Abstract

Isothermal oxidation kinetics of a fourth-generation powder metallurgy FGH4108 nickel-based superalloy is investigated at 800 °C to 1100 °C by X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy dispersive X-ray spectroscopy (EDS). At 800 °C and 900 °C, the oxidation kinetic curves of the FGH4108 superalloy follow parabolic law. At 1000 °C, the oxidation kinetic curve follows cubic law. At 1100 °C, the oxidation kinetic curve has two distinct parts: the first part follows a parabolic law, and the second one obeys a linear law. Cross-sectional morphologies and elemental distributions show that the oxide film consists of two parts at 800 °C: the outer layer is a continuous dense protective Cr2O3 oxide film, and the inner layer is a discontinuous Al2O3 oxide layer. At 900–1100 °C, the oxides consist of three layers: the outermost is the oxides of Cr2O3 and TiO2, the middle is a continuous oxide of Al2O3, and the innermost is dotted oxides of TiO2. The thickness of the inner TiO2 oxide layer increases with the increase of oxidation temperature. On this basis, the oxidation behavior of the FGH4108 superalloy at high temperatures is confirmed to be controlled by the diffusion of Cr, Al, Ti, and O. From the aspect of oxidation resistance, the long-term service temperature of the FGH4108 superalloy should not exceed 1000 °C.

1. Introduction

The term superalloy refers to Ni, Fe, or Co-based materials that can work continuously for a long time under high temperatures and complex stresses and are widely used in the preparation of hot end components of aero engines and gas turbines [1,2,3,4,5]. As the aerospace industry develops, the operating temperatures of aero engines are becoming higher and higher to achieve a higher thrust-to-weight ratio and higher fuel utilization efficiency [6,7,8]. With the aim of improving the properties of the alloy, the type and content of strengthening elements in the matrix are increasing, which leads to deformation resistance and severe segregation in the process of forging and casting [9,10,11]. However, the powder superalloy has good machinability because component segregation occurs only within the particle size of the metal powder [12,13]. The powder superalloy has a uniform fine microstructure and exhibits excellent strength, fatigue properties and surface stability at high temperatures [14,15,16]. Therefore, powder metallurgy nickel-based superalloys have received increasing attention as aerospace engine materials with excellent mechanical properties and corrosion resistance for manufacturing high-performance turbine disks [17,18].

It is well known that oxidation resistance is one of the most important aspects of nickel-based superalloys since poor oxidation resistance hinders their possible applications at high temperatures [12]. The oxidation behaviors of advanced nickel-based superalloys at temperatures higher than 700 °C have been studied extensively [19,20,21,22]. Brenneman et al. [19] studied the oxidation behavior of GTD111 superalloy at 900 °C in air and concluded that the oxidation resistance was provided by the continuous dense Cr2O3 oxide band, rather than the discontinuous Al2O3 oxide layer. Liu et al. [23] studied the oxidation behavior of single-crystal nickel-based superalloy DD32 in air at 900 °C and 1000 °C and found that two oxidation steps appeared in the oxidation kinetics, which were controlled by NiO growth and Al2O3 growth, respectively. Berthod et al. [20] studied the oxidation behavior of six (Co + Ni)-based Cr-rich alloys with different Co/Ni ratios at 1250 °C and concluded that the higher the Ni content, the better the oxidation resistance of the alloys. Moffat et al. [21] studied the oxidation behavior of a carbide network in low or high carbon Co-based superalloys at 1000 °C. They concluded that the carbide in low carbon alloys is more soluble than that in high carbon alloys, thus reducing the continuity of the carbide network and ultimately leading to an increase in the thickness of the oxide layer. Xiao et al. [24] studied the cyclic oxidation behavior of Pt-modified γ’ nanocrystalline coating at 1150 °C and confirmed that the nanocrystalline structure promoted the formation of α-Al2O3 oxide coating with lower Pt and Al contents, which improved the anti-spalling performance. As a fourth-generation powder metallurgy nickel-based superalloy, FGH4108 is highly alloyed and reinforced by γ’ precipitation with a mass fraction of about 60%. Therefore, it can work under harsh conditions of temperature and load. However, its oxidation behavior needs to be studied in detail.

In this paper, the high-temperature oxidation behavior and kinetics of FGH4108 superalloy at different temperatures are investigated by isothermal oxidation tests. The oxidation mechanism is analyzed to provide a general understanding for further improvement and better utilization of the FGH4108 superalloy.

2. Materials and Methods

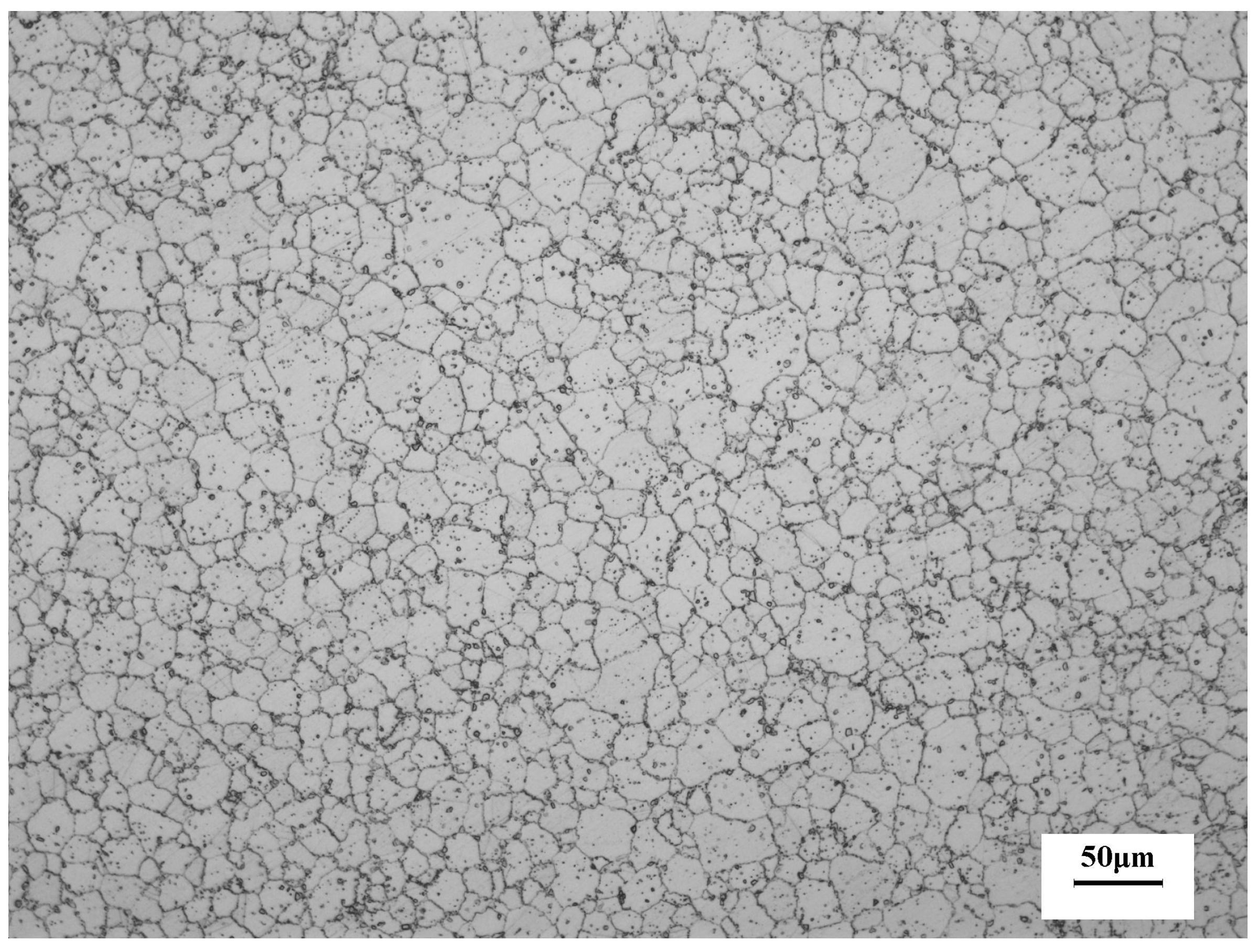

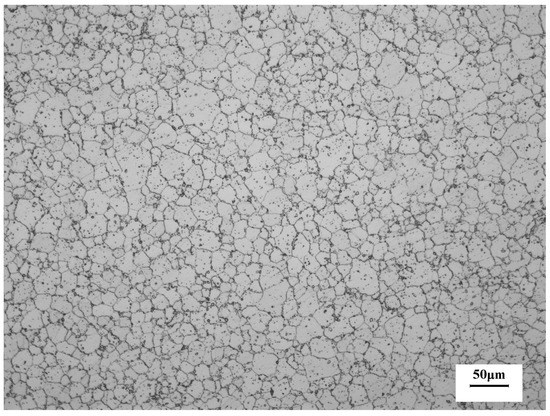

The composition of the FGH4108 superalloy is shown in Table 1. FGH4108 alloy was prepared by vacuum induction-melting gas atomization (VIGA) + hot isostatic pressing (HIP) + hot extrusion + forging + heat treatment. The relative density of the alloy was determined by the Archimedean drainage method to be 100%. The microstructure and crystallography of the alloy were investigated through optical microscopy (OM). Figure 1 shows the typical microstructure of the alloy. The grain size grade was estimated to be ASTM E112 class 6–7 using OM image processing software, ImageJ 1.52t.

Table 1.

Chemical compositions of FGH4108 superalloy (wt%).

Figure 1.

Typical microstructure of the alloy.

The specimens were wire cut into 15 × 10 × 5 mm3 sized oxidation test specimens, and their surfaces were sandpapered to 1000 #, ultrasonically cleaned, and then dried and set aside. Before oxidation, the specimens were weighed by an electronic balance with an accuracy of 0.1 mg. The high temperature oxidation resistance was tested by the weight gain at 800 °C, 900 °C, 1000 °C, and 1100 °C in ambient conditions. The oxidation times were set as 1 h, 3 h, 5 h, 10 h, 25 h, 50 h, 75 h, and 100 h. After oxidation, the specimen was air-cooled to room temperature and weighed by the electronic balance again. The surface morphologies of the oxidation products were detected by scanning electron microscopy (SEM), and the phase constitutions were analyzed by X-ray diffraction (XRD). The XRD data was processed by the Jade 6.5 software, and the Inorganics database of the software was used. The cross section of the oxidized specimen was observed by SEM to explore the morphology of the oxidation products. The samples for the observation cross section were mechanically polished with 60 #, 150 #, 800 #, to 2000 # SiC sandpaper in turn. Energy dispersive X-ray spectroscopy (EDS) was applied to study the elemental distribution of the oxidation product films. Without a particular explanation, the results in the figures and tables in this paper all represent the average data of three samples under specific experimental conditions.

