Weldability of Additive Manufactured Stainless Steel in Resistance Spot Welding

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Experimental Material

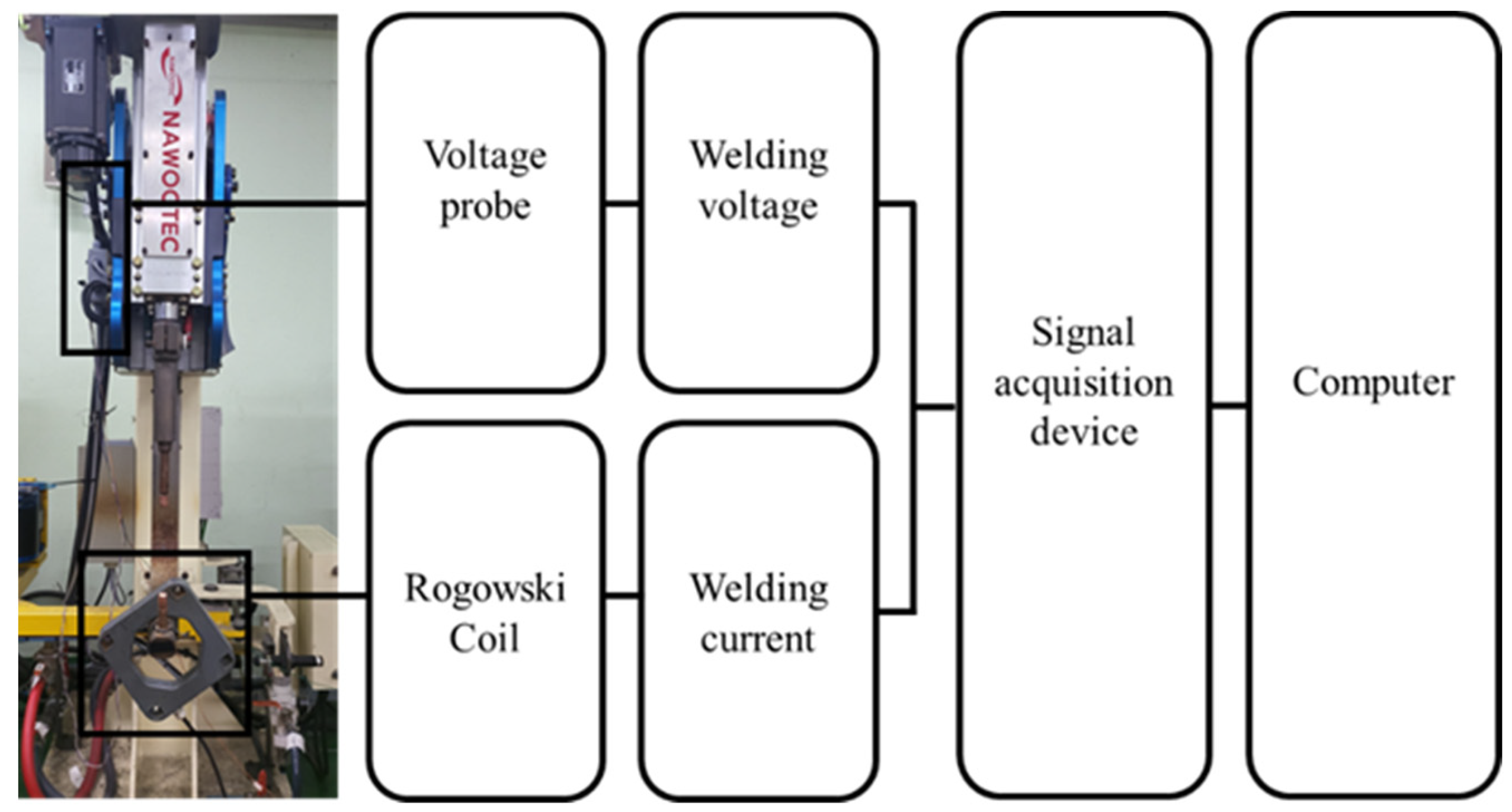

2.2. Experimental Setup

2.3. Cross-Section Analysis

2.4. Tensile Shear Strength Test

2.5. Welding Conditions

3. Results and Discussion

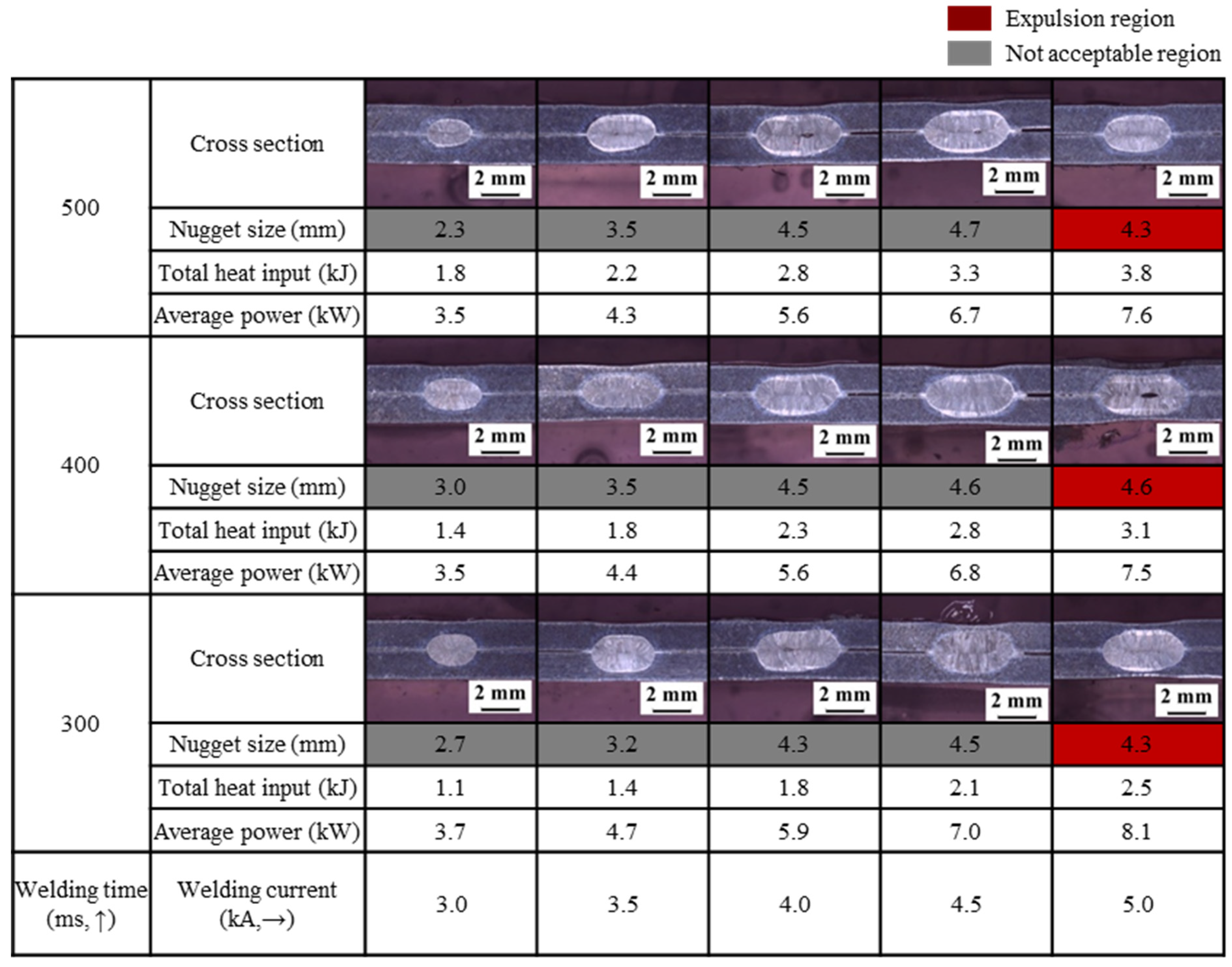

3.1. Weld Lobe Analysis for Two Materials

3.2. Analysis of Two Materials under Same Heat Input Condition

3.2.1. Cross-Section Analysis

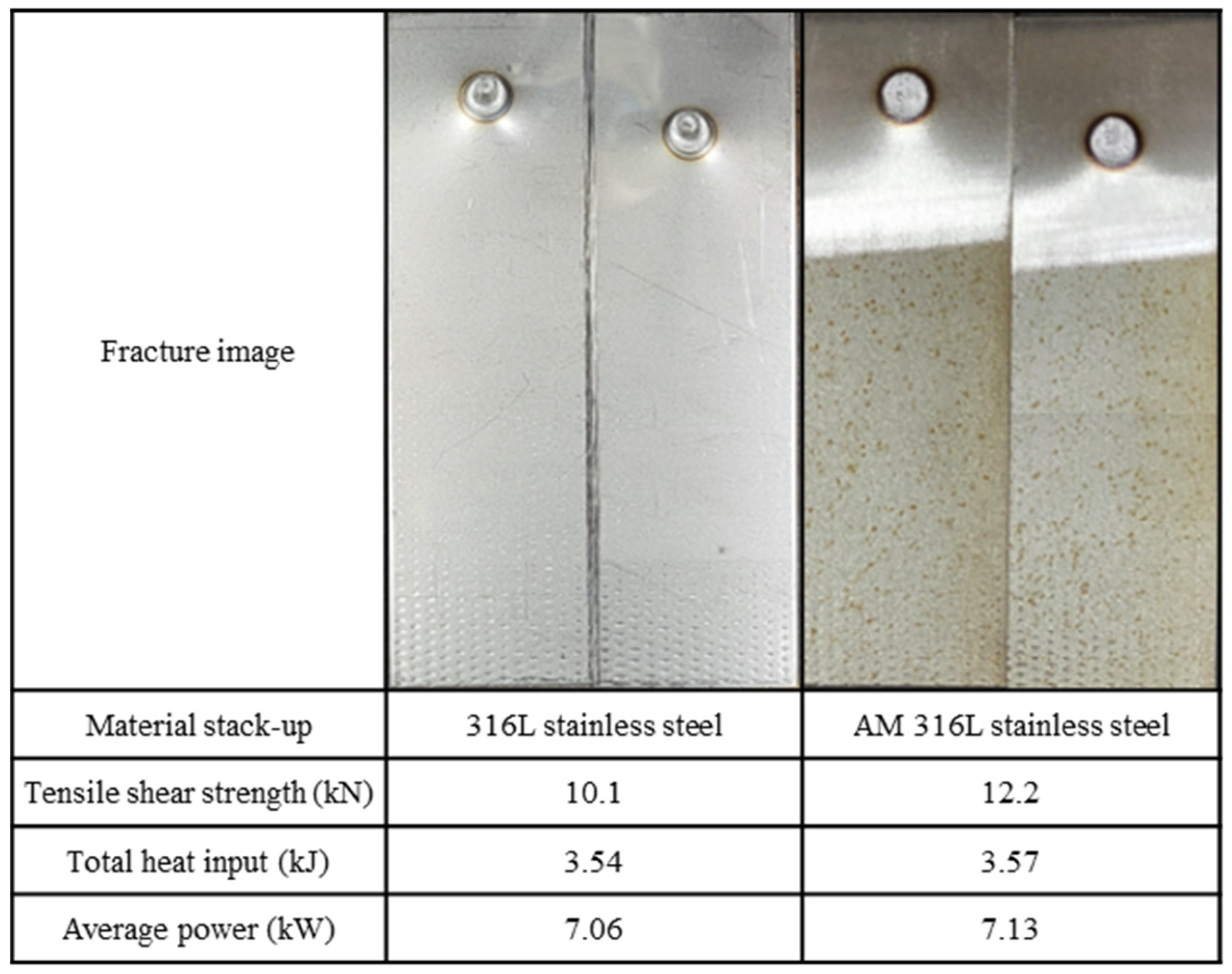

3.2.2. Tensile Shear Strength Test

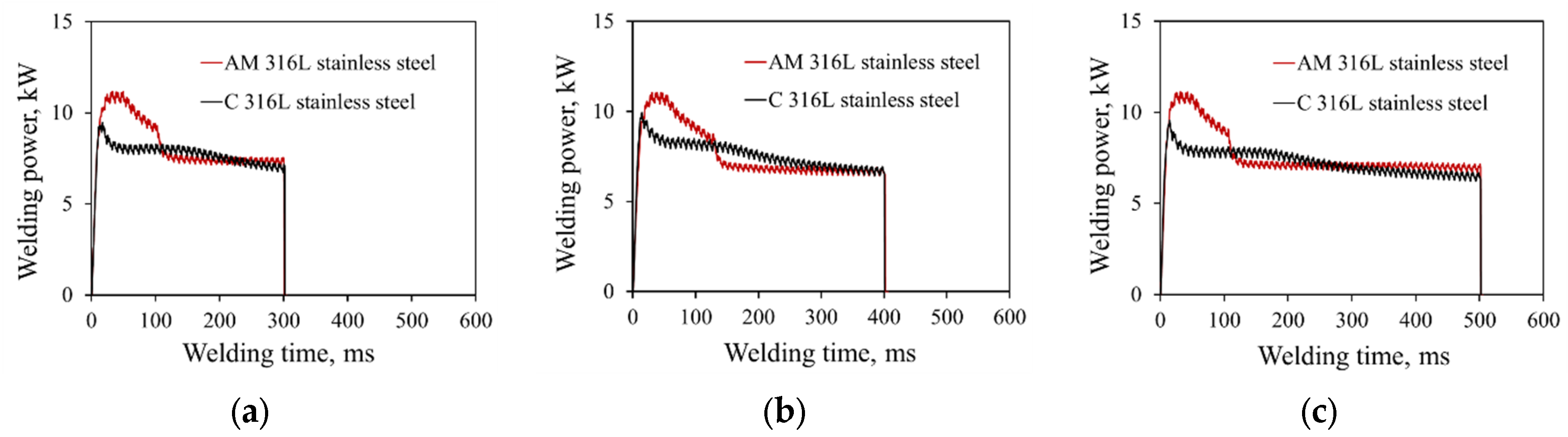

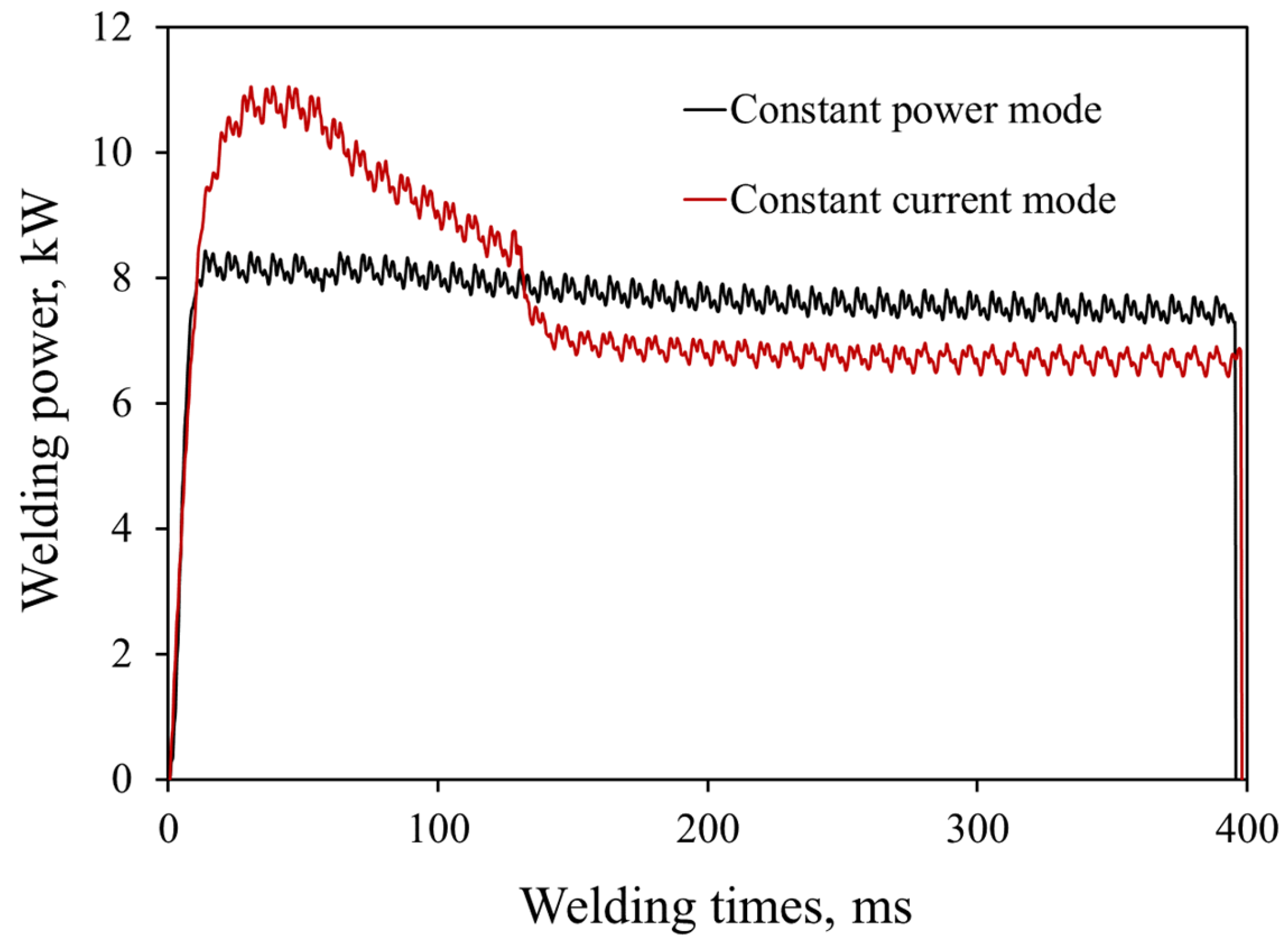

3.2.3. Welding Signal Analysis

3.2.4. Microhardness

3.3. Improved Weldability through CPC Mode

4. Conclusions

