Abstract

The application of high-strength Al-Zn-Mg-Cu alloy is seriously limited because of its poor formability. A novel electroshock treatment (EST) technique with low frequency combined with tensile deformation was proposed to address the issues of low plasticity and poor formability of Al-Zn-Mg-Cu alloy, which could revolutionize conventional plastic forming methods and realize near-room temperature forming of complex components. Al-Zn-Mg-Cu alloy was examined in this work to figure out how EST affects the tensile characteristics and dynamic recrystallization of the alloy during tensile deformation. The findings demonstrate that when electroshock with a current density of 30 A/mm² and a period of 5 s, the elongation of the alloy increased by 21.74%, and the fraction of dynamic recrystallization increased by 77.56% compared to the sample without EST at a temperature far below the recrystallization temperature. The electron back scatter diffraction (ESBD) results show that after appropriate EST, the average grain size decreased from 40 μm to 30 μm, the distribution of grain was more uniform, and the sample’s grain boundary angle generally increased, which is more attractive to facilitate the nucleation and growth of dynamic recrystallization. Additionally, transmission electron microscopy (TEM) results indicate that electroshock energy motivated the migration of dislocations from the grain interior to near the grain boundaries, improving the ability of Al-Zn-Mg-Cu alloy to dynamically recrystallize at near ambient temperature and enhancing elongation.

1. Introduction

Al-Zn-Mg-Cu alloys are frequently utilized in the aircraft, high-speed rail, and other industries due to their excellent properties, such as high specific strength, low density, and corrosion resistance [1]. However, issues that include coarse grains, extensive second phases, and element segregation still exist in the traditional plastic deformation process, which negatively impacts its formability and performance in service [2].

Electropulsing treatment is an advanced manufacturing technology developed in recent years that can be applied to the fields of component strengthening, heat treatment, and material deforming [3]. Electropulsing treatment can effectively enhance the mechanical properties and microstructure of materials. Zhu et al. [4] performed electropulsing uniaxial tensile testing on ZA22 alloy at ambient temperature to remove the Joule heat effect. The findings demonstrated that the nonthermal effects caused the sample’s elongation to rise by 43.7% after the electropulsing treatment. In addition, compared with the strength and elongation of AA6601 alloy under traditional heat treatment, Pan et al. [5] discovered that cyclic pulse current could considerably improve these properties. The yield strengths and elongations of the samples subjected to cyclic pulse current were 72.1% and 2.1% higher, respectively. Wang et al. [6] investigated the effects of pulse current on the plastic deformation of pre-deformed AZ31B Mg alloy. According to the findings, in comparison to the sample without current pulse, the yield tensile strength ratio rose by 42%, and the fracture strain and uniform strain of the sample treated with current pulse increased by 21.5% and 10%, respectively. Moreover, investigations have shown that, by mending metal flaws and fractures, pulse current may enhance the mechanical characteristics of metals [7,8].

In the field of material microstructure, researchers have mainly concentrated on investigating the mechanism of the effects of electropulsing treatment on material recrystallization, dislocation, and grain size. After examining the AZ31 alloy’s microstructure development under electropulsing treatment, Liu et al. [9] concluded that electropulsing treatment promoted the alloy’s static recrystallization behavior. Park et al. [10] investigated the effects of electric current on the static recrystallization kinetics of AZ31 alloy based on Vickers hardness measurements and microstructure observations during electropulsing treatment. The findings discovered that under the influence of electric current, nonthermal effects accelerated the nucleation rate of material recrystallization, making the dynamic recrystallization temperature of AZ31 alloy significantly lower. Moreover, by altering the dislocation slip process of materials, pulse current can influence the deformation behavior and macroscopic mechanical characteristics of materials [11,12]. Bumgardner et al. [13] discovered that the influence of current reduced the energy barrier of dislocation movement, promoting the dislocation pinning effect, increasing the number of mobile dislocations, and enhancing the plastic formability of aluminum alloys. Kim et al. [14] discovered that under the influence of current, the elongation of AA5052 alloy dramatically rose with a reduction in flow stress. Liang et al. [15] proposed that current stress will result in high dislocation density in brass, which will cause non-deformable crystallization. Compared with the brass that was subjected to annealing, the grain size of the brass subjected to electric current refined by 75%, and the microhardness enhanced by 28%. Furthermore, electron wind force [16,17] may also be used to refine grains. Electron wind force will contribute to the growth of cellular sub-grains, and the new grain boundaries that formed under electropulsing treatment will eventually consolidate to facilitate grain refining prominently. In conclusion, several researchers have conducted extensive studies in the area of electrically assisted deformation and have produced significant research findings. Unfortunately, there is currently little research on the comprehensive effects of electric pulse treatment on the dynamic recrystallization behavior of metal materials under plastic deformation, and the relevant mechanism is unknown.

Electroshock treatment (EST), a novel electropulsing treatment process proposed by our team, is characterized by adopting high energy density, low frequency, and instant intermittent pulse current to achieve ultra-high performance without changing surface quality and dimensional accuracy as much as possible. Song et al. [18] found that the low-cycle fatigue life of TC11 titanium alloy increased by 22.5% by the appropriate EST, resulting from microstructural evolution and nanoscale phase transformation. Liu et al. [19] demonstrated that the grain boundary and texture of TC11 titanium alloy were definitely influenced by EST. The results showed that the percentage of high-angle misorientation grain boundaries (HAGBs) in the β phase increased from 3.74% before EST to 11.15% after 0.04 s EST, and the proportion of HAGBs in the α phase increased from 23.16% before EST to 76.61% after 0.06 s EST. Moreover, the texture distribution of the α phase was uniform, with a maximum intensity of 5.47 after 0.06 s EST. Wu et al. [20] utilized EST to significantly improve the ductility and fatigue life of Al-Zn-Mg-Cu alloy without reducing its strength, and the reason could be attributed to the homogeneous distribution of dislocations and dislocation increments, especially edge dislocation, due to the cross-slip of screw dislocations induced by electron-dislocation scattering. The above research indicated that the microstructure and mechanical properties of Al-Zn-Mg-Cu alloy varied after EST; however, the influence mechanism of EST on microstructure and mechanical properties is still unclear, especially for dynamic recrystallization behavior at a low temperature rise.

In the present work, mechanical properties and microstructure evolution were investigated using electroshock-assisted tensile testing. The influence of EST on microstructure was explored using electron back scatter diffraction (EBSD) and transmission electron microscopy (TEM), and the effect mechanism of EST on the recrystallization behavior of Al-Zn-Mg-Cu alloy was revealed.

2. Materials and Methods

2.1. Materials

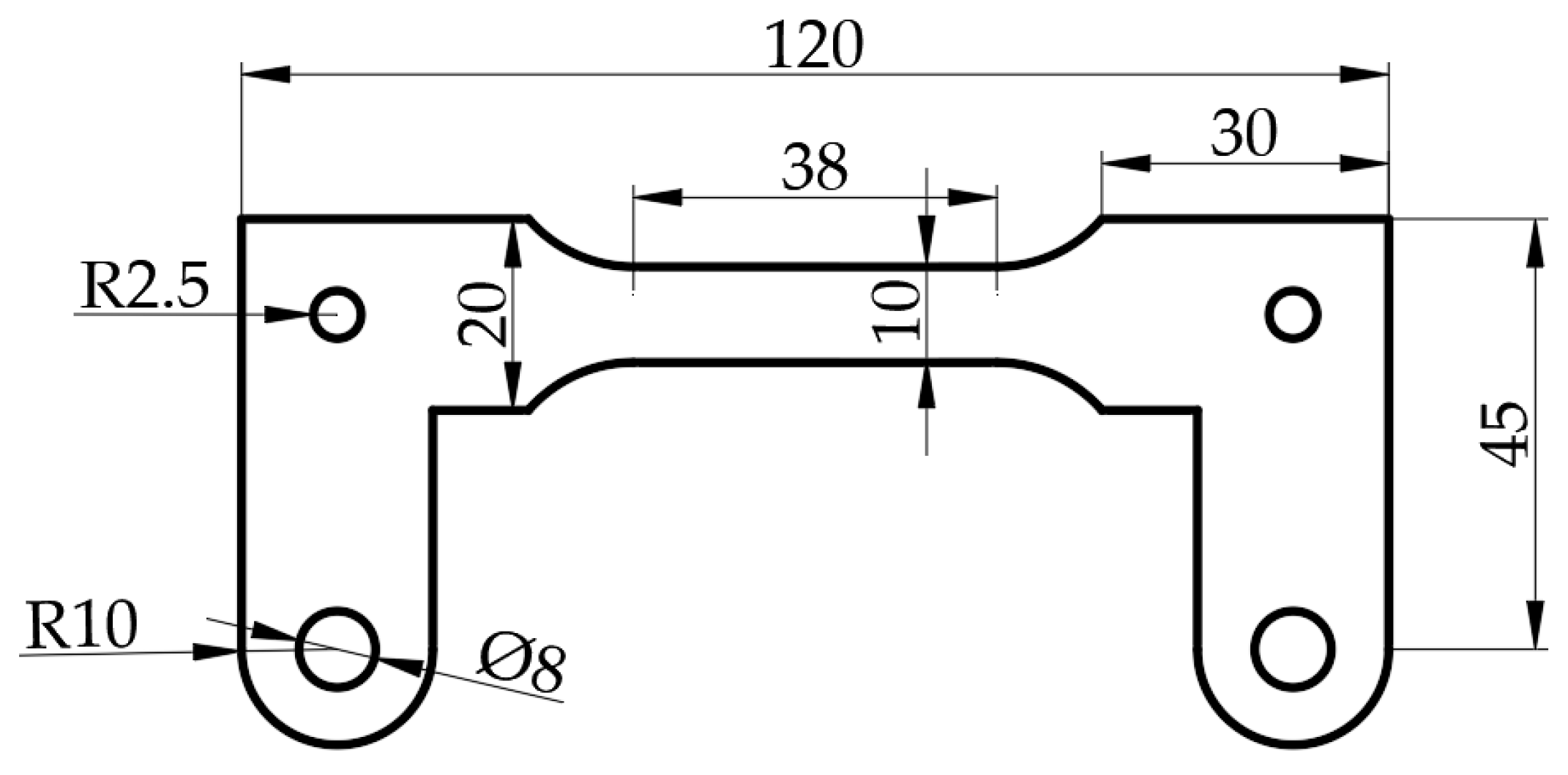

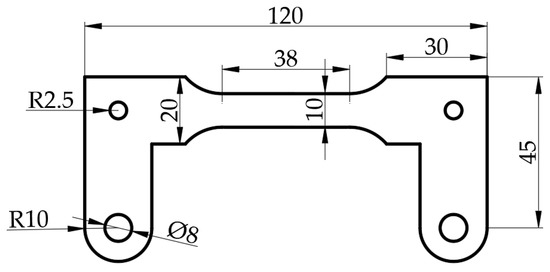

Al-Zn-Mg-Cu alloy in the T6 condition with a thickness of 1.5 mm was the material utilized in this study. The chemical composition is listed in Table 1. A special sample, as shown in Figure 1, was designed to facilitate clamping, and the samples were cut along the rolling direction.

Table 1.

Chemical composition of the Al-Zn-Mg-Cu alloy (Wt %).

Figure 1.

Schematic illustration of sample dimensions for the EST process (mm).

