Effect of Fast-Frequency Pulsed Current Parameters on FFP-TIG Arc Behavior and Its Implications for Inconel 718 Welding

Abstract

1. Introduction

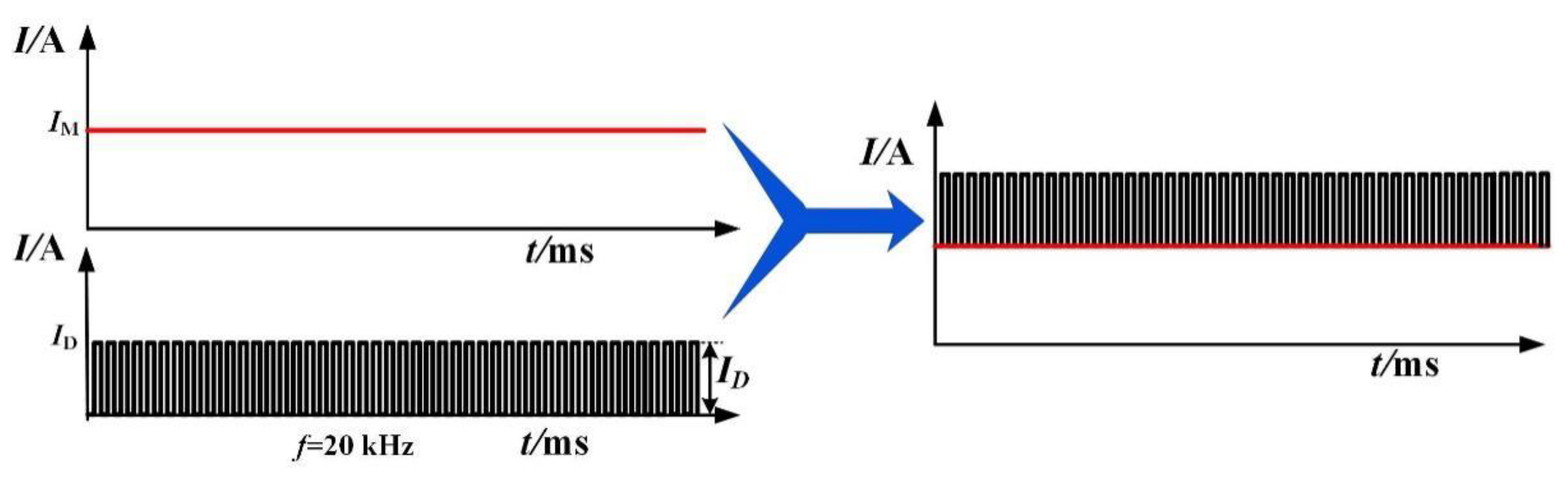

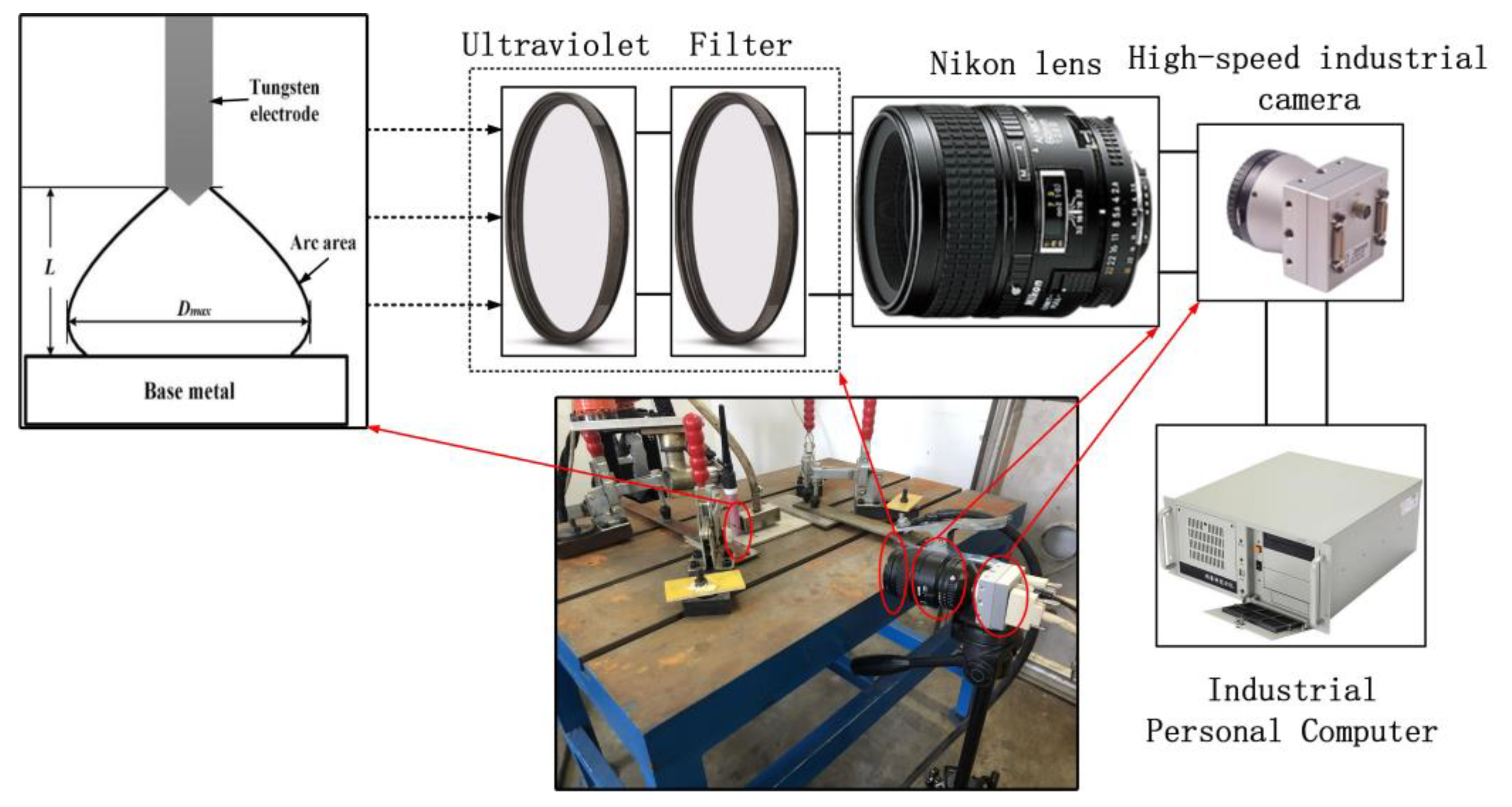

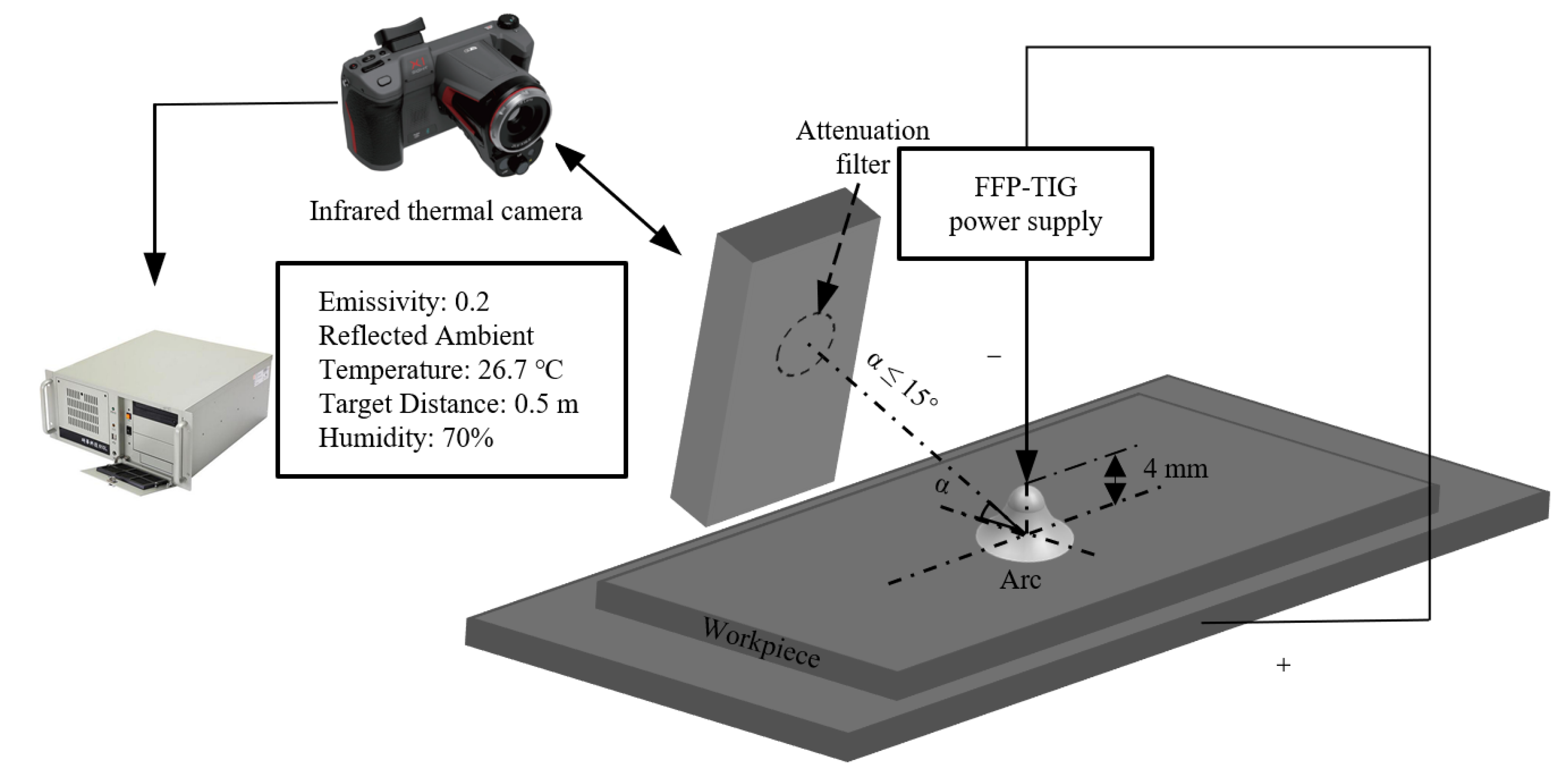

2. Equipment and Experimental Methods

3. Results and Discussion

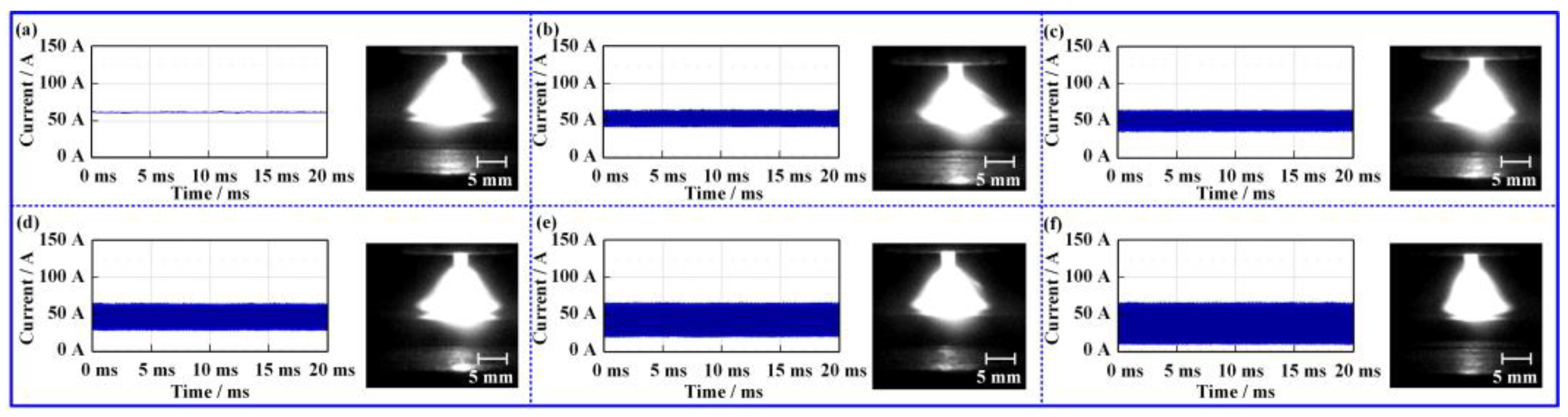

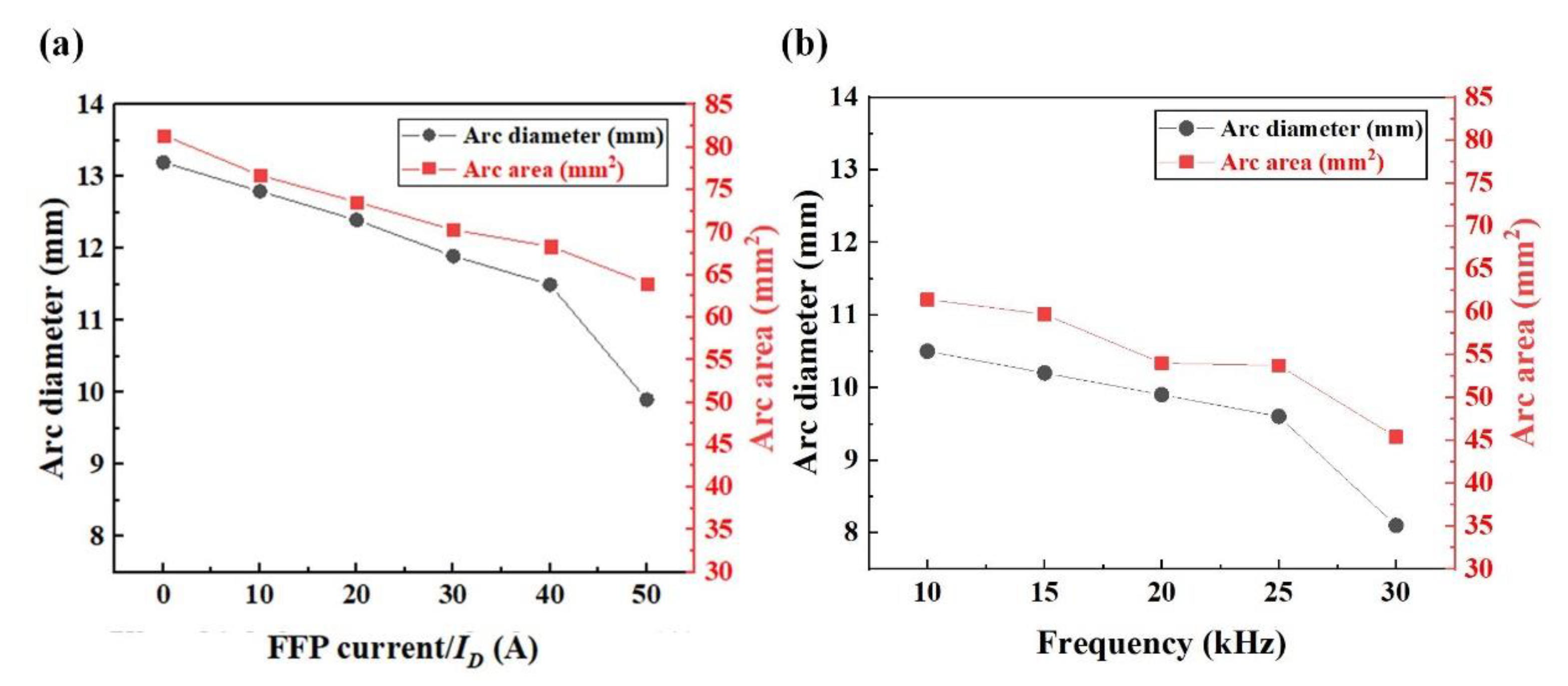

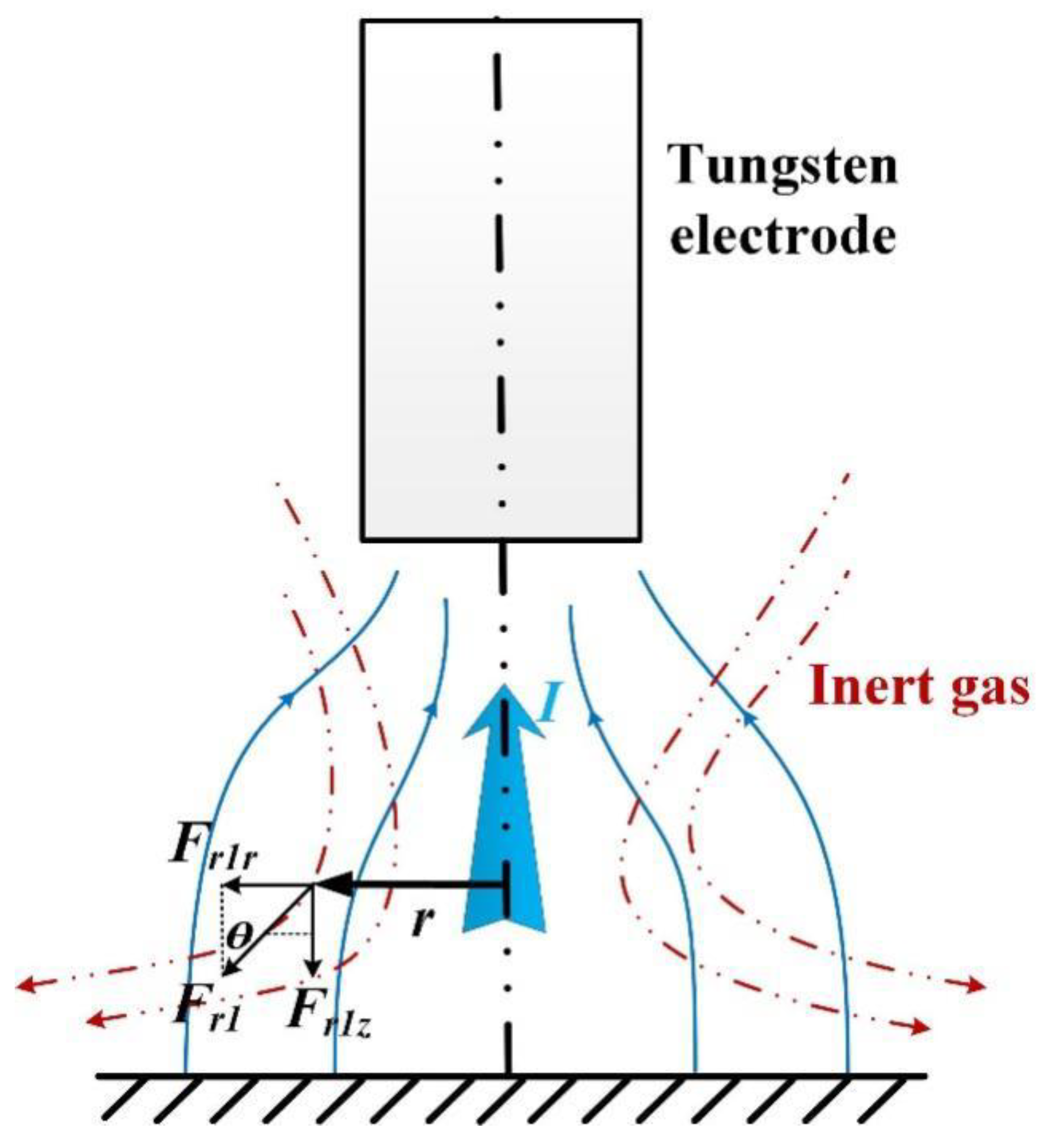

3.1. Arc Behavior Analysis of the FFP-TIG Arc

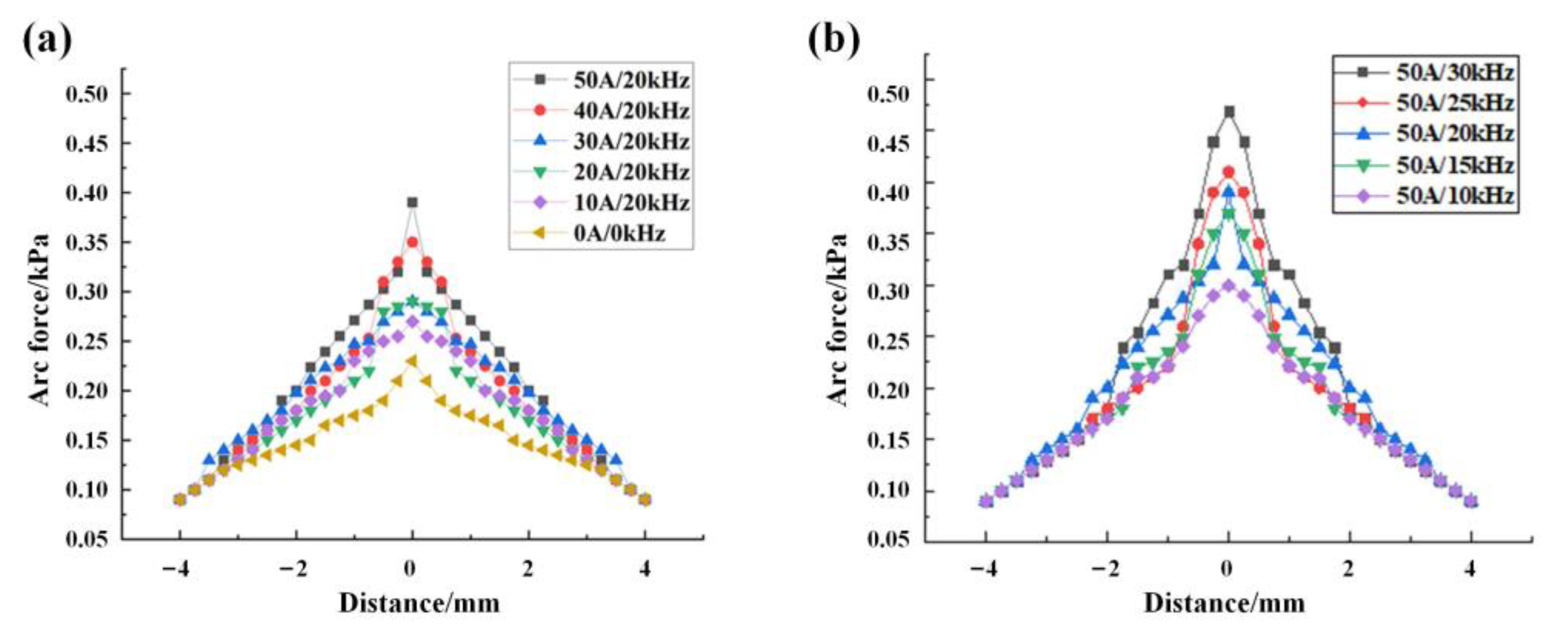

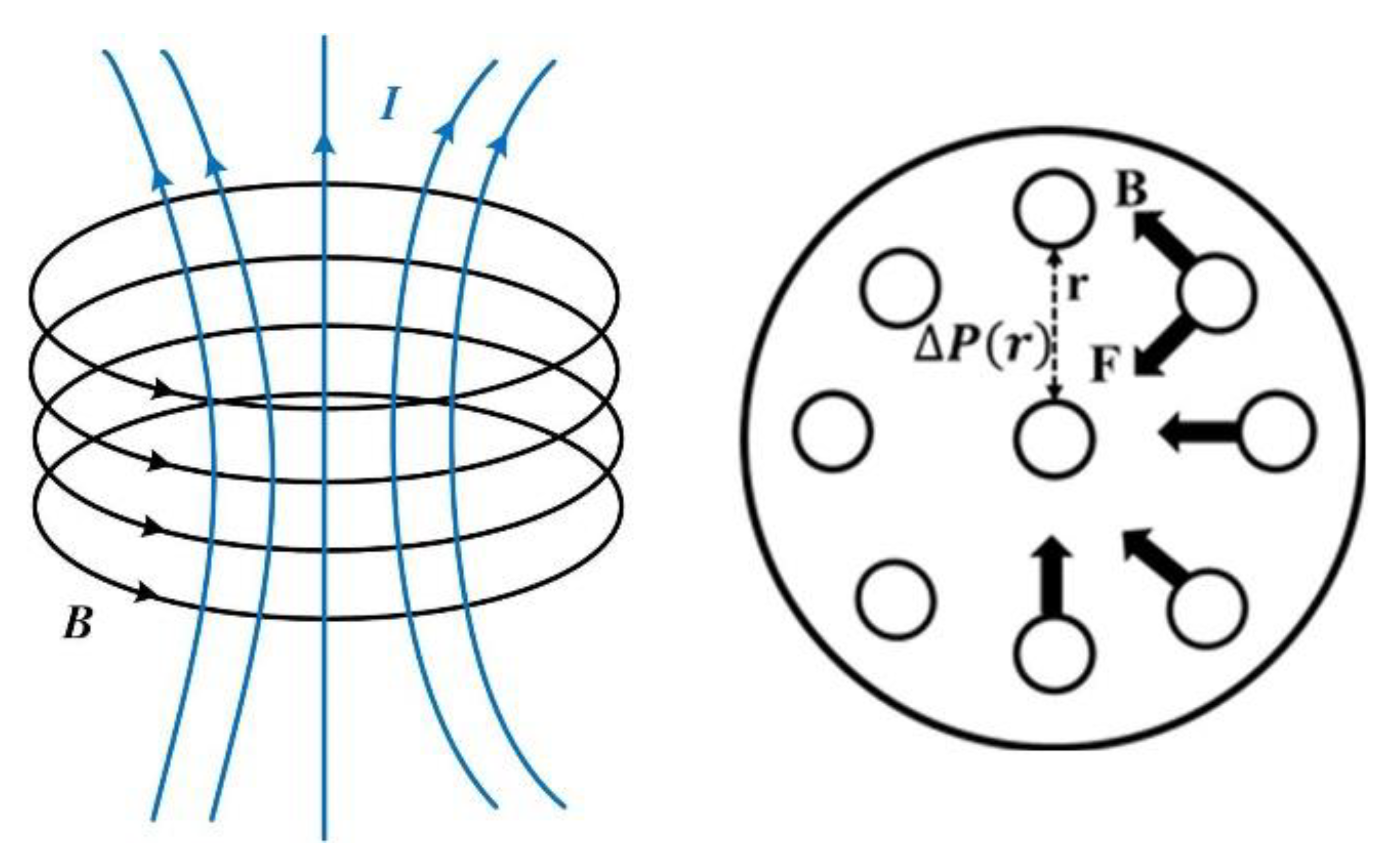

3.2. Arc Pressure Analysis of the FFP-TIG Arc

