R.K.; Bhattacharjee, P.P. Severe warm-rolling mediated microstructure and texture of equiatomic CoCrFeMnNi high entropy alloy: A comparison with cold-rolling. Intermetallics 2021, 129, 107029. [Google Scholar] [CrossRef]

- Hao, Y.L.; Zhang, Z.B.; Li, S.J.; Yang, R. Microstructure and mechanical behavior of a Ti-24Nb-4Zr-8Sn alloy processed by warm swaging and warm rolling. Acta Mater. 2012, 60, 2169–2177. [Google Scholar] [CrossRef]

- Kang, U.G.; Lee, H.J.; Nam, W.J. The achievement of high strength in an Al 6061 alloy by the application of cryogenic and warm rolling. J. Mater. Sci. 2012, 22, 7883–7887. [Google Scholar] [CrossRef]

- Cheng, L.; Cai, Q.; Lv, J.; Yu, W.; Miura, H. Superdense microbands strengthening of textured low alloy ferritic steel. J. Alloys Compd. 2018, 746, 482–4889. [Google Scholar] [CrossRef]

- Li, Y.; Du, Z.; Fan, J.; Lv, Y.; Lv, Y.; Ye, L.; Li, P. Microstructure and texture evolution in warm-rolled fine-grained tungsten. Int. J. Refract. Met. Hard Mat. 2021, 101, 105690. [Google Scholar] [CrossRef]

- Tanaka, H.; Minoda, T.; Esaki, H.; Shibue, K.; Yoshida, H. Grain Refinement of AA7475 Based Aluminum Alloy Sheets by a Warm Rolling with Heated Rolls and its Effect on Texture and Mechanical Properties. Mater. Sci. Forum 2002, 396–402, 499–504. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Nayan, N.; Kumar, P.; Narayanan, P.R.; Sharma, S.C.; George, K.M. Microstructure–texture–mechanical properties relationship in multi-pass warm rolled Ti–6Al–4V Alloy. Mater. Sci. Eng. A 2014, 589, 174–181. [Google Scholar] [CrossRef]

- Chun, Y.B.; Hwang, S.K. Static recrystallization of warm-rolled pure Ti influenced by microstructural inhomogeneity. Acta Mater. 2008, 56, 369–379. [Google Scholar] [CrossRef]

- Gatti, J.R.; Bhattacharjee, P.P. Annealing textures of severely cold and warm-rolled Al–2.5 wt.%Mg alloy. J. Alloys Compd. 2014, 615, 950–961. [Google Scholar] [CrossRef]

- Guo, W.; Yi, Y.; Huang, S.; He, H.; Fang, J. Effects of Warm Rolling Deformation on the Microstructure and Ductility of Large 2219 Al–Cu Alloy Rings. Met. Mater. Int. 2020, 21, 56–68. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Hao, X.B.; Ji, J.L.; Zhang, Z.Q.; Liu, Q. Orientation dependence of stored energy release and microstructure evolution in cold rolled tantalum. Int. J. Refract. Met. Hard Mat. 2014, 46, 24–29. [Google Scholar] [CrossRef]

- Long, D.; Liu, S.; Zhu, J.; Liu, Y.; Zhou, S.; Yuan, X.; Orlov, D. Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing. Metals 2021, 11, 1665. [Google Scholar] [CrossRef]

- Mishra, S.; Kulkarni, K.; Gurao, N.P. Effect of crystallographic texture on precipitation induced anisotropy in an aluminium magnesium silicon alloy. Mater. Des. 2015, 84, 507–519. [Google Scholar] [CrossRef]

- Huh, M.Y.; Engler, O.; Raabe, D. On the Influence of Cross-Rolling on Shear Band Formation and Texture Evolution in Low Carbon Steel Sheets. Textures Microstruct. 1995, 24, 225–237. [Google Scholar] [CrossRef]

- Fan, H.Y.; Liu, S.F.; Li, L.J.; Deng, C.; Liu, Q. Largely alleviating the orientation dependence by sequentially changing strain paths. Mater. Des. 2016, 97, 464–472. [Google Scholar] [CrossRef]

- Seeger, A.; Hollang, L. The flow-stress asymmetry of ultra-pure molybdenum single crystals. Mater. Trans. JIM 2000, 41, 141–151. [Google Scholar] [CrossRef]

- Liu, X.; Golubov, S.I.; Woo, C.H.; Huang, H. Glide of edge dislocations in tungsten and molybdenum. Mater. Sci. Eng. A 2004, 365, 96–100. [Google Scholar] [CrossRef]

- Woodward, C.; Rao, S.I. Ab-initio simulation of isolated screw dislocations in bcc Mo and Ta. Philos. Mag. 2001, 81, 1305–1316. [Google Scholar] [CrossRef]

- Mendis, B.G.; Mishin, Y.; Hartley, C.S. Use of the Nye tensor in analyzing HREM images of bcc screw dislocations. Philos. Mag. 2006, 86, 4607–4640. [Google Scholar] [CrossRef]

