Additive Manufacturing of AISI 316L Stainless Steel: A Review

Abstract

:1. Introduction

- ▪

- ▪

- ▪

- ▪

- ▪

- ▪

- ▪

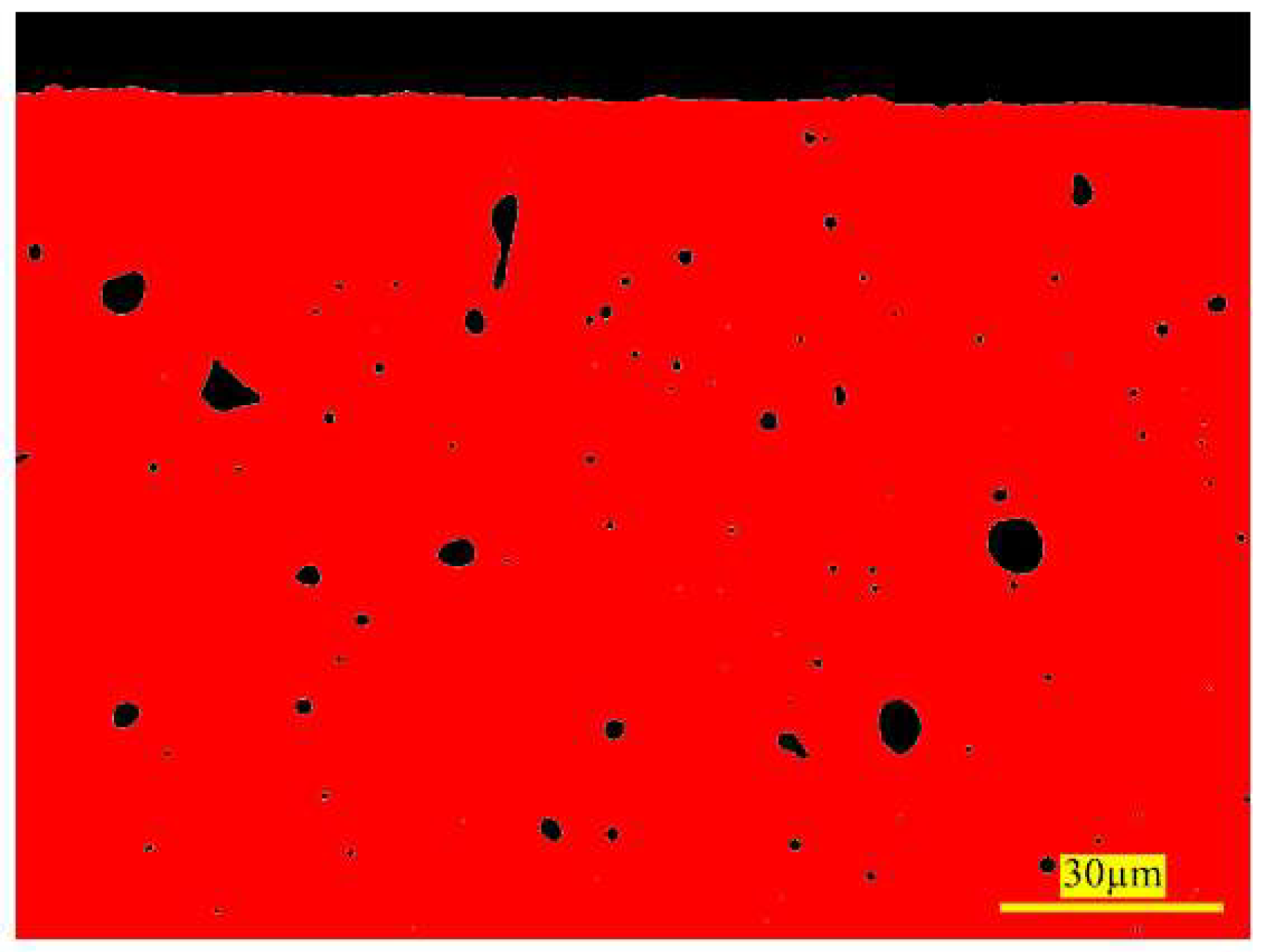

- Microstructure and mechanical properties [26]: In some cases, another disadvantage of AM is the microstructure of the printed parts, which is characterized by porosity [27], voids [28], grain growth, inclusions, and un-melted powders [29] that cause differences in material properties, such as strength, toughness, and fatigue resistance. The microstructure of printed materials is influenced by many factors, including the printing parameters [30,31,32], the type of material used, and the post-processing steps. It is possible to underline that, in many cases, the use of suitable printing parameters leads to the achievement of better mechanical properties even compared to traditional processes. In fact, the microstructure of a printed part can be improved through heat treatment or other post-processing steps.