3. Results and Discussion

3.1. Oxidation Kinetics

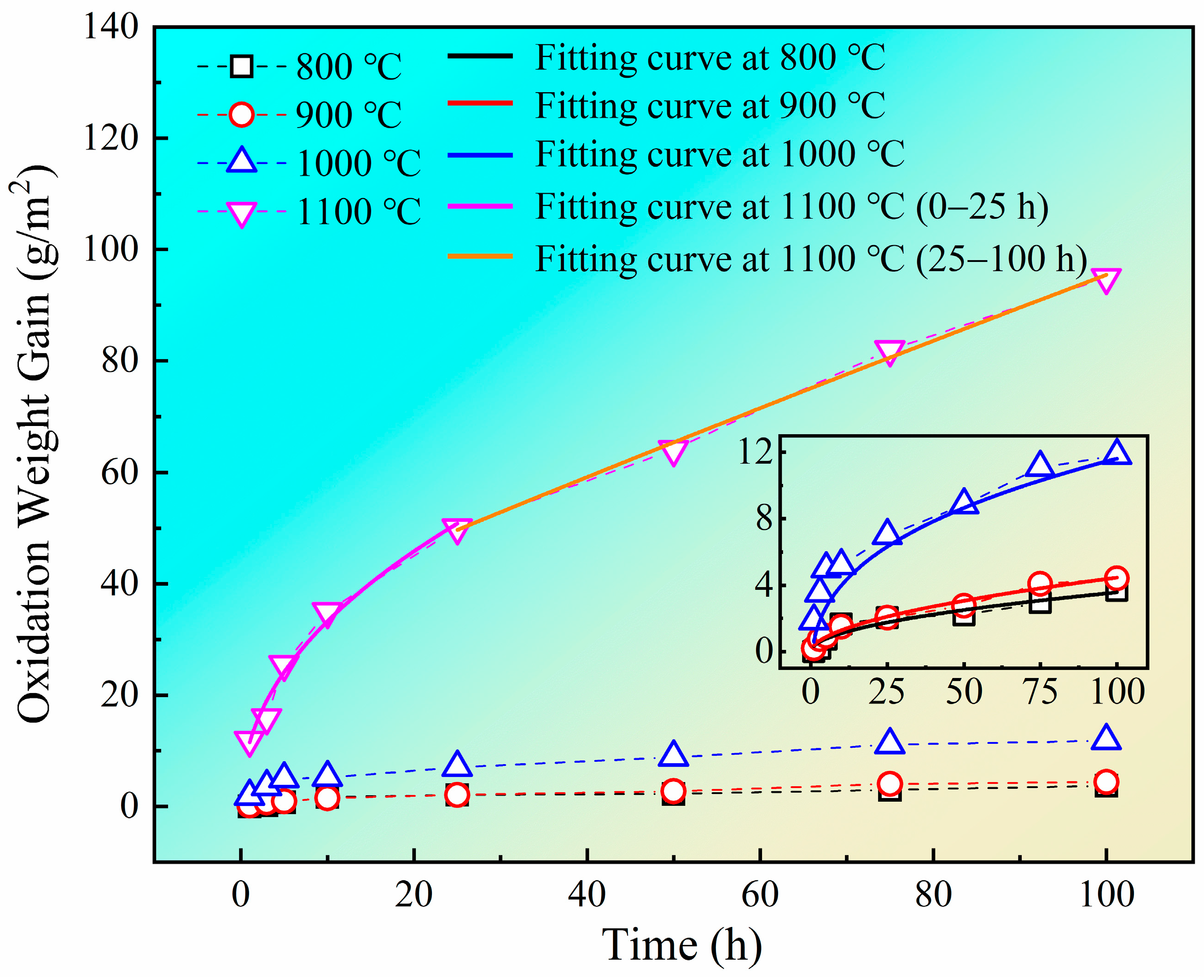

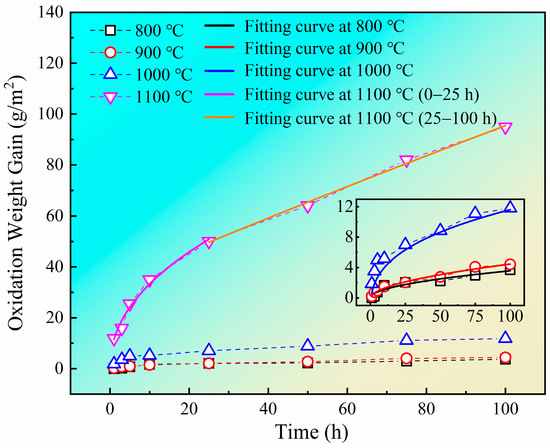

Figure 2 shows the kinetic curves of the FGH4108 alloy after 100 h of oxidation at 800 °C, 900 °C, 1000 °C, and 1100 °C. It can be seen that the weight gain increases as the temperature rises and the time increases. After 100 h oxidation, the oxidation weight gains are 3.69 g/m2, 4.41 g/m2, 11.82 g/m2, and 94.97 g/m2 at 800 °C, 900 °C, 1000 °C, and 1100 °C, respectively.

Figure 2.

Oxidation kinetic curves and fitting curves at 800 °C to 1100 °C for 100 h.

It is known that the mass gain of nickel-based superalloy during oxidation can be described by the Wanger formula [2,25,26]

where is the oxidation weight gain, S is the surface area of the specimen, k is a constant related to the oxidation rate, t is the oxidation time, and n is the oxidation rate index. Fitting equations for each temperature are shown in Table 2 and Figure 1. It can be seen that the oxidation rate of the FGH4108 alloy is mainly temperature dependent. With the increase in temperature, the n decreases, while the oxidation rate constant k increases by one order of magnitude. At 800–900 °C, FGH4108 alloy has good oxidation resistance, and the oxidation kinetic curves follow the parabolic law. At 1000 °C, oxidation gain increases and nearly follows cubic law. At 1100 °C, oxidation gain increases significantly, and the alloy has poor oxidation resistance. Besides, the oxidation kinetic curve can be divided into two parts; the pre-oxidation period follows the parabolic law but gradually changes to the linear law with increased oxidation time. It can be seen from Table 2 that with the increase of oxidation temperature, the value of k gradually increases, indicating that the degree of oxidation increases, especially when the temperature reaches 1100 °C; so, the parabolic rule is lost.

Table 2.

Fitting equations for each temperature.

