Structure Refinement and Bauschinger Effect in fcc and hcp Metals

Abstract

:1. Introduction

2. Materials and Methods

3. Results

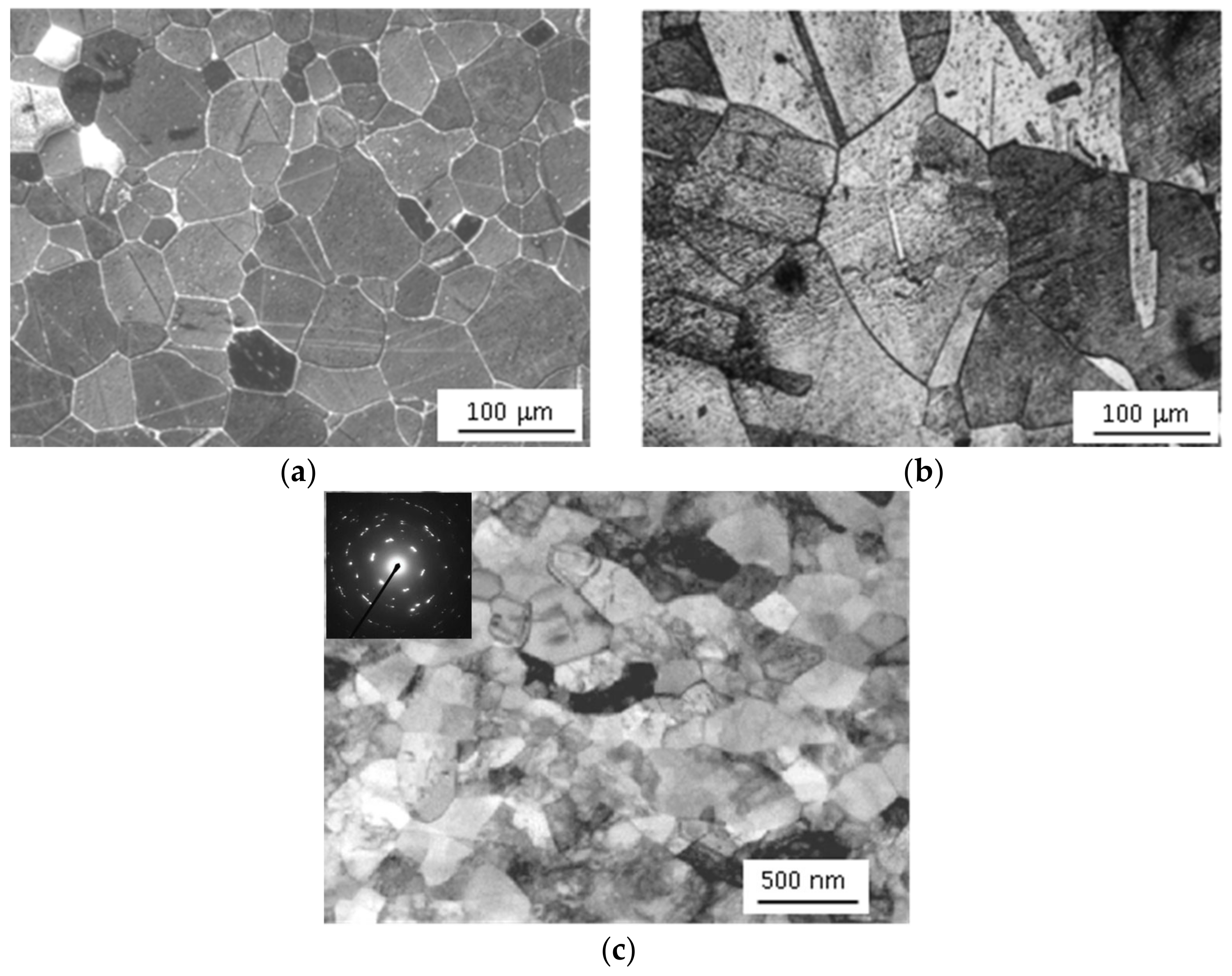

3.1. Microstructure

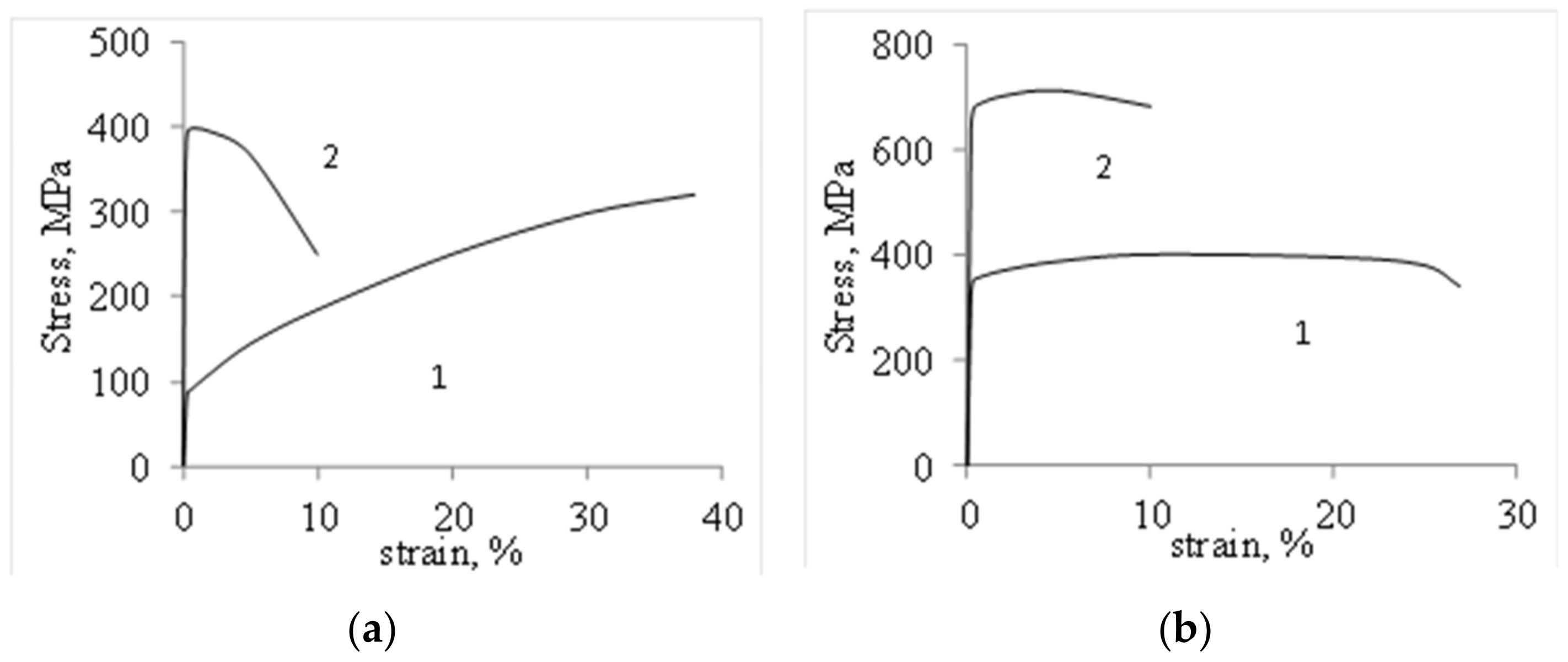

3.2. Tension Tests

3.3. Bauschinger Effect

4. Discussion

5. Conclusions

- It is confirmed that in commercially pure polycrystalline metals titanium and copper, a decrease in the average grain size in the range from tens of microns to hundreds of nanometers leads to an increase in the Bauschinger parameter β2 (an increase in the difference in flow stresses in one direction after deformation in the opposite direction).

- The opposite sign of the Bauschinger effect in copper and titanium in a wide grain-size range indicates the predominant deformation mechanism acting when the direction of deformation changes. In copper, such a mechanism is the most common typical softening, whereas in titanium, anomalous hardening is observed. A decrease in the magnitude of permanent deformation and the duration of exposure between direct and reverse loading contributes to an increase in the Bauschinger parameter in both metals and a change from a negative sign to a positive one.

