Investigating the Effects of Graphene Nanoplatelets and Al4C3 on the Tribological Performance of Aluminum-Based Nanocomposites

Abstract

1. Introduction

- To identify the optimal concentration of GNPs for minimizing the coefficient of friction and the mass wear of the nanocomposites, both annealed and non-annealed.

- To examine the role of Al4C3, which forms in the annealed Al/GNPs nanocomposite, on the tribological performance of the nanocomposites.

2. Materials and Methods

2.1. Materials

- -

- -

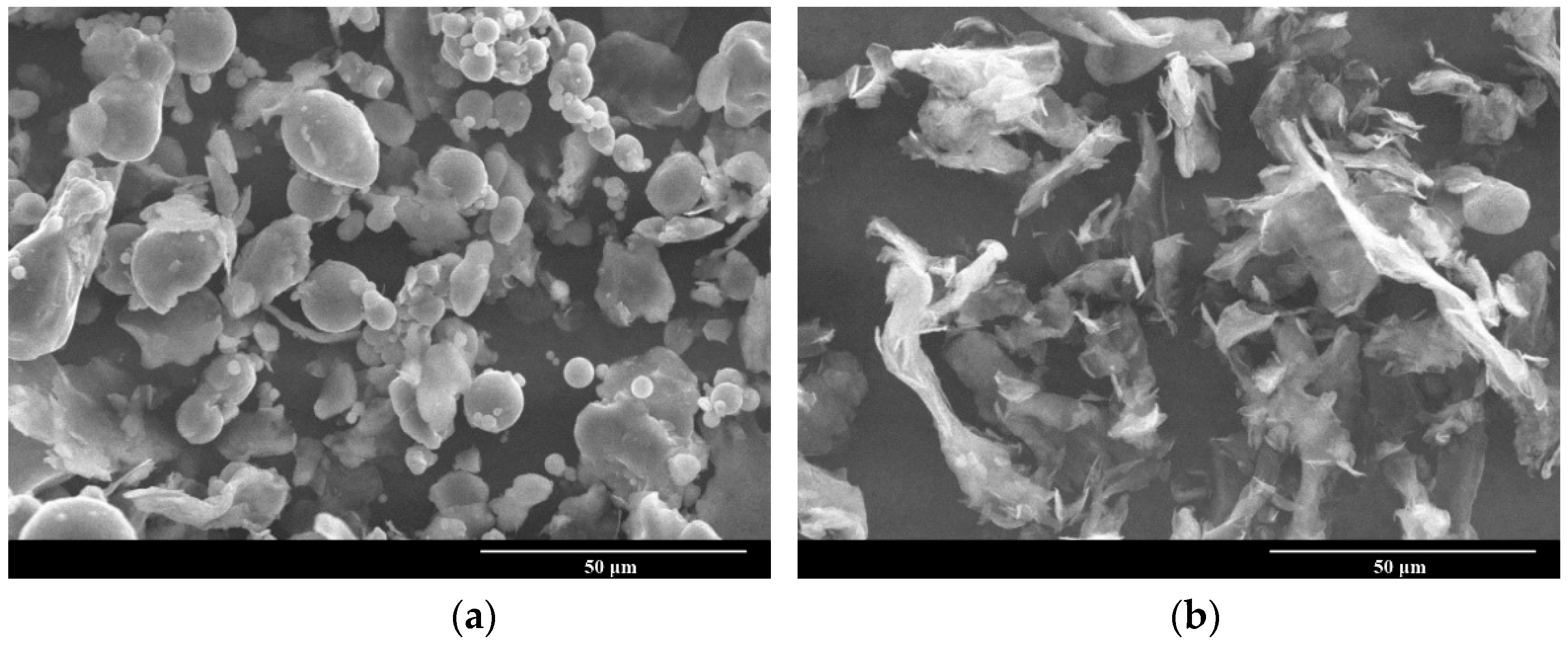

2.2. Production Method

- -

- Powder mixing in a planetary agate ball mill. The content of the graphene in the powder mixtures varied from 0.1 wt.% to 1.1 wt.% with an increment of 0.2 wt.%.

- -

- Hot extrusion. Seven bars of the aluminum-based nanocomposite reinforced with graphene nanoplatelets with 12 mm in diameter were produced, including one of pure aluminum.

- -

- Heat treatment. In order to obtain nanosized carbides at the Al/GNP interface, annealing with the following parameters was performed: heating temperature, 610 °C; holding time, 3 h; cooling ambiance, air out of the furnace.