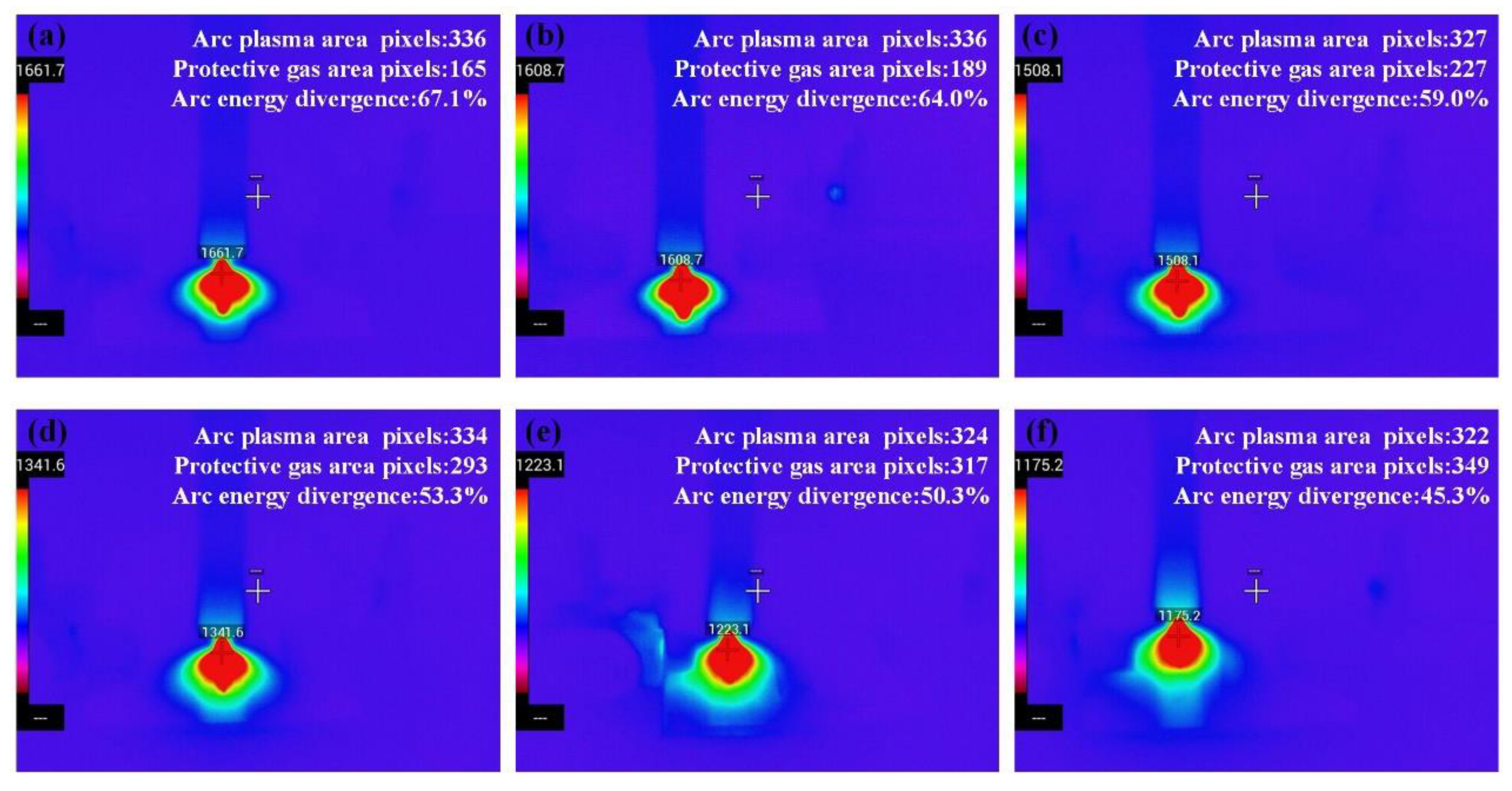

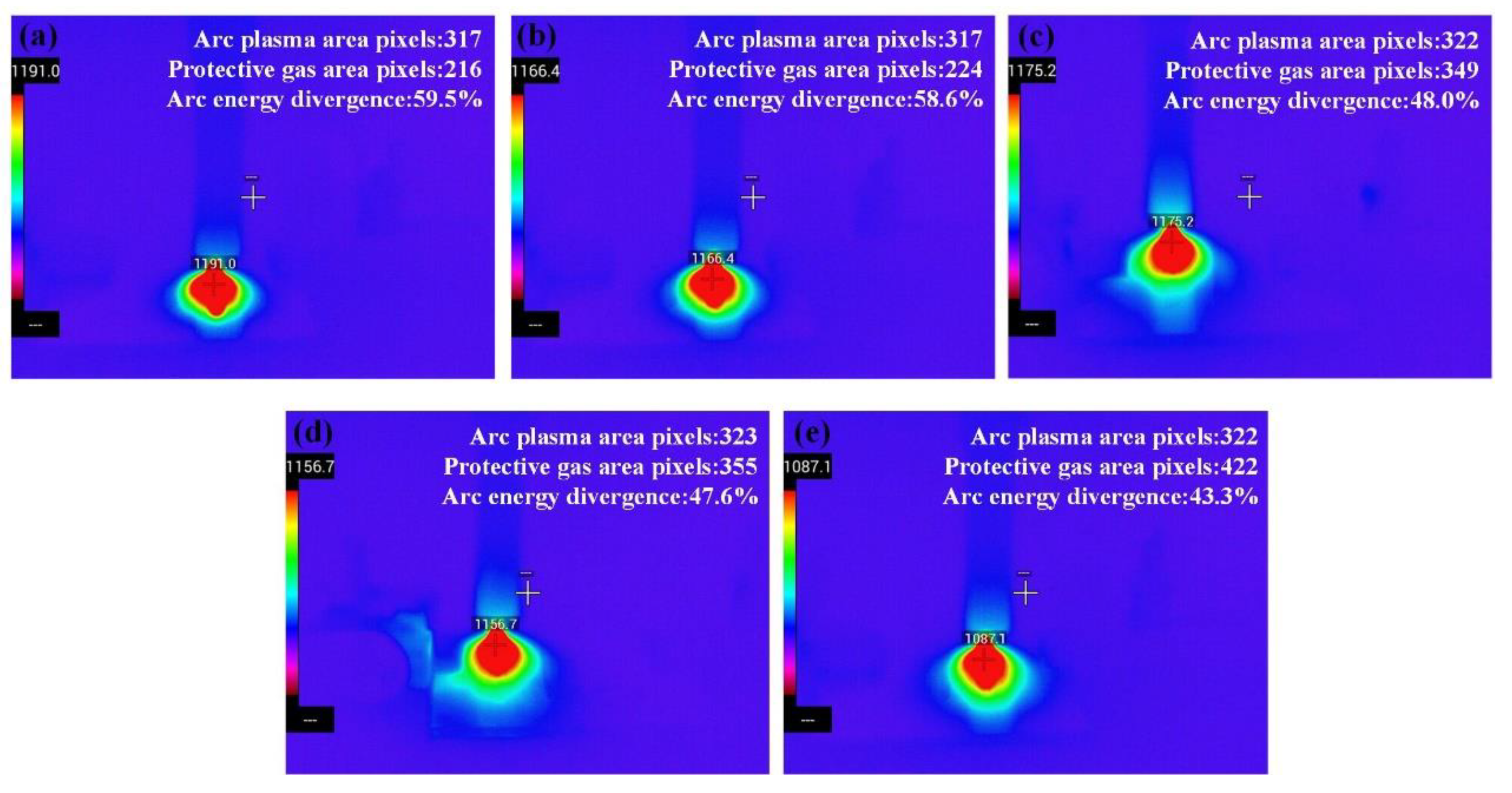

3.3. Infrared Image Analysis of FFP-TIG Arc Welding

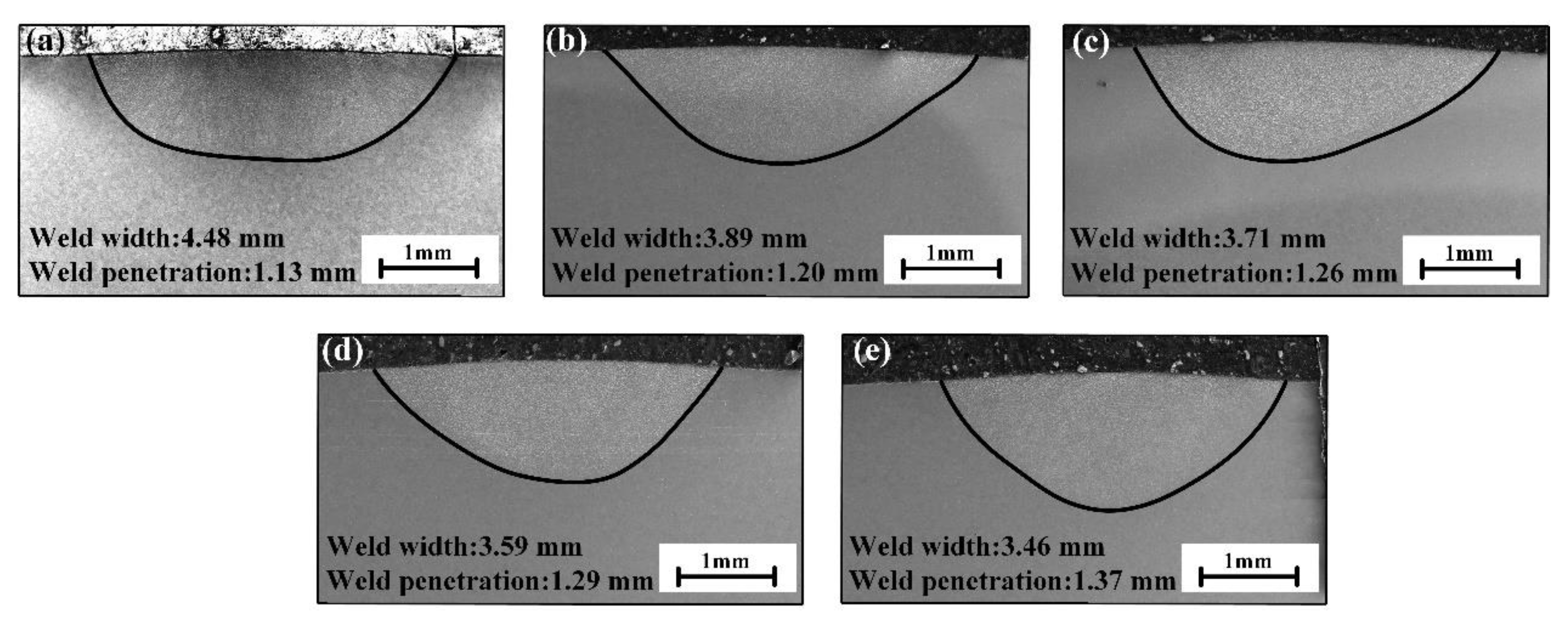

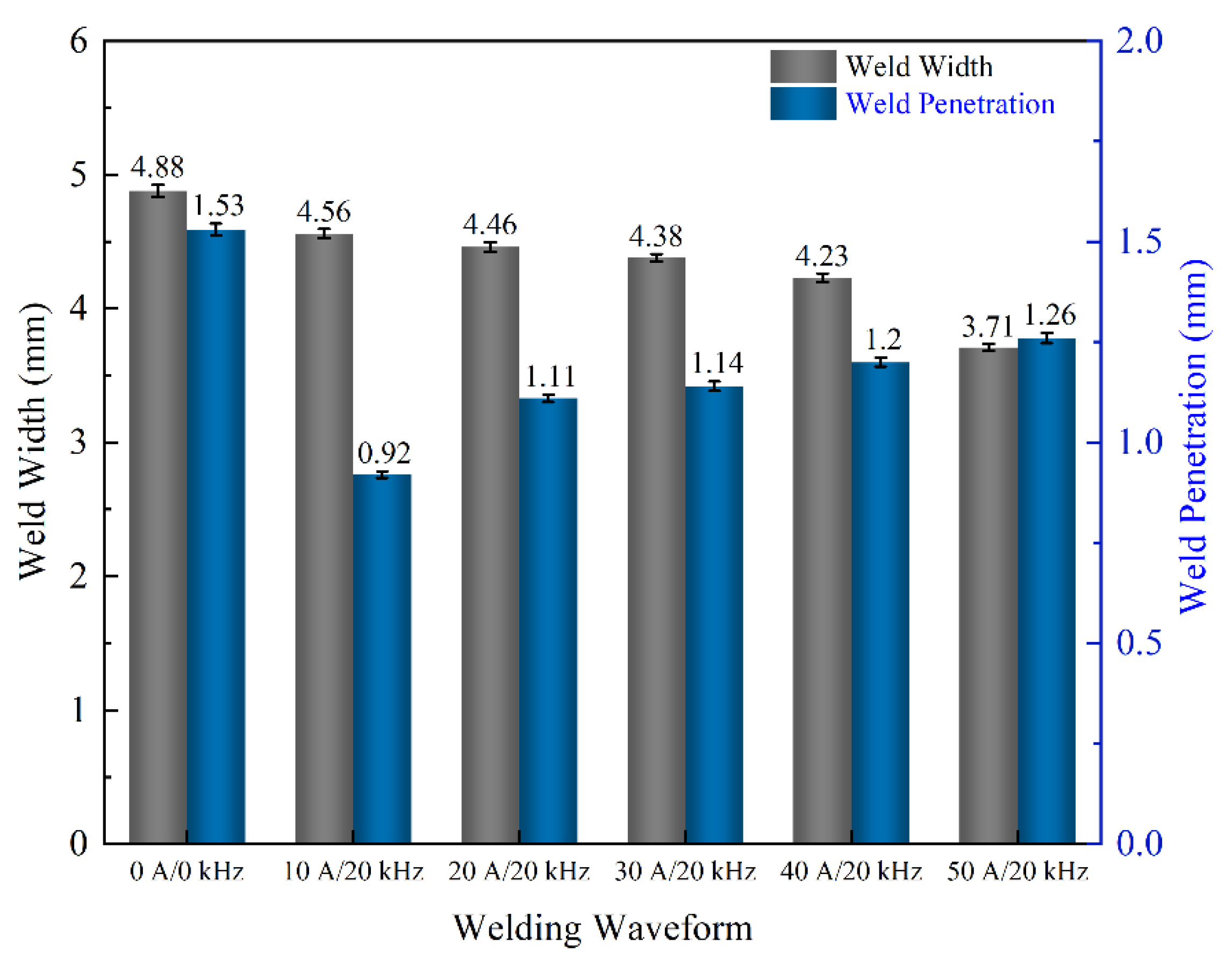

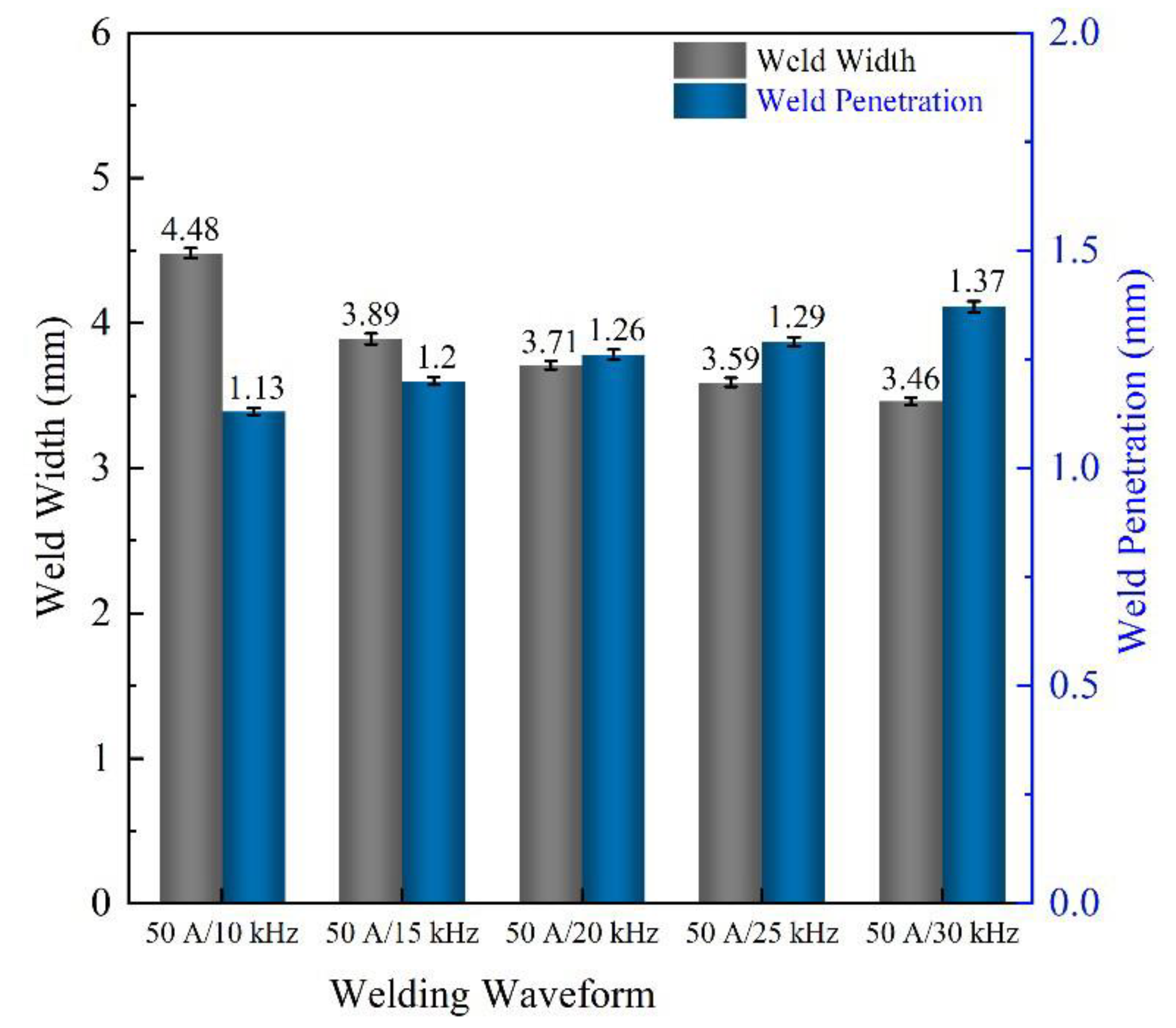

3.4. Surface Welding Analysis of FFP-TIG

3.5. Mechanism of FFP-TIG Arc Contraction

4. Conclusions

- With an increase in the FFP current amplitude or frequency, the arc diameter and arc area were reduced. Compared with conventional TIG, the arc diameter and arc area of FFP-TIG were reduced by approximately 38.2% and 29.2%, respectively.