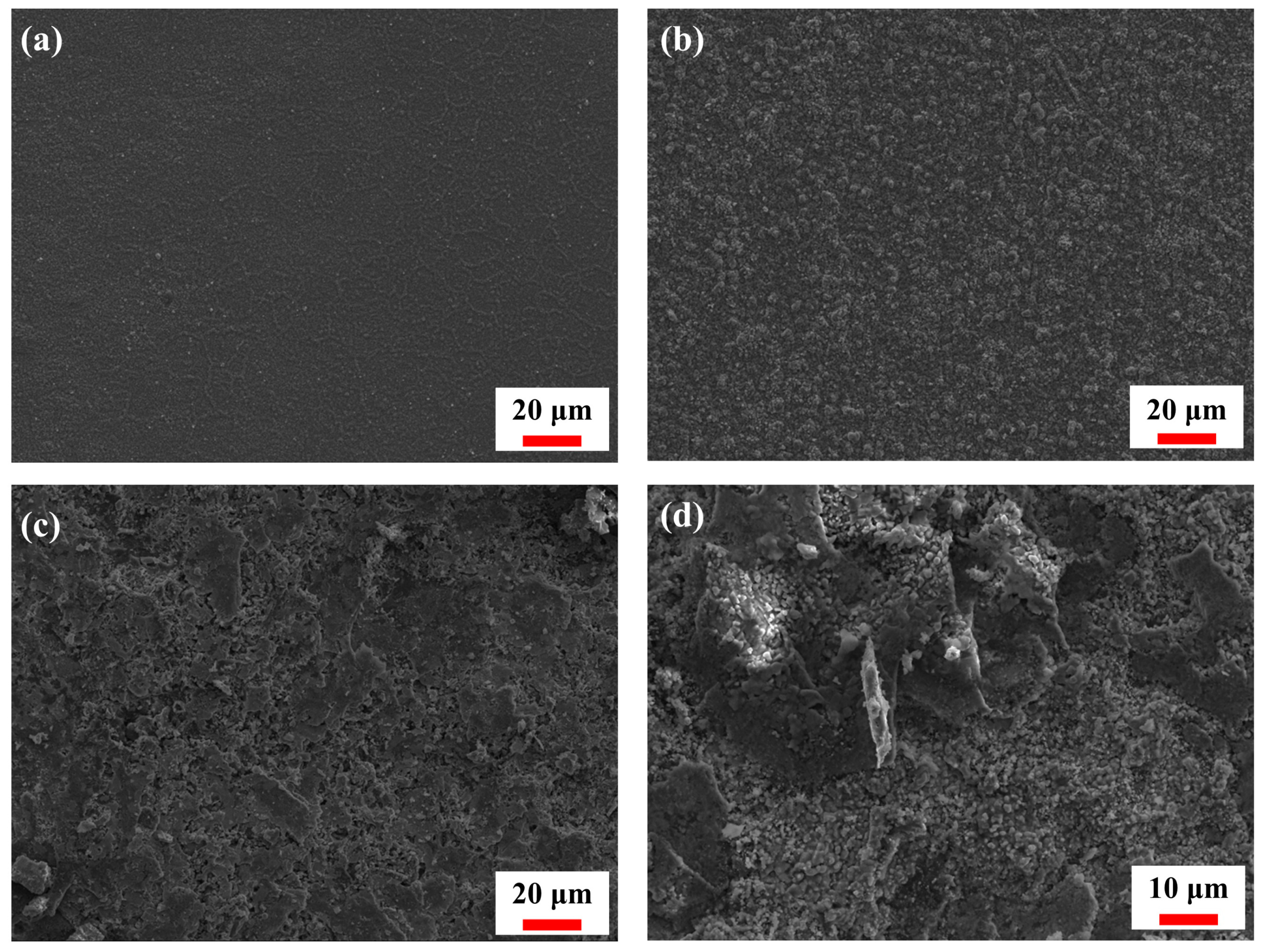

3.2. Surface Morphology and Phase Composition of the Oxide Layer

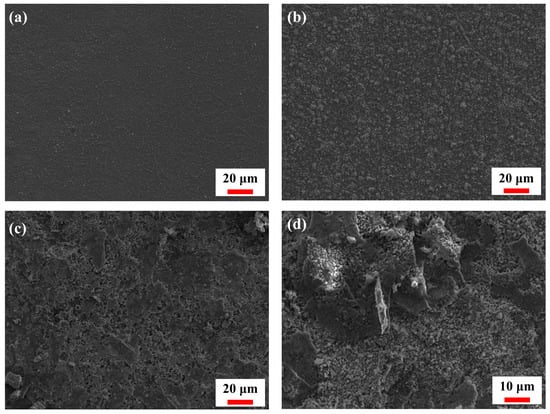

Figure 3 displays the surface morphologies after oxidation for 100 h. It can be seen from Figure 3a that the alloy is oxidized slightly at 800 °C, and only a small amount of oxides is observed at the surface. Figure 3b exhibits that after oxidation at 900 °C for 100 h, the oxide film starts to bulge, but no crack is found. Figure 3c indicates that after 1000 °C, the oxide film is relatively loose and poorly bonded to the substrate due to lateral growth or wrinkling. Besides, a small amount of spalling occurs during cooling, revealing surface holes and grain boundary grooves. Figure 3d shows that significant flaking occurs after oxidation at 1100 °C and the oxidation resistance greatly reduces.

Figure 3.

Surface morphologies after oxidation for time of 100 h at temperatures of (a) 800 °C, (b) 900 °C, (c) 1000 °C, and (d) 1100 °C.

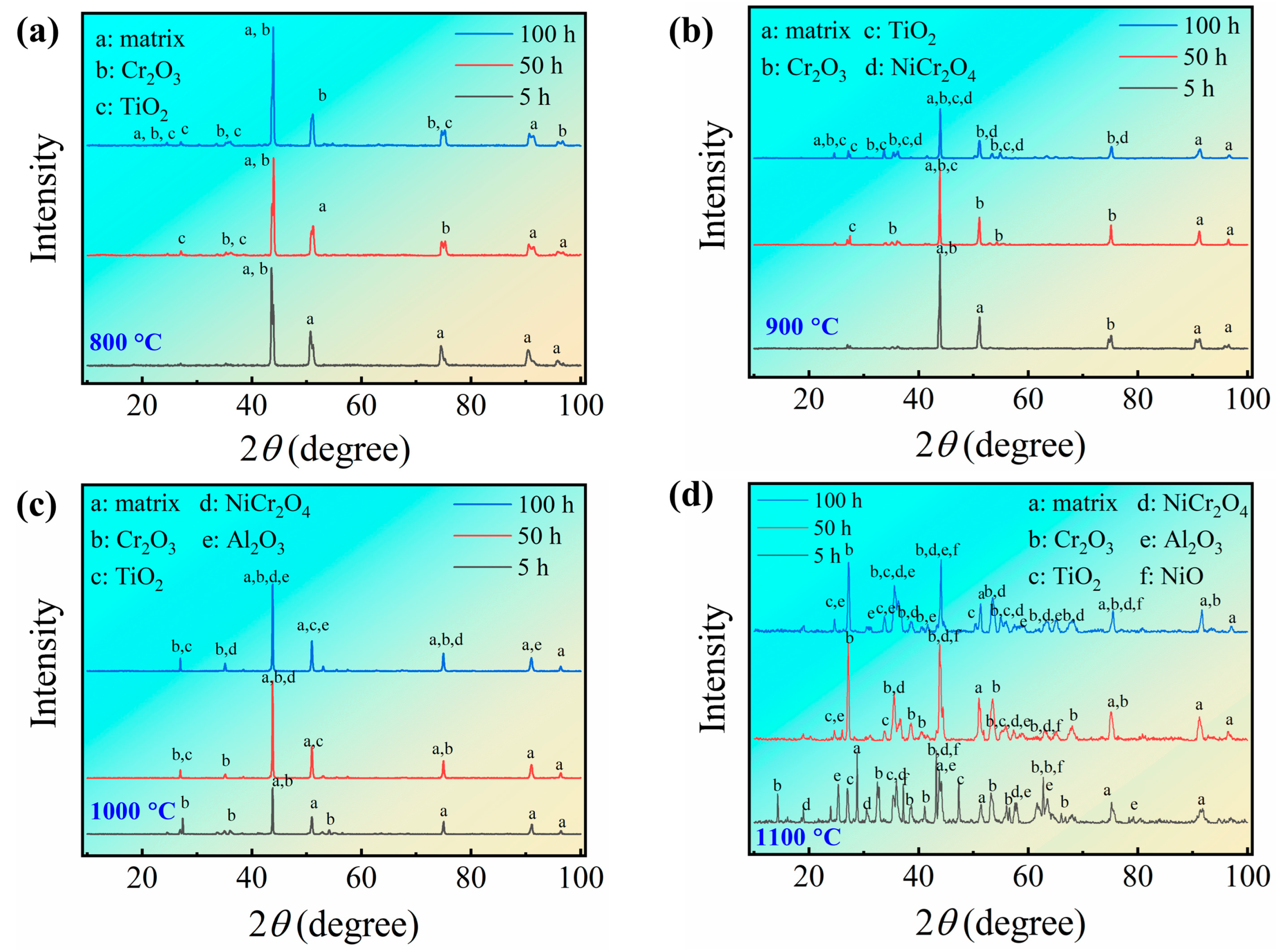

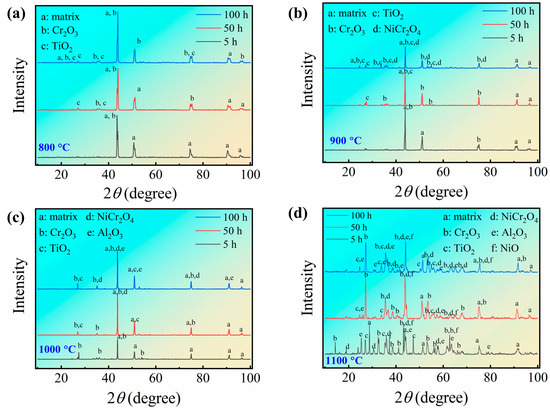

Figure 4 displays XRD analyses after oxidation for 5 h, 50 h, and 100 h. It can be seen from Figure 4a that only Cr2O3 can be identified after oxidation at 800 °C for 5 h, and a small amount of Cr2O3 emerges for 50 h while both TiO2 and Cr2O3 appear for 100 h. Figure 4b exhibits that only Cr2O3 can be identified after oxidation at 900 °C for 5 h, which is the same as that at 800 °C. After oxidation for 50 h, a small amount of Cr2O3 also emerges, and TiO2 can be identified. After oxidation for 100 h, a small amount of NiCr2O4 appears besides Cr2O3 and TiO2. Figure 4c indicates that TiO2 can be detected evidently after oxidation at 1000 °C for 5 h. When the oxidation time extends to 50 h, TiO2 appears in addition to Cr2O3. After oxidation for 100 h, Al2O3 and NiCr2O4 exist, as well as Cr2O3 and TiO2. Figure 4d shows that many oxidation products (TiO2, Cr2O3, Al2O3, NiO, and NiCr2O4) emerge at 1100 °C even for 5 h. As the oxidation time extends, the amounts of all oxides increase while their species remain unchanged.

Figure 4.

XRD analyses after oxidation for times of 5 h, 50 h, and 100 h at temperatures of (a) 800 °C, (b) 900 °C, (c) 1000 °C, and (d) 1100 °C.

3.3. Cross-Sectional Analysis of the Oxide Layer

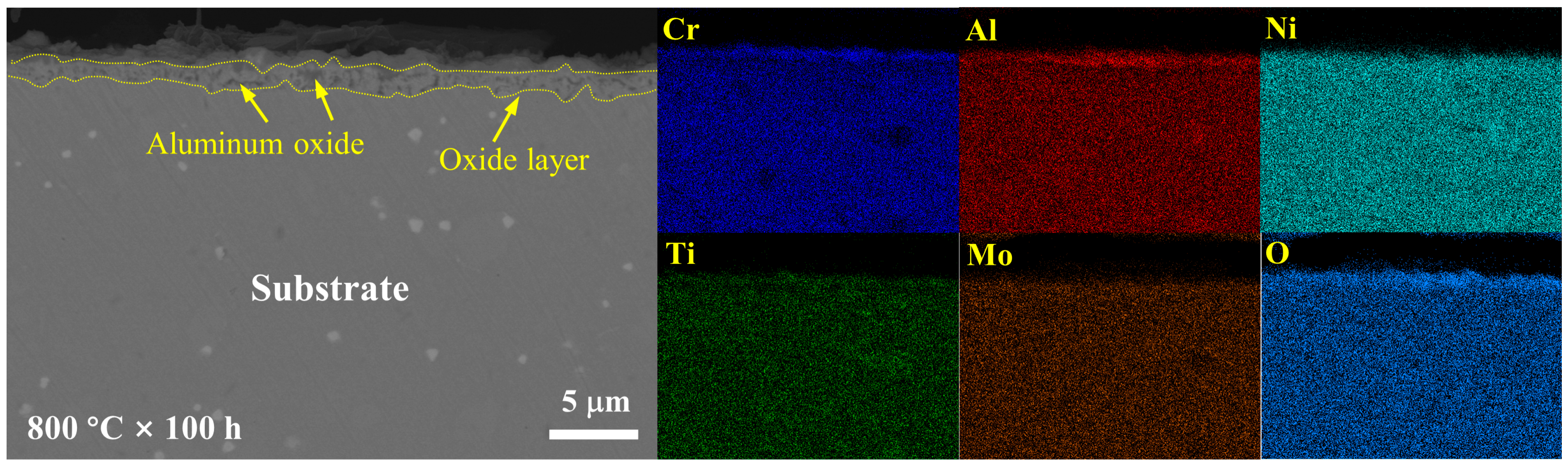

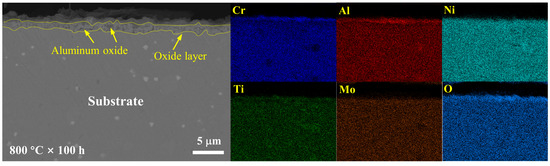

Figure 5 demonstrates the cross-sectional morphology and elemental distribution of the oxide layer after oxidation at 800 °C for 100 h. It can be seen that the oxide layer can be divided into two layers. The outermost layer is enriched in Cr due to a continuous dense protective Cr2O3 oxide film. The inner layer forms a black oxide of Al near the substrate as a discontinuous Al2O3 oxide film.