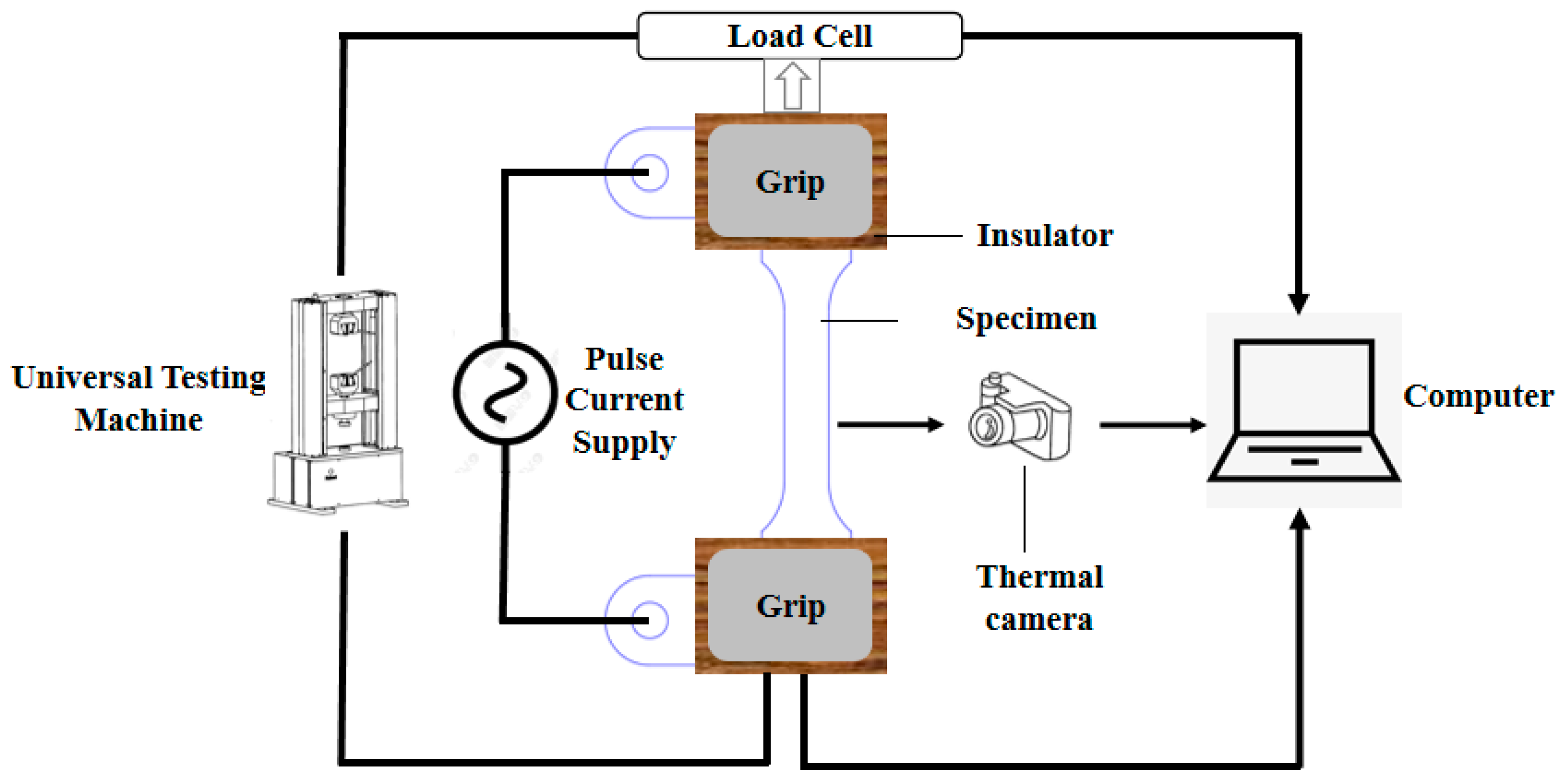

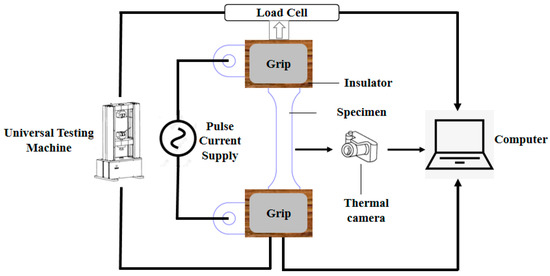

2.2. Electroshock-Assisted Tensile Test

The specimen and insulator were installed on an electronic universal testing machine (CMT5205–5305) with clamps, and the vertical extension of the electroshock tensile specimen was linked to the copper electrode on the electroshock generator with bolts. The pulsed power supply used in the test was produced by a self-developed electropulsing generator. The generator applies an ultra-low-frequency electroshock load to the sample as the electronic universal testing machine starts to apply tensile force, and a thermal camera (Fotric 226) is used to synchronously monitor the temperature of the deformation area of the sample. The electroshock-assisted tensile test process is shown in Figure 2.

Figure 2.

Experimental procedure of the electroshock-assisted tensile test.

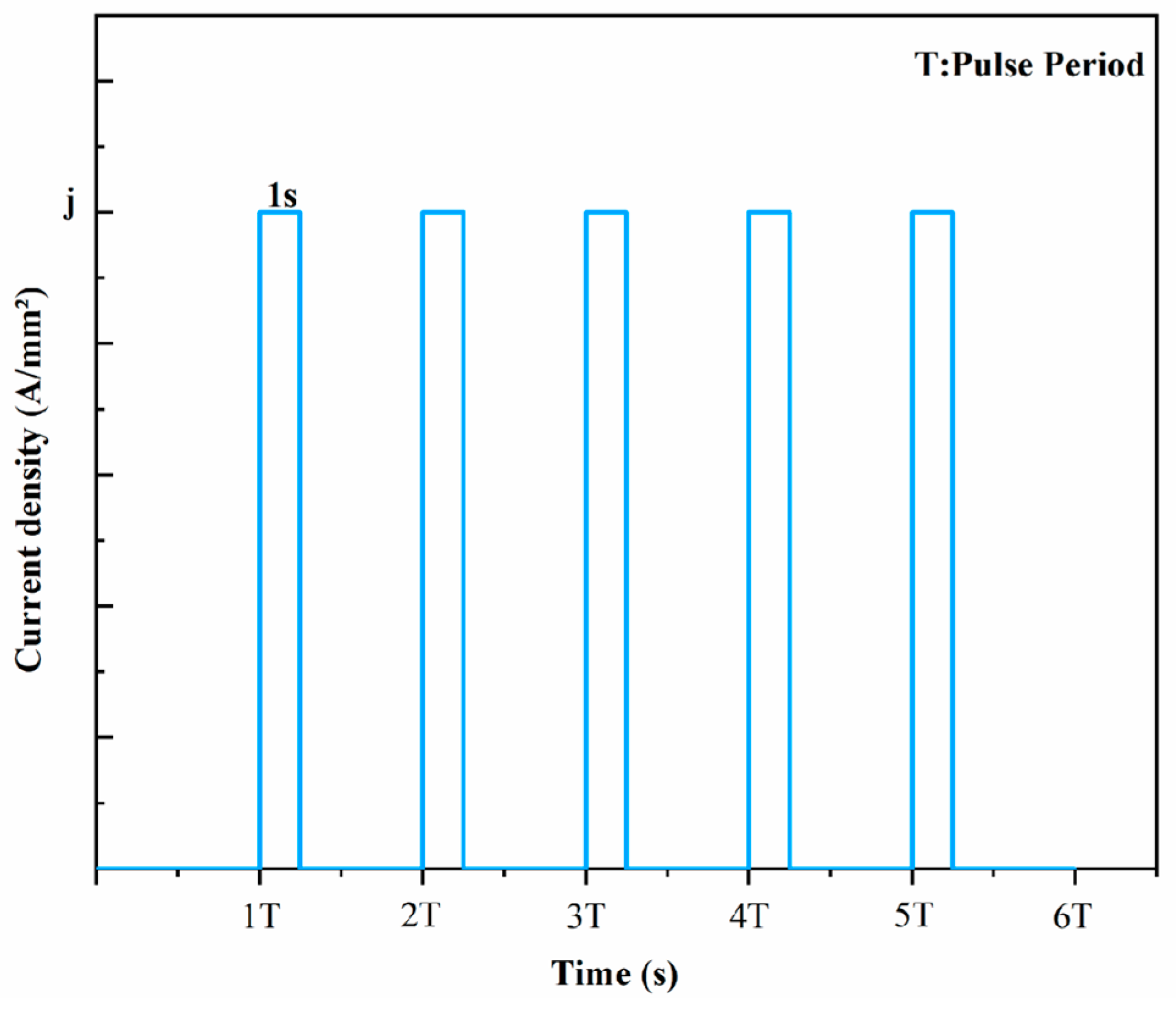

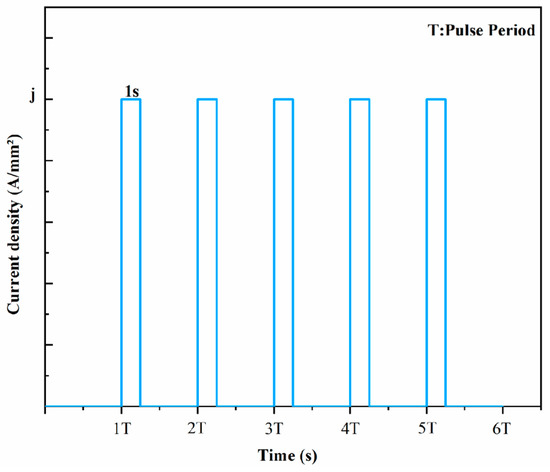

In order to analyze the true stress–strain curve changes and the dynamic recrystallization of Al-Zn-Mg-Cu alloy under electroshock-assisted tensile deformation, three sets of electroshock-assisted tensile tests were set up, and the main parameters are shown in Table 2. The strain rate of the three tests was 0.1 s−1. The electroshock generator produces a DC square wave electropulsing with a pulse period of 1 s and a current density of 0 during the pulse interval to enable the heat produced by the electroshock to evaporate. The electropulsing square wave is shown in Figure 3. It should be noted that the current used in EST has the characteristics of an ultra-low-frequency unidirectional positive pulse and very limited energy density, which minimizes the temperature rise and effectively weakens the thermal effect by the current impact.

Table 2.

Electroshock uniaxial tensile test parameters.

Figure 3.

Electropulsing square wave.

2.3. Microstructure Characterization

The deformed samples were sliced in a direction parallel to the tensile axis. After being roughly ground with #220, 500, and 1200 sandpaper, the sliced samples were mechanically polished with a 9 μm, 3 μm, and 1 μm diamond polisher and then polished with 0.05 μm SiO2 oxide suspension. Finally, the microstructure morphology was observed using Quanta FEG 450 scanning electron microscopy operated at 20 kV equipped with an EBSD system. TEM samples were prepared through focused ion beam grinding (Helios Nanolab G3 UC, Thermo Fisher, Waltham, MA, USA), and TEM observation was performed in the Talos F200S STEM with an acceleration voltage of 200 kV.