- It is assumed that the different sign and magnitude of the Bauschinger effect in ultrafine-grained copper and titanium are associated with a different type of crystal lattice and, as a result, a type of crystallographic texture.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bauschinger, J. Über die Veränderung der Elastizitätsgrenze und des Elastizitätsmoduls verschiedener Metalle. In Civilingenieur XXVII; Felix: Leipzig, Germany, 1881; pp. 289–348. [Google Scholar]

- Tan, Z.; Magnusson, C.; Persson, B. The Bauschinger effect in compression-tension of sheet metals. Mater. Sci. Eng. A 1994, 183, 31–38. [Google Scholar] [CrossRef]

- Kulawinski, D.; Nagel, K.; Henkel, S.; Hubner, P.; Kuna, M.; Biermann, H. Characterization of stress-strain behavior of a cast TRIP steel under different biaxial planar load rations. Eng. Fracture Mech. 2011, 78, 1684–1695. [Google Scholar] [CrossRef]

- Adigamov, R.R.; Andreev, V.A.; Rogachev, S.O.; Fedotov, E.S.; Khadeev, G.E.; Yusupov, V.S. Bauschinger effect during alternating deformation. Izv. Ferr. Met. 2022, 65, 455–466. (In Russian) [Google Scholar] [CrossRef]