- Po, G.; Cui, Y.; Rivera, D.; Cereceda, D.; Swinburne, T.D.; Marian, J.; Ghoniem, N. A phenomenological dislocation mobility law for bcc metals. Acta Mater. 2016, 119, 123–135. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T.; Klemm, V.; Chabok, A.; Pei, Y. Effect of stacking fault energy on the restoration mechanisms and mechanical properties of friction stir welded copper alloys. Mater. Des. 2019, 162, 185–197. [Google Scholar] [CrossRef]

- Gröger, R.; Vitek, V. Impact of non-Schmid stress components present in the yield criterion for bcc metals on the activity of {110}<111> slip systems. Comput. Mater. Sci. 2019, 159, 297–305. [Google Scholar] [CrossRef]

- Pegel, B. Stacking Faults on {110} Planes in the B.C.C. Lattice. Phys. Status Solidi B 1968, 28, 603–609. [Google Scholar] [CrossRef]

- Read, W.T.; Shockley, W. Dislocation Models of Crystal Grain Boundarm. Phys. Rev. 1950, 78, 275–289. [Google Scholar] [CrossRef]

- Lu, C.H.; Remington, B.A.; Maddox, B.R.; Kad, B.; Park, H.S.; Kawasaki, M.; Langdon, T.G.; Meyers, M.A. Laser compression of nanocrystalline tantalum. Acta Mater. 2013, 61, 7767–7780. [Google Scholar] [CrossRef]

- Godfrey, A.; Hansen, N.; Jensen, D.J. Microstructural-Based Measurement of Local Stored Energy Variations in Deformed Metals. Metall. Mater. Trans. A 2007, 38, 2329–2339. [Google Scholar] [CrossRef]

- Kim, D.I.; Kim, J.S.; Kim, J.H.; Choi, S.-H. A study on the annealing behavior of Cu-added bake-hardenable steel using an in situ EBSD technique. Acta Mater. 2014, 68, 9–18. [Google Scholar] [CrossRef]

- Srinivasan, R.; Viswanathan, G.B.; Levit, V.I.; Fraser, H.L. Orientation effect on recovery and recrystallization of cold rolled niobium single crystals. Mater. Sci. Eng. A 2009, 507, 179–189. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Modelling of plastic deformation via segmented voce curves, linked to characteristic LEDS’s which are generated by LEDS transformations between workhardening stages. Phys. Status Solidi B 1995, 149, 131–153. [Google Scholar] [CrossRef]

| Rolling Pass | Thickness After Rolling/mm | Single Pass Reduction/% | Total Rolling Reduction/% |

|---|---|---|---|

| 1 | 10.5 | 12.5 | 12.5 |

| 2 | 9.2 | 12.4 | 23.3 |

| 3 | 8.2 | 10.9 | 31.6 |

| 4 | 7.4 | 9.7 | 38.3 |

| 5 | 6.7 | 9.4 | 44.1 |

| 6 | 6 | 10.4 | 50 |

| 7 | 5.4 | 10 | 55 |

| 8 | 4.8 | 11.1 | 60 |

| 9 | 4.3 | 10.4 | 64.2 |

| 10 | 4.0 | 7.0 | 66.6 |

| 11 | 3.8 | 5.0 | 68.3 |

| 12 | 3.6 | 5.3 | 70 |

| Samples | Low-Angle Grain Boundaries (1.5° < θ < 5.5°) | Sub-Grain Boundaries (5.5° < θ < 15°) |

|---|---|---|

| UR-800 °C | 84.9% | 13.8% |

| CR-20 °C | 73.9% | 16.6% |

| CR-500 °C | 61.6% | 27.7% |

| CR-500 °C | 64.5% | 26.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Wang, S.; Zhang, M.; Zhou, S.; Liu, S.; Yuan, X. Effect of Warm Crossing Rolling on the Microstructure, Texture and Annealing Behavior of High-Purity Tantalum. Metals 2023, 13, 838. https://doi.org/10.3390/met13050838

Ding Y, Wang S, Zhang M, Zhou S, Liu S, Yuan X. Effect of Warm Crossing Rolling on the Microstructure, Texture and Annealing Behavior of High-Purity Tantalum. Metals. 2023; 13(5):838. https://doi.org/10.3390/met13050838

Chicago/Turabian StyleDing, Yuping, Song Wang, Min Zhang, Shiyuan Zhou, Shifeng Liu, and Xiaoli Yuan. 2023. "Effect of Warm Crossing Rolling on the Microstructure, Texture and Annealing Behavior of High-Purity Tantalum" Metals 13, no. 5: 838. https://doi.org/10.3390/met13050838

APA StyleDing, Y., Wang, S., Zhang, M., Zhou, S., Liu, S., & Yuan, X. (2023). Effect of Warm Crossing Rolling on the Microstructure, Texture and Annealing Behavior of High-Purity Tantalum. Metals, 13(5), 838. https://doi.org/10.3390/met13050838