3. Results and Discussion

3.1. Analysis of Temperature and True Stress–Strain Curves

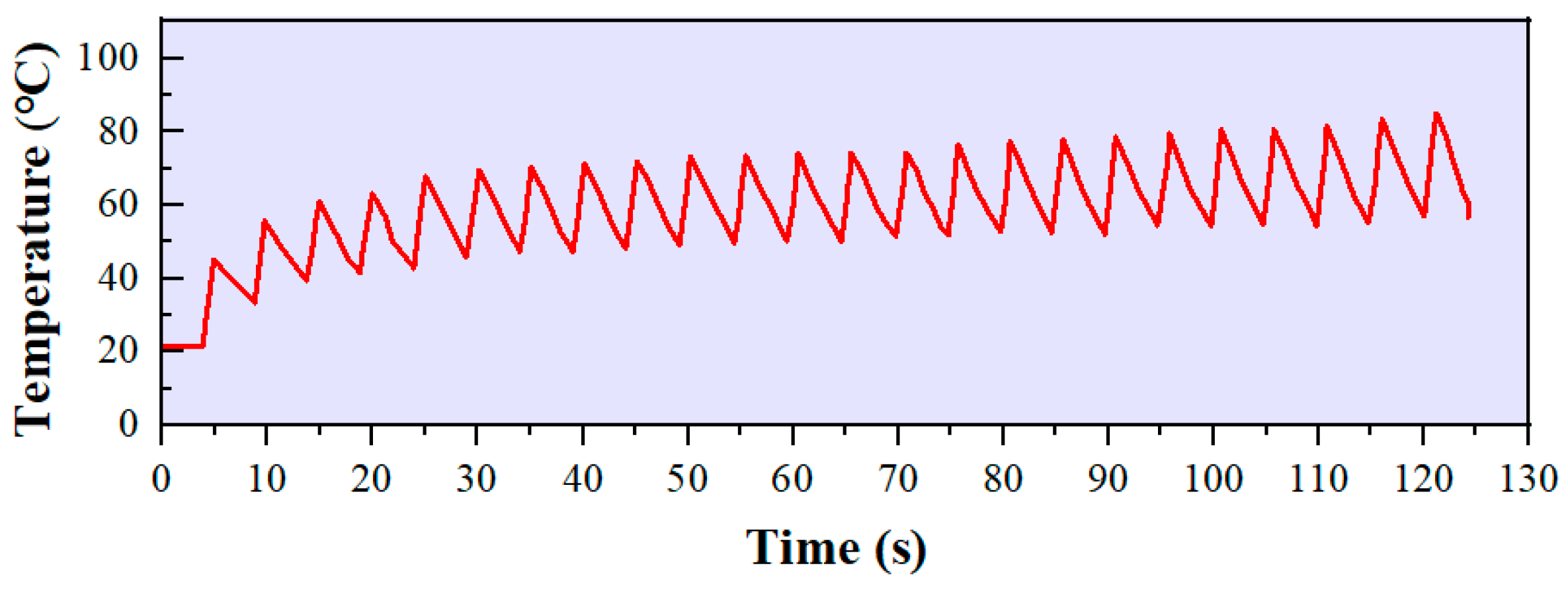

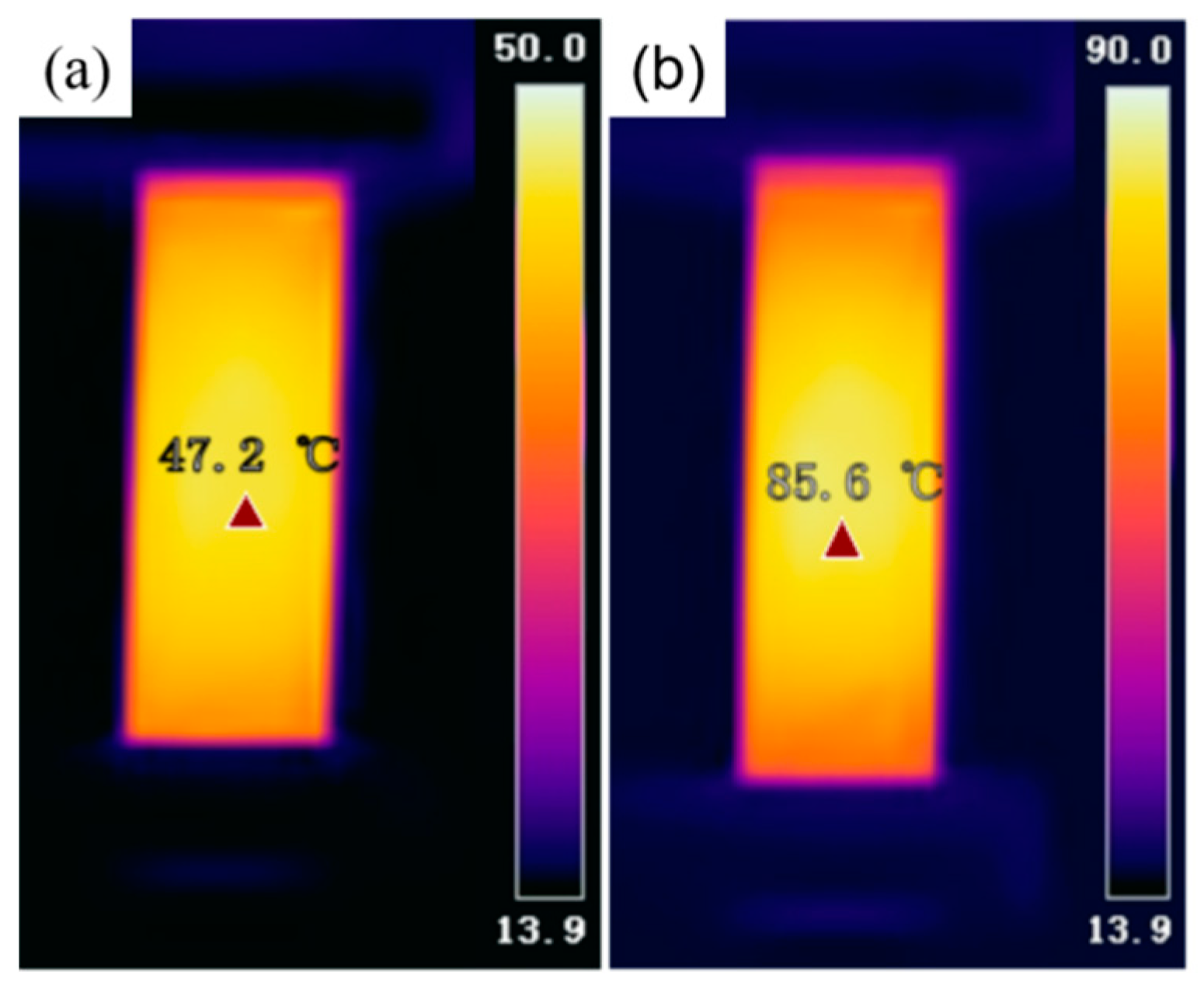

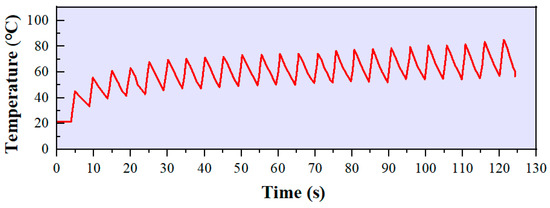

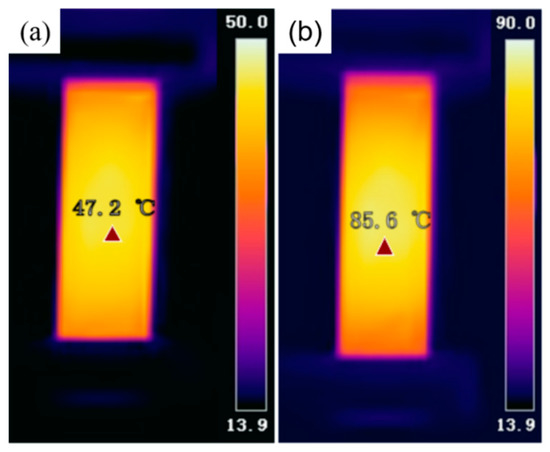

Figure 4 shows the temperature changes in the center of the EST2 sample during the electroshock-assisted tensile process. It can be seen from Figure 4 that the temperature change curve of the EST2 sample took on a zigzag pattern during the electroshock-assisted tensile process. This is due to the fact that the temperature of the sample rose immediately when the electroshock was applied, but the temperature of the air around the sample was low at that time. This will drop the temperature of the sample as a result of heat emitting into the surrounding atmosphere. Moreover, the heat produced by the electroshock will accumulate as a consequence of the short pulse interval, which makes it difficult to entirely dissipate. Hence, as shown in Figure 5b, the temperature in the center of the EST2 sample rose to the greatest level of 85.6 °C in the final pulse current during the electroshock-assisted tensile process. The temperature of the EST1 sample versus the time curve was similar to the regulations of the EST2 sample. The greatest temperature of the EST1 sample during the electroshock-assisted tensile process was 47.2 °C (Figure 5a). As can be seen, the maximum temperature of the electroshock-assisted tensile sample was much lower than the recrystallization temperature of Al-Zn-Mg-Cu alloy during the heat treatment process (approximately 200 °C).

Figure 4.

The temperature of EST2 changes during EST.

Figure 5.

Maximum temperatures during EST: (a) EST1 and (b) EST2.