2.3. Characterization Methods

3. Results and Discussion

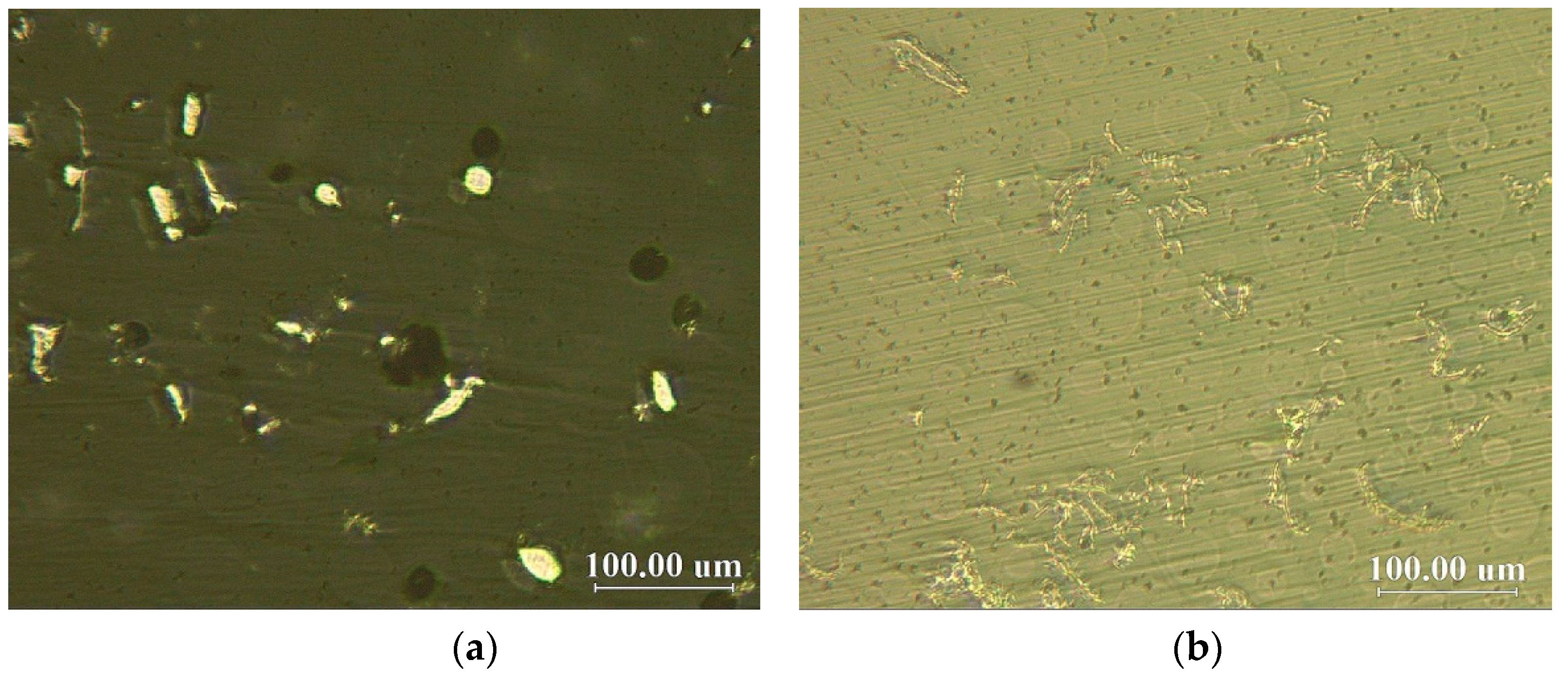

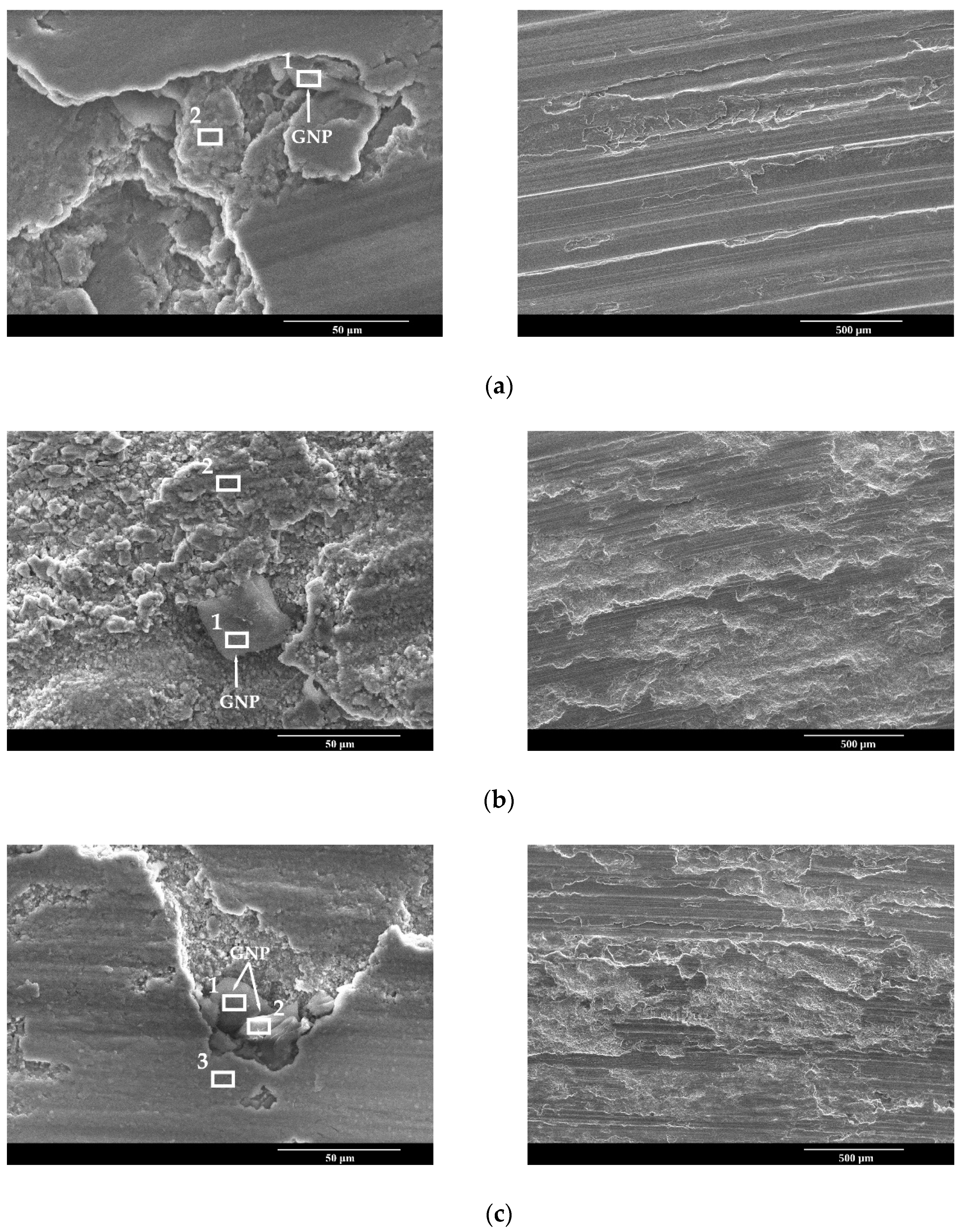

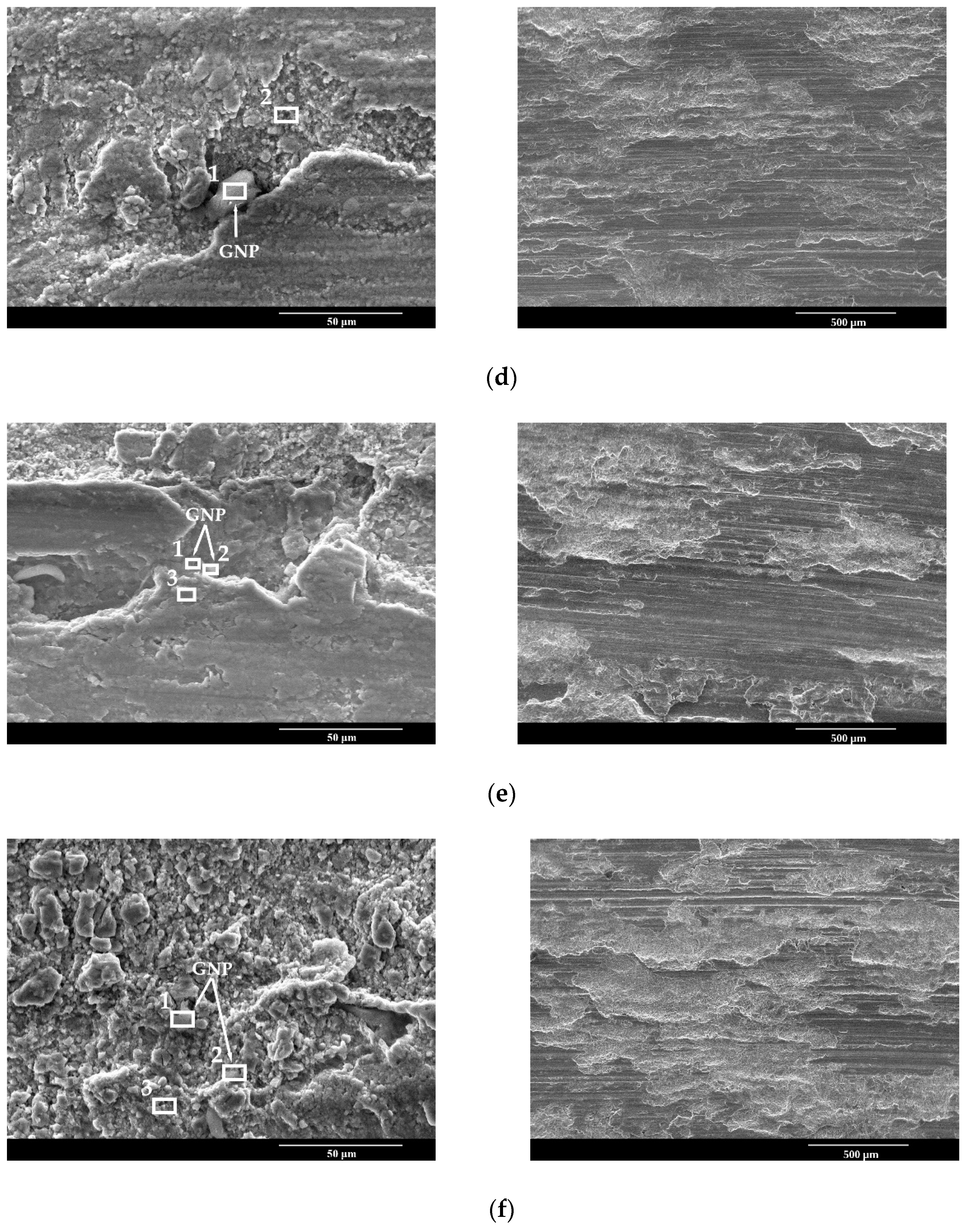

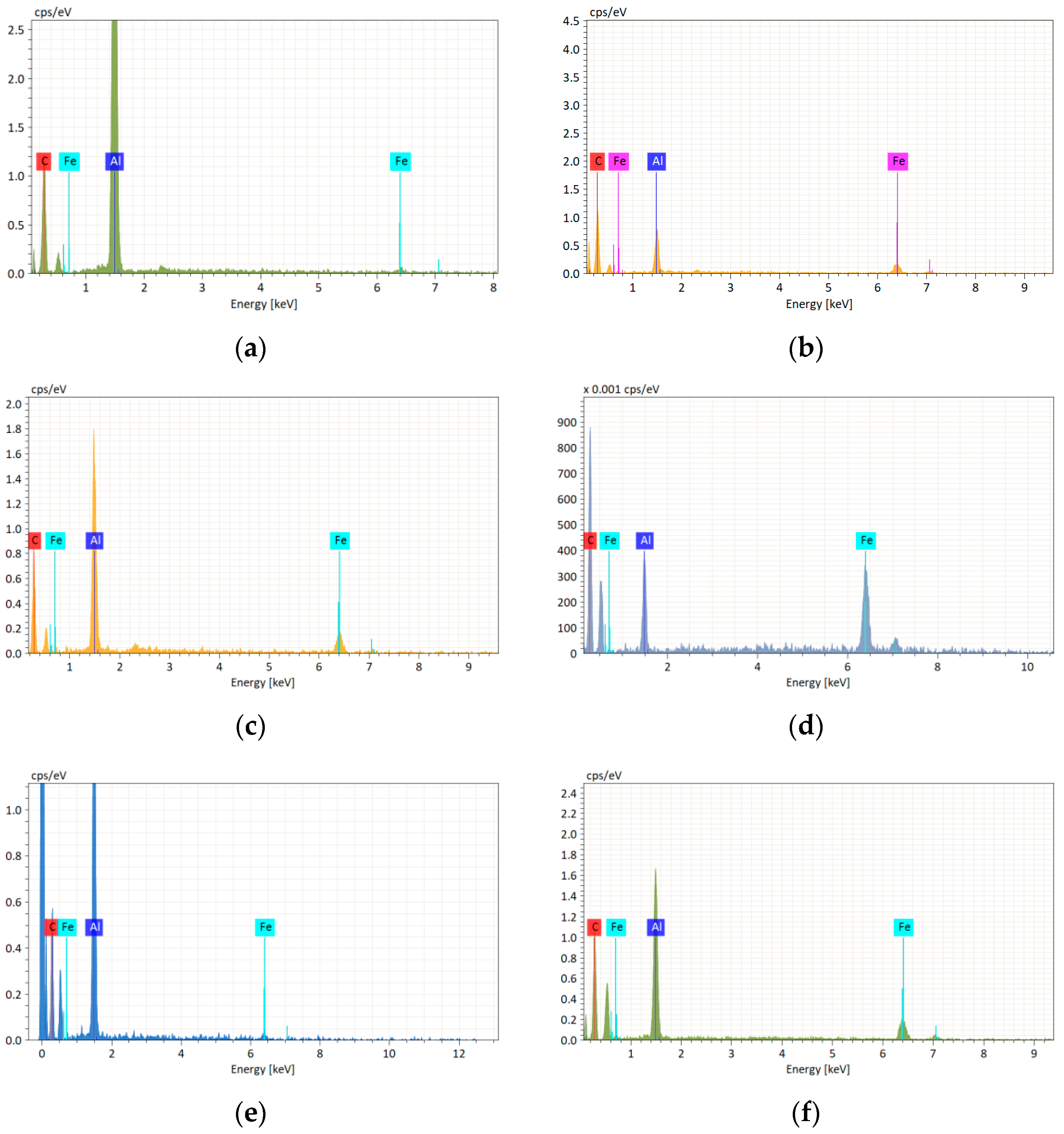

3.1. Morphological Analysis of the Worn Surfaces

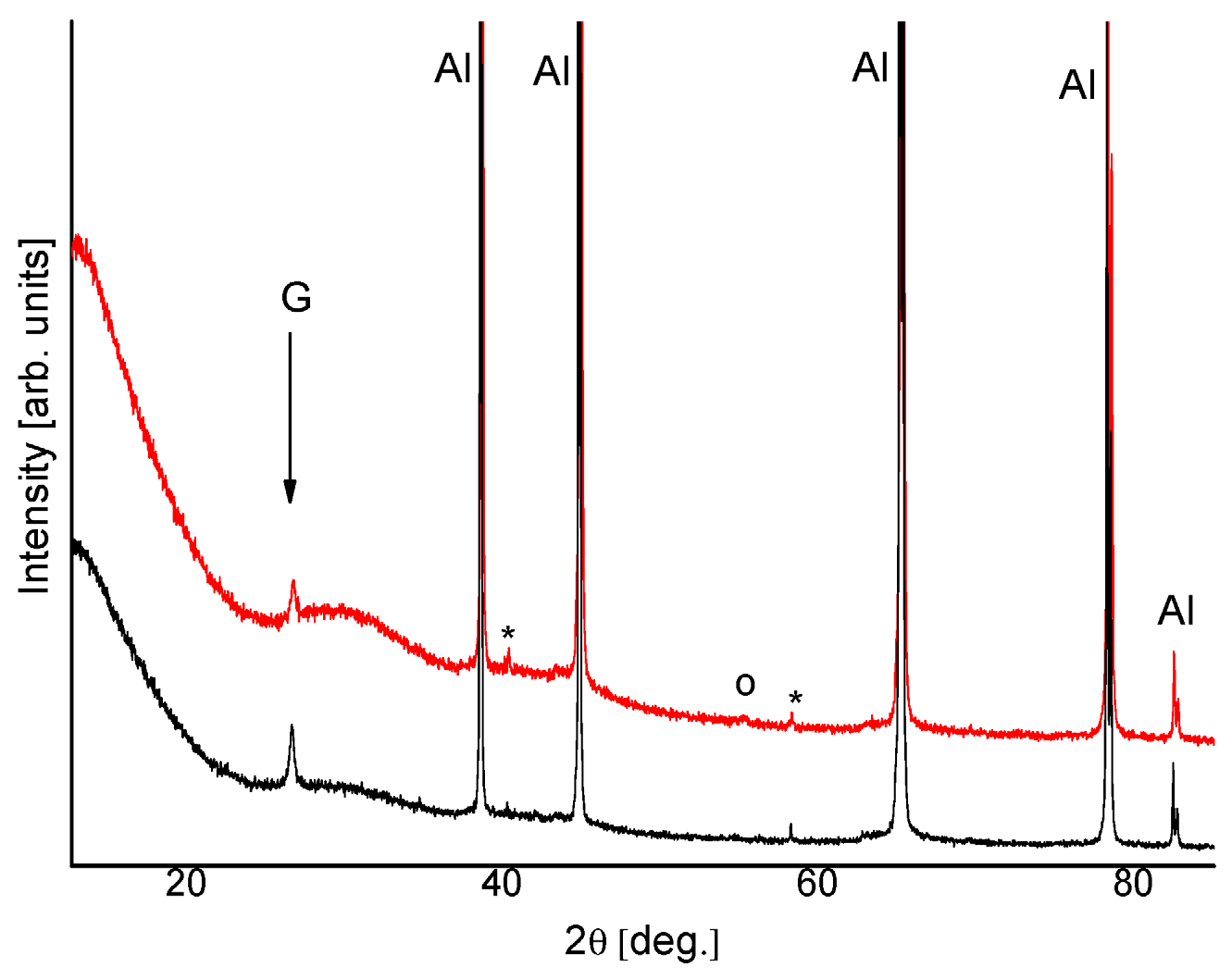

3.2. XRD and TEM Analysis

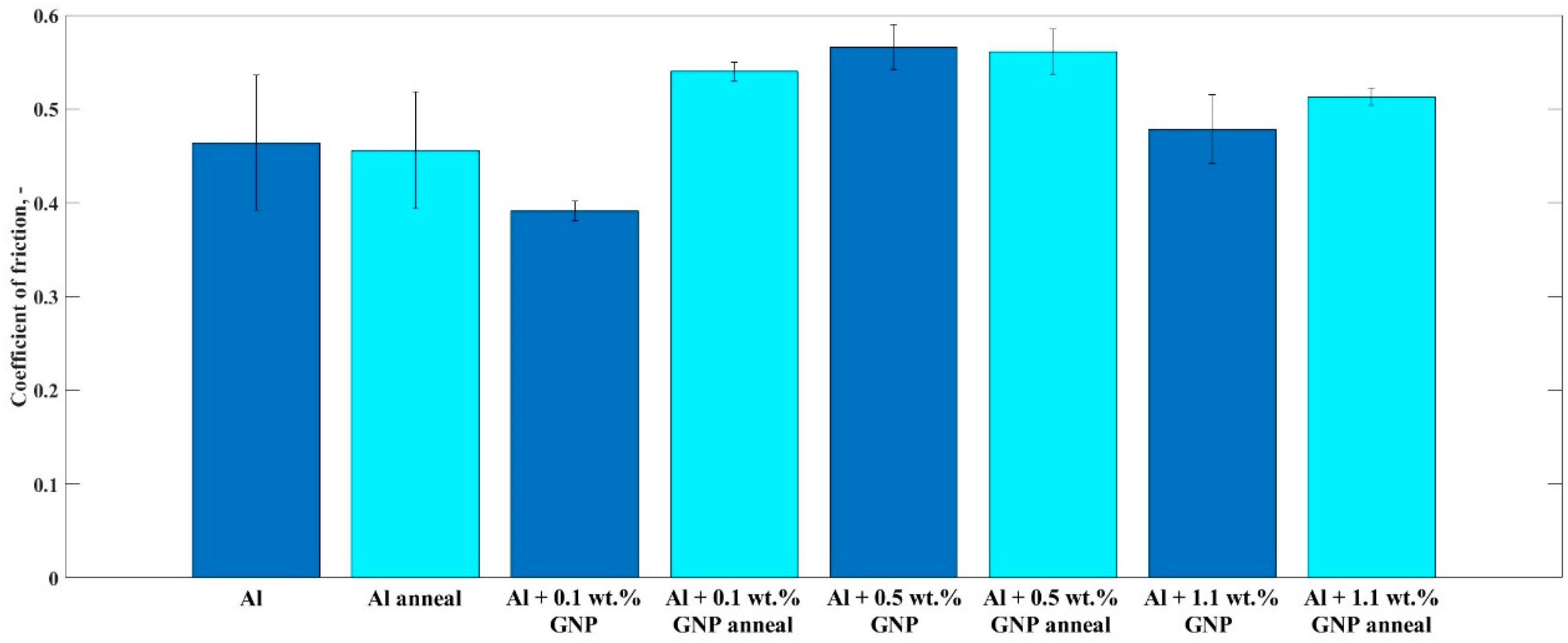

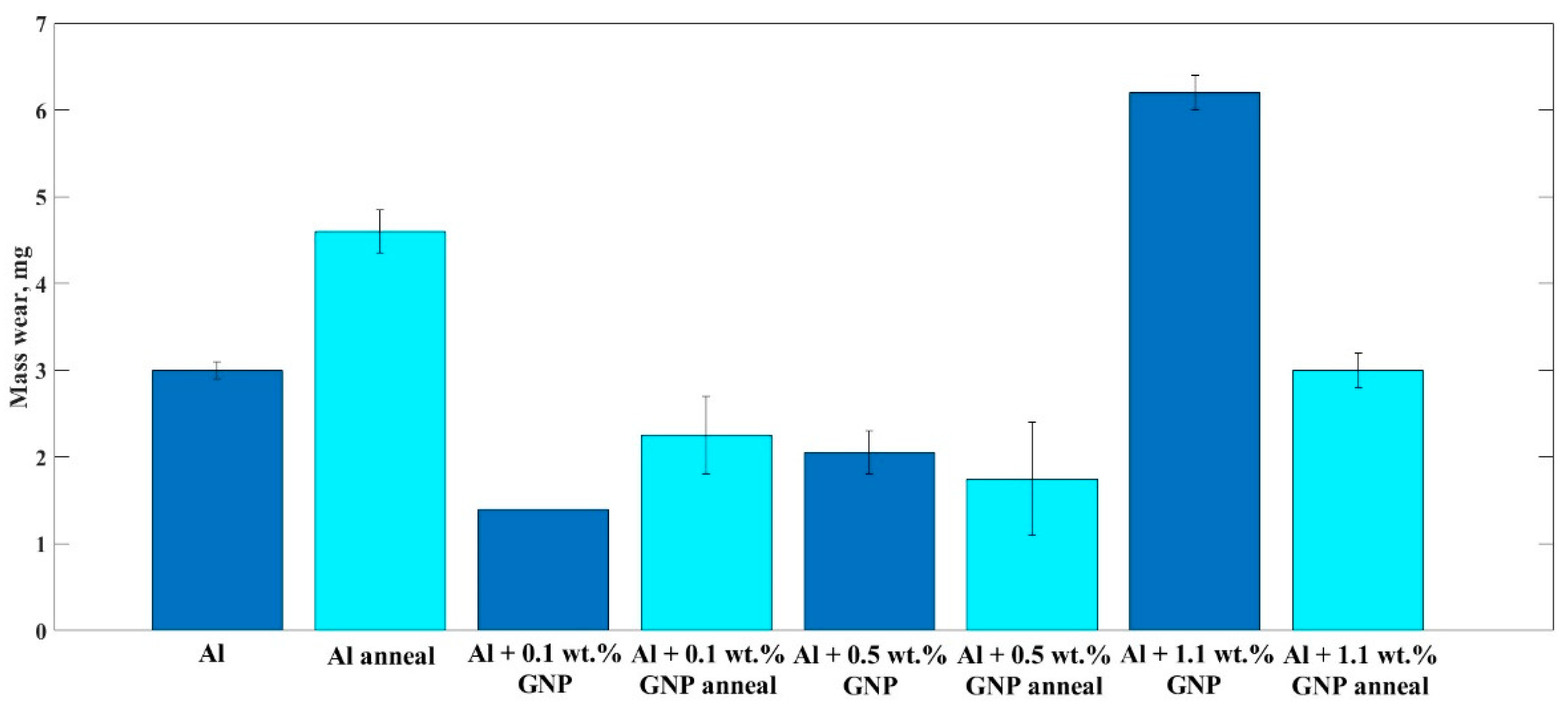

3.3. Wear Behavior

4. Conclusions

- The results showed that the addition of GNPs to aluminum-based nanocomposites increased the coefficient of friction (CF) by approximately 44% when comparing 0.1 wt.% GNP to 0.5 wt.% GNP. However, the CF decreased by 15% when the GNPs concentration increased to 1.1 wt.%. The optimal concentration of GNPs for minimizing the CF of Al-based nanocomposites was 0.1 wt.%.

