Abstract

In this study, we utilized MgO as an insulating buffer layer to enhance the thermal stability and soft magnetic properties of Fe-Ni soft magnetic composites (SMCs) and investigated the effect of high-temperature heat treatment on those soft magnetic properties. By employing the sol-gel process, a uniform MgO insulating layer with a thickness of 600 nm was coated onto Fe-Ni magnetic powder. Subsequently, high-density SMCs were fabricated through high-pressure compaction molding. The MgO layer remained intact up to 800 °C, leading to the FeNi@MgO@MK SMCs exhibiting enhanced permeability and reduced hysteresis loss due to grain enlargement and elimination of defects, such as dislocation stacking. Notably, the dynamic loss increase after high-temperature heat treatment was significantly regulated compared to the case of the uncoated counterpart. The results underscore the potential to improve the thermal stability and soft magnetic properties of MgO-coated Fe-Ni SMCs, rendering them suitable for various electromagnetic applications.

1. Introduction

Soft magnetic composites (SMCs) are formed by applying organic, inorganic, or hybrid organic-inorganic coatings to soft magnetic metal powders, followed by compression molding; this process is advantageous in controlling eddy current loss by forming an insulating layer between powders [1,2,3,4,5,6]. When a current is generated in the core, heat is generated, and the eddy current loss can be prevented by this insulating layer, thereby reducing core loss. For this reason, SMCs are widely used in high-frequency electromagnetic applications [7,8]. One major application of SMCs is inductors, which are manufactured by winding copper wire around various shaped cores made of soft magnetic powder; SMCs have greatly increased their application area, as the demand for electrical operations has increased. Recently, miniaturization and high efficiency have been required to apply SMCs to large-current power converters, especially for electric vehicles [9,10]. High saturation magnetization, high magnetic permeability, and low core loss are required, and interest in SMCs with these characteristics is increasing [11].

Fe-Ni alloy is an excellent magnetic material with low coercive force, high magnetic permeability, and low inherent thermal expansion coefficient; it has been used in various industrial applications for over 100 years [1,7]. In addition, SMCs made of Fe-Ni have excellent magnetic properties such as high magnetic permeability, low magnetic anisotropy, almost zero magnetostriction, and low core loss [7,12,13]. Due to these excellent properties, SMCs based on Fe-Ni powders are considered excellently suited materials for high efficiency and performance inductor cores.

However, recently, concerns have been raised about efficiency improvements and weight reduction of power conversion systems for future electric mobility, and improving the soft magnetic properties of Fe-Ni SMCs is seen as necessary. One possible method for improving the soft magnetic properties of SMCs is to apply high-temperature heat treatment. Through this, the grains inside of powders can be enlarged, and defects including dislocation stacking and grain boundaries can be effectively removed. Coercivity, which is inversely proportional to the grain size, can be reduced through high-temperature heat treatment; this heat treatment leads to decreased hysteresis loss and increased permeability [1,14].

However, when a high-temperature heat treatment is applied to an existing insulating coating, the insulating layer is dissolved between the powders, and the insulating properties are lost [14]. Therefore, it is important to select an insulating material that can withstand high temperatures. When metal powder is coated using conventional materials, including Al2O3, PO4, SiO2, ZrO2, etc., the insulating layer dissolves into the metallic powders when the heat treatment temperature exceeds 700 °C; eventually, the insulating layer cannot be maintained on the powder surface and is destroyed [4,15,16,17,18,19,20].

In this work, magnesium oxide (MgO), which has excellent thermal stability, was selected as a candidate to design an optimized insulating layer that can be maintained at high temperatures [21,22]. Several key material properties were considered in the selection of MgO. When selecting the insulating layer, mixing enthalpy, oxide formation energy, melting point, and coating method were considered key factors. It is important to consider the mixing enthalpy (ΔHmix in kJ/mol) between Fe and Ni and Mg elements. As is well known, positive mixing enthalpy values between Fe and Ni and metal elements can be regarded as an indicator that the formation of solid solution alloys between the elements will be prevented [23]. If there is a negative mixing enthalpy value, there is the possibility that metal elements of Fe-Ni and Fe-Ni surfaces will not exist in their respective states but dissolve in solid solution or form intermetallic compounds. The mixing enthalpy of Mg and Fe is +18 kJ/mol; the mixing enthalpy of Mg and Ni is −4 kJ/mol [24,25]. Although the enthalpy of mixing of Ni and Mg is negative, it is not very low, so the dissolution of MgO into Fe-Ni powder at a high temperature is expected to be negligibly small. It is also essential to use an element with high oxide formation energy, ΔG° (kJ/mol), which can oxidize before elemental Fe or Ni when exposed to an oxidizing atmosphere. By using elements that meet these conditions, the oxidation inhibition and insulation deterioration characteristics of Fe and Ni elements can be prevented when high-temperature heat treatment is applied. For elemental Fe, ΔG° is calculated at approximately −420, −410, and −400 kJ/mol at temperatures of 800 °C, 900 °C, and 1000 °C. For elemental Ni, ΔG° is calculated at approximately −220, −210, and −190 kJ/mol at temperatures of 800 °C, 900 °C, and 1000 °C. For elemental Mg, ΔG° is calculated at approximately −990 kJ/mol at the temperature of 1000 °C [26,27]. Since ΔG° is much lower for elemental Mg, MgO is a fairly good candidate for the insulating layer. In addition, MgO has a high melting point of 2852 °C, confirming that it will maintain its solid state even at high temperature annealing above 1000 °C. Therefore, it can be seen that the insulating layer is less likely to diffuse into the powders during heat treatment. A related study reported that an MgO insulating layer is a suitable material for reducing eddy current loss due to its higher resistivity and higher thermal resistance at high temperatures than those qualities of a PO4 insulating layer [28]. However, the effect of MgO on the magnetic properties at high temperatures above 800 °C has rarely been reported on, especially for Fe-Ni-based SMCs [29].

Therefore, MgO was selected as insulation material for the fabrication of Fe-Ni SMCs, and the effect of high-temperature heat treatment on the soft magnetic properties of FeNi@MgO SMCs were investigated in this work. In particular, the MgO insulation layer was coated on Fe-Ni powder using a sol-gel process that is advantageous for uniform and homogeneous coating [29]. An MgO insulating layer was successfully and uniformly coated on the Fe-Ni magnetic powder, and high-density SMCs were successfully fabricated through high-pressure compaction molding. Microstructure and soft magnetic properties, including magnetic permeability, core loss, and DC-Bias, were determined, and the effect of heat treatment temperature on these properties was thoroughly evaluated.

2. Experimental Section

2.1. Materials

The Fe54Ni46 powder used in the experiment was manufactured by Poongsan (Changwon, Republic of Korea). Cetyltrimethylammonium bromide (C19H42BrN, ≥ 95%) was purchased from MilliporeSigma (Burlington, MA, USA). Absolute ethyl alcohol (C2H5OH, 99.9%), ammonium hydroxide (NH4OH, 25%) and magnesium chloride hexahydrate (Cl2H12MgO6, 98%) were purchased from Samchun Chemicals (Seoul, Republic of Korea). High purity deionized (DI) water was used throughout the experiment.