Figure 5.

Cross-sectional morphology and elemental distribution after oxidation at 800 °C for 100 h.

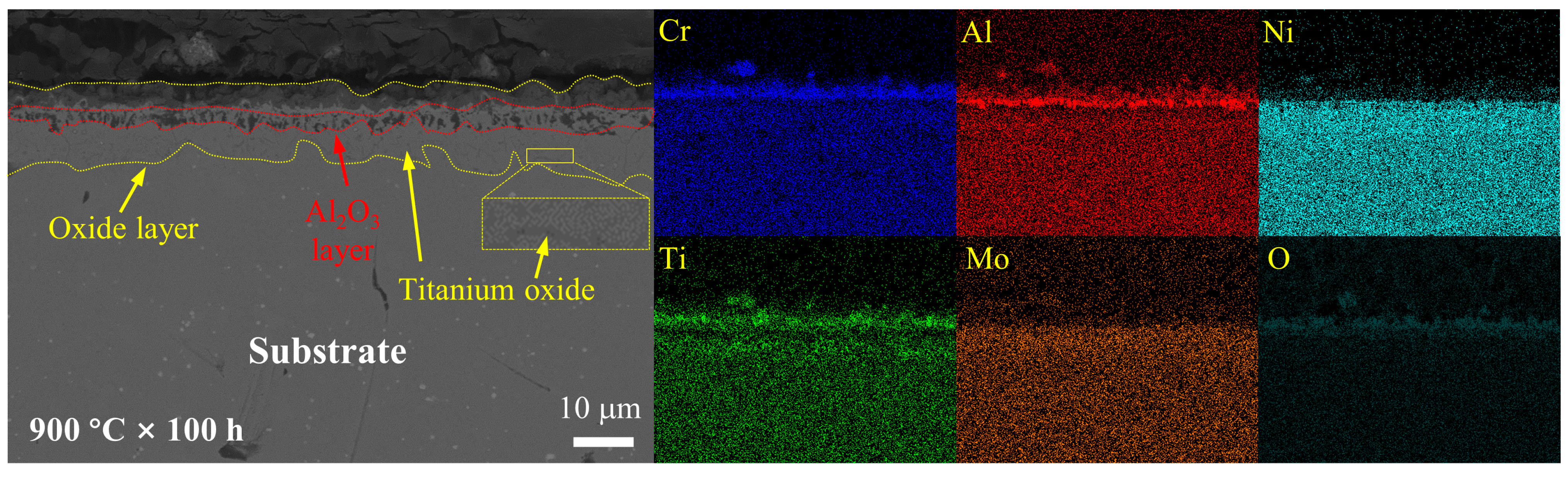

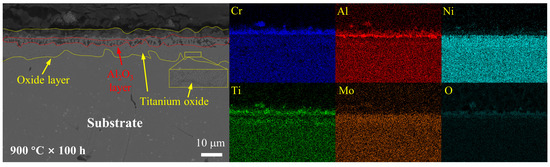

Figure 6 shows the cross-sectional morphology and elemental distribution of the oxide layer after oxidation at 900 °C for 100 h. It is seen that the oxide layer is composed of three parts. The outermost layer forms a continuous layer of dense Cr2O3 oxide with TiO2 present, i.e., a mixed layer of Cr2O3 and TiO2 oxide film. The middle layer is a continuous layer of Al2O3 oxide. The innermost layer is a dotted layer of uniformly distributed TiO2.

Figure 6.

Cross-sectional morphology and elemental distribution after oxidation at 900 °C for 100 h.

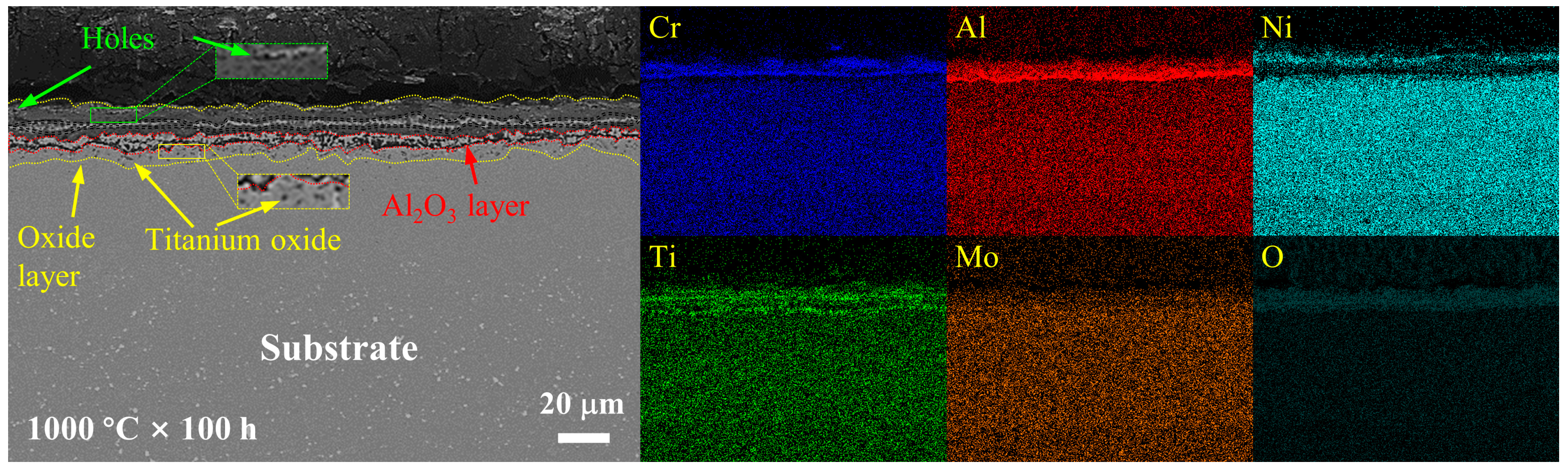

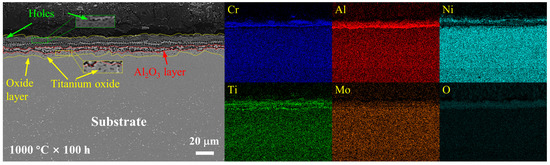

Figure 7 illustrates the cross-sectional morphology and elemental distribution of the oxide layer after oxidation at 1000 °C for 100 h. It is evident that the oxide layer also includes three parts. The outermost layer is enriched with Cr, Ti, and Ni owing to a mixed layer of loose Cr2O3, TiO2, and spinel oxide NiCr2O4 film. Many holes form in the oxide film, and the oxides appear to flake off. The middle layer is a continuous layer of Al2O3 oxide. The innermost layer is a dotted, uniformly distributed layer of TiO2.

Figure 7.

Cross-sectional morphology and elemental distribution after oxidation at 1000 °C for 100 h.

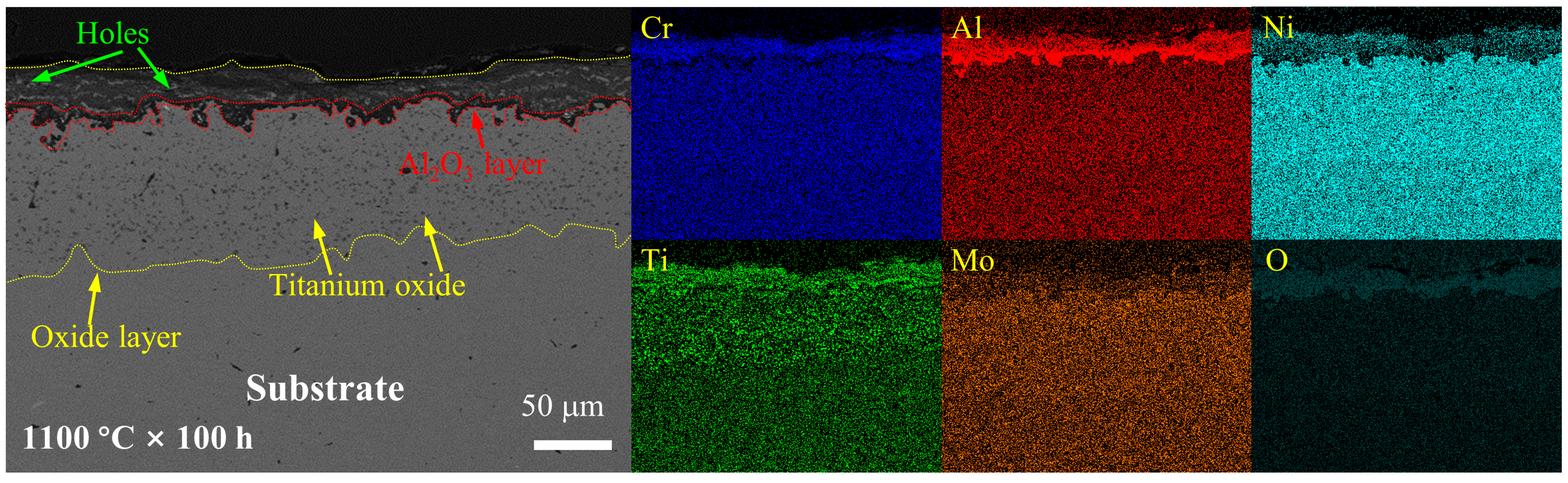

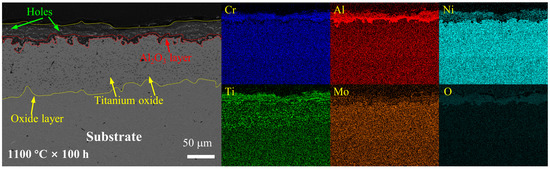

Figure 8 shows the cross-sectional morphology and elemental distribution of the oxide layer after oxidation at 1100 °C for 100 h. It is seen that the oxide layer still includes three parts. The outermost layer is enriched with Cr and Ti and is loose and porous. The Cr2O3 oxide film continues to form and flakes off. The middle layer is a continuous Al2O3 oxide with varying thicknesses at different locations. The innermost layer is a layer of TiO2 oxide uniformly distributed in the shape of spots.