- Moan, G.D.; Embury, J.D. A study of the bauschinger effect in Al–Cu alloys. Acta Met. 1979, 27, 903–914. [Google Scholar] [CrossRef]

- Grachev, S.V.; Kazyaeva, I.D.; Pumpyanskii, D.A. Thermal stability of the Bauschinger effect in the cold-deformed steel. Phys. Met. Metallogr. 2004, 97, 217–219. [Google Scholar]

- Mamun, A.; Moat, R.; Kelleher, J.; Bouchard, P. Origin of the Bauschinger effect in a polycrystalline material. Mater. Sci. Eng. A 2017, 707, 576–584. [Google Scholar] [CrossRef] [Green Version]

- Trelewicz, J.R.; Schuh, C.A. The Hall–Petch breakdown in nanocrystalline metals: A crossover to glass-like deformation. Acta Mater. 2007, 55, 5948–5958. [Google Scholar] [CrossRef]

- Woolley, R.L. The Bauschinger effect in some face-centered and body-centered cubic metals. Philos. Mag. 1953, 44, 597–618. [Google Scholar] [CrossRef]

- Skelton, R.P. Bauschinger yield in the range 400–1025 °C during cyclic deformation of high temperature alloys. Mater. High Temp. 2013, 30, 241–260. [Google Scholar] [CrossRef]

- Kim, H.L.; Park, S.H. Loading Direction Dependence of Yield-Point Phenomenon and Bauschinger Effect in API X70 Steel Sheet. Met. Mater. Int. 2020, 26, 14–24. [Google Scholar] [CrossRef]

- Toribio, J.; Kharin, V.; Ayaso, F.-J.; Lorenzo, M.; González, B.; Matos, J.-C.; Aguado, L. Analysis of the Bauschinger Effect in Cold Drawn Pearlitic Steels. Metals 2020, 10, 114. [Google Scholar] [CrossRef] [Green Version]

- Ratner, S.I.; Danilov, Y.S. Changes of proportional limits and yield point at repeated loading. Zavod. Lab. 1950, 4, 46–47. (In Russian) [Google Scholar]

- Mahato, J.K.; De, P.S.; Sarkar, A.; Kundu, A.; Chakraborti, P.C. Effect of deformation mode and grain size on Bauschinger behavior of annealed copper. Int. J. Fatigue 2016, 83, 42–52. [Google Scholar] [CrossRef]

- Canel, G.I.; Savinykh, A.S.; Garkushin, G.V.; Razorenov, S.V. High-speed deformation of titanium in shock waves at normal and elevated temperatures. ZhETF 2021, 159, 524–532. [Google Scholar] [CrossRef]

- Sole, N.C. An Investigation on the Bauschinger Effect in Titanium Alloys for Aerospace Applications: Strain Rate and Pressure Dependence. Master’s Thesis, University of Oxford, Oxford, UK, 2021; 124p. [Google Scholar]

- Yu, X.; Ji, H.; Zhang, H.; Xu, D. Experimental and numerical investigation on the Bauschinger effect during cold forming of TC4 ELI alloy. Int. J. Mater. Form. 2022, 15, 16. [Google Scholar] [CrossRef]

- Vinogradov, A.; Kaneko, Y.; Kitagawa, K.; Hashimoto, S.; Stolyarov, V.; Valiev, R. Cyclic response of ultrafine-grained copper at constant plastic strain amplitude. Scr. Mater. 1997, 36, 1345–1351. [Google Scholar] [CrossRef]

- Shen, J.; Zhou, J.; Zhao, G.; Gong, C.; Yu, J.; Xia, X.; Xian, F. Attenuation of the Bauschinger effect and enhancement of tension–compression asymmetry in single crystal aluminum by temperature. RSC Adv. 2022, 12, 21235–21246. [Google Scholar] [CrossRef]

- Gao, S.; Yoshino, K.; Terada, D.; Kaneko, Y.; Tsuji, N. Significant Bauschinger effect and back stress strengthening in an ultrafine grained pure aluminum fabricated by severe plastic deformation process. Scr. Mater. 2022, 211, 114503. [Google Scholar] [CrossRef]

- Brown, L.M. Orowan’s explanation of the Bauschinger effect. Scr. Met. 1977, 11, 127–131. [Google Scholar] [CrossRef]

- Hu, X.; Way, C.; Margolin, H.; Nourbakhsh, S. The Bauschinger effect and the stresses in a strained single crystal. Scr. Met. Mater. 1992, 27, 865–870. [Google Scholar] [CrossRef]