2. AM Technologies for AISI 316L

2.1. Powder Bed Fusion (PBF) Technology

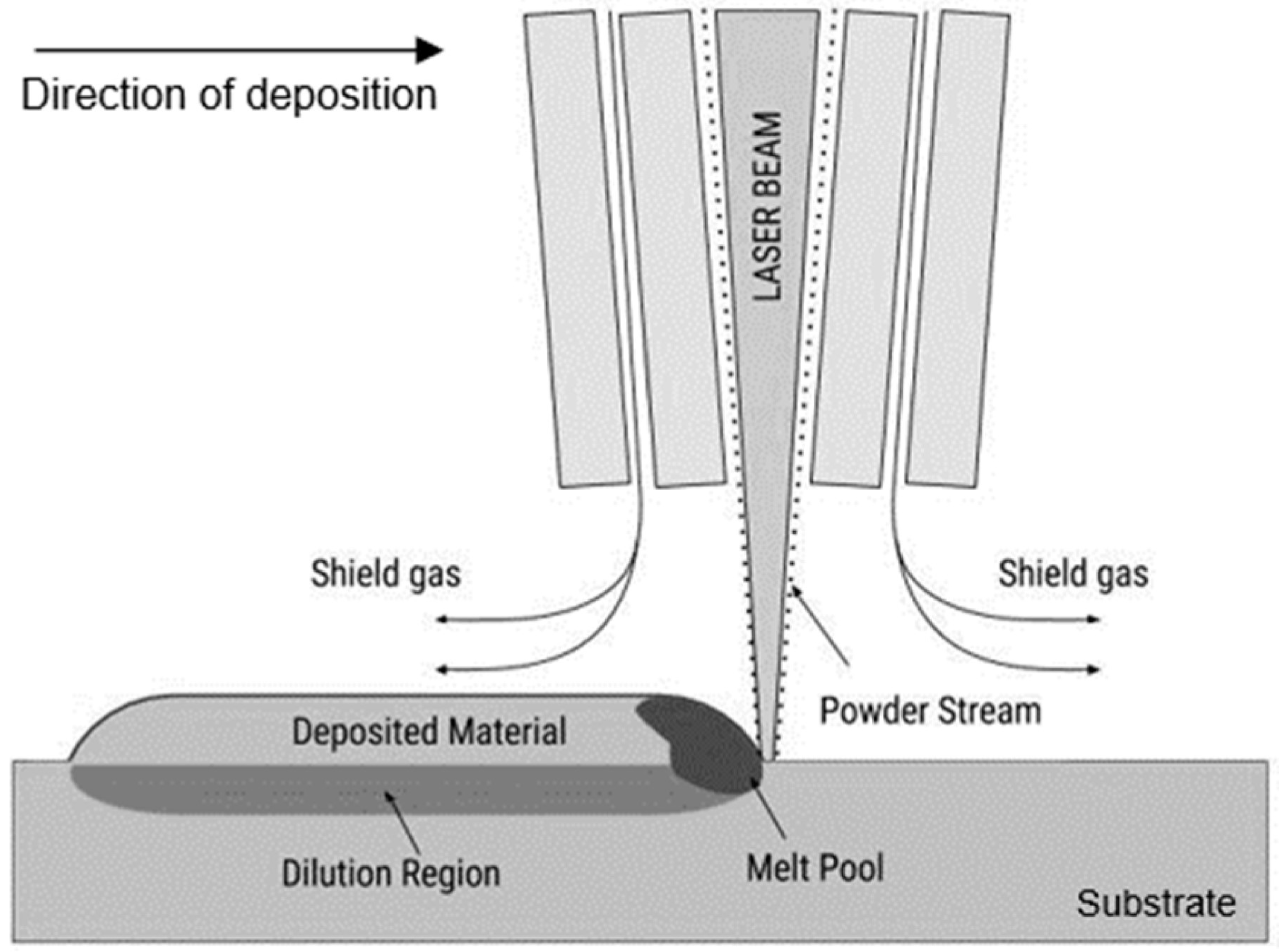

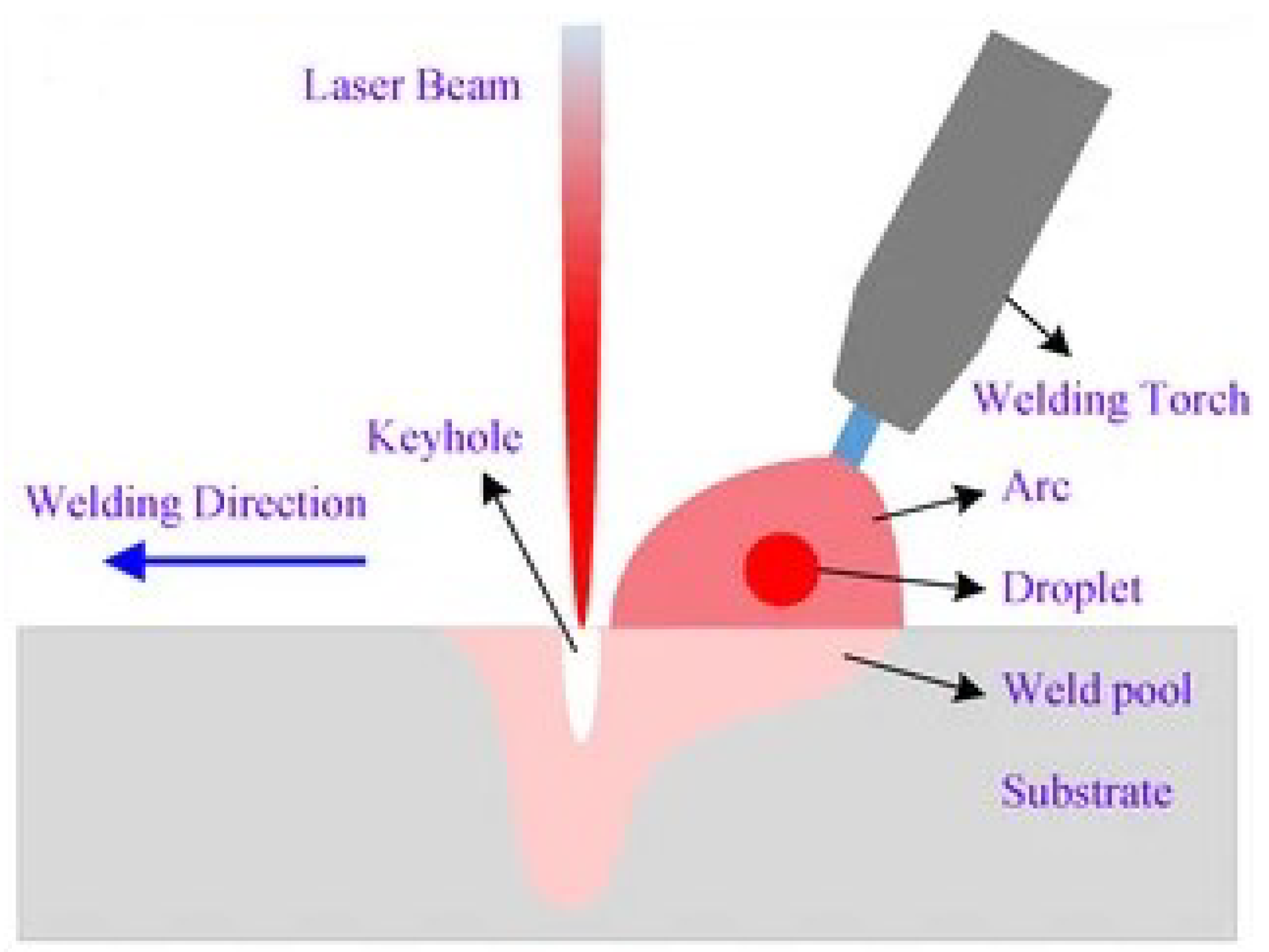

2.2. Directed Energy Deposition (DED) Technology

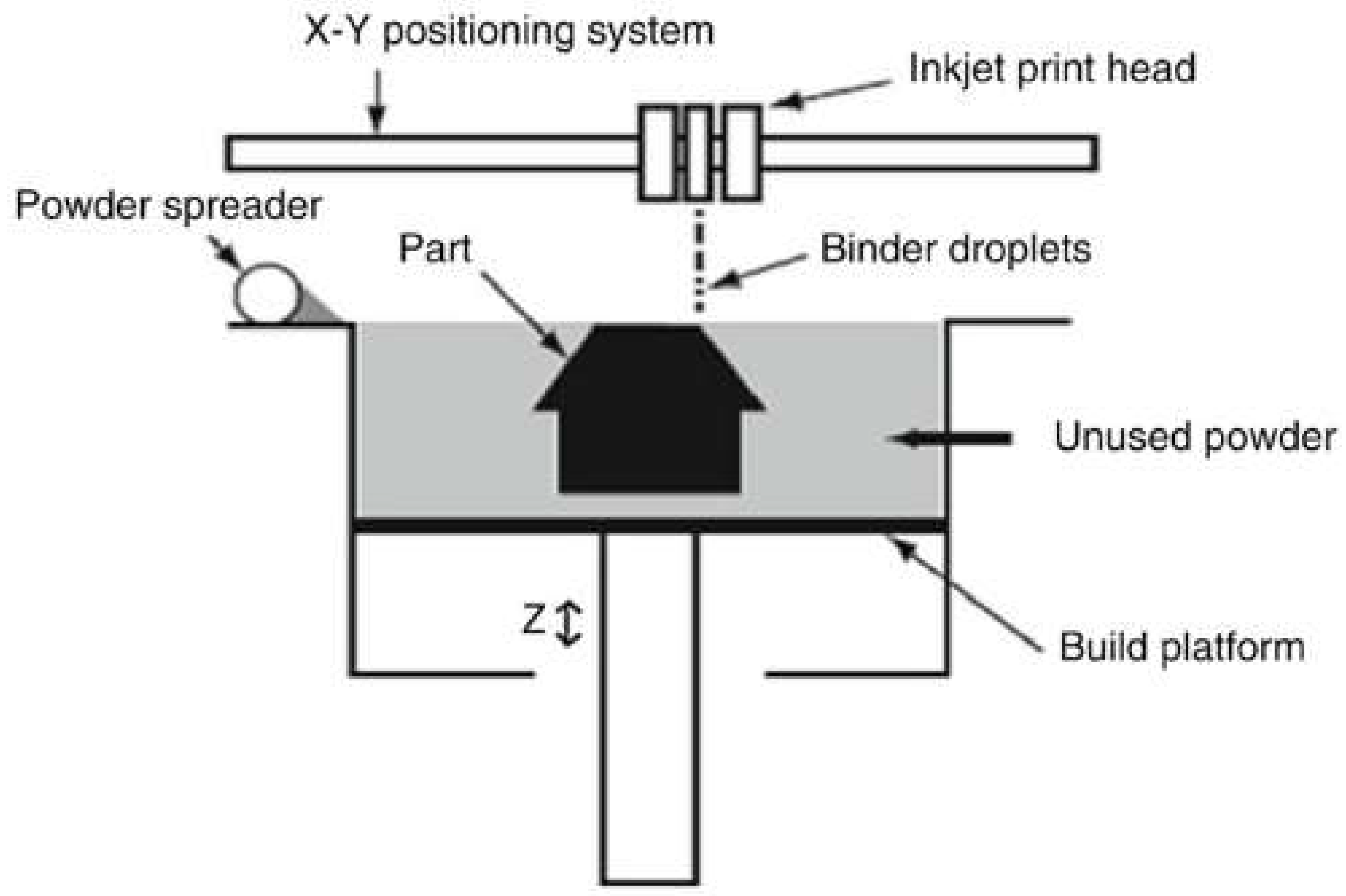

2.3. Binder Jetting (BJ) Tehcnology

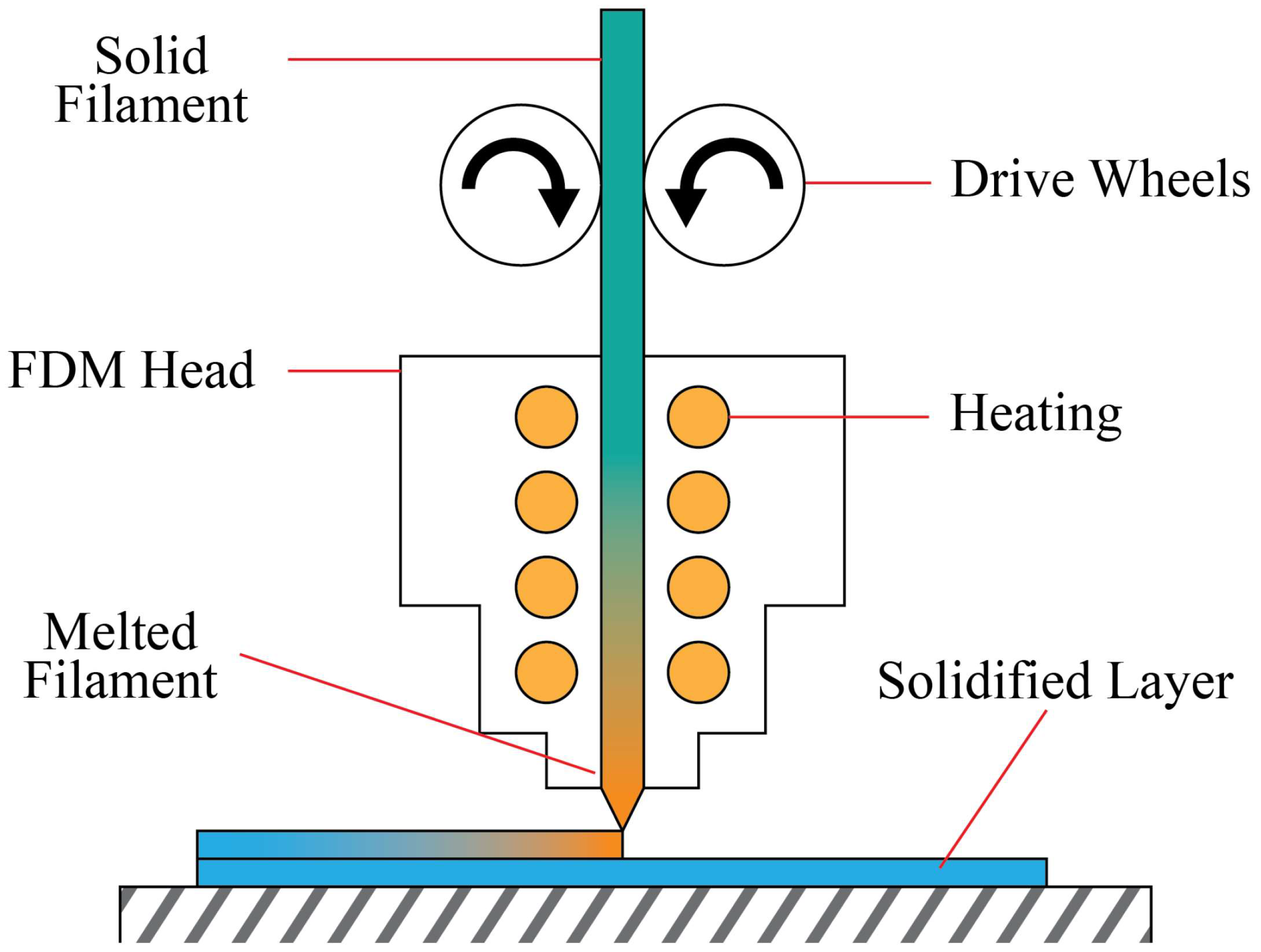

2.4. Fused Deposition Modeling (FDM) Technology

2.5. Emerging Technologies

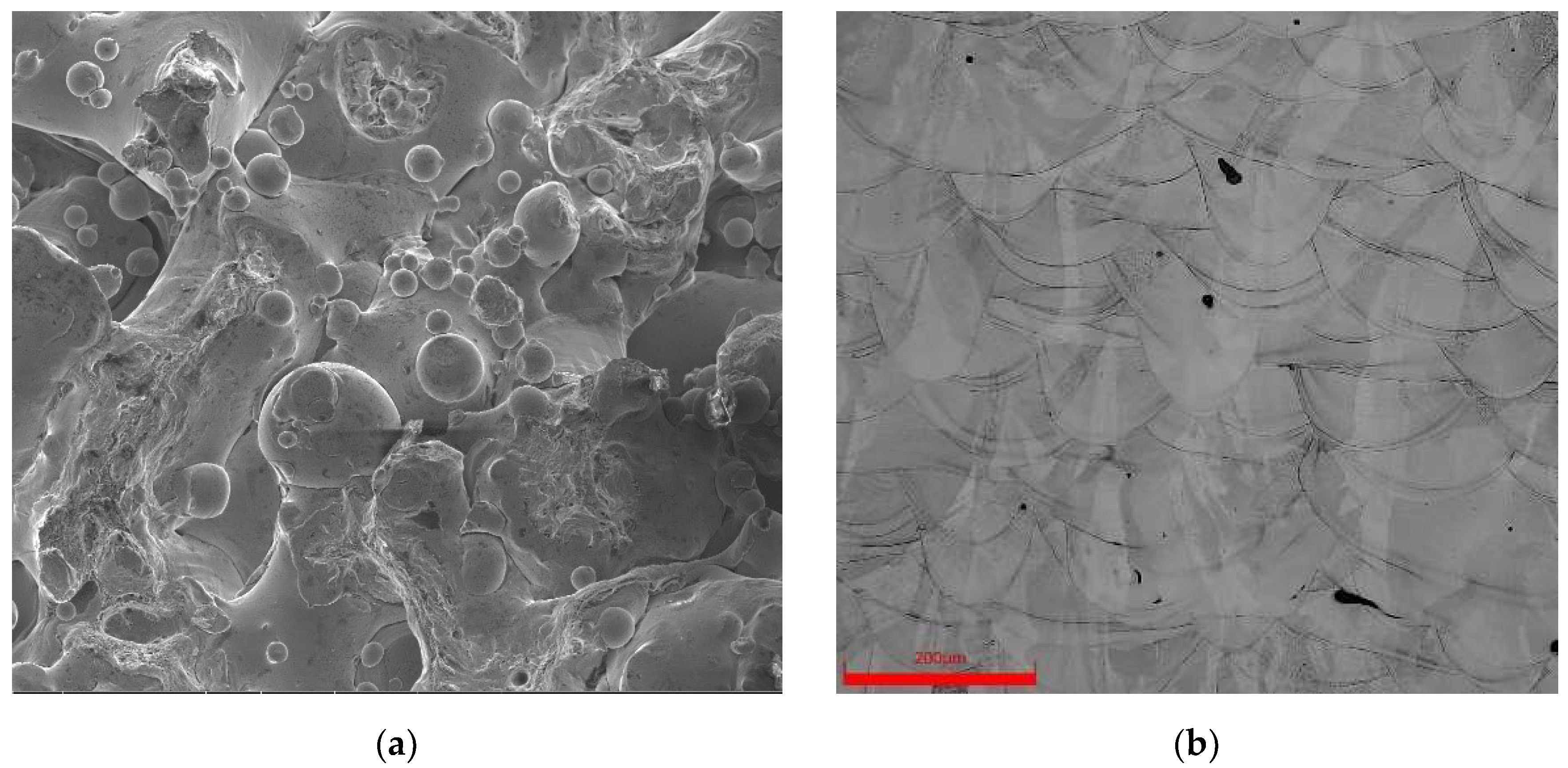

3. Microstructure Defects in AM AISI 316L

3.1. Lack of Fusion and Keyhole Collapse

3.2. Gas Porosity

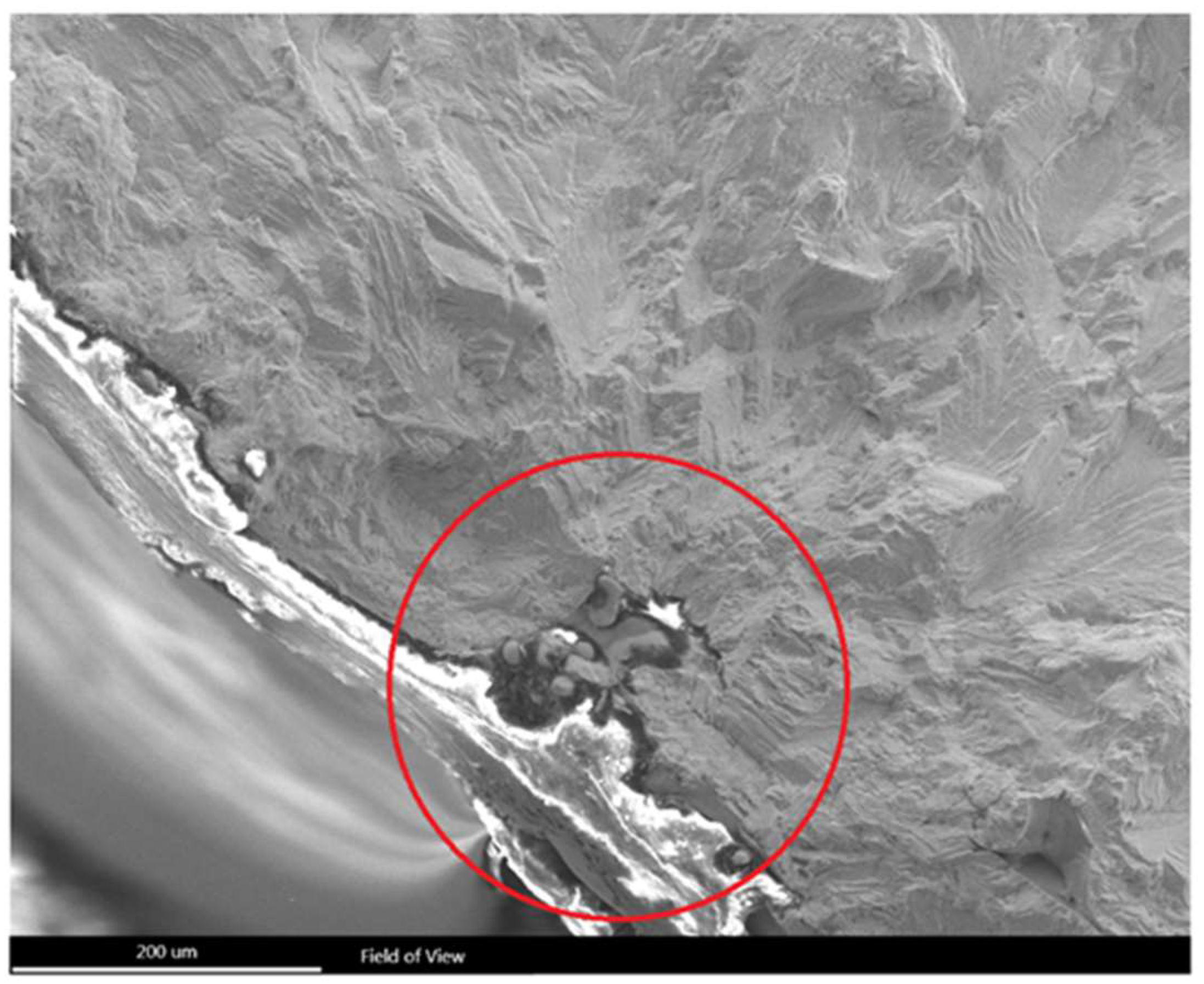

3.3. Surface Quality

3.4. Solidification Cracking and Residual Stresses

3.5. Influence of Printing Parameters and Mitigation Strategies

4. Mechanical Properties

4.1. Hardness

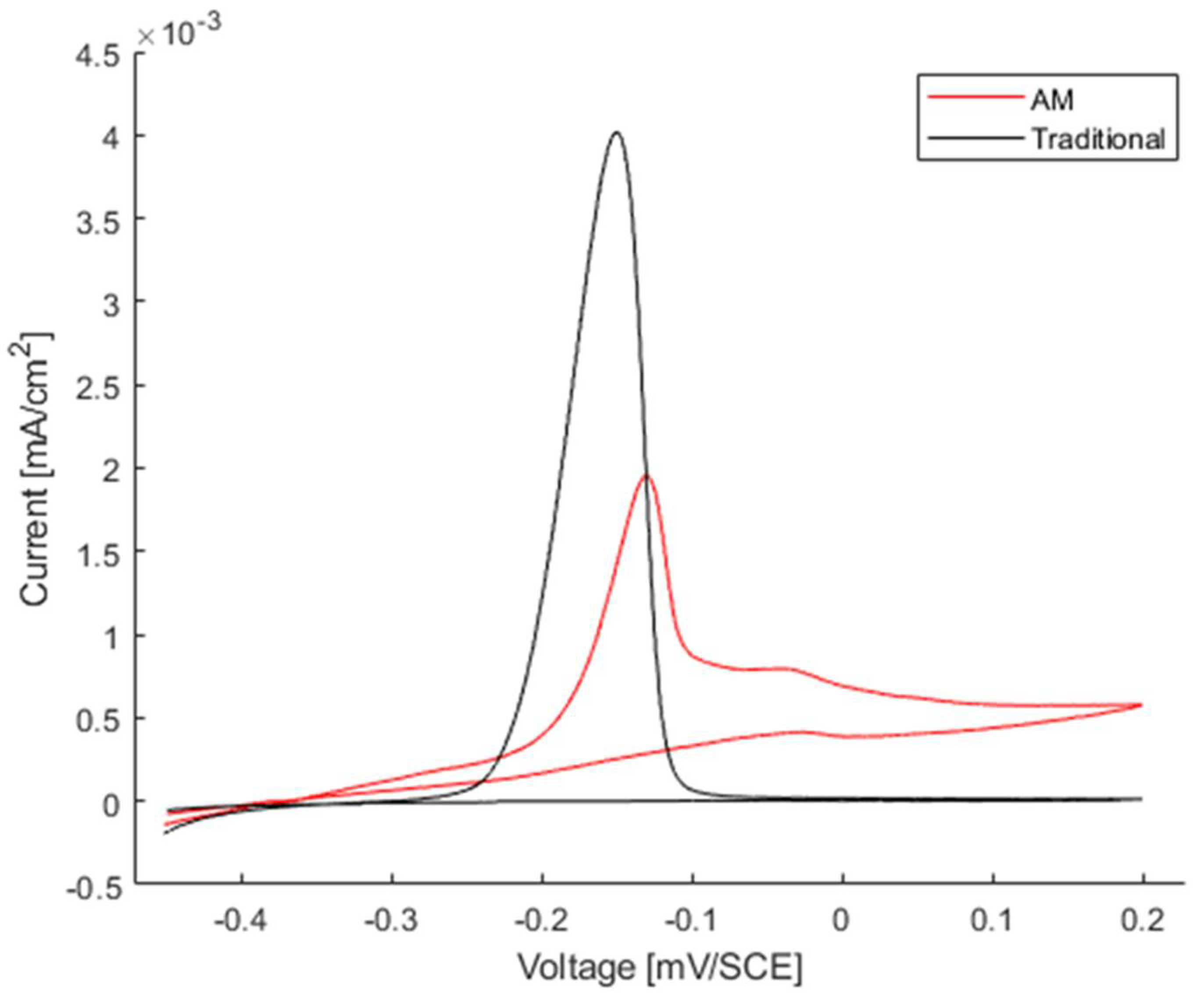

4.2. Corrosion Resistance

4.3. Tensile and Fatigue Properties

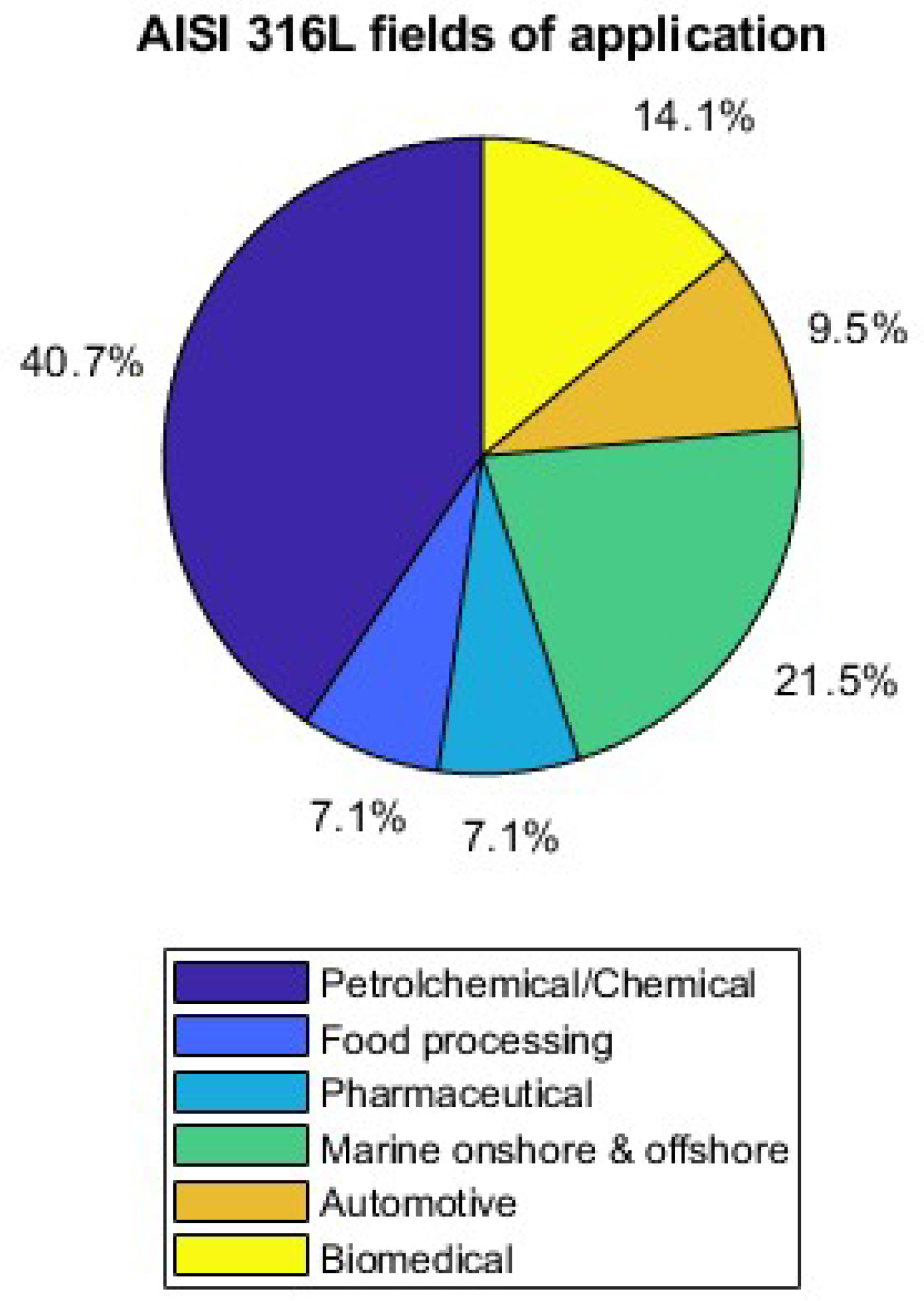

5. Applications

6. Challenges and Future Trends

- ▪

- The high manufacturing time and therefore the low production volumes, which make AM suitable today for particular markets such as aerospace or prosthetics.

- ▪

- The surface quality of the finished components, which is a function of the layer resolution. While a higher layer resolution provides a better surface finish, it greatly increases the total build time.

- ▪

- The limited variety of materials that can be used in AM units, with the difficulty of printing multiple materials simultaneously, limit the use of this technology to particular sectors.

- ▪

- The need for post-processing treatments to eliminate excess material, supports, residual stresses and, where possible, improve the surface finish, represent a barrier to AM accessibility.

Funding

Data Availability Statement

Conflicts of Interest

References

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing—An Overview. Mater. Today Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Karakurt, I.; Lin, L. 3D Printing Technologies: Techniques, Materials, and Post-Processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Francois, M.M.; Sun, A.; King, W.E.; Henson, N.J.; Tourret, D.; Bronkhorst, C.A.; Carlson, N.N.; Newman, C.K.; Haut, T.; Bakosi, J.; et al. Modeling of Additive Manufacturing Processes for Metals: Challenges and Opportunities. Curr. Opin. Solid State Mater. Sci. 2017, 21, 198–206. [Google Scholar] [CrossRef]

- Pelz, J.S.; Ku, N.; Meyers, M.A.; Vargas-Gonzalez, L.R. Additive Manufacturing of Structural Ceramics: A Historical Perspective. J. Mater. Res. Technol. 2021, 15, 670–695. [Google Scholar] [CrossRef]

- Bove, A.; Calignano, F.; Galati, M.; Iuliano, L. Photopolymerization of Ceramic Resins by Stereolithography Process: A Review. Appl. Sci. 2022, 12, 3591. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 638905 8 August 1984. [Google Scholar]

- Maas, J.; Liu, B.; Hajela, S.; Huang, Y.; Gong, X.; Chappell, W.J. Laser-Based Layer-by-Layer Polymer Stereolithography for High-Frequency Applications. Proc. IEEE 2017, 105, 645–654. [Google Scholar] [CrossRef]

- Gornet, T. History of Additive Manufacturing. In 3D Printing and Its Impact on the Production of Fully Functional Components: Emerging Research and Opportunities; IGI Global: Hershey, PA, USA, 2017; pp. 1–24. [Google Scholar] [CrossRef]