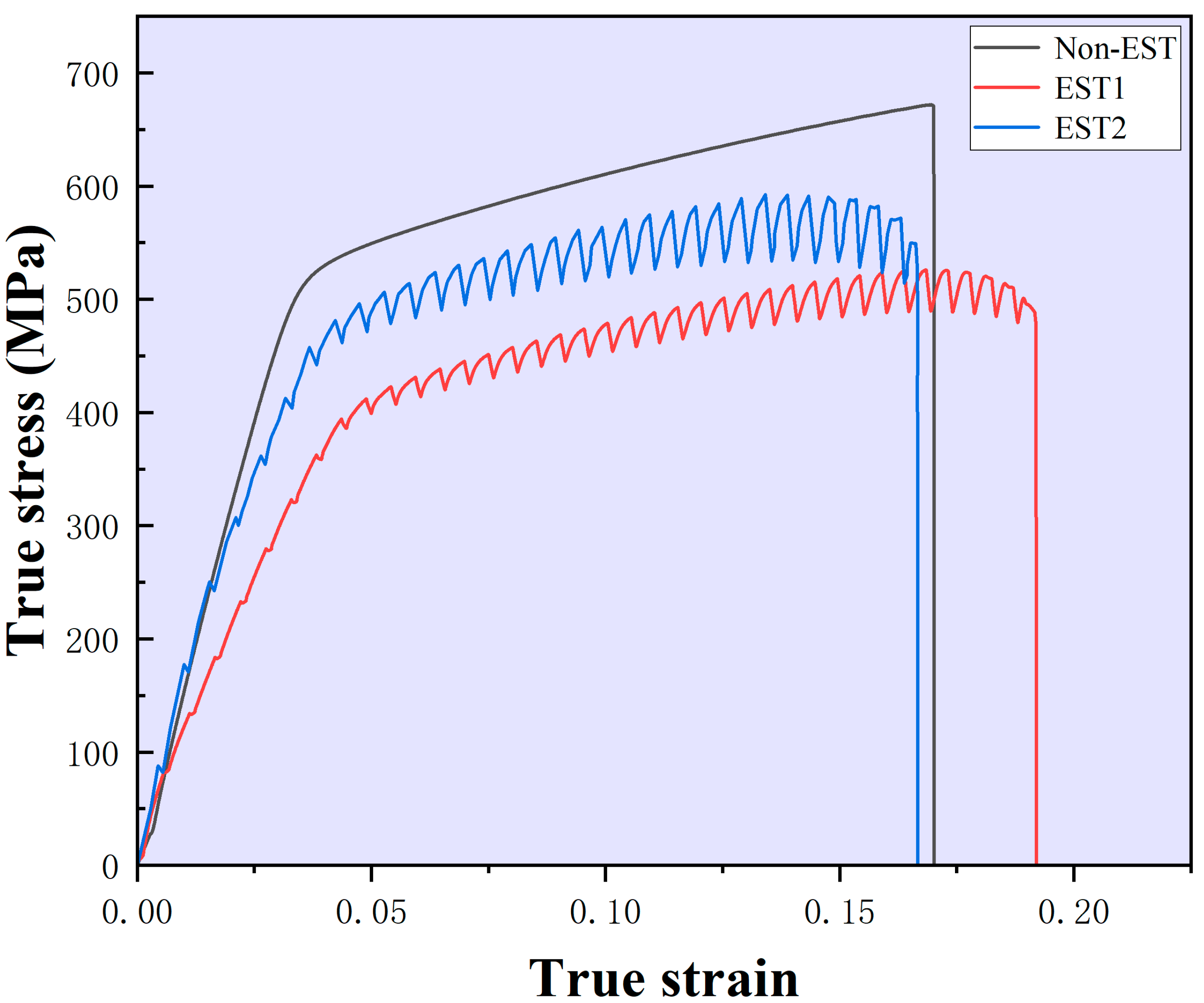

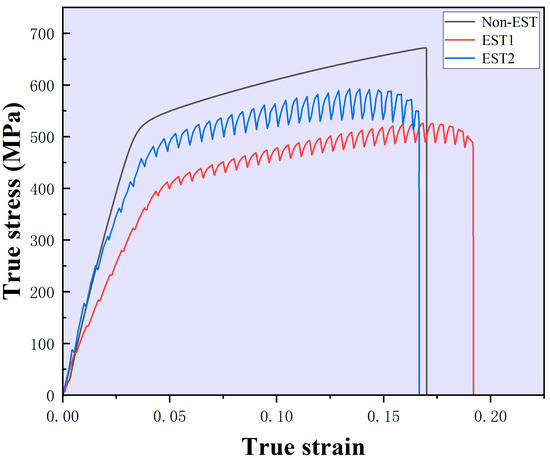

Figure 6 displays the true stress–strain curves for each experiment in the electroshock-assisted tensile test. Compared with the Non-EST sample, the true stress–strain curves of the electroshock-assisted tensile samples took on a zigzag pattern. The rapid reduction in stress of the electroshock sample was strongly correlated with the internal temperature of the sample. When the electroshock was applied, the internal temperatures of the EST1 and EST2 samples rose quickly, causing thermal expansion [21], which contributed to a rapid reduction in stress. The stress of the sample will progressively rise as the heat dissipates during the short time interval of the EST, and the sample will enter the yield stage and complete a stress drop-rise cycle until it breaks.

Figure 6.

True stress–strain curves under different parameters [22].

The electroshock-assisted tensile test revealed that the elongations of the three samples were 10.95%, 13.33%, and 10.67%. The elongation of the EST1 sample increased by 21.74%, and the fraction of dynamic recrystallization content increased by 77.56%, which was in contrast to the Non-EST sample. Thus, appropriate EST can increase the plastic formability of material.

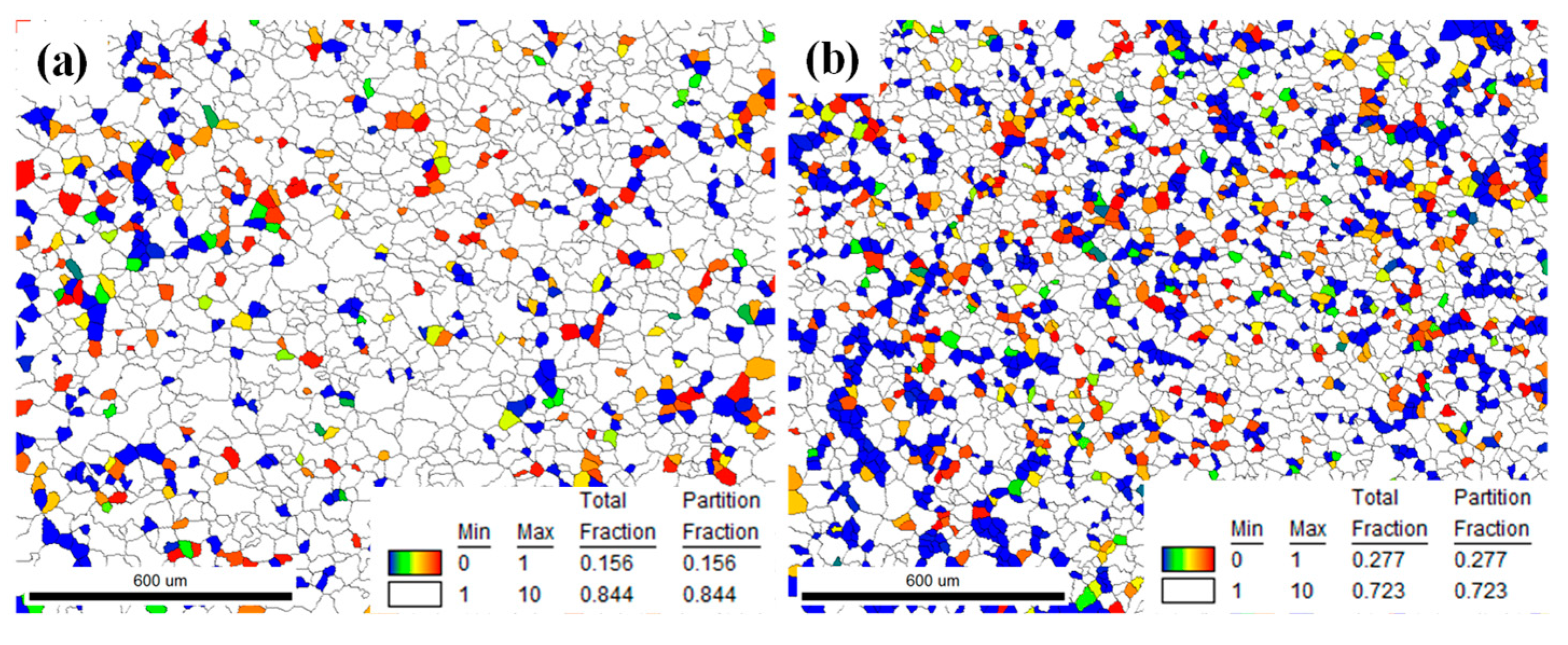

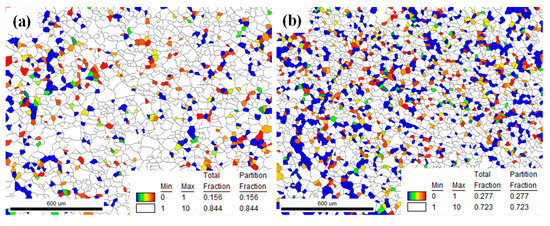

3.2. Effect of EST on Dynamic Recrystallization

Figure 7 displays the grain orientation spread (GOS) diagram of Al-Zn-Mg-Cu alloy under Non-EST and EST1. The GOSs of typical dynamic recrystallized grains are generally less than 1° [23]. It can be seen from Figure 7 that the dynamic recrystallization percentage of the Non-EST sample was 15.6%, while the dynamic recrystallization percentage of the EST1 sample was 27.7%, with an increase rate of 77.56%. The results indicate that recrystallization behavior may be considerably promoted by using proper EST parameters.

Figure 7.

GOS diagram of Al-Zn-Mg-Cu alloy: (a) Non-EST and (b) EST1.