- Liu, X.; Yuan, F.; Zhu, Y.; Wu, X. Extraordinary Bauschinger effect in gradient structured copper. Scr. Mater. 2018, 150, 57–60. [Google Scholar] [CrossRef] [Green Version]

- Rajagopalan, J.; Rentenberger, C.; Karnthaler, H.P.; Dehm, G.; Saif, M.T.A. In situ TEM study of microplasticity and Bauschinger effect in nanocrystalline metals. Acta Mater. 2010, 58, 4772–4782. [Google Scholar] [CrossRef]

- Bouaziz, O.; Moon, J.; Kim, H.S.; Estrin, Y. Isotropic and kinematic hardening of a high entropy alloy. Scr. Mater. 2020, 191, 107–110. [Google Scholar] [CrossRef]

- Bouaziz, O.; Kim, H.S.; Lee, J.; Estrin, Y. Bauschinger Effect or Kinematic Hardening: Bridging Microstructure and Continuum Mechanics. Met. Mater. Int. 2022, 29, 280–292. [Google Scholar] [CrossRef]

- Roostaei, A.A.; Jahed, H. Experimental observations in cyclic loading of metals. In Cyclic Plasticity of Metals; Jahed, H., Roostaei, A.A., Eds.; Elsevier Series on Plasticity of Materials; Elsevier: Amsterdam, The Netherlands, 2022; pp. 3–22. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Influence of ECAP routes on the microstructure and properties of pure Ti. Mater. Sci. Eng. A 2001, 299, 59–67. [Google Scholar] [CrossRef]

- Valiev, R.; Kozlov, E.; Ivanov, Y.; Lian, J.; Nazarov, A.; Baudelet, B. Deformation behaviour of ultra-fine-grained copper. Acta Met. Mater. 1994, 42, 2467–2475. [Google Scholar] [CrossRef]

- Khvan, A.D.; Khvan, D.V.; Voropaev, A.A. One-sample method of evaluation of Bauschinger effect. Ind. Lab. Diagn. Mater. 2020, 86, 55–58. [Google Scholar] [CrossRef]

- Danilov, Y.S. Influence of grain size on Bauschinger effect. Met. Sci. Heat Treat. 1964, 6, 563–565. [Google Scholar] [CrossRef]

- Alexandrov, I.V.; Sitdikov, V.D. Crystallographic Texture Development in CP Ti Subjected to ECAP. Mater. Sci. Forum 2008, 584–586, 765–770. [Google Scholar]

- Vinogradov, A.Y.; Stolyarov, V.V.; Hashimoto, S.; Valiev, R.Z. Cyclic behavior of ultrafine-grain titanium produced by severe plastic deformation. Mater. Sci. Eng. A 2001, 318, 163–173. [Google Scholar] [CrossRef]

| Materials | Fe | O | N | Si | C |

|---|---|---|---|---|---|

| titanium | 0.18 | 0.12 | 0.04 | 0.1 | 0.07 |

| copper | 0.005 | 0.05 | - | - | - |

| Treatment Method | d, µm | τ, min | ε, % | Bauschinger Parameters | |

|---|---|---|---|---|---|

| β1 | β2 | ||||

| copper | |||||

| ECAP + annealing at 600 °C–1 h | 100 | 60 | 1 | 0.87 | +0.04 |

| As-received state | 30 | 60 | 1 | 0.80 | +0.13 |

| ECAP | 0.3 | 60 | 1 | 0.95 | +0.20 |

| 0.3 | 1 | 0.2 | 0.72 | +0.26 | |

| titanium | |||||

| ECAP + annealing at 600 °C–1 h | 50 | 60 | 1 | 1.08 | −0.28 |

| As-received state | 25 | 60 | 1 | 0.95 | −0.21 |

| ECAP | 0.3 | 60 | 1 | 0.83 | −0.07 |

| 0.3 | 1 | 0.2 | 0.91 | +0.05 | |

| ECAP + annealing at 300 °C–1 h | 0.3 | 60 | 1 | 0.86 | −0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stolyarov, V.V. Structure Refinement and Bauschinger Effect in fcc and hcp Metals. Metals 2023, 13, 1307. https://doi.org/10.3390/met13071307

Stolyarov VV. Structure Refinement and Bauschinger Effect in fcc and hcp Metals. Metals. 2023; 13(7):1307. https://doi.org/10.3390/met13071307

Chicago/Turabian StyleStolyarov, Vladimir V. 2023. "Structure Refinement and Bauschinger Effect in fcc and hcp Metals" Metals 13, no. 7: 1307. https://doi.org/10.3390/met13071307

APA StyleStolyarov, V. V. (2023). Structure Refinement and Bauschinger Effect in fcc and hcp Metals. Metals, 13(7), 1307. https://doi.org/10.3390/met13071307