Microstructure and Mechanical Properties of Hastelloy X Fabricated Using Directed Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Properties

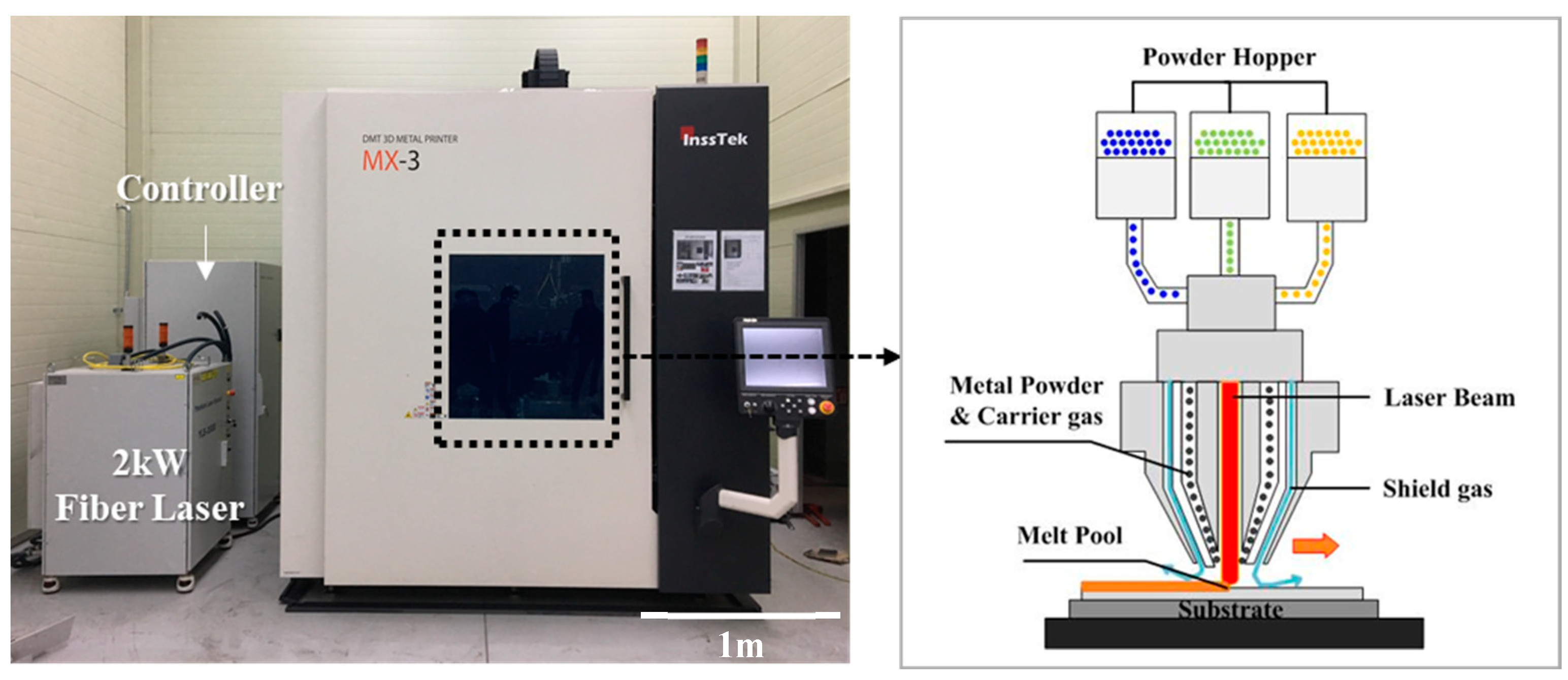

2.2. Direct Energy Deposition (DED) Process