2.2. Fabrication of FeNi@MgO SMCs

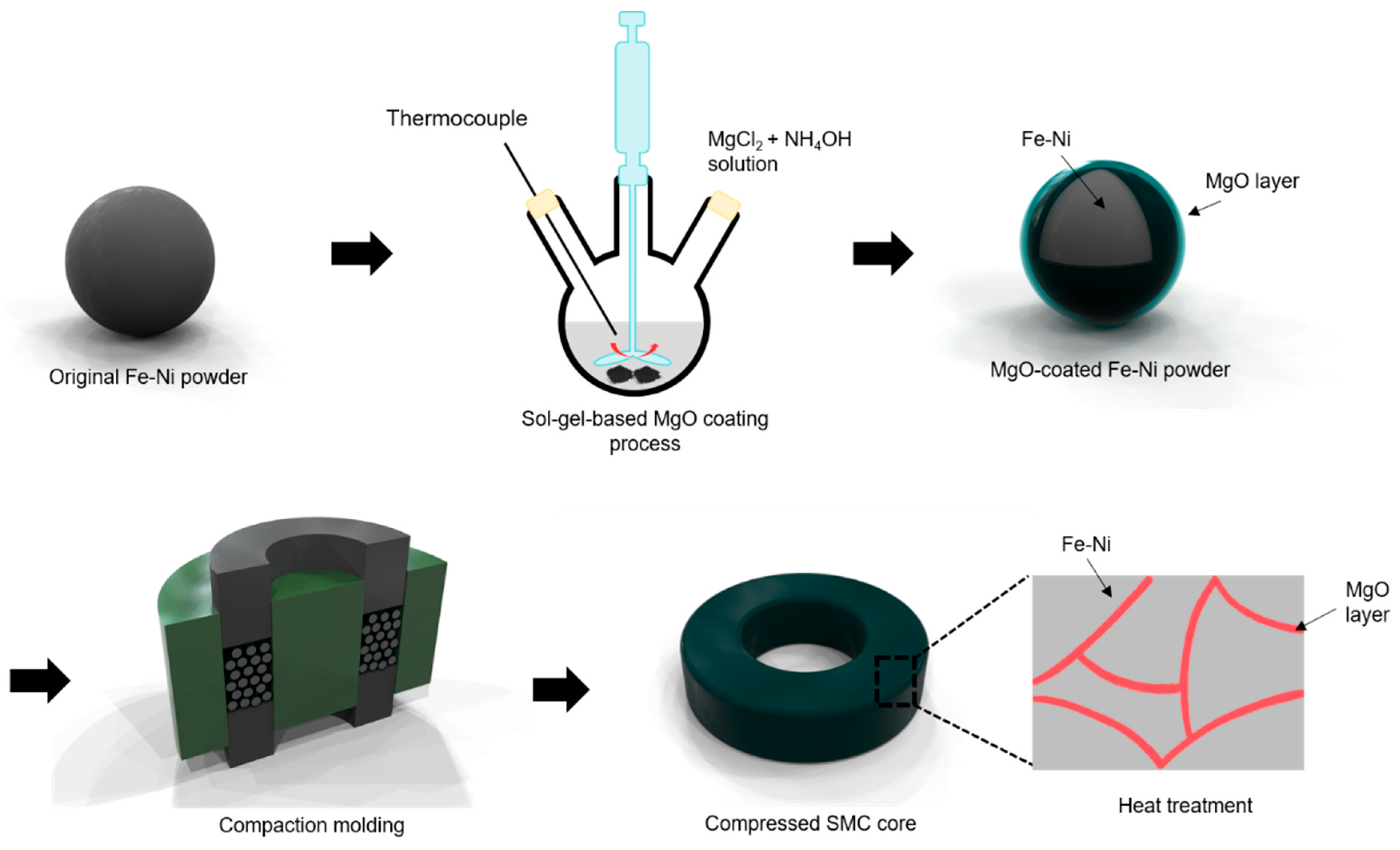

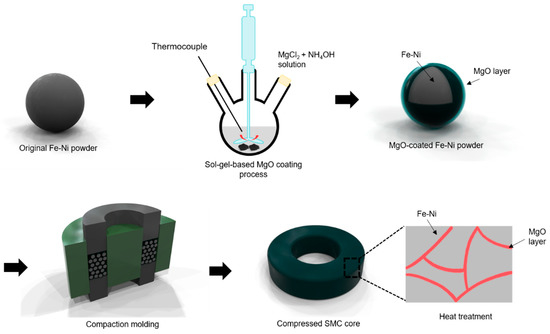

Figure 1 is a flow diagram of the preparation process of FeNi@MgO by sol-gel method. The detailed experimental procedures are described below. Fe-Ni powder (50 g) was dispersed in cetyltrimethylammonium bromide (CTAB) and H2O for 10 min, washed 5 times with EtOH, and stirred at 400 rpm for 4 h at 60 °C in 1.5 M of MgCl2 solution and 60 mL of NH4OH. After that, it was washed 5 times with EtOH and dried in vacuum at 70 °C. The dried powder was annealed at 500 °C for 4 h in an argon atmosphere. As a result, MgO was uniformly coated on the Fe-Ni powder, and binders and additives were mixed with the FeNi@MgO powder. The prepared FeNi@MgO powder was compressed at a pressure of 1.9 GPa and air-cooled at 700 °C, 750 °C, 800 °C, and 850 °C in an argon atmosphere for 1 h.

Figure 1.

Schematic illustration of synthetic process to produce MgO layer on surface of Fe-Ni powder.

2.3. Characterization

The obtained morphological features were characterized by field emission scanning electron microscopy (FE-SEM, MIRA3 LM, TESCAN, Brno, Czech Republic). In addition, energy dispersive X-ray spectroscopy (EDS, MIRA3 LM, TESCAN, Brno, Czech Republic) was used for elemental analysis and chemical characterization of the sample. For the SMC test, FeNi@MgO SMCs with copper wire with 31 turns of both primary and secondary windings were used. Core loss of FeNi@MgO SMCs was measured at frequencies ranging from 10 kHz to 200 kHz using an AC B-H analyzer (SY-8219, IWATSU ELECTRIC, Tokyo, Japan). Permeability and DC-Bias characteristics of FeNi@MgO SMCs were measured using an LCR meter (3260B, WAYNE KERR Electronics, Bognor Regis, UK) in the range of 0 kHz to 200 kHz; and DC-Bias characteristics were measured at a frequency of 50 kHz.

3. Results and Discussion

The process of coating MgO on Fe-Ni powder and the process of manufacturing a toroidal core by molding the coated powder are schematically shown in Figure 1. Crystalline MgO as the first insulating layer was uniformly formed on the surface of the Fe-Ni powder through sol-gel method. Then, metakaolin, an additive to reinforce the insulation properties of SMCs, was coated on top of the FeNi@MgO powder with a water glass binder. There are various coating methods for insulation coating, but the sol-gel coating method, a method of forming a uniform and continuous insulating layer, was applied in this work [28,29]. CTAB was used as a surfactant; it made the powder surface negatively charged, facilitating the MgO coating process. A thin and soft MgO layer was formed based on a chemical reaction using MgCl2 and NH4OH as precursors [30]. After forming a uniform crystalline MgO insulating layer on Fe-Ni powder, metakaolin and binder were added to the powder and water blend, and it was dried. Finally, a toroidal core was fabricated through the powder compaction route; it was heat-treated at various temperatures.

