A Model for Direct Effect of Graphene on Mechanical Property of Al Matrix Composite

Abstract

:1. Introduction

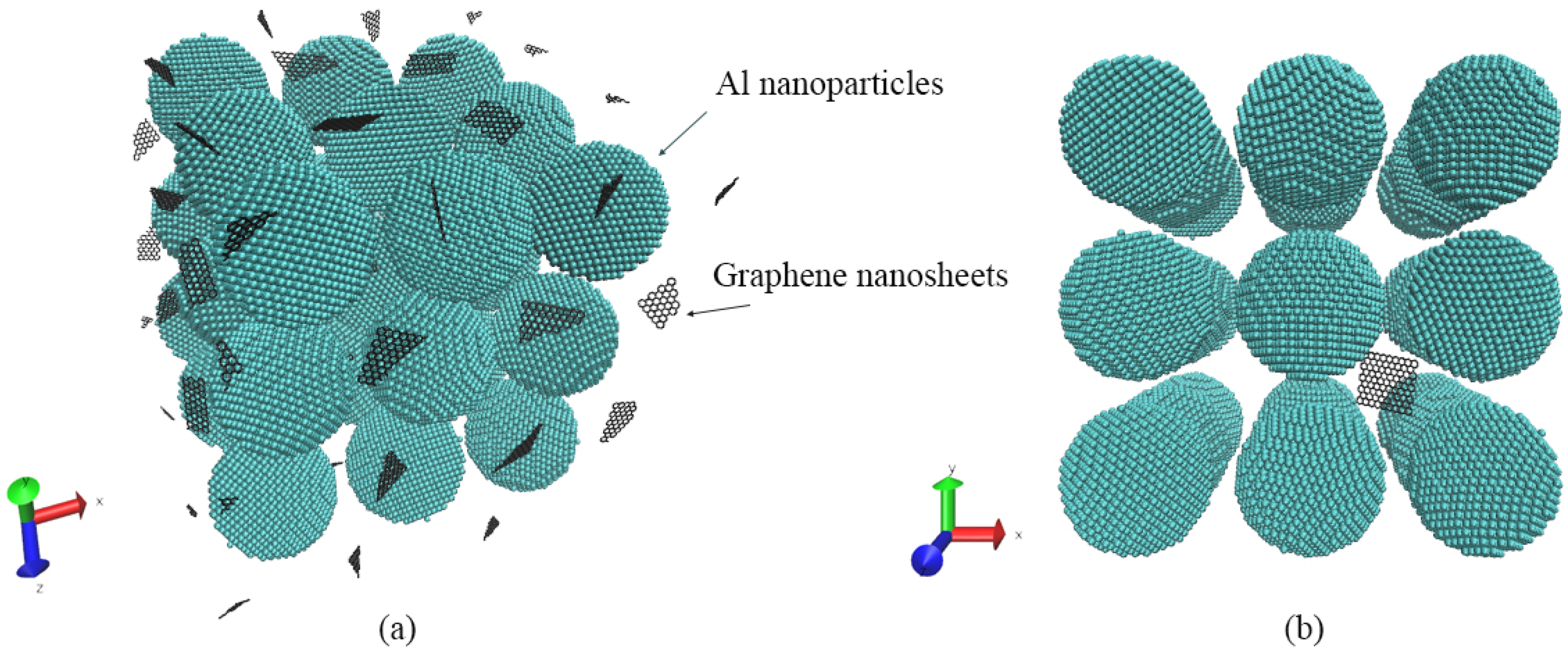

2. Model and Method

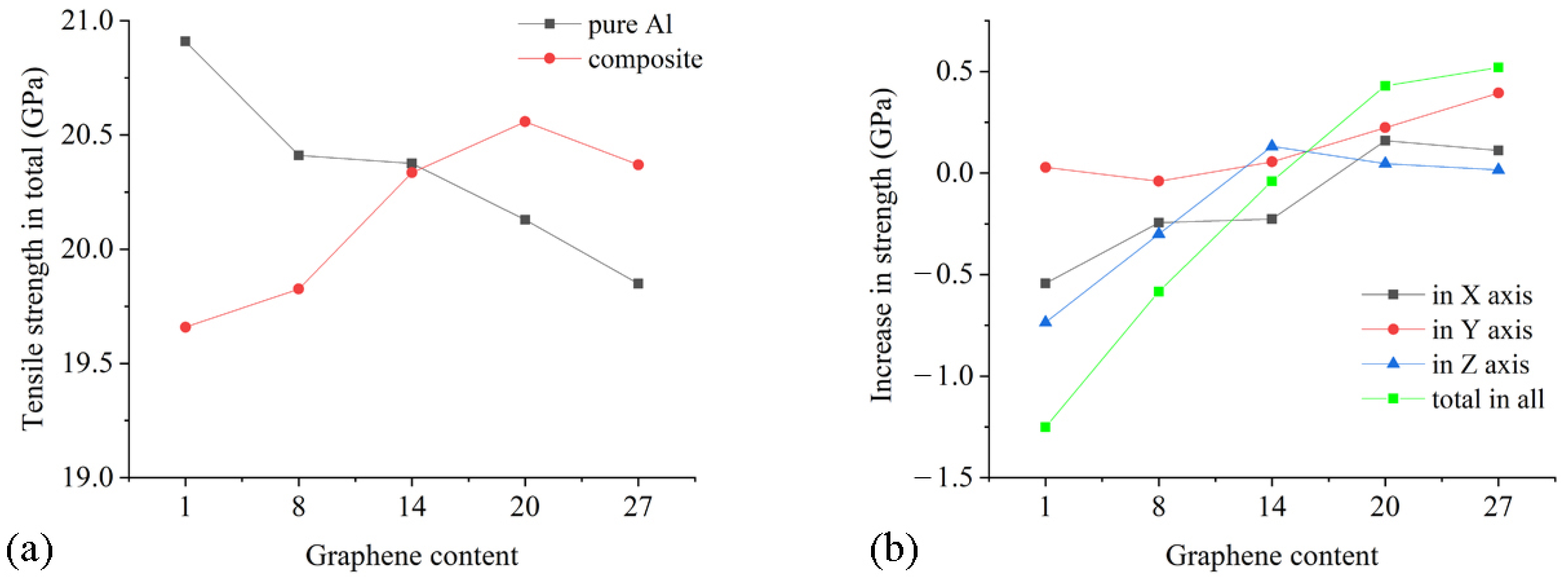

3. Results and Discussion

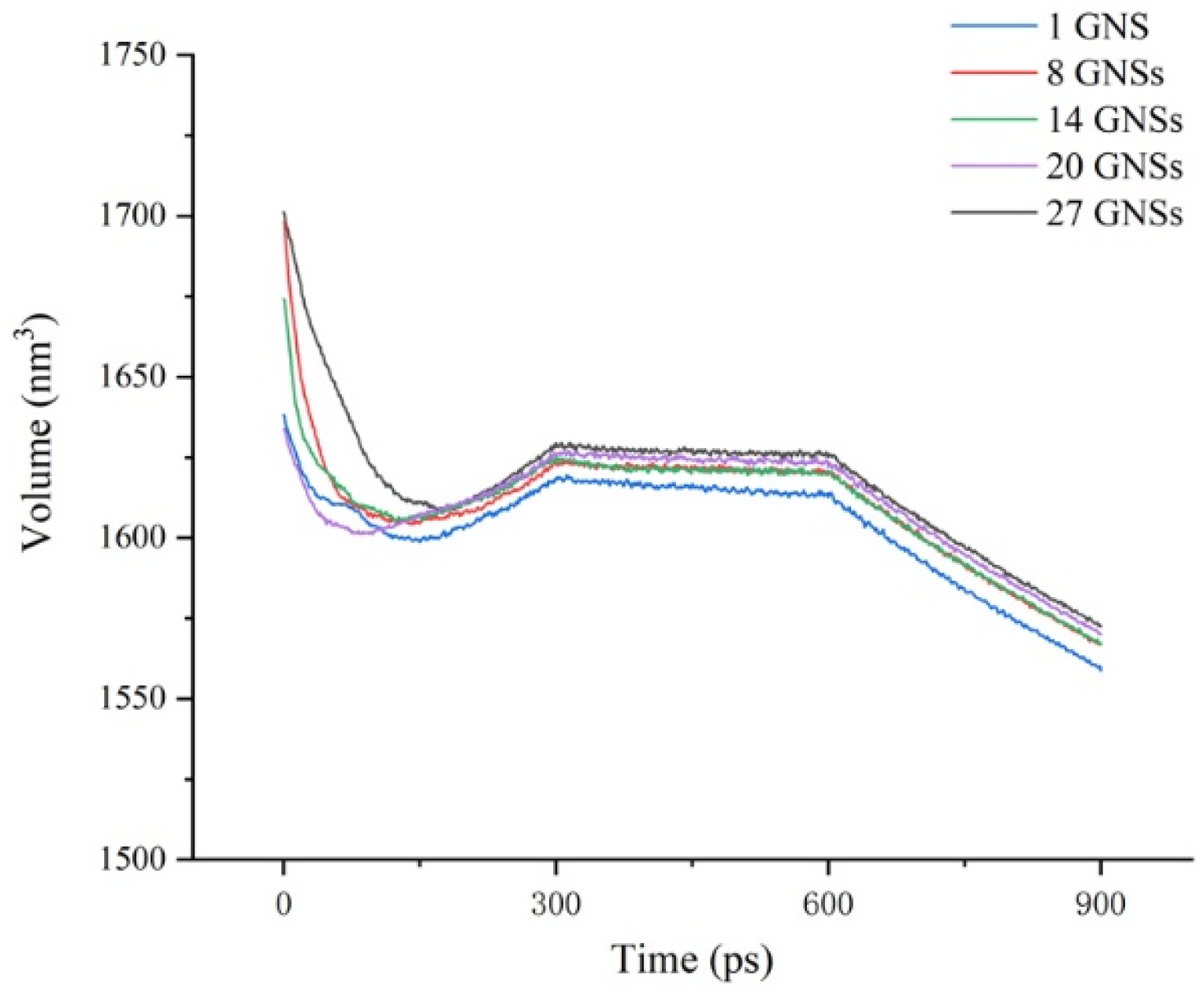