Figure 8.

Cross-sectional morphology and elemental distribution after oxidation at 1100 °C for 100 h.

3.4. Oxidation Mechanism

3.4.1. Oxidation Kinetics

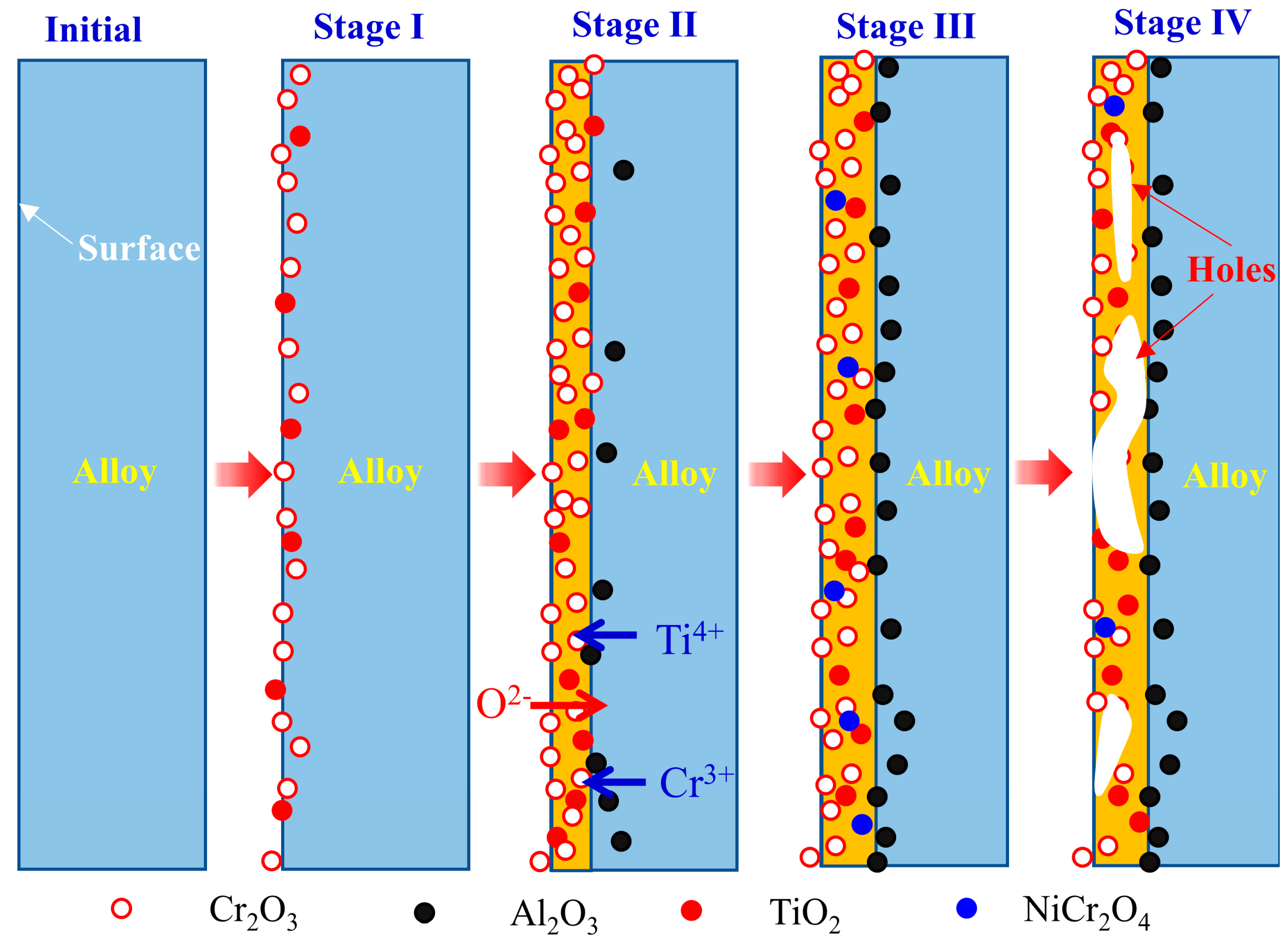

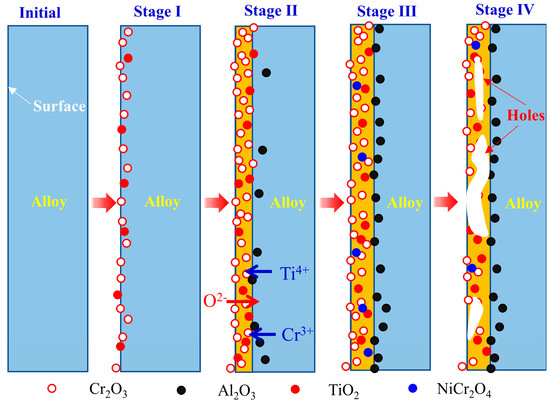

According to the oxidation kinetics, together with surface morphology and phase composition, the oxidation process can be separated into four stages (see Figure 9).

Figure 9.

Diagram of the oxidation process.

At Stage I, oxygen molecules in the air are physically adsorbed on the surface of the alloy due to van der Waals forces, followed by the decomposition of the oxygen molecules and the chemisorption of free electrons in the alloy [14]. Afterwards, the alloying elements on the surface react with O, and the oxide starts to nucleate. Due to the easy diffusion of alloying elements through grain boundaries, grain boundaries provide a favorable location for the nucleation and growth of the oxide. Notably, Ti reacts more readily with O than Cr to form oxides thermodynamically, but Cr2O3 oxide appears earlier than TiO2 (see Figure 4). Actually, the Cr content in the alloy is much higher than that of Ti. As a result, the oxide detected first is Cr2O3. Subsequently, a mixed layer of Cr2O3 and TiO2 oxide films comes into being. The oxide film produced at this stage is not dense.

At Stage II, Ti and Cr in the matrix continue to diffuse towards the outer oxide film. Simultaneously, O diffuses inwards, and the oxidation reactions continue to occur, forming a continuous dense oxide film. Due to the Cr depletion in this region, internal oxidation of Al in the alloy begins to occur.

At Stage III, the oxide film grows further inwards, which increases the thickness of the film and makes the Ti and Cr outward diffusion more difficult. At this moment, Al oxidation proceeds, and a continuous layer of Al2O3 oxide in the inner layer generates. At the same time, Ni reacts with O to produce an unstable NiO oxide. Afterwards, NiO reacts with Cr2O3 to produce NiCr2O4. This hinders the occurrence of internal oxidation due to the more protective NiCr2O4. Accordingly, a dense oxide film forms. As the reaction progresses, holes are created in the oxide layer and at the interface due to the Kirkendall effect. As the holes are created, the oxide film becomes less dense, and O continues to diffuse through the holes into the inner layer of the substrate. Consequently, the depletion of Cr and Al occurs near the substrate due to the creation of a continuous Cr2O3 outer oxide layer and Al2O3 inner oxide. Besides, Ti reacts with O in the innermost layer to create a dotted TiO2 oxide. Therefore, this oxide is not protective since it is distributed discontinuously and thus cannot block the diffusion of O. At this stage, the oxide layer can be clarified. The outermost layer forms a continuous dense mixed layer of Cr2O3 and TiO2 oxide with NiCr2O4 spinel oxide. The middle layer forms a continuous layer of Al2O3 internal oxide. The innermost layer forms a discontinuously dotted layer of TiO2 oxide.

At Stage IV, the oxide flakes off and regrows. When the dense oxide film breaks down due to a large difference in expansion coefficient, the substrate is exposed to the air and continues to oxidize [27,28,29]. In this case, a new oxide film appears and hinders further oxidation until the oxide flakes off again. On this basis, oxidation is an iterative process of growth-flaking-regrowth-flaking of the oxide film.