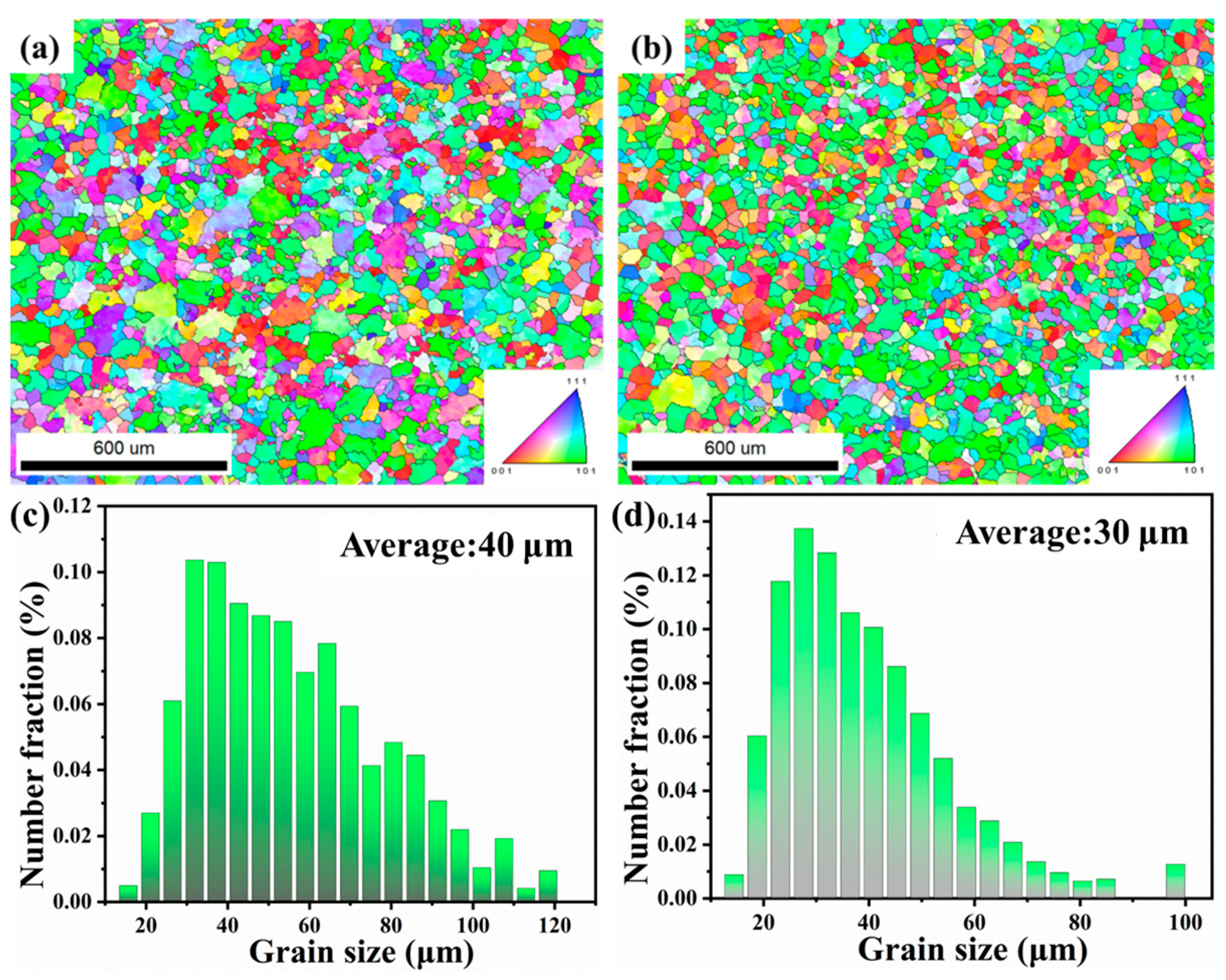

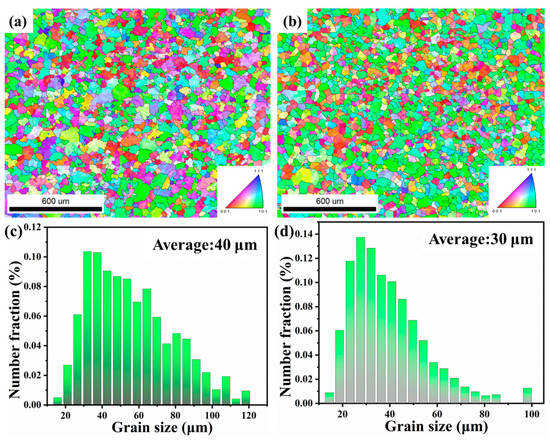

Figure 8 shows the inverse pole figure (IPF) and grain size distribution histogram of the Non-EST and EST1 samples. The red area symbolizes the orientation of (001), the green represents the orientation of (101), and the blue grains represent the orientation of (111). As can be observed in Figure 8a,b, the EST1 and Non-EST samples have noticeable variations in grain shape and orientation. The Non-EST sample has an uneven distribution of grain sizes, with many grains that are excessively large, while the EST1 sample has fine, evenly dispersed grains, and many equiaxed, recrystallized grains of moderate size can be observed. In addition, the statistics indicate that the average grain size of the Non-EST sample was 40 μm, and the distribution of grain size had a rather broad range, with some grain sizes exceeding 100 μm. In the case of EST1, the average grain size shrank to 30 μm, and the distribution of grain size was more uniform. The number of small-size grains increased significantly, while the number of large-size grains decreased significantly, and the maximum grain size was less than 100 μm. This suggests that electroshock can facilitate recrystallization. Under proper EST parameters, the role of electricity acts as a strong driving force for the nucleation and growth of recrystallization, resulting in the production of more small recrystallization grains. On the one hand, Joule heat is produced by the ferocious collisions of atoms and electrons in the material, which boosts atom mobility. On the other hand, the directional movement of free electrons improves the nucleation of recrystallization by enhancing the mobility and recovery of dislocations [22].

Figure 8.

Inverse pole figure (IPF) and grain size distribution histogram of Al-Zn-Mg-Cu alloy under different deformation conditions: (a,c) Non-EST and (b,d) EST1.

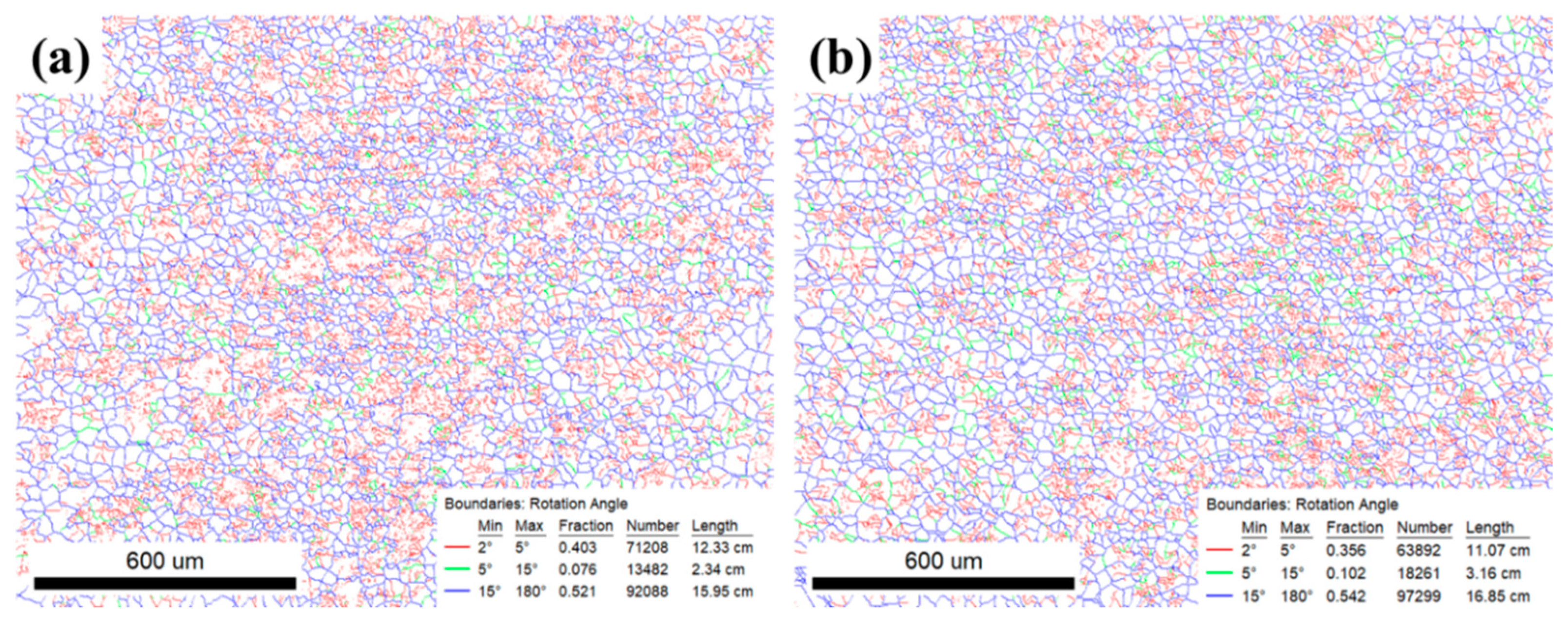

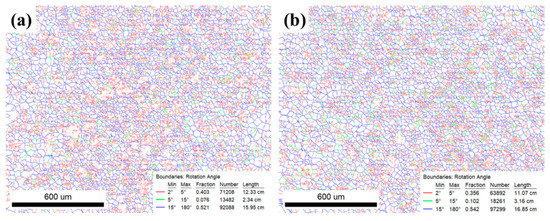

Figure 9 displays the grain boundary and misorientation distribution of the Non-EST and EST1 samples. The grain boundaries with an angle of 2°–5° are shown by the red lines, and the grain boundaries with an angle of 5°–15° are represented by the green lines. Both are collectively referred to as small-angle grain boundaries. The blue lines represent grain boundaries with high angles ranging from 15°–180°. It can be observed in Figure 9 that the small-angle grain boundaries of the Non-EST sample mainly exist inside the grains. The reason is that aluminum alloy is a high-fault energy metal, and the dislocation density inside the grains will constantly accumulate and form a dislocation wall during deformation. When the degree of material deformation increases, the dislocation wall transforms into small-angle grain boundaries, which are also called sub-grain boundaries [24]. The abundance of these sub-grain boundaries inside the grains suggests that dynamic recovery is the primary deformation process of Al-Zn-Mg-Cu alloy. The small-angle grain boundaries of the EST1 sample were mostly found near the grain boundaries, particularly at the triangular boundaries, which suggests that the nucleation of recrystallization occurs mostly at the grain boundaries during electroshock-assisted deformation. Additionally, the percentage of small-angle grain boundaries in the electroshock-assisted tensile specimen (35.6%) was lower than that of the Non-EST sample (40.3%), showing that the overall grain boundary angle of the EST1 sample was larger, which is more favorable to the nucleation and growth of recrystallization. As a result, the grain morphology of the EST1 sample was finer and more uniform.

Figure 9.

Grain boundary and misorientation distribution of Al-Zn-Mg-Cu alloy: (a) Non-EST and (b) EST1.

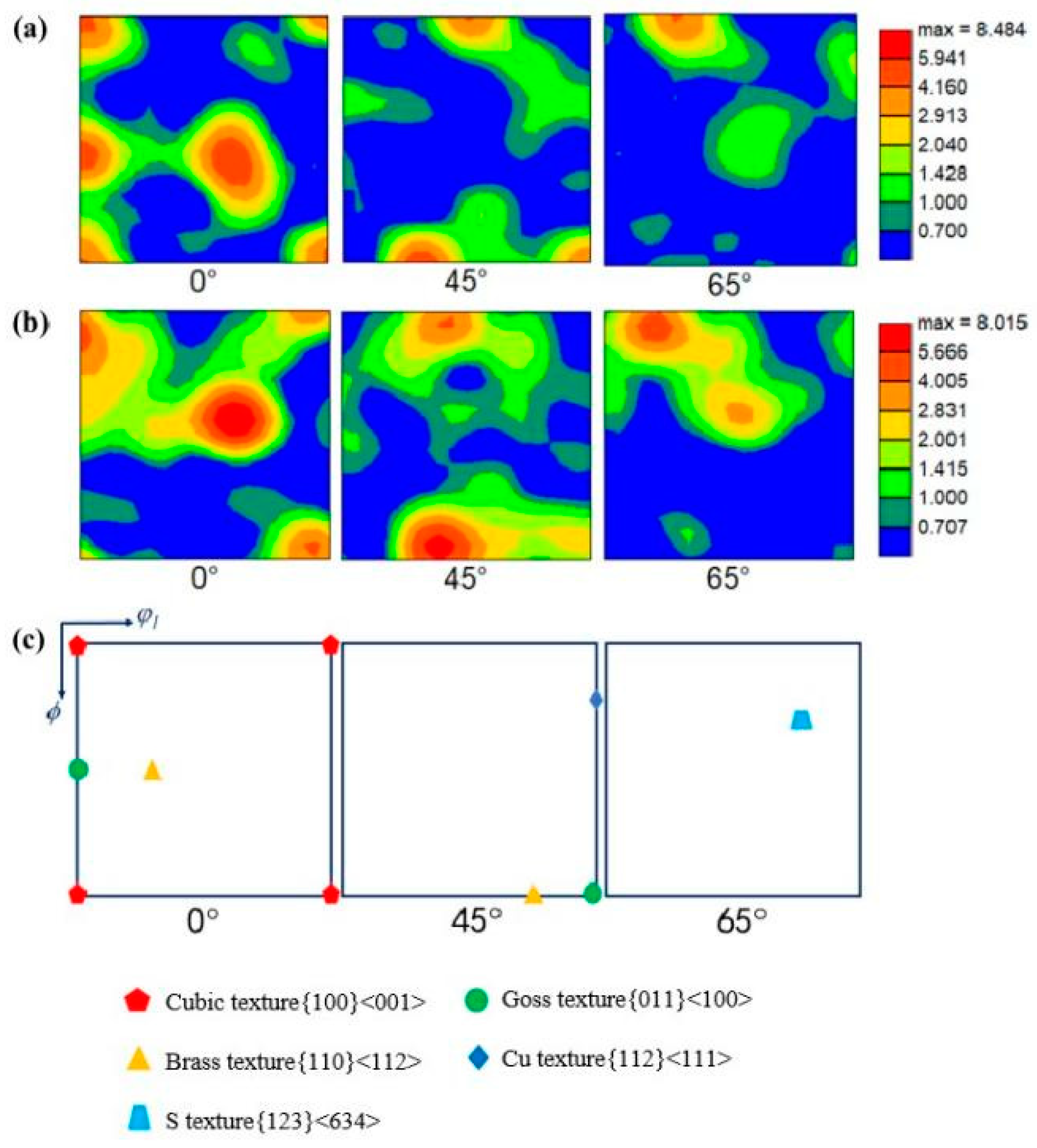

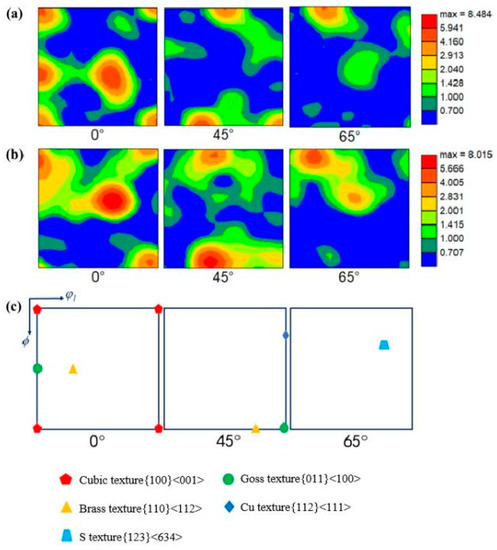

In order to investigate the effects of EST on texture, the orientation distribution functions (ODFs) of the Non-EST and EST1 samples were analyzed.