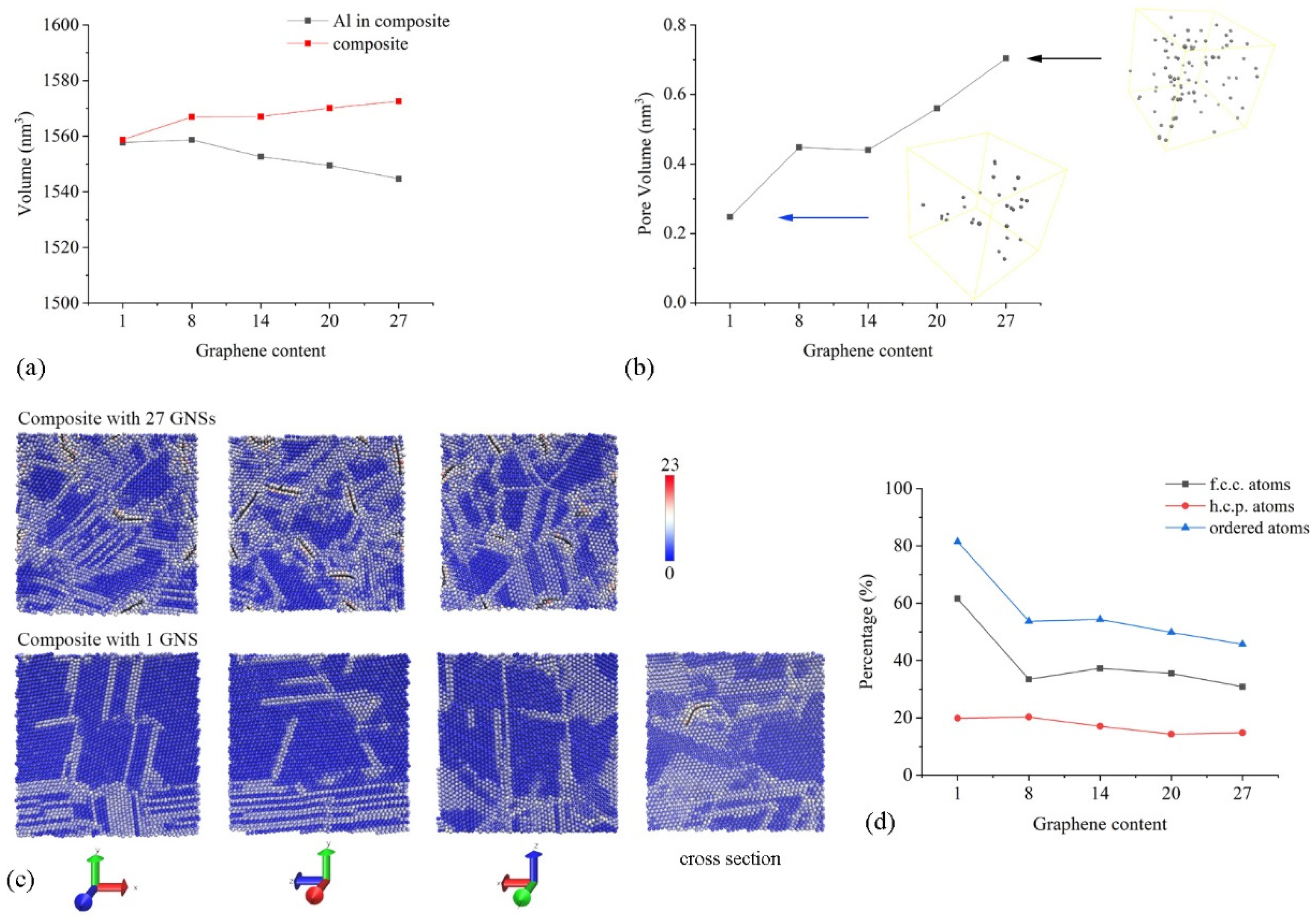

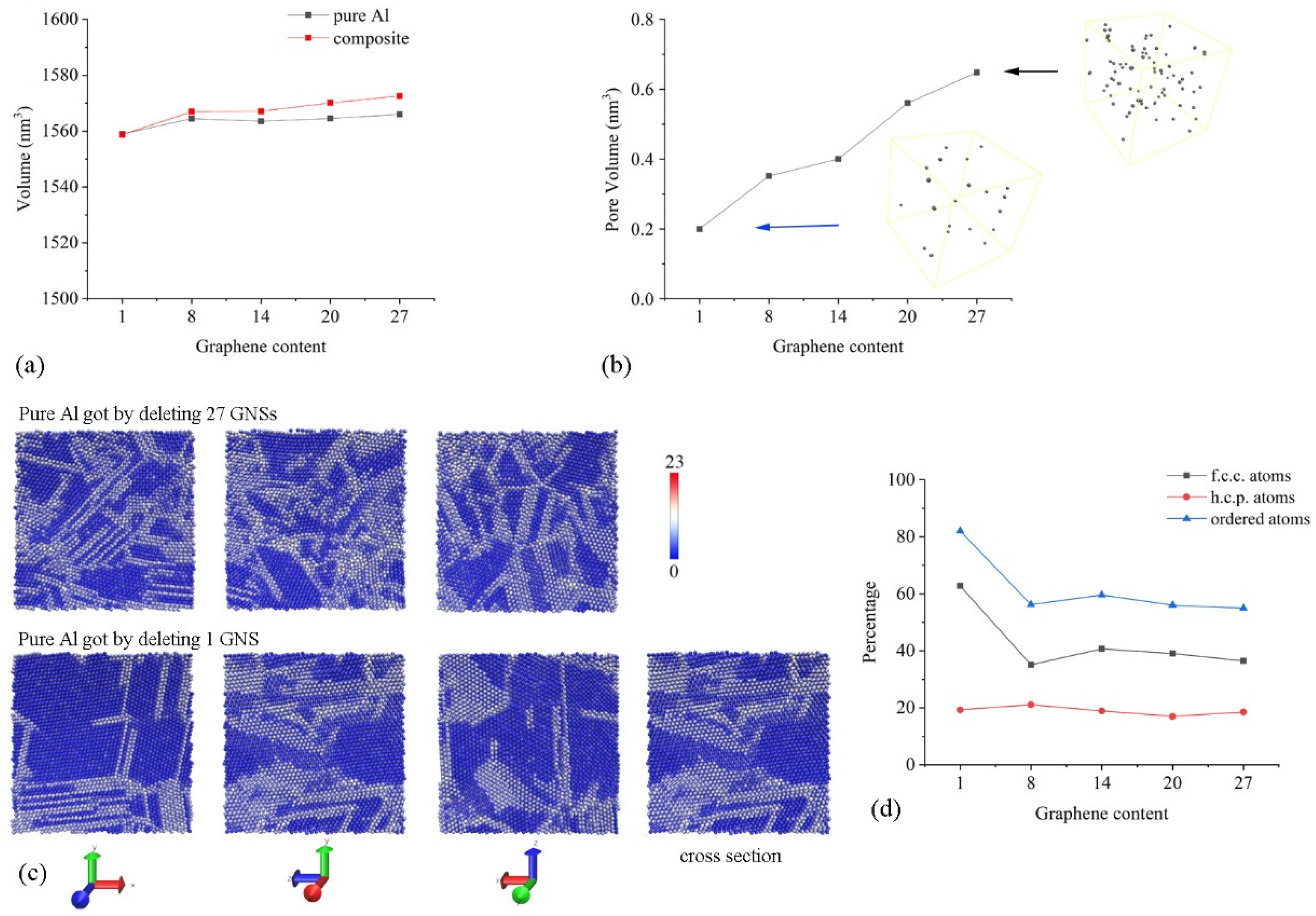

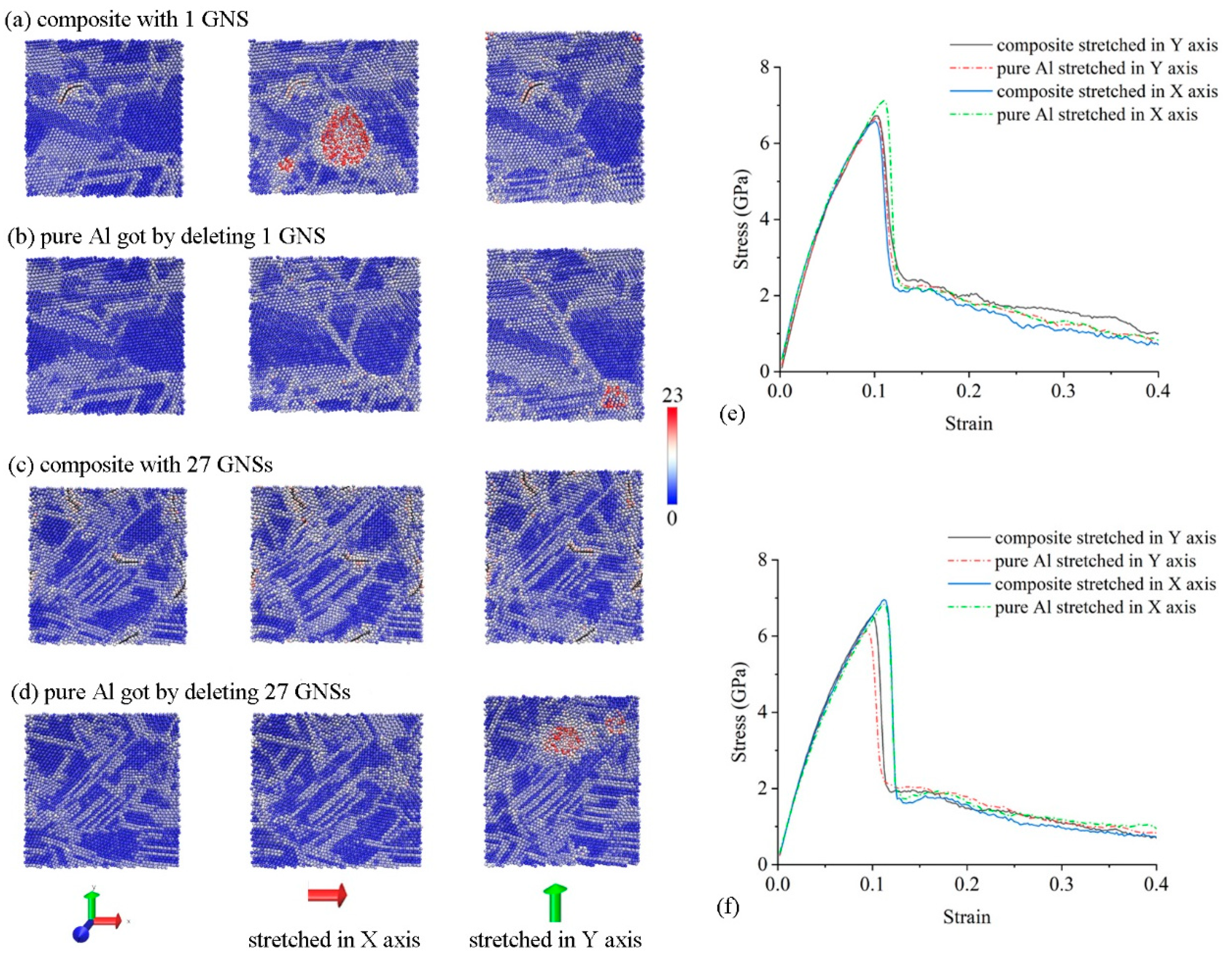

3.1. Comparisons on the Inner Structures

3.2. Comparisons on the Tensile Processes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chawla, N.; Shen, Y.L. Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, X.; Wang, R.; Li, M. Enhancement of the mechanical properties of graphene-copper composites with graphene-nickel hybrids. Mater. Sci. Eng. A 2014, 599, 247–254. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C. Enhanced strength in bulk graphene–copper composites. Phys. Status Solidi 2014, 211, 184–190. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Hwang, J.Y.; Bae, D.H. Strengthening behavior of carbon/metal nanocomposites. Sci. Rep. 2015, 5, 16114. [Google Scholar] [CrossRef] [Green Version]

- Duan, K.; Zhu, F.; Tang, K.; He, L.; Chen, Y.; Liu, S. Effects of chirality and number of graphene layers on the mechanical properties of graphene-embedded copper nanocomposites. Comput. Mater. Sci. 2016, 117, 294–299. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, Q.; Liu, X. Investigation on the Tensile Behavior of Graphene-Aluminum Nano-Laminated Composites by Molecular Dynamics Simulation. Key Eng. Mater. 2019, 804, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Li, N.; Zhang, L.; Zhang, J.; Niu, L.; Li, W.; Li, S. Atomistic Investigation of the Effects of Different Reinforcements on Al Matrix Composite. Metals 2022, 12, 1252. [Google Scholar] [CrossRef]