- (1)

- The lobe diagram and appropriate welding section were derived for the two materials according to the nugget diameter, and the difference between the two materials was analyzed through waveform analysis.

- (2)

- When the same heat input was applied to the two materials, the nugget diameter was identical. However, there was a difference in tensile shear strength value. This difference could be explained by the hardness analysis results.

- (3)

- The weldability of AM 316L stainless steel was improved and, thus, an appropriate nugget diameter could be secured through the application of the CPC mode.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Yao, J.; Man, C.; Cheng, X.; Xiao, K.; Li, X. Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes. J. Mater. Sci. Technol. 2019, 35, 1499–1507. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Danial, K.; Mostafaei, A.; Amadeh, A. Resistance spot welding joints of AlSI 316L austenitic stainless steel sheets: Phase transformations, mechanical properties and microstructure characterizations. J. Mater. Sci. 2014, 61, 251–263. [Google Scholar]

- Cheng, L.; Yansong, Z. Fusion zone characterization of resistance spot welded maraging steels via selective laser melting. J. Mater. Process. Technol. 2019, 273, 116253. [Google Scholar]

- Pham, M.S.; Dovgyy, B.; Hooper, P.A. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Elif, K.; Yahya, B. Additive manufacturing method and different welding applications. Mater. Res. Technol. 2020, 9, 11424–11438. [Google Scholar]

