Transient Strain Monitoring of Weldments Using Distributed Fiber Optic System

Abstract

:1. Introduction

2. Methodology

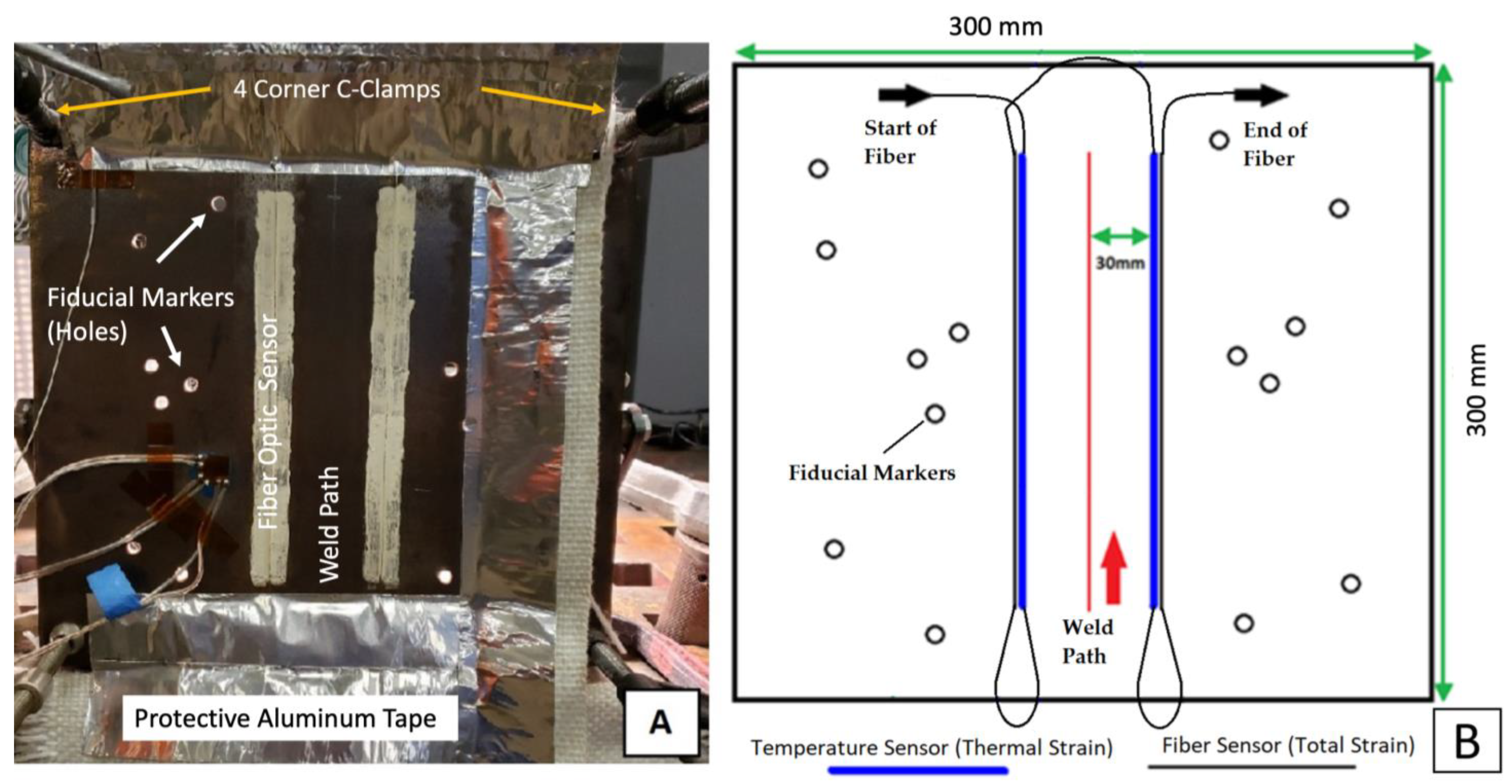

2.1. Experimental Setup

2.2. Specimen Instrumentation

2.3. Experimental Method

3. Computational FEA with VrWeld

- 1.