- Krajewski, P.E.; Allison, J.E.; Jones, J.W. The influence of matrix microstructure and particle reinforcement on the creep behavior of 2219 aluminum. Metall. Mater. Trans. A 1993, 24, 2731–2741. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Ferguson, J.B.; Schultz, B.F.; Kim, C.-S.; Cho, K.; Rohatgi, P.K. Strengthening mechanisms of graphene- and Al2O3-reinforced aluminum nanocomposites synthesized by room temperature milling. Mater. Des. 2016, 92, 79–87. [Google Scholar] [CrossRef]

- Choi, H.J.; Shin, J.H.; Bae, D.H. Grain size effect on the strengthening behavior of aluminum-based composites containing multi-walled carbon nanotubes. Compos. Sci. Technol. 2011, 71, 1699–1705. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Shin, J.H.; Bae, D.H. Strengthening behavior of few-layered graphene/aluminum composites. Carbon 2015, 82, 143–151. [Google Scholar] [CrossRef]

- Bisht, A.; Srivastava, M.; Kumar, R.M.; Lahiri, I.; Lahiri, D. Strengthening mechanism in graphene nanoplatelets reinforced aluminum composite fabricated through spark plasma sintering. Mater. Sci. Eng. A 2017, 695, 20–28. [Google Scholar] [CrossRef]

- Kumar; Prashantha, H.G.; Anthony, M. Fatigue and Wear Behavior of Al6061–Graphene Composites Synthesized by Powder Metallurgy. Trans. Indian Inst. Met. 2016, 69, 415–419. [Google Scholar] [CrossRef]

- Li, Z.; Guo, Q.; Li, Z.; Fan, G.; Xiong, D.B.; Su, Y.; Zhang, J.; Zhang, D. Enhanced Mechanical Properties of Graphene (Reduced Graphene Oxide)/Aluminum Composites with a Bioinspired Nanolaminated Structure. Nano Lett. 2015, 15, 8077–8083. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Xiong, B. Effects of graphene content on microstructures and tensile property of graphene-nanosheets/aluminum composites. J. Alloys Compd. 2017, 697, 31–36. [Google Scholar] [CrossRef]

- Niteesh Kumar, S.J.; Keshavamurthy, R.; Haseebuddin, M.R.; Koppad, P.G. Mechanical Properties of Aluminium-Graphene Composite Synthesized by Powder Metallurgy and Hot Extrusion. Trans. Indian Inst. Met. 2017, 70, 605–613. [Google Scholar] [CrossRef]

- Huo, S.; Xie, L.; Xiang, J.; Pang, S.; Hu, F.; Umer, U. Atomic-level study on mechanical properties and strengthening mechanisms of Al/SiC nano-composites. Appl. Phys. A 2018, 124, 209. [Google Scholar] [CrossRef]

- Tavakol, M.; Mahnama, M.; Naghdabadi, R. Shock wave sintering of Al/SiC metal matrix nano-composites: A molecular dynamics study. Comput. Mater. Sci. 2016, 125, 255–262. [Google Scholar] [CrossRef]

- Kvashnin, D.G.; Ghorbani-Asl, M.; Shtansky, D.V.; Golberg, D.; Krasheninnikov, A.V.; Sorokin, P.B. Mechanical properties and current-carrying capacity of Al reinforced with graohene/BN nanoribbons: A computational study. Nanoscale 2016, 8, 20080. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.K.; Pathak, V.K.; Singh, R.; Dikshit, M.K. Stress-strain behaviour of graphene reinforced aluminum nanocompositeunder compressive loading using molecular dynamics. Mater. Today Proc. 2021, 44, 4521–4525. [Google Scholar] [CrossRef]