- Huang, B.; Singamneni, S.B. Curved Layer Adaptive Slicing (CLAS) for Fused Deposition Modelling. Rapid Prototyp. J. 2015, 21, 354–367. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical Property of FDM Printed ABS: Influence of Printing Parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Lannunziata, E.; Saboori, A.; Galati, M.; Iuliano, L. Laser Powder Bed Fusion of AISI 316L Lattice Structures for Biomedical Applications. Mater. Today Proc. 2022, 70, 345–351. [Google Scholar] [CrossRef]

- Olivas-Alanis, L.H.; Fraga-Martínez, A.A.; García-López, E.; Lopez-Botello, O.; Vazquez-Lepe, E.; Cuan-Urquizo, E.; Rodriguez, C.A. Mechanical Properties of AISI 316L Lattice Structures via Laser Powder Bed Fusion as a Function of Unit Cell Features. Materials 2023, 16, 1025. [Google Scholar] [CrossRef] [PubMed]

- Devarajan, B.; Bhuvaneswari, V.; Arulmurugan, B.; Narayana, A.V.N.S.L.; Priya, A.K.; Abbaraju, V.D.N.K.; Mukunthan, K.S.; Sharma, A.K.; Ting, S.S.; Masi, C. Hybrid Novel Additive Manufacturing for Sustainable Usage of Waste. J. Nanomater. 2022, 2022, 2697036. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing Environmental Impacts of Additive Manufacturing vs Traditional Machining via Life-Cycle Assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef] [Green Version]

- Von Cieminski, G. Advances in Production Management Systems; Springer: Cham, Switzerland, 1983; Volume 4, ISSN 9783319227580. [Google Scholar]

- Atzeni, E.; Iuliano, L.; Marchiandi, G.; Minetola, P.; Salmi, A.; Bassoli, E.; Denti, L.; Gatto, A. Additive Manufacturing as a Cost-Effective Way to Produce Metal Parts. In Proceedings of the High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping-Proceedings of the 6th International Conference on Advanced Research and Rapid Prototyping, VR@ P, Leiria, Portugal, 1–5 October 2013; pp. 3–8. [Google Scholar]

- Thomas, D. Costs, Benefits, and Adoption of Additive Manufacturing: A Supply Chain Perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Delic, M.; Eyers, D.R. The Effect of Additive Manufacturing Adoption on Supply Chain Flexibility and Performance: An Empirical Analysis from the Automotive Industry. Int. J. Prod. Econ. 2020, 228, 107689. [Google Scholar] [CrossRef]

- Luomaranta, T.; Martinsuo, M. Supply Chain Innovations for Additive Manufacturing. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 54–79. [Google Scholar] [CrossRef]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Sci. Manag. 2017, 10, 189–206. [Google Scholar] [CrossRef] [Green Version]

- Yadav, A.; Srivastav, A.; Singh, A.; Mushtaque, M.D.; Khan, S.A.; Kumar, H.; Arora, P.K. Investigation on the Materials Used in Additive Manufacturing: A Study. Mater. Today Proc. 2020, 43, 154–157. [Google Scholar] [CrossRef]

- Bhuvanesh Kumar, M.; Sathiya, P. Methods and Materials for Additive Manufacturing: A Critical Review on Advancements and Challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods Used to Improve Surface Finish of Products Which Are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Cao, L.; Li, J.; Hu, J.; Liu, H.; Wu, Y.; Zhou, Q. Optimization of Surface Roughness and Dimensional Accuracy in LPBF Additive Manufacturing. Opt. Laser Technol. 2021, 142, 107246. [Google Scholar] [CrossRef]