- Huysmans, S.; Peeters, E.; De Bruycker, E.; De Prins, K. Weldability study of additive manufactured 316L austenitic stainless steel components—Welding of AM with conventional 316L components. Mater. Sci. 2021, 65, 1415–1427. [Google Scholar] [CrossRef]

- Järvinen, J. Welding of Additively Manufactured Stainless Steel Parts: Comparative Study Between Sheet Metal and Selective Laser Melted Parts. Mater. Sci. 2014, 51–60. [Google Scholar]

- Murat, V.; Ahmet, A. On the resistance spot weldability of galvanized interstitial free steel sheets with austenitic stainless steel sheets. J. Mater. Process. Technol. 2004, 153–154, 1–6. [Google Scholar]

- Ruizhi, Z.; Craig, B.; Ville-Pekka, M.; Dafni, D.; Ben, B.; Heidi, P.; Antti, S.; Leroy, G. Mechanical properties and microstructure of additively manufactured stainless steel with laser welded joints. Mater. Des. 2021, 208, 109221. [Google Scholar]

- Ville-Pekka, M.; Joonas, P.; Antti, S. Weldability of additive manufactured stainless steel. Phys. Procedia 2016, 83, 807–817. [Google Scholar]

- Giuseppe, C.; Sabina, L.C.; Antonio, D.L. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Technol. 2013, 68, 209–216. [Google Scholar]

- Jingjing, Y.; Yun, W.; Fangzhi, L.; Wenpu, H.; Guanyi, J.; Zemin, W.; Xiaoyan, Z. Weldability, microstructure and mechanical properties of laser-welded selective laser melted 304 stainless steel joints. J. Mater. Sci. 2019, 35, 1817–1824. [Google Scholar]

- Laitinen, V. Weldability of Powder Bed Fusion Fabricated Stainless Steel 316L Sheets to Cold Rolled Sheet Metal. Master’s Thesis, LUT University, Lappeenranta, Finland, 2015. [Google Scholar]