3.4.2. Selective Oxidation

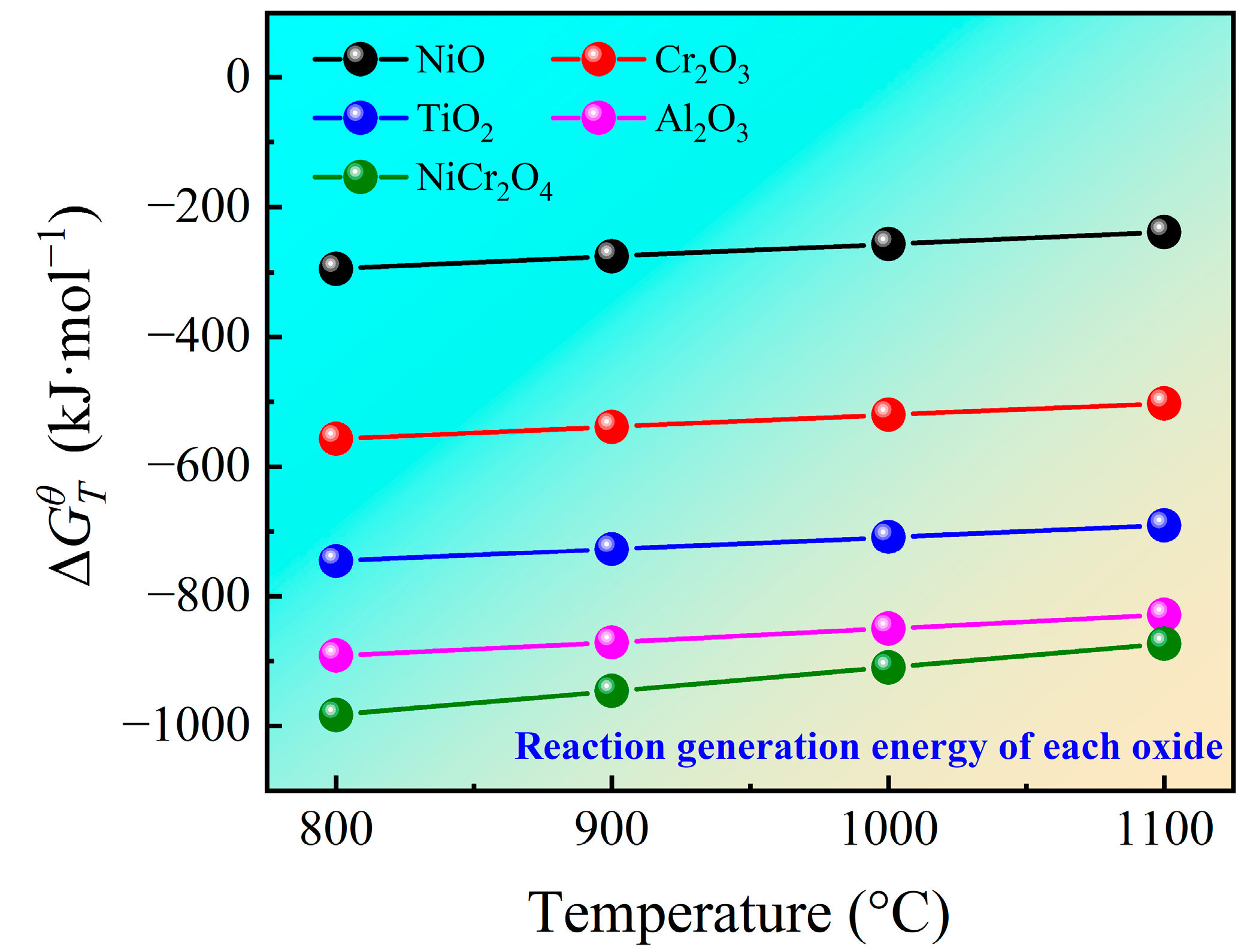

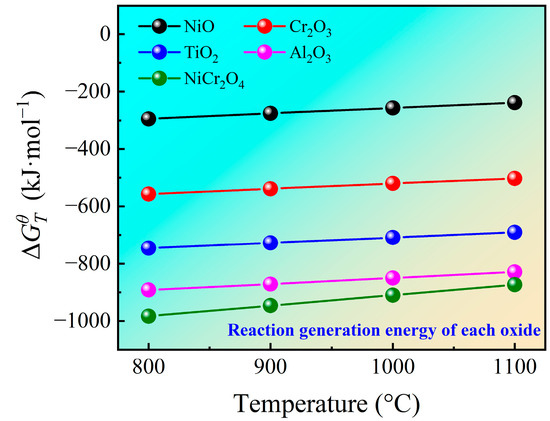

Figure 4 confirms that at a temperature range of 800 °C to 1100 °C, the oxides include Cr2O3, TiO2, Al2O3, and NiCr2O4, which aligns with the reported results [30,31,32]. For the oxidation of metals [13,33], the Ellingham diagram is widely used to calculate the free energy, , and describe the oxide species thermodynamically [14,34,35,36,37]. As a function of temperature, , , , and are expressed by [13,14,36,37] as

in which T denotes the temperature (K). NiCr2O4 is formed from NiO and Cr2O3 according to the following reaction.

In terms of Equations (2)–(6), the free energies of the above five oxides at 800 °C to 1100 °C are calculated and shown in Figure 10. It is clear that all calculated values of the free energies are negative, indicating that all these alloying elements are likely to undergo oxidation reactions to form the corresponding oxides. Moreover, NiCr2O4 is formed from NiO and Cr2O3 spontaneously.

Figure 10.

Calculated free energies of the oxides.

It is notable from Figure 10 that Al has the highest affinity to O among the alloying elements in FGH4108, and Al2O3 is the stablest oxide. However, Figure 4 demonstrates that Cr2O3 appears first. This is because the Ellingham diagram only illustrates the magnitude of the affinity of the different alloying elements for oxygen, but the type of oxides that emerge is also influenced by the elemental content factor. Although Cr2O3 is not as stable as Al2O3, the content of Cr in the alloy (12.24 wt%) is much higher than that of Al (2.96 wt%). As a result, Cr2O3 appears firstly by selective oxidation.

In addition, Al2O3 is a typical n-structured oxide, and the n-structured oxide film contains anionic vacancies and excess electrons [38]. This oxide relies on the inward diffusion of O2− to the Al and the bonding reaction at the oxide film–substrate interface [39]. Hence, the Al2O3 oxide layer in the inner layer of the oxide film is observed by the cross-sectional analysis. Furthermore, the selective oxidation of the alloy is controlled by the diffusion of the elements, and Al diffuses much more slowly in the oxide film than Cr and Ti. This causes the presence of the Al2O3 oxide layer in the inner layer. Consequently, Cr and Ti diffuse to the outer layer to react first with O to form oxides, whereas Al oxidation occurs mainly in the inner layer.

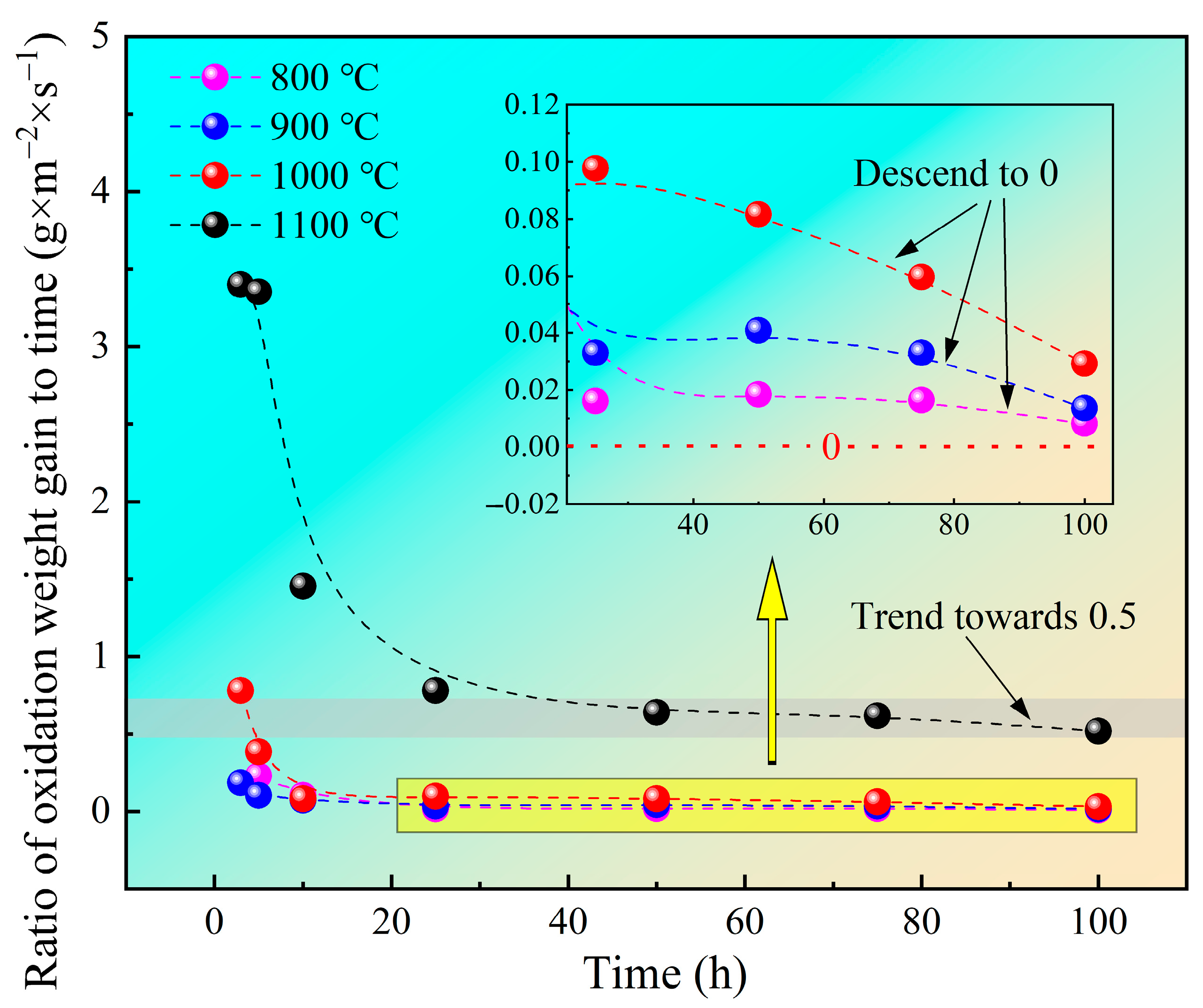

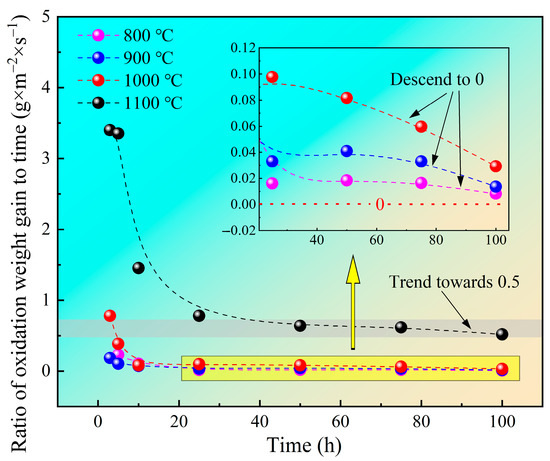

3.4.3. Spalling of Oxides

As mentioned in the previous section, the oxidation behavior of FGH4108 superalloy is controlled by the diffusion of Cr, Al, Ti, and O. As shown in Figure 2, the oxidation kinetic curves present a parabolic rule at 800–1000 °C, indicating that the growth rate of the oxide film is inversely proportional to the thickness of the film. At this time, a thick protective film is formed on the metal surface, and the growth rate of the film is determined by the diffusion rate [14,25]. At 1100 °C, the front part of the oxidation kinetics curve is parabolic, and the second part is linear. Figure 11 shows the ratio of oxidation weight gain to time at 800 °C to 1100 °C. At 800–1000 °C, the ratio of oxidation weight gain to time gradually decreases with the increase of time and eventually trends towards 0 g·m−2·s−1. This indicates that a dense oxide film is formed on the surface of the alloy, and with the gradual thickening of the oxide film, the diffusion rate of ions decreases, thus reducing the weight gain rate of oxides. At 1100 °C, although the ratio of oxidation weight gain to time also decreases with the increase of time, when the time exceeds 30 h, the ratio of oxidation weight gain to time trends towards 0.5 g·m−2·s−1. This indicates that, in this case, the oxide film does not play an adequate role in protecting the alloy, i.e., it does not form a sufficiently dense oxide film. Therefore, oxidation weight gain increases linearly with time. From the aspect of oxidation resistance, it can be concluded that the long-term service temperature of the FGH4108 superalloy should not exceed 1000 °C.

Figure 11.

The ratio of oxidation weight gain to time at 800 °C to 1100 °C for 100 h.