- Brennan, M.C.; Keist, J.S.; Palmer, T.A. Defects in Metal Additive Manufacturing Processes. J. Mater. Eng. Perform. 2021, 30, 4808–4818. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Breese, P.P.; Lutz, B.S.; Pantano, M.; Nalam, Y.; Bela, K.; Kamps, T.; Volpp, J.; Kaplan, A.F.H. Porosity in Wire Arc Additive Manufacturing of Aluminium Alloys. Addit. Manuf. 2021, 41, 101993. [Google Scholar] [CrossRef]

- Hernandez-Contreras, A.; Ruiz-Huerta, L.; Caballero-Ruiz, A.; Moock, V.; Siller, H.R. Extended CT Void Analysis in FDM Additive Manufacturing Components. Materials 2020, 13, 3831. [Google Scholar] [CrossRef] [PubMed]

- Gui, Y.; Aoyagi, K.; Bian, H.; Chiba, A. Detection, Classification and Prediction of Internal Defects from Surface Morphology Data of Metal Parts Fabricated by Powder Bed Fusion Type Additive Manufacturing Using an Electron Beam. Addit. Manuf. 2022, 54, 102736. [Google Scholar] [CrossRef]

- Raam Kumar, S.; Sridhar, S.; Venkatraman, R.; Venkatesan, M. Polymer Additive Manufacturing of ASA Structure: Influence of Printing Parameters on Mechanical Properties. Mater. Today Proc. 2020, 39, 1316–1319. [Google Scholar] [CrossRef]

- Hu, Q.; Rance, G.A.; Trindade, G.F.; Pervan, D.; Jiang, L.; Foerster, A.; Turyanska, L.; Tuck, C.; Irvine, D.J.; Hague, R.; et al. The Influence of Printing Parameters on Multi-Material Two-Photon Polymerisation Based Micro Additive Manufacturing. Addit. Manuf. 2022, 51, 102575. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C.; Varela-Soriano, J.; Rojas-Carreón, J.J. The Effects of Printing Parameters on Quality, Strength, Mass, and Processing Time of Polylactic Acid Specimens Produced by Additive Manufacturing. Prog. Addit. Manuf. 2021, 6, 821–840. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.H.; Rolfe, B.; Gibson, I. Additive Manufacturing a Powerful Tool for the Aerospace Industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace Applications of Laser Additive Manufacturing; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081004340. [Google Scholar]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive Manufacturing Tooling for the Automotive Industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Dwivedi, G.; Srivastava, S.K.; Srivastava, R.K. Analysis of Barriers to Implement Additive Manufacturing Technology in the Indian Automotive Sector. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 972–991. [Google Scholar] [CrossRef]

- Salifu, S.; Desai, D.; Ogunbiyi, O.; Mwale, K. Recent Development in the Additive Manufacturing of Polymer-Based Composites for Automotive Structures—A Review. Int. J. Adv. Manuf. Technol. 2022, 119, 6877–6891. [Google Scholar] [CrossRef]

- Böckin, D.; Tillman, A.-M. Environmental Assessment of Additive Manufacturing in the Automotive Industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Vignesh, M.; Ranjith Kumar, G.; Sathishkumar, M.; Manikandan, M.; Rajyalakshmi, G.; Ramanujam, R.; Arivazhagan, N. Development of Biomedical Implants through Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2021, 30, 4735–4744. [Google Scholar] [CrossRef]