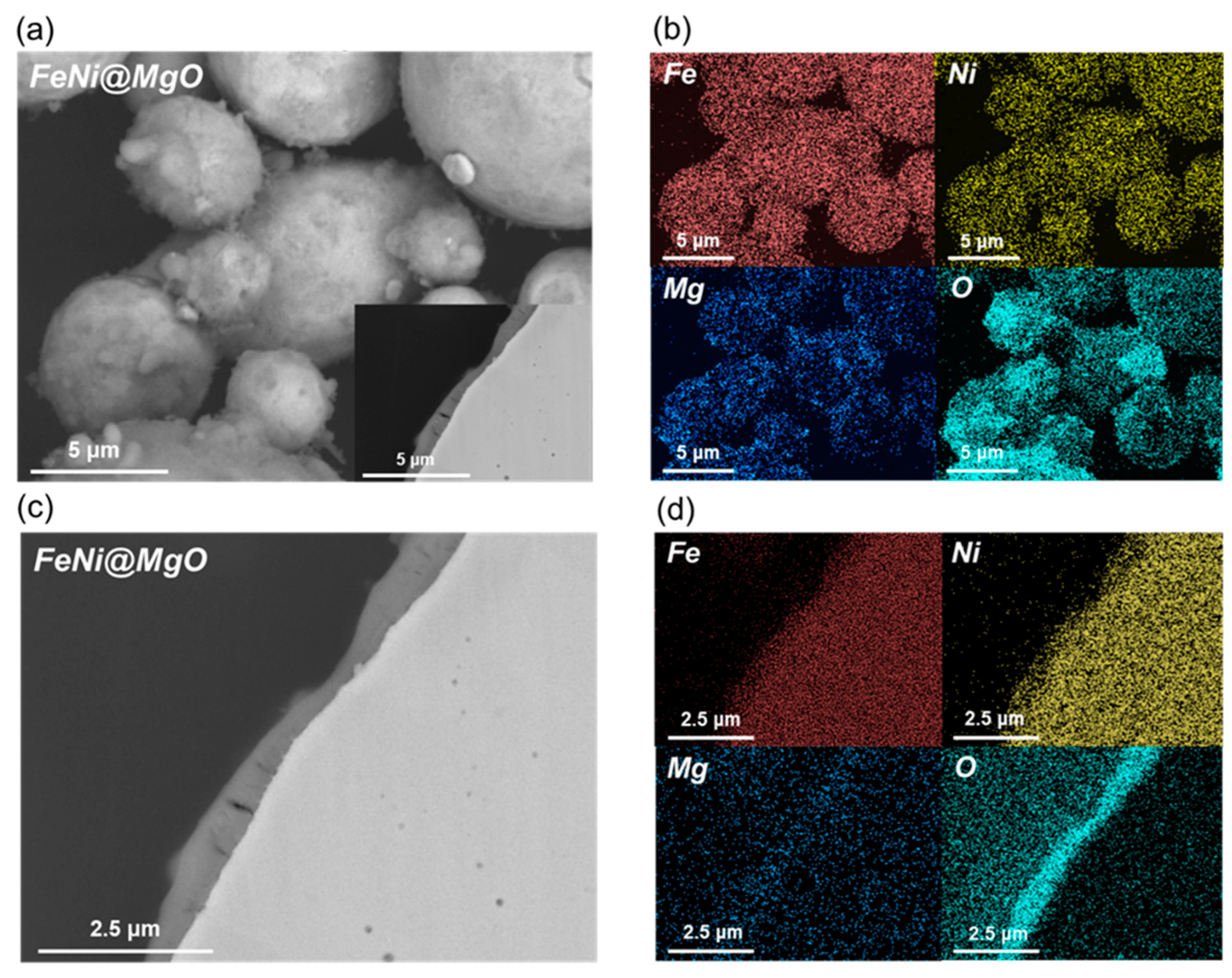

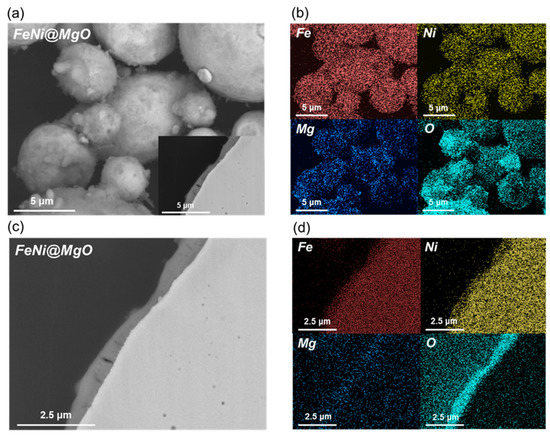

For characterization of the MgO insulating layer, surface and cross-sectional SEM analyses were performed on the FeNi@MgO powders. Figure 2a shows a surface SEM image of Fe-Ni powders uniformly coated with a crystalline MgO layer. From the EDS mapping results in Figure 2b,d, it can be seen that Mg and O elements were homogeneously distributed along the powder surfaces, and the entire surface of the powder was covered with a layer composed of clusters of nano-sized MgO particles. Looking at the cross-sectional SEM images in Figure 2c, a thin and relatively smooth surface of the MgO insulation layer can be observed; this is attributed to the sol-gel-based coating process. The thickness of the MgO insulation layer was estimated at approximately 600 nm from the SEM images. Figure 2 confirms that a thin and uniform MgO insulating layer was formed on the surface of the spherical Fe-Ni powder through the sol-gel process.

Figure 2.

SEM images and EDS elemental distribution maps of MgO-coated Fe-Ni powders (a,b): Surface, (c,d): Cross-sectional.

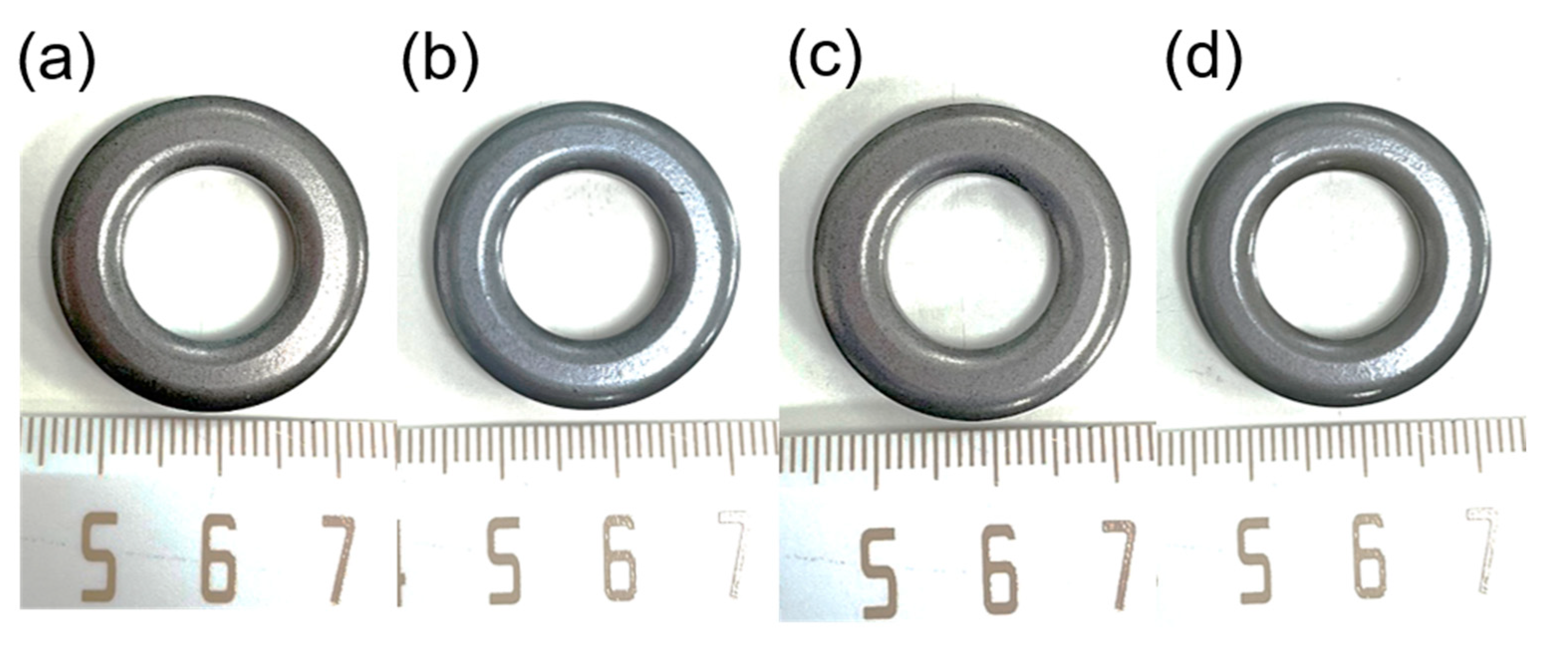

Figure 3 shows photographs of the toroidal SMCs prepared by mold compaction of FeNi@MgO powders followed by heat treatment at temperatures of 700–850 °C for 1 h. The outer diameter was 26.9 mm, the inner diameter was 14.8 mm, and the height was approximately 5.5 mm. The photographs of the cores show no significant differences in their appearance or noticeable damage to the core, even after heat treatment at temperatures up to 850 °C.