2.3. Microstructure Evaluation

2.4. Evaluation of Mechanical Properties

3. Results and Discussion

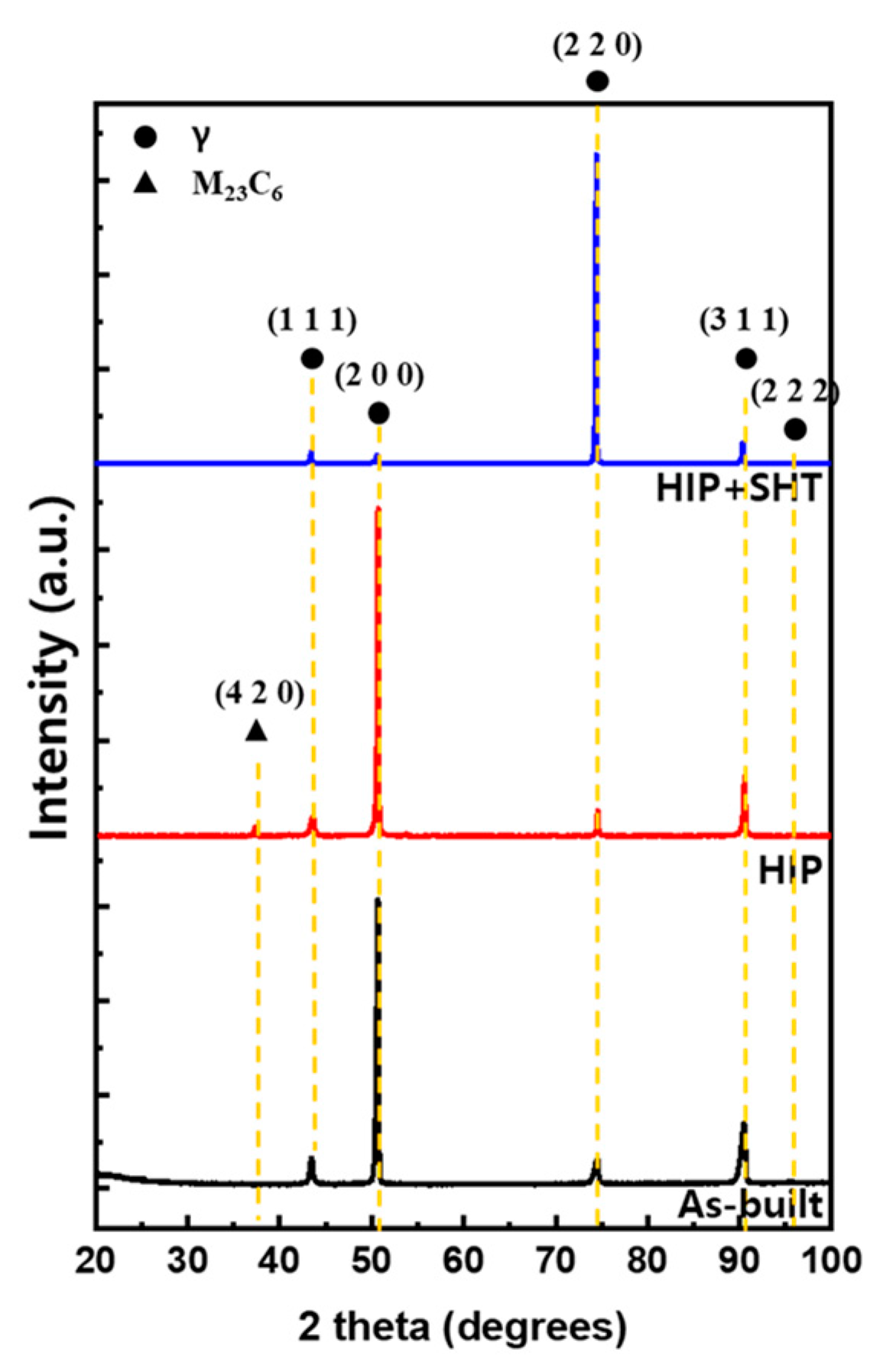

3.1. Microstructure

3.2. Tensile Properties

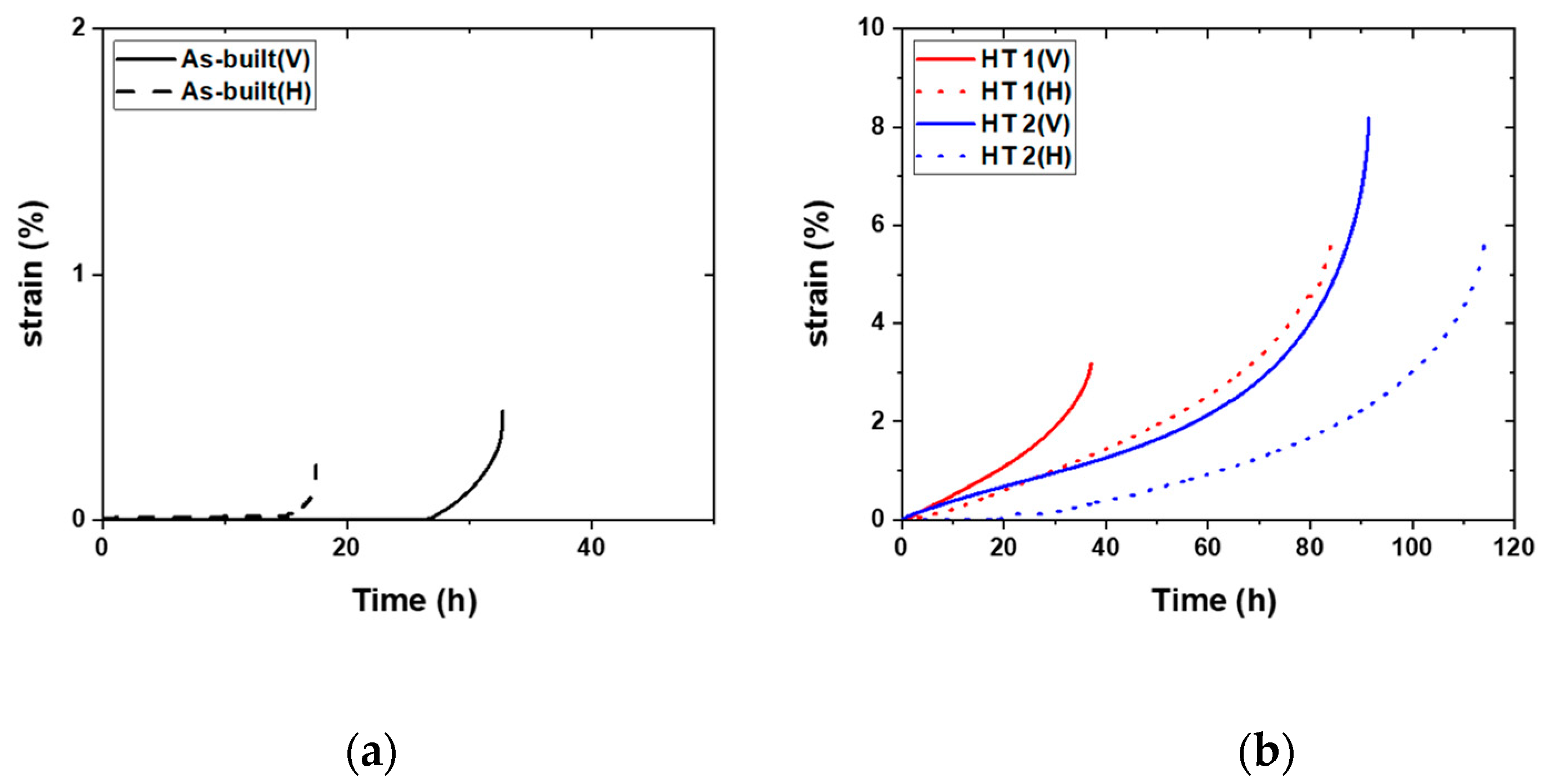