- Teerawut, K.; Kannachai, K. Resistance Spot Welding of SUS316LAustenitic/SUS425 Ferritic Stainless Steels: Weldment Characteristics, Mechanical Properties, Phase Transformation and Solidification. Metals 2019, 9, 710. [Google Scholar]

- Bayram, K.; Ramazan, K.; Süleyman, G.; Fatih, H. An effect of heat input, weld atmosphere and weld cooling conditions on the resistance spot weldability of 316L austenitic stainless steel. J. Mater. Process. Technol. 2008, 195, 327–335. [Google Scholar]

- ISO 14273; International Organization for Standardization: Specimen Dimensions and Procedure for Shear Testing Resistance Spot, Seam and Embossed Projection Welds. ISO: Geneva, Switzerland, 2001; pp. 3–4.

- Su, Z.-W.; Xia, Y.-J.; Shen, Y.; Li, Y.-B. A novel real-time measurement method for dynamic resistance signal in medium frequency, DC resistance spot welding. Meas. Sci. Technol. 2020, 31, 055011. [Google Scholar] [CrossRef]

- Cho, Y.; Rhee, S. Primary circuit dynamic resistance monitoring and its application to quality estimation during resistance spot welding. Weld. J. 2002, 81, 104-s–111-s. [Google Scholar]

- Kim, S.; Hwang, I.; Kim, D.Y.; Kim, Y.M.; Kang, M.; Yu, J. Weld-quality prediction algorithm based on multiple models using process signals in resistance spot welding. Metals 2021, 11, 1459. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Zhan, M. Mechanism for the macro and micro behaviors of the Ni-based superalloy during electrically-assisted tension: Local Joule heating effect. J. Alloy. Compd. 2018, 742, 480–489. [Google Scholar] [CrossRef]

- Sumirat, I.; Ando, Y.; Shimamura, S. Theoretical consideration of the effect of porosity on thermal conductivity of porous materials. J. Porous Mater. 2006, 13, 439–443. [Google Scholar] [CrossRef]

- Dursun, Ö. An effect of weld current and weld atmosphere on the resistance spot weldability of 304L austenitic stainless steel. Mater. Des. 2008, 29, 597–603. [Google Scholar]

- Yu, J.; Choi, D.; Rhee, S. Improvement of Weldability of 1 GPa Grade Twin-Induced Plasticity Steel. Weld. J. 2014, 93, 78s–84s. [Google Scholar]

| Material | Element | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Mo | Fe | |

| C 316L stainless steel | 0.016 | 0.63 | 1.07 | 0.012 | 0.001 | 10.4 | 16.8 | 2.03 | Balance |

| AM 316L stainless steel | 0.017 | 0.69 | 0.96 | 0.001 | 0.004 | 12.7 | 17.0 | 2.56 | Balance |

| Items | Conditions |

|---|---|

| Electrode type | Tip diameter: 6 mm Materials: Cu-CR |

| Electrode force (kN) | 3.4 |

| Squeeze time (ms) | 167 |

| Hold time (ms) | 167 |

| Welding time (ms) | 300, 400, 500 |

| Welding current (CCC mode, kA) | 3.0~6.5 |

| Welding power (CPC mode, kW) | 7.0~8.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Park, S.; Kim, M.; Kim, D.-Y.; Park, J.; Yu, J. Weldability of Additive Manufactured Stainless Steel in Resistance Spot Welding. Metals 2023, 13, 837. https://doi.org/10.3390/met13050837

Kim S, Park S, Kim M, Kim D-Y, Park J, Yu J. Weldability of Additive Manufactured Stainless Steel in Resistance Spot Welding. Metals. 2023; 13(5):837. https://doi.org/10.3390/met13050837

Chicago/Turabian StyleKim, Sehyeon, Seonghwan Park, Mingyu Kim, Dong-Yoon Kim, Jiyong Park, and Jiyoung Yu. 2023. "Weldability of Additive Manufactured Stainless Steel in Resistance Spot Welding" Metals 13, no. 5: 837. https://doi.org/10.3390/met13050837

APA StyleKim, S., Park, S., Kim, M., Kim, D.-Y., Park, J., & Yu, J. (2023). Weldability of Additive Manufactured Stainless Steel in Resistance Spot Welding. Metals, 13(5), 837. https://doi.org/10.3390/met13050837