Figure 3.

Photographs of toroidal FeNi@MgO@MK cores annealed at 700 °C (a), 750 °C (b), 800 °C (c), and 850 °C (d).

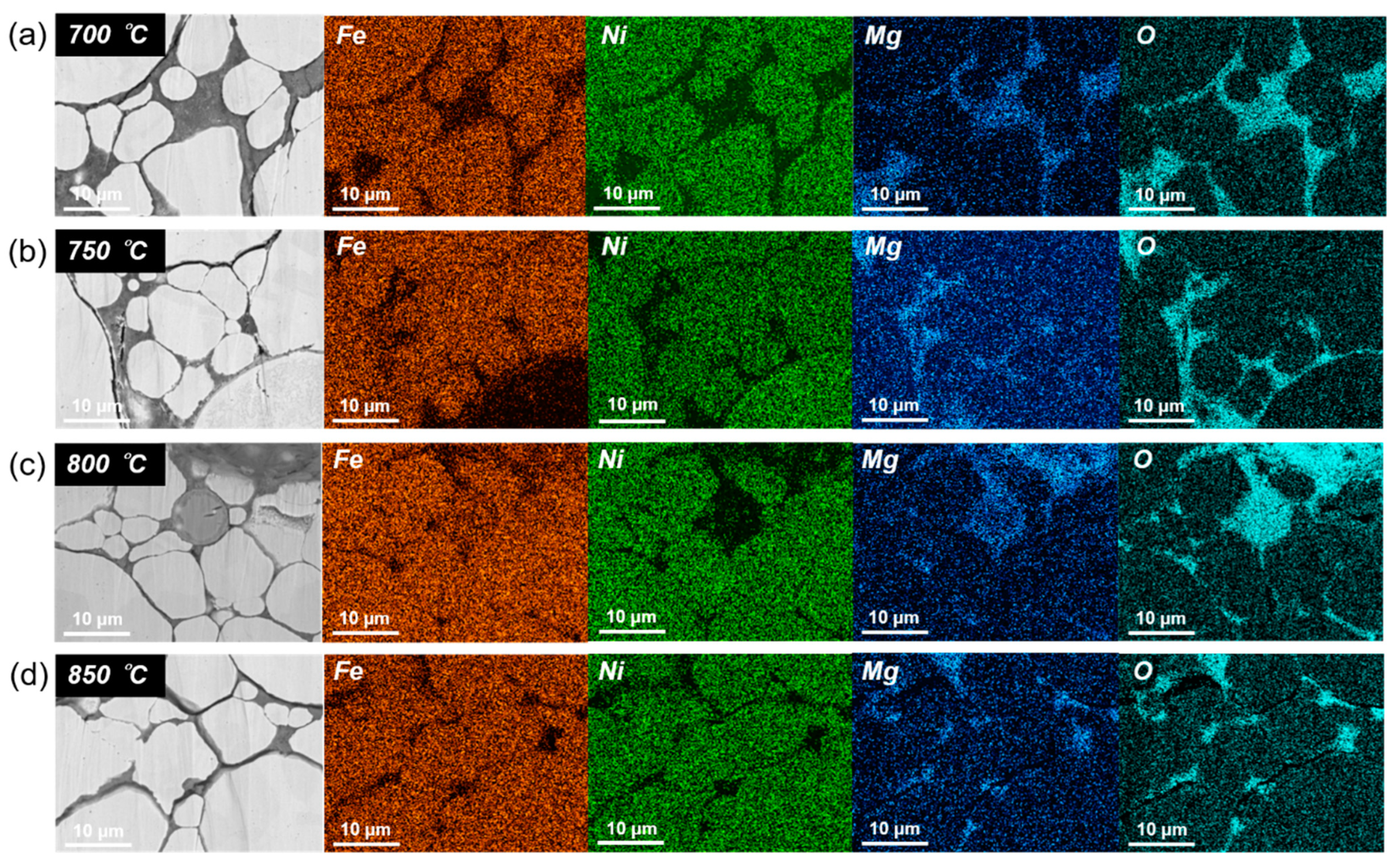

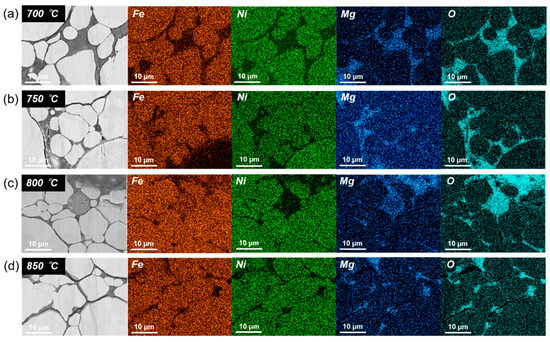

A cross-sectional SEM images of the toroidal core is presented in Figure 4. First, the MgO insulating layer is obviously uniformly coated on the surface of the Fe-Ni powder at 700 °C. When the heat treatment temperature was 850 °C, the MgO coating layer diffused into the Fe-Ni magnetic powder and the coating layer partially disappeared. In the EDS mapping results, Mg and O are clear at heat treatment temperatures up to 800 °C, but Mg and O become very faint at 850 °C, clearly confirming that diffusion of the MgO insulating layer has progressed. According to the SEM and EDS image results in Figure 4, the MgO insulating layer can withstand a high temperature of up to 800 °C. The cross-sectional photograph in Figure 4 shows that the MgO insulating layer is most uniformly coated on the surface of Fe-Ni powder at 700 °C and, while it can withstand a high temperature of 800 °C, diffusion of the insulating layer into powders is observed at 850 °C.

Figure 4.

EDS elemental distribution maps of cross-sectional morphologies of FeNi@MgO@MK cores annealed at 700 °C (a), 750 °C (b), 800 °C (c), and 850 °C (d).