- The presence of Al4C3 in the annealed Al/GNPs composite had a positive effect on the CF at low GNP concentrations, with a 38% increase at 0.1 wt.% GNPs. However, this effect diminished as the concentration of GNPs increased.

- The findings also indicated that the mass wear of the Al-based nanocomposites increased with the concentration of GNPs. When comparing the Al with 0.1 wt.% GNP to 0.5 wt.% GNP, it showed a 46% increase in the mass wear. Further increasing the GNPs concentration to 1.1 wt.% led to a 202% increase in the mass wear, which may have been due to the agglomeration of GNPs at higher concentrations.

- By comparing all the concentrations of the annealed Al/GNPs (0.1–1.1 wt.%) composite with the presence of Al4C3, an increase in the mass wear was observed corresponding to the increase in the GNPs concentrations. The annealed Al/GNPs with 0.1 wt.% GNP and Al4C3 had a mass wear that was approximately 38% higher than that of Al with 0.1 wt.% GNPs. However, the effect of Al4C3 on the mass wear tended to diminish as the concentration of GNPs increased.

- The mass wear of the annealed Al with 0.5 wt.% GNPs and Al4C3 was 27% higher than that of Al with 0.5 wt.% GNPs. The mass wear of the annealed Al with 1.1 wt.% GNPs with Al4C3 was 52% lower than the Al composite with 1.1 wt.% GNPs. This may have been due to the agglomeration of GNPs at higher concentrations and the formation of weak interfacial bonding between the Al matrix and GNPs.

5. Future Scope

- Investigating the effect of the different processing techniques on the tribological properties of Al-based nanocomposites, such as the varying extrusion parameters or annealing temperatures.