- There was a significant increase in arc pressure by FFP-TIG. The arc pressure is normally distributed as a whole, and the arc pressure is symmetrically distributed with a change in FFP current amplitude or frequency. With an increase in the FFP current amplitude or frequency, the arc pressure at the center of the arc increased greatly.

- In FFP-TIG, the change in fast-frequency arc shape affects the arc energy concentration. The arc energy divergence and arc temperature in FFP-TIG with the FFP parameter of 50 A/20 kHz are reduced by approximately 19.1 and 29.3%, respectively. With an increase in the FFP current amplitude or frequency, the arc energy divergence reduced greatly.

- With the effects of FFP-TIG, a change in arc and molten pool behavior leads to a change in surface welding by adding FFP current. The higher the FFP current amplitude or frequency, the stronger the arc contraction effect, the smaller the weld width, and the greater the weld penetration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qi, B.; Xu, H.; Zhang, W. Microstructure and property analysis of 0Cr18Ni9Ti joints welded by ultra-sonic pulse tungsten-inert-gas welding technology. J. Beijing Univ. Aeronaut. Astronaut. 2009, 35, 132–136. [Google Scholar]

- Dai, W.L. Effects of high-intensity ultrasonic-wave emission on the weldability of aluminum alloy 7075-T6. Mater. Lett. 2003, 57, 2447–2454. [Google Scholar] [CrossRef]