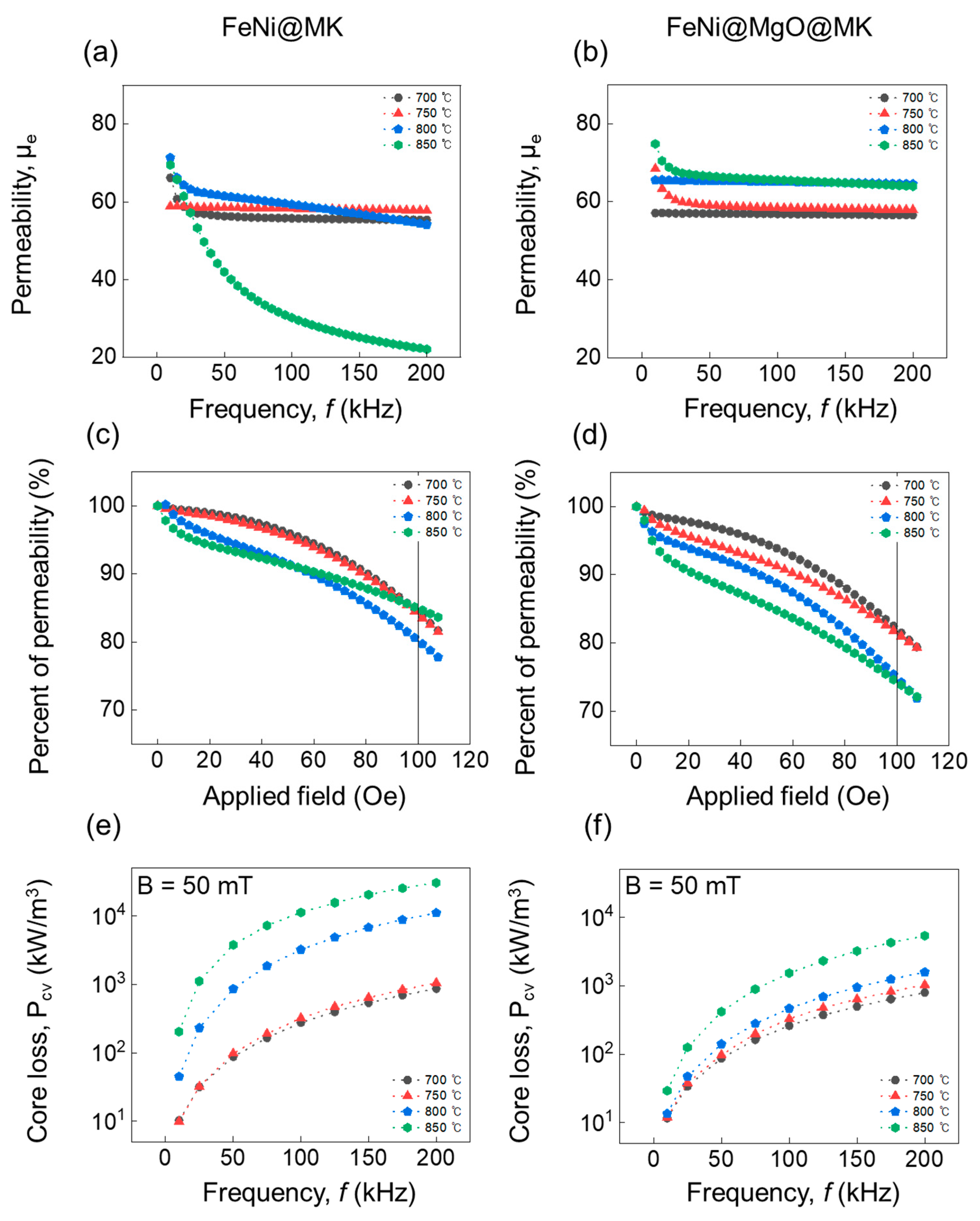

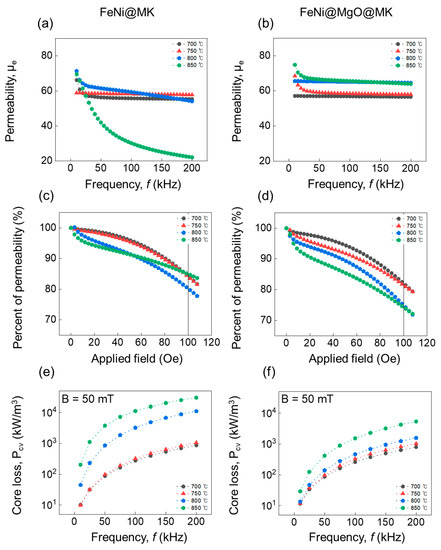

Various tests were conducted to evaluate the soft magnetic properties of FeNi@MgO SMCs. Figure 5 shows the effective permeability, DC-Bias characteristics, and core loss of FeNi@MK SMCs and FeNi@MgO@MK SMCs annealed at temperatures of 700–850 °C. Figure 5a,b show graphs of effective permeability (μe) of Fe-Ni SMCs according to the frequency [31]. First, Figure 5a shows the graph of μe of FeNi@MK SMCs according to the frequency. Relatively good frequency stability was shown up to 200 kHz. At 100 kHz, the μe values were 55.75, 58.22, 59.35, and 30.15 at 700 °C, 750 °C, 800 °C, and 850 °C, respectively. As the heat treatment temperature increased, the permeability tended to increase up to 800 °C, but a remarkably low value appeared at the annealing temperature of 850 °C. The increase in magnetic permeability with annealing temperature may be due to reduced coercive force and easier alignment of magnetic moments due to grain growth and elimination of defects such as dislocation stacking. The core annealed at 850 °C exhibits a notable decline in μe, primarily resulting from a rapid decrease in μe at high frequencies (100 kHz) due to the generated eddy currents. This occurrence can be attributed to the disappearance of the insulating layer, which dissolved into the powders during the high-temperature annealing process. Figure 5b shows the graph of μe of FeNi@MgO@MK SMCs according to the frequency. At 100 kHz, when the heat treatment temperatures were 700 °C, 750 °C, 800 °C, and 850 °C, the μe values were 56.87, 58.43, 65.18, and 65.60, respectively. μe of the FeNi@MgO@MK SMCs prepared by the sol-gel method tended to increase as the heat treatment temperature increased. Compared to the magnetic permeability of FeNi@MK SMCs, higher magnetic permeability was observed for FeNi@MgO@MK SMCs, especially at an annealing temperature of 800 °C or higher. The magnetic permeability of FeNi@MK and FeNi@MgO@MK SMCs was measured at different heat treatment temperatures and frequencies, and FeNi@MgO@MK SMCs showed higher permeability at 800 °C or higher.

Figure 5.

The frequency dependence of effective permeability (a,b), DC-Bias characteristics (c,d), and core loss (e,f) for FeNi@MK and FeNi@MgO@MK cores.

Figure 5c shows the graph of DC-Bias according to the applied field of FeNi@MK SMCs. DC-Bias performance is an essential performance indicator of a material’s ability to maintain its magnetic permeability in a DC-Bias field. The change of DC-Bias was opposite to the change trend of magnetic permeability [32]. Soft magnetic composites (SMCs) featuring high permeability levels saturate more readily when exposed to lower magnitude currents, given that they affect DC-Bias performance, a property that is inversely proportional to the effective permeability of the core [33,34]. When a magnetic field of 50 kHz and 100 Oe was applied, the values were 83.74, 83.49, 79.68, and 75.60 at 700 °C, 750 °C, 800 °C, and 850 °C, respectively. As the heat treatment temperature increased, the DC-Bias characteristics tended to decrease. Figure 5d shows the graph of DC-Bias characteristics of FeNi@MgO@MK SMCs according to the applied field. When a magnetic field of 100 Oe was applied, the values were 81.48, 80.99, 74.23, and 73.82 at 700 °C, 750 °C, 800 °C, and 850 °C, respectively. As the heat treatment temperature increased, the DC-Bias characteristics tended to decrease. This is because the magnetic permeability increased as the heat treatment temperature increased, resulting in a decrease in DC-Bias characteristics. The DC-Bias performance of FeNi@MK and FeNi@MgO@MK SMCs decreased as the heat treatment temperature increased, as shown by the opposite trend of DC-Bias characteristics to magnetic permeability, indicating that SMCs with higher permeability saturate more easily at lower currents.

Figure 5e,f show graphs of core loss (Pcv) of FeNi@MK SMCs and FeNi@MgO@MK SMCs annealed at temperatures of 700–850 °C according to frequency. Pcv was observed to increase with frequency in all samples, but the rate of increase was different. First, Figure 5e shows the graph of core loss (Pcv) of FeNi@MK SMCs according to the frequency. Under the conditions of f = 50 kHz and Bm = 50 mT, the core loss (Pcv) was 87.826, 98.007, 861.39, and 3790.2 mW/cc when the heat treatment temperature was 700 °C, 750 °C, 800 °C, and 850 °C, respectively. In the case of FeNi@MK SMCs, it can be seen that the core loss increases as the heat treatment temperature increases. In particular, it can be confirmed that the core loss value greatly increased when heat treatment was performed at 800 °C or higher. Figure 5f shows the graph of core loss (Pcv) of FeNi@MgO@MK SMCs according to the frequency. Core loss (Pcv) was 87.056, 97.647, 140.93, and 419.14 mW/cc at 700 °C, 750 °C, 800 °C, and 850 °C at f = 50 kHz and Bm = 50 mT, respectively. In the case of SMCs with MgO coating applied, it can be seen that the loss increase after high temperature heat treatment is significantly regulated when compared to SMCs without application of MgO coating. In the case of FeNi@MgO@MK SMCs, it can be confirmed that the core loss increases only after heat treatment at 800 °C and higher. In particular, in the case of the core subjected to heat treatment at a temperature of 850 °C, it can be seen that the MgO insulating layer has begun to be destroyed, seeing that the core loss has increased rapidly. When compared with the result of Figure 5e, it can be seen that when the MgO insulating coating is applied, it is effective in reducing core loss at high temperatures due to the MgO buffer layer. The graphs in Figure 5 show that the core loss (Pcv) increases with frequency in all samples, but the rate of increase differs, and the MgO insulating layer applied in FeNi@MgO@MK SMCs is effective in reducing core loss at high temperatures.