Figure 10 shows the ODF maps and standard texture components of the Non-EST and EST1 samples. Three sections of = 0°, = 45°, and = 65° were selected for analysis. The three major textures in the Non-EST sample were the Cubic texture {100}<001>, the Goss texture {011}<100>, and the Brass texture {110}<112>. Moreover, there were slight quantities of the Cu texture {112}<111> and S texture {123}<634>. However, the Cubic texture {100}<001> remained basically unchanged, while the Goss texture {011}<100> increased, and the Cu texture {112}<111>, Brass texture {110}<112>, and S texture {123}<634> decreased under EST. This indicates that under the influence of electroshock, the increase and recombination of dislocations in the EST1 sample attained a dynamic equilibrium, and the dynamic recrystallization was strengthened under the effects of electroshock.

Figure 10.

ODF maps of (a) Non-EST and (b) EST1; (c) schematic illustration of the standard.

3.3. High-Strength Aluminum Alloy Dynamic Recrystallization Mechanism via EST

Kravchenko [25], Klimov [26], and Roschupkin [27] initially provided theoretical formulas for the electron wind force acting on a unit dislocation in associated studies on the effects of electroshocks on dislocations. These formulas can be expressed, respectively, as follows:

where f/l is the electron wind force on a unit dislocation; J is the current density; ∆ is the constant of the deformation potential; e is the elementary charge; b is Burger’s vector; Ef is the Fermi energy; gF is the Fermi velocity; h is the Planck constant; and m* is the effective mass. From Equations (1)–(3), it can be seen that in the electroshock-assisted deformation process, the magnitude of the electron wind force is proportional to the current density of the electroshock. The higher the current density, the greater the influence of electron wind force on dislocations. Uneven Joule heat effects occur at defects, such as dislocation entanglements and lattice distortions, within a deformed alloy when electroshock is applied. High thermal compressive stress is produced instantly in these defects due to the high resistivity of these defects, which causes vacancies and dislocations to migrate rapidly to stimulate the nucleation and growth of recrystallization.

The stable nucleation of dynamic recrystallization must simultaneously satisfy the critical driving force and critical grain nucleation size for recrystallization in the electroshock-assisted deformation process. The nucleation and growth of recrystallization occurs only when these two requirements are fulfilled. During EST, the instantaneous high energy generated by the electroshock causes dislocation and vacancy to move at a high speed, which in turn accelerates the migration of the low-angle and high-angle grain boundaries. Then, the nucleation rate of dynamic recrystallization increases, and the growth rate of recrystallization grains slows down. Thermal and nonthermal effects during EST provide a driving force to promote recrystallization, which combines with the critical grain nucleation size, Rc, to impact the dynamic recrystallization of materials. The critical grain nucleation size Rc can be calculated according to the following equation [22]:

where γ is the grain boundary energy; P is the driving force in the dynamic recrystallization process; and ΔP is the additional recrystallization driving force generated by electrical and thermal energy during the electroshock.

The nucleation rate N caused by the migration of grain boundaries can be expressed as [22]:

where Rs is the pre-existing grain size; is the energy of per-unit dislocation; and K is a constant. Equation (5) shows that during EST, as the additional driving force increases, the critical grain nucleation size for forming stable recrystallized grain nuclei decreases. As a result, the nucleation rate of recrystallization increases after EST. Grain growth includes the growth of recrystallized and original grains. Under the composite influence of the electric–thermal–mechanical energy field, the initial grains continue to expand, while the growth rate of dynamic recrystallization during EST is actually lower than it is during heat treatment [28]. From this viewpoint, electroshock will, under certain electroshock parameters, inhibit the growth of recrystallized grain nuclei, and this inhibition is strongly connected to current density. The process of the growth of recrystallization grains can be regarded as the migration process of grain boundaries, which is simply the directional movement of atoms on both sides of the grain boundary under the influence of driving forces. The process of recrystallization continues to consume storage energy that is generated by the accumulation of a significant amount of dislocations inside the grains during the process of electroshock-assisted deformation. Consequently, the dislocation density in the recrystallized area will decrease, and there will be a storage energy difference between the original grains and the recrystallized grains, which serves as a driving force for the growth of recrystallized grains. The growth rate of recrystallized grain nuclei can be calculated according to the following equation [29]:

where G0 is the initial growth rate of the grain nucleus; E0 is the initial storage energy; dt is the grain diameter after growth; d0 is the initial grain diameter; C is the positive coefficient; λ is the grain boundary diffusion coefficient; eZb* is the effective charge of metal ions at the grain boundary; ρ is the resistance; Ω is the atomic volume; Nb is the atomic density at grain boundary; and J is the current density.

Equation (6) shows that the growth rate of recrystallized grains is lower than that of grains without EST. Furthermore, the growth rate of grains decreases with increasing current density J, which indicates that a large pulse current will inhibit the growth of recrystallized grains. Consequently, under certain conditions, electroshock may restrict the growth of recrystallized grain nuclei, and this inhibition has a positive relationship with current density. In addition, due to the low deformation temperature during EST, the energy produced by the immediate electroshock is the primary driving force for the formation of recrystallization, resulting in relatively tiny grains.