As shown in Figure 3, obvious oxide spalling occurs in the sample oxidized at 1100 °C. This oxidative spalling results in a linear increase of oxidation weight gain. The falling oxide particles will cause solid particle erosion of the engine parts, making the engine efficiency decrease rapidly and even endanger the operation safety of the engine. The spalling of the oxide film is closely related to the volume ratio between the oxide and the alloy consumed to form the oxide (Pilling-Bedworth Ratio, PBR), and the value of PBR is an important criterion for judging the integrity of oxide film, and is expressed in [40] as

in which VO denotes the volume of the oxide, and VA denotes the volume of the alloy consumed to form the oxide. When the PBR of oxide is less than one, the volume of the oxide film is too small to cover the entire alloy surface, and tensile stress exists in the oxide film [34]. In this case, the oxide film is easy to crack, so the oxide film does not have a protective action. When the PBR of the oxide is greater than three, the oxide is subject to large compressive stress. Therefore, the PBR value of oxides with protective properties is usually in the range of one to two [33]. However, in addition to PBR, the bond strength of the interface should be combined to analyze whether the oxide film falls off easily. The strain (ε) caused by the volume difference between oxide and alloy can be expressed as [33],

According to Hooke’s law, stress (σO) can be obtained by combining strain:

in which EO denotes the Young’s modulus of oxides. According to Figure 4 and Figure 8, XRD and EDS analysis confirmed that the oxide film of the alloy at 1100 °C is mainly composed of NiCr2O4, Cr2O3, and Al2O3. The PBR and Young’s modulus of NiCr2O4, Cr2O3, and Al2O3 are listed in Table 3. Put the values in Table 3 into Equations (8) and (9), and the growth stresses are obtained (see Table 3). It can be seen that the growth stress of the Al2O3 film is smaller than that of Cr2O3 and NiCr2O4. As a result, only de-cohesion occurs on the Al2O3 scale, while cracking and spalling occur on the Cr2O3 and NiCr2O4 scales. The spalling of the Cr2O3 and NiCr2O4 scale induces the linearly increasing oxidation weight gain at 1100 °C.

Table 3.

Material parameters of oxides.

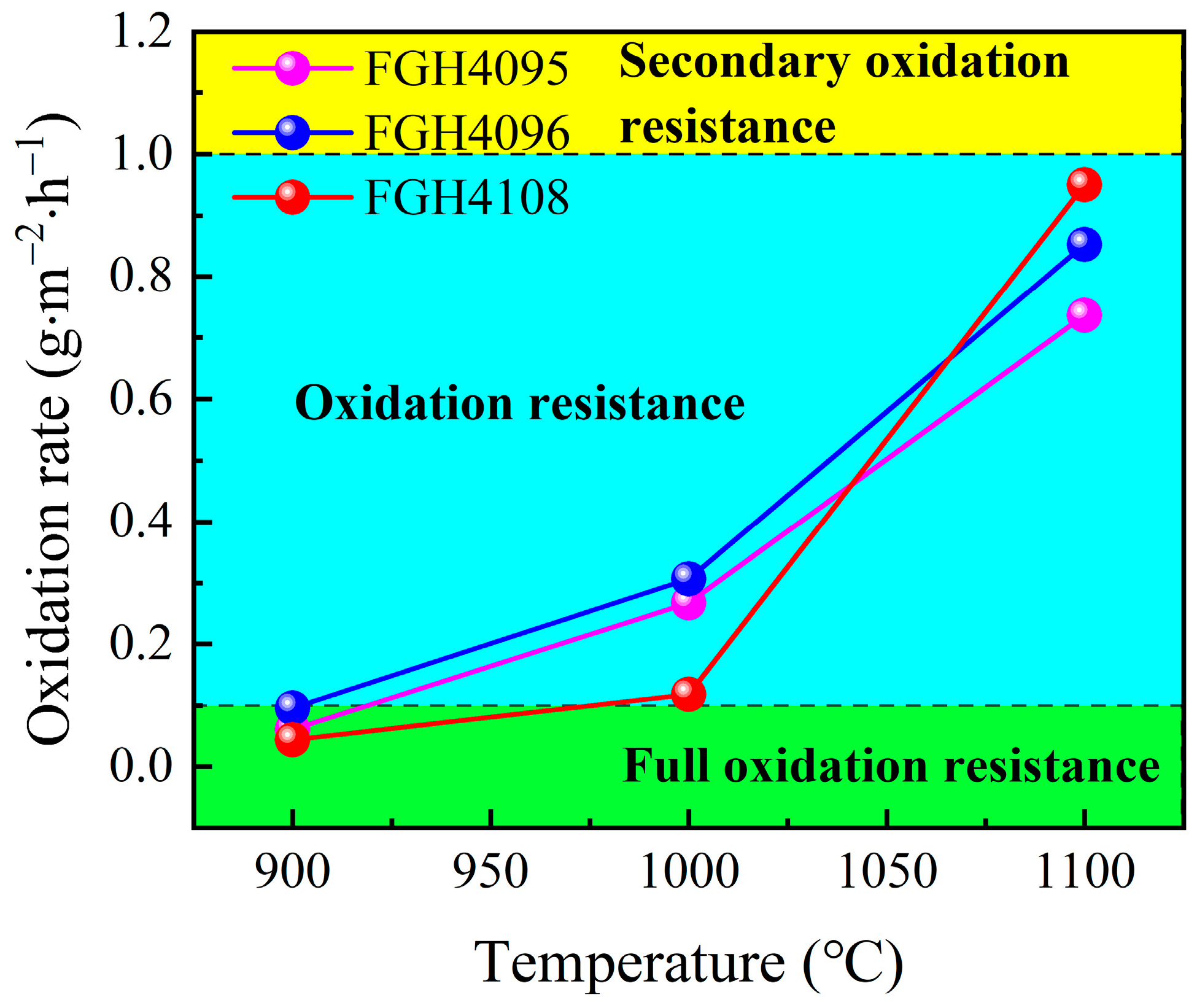

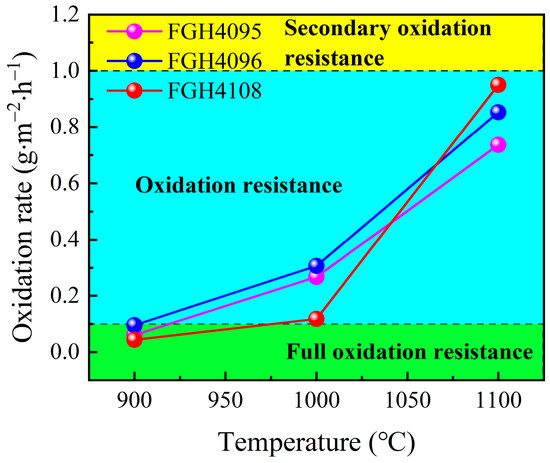

3.5. Comparison of Antioxidant Properties

Figure 12 illustrates the oxidation rate for 100 h at different temperatures. Figure 12 illustrates the oxidation rates for 100 h of FGH4095 (first-generation powder superalloy) [23], FGH4096 (second generation) [22] and FGH4108 at different temperatures. It can be seen that, compared with FGH4095 and FGH4096, FGH4108 has excellent oxidation resistance at no more than 1000 °C. According to HB 5258, “Test Method for Determination of Oxidation Resistance of Steels and Superalloys” (China Standard), FGH4108 belongs to the full oxidation resistance grade at 1000 °C or less. Due to the high Al content of FGH4108, a dense Al2O3 layer can be formed during the oxidation process (Figure 4a–c), which prevents the further diffusion of metal ions and oxygen and inhibits the occurrence of internal oxidation. In particular, the higher Hf content in FGH4108 further promotes the rapid formation of an α-Al2O3 oxide film and improves the oxidation stripping resistance of the alloy [43]. Therefore, it has a better antioxidant capacity at less than 1000 °C. When the temperature reaches 1100 °C, compared with FGH4095 and FGH4096, FGH4108 showed poor antioxidant activity but still belonged to the antioxidant class (Figure 12). The main reason is that the Al2O3 layer on the surface is no longer dense at high temperatures (Figure 9), which facilitates the diffusion of oxygen and leads to serious internal oxidation. Furthermore, since the internal oxidation mainly generates TiO2, the higher Ti content of FGH4108 further promotes internal oxidation. The repeated spalling of the oxide film in the oxidation process ultimately leads to higher oxidation weight gain.

Figure 12.

The oxidation rate for 100 h at different temperatures.

4. Conclusions

The oxidation kinetic curves of the alloy at 800 °C and 900 °C conform to the parabolic law. The oxidation kinetic curve at 1000 °C conforms to the cubic law. The oxidation kinetic curve at 1100 °C consists of the parabola and linear laws.

At 800 °C, the oxide film consists of two parts: the outer layer is a continuous dense protective Cr2O3 oxide film, and the inner layer is a discontinuous Al2O3 oxide layer. At 900–1100 °C, the oxide film consists of three layers: the outermost layer is a mixed layer of Cr2O3 and TiO2 oxide film, the middle layer is a continuous layer of Al2O3 inner oxide, and the innermost layer is a dotted TiO2.

The oxidation behavior of the FGH4108 superalloy is confirmed to be controlled by the diffusion of Cr, Al, Ti, and O through a selective oxidation process. The spalling of the Cr2O3 and NiCr2O4 scale induces the linearly increasing oxidation weight gain at 1100 °C. From the aspect of oxidation resistance, the long-term service temperature of the FGH4108 superalloy should not exceed 1000 °C.