- The FEM/SPH WP solver computes a macroscopic transient temperature and the WP geometry by solving the Conservation of Energy equation as outlined in Equation (1):where is the rate of change of the specific enthalpy, q is the thermal flux, and Q is the power density function. The thermal flux can be expressed aswhere κ is the thermal conductivity tensor, and ∇T is the temperature gradient at a point. In addition, the change in specific enthalpy is expressed aswhere is the specific heat and dT represents the temperature change. VrWeld solves this partial differential equation on a domain defined by a FE mesh. In this study, the steel plate was modeled using a mesh of 147,360 eight-node brick elements. The element size was generally 2 mm × 2 mm × 2 mm around the plate; however, near the weld, this was reduced to 1 mm × 1 mm × 0.8 mm. This translates into six eight-node bricks across the width, and ten along the length, of the weld pool, which has been found to resolve the transient temperature field around the weld pool adequately. This satisfies the requirements established by ISO Document ISO/TC 44/WG 5—Welding simulation [28]. The initial condition is assumed to be a constant temperature of 300 °K. The material properties κ and are temperature and microstructure dependent. The heating effect of the arc is often modeled by a double ellipsoid power density distribution that approximates the WP as measured from macro-graphs of the cross-section of several weld passes [29]. A convection boundary condition q = h (T − Tamb) is applied to external surfaces. The FEM formulation of the heat equation leads to a system of ordinary differential equations that are integrated in time using a backward Euler integration scheme. Finally, this solver computes the thermal cycle as an output which serves as an input into the Austenite–Ferrite microstructure solver. The solvers were written in C++ over the last 20 years by Goldak Technologies Inc. for the analysis of welds. They are based on numerical algorithms described in [30] and the references therein.Figure 2. The workflow for a VrWeld analysis of a weld in a structure. Each rectangular box with rounded corners is a solver, usually a 3D transient non-linear FEM solver. (1) Represents the FEM Weld Pool Solver; (2) Represents the Austenite Ferrite Solver; (3) The Carbon Diffusion Solver; (4) the Microstructure Solver, while (5 and 6) are the stress solvers in charge of determining residual stress and strains and micros stress-strain curves [31].Figure 2. The workflow for a VrWeld analysis of a weld in a structure. Each rectangular box with rounded corners is a solver, usually a 3D transient non-linear FEM solver. (1) Represents the FEM Weld Pool Solver; (2) Represents the Austenite Ferrite Solver; (3) The Carbon Diffusion Solver; (4) the Microstructure Solver, while (5 and 6) are the stress solvers in charge of determining residual stress and strains and micros stress-strain curves [31].

- 2.

- The austenite–ferrite solver computes the transient decomposition of ferrite to austenite and then to liquid upon heating. This analysis is followed by the transient transformations of the liquid to austenite, ferrite, pearlite, bainite, and martensite upon cooling, depending on the composition of the steel base metal. The output of this solver is the carbon composition and new grain microstructures serving as the input to the carbon-diffusion solver.

- 3.

- The carbon-diffusion solver computes the diffusion of carbon between phases in each transient phase transformation of heating and cooling.

- 4.

- The microstructure solver computes the nucleation and growth of phases based on equilibrium thermodynamics, i.e., the phase diagram for the composition, temperature, and pressure of the system, and irreversible thermodynamics, i.e., the second law of thermodynamics—kinetics, entropy, and dissipation. However, there is not enough space to deal with these complex phenomena in this manuscript.

- 5.

- The stress solver computes transient stress during the welding process. When the structure has been welded, cooled down and any constraints have been removed, the stress that remains is called the RS.

- 6.

- The stress solver takes the initial state with RS, microstructure, and distortion from the as-welded structure and applies in-service loads applied to the welded structure.

4. Experimental Results

4.1. Welding Power

4.2. Fiber Optic Strain Results

5. VrWeld Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maddox, S.J. Fatigue design rules for welded structures. Prog. Struct. Eng. Mater. 2000, 2, 102–109. [Google Scholar] [CrossRef]

- Taniguchi, K.; Lim, Y.C.; Flores-Betancourt, A.; Feng, Z. Transient Microstructure Evolutions and Local Properties of Dual-Phase 980 MPa Grade Steel Via Friction Stir Spot Processing. Materials 2020, 13, 4406. [Google Scholar] [CrossRef] [PubMed]

- Sutton, M.A.; Orteu, J.-J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer Publishing Company, Incorporated: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Yin, S.; Ruffin, P.B.; Yu, F.T.S. Fiber Optic Sensors, 2nd ed.; CRC Press—Taylor & Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2008. [Google Scholar]

- Freddi, A.; Olmi, G.; Cristofolini, L. Experimental Stress Analysis for Materials and Structures: Stress Analysis Models for Developing Design Methodologies. In Springer Series in Solid and Structural Mechanics Book, 4th ed.; Frémond, M., Maceri, F., Eds.; Springer: Cham, Switzerland; Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2015. [Google Scholar]