When comparing FeNi@MK SMCs and FeNi@MgO@MK SMCs, it was confirmed that when MgO insulating layer coating was applied, core loss decreased, magnetic permeability improved, and DC-Bias characteristics decreased accordingly. Core loss (Pcv) is the loss of energy that occurs when the SMC receives an alternating magnetic field. An increase in the core loss of SMC leads to an increase in heat generation. Therefore, reducing core loss is an important factor to consider when applying SMC.

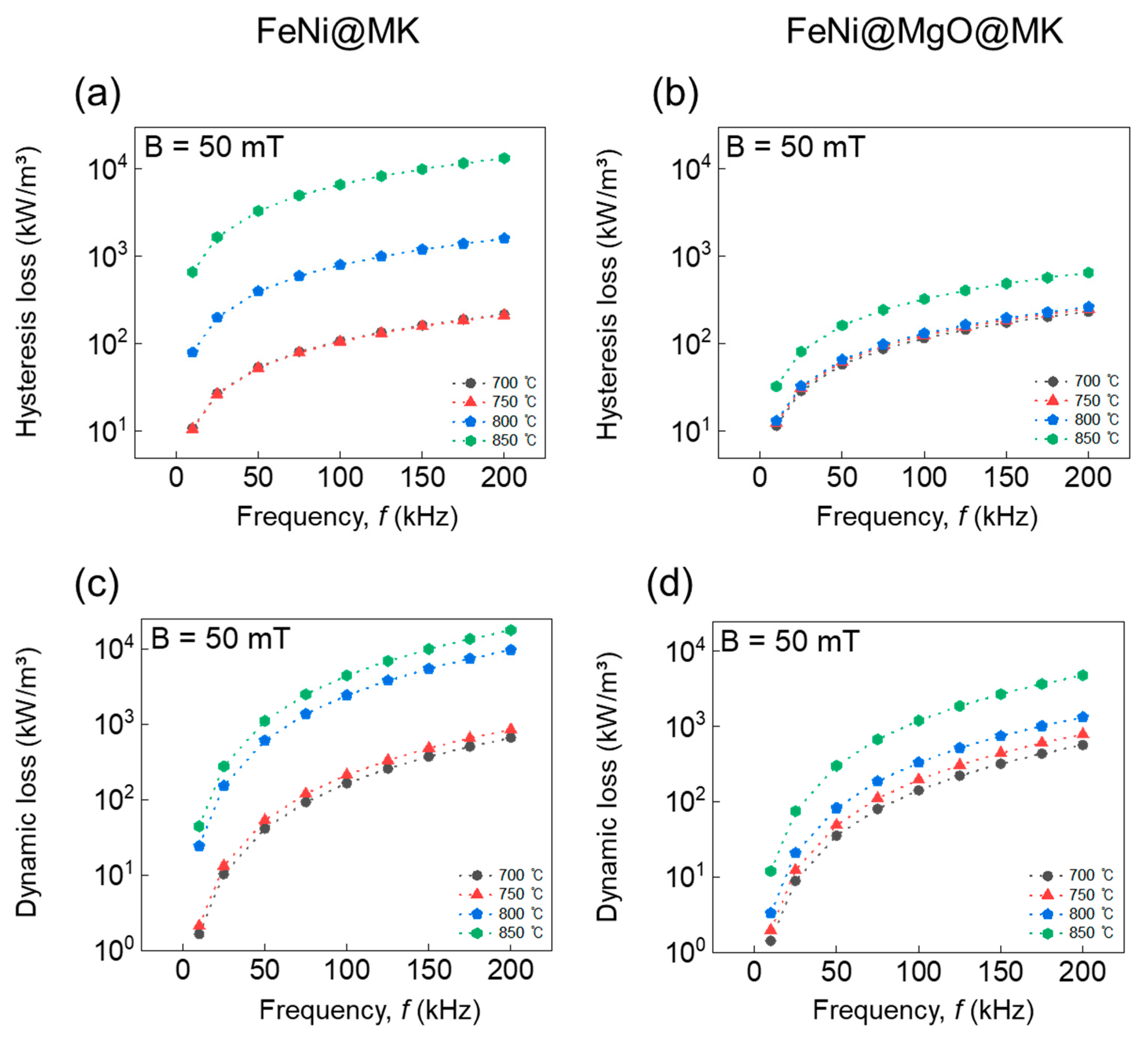

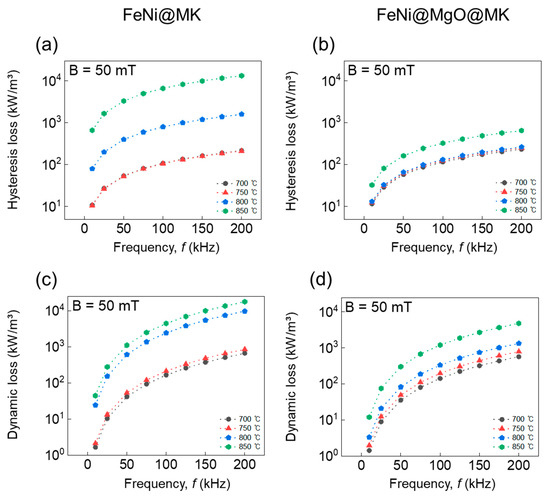

Figure 6 is the result of separation of core loss according to frequency at 50 mT. In general, Pcv is composed of hysteresis loss (Ph), eddy current loss (Pe), and residual loss (Pr). The Pr can be considered proportional to the square of frequency, similar to Pe, and thus Pcv can be expressed as follows [1,14,35,36,37]:

Figure 6.

The frequency dependence of hysteresis loss (a,b) and dynamic loss (c,d) of FeNi@MK and FeNi@MgO@MK cores.

Here, Kh and Kdyn represent the hysteresis loss factor and dynamic loss factor, respectively.

To further investigate the difference in the Pcv for FeNi@MK SMCs and FeNi@MgO@MK SMCs, loss separation was performed using the above equation and the contributions of Ph and Pdyn are shown in Figure 6. Figure 6a is the hysteresis loss of FeNi@MK SMCs according to the frequency at 50 mT. The Ph values at the heat treatment temperatures of 700 and 750 °C are almost similar, but the hysteresis loss starts to increase from 800 °C. Figure 6b is the hysteresis loss of FeNi@MgO@MK SMCs at 50 mT according to the frequency. The Ph values at the heat treatment temperatures of 700, 750, and 800 °C are almost similar, but the hysteresis loss starts to increase slightly from 850 °C. Figure 6c is the dynamic loss of FeNi@MK SMCs at 50 mT according to the frequency. The Pdyn values at the heat treatment temperatures of 700 and 750 °C are almost similar, but the dynamic loss starts to increase slightly from 800 °C. Figure 6d is the dynamic loss of FeNi@MgO@MK SMCs at 50 mT according to the frequency. The Pdyn value up to 800 °C in heat treatment temperature is almost similar, but the eddy current loss starts to increase slightly from 850 °C. This may be because a part of the coating layer was ruptured due to the high temperature heat treatment and Pdyn was concomitantly elevated. The decrease in Pdyn may be due to the formation of an evenly distributed MgO insulating layer having an appropriate thickness on the surface of the Fe-Ni magnetic powder. The MgO insulating coating was able to effectively block eddy currents between particles and reduce the Pdyn of FeNi@MgO@MK SMCs. The hysteresis loss and dynamic loss of FeNi@MK and FeNi@MgO@MK SMCs were measured at different heat treatment temperatures; they showed increases in loss with increasing temperature, with FeNi@MgO@MK SMCs having lower dynamic loss due to the MgO insulating layer.