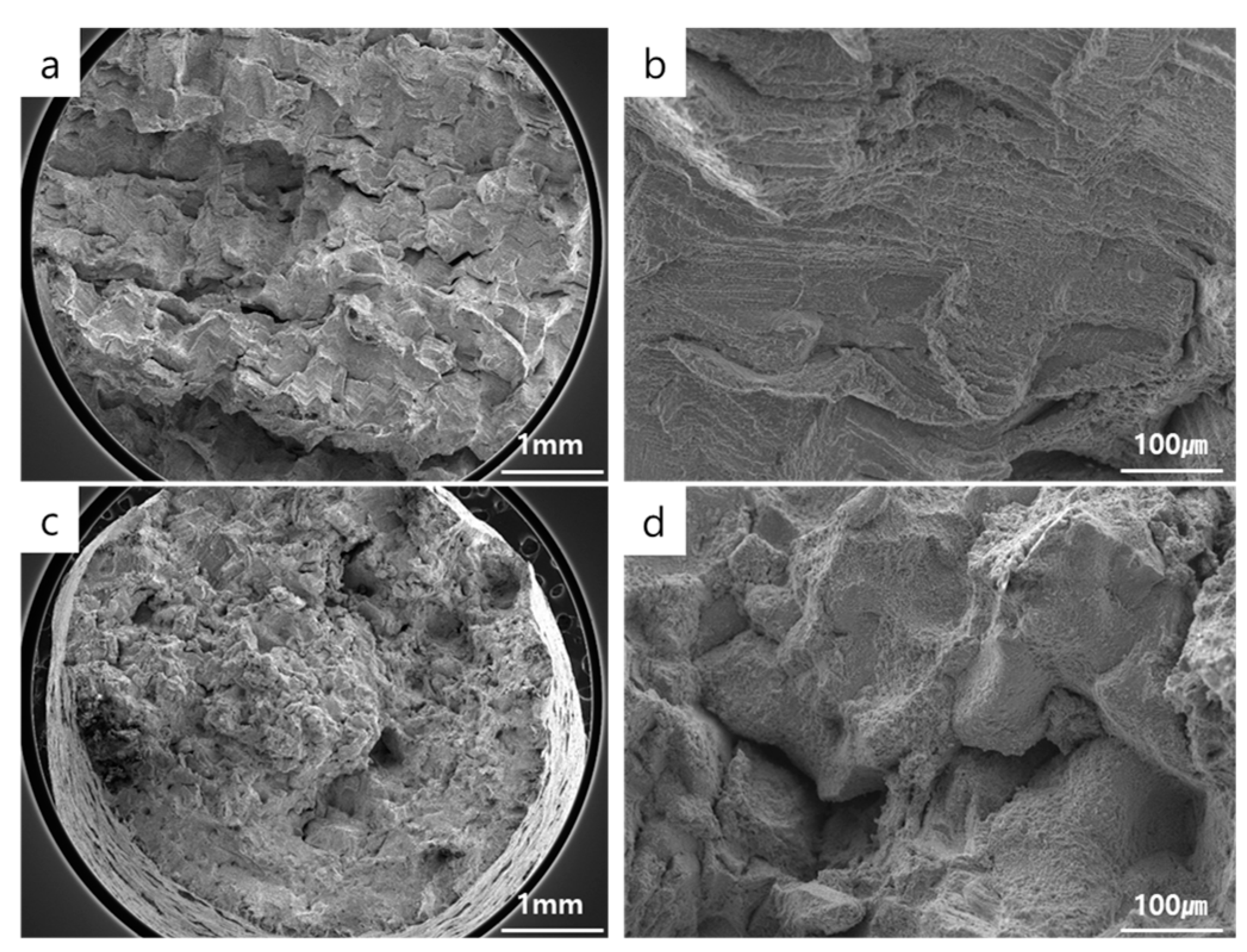

3.3. Analysis of High-Temperature (816 °C) Creep Rupture Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.C.; Larsen, M.; Ravikumar, V. Phase precipitation and time–temperature-transformation diagram of Hastelloy X. Mater. Sci. Eng. A 2000, 293, 112–119. [Google Scholar] [CrossRef]

- Haynes-International. Hastelloy X Alloy; Haynes-International: Kokomo, IN, USA, 1997; Volume 16. [Google Scholar]