Author Contributions

Conceptualization, J.L. (Jiantao Liu), J.L. (Jinjuan Lv), Z.W. and X.Z.; methodology, J.L. (Jiantao Liu) and X.L.; validation, L.Z.; formal analysis, X.L., Z.W. and J.L. (Jiantao Liu); investigation, X.Z., J.L. (Jinjuan Lv), and X.L.; resources, X.Z.; data curation, J.L. (Jiantao Liu); writing—original draft preparation, Z.W. and X.Z.; writing—review and editing, X.Z. and L.Z.; supervision, L.Z.; project administration, L.Z. and J.L. (Jiantao Liu); funding acquisition, L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52171094.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zheng, L.; Schmitz, G.; Meng, Y.; Chellali, R.; Schlesiger, R. Mechanism of Intermediate Temperature Embrittlement of Ni and Ni-based Superalloys. Crit. Rev. Solid State Mater. Sci. 2012, 37, 181–214. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Ouyang, X.; Liu, F.; Huang, L.; Ye, L.; Dong, H.; Tan, L.; Wang, L.; Jin, X.; Liu, Y. The Effects of Co on the Microstructure and Mechanical Properties of Ni-Based Superalloys Prepared via Selective Laser Melting. Materials 2023, 16, 2926. [Google Scholar] [CrossRef]

- Gao, Z.; Li, S.; Liu, G.; Shang, Z.; Song, D.; Yang, G.; Zou, J.; Liang, S. Microstructural Evolution and Tensile Properties of a Corrosion-Resistant Ni-Based Superalloys Used for Industrial Gas Turbines. Crystals 2023, 13, 669. [Google Scholar] [CrossRef]

- Alano, J.H.; Siqueira, R.L.; Júnior, C.B.M.; Silva, R.; Vacchi, G.D.S.; Della Rovere, C.A. A Survey on the Oxidation Behavior of a Nickel-Based Alloy Used in Natural Gas Engine Exhaust Valve Seats. Metals 2023, 13, 49. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X.; Liu, X.; Lv, J.; Zheng, L. Deformation and damage mechanisms during stress rupture of Waspaloy after vacuum solution plus aging treatment. J. Alloys Compd. 2023, 946, 169461. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, L.; Wang, D.; Wei, X.; Min, H.; Jin, Y.; Tai, Q. Dissolution and Coarsening Kinetics of γ′ Precipitates in Waspaloy during Solution Treatment at Temperatures of 1000–1045 °C. J. Mater. Eng. Perform. 2022, 31, 7748–7756. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X.; Dong, J.; Zheng, L. Inhomogeneous Planar Distribution of γ′ Precipitates in Waspaloy Caused by Local Spatial Consumption of MC Carbides. J. Mater. Eng. Perform. 2022, 31, 1397–1404. [Google Scholar] [CrossRef]

- Zhao, X.; Lv, J.; Liu, H.; Zheng, L. Hot deformation behavior of a novel Ni–W–Co high-density Ni-based alloy with ul-tra-high W content. J. Alloys Compd. 2023, 950, 169937. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, M.; Xia, H.; Zheng, L.; Ta, N.; Meng, Y.; Cui, F. Pseudobinary Phase Diagrams of Eutectic Reaction for Pt-containing and Pt-free 718Plus Alloys. Adv. Eng. Mater. 2021, 23, 2001233. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, M.; Xu, M.; Meng, Y.; Xu, G.; Ta, N.; Zheng, L. Microstructure evolution dependence of work-hardening characteristic in cold deformation of a difficult-to-deform nickel-based superalloy. Mater. Sci. Eng. A 2021, 800, 140280. [Google Scholar] [CrossRef]

- Zhong, W.; Jiao, D.; Qiu, W.; Liu, Z.; Xu, W.; Li, Z.; Zhang, G. Oxidation Characteristics of Nickel-Based Superalloy Powders Exposed at Ambient Condition. Metals 2022, 12, 972. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, M.C.; Chellali, R.; Bouchikhaoui, H.; Dong, J.X. Oxidation property of powder metallurgy EP741NP Ni based superalloy at elevated temperatures. Mater. Technol. 2013, 28, 122–128. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, M.; Dong, J. Oxidation behavior and mechanism of powder metallurgy Rene95 nickel based superalloy between 800 and 1000 °C. Appl. Surf. Sci. 2010, 256, 7510–7515. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.; Sun, P.; Yang, G.; Song, W.; Wang, X. Effect of Solution Treatment on Microstructure Evolution of a Powder Metallurgy Nickel Based Superalloy with Incomplete Dynamic Recrystallization Microstructure. Metals 2023, 13, 239. [Google Scholar] [CrossRef]

- Li, G.; Sun, D.; Kang, J.; Gao, Y.; Yan, X.; Gao, Q.; Gao, K. The Effect of Hot Oscillatory Pressing Temperature on Microstructure and Tensile Behavior of Powder Metallurgy Superalloy. Metals 2022, 12, 1652. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2020, 11, 58. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Brenneman, J.; Wei, J.; Sun, Z.; Liu, L.; Zou, G.; Zhou, Y. Oxidation behavior of GTD111 Ni-based superalloy at 900 °C in air. Corros. Sci. 2015, 100, 267–274. [Google Scholar] [CrossRef]

- Berthod, P.; Wora, S.A.O.; Aranda, L.; Medjahdi, G.; Etienne, E. Kinetic and Metallography Study of the Oxidation at 1250 °C of {Co+Ni}-Based Superalloys Containing Ti to Form MC Carbides. Metals 2021, 12, 10. [Google Scholar] [CrossRef]

- Moffat, J.P.; Whitfield, T.E.; Christofidou, K.A.; Pickering, E.J.; Jones, N.G.; Stone, H.J. The Effect of Heat Treatment on the Oxidation Resistance of Cobalt-Based Superalloys. Metals 2020, 10, 248. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Y.; Liu, D.; Zou, J. High temperature oxidation resistance of PM superalloys FGH4095 and FGH4096. J. Mater. Eng. 2023, 51, 122–131. [Google Scholar]

- Liu, C.; Sun, X.; Guan, H.; Hu, Z. Oxidation of the single-crystal Ni-base superalloy DD32 containing rhenium in air at 900 and 1000 °C. Surf. Coat. Technol. 2005, 197, 39–44. [Google Scholar] [CrossRef]

- Xiao, Q.; Huang, Q.; Yang, L.; Ren, P.; Yang, Y.; Wang, Q.; Li, W.; Zhu, S.; Wang, F. The cyclic oxidation behavior of a Pt modified γ’ nanocrystalline coating at 1150 °C. Corros. Sci. 2022, 208, 110638. [Google Scholar] [CrossRef]

- Zheng, J.; Hou, X.; Wang, X.; Meng, Y.; Zheng, X.; Zheng, L. Isothermal oxidation mechanism of a newly developed Nb–Ti–V–Cr–Al–W–Mo–Hf alloy at 800–1200 °C. Int. J. Refract. Met. Hard Mater. 2016, 54, 322–329. [Google Scholar] [CrossRef]

- Zheng, J.; Hou, X.; Wang, X.; Meng, Y.; Zheng, X.; Zheng, L. Isothermal oxidation mechanism of Nb–Ti–V–Al–Zr alloy at 700–1200 °C: Diffusion and interface reaction. Corros. Sci. 2015, 96, 186–195. [Google Scholar] [CrossRef]

- Busso, E.P.; Evans, H.E.; Qian, Z.Q.; Taylor, M.P. Effects of breakaway oxidation on local stresses in thermal barrier coatings. Acta Mater. 2010, 58, 1242–1251. [Google Scholar] [CrossRef]

- Mikkelsen, L.; Linderoth, S. High temperature oxidation of Fe–Cr alloy in O2–H2–H2O atmospheres; microstructure and kinetics. Mater. Sci. Eng. A 2003, 361, 198–212. [Google Scholar] [CrossRef]

- Gao, W.; Li, Z.; Wu, Z.; Li, S.; He, Y. Oxidation behavior of Ni3Al and FeAl intermetallics under low oxygen partial pressures. Intermetallics 2002, 10, 263–270. [Google Scholar] [CrossRef]

- Liu, C.; Ma, J.; Sun, X. Oxidation behavior of a single-crystal Ni-base superalloy between 900 and 1000 °C in air. J. Alloys Compd. 2010, 491, 522–526. [Google Scholar] [CrossRef]

- Kamal, S.; Jayaganthan, R.; Prakash, S. High temperature oxidation studies of detonation-gun-sprayed Cr3C2–NiCr coating on Fe- and Ni-based superalloys in air under cyclic condition at 900 °C. J. Alloys Compd. 2009, 472, 378–389. [Google Scholar] [CrossRef]

- Zhao, S.; Xie, X.; Smith, G.D.; Patel, S.J. Research and improvement on structure stability and corrosion resistance of nickel-base superalloy INCONEL alloy 740. Mater. Des. 2006, 27, 1120–1127. [Google Scholar] [CrossRef]

- Li, M. High Temperature Corrosion of Metals; Metallurgical Industry Press: Beijing, China, 2001. [Google Scholar]

- Liu, F.; Zhang, M.; Dong, J.; Zhang, Y. High-temperature oxidation of FGH96 P/M superalloy. Acta Met. Sin. Engl. Lett. 2007, 20, 102–110. [Google Scholar] [CrossRef]

- Ellingham, H. The physical chemistry of process metallurgy. J. Indian Chem. Soc. 1944, 63, 125–133. [Google Scholar]

- Zhao, S.; Xie, X.; Smith, G.D. The oxidation behavior of the new nickel-based superalloy Inconel 740 with and without Na2SO4 deposit. Surf. Coat. Technol. 2004, 185, 178–183. [Google Scholar] [CrossRef]

- Robino, C.V. Representation of mixed reactive gases on free energy (Ellingharn-Richardson) diagrams. Met. Mater. Trans. B 1996, 27, 65–69. [Google Scholar] [CrossRef]

- Gold, T. Hearing. II. The physical basis of the action of the cochlea. Proc. R. Soc. Lond. Ser. B-Biol. Sci. 1948, 135, 492–498. [Google Scholar] [CrossRef]

- Duval, A.; Miserque, F.; Tabarant, M.; Nogier, J.P.; Gédéon, A. Influence of the oxygen partial pressure on the oxidation of Inconel 617 alloy at high temperature. Oxid. Met. 2010, 74, 215–238. [Google Scholar] [CrossRef]

- Xu, C.; Gao, W. Pilling-Bedworth ratio for oxidation of alloys. Mater. Res. Innov. 2000, 3, 231–235. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, T.-S.; Li, G.-L.; Wang, R.; Ma, G.-Z.; Zhao, X.-W.; Liu, Q. The roles of stress in the thermal shock failure of YSZ TBCs before and after laser remelting. J. Alloys Compd. 2020, 828, 154417. [Google Scholar] [CrossRef]

- Evans, H.; Lobb, R. Conditions for the initiation of oxide-scale cracking and spallation. Corros. Sci. 1984, 24, 209–222. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Y.; Zhang, H.; Ni, N.; Li, L.; He, L.; Mu, R.; Zhao, X.; Guo, F. Y/Hf-doped AlCoCrFeNi high-entropy alloy with ultra oxidation and spallation resistance. Corros. Sci. 2020, 166, 108426. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).