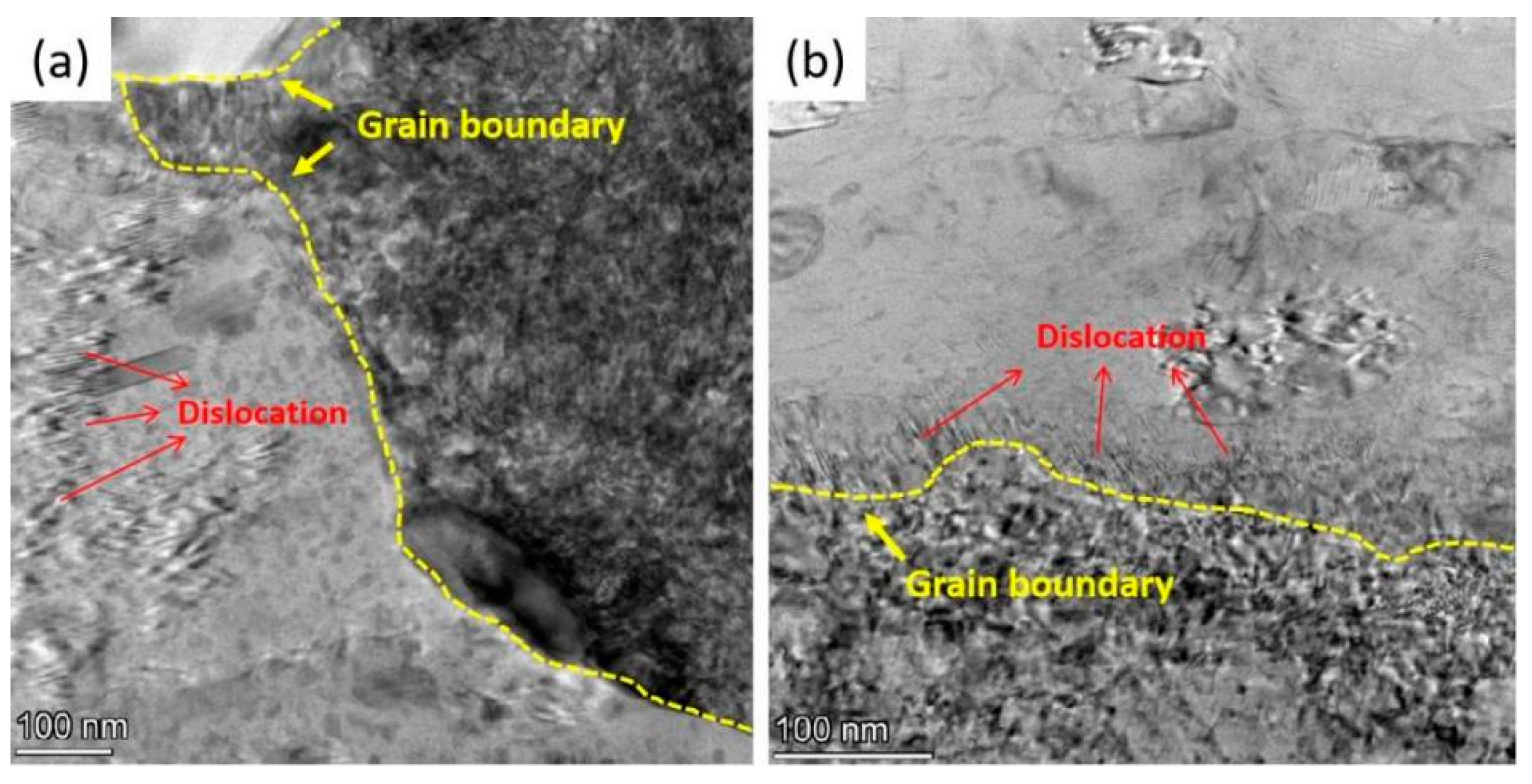

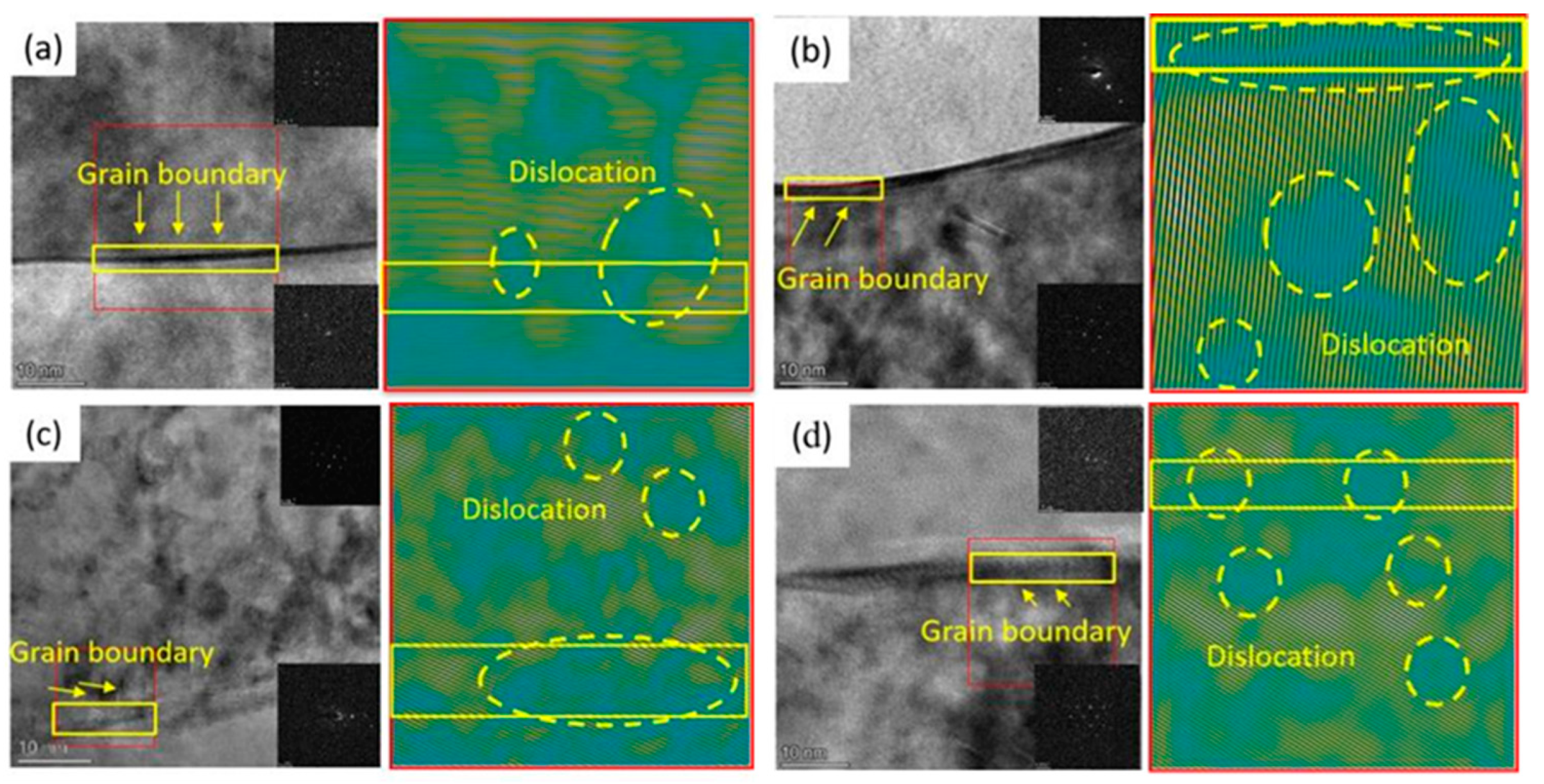

In order to further explore the mechanism of the effects of dislocations on the dynamic recrystallization of materials, the TEM morphologies of the Non-EST and EST1 samples were observed. Due to the fact that the majority of the dislocations were pinned by precipitation, the free ends of the dislocations rotated around these particles until the dislocation lines were parallel to the direction of current, at which time the dislocations received the smallest electron wind force [30].

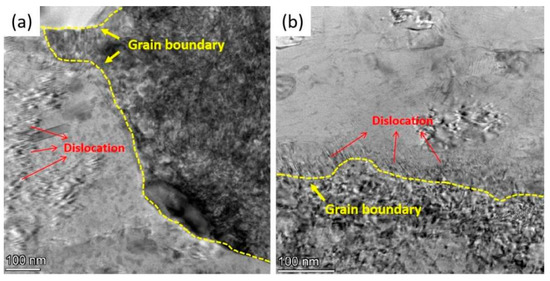

Figure 11 displays bright-field TEM images of the Non-EST and EST1 samples along the zone axis of [110]. It is obvious that the dislocations of the EST1 sample mainly gather at the grain boundaries, while a significant percentage of the dislocations of the non-EST sample gather inside the grains. This phenomenon might be caused by the fact that EST causes a significant decrease in the number and size of precipitates in Al-Zn-Mg-Cu alloy and weakens the pinning effect of dislocation. This makes it easier for dislocations to drift integrally under the influence of electron wind force, which causes dislocations to aggregate toward grain boundaries.

Figure 11.

Bright-field TEM images along the zone axis of [110] of (a) the non-EST sample and (b) the EST1 sample.

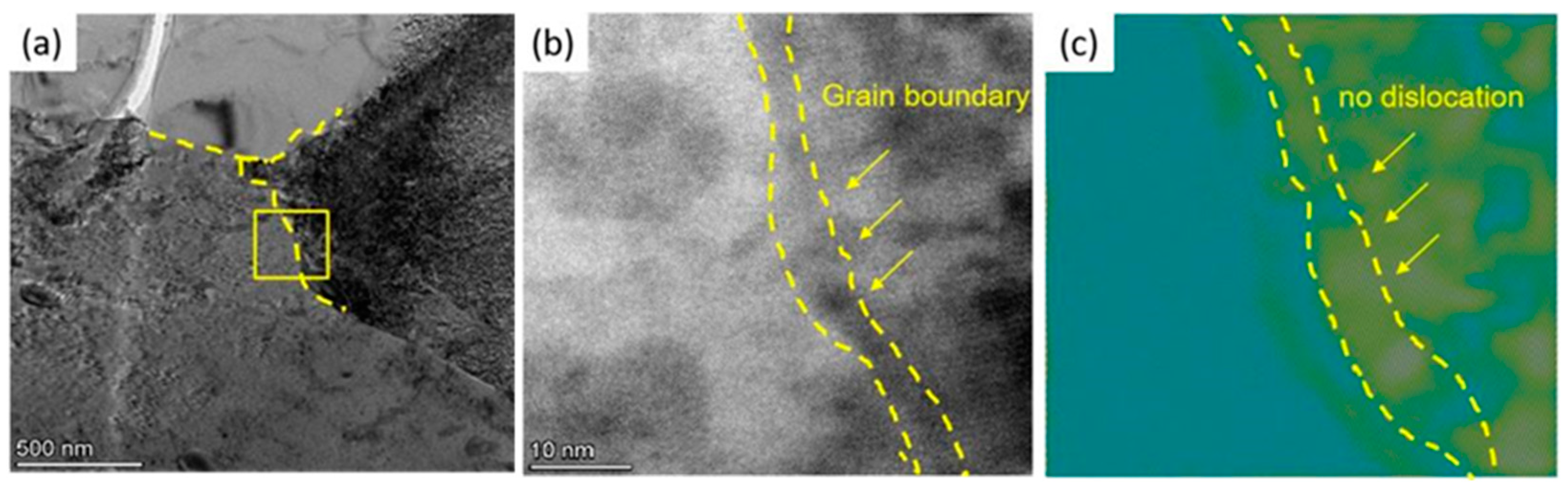

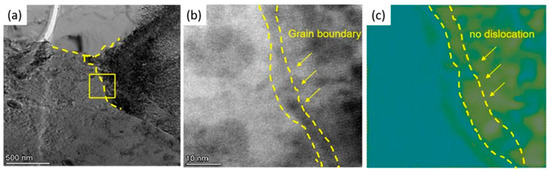

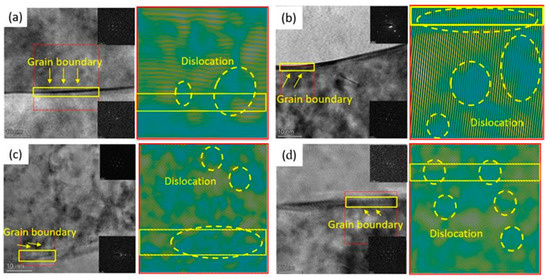

To verify the above conclusions, high-resolution TEM (HRTEM) characterization was performed on the grain boundaries of the Non-EST and EST1 samples. Figure 12a shows the TEM image of the Non-EST sample, Figure 12b shows the HRTEM image of the grain boundaries enlarged on the yellow rectangular frame in Figure 12a, and Figure 12c indicates the inverse fast Fourier transformation (IFFT) of Figure 12b. The findings demonstrate that there is no appreciable dislocation aggregation at the grain boundary of the Non-EST sample. As shown in Figure 13, HRTEM and IFFT were carried out on the grain boundaries of four separate locations of the EST1 sample. The results indicate that there were many dislocations at the grain boundaries in the four distinct areas. It was demonstrated that during electroshock-assisted deformation, the electron wind force promoted the movement of dislocations, resulting in the concentration of recrystallization energy, which then makes it more likely for the nucleation of recrystallization to occur at low temperatures. In addition, the fewer dislocations in recrystallized grains suggests that a significant amount of deformation storage energy is consumed during recrystallization growth, leading to a decrease in the dislocation density of the grain, which makes it easier for dislocations to reserve at grain boundaries.

Figure 12.

(a) TEM image of the non-EST sample; (b) HRTEM image of the grain boundaries enlarged at the yellow rectangular frame in (a); (c) IFFT of (b).

Figure 13.

HRTEM images of the grain boundaries of the EST1 sample at four locations: (a) location 1, (b) location 2, (c) location 3, and (d) location 4.

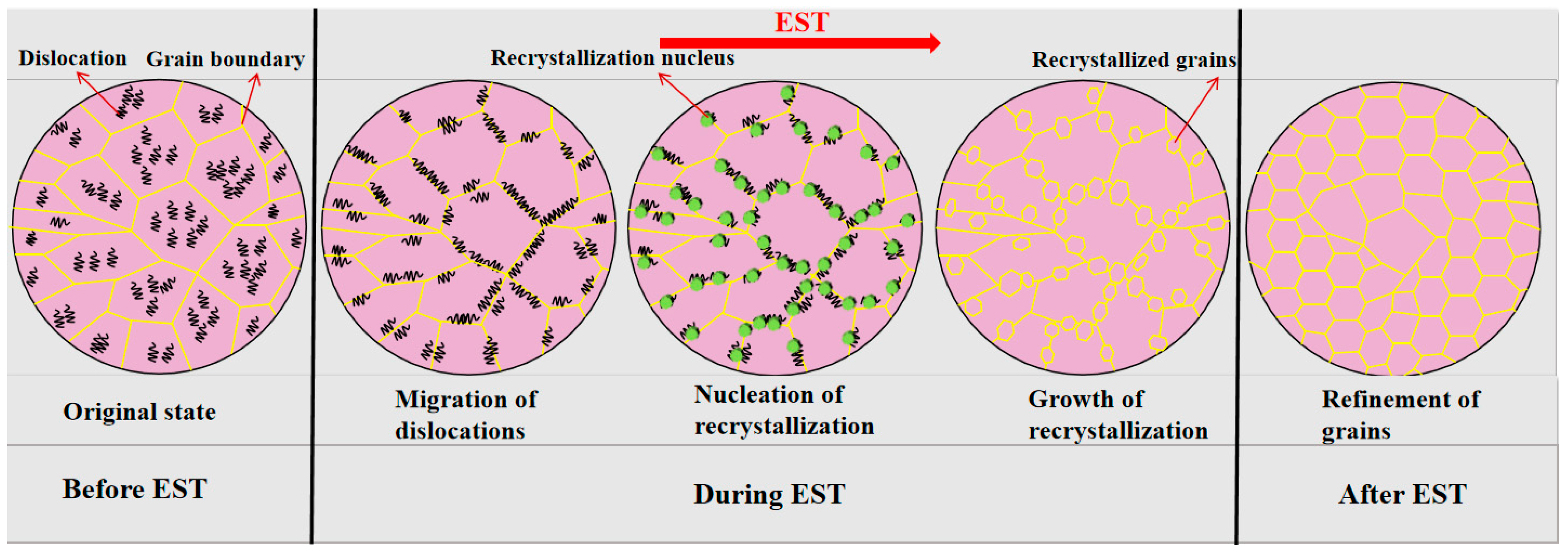

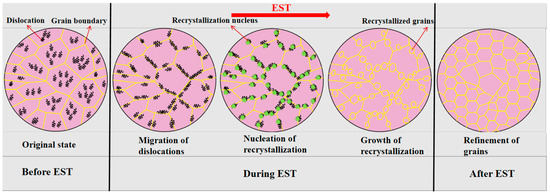

In order to more intuitively present how EST affects the recrystallization behavior of Al-Zn-Mg-Cu alloy, a schematic diagram of the microscopic mechanism is depicted in Figure 14. Dislocations were mostly observed inside the grains for materials without EST after deformation. Aluminum alloy, a high-fault energy metal, has a limited ability to undergo dynamic recrystallization. When EST is applied during the process of deformation, dislocations move from the grain interior to near the grain boundaries under the influence of electron wind force (Figure 11, Figure 12 and Figure 13). These dislocations can act as nucleation points for recrystallization in the subsequent EST. Due to the effects of EST, the critical grain nucleation size for recrystallization decreases, while the driving force for recrystallization increases (Equation (4)). Therefore, the potential for dynamic recrystallization can be increased. Furthermore, the growth rate of dynamic recrystallization can be decreased due to the effects of EST energy (Equation (5)); meanwhile, the EST action time is very short. As a result, fine recrystallized grains are formed (Figure 7).