- Hong, H.U.; Kim, I.S.; Choi, B.G.; Jeong, H.W.; Jo, C.Y. Effects of temperature and strain range on fatigue cracking behavior in Hastelloy X. Mater. Lett. 2008, 62, 4351–4353. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of micro-cracking in nickel superalloys processed by selective laser melting: A fundamental alloy design approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Trojan, K.; Ocelík, V.; Capek, J.; Cech, J.; Canelo-Yubero, D.; Ganev, N.; Kolarík, K.; De Hosson, J.T.M. Microstructure and Mechanical Properties of Laser Additive Manufactured H13 Tool Steel. Metals 2022, 12, 243. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, L.; Bi, G. Feasibility Study on Deposition of Tribaloy T800 on Cobalt-Based L605 Using Micro-Laser-Aided Additive Manufacturing. Metals 2022, 12, 586. [Google Scholar] [CrossRef]

- Vu, H.M.; Meiniger, S.; Ringel, B.; Hoche, H.C.; Oechsner, M.; Weigold, M.; Schmitt, M.; Schlick, G. Investigation of Material Properties of Wall Structure from Stainless Steel 316L Manufactured by Laser Powder Bed Fusion. Metals 2022, 12, 285. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Bassini, E. Directed Energy Deposition of AISI 316L Stainless Steel Powder: Effect of Process Parameters. Metals 2021, 11, 932. [Google Scholar] [CrossRef]

- Wang, F. Mechanical property study on rapid additive layer manufacturing Hastelloy X alloy by selective laser melting technology. Int. J. Adv. Manuf. Technol. 2012, 58, 545–551. [Google Scholar] [CrossRef]

- Montero-Sisroaga, M.L.; Liu, Z.; Bautmans, L.; Nardone, S.; Ji, G.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Effect of temperature on the microstructure and tensile properties of micro-crack free hastelloy X produced by selective laser melting. Addit. Manuf. 2020, 31, 100995. [Google Scholar] [CrossRef]

- Marchese, G.; Bassini, E.; Aversa, A.; Lombardi, M.; Ugues, D.; Fino, P.; Biamino, S. Microstructural Evolution of Post-Processed Hastelloy X Alloy Fabricated by Laser Powder Bed Fusion. Materials 2019, 12, 486. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qi, H.; Hou, H.; Lei, L. Effects of Hot Isostatic Pressing on Microstructure and Mechanical Properties of Hastelloy X Samples Produced by Selective Laser Melting. Adv. Eng. Res. 2017, 102, 31–40. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Lin, X.; Huang, Y.; Zhang, Y.; Guo, P.; Li, J.; Huang, W. Microstructure and anodic electrochemical behavior of additive manufactured Hastelloy X alloy via directed energy deposition. Addit. Manuf. 2021, 39, 101824. [Google Scholar] [CrossRef]

- Xu, L.; Gao, Y.; Zhao, L.; Han, Y.; Jing, H. Ultrasonic micro-forging post-treatment assisted laser directed energy deposition approach to manufacture high-strength Hastelloy X superalloy. J. Mater. Process. Technol. 2022, 299, 117324. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Laser Metal Deposition of Ti6Al4V: A Study on the Effect of Laser Power on Microstructure and Microhardness. In Proceedings of the International MultiConference of Engineering and Computer Scientists (ICMCS 2013), Hong Kong, China, 13–15 March 2013. [Google Scholar]

- Kim, J.S.; Kang, B.J.; Lee, S.W. An experimental study microstructure characteristics and mechanical properties of stainless-steel 316L parts using directed energy deposition (DED) process. J. Mech. Sci. Technol. 2019, 33, 5731–5737. [Google Scholar] [CrossRef]

- Mathoho, I.; Akinlabi, E.T.; Arthur, N.; Tlotleng, M. Impact of DED process parameters on the metallurgical characteristics of 17-4PH SS deposited using DED. CIRP J. Manuf. Sci. Technol. 2020, 31, 450–458. [Google Scholar] [CrossRef]