- Short, A.B. Gas tungsten arc welding of alpha plus beta titanium alloys: A review. Mater. Sci. Technol. 2009, 25, 309–324. [Google Scholar] [CrossRef]

- Li, L.; Yang, M.; Qi, B.; Liu, H. Study of high frequency pulsed arc on molten pool thermal properties of Ti-6Al-4V. J. Manuf. Process. 2019, 38, 308–312. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, D.; Wu, J.; Xu, M. A review on high-frequency pulsed arc welding. J. Manuf. Process. 2020, 60, 503–519. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, H.; Qi, B.; Yang, Z. Effect of arc behavior on Ti-6A1-4V welds during high frequency pulsed arc welding. J. Mater. Process. Technol. 2017, 243, 9–15. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Z.; Lin, S.; Xie, Z.; Xu, M.; Tian, J.; Guo, C. Effect of fast-frequency pulsed waveforms on the microstructure and mechanical properties of Ti-6Al-4V alloy welded by FFP-TIG. J. Mater. Res. Technol. 2022, 20, 516–531. [Google Scholar] [CrossRef]

- Wu, J.; Xu, M.; Lin, S.; Zhang, Q.; Wu, X.; Tian, J.; Wang, Z. Refining microstructures and enhancing mechanical properties of Inconel 718 weldment via fast-frequency double pulsed waveforms adopting in FFP-TIG. J. Mater. Process. Technol. 2023, 314, 117882. [Google Scholar] [CrossRef]

- Farzadi, A.; Serajzadeh, S.; Kokabi, A.H. Modeling of heat transfer and fluid flow during gas tungsten arc welding of commercial pure aluminum. Int. J. Adv. Manuf. Technol. 2008, 38, 258–267. [Google Scholar] [CrossRef]

- Balasubramanian, M.; Jayabalan, V.; Balasubramanian, V. Effect of pulsed gas tungsten arc welding on corrosion behavior of Ti-6Al-4V titanium alloy. Mater. Des. 2008, 29, 1359–1363. [Google Scholar] [CrossRef]

- Babu, N.K.; Raman, S.G.S. Influence of current pulsing on microstructure and mechanical properties of Ti–6Al–4V TIG beads. Sci. Technol. Weld. Join. 2006, 11, 442–447. [Google Scholar] [CrossRef]