- De Strycker, M.; Lava, P.; Van Paepegem, W.; Schueremans, L.; Debruyne, D. Measuring welding deformations with the digital image correlation technique. Weld. J. 2011, 90, 107S–112S. [Google Scholar]

- Pliazhuk, M.; Reyes, C.; Martinez, M.; Goldak, J.; Nimrouzi, H.; Aidun, D.K. In-situ Monitoring of Transient Strain Formation in Vertical Welds. Weld. J. (AWS) 2019, 98, 251–262. [Google Scholar]

- Chen, J.; Yu, X.; Miller, R.G.; Feng, Z. In situ strain and temperature measurement and modelling during arc welding. Sci. Technol. Weld. Join. 2015, 20, 181–188. [Google Scholar] [CrossRef]

- Hagenlocher, C.; Stritt, P.; Friebe, H.; Blumenthal, C.; Weber, R.; Graf, T. Space and time resolved determination of thermomechanical deformation adjacent to the solidification zone during hot crack formation in laser welding. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Orlando, FL, USA, 14–18 October 2018. [Google Scholar]

- Keller, D., Jr. Comparison of Resistance-Based Strain Gauges and Fiber Bragg Gratings in the Presence of Electromagnetic Interference Emitted from an Electric Motor; Department of Mechanical Engineering, University of Alaska Fairbanks: Fairbanks, AK, USA, 2018. [Google Scholar]

- Barazanchy, D.; Martinez, M.; Rocha, B.; Yanishevsky, M. A Hybrid Structural Health Monitoring System for the Detection and Localization of Damage in Composite Structures. J. Sens. 2014, 2014, 109403. [Google Scholar] [CrossRef]

- Luis Rodriguez-Cobo, J.M.; Ruiz-Lombera, R.; Cobo, A.; López-Higuera, J.-M. Fiber Bragg grating sensors for on-line welding diagnostics. J. Mater. Process. Technol. 2014, 214, 839–843. [Google Scholar] [CrossRef]

- Suárez, J.C.; Remartınez, B.; Menéndez, J.M.; Güemes, A.; Molleda, F. Optical fibre sensors for monitoring of welding residual stresses. J. Mater. Process. Technol. 2003, 143, 316–320. [Google Scholar] [CrossRef]

- Petrie, C.M.; Sridharan, N. In situ measurement of phase transformations and residual stress evolution during welding using spatially distributed fiber-optic strain sensors. Meas. Sci. Technol. 2020, 31, 125602. [Google Scholar] [CrossRef]

- Schricker, K.; Ganß, M.; Könke, C.; Bergmann, J.P. Feasibility study of using integrated fiber optical sensors to monitor laser-assisted metal–polymer joining. Weld. World 2020, 64, 156–1578. [Google Scholar] [CrossRef]

- Van De Giesen, N.; Steele-Dunne, S.C.; Jansen, J.; Hoes, O.; Hausner, M.B.; Tyler, S.; Selker, J. Double-Ended Calibration of Fiber-Optic Raman Spectra Distributed Temperature Sensing Data. Sensors 2012, 12, 5471–5485. [Google Scholar] [CrossRef]

- Mizuno, Y.; Hayashi, N.; Tanaka, H.; Wada, Y.; Nakamura, K. Brillouin scattering in multi-core optical fibers for sensing applications. Sci. Rep. 2015, 5, 11388. [Google Scholar] [CrossRef] [PubMed]

- Rahim, N.A.A.; Pandher, J.; Coppola, N.; Penumetsa, V.; Michel, D.; Tooren, V. In-situ monitoring and control of induction welding in thermoplastic composites using high definition fiber optic sensors. In Proceedings of the Composites and Advanced Materials Expo, CAMX, Anaheim, CA, USA, 17–20 October 2022. [Google Scholar]

- Martinez-Bueno, P.; Martinez, M.; Rans, C.; Benedictus, R. Strain Monitoring using a Rayleigh Backscattering System for a composite UAV wing instrumeted with an embedded Optical Fiber. Adv. Mater. Res. 2016, 1135, 1–19. [Google Scholar] [CrossRef]

- Baldassarre, A.; Ocampo, J.; Martinez, M.; Rans, C. Accuracy of Strain Measurement Systems on a Non-Isotropic Material and its Uncertainty on Finite Element Analysis. J. Strain Anal. Eng. Des. 2020, 56, 76–95. [Google Scholar] [CrossRef]

- Edmund, E. FLIR Grasshopper High Performance USB 3.0 Cameras. 2022; High Performance USB 3.0 Cameras for Digital Image Correlation. Available online: https://www.edmundoptics.com/f/flir-grasshopper3-high-performance-usb-30-cameras/14785/ (accessed on 20 March 2022).