- Han, R.Q.; Song, H.Y.; An, M.R. Atomic simulation of interaction mechanism between dislocation and graphene in graphene/aluminum composites. Comput. Mater. Sci. 2021, 197, 110604. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, L.; Zhu, Y.; Li, N.; Sun, Y.; Zhang, J.; Ma, H. Mechanical properties of graphene nanoplatelets reinforced 7075 aluminum alloy composite fabricated by spark plasma sintering. Int. J. Miner. Metall. Mater. 2020, 27, 1295–1300. [Google Scholar] [CrossRef]

- He, H.P.; Rong, Y.; Zhang, L. Molecular dynamics studies on the sintering and mechanical behaviors of graphene nano-platelet reinforced aluminum matrix composites. Model. Simul. Mater. Sci. Eng. 2019, 27, 065006. [Google Scholar] [CrossRef]

- Jacobsen, K.W.; Norskov, J.K.; Puska, M.J. Interatomic interactions in the effective-medium theory. Phys. Rev. B 1987, 35, 7423–7442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brenner, D.W.; Shenderova, O.A.; Harrison, J.A.; Stuart, S.J.; Ni, B.; Sinnott, S.B. A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. J. Phys.-Condens. Matter 2002, 14, 783–802. [Google Scholar] [CrossRef] [Green Version]

- Dandekar, C.R.; Shin, Y.C. Molecular dynamics based cohesive zone law for describing Al–SiC interface mechanics. Compos. Part A 2011, 42, 355–363. [Google Scholar] [CrossRef]

- Kumar, S. Graphene Engendered aluminium crystal growth and mechanical properties of its composite: An atomistic investigation. Mater. Chem. Phys. 2018, 208, 41–48. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, N.; Li, W.; Niu, L.; Li, Z. Atomistic Study on the Sintering Process and the Strengthening Mechanism of Al-Graphene System. Materials 2022, 15, 2644. [Google Scholar] [CrossRef]

- Tian, W.M.; Li, S.M.; Wang, B.; Chen, X.; Liu, J.H.; Yu, M. Graphene-reinforced aluminum matrix composites prepared by spark plasma sintering. Int. J. Miner. Metall. Mater. 2016, 23, 723–729. [Google Scholar] [CrossRef]

- Kuang, D.; Xu, L.; Liu, L.; Hu, W.; Wu, Y. Graphene-nickel composites. Appl. Surf. Sci. 2013, 273, 484–490. [Google Scholar] [CrossRef]

- Schiøtz, J.; Tolla, F.D.; Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 1998, 391, 561–563. [Google Scholar] [CrossRef]

- Shin, S.E.; Bae, D.H. Deformation behavior of aluminum alloy matrix composites reinforced with few-layer graphene. Compos. Part A Appl. Sci. Manuf. 2015, 78, 42–47. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Li, N.; Zhu, Y.; Liu, K. A Model for Direct Effect of Graphene on Mechanical Property of Al Matrix Composite. Metals 2023, 13, 1351. https://doi.org/10.3390/met13081351

Sun H, Li N, Zhu Y, Liu K. A Model for Direct Effect of Graphene on Mechanical Property of Al Matrix Composite. Metals. 2023; 13(8):1351. https://doi.org/10.3390/met13081351

Chicago/Turabian StyleSun, Hongshuo, Na Li, Yongchao Zhu, and Kailiang Liu. 2023. "A Model for Direct Effect of Graphene on Mechanical Property of Al Matrix Composite" Metals 13, no. 8: 1351. https://doi.org/10.3390/met13081351

APA StyleSun, H., Li, N., Zhu, Y., & Liu, K. (2023). A Model for Direct Effect of Graphene on Mechanical Property of Al Matrix Composite. Metals, 13(8), 1351. https://doi.org/10.3390/met13081351