Figure 14.

Schematic diagram of the mechanism of EST promoting recrystallization.

4. Conclusions

The effects of various EST parameters on the microstructure and mechanical properties of Al-Zn-Mg-Cu high-strength aluminum alloy during plastic deformation were studied in this study. Moreover, the underlying effect mechanism of EST on the dynamic recrystallization behavior of Al-Zn-Mg-Cu high-strength aluminum alloy was also revealed. The following are the primary conclusions:

- (1)

- The flow stress of Al-Zn-Mg-Cu alloy is greatly decreased by the effects of EST, which improves the elongation of the material. The findings demonstrate that when electroshocked with a current density of 30 A/mm2 and a period of 5 s, the elongation of the sample increased by 21.74%, and the percentage of dynamic recrystallization increased by 77.56% compared to the sample without EST.

- (2)

- After appropriate EST, the average grain size reduced from 40 μm to 30 μm, and the distribution of grain size became more uniform. The electron wind force produced by the electroshock drove the transformation of grain orientation, causing small-angle grain boundaries to gather on the grain boundaries, resulting in a finer and more uniform grain morphology. The total grain boundary angle will be larger, which is more favorable to the nucleation and growth of recrystallization.

- (3)

- Under the influence of electroshock, electron wind force promotes the movement of dislocations in Al-Zn-Mg-Cu alloy, causing the dislocations to become more concentrated at the grain boundaries, improving the ability to recrystallize at near ambient temperature, and enhancing the elongation of the alloy.

Author Contributions

Conceptualization, Y.S., J.L. and Y.W.; methodology, Y.S. and J.L.; software, J.L. and Y.W.; validation, Y.S., J.L., M.M. and C.H.; formal analysis, Y.S.; investigation, Y.S.; data curation, J.L.; writing—original draft preparation, Y.S. and Y.W.; writing—review and editing, J.L., L.X, and Y.W.; visualization, J.L. and Y.W.; supervision, Y.S., J.L. and L.X.; project administration, Y.S. and J.L.; funding acquisition, Y.S. and J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No.51975440 and No.52205410), the National Key R&D Program of China (Grant No. 2020YFA0714900), the 111 Project (Grant No. B17034), the Innovative Research Team Development Program of the Ministry of Education of China (Grant No. IRT17R83), and the Fundamental Research Funds for the Central Universities (WUT: 2022III006XZ).

Data Availability Statement

The data that support the findings of this study are available upon reasonable request from the authors.

Conflicts of Interest

We declare that we do not have any commercial or associative interests that would represent conflicts of interest in connection with the work submitted.

References

- Sun, W.; Zhu, Y.; Marceau, R.; Wang, L.; Zhang, Q.; Gao, X.; Hutchinson, C. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity. Science 2019, 363, 972–975. [Google Scholar] [CrossRef]

- Peng, X.; Liu, W.; Wu, G.; Ji, H.; Ding, W. Plastic deformation and heat treatment of Mg-Li alloys: A review. J. Mater. Sci. Technol. 2022, 99, 193–206. [Google Scholar] [CrossRef]

- Biesuz, M.; Saunders, T.; Ke, D.; Reece, M.J.; Hu, C.; Grasso, S. A review of electromagnetic processing of materials (EPM): Heating, sintering, joining and forming. J. Mater. Sci. Technol. 2021, 69, 239–272. [Google Scholar] [CrossRef]

- Zhu, Y.; To, S.; Lee, W.B.; Liu, X.; Jiang, Y.; Tang, G. Electropulsing-induced phase transformations in a Zn–Al-based alloy. J. Mater. Res. 2011, 24, 2661–2669. [Google Scholar] [CrossRef]

- Pan, D.; Wang, Y.; Guo, Q.; Zhang, D.; Xu, X.; Zhao, Y. Grain refinement of Al–Mg–Si alloy without any mechanical deformation and matrix phase transformation via cyclic electro-pulsing treatment. Mater. Sci. Eng. A 2021, 807, 140916. [Google Scholar] [CrossRef]

- Wang, S.; Sun, W.; Sun, X.; Ji, Y.; Yang, H.; Cui, X. Influence of non-thermal effect caused by pulse current on AZ31B magnesium alloy deformation. Mater. Sci. Eng. A 2023, 871, 144899. [Google Scholar] [CrossRef]

- Song, H.; Wang, Z.J.; He, X.D.; Duan, J. Self-healing of damage inside metals triggered by electropulsing stimuli. Sci. Rep. 2017, 7, 7097. [Google Scholar] [CrossRef]

- Ma, R.; Xiang, S.; Zhang, X. Repairing irreversible hydrogen–induced damages using electric current pulse. Int. J. Hydrogen Energy 2020, 45, 16909–16917. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, J.; Zhang, H.; Jin, W.; Dong, H.; Xu, B. Recrystallization and microstructure evolution of the rolled Mg–3Al–1Zn alloy strips under electropulsing treatment. J. Alloys Compd. 2015, 622, 229–235. [Google Scholar] [CrossRef]

- Park, J.-W.; Jeong, H.-J.; Jin, S.-W.; Kim, M.-J.; Lee, K.; Kim, J.J.; Hong, S.-T.; Han, H.N. Effect of electric current on recrystallization kinetics in interstitial free steel and AZ31 magnesium alloy. Mater. Charact. 2017, 133, 70–76. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, R.; Chong, Y.; Li, X.; Abu-Odeh, A.; Rothchild, E.; Chrzan, D.C.; Asta, M.; Morris, J.W., Jr.; Minor, A.M. Defect reconfiguration in a Ti-Al alloy via electroplasticity. Nat. Mater. 2021, 20, 468–472. [Google Scholar] [CrossRef]

- Li, W.; Shen, Y.; Liu, H.; Wang, Y.; Zhu, W.; Xie, C. Non-octahedral-like dislocation glides in aluminum induced by athermal effect of electric pulse. J. Mater. Res. 2016, 31, 1193–1200. [Google Scholar] [CrossRef]

- Bumgardner, C.H.; Croom, B.P.; Song, N.; Zhang, Y.; Li, X. Low energy electroplasticity in aluminum alloys. Mater. Sci. Eng. A 2020, 798, 140235. [Google Scholar] [CrossRef]

- Kim, M.-J.; Lee, K.; Oh, K.H.; Choi, I.-S.; Yu, H.-H.; Hong, S.-T.; Han, H.N. Electric current-induced annealing during uniaxial tension of aluminum alloy. Scr. Mater. 2014, 75, 58–61. [Google Scholar] [CrossRef]

- Liang, P.; Lin, K.-L. Non-deformation recrystallization of metal with electric current stressing. J. Alloys Compd. 2017, 722, 690–697. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Xu, X.; Pan, D.; Jiang, W.; Chong, X. Simultaneously Enhanced Strength and Ductility of Al-Mg-Si Alloys during Aging Process Induced by Electro-Pulsing Treatment. Materials 2019, 12, 1383. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.-L.; Lin, K.-L. The microstructure and property variations of metals induced by electric current treatment: A review. Mater. Charact. 2018, 145, 545–555. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Yu, Y.; Wu, W.; Wang, Z.; Lu, J.; Sun, Q.; Xie, L.; Hua, L. Fatigue life improvement of TC11 titanium alloy by novel electroshock treatment. Mater. Des. 2022, 221, 110902. [Google Scholar] [CrossRef]

- Liu, C.; Yin, F.; Xie, L.; Qian, D.; Song, Y.; Wu, W.; Wang, L.; Zhang, L.-C.; Hua, L. Evolution of grain boundary and texture in TC11 titanium alloy under electroshock treatment. J. Alloys Compd. 2022, 904, 163969. [Google Scholar] [CrossRef]

- Wu, W.; Song, Y.; Lu, J.; Yu, Y.; Hua, L. Novel strategy of electroshock treatment for improving mechanical performances of Al–Zn–Mg–Cu alloy by edge dislocation increment. Mater. Sci. Eng. A 2022, 854, 143805. [Google Scholar] [CrossRef]

- Guan, L.; Tang, G.; Chu, P.K.; Jiang, Y. Enhancement of ductility in Mg–3Al–1Zn alloy with tilted basal texture by electropulsing. J. Mater. Res. 2011, 24, 3674–3679. [Google Scholar] [CrossRef]

- Mei, M.; Song, Y.; Lu, J.; Chuanchuan, H.; Lechun, X. Modeling dynamic recrystallization behavior of Al-Zn-Mg-Cu alloy during electroshock assisted tension based on cellular automata. Mater. Res. Express 2022, 9, 036513. [Google Scholar] [CrossRef]

- Barrett, C.D.; Imandoust, A.; Oppedal, A.L.; Inal, K.; Tschopp, M.A.; El Kadiri, H. Effect of grain boundaries on texture formation during dynamic recrystallization of magnesium alloys. Acta Mater. 2017, 128, 270–283. [Google Scholar] [CrossRef]

- Lu, J.; Song, Y.; Hua, L.; Zheng, K.; Dai, D. Thermal deformation behavior and processing maps of 7075 aluminum alloy sheet based on isothermal uniaxial tensile tests. J. Alloys Compd. 2018, 767, 856–869. [Google Scholar] [CrossRef]

- Kravchenko, V.Y. Effect of directed electron beam on moving dislocations. Sov. Phys. Dokl. 1975, 18, 787–788. [Google Scholar]

- Klimov, K.M.; Shnyrev, G.D.; Novikov, I.I. Electroplasticity of metals. Dokl. Akad. Nauk. SSSR 1974, 19, 787–788. [Google Scholar]

- Roshchupkin, A.M.; Miloshenko, V.E.; Kalinin, V.E. Electron drag of dislocations in metals. Fiz. Tverd. Tela 1979, 21, 532. [Google Scholar]

- Song, H.; Wang, Z. Grain refinement by means of phase transformation and recrystallization induced by electropulsing. Trans. Nonferrous Met. Soc. China 2011, 21, s353–s357. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, X.; Weng, Y. Effects of electric current pulse on the dynamics of dynamic recrystallization in 2091 Al-Li alloy. Chin. J. Mater. Res. 2001, 15, 358–366. (In Chinese) [Google Scholar]

- Han, K.; Qin, S.; Li, H.; Liu, J.; Wang, Y.; Zhang, C.; Zhang, P.; Zhang, S.; Zhang, H.; Zhou, H. EBSD study of the effect of electropulsing treatment on the microstructure evolution in a typical cold-deformed Ni-based superalloy. Mater. Charact. 2019, 158, 109936. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).