- Investigate the effect of GNPs on the mechanical and wear behavior of the Al/Al2O3 composites.

- Conducting in-depth studies to understand the mechanisms behind the observed changes in the tribological behavior with varying GNP concentrations, including the role of agglomeration, interfacial bonding and other factors.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alizadeh, A.; Khayami, A.; Karamouz, M.; Hajizamani, M. Mechanical Properties and Wear Behavior of Al5083 Matrix Composites Reinforced with High Amounts of SiC Particles Fabricated by Combined Stir Casting and Squeeze Casting; A Comparative Study. Ceram. Int. 2022, 48, 179–189. [Google Scholar] [CrossRef]

- Prakash, C.; Senthil, P.; Lakshmi Narayana, S.; Ravichandran, A. Tribological Behaviour of Hybrid AMMC Sliding against EN 31 Steel. Mater. Today Proc. 2022, 68, 1750–1756. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V.; Dimitrova, R. Production and Tribological Characterization of Advanced Open-Cell AlSi10Mg-Al2O3 Composites. Metals 2023, 13, 131. [Google Scholar] [CrossRef]

- Stanev, L.; Kolev, M.; Drenchev, L. Enhanced Tribological Properties of an Advanced Al–Al2O3 Composite Infiltrated with a Tin-Based Alloy. J. Tribol. 2021, 143, 064502. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Jeong, Y.-H.; Seo, J.-J.; Tien, H.N.; Hong, S.-T.; Yum, Y.-J.; Hur, S.-H.; Lee, K.-J. Material Properties of Graphene/Aluminum Metal Matrix Composites Fabricated by Friction Stir Processing. Int. J. Precis. Eng. Manuf. 2014, 15, 1235–1239. [Google Scholar] [CrossRef]