- Cotronics Corporation, 4000°F Resbond™ 904 Ultra Temp. 2022. Available online: http://www.cotronics.com/vo/cotr/ca_onecomp.htm (accessed on 20 March 2022).

- Luna Innovations Inc., Optical Distributed Sensor Interrogator. 2021. Available online: https://lunainc.com/sites/default/files/assets/files/data-sheet/ODB5_DataSheet_Rev13_020217.pdf (accessed on 20 March 2022).

- Teledyne FLIR, FLIR One Pro. 2022. Available online: https://www.flir.com/products/flir-one-pro/ (accessed on 20 March 2022).

- Apple Inc., iPhone X. 2017. Available online: https://www.apple.com/newsroom/2017/09/the-future-is-here-iphone-x/ (accessed on 12 September 2017).

- Bayley, C.; Goldak, J. Welding Induced Distortions and Strains of a Built-Up Panel, Experiment and Numerical Validation. J. Press. Vessel Technol. 2012, 134, 021212. [Google Scholar] [CrossRef]

- Goldak, J.; Asadi, M. Challenges in Verification of CWM Software to Compute Residual Stress and Distortion in Weld. In Proceedings of the International ASME 2010 Pressure Vessel and Piping Division Conference, Bellevue, WA, USA, 18–22 July 2010. [Google Scholar]

- Standard, I. Welding and Allied Processes. 1947; Standardization of Welding, by All Processes, as well as Allied Processes; These Standards Include Terminology, Definitions and the Symbolic Representation of Welds on Drawings, Ap-Paratus and Equipment for Welding, Raw Materials (Gas, Parent and Filler Metals) Welding Processes and Rules, Methods of Test and Control, Calculations and Design of Welded Assemblies, Welders’ Qualifications, as well as Safety and Health. Available online: https://www.iso.org/committee/48602.html (accessed on 22 March 2023).

- John Goldak, E.J.; El-Zein, M.; Zhou, J.; Tchernov, S.; Downey, D.; Wang, S.; Coulombe, M. The L2 norm of the deviation between the measured and computed transient displacement field in a test weld. In. J. Mat. 2008, 99, 428–433. [Google Scholar]

- Simo, J.C. Numerical Analysis of Classical Plasticity, Handbook for Numerical Analysis. Handb. Numer. Anal. 1988, VI, 183–499. [Google Scholar] [CrossRef]

- Zarkouei, K.K. A Holistic Micro-Macro Model of an Arc Weld Pool with Microstructure Evolution in the Fusion and Heat-Affected Zones. In Mechanical and Aerospace Engineering; Carleton University: Ottawa, ON, Canada, 2015; p. 198. [Google Scholar]

- Rankin, C.C.; Nour-Omid, B. The use of projectors to improve finite element performance. Comput. Struct. 1988, 30, 257–268. [Google Scholar] [CrossRef]

- Bao, X.; Wang, Y. Recent Advancements in Rayleigh Scattering-Based Distributed Fiber Sensors. Adv. Devices Instrum. 2020, 2021, 17. [Google Scholar] [CrossRef]

- Teledyne. Getting Started with FLIR Science File SDK for Matlbab. 2023; Instllation of FLIR SDK for Matlab. Available online: https://flir.custhelp.com/app/answers/detail/a_id/3374/~/getting-started-with-flir-science-file-sdk-for-matlab (accessed on 16 March 2023).

| Material | Tensile Strength lb/in2, [MPa] | Yield Strength lb/in2, [MPa] | Elongation in 2 in. (%) | Reduction of Area (%) |

|---|---|---|---|---|

| A36 Steel Plate | 63,800 | 53,700 | 15 | 40 |

| [439.9] | [370.20] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mackey, D.; Martinez, M.; Goldak, J.; Tchernov, S.; Aidun, D.K. Transient Strain Monitoring of Weldments Using Distributed Fiber Optic System. Metals 2023, 13, 865. https://doi.org/10.3390/met13050865

Mackey D, Martinez M, Goldak J, Tchernov S, Aidun DK. Transient Strain Monitoring of Weldments Using Distributed Fiber Optic System. Metals. 2023; 13(5):865. https://doi.org/10.3390/met13050865

Chicago/Turabian StyleMackey, David, Marcias Martinez, John Goldak, Stanislav Tchernov, and Daryush K. Aidun. 2023. "Transient Strain Monitoring of Weldments Using Distributed Fiber Optic System" Metals 13, no. 5: 865. https://doi.org/10.3390/met13050865