- Oliveira, T.T.; Reis, A.C. Fabrication of Dental Implants by the Additive Manufacturing Method: A Systematic Review. J. Prosthet. Dent. 2019, 122, 270–274. [Google Scholar] [CrossRef] [PubMed]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and Electron-Beam Powder-Bed Additive Manufacturing of Metallic Implants: A Review on Processes, Materials and Designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef]

- Wang, Y.; Fu, P.; Wang, N.; Peng, L.; Kang, B.; Zeng, H.; Yuan, G.; Ding, W. Challenges and Solutions for the Additive Manufacturing of Biodegradable Magnesium Implants. Engineering 2020, 6, 1267–1275. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Tatineni, J.; Cadd, B.; Peart, G.; Gibson, I. Applications of 3D Topography Scanning and Multi-Material Additive Manufacturing for Facial Prosthesis Development and Production. In Proceedings of the Solid Freeform Fabrication 2016: Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016; pp. 1695–1707. [Google Scholar]

- Coulter, F.B.; Schaffner, M.; Faber, J.A.; Rafsanjani, A.; Smith, R.; Appa, H.; Zilla, P.; Bezuidenhout, D.; Studart, A.R. Bioinspired Heart Valve Prosthesis Made by Silicone Additive Manufacturing. Matter 2019, 1, 266–279. [Google Scholar] [CrossRef] [Green Version]

- Soares, B.; Ribeiro, I.; Cardeal, G.; Leite, M.; Carvalho, H.; Peças, P. Social Life Cycle Performance of Additive Manufacturing in the Healthcare Industry: The Orthosis and Prosthesis Cases. Int. J. Comput. Integr. Manuf. 2021, 34, 327–340. [Google Scholar] [CrossRef]

- ISO/ASTM 52900; Standard Terminology for Additive Manufacturing–General Principles–Terminology. International Organization for Standardization: Geneva, Switzerland, 2015.

- Mazurchevici, A.D.; Nedelcu, D.; Popa, R. Additive Manufacturing of Composite Materials by FDM Technology: A Review. Indian J. Eng. Mater. Sci. 2020, 27, 179–192. [Google Scholar] [CrossRef]

- D’andrea, D.; Risitano, G.; Raffaele, M.; Cucinotta, F.; Santonocito, D. Damage Assessment of Different FDM-Processed Materials Adopting Infrared Thermography. Frat. Integr. Strutt. 2022, 16, 75–90. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic Stereolithography: Additive Manufacturing for Ceramics by Photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Li, H.; Song, L.; Sun, J.; Ma, J.; Shen, Z. Dental Ceramic Prostheses by Stereolithography-Based Additive Manufacturing: Potentials and Challenges. Adv. Appl. Ceram. 2019, 118, 30–36. [Google Scholar] [CrossRef] [Green Version]

- Borlaf, M.; Serra-Capdevila, A.; Colominas, C.; Graule, T. Development of UV-Curable ZrO2 Slurries for Additive Manufacturing (LCM-DLP) Technology. J. Eur. Ceram. Soc. 2019, 39, 3797–3803. [Google Scholar] [CrossRef]

- Wiese, M.; Kwauka, A.; Thiede, S.; Herrmann, C. Economic Assessment for Additive Manufacturing of Automotive End-Use Parts through Digital Light Processing (DLP). CIRP J. Manuf. Sci. Technol. 2021, 35, 268–280. [Google Scholar] [CrossRef]

- D’Andrea, D.; Risitano, G.; Guglielmino, E.; Piperopoulos, E.; Santonocito, D. Correlation between Mechanical Behaviour and Microstructural Features of AISI 316L Produced by SLM. Procedia Struct. Integr. 2022, 41, 199–207. [Google Scholar] [CrossRef]

- Zhang, L.C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Azami, M.; Siahsarani, A.; Hadian, A.; Kazemi, Z.; Rahmatabadi, D.; Kashani-Bozorg, S.F.; Abrinia, K. Laser Powder Bed Fusion of Alumina/Fe–Ni Ceramic Matrix Particulate Composites Impregnated with a Polymeric Resin. J. Mater. Res. Technol. 2023, 24, 3133–3144. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef] [Green Version]

- Haley, J.C.; Schoenung, J.M.; Lavernia, E.J. Modelling Particle Impact on the Melt Pool and Wettability Effects in Laser Directed Energy Deposition Additive Manufacturing. Mater. Sci. Eng. A 2019, 761, 138052. [Google Scholar] [CrossRef]

- Gaytan, S.M.; Cadena, M.A.; Karim, H.; Delfin, D.; Lin, Y.; Espalin, D.; MacDonald, E.; Wicker, R.B. Fabrication of Barium Titanate by Binder Jetting Additive Manufacturing Technology. Ceram. Int. 2015, 41, 6610–6619. [Google Scholar] [CrossRef] [Green Version]

- Lores, A.; Azurmendi, N.; Agote, I.; Zuza, E. A Review on Recent Developments in Binder Jetting Metal Additive Manufacturing: Materials and Process Characteristics. Powder Metall. 2019, 62, 267–296. [Google Scholar] [CrossRef]

- Vu, I.Q.; Bass, L.B.; Williams, C.B.; Dillard, D.A. Characterizing the Effect of Print Orientation on Interface Integrity of Multi-Material Jetting Additive Manufacturing. Addit. Manuf. 2018, 22, 447–461. [Google Scholar] [CrossRef]

- Sturm, L.D.; Albakri, M.I.; Tarazaga, P.A.; Williams, C.B. In Situ Monitoring of Material Jetting Additive Manufacturing Process via Impedance Based Measurements. Addit. Manuf. 2019, 28, 456–463. [Google Scholar] [CrossRef]

- Ghajari, A. Sheet Lamination Additive Manufacturing of 316L/AISI 4140 Parts Using Friction Stir Method. 2023. preprint. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Kabir, A.M.; Peralta, M.; Bruck, H.A.; Gupta, S.K. A Robotic Cell for Performing Sheet Lamination-Based Additive Manufacturing. Addit. Manuf. 2019, 27, 278–289. [Google Scholar] [CrossRef]

- Bedmar, J.; Riquelme, A.; Rodrigo, P.; Torres, B.; Rams, J. Comparison of Different Additive Manufacturing Methods for 316l Stainless Steel. Materials 2021, 14, 6504. [Google Scholar] [CrossRef]

- Avanzini, A. Fatigue Behavior of Additively Manufactured Stainless Steel 316L. Materials 2023, 16, 65. [Google Scholar] [CrossRef]

- Kasha, A.; Obadimu, S.O.; Kourousis, K.I. Flexural Characteristics of Material Extrusion Steel 316L: Influence of Manufacturing Parameters. Addit. Manuf. Lett. 2022, 3, 100087. [Google Scholar] [CrossRef]

- Aversa, A.; Saboori, A.; Librera, E.; de Chirico, M.; Biamino, S.; Lombardi, M.; Fino, P. The Role of Directed Energy Deposition Atmosphere Mode on the Microstructure and Mechanical Properties of 316L Samples. Addit. Manuf. 2020, 34, 101274. [Google Scholar] [CrossRef]

- Kale, A.B.; Kim, B.K.; Kim, D.I.; Castle, E.G.; Reece, M.; Choi, S.H. An Investigation of the Corrosion Behavior of 316L Stainless Steel Fabricated by SLM and SPS Techniques. Mater. Charact. 2020, 163, 110204. [Google Scholar] [CrossRef]

- Nguyen, D.; Park, H.; Lee, C. Applying Selective Laser Melting to Join Al and Fe: An Investigation of Dissimilar Materials. Appl. Sci. 2019, 9, 3031. [Google Scholar] [CrossRef] [Green Version]

- Dzogbewu, T.C.; du Preez, W.B. Additive Manufacturing of Ti-Based Intermetallic Alloys: A Review and Conceptualization of a next-Generation Machine. Materials 2021, 14, 4317. [Google Scholar] [CrossRef]

- Gokuldoss, P.K. Selective Laser Melting: Materials and Applications; MDPI: Basel, Switzerland, 2020; ISSN 3039285785. [Google Scholar]

- Yadroitsev, I.; Yadroitsava, I.; Du Plessis, A.; MacDonald, E. Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 0128240911. [Google Scholar]

- Yadroitsev, I.; Yadroitsava, I.; Du Plessis, A. Basics of Laser Powder Bed Fusion. In Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021; pp. 15–38. [Google Scholar]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical Behavior of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Siri, C.; Popa, I.; Vion, A.; Langlade, C.; Chevalier, S. Impact of Selective Laser Melting Additive Manufacturing on the High Temperature Behavior of AISI 316L Austenitic Stainless Steel. Oxid. Met. 2020, 94, 527–548. [Google Scholar] [CrossRef]

- Rosa, F.; Manzoni, S.; Casati, R. Damping Behavior of 316L Lattice Structures Produced by Selective Laser Melting. Mater. Des. 2018, 160, 1010–1018. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.X.; Zhang, Y.W. Modeling and Control of Remelting in High-Energy Beam Additive Manufacturing. Addit. Manuf. 2015, 7, 57–63. [Google Scholar] [CrossRef]

- Astafurova, E.G.; Panchenko, M.Y.; Moskvina, V.A.; Maier, G.G.; Astafurov, S.V.; Melnikov, E.V.; Fortuna, A.S.; Reunova, K.A.; Rubtsov, V.E.; Kolubaev, E.A. Microstructure and Grain Growth Inhomogeneity in Austenitic Steel Produced by Wire-Feed Electron Beam Melting: The Effect of Post-Building Solid-Solution Treatment. J. Mater. Sci. 2020, 55, 9211–9224. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Liu, E.; Tor, S.B. Process Parameter Optimization and Mechanical Properties for Additively Manufactured Stainless Steel 316L Parts by Selective Electron Beam Melting. Mater. Des. 2018, 147, 157–166. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of Process Time Interval and Heat Treatment on the Mechanical and Microstructural Properties of Direct Laser Deposited 316L Stainless Steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on Microstructure, Mechanical Properties and Machinability of Efficiently Additive Manufactured AISI 316L Stainless Steel by High-Power Direct Laser Deposition. J. Mater. Process. Technol. 2017, 240, 12–22. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Microstructure and Mechanical Properties of AISI 316L Produced by Directed Energy Deposition-Based Additive Manufacturing: A Review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Moheimani, S.K.; Iuliano, L.; Saboori, A. The Role of Substrate Preheating on the Microstructure, Roughness, and Mechanical Performance of AISI 316L Produced by Directed Energy Deposition Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2022, 119, 7159–7174. [Google Scholar] [CrossRef]

- Azinpour, E.; Darabi, R.; Cesar de Sa, J.; Santos, A.; Hodek, J.; Dzugan, J. Fracture Analysis in Directed Energy Deposition (DED) Manufactured 316L Stainless Steel Using a Phase-Field Approach. Finite Elem. Anal. Des. 2020, 177, 103417. [Google Scholar] [CrossRef]