- Alipour, M.; Eslami-Farsani, R. Synthesis and Characterization of Graphene Nanoplatelets Reinforced AA7068 Matrix Nanocomposites Produced by Liquid Metallurgy Route. Mater. Sci. Eng. A 2017, 706, 71–82. [Google Scholar] [CrossRef]

- Yang, X.; Zou, T.; Shi, C.; Liu, E.; He, C.; Zhao, N. Effect of Carbon Nanotube (CNT) Content on the Properties of in-Situ Synthesis CNT Reinforced Al Composites. Mater. Sci. Eng. A 2016, 660, 11–18. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Yan, S.; Lin, F.; Hong, Q.; Kinloch, I.A.; Chen, X.; Young, R.J.; Zhang, X.; Dai, S. Microstructure and Mechanical Behaviour of Aluminium Matrix Composites Reinforced with Graphene Oxide and Carbon Nanotubes. J. Mater. Sci. 2017, 52, 13466–13477. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, C.; Xiao, W.; Ameyama, K.; Ma, C. Enhanced Mechanical Properties of Al5083 Alloy with Graphene Nanoplates Prepared by Ball Milling and Hot Extrusion. Mater. Sci. Eng. A 2016, 658, 8–15. [Google Scholar] [CrossRef]

- Li, G.; Xiong, B. Effects of Graphene Content on Microstructures and Tensile Property of Graphene-Nanosheets/Aluminum Composites. J. Alloys Compd. 2017, 697, 31–36. [Google Scholar] [CrossRef]

- Bisht, A.; Srivastava, M.; Manoj Kumar, R.; Lahiri, I.; Lahiri, D. Strengthening Mechanism in Graphene Nanoplatelets Reinforced Aluminum Composite Fabricated through Spark Plasma Sintering. Mater. Sci. Eng. A 2017, 695, 20–28. [Google Scholar] [CrossRef]

- Bhadauria, A.; Singh, L.K.; Laha, T. Effect of Physio-Chemically Functionalized Graphene Nanoplatelet Reinforcement on Tensile Properties of Aluminum Nanocomposite Synthesized via Spark Plasma Sintering. J. Alloys Compd. 2018, 748, 783–793. [Google Scholar] [CrossRef]

- Alam, S.N.; Kumar, L. Mechanical Properties of Aluminium Based Metal Matrix Composites Reinforced with Graphite Nanoplatelets. Mater. Sci. Eng. A 2016, 667, 16–32. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Yu, Z.; Asif, M.; Lin, H.; Pan, R. Investigation on Microstructural, Mechanical and Electrochemical Properties of Aluminum Composites Reinforced with Graphene Nanoplatelets. Prog. Nat. Sci. Mater. Int. 2015, 25, 460–470. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhong, S.; Zhang, X.; Li, J.; Geng, L. Graphene Nano-Platelets Reinforced Aluminum Composites with Anisotropic Compressive Properties. Mater. Sci. Eng. A 2020, 798, 140234. [Google Scholar] [CrossRef]

- Lazarova, R.; Mourdjeva, Y.; Nihtianova, D.; Stefanov, G.; Petkov, V. Fabrication and Characterization of Aluminum-Graphene Nano-Platelets—Nano-Sized Al4C3 Composite. Metals 2022, 12, 2057. [Google Scholar] [CrossRef]

- Nathan, S.R.; Suganeswaran, K.; Kumar, S.; Thangavel, P.; Gobinath, V.K. Investigations on Microstructure, Thermo-Mechanical and Tribological Behavior of Graphene Oxide Reinforced AA7075 Surface Composites Developed via Friction Stir Processing. J. Manuf. Process. 2023, 90, 139–150. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, S.; Angra, S. Dry Sliding Wear and Microstructural Behavior of Stir-Cast Al6061-Based Composite Reinforced with Cerium Oxide and Graphene Nanoplatelets. Wear 2023, 516–517, 204615. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, Z.; Bai, P.; Zhao, W.; Li, Y.; Liang, M.; Liao, H.; Huo, P.; Li, J. Wear Resistance of Graphene Nano-Platelets (GNPs) Reinforced AlSi10Mg Matrix Composite Prepared by SLM. Appl. Surf. Sci. 2020, 503, 144156. [Google Scholar] [CrossRef]

- Liu, X.; Liu, E.; Li, J.; He, C.; Zhao, N. Investigation of the Evolution and Strengthening Effect of Aluminum Carbide for In-Situ Preparation of Carbon Nanosheets/Aluminum Composites. Mater. Sci. Eng. A 2019, 764, 138139. [Google Scholar] [CrossRef]

- Shao, P.; Yang, W.; Zhang, Q.; Meng, Q.; Tan, X.; Xiu, Z.; Qiao, J.; Yu, Z.; Wu, G. Microstructure and Tensile Properties of 5083 Al Matrix Composites Reinforced with Graphene Oxide and Graphene Nanoplates Prepared by Pressure Infiltration Method. Compos. Part A Appl. Sci. Manuf. 2018, 109, 151–162. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Imai, H.; Umeda, J.; Takahashi, M.; Kondoh, K. Solid-State Interfacial Reaction and Load Transfer Efficiency in Carbon Nanotubes (CNTs)-Reinforced Aluminum Matrix Composites. Carbon N. Y. 2017, 114, 198–208. [Google Scholar] [CrossRef]