- Jinoop, A.N.; Paul, C.P.; Bindra, K.S. Laser assisted direct energy deposition of Hastelloy X. Opt. Laser Technol. 2019, 109, 14–19. [Google Scholar] [CrossRef]

- Woo, I.Y.; Lyu, M.Y. Variations in the Impact strength of material extrusion-type 3D printed specimens depending on tool path and building direction. Polym. Korea 2020, 44, 471–478. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti–6Al–4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Tomus, D.; Tian, Y.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Influence of post heat treatment on anisotropy of mechanical behavior and microstructure of Hastelloy-X parts produced by selective laser melting. Mater. Sci. Eng. A 2016, 667, 42–53. [Google Scholar] [CrossRef]

- Choi, B.G.; Kim, I.S.; Do, J.H.; Jung, J.E.; Jung, I.Y.; Hong, H.U.; Jo, C.Y. The Effect of Thermal Exposure on the Microstructural Evolution and Tensile Properties in Cast Hastelloy X. J. Korea Foundry Soc. 2017, 37, 139–147. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 2021, 28, 101804. [Google Scholar] [CrossRef]

- Jiang, L.; Hu, R.; Kou, H.; Li, J.; Bai, G.; Fu, H. The effect of M23C6 carbides on the formation of grain boundary serration in a wrought Ni-based superalloy. Mater. Sci. Eng. A 2012, 536, 37–44. [Google Scholar] [CrossRef]

- Tawancy, H.M. Long-term ageing characteristics of Hastelloy alloy X. J. Mater. 1983, 18, 2976–2986. [Google Scholar] [CrossRef]

- Marchese, G.; Basile, G.; Bassini, E.; Aversa, A.; Lombardi, M.; Ugues, D.; Fino, P.; Biamino, S. Study of the microstructure and cracking mechanisms of hastelloy X Produced by laser powder bed fusion. Materials 2018, 11, 106. [Google Scholar] [CrossRef]

- Jang, J.E.; Kim, Y.S.; Sung, J.H.; Kim, Y.J.; Park, S.H.; Kim, D.H. Microstructural control strategy based on optimizing laser powder bed fusion for different Hastelloy X powder size. Materials 2022, 15, 6191. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Van Humbeeck, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Tao, P.; Li, H.-X.; Huang, B.-Y.; Hu, Q.-D.; Gong, S.-L.; Xu, Q.-Y. Tensile behavior of Ti-6Al-4V alloy fabricated by selective laser melting: Effects of microstructures and as-built surface quality. China Foundry 2018, 15, 243–252. [Google Scholar] [CrossRef]

- Mahmud, A.; Huynh, T.; Zhou, L.; Hyer, H.; Mehta, A.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; Sohn, Y. Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion. Metals 2021, 11, 1671. [Google Scholar] [CrossRef]

- Banoth, S.; Palleda, T.N.; Saito, T.; Murakami, H.; Kakehi, K. Effect of yttrium and silicon contents in Hastelloy-X built by selective laser melting process. J. Alloys Compd. 2022, 896, 163050. [Google Scholar] [CrossRef]

- Thébaud, L.; Villechaise, P.; Crozet, C.; Devaux, A.; Béchet, D.; Franchet, J.M.; Rouffie, A.L.; Mills, M.; Cormier, J. Is there an optimal grain size for creep resistance in Ni-based disk superalloys? Mater. Sci. Eng. A 2018, 716, 274–283. [Google Scholar] [CrossRef]

- Bang, J.H.; Kang, Y.J.; Kim, N.K.; Seo, S.M.; Lee, S.H.; Song, S.W.; Kang, N.H. Effect of aging heat treatment conditions on the mechanical properties and microstructure of base and weld metal of alloy 282 superalloy. Korean J. Met. Mater. 2020, 8, 540–549. [Google Scholar] [CrossRef]