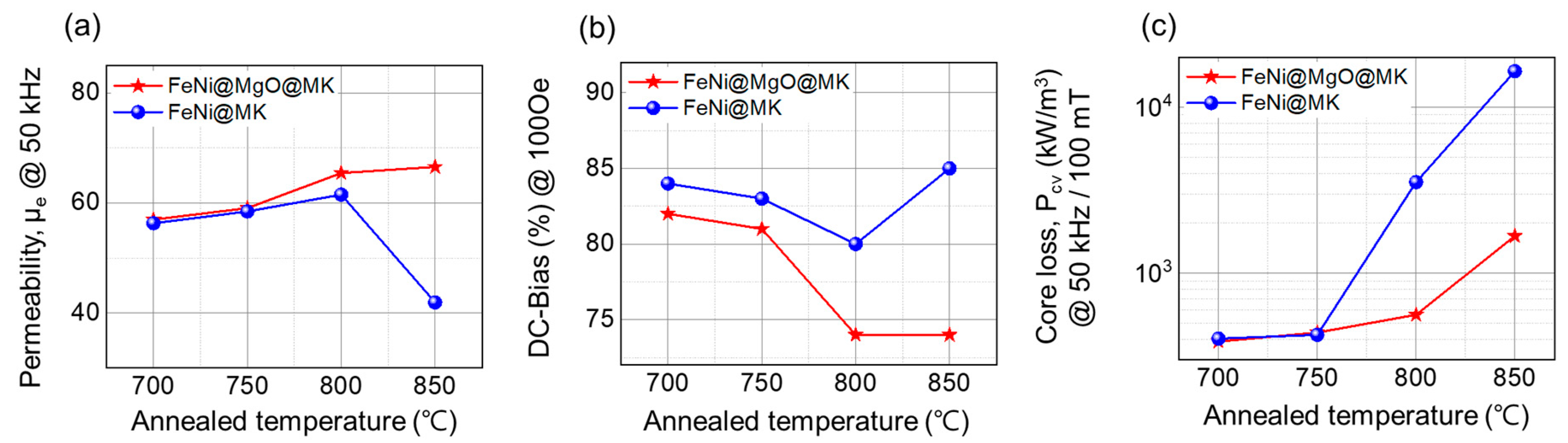

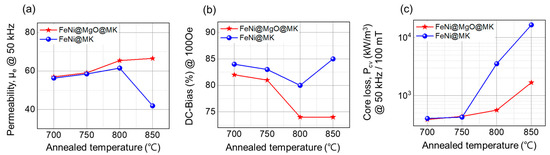

Figure 7 shows a summary of the various magnetic properties according to the heat treatment temperature of the core. Figure 7a is a graph of the permeability. Up to 800 °C, the magnetic permeability of both FeNi@MK and FeNi@MgO@MK SMCs gradually increased; however, at higher temperatures, the value of μe of FeNi@MK SMCs decreased significantly. In the case of FeNi@MgO@MK SMCs, however, the magnetic permeability gradually increased up to 850 °C. When high-temperature heat treatment is applied, therefore, grain growth occurs and defects such as dislocation stacking decrease, thereby reducing the coercive force and facilitating alignment of the magnetic moment. Figure 7b provides a graph showing DC-Bias characteristics at 100 Oe. As the heat treatment temperature increased, the magnetic permeability increased, and the DC-Bias characteristics also tended to decrease accordingly. Figure 7c provides a graph showing core loss. When heat treatment was performed at 800 °C or more, the rate of increase in core loss of the core to which the MgO coating was applied decreased significantly because the increase of eddy current loss was regulated by the MgO buffer layer. Table 1 shows for comparison the soft magnetic properties of the Fe-Ni powder cores mentioned so far. Additionally, the soft magnetic properties of MgO-coated Fe-Ni SMCs were compared with those reported in the literature, which investigated magnetic properties using various coating materials and methods, as presented in Table 2.

Figure 7.

The Annealing temperature dependence of effective permeability (a), DC-Bias characteristics (b) and core loss (c) of FeNi@MK and FeNi@MgO@MK cores.

Table 1.

Comparison of soft magnetic properties of Fe-Ni powder cores with and without MgO insulation layer.

Table 2.

Soft magnetic properties of reported SMCs.

4. Conclusions

In this work, MgO was selected as insulation material for the fabrication of Fe-Ni SMCs; effects of high-temperature heat treatment on soft magnetic properties of Fe-Ni@MgO SMCs were investigated. A uniform MgO insulating layer with a thickness of 600 nm was successfully coated on Fe-Ni magnetic powder using the sol-gel process, and high-density SMCs were then fabricated through high-pressure compaction molding. Microstructure analysis revealed that the MgO insulating layer remained intact up to 800 °C, with only slight diffusion observed at 850 °C. The value of μe of the FeNi@MgO SMCs prepared by sol-gel method tended to increase as the heat treatment temperature increased. Compared to the magnetic permeability of FeNi@MK SMC, higher magnetic permeability was observed, especially at annealing temperatures above 800 °C, indicating that it saturates more easily at lower currents. For the FeNi@MgO@MK SMCs, core loss increase after high temperature heat treatment was significantly regulated compared to the case of SMCs without application of MgO coating; this increase is attributed to grain enlargement and the elimination of defects such as dislocation stacking. The process also effectively reduced the eddy currents between the grains and Pdyn due to the presence of the MgO insulating layer even after high-temperature heat treatment. This study reveals that employing MgO as an insulating buffer layer significantly enhances the thermal stability and soft magnetic properties of Fe-Ni SMCs, emphasizing the potential of FeNi@MgO@MK SMCs for various electromagnetic applications.

Author Contributions

J.-H.P.: Investigation, writing—original draft. H.-R.K.: Methodology. J.-W.L.: writing—review and editing, supervision. J.-W.J.: Conceptualization, writing—review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Steel Re-Leap Project and Automotive Technology Development Project funded by the Korea Ministry of Trade, Industry and Energy (MOTIE, Republic of Korea). [Project number: 20015645 and 20018921].

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Hu, F.; Ni, J.; Feng, S.; Kan, X.; Yang, Y.; Lv, Q.; Liu, X. Soft Magnetic Properties of Fe-6.5 wt% Si/SrFe12O 19 Composites. J. Supercond. Nov. Magn. 2020, 33, 2779–2785. [Google Scholar] [CrossRef]

- Hu, F.; Ni, J.; Feng, S.; Kan, X.; Zhu, R.; Yang, W.; Yang, Y.; Lv, Q.; Liu, X. Low melting glass as adhesive and insulating agent for soft magnetic composites: Case in FeSi powder core. J. Magn. Magn. Mater. 2020, 501, 166480. [Google Scholar] [CrossRef]

- Hemmati, I.; Hosseini, H.M.; Kianvash, A. The correlations between processing parameters and magnetic properties of an iron–resin soft magnetic composite. J. Magn. Magn. Mater. 2006, 305, 147–151. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Cui, Z.; Gao, Z.; Huang, Z.; Wu, Z. Selective oxidation of rare metal oxide insulation layers on particle substrates for optimizing the performance of FeSiCr-based soft magnetic composites. Mater. Des. 2023, 230, 111984. [Google Scholar] [CrossRef]

- Wu, Z.; Kang, L.; Liao, X.; Kong, H.; Wang, H.; Wang, R. Realizing high-resistivity and low-loss Fe–Si–Al based soft magnetic powder cores through interfacial chemistry regulation. Ceram. Int. 2023, 49, 19870–19878. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, W.; Guo, T.; Jiang, Y.; Yan, M. Effect of processing parameters on the magnetic properties and microstructures of molybdenum permalloy compacts made by powder metallurgy. J. Alloys Compd. 2014, 594, 153–157. [Google Scholar] [CrossRef]