- Zhou, W.; Yamaguchi, T.; Kikuchi, K.; Nomura, N.; Kawasaki, A. Effectively Enhanced Load Transfer by Interfacial Reactions in Multi-Walled Carbon Nanotube Reinforced Al Matrix Composites. Acta Mater. 2017, 125, 369–376. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent Progress in the Development and Properties of Novel Metal Matrix Nanocomposites Reinforced with Carbon Nanotubes and Graphene Nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Zhou, W.; Mikulova, P.; Fan, Y.; Kikuchi, K.; Nomura, N.; Kawasaki, A. Interfacial Reaction Induced Efficient Load Transfer in Few-Layer Graphene Reinforced Al Matrix Composites for High-Performance Conductor. Compos. Part B 2019, 167, 93–99. [Google Scholar] [CrossRef]

- Jiang, Y.; Tan, Z.; Fan, G.; Zhang, Z.; Xiong, D.-B.; Guo, Q.; Li, Z.; Zhang, D. Nucleation and Growth Mechanisms of Interfacial Carbide in Graphene Nanosheet/Al Composites. Carbon N. Y. 2020, 161, 17–24. [Google Scholar] [CrossRef]

- Xiong, B.; Liu, K.; Xiong, W.; Wu, X.; Sun, J. Strengthening Effect Induced by Interfacial Reaction in Graphene Nanoplatelets Reinforced Aluminum Matrix Composites. J. Alloys Compd. 2020, 845, 156282. [Google Scholar] [CrossRef]

- El-Ghazaly, A.; Anis, G.; Salem, H.G. Effect of Graphene Addition on the Mechanical and Tribological Behavior of Nanostructured AA2124 Self-Lubricating Metal Matrix Composite. Compos. Part A Appl. Sci. Manuf. 2017, 95, 325–336. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Tribological Performance of Self-Lubricating Aluminum Matrix Nanocomposites: Role of Graphene Nanoplatelets. Eng. Sci. Technol. Int. J. 2016, 19, 463–469. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Z.; Wu, H.; Zhao, J.; Jiang, Z. Effect of Graphene on the Tribolayer of Aluminum Matrix Composite during Dry Sliding Wear. Surf. Coat. Technol. 2019, 358, 907–912. [Google Scholar] [CrossRef]

- Ghazaly, A.; Seif, B.; Salem, H.G. Mechanical and Tribological Properties of AA2124-Graphene Self Lubricating Nanocomposite. In Light Metals 2013; Sadler, B.A., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 411–415. ISBN 9783319651361. [Google Scholar]

- Zhang, X.; Dong, P.; Chen, Y.; Yang, W.; Zhan, Y.; Wu, K.; Chao, Y. Fabrication and Tribological Properties of Copper Matrix Composite with Short Carbon Fiber/Reduced Graphene Oxide Filler. Tribol. Int. 2016, 103, 406–411. [Google Scholar] [CrossRef]

- Xu, Z.; Shi, X.; Zhai, W.; Yao, J.; Song, S.; Zhang, Q. Preparation and Tribological Properties of TiAl Matrix Composites Reinforced by Multilayer Graphene. Carbon N. Y. 2014, 67, 168–177. [Google Scholar] [CrossRef]

- Wei, C.; Li, K.; Yao, L.; Zhou, N. Influence of Fe on Al4C3 as a Heterogeneous Nucleation Substrate: A First-Principles Study. Mater. Res. Express 2017, 4, 106517. [Google Scholar] [CrossRef]

| No. Analysis | C | Al | Fe |

|---|---|---|---|

| 1 | 82.74 | 15.85 | 0.67 |

| 2 | - | 97.70 | 2.30 |

| No. Analysis | C | Al | Fe |

|---|---|---|---|

| 1 | 77.57 | 10.38 | 12.04 |

| 2 | 6.97 | 49.86 | 43.17 |

| No. Analysis | C | Al | Fe |

|---|---|---|---|

| 1 | 87.34 | 8.95 | 3.71 |

| 2 | 74.09 | 18.55 | 7.36 |

| 3 | 13.70 | 61.38 | 24.91 |

| No. Analysis | C | Al | Fe |

|---|---|---|---|

| 1 | 82.36 | 8.12 | 9.53 |

| 2 | 13.15 | 49.22 | 37.63 |

| No. Analysis | C | Al | Fe |

|---|---|---|---|

| 1 | 71.82 | 26.00 | 2.18 |

| 2 | 62.50 | 35.19 | 2.30 |

| 3 | - | 85.89 | 14.11 |

| No. Analysis | C | Al | Fe |

|---|---|---|---|

| 1 | 72.30 | 16.46 | 11.23 |

| 2 | 52.46 | 31.17 | 5.04 |

| 3 | 12.94 | 65.75 | 21.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolev, M.; Lazarova, R.; Petkov, V.; Mourdjeva, Y.; Nihtianova, D. Investigating the Effects of Graphene Nanoplatelets and Al4C3 on the Tribological Performance of Aluminum-Based Nanocomposites. Metals 2023, 13, 943. https://doi.org/10.3390/met13050943

Kolev M, Lazarova R, Petkov V, Mourdjeva Y, Nihtianova D. Investigating the Effects of Graphene Nanoplatelets and Al4C3 on the Tribological Performance of Aluminum-Based Nanocomposites. Metals. 2023; 13(5):943. https://doi.org/10.3390/met13050943

Chicago/Turabian StyleKolev, Mihail, Rumyana Lazarova, Veselin Petkov, Yana Mourdjeva, and Diana Nihtianova. 2023. "Investigating the Effects of Graphene Nanoplatelets and Al4C3 on the Tribological Performance of Aluminum-Based Nanocomposites" Metals 13, no. 5: 943. https://doi.org/10.3390/met13050943

APA StyleKolev, M., Lazarova, R., Petkov, V., Mourdjeva, Y., & Nihtianova, D. (2023). Investigating the Effects of Graphene Nanoplatelets and Al4C3 on the Tribological Performance of Aluminum-Based Nanocomposites. Metals, 13(5), 943. https://doi.org/10.3390/met13050943