- Wang, L.; Wang, D.; Liu, T.; Li, X.W.; Jiang, W.G.; Zhang, G.; Lou, L.H. Effect of minor carbon additions on the high-temperature creep behavior of a single-crystal nickel-based superalloy. Mater. Char. 2015, 104, 81–85. [Google Scholar] [CrossRef]

| Element (wt%) | Ni | Cr | Fe | Mo | W | Co | C | Si | Mn |

|---|---|---|---|---|---|---|---|---|---|

| Powder HX | Bal. | 21.3 | 19.1 | 8.6 | 0.65 | 0.96 | 0.07 | 0.16 | 0.54 |

| Power (W) | Scanning Speed (m/min) | Powder Feeding Rate (g/min) | Overlap Ratio (%) | Layer Thickness (mm) |

|---|---|---|---|---|

| 450 | 0.85 | 3.5 | 60 | 0.25 |

| Specimen | As-Built | HT1 | HT2 |

|---|---|---|---|

| Conditions | As-built | 1150 °C, 4 h, 100 MPa (Furnace cooling) | 1150 °C, 4 h, 100 MPa + 1177 °C, 30 min (N2 gas cooling) |

| Specimen | As-Built | HT1 | HT2 |

|---|---|---|---|

| Cross-sectional porosity (%) | 0.043 | 0.004 | 0.003 |

| Maximum pore size (μm) | 93.626 | 27.563 | 11.666 |

| Tracked Pore number | 71 | 12 | 19 |

| Specimen | R.T. (24 °C) | H.T. (816 °C) | |||||

|---|---|---|---|---|---|---|---|

| Y.S (MPa) | UTS (MPa) | Elongation (%) | Y.S (MPa) | UTS (MPa) | Elongation (%) | ||

| Raw | 324 ± 1.4 | 739.5 ± 4.9 | 53.3 ± 2.8 | 210.5 ± 21.9 | 343 ± 1.4 | 67.2 ± 0.4 | |

| As -built | H | 508 ± 0.0 | 566 ± 1.4 | 5.75 ± 1.1 | 244 ± 0.0 | 312.5 ± 2.1 | 3.5 ± 3.5 |

| V | 524.5 ± 27.6 | 693 ± 26.9 | 52.4 ± 2.1 | 259.5 ± 3.5 | 328 ± 1.4 | 19.4 ± 2.3 | |

| HT1 | H | 361.5 ± 9.2 | 796.5 ± 4.9 | 30 ± 1.4 | 214.5 ± 0.7 | 348 ± 2.8 | 28.5 ± 3.5 |

| V | 296.5 ± 46.0 | 672.5 ± 43.1 | 50.3 ± 0.7 | 166.5 ± 2.1 | 305.5 ± 0.7 | 49.2 ± 1.5 | |

| HT2 | H | 311 ± 9.9 | 758 ± 4.2 | 48.7 ± 7.2 | 197 ± 1.4 | 333.5 ± 3.5 | 96.6 ± 11.3 |

| V | 294.5 ± 0.7 | 695.5 ± 50.2 | 57 ± 7.3 | 185 ± 0.0 | 309 ± 4.2 | 88.9 ± 37.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-S.; Sung, J.-H. Microstructure and Mechanical Properties of Hastelloy X Fabricated Using Directed Energy Deposition. Metals 2023, 13, 885. https://doi.org/10.3390/met13050885

Lee Y-S, Sung J-H. Microstructure and Mechanical Properties of Hastelloy X Fabricated Using Directed Energy Deposition. Metals. 2023; 13(5):885. https://doi.org/10.3390/met13050885

Chicago/Turabian StyleLee, Yoon-Sun, and Ji-Hyun Sung. 2023. "Microstructure and Mechanical Properties of Hastelloy X Fabricated Using Directed Energy Deposition" Metals 13, no. 5: 885. https://doi.org/10.3390/met13050885

APA StyleLee, Y.-S., & Sung, J.-H. (2023). Microstructure and Mechanical Properties of Hastelloy X Fabricated Using Directed Energy Deposition. Metals, 13(5), 885. https://doi.org/10.3390/met13050885