- Yao, Z.; Peng, Y.; Xia, C.; Yi, X.; Mao, S.; Zhang, M. The effect of calcination temperature on microstructure and properties of FeNiMo@Al2O3 soft magnetic composites prepared by sol-gel method. J. Alloys Compd. 2020, 827, 154345. [Google Scholar] [CrossRef]

- Perigo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Neamţu, B.; Pszola, M.; Opriş, A.; Popa, F.; Marinca, T.; Chicinaş, I. Influence of fibres diameter on the AC and DC magnetic characteristics of Fe/Fe3O4 fibres based soft magnetic composites. Ceram. Int. 2021, 47, 1865–1874. [Google Scholar] [CrossRef]

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt% Si high silicon steel—A promising soft magnetic material for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Waeckerlé, T.; Fraisse, H.; Furnemont, Q. Soft magnetic FeNi alloys for DC current sensors with high accuracy. J. Magn. Magn. Mater. 2005, 290, 1584–1588. [Google Scholar] [CrossRef]

- Olekšáková, D.; Kollár, P.; Füzer, J. Structure and magnetic properties of powdered and compacted FeNi alloys. J. Electr. Eng. 2017, 68, 163–166. [Google Scholar] [CrossRef]

- Yaghtin, M.; Taghvaei, A.H.; Hashemi, B.; Janghorban, K. Effect of heat treatment on magnetic properties of iron-based soft magnetic composites with Al2O3 insulation coating produced by sol–gel method. J. Alloys Compd. 2013, 581, 293–297. [Google Scholar] [CrossRef]

- Taghvaei, A.; Shokrollahi, H.; Janghorban, K. Properties of iron-based soft magnetic composite with iron phosphate–silane insulation coating. J. Alloys Compd. 2009, 481, 681–686. [Google Scholar] [CrossRef]

- Peng, Y.; Yi, Y.; Li, L.; Yi, J.; Nie, J.; Bao, C. Iron-based soft magnetic composites with Al2O3 insulation coating produced using sol–gel method. Mater. Des. 2016, 109, 390–395. [Google Scholar] [CrossRef]

- Wu, Z.; Fan, X.; Li, G.; Wang, J.; Gan, Z. Intergranular insulated Fe-6.5 wt% Si/SiO2 composite compacts with tunable insulating layer thickness for low core loss applications. RSC Adv. 2015, 5, 67031–67040. [Google Scholar] [CrossRef]

- Geng, K.; Xie, Y.; Xu, L.; Yan, B. Structure and magnetic properties of ZrO2-coated Fe powders and Fe/ZrO2 soft magnetic composites. Adv. Powder Technol. 2017, 28, 2015–2022. [Google Scholar] [CrossRef]

- Lee, S.; Choi, M.; Kim, J. Magnetic properties of pure iron soft magnetic composites coated by manganese phosphates. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Geng, K.; Xie, Y.; Yan, L.; Yan, B. Fe-Si/ZrO2 composites with core-shell structure and excellent magnetic properties prepared by mechanical milling and spark plasma sintering. J. Alloys Compd. 2017, 718, 53–62. [Google Scholar] [CrossRef]

- Rani, N.; Chahal, S.; Kumar, P.; Kumar, A.; Shukla, R.; Singh, S. MgO nanostructures at different annealing temperatures for d0 ferromagnetism. Vacuum 2020, 179, 109539. [Google Scholar] [CrossRef]

- Uozumi, G.; Watanabe, M.; Nakayama, R.; Igarashi, K.; Morimoto, K. Properties of soft magnetic composite with evaporated MgO insulation coating for low iron loss. Mater. Sci. Forum 2007, 534–536, 1361–1364. [Google Scholar]

- Wu, M.; Yuan, J.; Diao, G.; Li, D. Achieving a Combination of Higher Strength and Higher Ductility for Enhanced Wear Resistance of AlCrFeNiTi0. 5 High-Entropy Alloy by Mo Addition. Metals 2022, 12, 1910. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Sluiter, M.; Kawazoe, Y. Prediction of the mixing enthalpy of alloys. Europhys. Lett. 2002, 57, 526. [Google Scholar] [CrossRef]

- Grant, R.M. Lead Production. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 4439–4442. [Google Scholar]

- Parker, G. Encyclopedia of Materials: Science and Technology. Elsevier Science: Osaka, Japan, 2001. [Google Scholar]

- Taghvaei, A.H.; Ebrahimi, A.; Gheisari, K.; Janghorban, K. Analysis of the magnetic losses in iron-based soft magnetic composites with MgO insulation produced by sol–gel method. J. Magn. Magn. Mater. 2010, 322, 3748–3754. [Google Scholar] [CrossRef]

- Wu, S.; Dong, Y.; Li, X.; Gong, M.; Zhao, R.; Gao, W.; Wu, H.; He, A.; Li, J.; Wang, X. Microstructure and magnetic properties of FeSiCr soft magnetic powder cores with a MgO insulating layer prepared by the sol-gel method. Ceram. Int. 2022, 48, 22278–22286. [Google Scholar] [CrossRef]

- Mahdi, H.S.; Parveen, A.; Agrawal, S.; Azam, A. Microstructural and optical properties of sol gel synthesized CdS nano particles using CTAB as a surfactant. AIP Conf. Proc. 2017, 1832, 050012. [Google Scholar]

- Vesa, J.; Rasilo, P. Permeability estimations of SMC material particles. IEEE Trans. Magn. 2020, 56, 1–7. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Pauly, S.; Chang, C.; Wei, R.; Li, F.; Wang, X.-M. Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J. Alloys Compd. 2017, 706, 1–6. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, Y.; Liu, X.; Lu, H.; Wu, Y.; Zhang, H.; He, A.; Li, J.; Wang, X. Microstructure and soft magnetic properties of Fe85− xSi9. 6Al5. 4Tix composite magnetic powder cores. J. Alloys Compd. 2021, 885, 160924. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Mo, J.; Mao, X.; Luo, Z. The influence of doping Ti on the microstructure and magnetic performances of Fe-6.5 Si soft magnetic composites. J. Alloys Compd. 2018, 766, 769–774. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, W.; Yuan, W.; Peng, K. Preparation and magnetic properties of core–shell structured Fe-Si/Fe3O4 composites via in-situ reaction method. J. Magn. Magn. Mater. 2021, 531, 167955. [Google Scholar] [CrossRef]

- Ni, J.; Duan, F.; Feng, S.; Hu, F.; Kan, X.; Liu, X. High performance of FeSiAl/hBN soft magnetic composites. J. Alloys Compd. 2022, 897, 163191. [Google Scholar] [CrossRef]

- Guo, R.; Yu, G.; Zhu, M.; Qiu, Y.; Wu, G.; Zhou, H. Regulation of magnetic and electrical performances in core-shell-structured FeSiCr@ BaTiO3 soft magnetic composites. J. Alloys Compd. 2022, 895, 162724. [Google Scholar] [CrossRef]

- Streckova, M.; Szabo, J.; Batko, I.; Batkova, M.; Bircakova, Z.; Fuzer, J.; Kollar, P.; Kovalcikova, A.; Bures, R.; Medvecky, L. Design of Permalloy–ferrite–polymer soft magnetic composites doped by ferrite nanoparticles and visualization of magnetic domains. Bull. Mater. Sci. 2020, 43, 37. [Google Scholar] [CrossRef]

- Lin, S.; Zhou, Z.; Jin, J.; Hu, X.; Li, S.; Ju, N. Effect of SiO2/Organosilicone Double Insulation Coating Processes on the Properties of Ferrosilicon Magnetic Cores. Magnetochemistry 2023, 9, 126. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).