- Xu, K.; Li, B.; Jiang, C. Adjusting Microstructure and Improving Mechanical Property of Additive Manufacturing 316L Based on Process Optimization. Mater. Sci. Eng. A 2023, 870, 144824. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Pasebani, S. A Review on Binder Jet Additive Manufacturing of 316L Stainless Steel. J. Manuf. Mater. Process. 2019, 3, 8–12. [Google Scholar] [CrossRef] [Green Version]

- Meenashisundaram, G.K.; Xu, Z.; Nai, M.L.S.; Lu, S.; Ten, J.S.; Wei, J. Binder Jetting Additive Manufacturing of High Porosity 316L Stainless Steel Metal Foams. Materials 2020, 13, 3744. [Google Scholar] [CrossRef]

- Atapour, M.; Wang, X.; Persson, M.; Odnevall Wallinder, I.; Hedberg, Y.S. Corrosion of Binder Jetting Additively Manufactured 316L Stainless Steel of Different Surface Finish. J. Electrochem. Soc. 2020, 167, 131503. [Google Scholar] [CrossRef]

- Lecis, N.; Mariani, M.; Beltrami, R.; Emanuelli, L.; Casati, R.; Vedani, M.; Molinari, A. Effects of Process Parameters, Debinding and Sintering on the Microstructure of 316L Stainless Steel Produced by Binder Jetting. Mater. Sci. Eng. A 2021, 828, 142108. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, B.; Qu, X. Microstructure Evolution and Mechanical Behavior of SS316L Alloy Fabricated by a Non-Toxic and Low Residue Binder Jetting Process. Appl. Surf. Sci. 2023, 616, 156589. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A Simple Route for Additive Manufacturing of 316L Stainless Steel via Fused Filament Fabrication. J. Manuf. Process. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Carminati, M.; Quarto, M.; D’urso, G.; Giardini, C.; Borriello, C. A Comprehensive Analysis of AISI 316L Samples Printed via FDM: Structural and Mechanical Characterization. Key Eng. Mater. 2022, 926, 46–55. [Google Scholar] [CrossRef]

- Carminati, M.; Quarto, M.; D’urso, G.; Giardini, C.; Maccarini, G. Mechanical Characterization of AISI 316L Samples Printed Using Material Extrusion. Appl. Sci. 2022, 12, 1433. [Google Scholar] [CrossRef]

- Quarto, M.; Carminati, M.; D’Urso, G. Density and Shrinkage Evaluation of AISI 316L Parts Printed via FDM Process. Mater. Manuf. Process. 2021, 36, 1535–1543. [Google Scholar] [CrossRef]

- Sampedro, G.A.R.; Rachmawati, S.M.; Kim, D.S.; Lee, J.M. Exploring Machine Learning-Based Fault Monitoring for Polymer-Based Additive Manufacturing: Challenges and Opportunities. Sensors 2022, 22, 9446. [Google Scholar] [CrossRef] [PubMed]

- Vinoth, V.; Sathiyamurthy, S.; Natarajan, U.; Venkatkumar, D.; Prabhakaran, J.; Sanjeevi Prakash, K. Examination of Microstructure Properties of AISI 316L Stainless Steel Fabricated by Wire Arc Additive Manufacturing. Mater. Today Proc. 2022, 66, 702–706. [Google Scholar] [CrossRef]

- Ivántabernero; Paskual, A.; Álvarez, P.; Suárez, A. Study on Arc Welding Processes for High Deposition Rate Additive Manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar] [CrossRef]

- Sowrirajan, M.; Vijayananthan, M.; Seenivasagan, G.; Sundaresan, J. A New Approach to the Fabrication of Thin-Walled Plate Component through Typical Wire Arc Additive Manufacturing. J. Adv. Mech. Sci. 2022, 1, 8–13. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Cipriano Farias, F.W.; Zhang, K.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Schell, N.; Capek, J.; Polatidis, E.; Santos, T.G.; et al. Wire and Arc Additive Manufacturing of 316L Stainless Steel/Inconel 625 Functionally Graded Material: Development and Characterization. J. Mater. Res. Technol. 2022, 21, 237–251. [Google Scholar] [CrossRef]

- Ozsoy, A.; Tureyen, E.B.; Baskan, M.; Yasa, E. Microstructure and Mechanical Properties of Hybrid Additive Manufactured Dissimilar 17-4 PH and 316L Stainless Steels. Mater. Today Commun. 2021, 28, 102561. [Google Scholar] [CrossRef]

- Hietala, M.; Rautio, T.; Makikangas, J.; Jaskari, M.; Keskitalo, M.; Jarvenpaa, A. Static Properties and Fatigue Strength of Wire Arc Additive Manufactured 316L. In Proceedings of the 2022 7th National Scientific Conference on Applying New Technology in Green Buildings (ATiGB), Da Nang, Vietnam, 11–12 November 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of Stainless Steel Parts by Laser Metal Deposition Shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

- Zhong, Y.; Rännar, L.E.; Liu, L.; Koptyug, A.; Wikman, S.; Olsen, J.; Cui, D.; Shen, Z. Additive Manufacturing of 316L Stainless Steel by Electron Beam Melting for Nuclear Fusion Applications. J. Nuclear Mater. 2017, 486, 234–245. [Google Scholar] [CrossRef]

- Nastac, M.; Klein, R.L.A. Microstructure and Mechanical Properties Comparison of 316L Parts Produced by Different Additive Manufacturing Processes. In Proceedings of the Solid Freeform Fabrication 2017: Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; pp. 332–341. [Google Scholar]

- Kim, F.H.; Moylan, S.P. Literature Review of Metal Additive Manufacturing Defects; NIST Advanced Manufacturing Series; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018; pp. 1–17. [Google Scholar]

- Stern, F.; Tenkamp, J.; Walther, F. Non-Destructive Characterization of Process-Induced Defects and Their Effect on the Fatigue Behavior of Austenitic Steel 316L Made by Laser-Powder Bed Fusion. Prog. Addit. Manuf. 2020, 5, 287–294. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Jarama, A.; Jones, J.; Li, X. Prediction of Microstructural Defects in Additive Manufacturing from Powder Bed Quality Using Digital Image Correlation. Mater. Sci. Eng. A 2020, 794, 140002. [Google Scholar] [CrossRef]

- Snow, Z.; Scime, L.; Ziabari, A.; Fisher, B.; Paquit, V. Observation of Spatter-Induced Stochastic Lack-of-Fusion in Laser Powder Bed Fusion Using in Situ Process Monitoring. Addit. Manuf. 2023, 61, 103298. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. (Engl. Ed.) 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Santonocito, D.; Fintová, S.; Di Cocco, V.; Iacoviello, F.; Risitano, G.; D’Andrea, D. Comparison on Mechanical Behaviour and Microstructural Features Between Traditional and AM AISI 316L. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 379–395. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. Mitigation of Lack of Fusion Defects in Powder Bed Fusion Additive Manufacturing. J. Manuf. Process. 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Martin, A.A.; Calta, N.P.; Khairallah, S.A.; Wang, J.; Depond, P.J.; Fong, A.Y.; Thampy, V.; Guss, G.M.; Kiss, A.M.; Stone, K.H.; et al. Dynamics of Pore Formation during Laser Powder Bed Fusion Additive Manufacturing. Nat. Commun. 2019, 10, 1987. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, L.; Zhao, Y.; Li, Y.; Zhan, X. Droplet Transfer Induced Keyhole Fluctuation and Its Influence Regulation on Porosity Rate during Hybrid Laser Arc Welding of Aluminum Alloys. Metals 2021, 11, 1510. [Google Scholar] [CrossRef]

- Rabin, B.H.; Smolik, G.R.; Korth, G.E. Characterization of Entrapped Gases in Rapidly Solidified Powders. Mater. Sci. Eng. A 1990, 124, 1–7. [Google Scholar] [CrossRef]

- Elmer, J.W.; Vaja, J.; Carlton, H.D.; Pong, R. The Effect of Ar and N2 Shielding Gas on Laser Weld Porosity in Steel, Stainless Steels, and Nickel. Weld. J. 2015, 94, 313s–325s. [Google Scholar]

- Kaynak, Y.; Kitay, O. Porosity, Surface Quality, Microhardness and Microstructure of Selective Laser Melted 316l Stainless Steel Resulting from Finish Machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef] [Green Version]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity Measurements and Analysis for Metal Additive Manufacturing Process Control. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 494–528. [Google Scholar] [CrossRef]

- Ziółkowski, G.; Chlebus, E.; Szymczyk, P.; Kurzac, J. Application of X-Ray CT Method for Discontinuity and Porosity Detection in 316L Stainless Steel Parts Produced with SLM Technology. Arch. Civ. Mech. Eng. 2014, 14, 608–614. [Google Scholar] [CrossRef]

- Jaskari, M.; Mäkikangas, J.; Järvenpää, A.; Mäntyjärvi, K.; Karjalainen, P. Effect of High Porosity on Bending Fatigue Properties of 3D Printed AISI 316L Steel. Procedia Manuf. 2019, 36, 33–41. [Google Scholar] [CrossRef]

- Karakaş, Ö.; Kardeş, F.B.; Foti, P.; Berto, F. An Overview of Factors Affecting High-Cycle Fatigue of Additive Manufacturing Metals. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 1649–1668. [Google Scholar] [CrossRef]

- Solberg, K.; Guan, S.; Razavi, S.M.J.; Welo, T.; Chan, K.C.; Berto, F. Fatigue of Additively Manufactured 316L Stainless Steel: The Influence of Porosity and Surface Roughness. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2043–2052. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual Stresses in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Chen, S.; Gao, H.; Zhang, Y.; Wu, Q.; Gao, Z.; Zhou, X. Review on Residual Stresses in Metal Additive Manufacturing: Formation Mechanisms, Parameter Dependencies, Prediction and Control Approaches. J. Mater. Res. Technol. 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual Stress Measurements on AISI 316L Samples Manufactured by Selective Laser Melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, S.; Zhang, C.H.; Wu, C.; Wang, J.; Chen, J.; Sun, Z. Microstructure Evolution and EBSD Analysis of a Graded Steel Fabricated by Laser Additive Manufacturing. Vacuum 2017, 141, 68–81. [Google Scholar] [CrossRef]

- Sander, G.; Babu, A.P.; Gao, X.; Jiang, D.; Birbilis, N. On the Effect of Build Orientation and Residual Stress on the Corrosion of 316L Stainless Steel Prepared by Selective Laser Melting. Corros. Sci. 2021, 179, 109149. [Google Scholar] [CrossRef]

- Barroqueiro, B.; Andrade-Campos, A.; Valente, R.A.F.; Neto, V. Metal Additive Manufacturing Cycle in Aerospace Industry: A Comprehensive Review. J. Manuf. Mater. Process. 2019, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Hajnys, J.; Pagáč, M.; Měsíček, J.; Petru, J.; Król, M. Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials 2020, 13, 1659. [Google Scholar] [CrossRef] [Green Version]

- Vinoth Jebaraj, A.; Sugavaneswaran, M. Influence of Shot Peening on Residual Stress Distribution and Corrosion Resistance of Additive Manufactured Stainless Steel AISI 316L. Trans. Indian Inst. Met. 2019, 72, 1651–1653. [Google Scholar] [CrossRef]

- Castro, H.F.; Carvalho, A.R.F.; Leal, F.; Gouveia, H. Assessing Industry 4.0 Readiness of Portuguese Companies; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 9783030290405. [Google Scholar]