- Giridharan, P.K.; Murugan, N. Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets. Int. J. Adv. Manuf. Technol. 2009, 40, 478–489. [Google Scholar] [CrossRef]

- Chen, S.J.; Zhang, B.L.; Yin, S.Y.; Wu, H.R. Effect on aluminum-alloy TIG welding quality of double pulse modulated variable polarity waveform. Electr. Weld. Mach. 2006, 36, 7–14. [Google Scholar]

- Balasubramanian, M.; Jayabalan, V.; Balasubramanian, V. A mathematical model to predict impact toughness of pulsed-current gas tungsten arc-welded titanium alloy. Int. J. Adv. Manuf. Technol. 2008, 35, 852–858. [Google Scholar] [CrossRef]

- Qi, B.J.; Yang, M.X.; Cong, B.Q.; Li, W. Study on Fast-Convert Ultrasonic Frequency Pulse TIG Welding Arc Characteristic. Mater. Sci. Forum 2011, 37, 704–705. [Google Scholar] [CrossRef]

- Cook, G.E.; Eassa, H.E.E.H. The Effect of High-Frequency Pulsing of a Welding Arc. IEEE Trans. Ind. Appl. 1985, 21, 1294–1299. [Google Scholar] [CrossRef]

- Sivaprasad, K.; Raman, S. Influence of magnetic arc oscillation and current pulsing on fatigue behavior of alloy 718 TIG weldments. Mater. Sci. Eng. A 2007, 448, 120–127. [Google Scholar] [CrossRef]

- Palani, P.K.; Murugan, N. Selection of parameters of pulsed current gas metal arc welding. J. Mater. Process. Technol. 2006, 172, 1–10. [Google Scholar] [CrossRef]

- Zacharia, T.; David, S.A.; Vitek, J.M.; Debroy, T. Weld pool development during GTA and laser beam welding of Type 304 stainless steel; Part I—Theoretical analysis. Weld. J. 1989, 68, 510s–519s. [Google Scholar]

- Sun, Q.J.; Lin, S.B.; Yang, C.L.; Zhao, G.Q. Penetration increase of AISI 304 using ultrasonic assisted tungsten inert gas welding. Sci. Technol. Weld. Join. 2009, 14, 765–767. [Google Scholar] [CrossRef]

- Reis, R.P.; Scotti, A.; Norrish, J.; Cuiuri, D. Investigation on Welding Arc Interruptions in the Presence of Magnetic Fields: Arc Length, Torch Angle and Current Pulsing Frequency Influence. IEEE Trans. Plasma Sci. 2013, 41, 133–139. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, R.L.; Hao, Y.Z. Gas Pool Coupled Activating TIG Welding Method with Coupling Arc Electrode. Chin. J. Mech. Eng. 2018, 6, 8. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Dorn, L.; Hübner, M.; Goyal, V.K. Arc characteristics and behaviour of metal transfer in pulsed current GMA welding of aluminium alloy. J. Mater. Process. Technol. 2007, 194, 163–175. [Google Scholar] [CrossRef]

- Onuki, J.; Anazawa, Y.; Nihei, M.; Katou, M.; Onuma, A.; Funamoto, T. Development of A New High-Frequency, High-Peak Current Power Source for High Constricted Arc Formation. Jpn. J. Appl. Phys. 2002, 41, 5821–5826. [Google Scholar] [CrossRef]

- Kumar, A.; DebRoy, T. Calculation of three-dimensional electromagnetic force field during arc welding. J. Appl. Phys. 2003, 94, 1267–1277. [Google Scholar] [CrossRef]

- Yang, M.X.; Qi, B.J.; Cong, B.Q.; Li, W. Influence of pulse current parameters on arc behavior by austenite stainless steel. Hanjie Xuebao/Trans. China Weld. Inst. 2012, 33, 67–70. [Google Scholar]

- da Cunha, T.V.; Bohórquez, C.E.N. Effects of current pulsation at ultra-high frequency on physical aspects of the arc and its implications in the weld bead morphology in the GTAW process. Weld World 2021, 65, 251–261. [Google Scholar] [CrossRef]

| Ni | Cr | Fe | C | Mn | Si | Mo | Cu | Co | Al | Ti | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | 50 | 17 | Bal. | -- | -- | -- | 2.8 | -- | -- | 0.2 | 0.65 |

| Max | 55 | 21 | 0.08 | 0.35 | 0.35 | 3.3 | 0.3 | 1.0 | 0.8 | 1.15 |

| Welding Current | Welding Voltage | Welding Speed | Shield Gas Flow (Ar) | Electrode Diameter |

|---|---|---|---|---|

| 10~60 A | 10 V | 2 mm/s | 15 L/min | 2 mm |

| Case 1 | ||||

|---|---|---|---|---|

| Welding Current (A) | FFP Current/ID (A) | Steady Direct Current/IM (A) | Frequency (kHz) | Average Current (A) |

| 60/60 | 0 | 60 | / | 60 |

| 60/50 | 10 | 50 | 20 | D55 |

| 60/40 | 20 | 40 | 20 | 50 |

| 60/30 | 30 | 30 | 20 | 45 |

| 60/20 | 40 | 20 | 20 | 40 |

| 60/10 | 50 | 10 | 20 | 35 |

| Case 2 | ||||

| Welding Current (A) | FFP Current/ID (A) | Steady Direct Current/IM (A) | Frequency (kHz) | Average Current (A) |

| 60/10 | 50 | 10 | 10 | 35 |

| 60/10 | 50 | 10 | 15 | 35 |

| 60/10 | 50 | 10 | 20 | 35 |

| 60/10 | 50 | 10 | 25 | 35 |

| 60/10 | 50 | 10 | 30 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Wang, Z.; Zhu, Z.; Fan, W.; Lin, S.; Cai, X.; Tian, J.; Guo, C. Effect of Fast-Frequency Pulsed Current Parameters on FFP-TIG Arc Behavior and Its Implications for Inconel 718 Welding. Metals 2023, 13, 848. https://doi.org/10.3390/met13050848

Wu J, Wang Z, Zhu Z, Fan W, Lin S, Cai X, Tian J, Guo C. Effect of Fast-Frequency Pulsed Current Parameters on FFP-TIG Arc Behavior and Its Implications for Inconel 718 Welding. Metals. 2023; 13(5):848. https://doi.org/10.3390/met13050848

Chicago/Turabian StyleWu, Jianwen, Zhenmin Wang, Zeguang Zhu, Wenyan Fan, Sanbao Lin, Xiaoyu Cai, Jiyu Tian, and Chunfu Guo. 2023. "Effect of Fast-Frequency Pulsed Current Parameters on FFP-TIG Arc Behavior and Its Implications for Inconel 718 Welding" Metals 13, no. 5: 848. https://doi.org/10.3390/met13050848

APA StyleWu, J., Wang, Z., Zhu, Z., Fan, W., Lin, S., Cai, X., Tian, J., & Guo, C. (2023). Effect of Fast-Frequency Pulsed Current Parameters on FFP-TIG Arc Behavior and Its Implications for Inconel 718 Welding. Metals, 13(5), 848. https://doi.org/10.3390/met13050848