- Khalid, M.; Peng, Q. Investigation of Printing Parameters of Additive Manufacturing Process for Sustainability Using Design of Experiments. J. Mech. Des. 2021, 143, 32001. [Google Scholar] [CrossRef]

- Ingrassia, T.; Nigrelli, V.; Ricotta, V.; Tartamella, C. Process Parameters Influence in Additive Manufacturing. In Proceedings of the Advances on Mechanics, Design Engineering and Manufacturing: Proceedings of the International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing (JCM 2016), Catania, Italy, 14–16 September 2016; pp. 261–270. [Google Scholar] [CrossRef]

- Ahmadi, M.; Tabary, S.A.A.B.; Rahmatabadi, D.; Ebrahimi, M.S.; Abrinia, K.; Hashemi, R. Review of Selective Laser Melting of Magnesium Alloys: Advantages, Microstructure and Mechanical Characterizations, Defects, Challenges, and Applications. J. Mater. Res. Technol. 2022, 19, 1537–1562. [Google Scholar] [CrossRef]

- Fongsamootr, T.; Thawon, I.; Tippayawong, N.; Tippayawong, K.Y.; Suttakul, P. Effect of Print Parameters on Additive Manufacturing of Metallic Parts: Performance and Sustainability Aspects. Sci. Rep. 2022, 12, 19292. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Santos Macías, J.G.; Dolimont, A.; Simar, A.; Rivière-Lorphèvre, E. Comparison of Residual Stresses Obtained by the Crack Compliance Method for Parts Produced by Different Metal Additive Manufacturing Techniques and after Friction Stir Processing. Addit. Manuf. 2020, 36, 101499. [Google Scholar] [CrossRef]

- Mostafaei, A.; Zhao, C.; He, Y.; Reza Ghiaasiaan, S.; Shi, B.; Shao, S.; Shamsaei, N.; Wu, Z.; Kouraytem, N.; Sun, T.; et al. Defects and Anomalies in Powder Bed Fusion Metal Additive Manufacturing. Curr. Opin. Solid State Mater. Sci. 2022, 26, 100974. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel Using Electron Beam Melting Additive Manufacturing Technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef] [Green Version]

- Kruth, J.P.; Deckers, J.; Yasa, E.; Wauthlé, R. Assessing and Comparing Influencing Factors of Residual Stresses in Selective Laser Melting Using a Novel Analysis Method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Röttger, A.; Geenen, K.; Windmann, M.; Binner, F.; Theisen, W. Comparison of Microstructure and Mechanical Properties of 316 L Austenitic Steel Processed by Selective Laser Melting with Hot-Isostatic Pressed and Cast Material. Mater. Sci. Eng. A 2016, 678, 365–376. [Google Scholar] [CrossRef]

- Do, T.; Bauder, T.J.; Suen, H.; Rego, K.; Yeom, J.; Kwon, P. Additively Manufactured Full-Density Stainless Steel 316L with Binder Jet Printing. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; American Society of Mechanical Engineers; Volume 51357, p. V001T01A017. [Google Scholar]

- D’Andrea, D.; Gatto, A.; Guglielmino, E.; Risitano, G.; Santonocito, D. A Comparison on Static and Fatigue Behaviour between Traditional and SLM AISI 316L. J. Mech. Sci. Technol. 2022, 37, 1083–1088. [Google Scholar] [CrossRef]

- Britt, C.; Montgomery, C.J.; Brand, M.J.; Liu, Z.K.; Carpenter, J.S.; Beese, A.M. Effect of Processing Parameters and Strut Dimensions on the Microstructures and Hardness of Stainless Steel 316L Lattice-Emulating Structures Made by Powder Bed Fusion. Addit. Manuf. 2021, 40, 101943. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Carvalho, O.; Silva, F.S.; Miranda, G. 316L Stainless Steel Mechanical and Tribological Behavior—A Comparison between Selective Laser Melting, Hot Pressing and Conventional Casting. Addit. Manuf. 2017, 16, 81–89. [Google Scholar] [CrossRef]

- Sun, Y.; Moroz, A.; Alrbaey, K. Sliding Wear Characteristics and Corrosion Behaviour of Selective Laser Melted 316L Stainless Steel. J. Mater. Eng. Perform. 2014, 23, 518–526. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of Metal Powder Layers in Laser Powder Bed Fusion Processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Zhao, C.; Escano, L.I.; Young, Z.; Xiong, L.; Fezzaa, K.; Everhart, W.; Brown, B.; Sun, T.; Chen, L. Transient Dynamics of Powder Spattering in Laser Powder Bed Fusion Additive Manufacturing Process Revealed by In-Situ High-Speed High-Energy x-Ray Imaging. Acta Mater. 2018, 151, 169–180. [Google Scholar] [CrossRef]

- Bassis, M.; Kotliar, A.; Koltiar, R.; Ron, T.; Leon, A.; Shirizly, A.; Aghion, E. The Effect of a Slow Strain Rate on the Stress Corrosion Resistance of Austenitic Stainless Steel Produced by the Wire Laser Additive Manufacturing Process. Metals 2021, 11, 1930. [Google Scholar] [CrossRef]

- Bae, K.; Shin, D.; Lee, J.; Kim, S.; Lee, W.; Jo, I.; Lee, J. Corrosion Resistance of Laser Powder Bed Fused AISI 316L Stainless Steel and Effect of Direct Annealing. Materials 2022, 15, 6336. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Wang, D.; Zeng, X. Control of Shape and Performance for Direct Laser Fabrication of Precision Large-Scale Metal Parts with 316L Stainless Steel. Opt. Laser Technol. 2013, 45, 209–216. [Google Scholar] [CrossRef]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of Processing Parameters on Tensile Properties of Selective Laser Melted 304 Stainless Steel. Mater. Des. 2013, 50, 581–586. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of Mechanical Properties of AISI 316 Stainless Steel Processed by “Selective Laser Melting”, Following Different Manufacturing Strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Werner, T.; Madia, M.; Zerbst, U. Comparison of the Fatigue Behavior of Wrought and Additively Manufactured AISI 316L. Procedia Struct. Integr. 2021, 38, 554–563. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Panciroli, R.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Experimental Investigation on the Fatigue Behavior of Laser Powder Bed Fused 316L Stainless Steel. CIRP J. Manuf. Sci. Technol. 2022, 38, 787–800. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An Investigation of the Microstructure and Fatigue Behavior of Additively Manufactured AISI 316L Stainless Steel with Regard to the Influence of Heat Treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef] [Green Version]

- Santonocito, D.; Gatto, A.; Risitano, G. Energy Release as a Parameter for Fatigue Design of Additive Manufactured Metals. Mater. Des. Process. Commun. 2021, 3, e255. [Google Scholar] [CrossRef]

- Kerner, Z.; Horváth, Á.; Nagy, G. Comparative Electrochemical Study of 08H18N10T, AISI 304 and AISI 316L Stainless Steels. Electrochim. Acta 2007, 52, 7529–7537. [Google Scholar] [CrossRef]

- La Barbera, A.; Mignone, A.; Tosto, S.; Vignaud, C. Electron Beam Cladding and Alloying of AISI 316 on Plain Carbon Steel: Microstructure and Electrochemical Corrosion Behaviour. Surf. Coatings Technol. 1991, 46, 317–329. [Google Scholar] [CrossRef]

- Li, Q.; Shen, Y.; Han, P. Serrated Flow Behavior of Aisi 316l Austenitic Stainless Steel for Nuclear Reactors. IOP Conf. Ser. Mater. Sci. Eng. 2017, 250, 012013. [Google Scholar] [CrossRef]

- Jafarpour, S.M.; Puth, A.; Dalke, A.; Böcker, J.; Pipa, A.V.; Röpcke, J.; van Helden, J.P.H.; Biermann, H. Solid Carbon Active Screen Plasma Nitrocarburizing of AISI 316L Stainless Steel in Cold Wall Reactor: Influence of Plasma Conditions. J. Mater. Res. Technol. 2020, 9, 9195–9205. [Google Scholar] [CrossRef]

- de Abreu Mendonça Schvartzman, M.M.; Quinan, M.A.D.; da Costa Campos, W.R.; Lima, L.I.L. Stress Corrosion Cracking of the Aisi 316l Stainless Steel Haz in a Pwr Nuclear Reactor Environment. Weld. Int. 2011, 25, 15–23. [Google Scholar] [CrossRef]

- Chen, C.J.; Wang, M.C.; Wang, D.S.; Liang, H.S.; Feng, P. Characterisations of Electrospark Deposition Stellite 6 Alloy Coating on 316L Sealed Valve Used in Nuclear Power Plant. Mater. Sci. Technol. 2010, 26, 276–280. [Google Scholar] [CrossRef]

- Banerjee, A.; Ntovas, M.; Da Silva, L.; Rahimi, S. Microstructure and Mechanical Properties of Dissimilar Inertia Friction Welded 316L Stainless Steel to A516 Ferritic Steel for Potential Applications in Nuclear Reactors. Manuf. Lett. 2022, 33, 33–37. [Google Scholar] [CrossRef]

- Muthu, S.M.; Mohana Bharathi, C.; Vishal Gukhan, N.; Vignesh Kumar, S.; Venkatesh Kannan, M.; Arivarasu, M.; Manikandan, M.; Arivazhagan, N. Hot Corrosion Studies on Dissimilar Weldments C-22 and AISI 316L in the Molten Salt K2SO4 + 60%wt NaCl Environment. Mater. Today Proc. 2018, 5, 13340–13346. [Google Scholar] [CrossRef]

- Ghosh, N.; Kumar Pal, P.; Nandi, G.; Rudrapati, R. Parametric Optimization of Gas Metal Arc Welding Process by PCA Based Taguchi Method on Austenitic Stainless Steel AISI 316L. Mater. Today Proc. 2018, 5, 1620–1625. [Google Scholar] [CrossRef]

- Abass, M.H.; Alali, M.S.; Abbas, W.S.; Shehab, A.A. Study of Solidification Behaviour and Mechanical Properties of Arc Stud Welded AISI 316L Stainless Steel. J. Achiev. Mater. Manuf. Eng. 2019, 97, 5–14. [Google Scholar] [CrossRef]

- Sánchez-Tovar, R.; Montañés, M.T.; García-Antón, J. Effects of Microplasma Arc AISI 316L Welds on the Corrosion Behaviour of Pipelines in LiBr Cooling Systems. Corros. Sci. 2013, 73, 365–374. [Google Scholar] [CrossRef]

- Kožuh, S.; Gojić, L.V.; Ivković, B. Corrosion failure and microstructure analysis of AISI 316L stainless steels for ship pipeline before and after welding. Kovove Mater. 2013, 51, 53–61. [Google Scholar] [CrossRef]

- Tang, J.; Liu, M.; Huang, Y.; Liu, G.; Zang, J.; Liu, S. Effect of Manufacturing Deviations on the Thermohydraulic Performance of Printed Circuit Heat Exchangers with Zigzag Channels. Appl. Therm. Eng. 2023, 219, 119496. [Google Scholar] [CrossRef]

- Solano, J.P.; Martínez, D.S.; Vicente, P.G.; Viedma, A. Enhanced Thermal-Hydraulic Performance in Tubes of Reciprocating Scraped Surface Heat Exchangers. Appl. Therm. Eng. 2023, 220, 119667. [Google Scholar] [CrossRef]

- da Silva, R.P.P.; Mortean, M.V.V.; de Paiva, K.V.; Beckedorff, L.E.; Oliveira, J.L.G.; Brandão, F.G.; Monteiro, A.S.; Carvalho, C.S.; Oliveira, H.R.; Borges, D.G.; et al. Thermal and Hydrodynamic Analysis of a Compact Heat Exchanger Produced by Additive Manufacturing. Appl. Therm. Eng. 2021, 193, 116973. [Google Scholar] [CrossRef]

- Petrescu, D.; Nitu, A.; Golgovici, F.; Demetrescu, I.; Corban, M. Behaviour Aspects of an EB-PVD Alumina (Al2O3) Film with an Interlayer (NiCrAlY) Deposited on AISI 316L Steel Investigated in Liquid Lead. Metals 2023, 13, 616. [Google Scholar] [CrossRef]

- Benes, L.; Mouralova, K.; Midula, P.; Snow, J.; Lysonkova, I.; Pilnaj, D.; Burdova, H.; Prokes, T.; Zahradnicek, R.; Fries, J.; et al. The Corrosion Behavior of WEDM Machined Stainless Steels in a Pyrolysis Environment. Metals 2023, 13, 144. [Google Scholar] [CrossRef]

- Silva, C.C.; Farias, J.P.; de Sant’Ana, H.B. Evaluation of AISI 316L Stainless Steel Welded Plates in Heavy Petroleum Environment. Mater. Des. 2009, 30, 1581–1587. [Google Scholar] [CrossRef]

- Zaffora, A.; Di Franco, F.; Santamaria, M. ScienceDirect Electrochemistry Corrosion of Stainless Steel in Food and Pharmaceutical Industry. Curr. Opin. Electrochem. 2021, 29, 100760. [Google Scholar] [CrossRef]

- Le Gentil, C.; Sylla, Y.; Faille, C. Bacterial Re-Contamination of Surfaces of Food Processing Lines during Cleaning in Place Procedures. J. Food Eng. 2010, 96, 37–42. [Google Scholar] [CrossRef]

- Gaylarde, C.C. Comparison of Sodium Hypochlorite and Peracetic Acid as Sanitising Agents for Stainless Steel Food Processing Surfaces Using Epifluorescence Microscopy. Int. J. Food Microbiol. 2000, 61, 81–85. [Google Scholar]

- Tiwari, S.K.; Mishra, T.; Gunjan, M.K.; Bhattacharyya, A.S.; Singh, T.B.; Singh, R. Development and Characterization of Sol—Gel Silica—Alumina Composite Coatings on AISI 316L for Implant Applications. Surf. Coat. Technol. 2007, 201, 7582–7588. [Google Scholar] [CrossRef]

- Hryniewicz, T.; Rokosz, K.; Filippi, M. Biomaterial Studies on AISI 316L Stainless Steel after Magnetoelectropolishing. Materials 2009, 2, 129–145. [Google Scholar] [CrossRef] [Green Version]

- Muthukumaran, V.; Selladurai, V.; Nandhakumar, S.; Senthilkumar, M. Experimental Investigation on Corrosion and Hardness of Ion Implanted AISI 316L Stainless Steel. Mater. Des. 2010, 31, 2813–2817. [Google Scholar] [CrossRef]

- Lodhi, M.J.K.; Deen, K.M.; Greenlee-Wacker, M.C.; Haider, W. Additively Manufactured 316L Stainless Steel with Improved Corrosion Resistance and Biological Response for Biomedical Applications. Addit. Manuf. 2019, 27, 8–19. [Google Scholar] [CrossRef]

- Al-Mamun, N.S.; Mairaj Deen, K.; Haider, W.; Asselin, E.; Shabib, I. Corrosion Behavior and Biocompatibility of Additively Manufactured 316L Stainless Steel in a Physiological Environment: The Effect of Citrate Ions. Addit. Manuf. 2020, 34, 101237. [Google Scholar] [CrossRef]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective Laser Melting of a Stainless Steel and Hydroxyapatite Composite for Load-Bearing Implant Development. J. Mater. Process. Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Wei, Q.; Li, S.; Han, C.; Li, W.; Cheng, L.; Hao, L.; Shi, Y. Selective Laser Melting of Stainless-Steel/Nano-Hydroxyapatite Composites for Medical Applications: Microstructure, Element Distribution, Crack and Mechanical Properties. J. Mater. Process. Technol. 2015, 222, 444–453. [Google Scholar] [CrossRef]

- Čapek, J.; Machová, M.; Fousová, M.; Kubásek, J.; Vojtěch, D.; Fojt, J.; Jablonská, E.; Lipov, J.; Ruml, T. Highly Porous, Low Elastic Modulus 316L Stainless Steel Scaffold Prepared by Selective Laser Melting. Mater. Sci. Eng. C 2016, 69, 631–639. [Google Scholar] [CrossRef]

- Mondal, P.; Das, A.; Wazeer, A.; Karmakar, A. Biomedical Porous Scaffold Fabrication Using Additive Manufacturing Technique: Porosity, Surface Roughness and Process Parameters Optimization. Int. J. Lightweight Mater. Manuf. 2022, 5, 384–396. [Google Scholar] [CrossRef]

- Jebaraj, A.V.; Ajaykumar, L.; Deepak, C.R.; Aditya, K.V.V. Weldability, Machinability and Surfacing of Commercial Duplex Stainless Steel AISI2205 for Marine Applications—A Recent Review. J. Adv. Res. 2017, 8, 183–199. [Google Scholar] [CrossRef]

- Sup, W.; Sung, M.; Soo, M.; Hyun, M.; Myung, J. Comparative Study on Mechanical Behavior of Low Temperature Application Materials for Ships and Offshore Structures: Part I—Experimental Investigations. Mater. Sci. Eng. A 2011, 528, 5790–5803. [Google Scholar] [CrossRef]

- Peter, L.; Allen, M.; Mark, L.; Martin, L.P. Evaluation of Additive Friction Stir Deposition of AISI 316L for Repairing Surface Material Loss in AISI 4340. Int. J. Adv. Manuf. Technol. 2022, 121, 2365–2381. [Google Scholar] [CrossRef]

- Li, D.; Liu, Q.; Wang, W.; Jin, L.; Xiao, H. Corrosion Behavior of AISI 316L Stainless Steel Used as Inner Lining of Bimetallic Pipe in a Seawater Environment. Materials 2021, 14, 1539. [Google Scholar] [CrossRef]

- Gupta, S.; Singh, D.; Yadav, A.; Jain, S.; Pratap, B. Materials Today: Proceedings A Comparative Study of 5083 Aluminium Alloy and 316L Stainless Steel for Shipbuilding Material. Mater. Today Proc. 2020, 28, 2358–2363. [Google Scholar] [CrossRef]

- Ren, P.; Meng, H.; Xia, Q.; Zhu, Z.; He, M. Tribocorrosion of 316L Stainless Steel by In-Situ Electrochemical Methods under Deep-Sea High Hydrostatic Pressure Environment. Corros. Sci. 2022, 202, 110315. [Google Scholar] [CrossRef]

- Hajian, M.; Abdollah-zadeh, A.; Rezaei-nejad, S.S.; Assadi, H.; Hadavi, S.M.M. Applied Surface Science Improvement in Cavitation Erosion Resistance of AISI 316L Stainless Steel by Friction Stir Processing. Appl. Surf. Sci. 2014, 308, 184–192. [Google Scholar] [CrossRef]

- Bilgili, L.; Mert, T.; Celebi, U.B. Fume Formation Rate of Shielded Metal Arc Welding of Stainless Steel Used in Chemical Tankers In Shipbuilding Fume Formation Rate Of Shielded Metal Arc Welding Of Stainless Steel Used In Chemical Tankers In Shipbuilding. In Proceedings of the 8th International Scientific Conference on Naval, Mechanical and Industrial Engineering, TEHNONAV-2015, Constanta, Romania, 2–4 July 2015. [Google Scholar]

- Kaya, Y.; Kahraman, N.; Durgutlu, A.; Gu, E.T. Investigation of the Microstructural, Mechanical and Corrosion Properties of Grade A Ship Steel-Duplex Stainless Steel Composites Produced via Explosive Welding. Metall. Mater. Trans. A 2017, 48, 3721–3733. [Google Scholar] [CrossRef]

- Kaestner, P.; Michler, T.; Weidner, H.; Rie, K.; Bräuer, G. Surface & Coatings Technology Plasma Nitrided Austenitic Stainless Steels for Automotive Hydrogen Applications. Surf. Coat. Technol. 2008, 203, 897–900. [Google Scholar] [CrossRef]

- Karl, A.; Beamer, C. Applications and Design of Low Temperature Surface Hardened Stainless Steel Components in Automotive Applications. SAE Int. J. Mater. Manuf. 2016, 9, 679–684. [Google Scholar] [CrossRef]

| Categories | Techniques | Materials | Strengths/Downsides | References |

|---|---|---|---|---|

| Material extrusion | Fused Deposition Modeling (FDM) | Polymers, ceramic |

| [47,48] |

| Vat photopolymerization | Stereolithography (SLA) Digital Light Processing (DLP) | Photopolymers Photopolymers |

| [49,50] [51,52] |

| Powder bad fusion | Selective Laser Melting (SLM) Electron Beam Melting (EBM) | Metals, polymers, ceramic |

| [53,54,55] |

| Direct energy deposition | DED | Metals, polymers, ceramic |

| [56,57] |

| Binder Jetting | Binder Jetting | Metals |

| [58,59] |

| Material Jetting | Drop on Demand (DOD) | Polymers, waxes |

| [60,61] |

| Sheet lamination | Ultrasonic additive manufacturing (UAM) Laminated object manufacturing (LOM) | Metals, polymers |

| [62,63] |

| Techniques | Mechanical Properties | Microstructure | Ref | ||

|---|---|---|---|---|---|

| Yield Strength (MPa) | Ultimate Strength (MPa) | Hardness | |||

| DED | 352 | 536 | Columnar and equiaxed grain | [102] | |

| EBM | 253 | 509 | Columnar grain microstrutture | [103] | |

| SLM | 172 | 482 | 77 | Columnar grain microstrutture | [104] |

| FDM | 142 | 427 | Layered microstructure | [92] | |

| BJ | 214 | 517 | 66 | Fine equiaxed grain microstructure | [86] |

| Techniques | Defect Type | Mitigation Strategies | Ref |

|---|---|---|---|

| DED | Porosity and less integral metallurgical bonds |

| [80] |

| EBM | Strain-aging cracking |

| [140] |

| SLM | Residual stress and cracking |

| [141] |

| SLM | Cracking |

| [142] |

| BJ | Surface roughness |

| [143] |

| BJ | Surface roughness |

| [86] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Andrea, D. Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals 2023, 13, 1370. https://doi.org/10.3390/met13081370

D’Andrea D. Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals. 2023; 13(8):1370. https://doi.org/10.3390/met13081370

Chicago/Turabian StyleD’Andrea, Danilo. 2023. "Additive Manufacturing of AISI 316L Stainless Steel: A Review" Metals 13, no. 8: 1370. https://doi.org/10.3390/met13081370

APA StyleD’Andrea, D. (2023). Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals, 13(8), 1370. https://doi.org/10.3390/met13081370