Effect of Thermo-Mechanical Processing on Initiation and Propagation of Stress Corrosion Cracking in 304L Austenitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

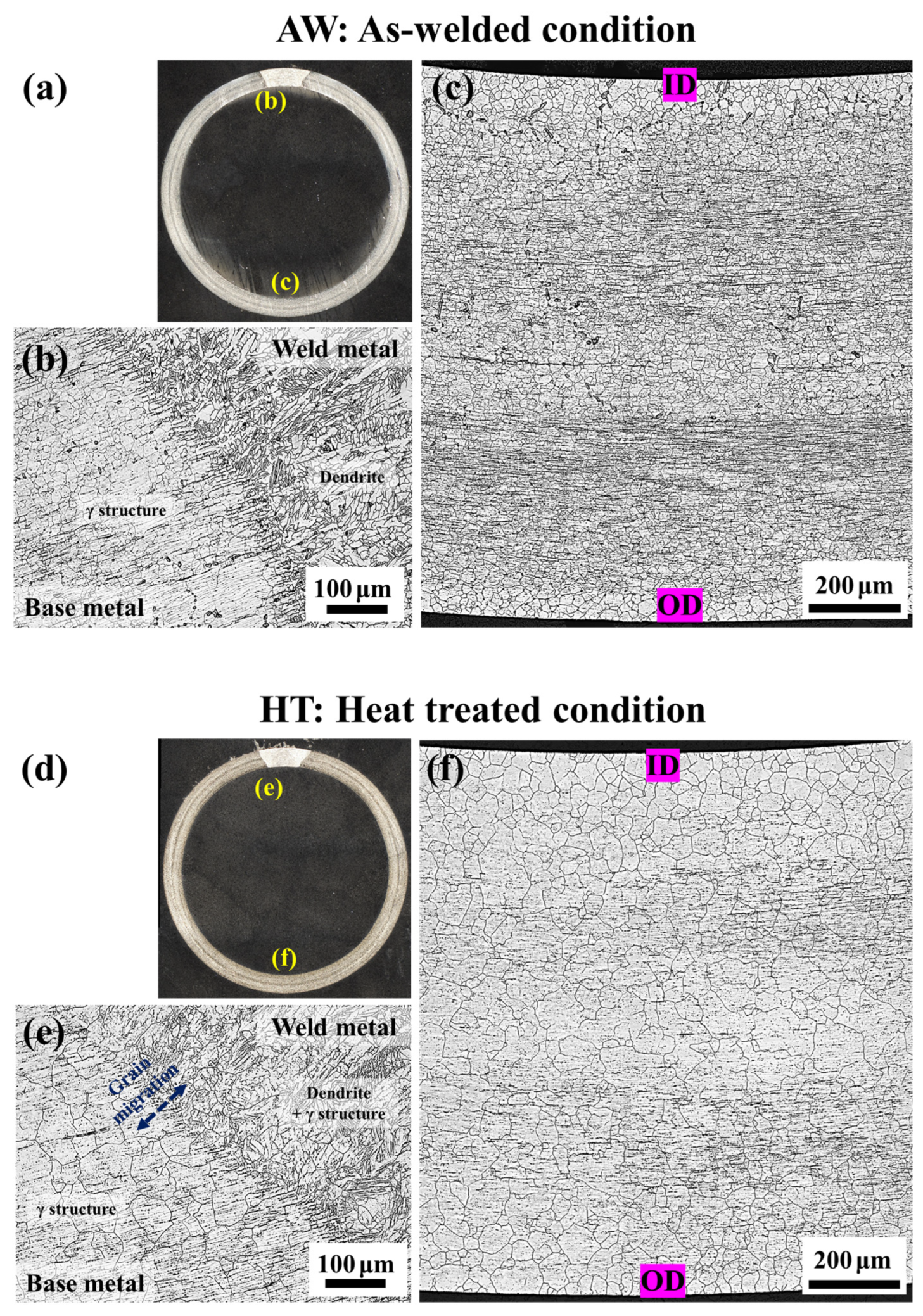

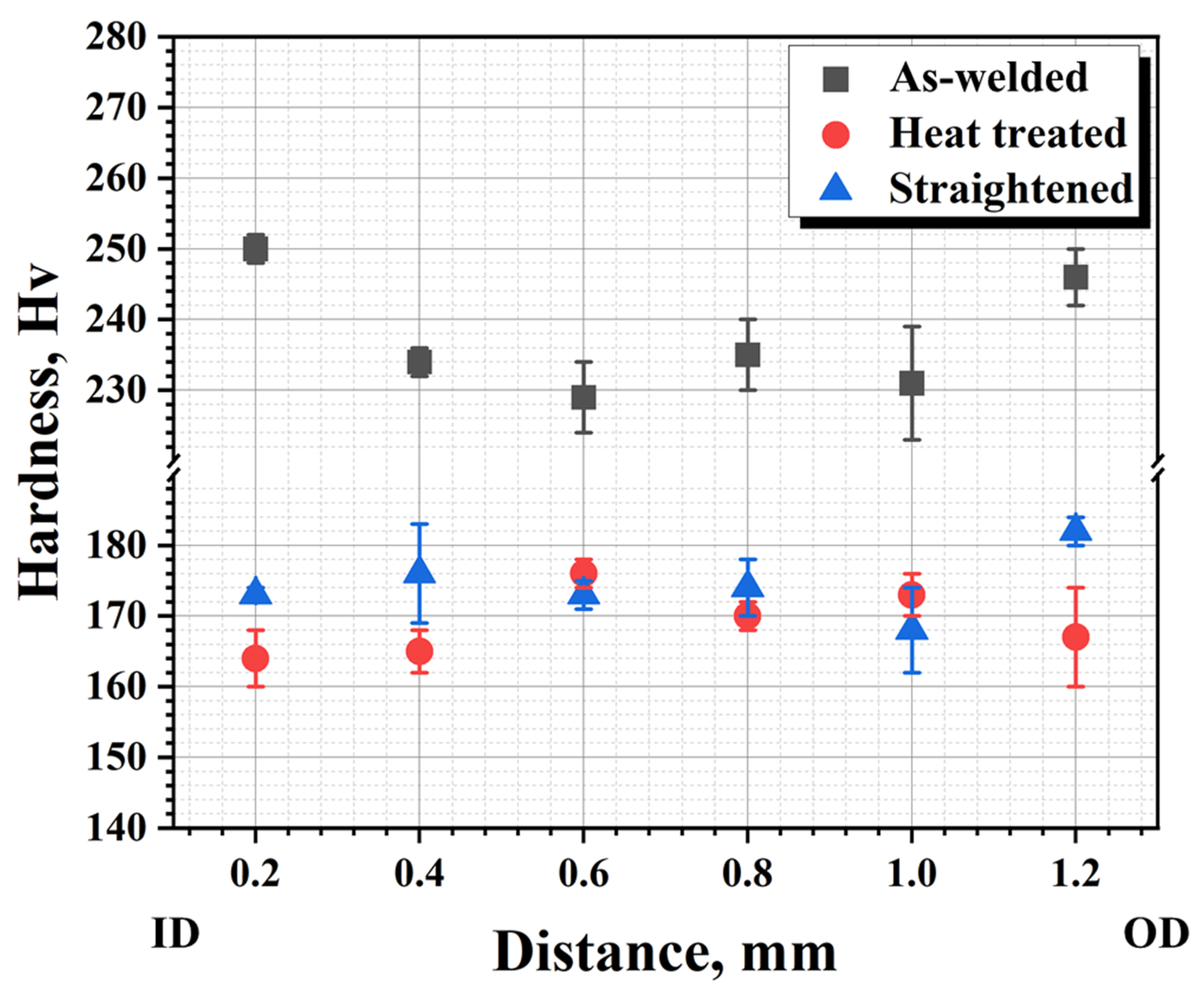

3.1. Initial Microstructure Depending on the TMP condition

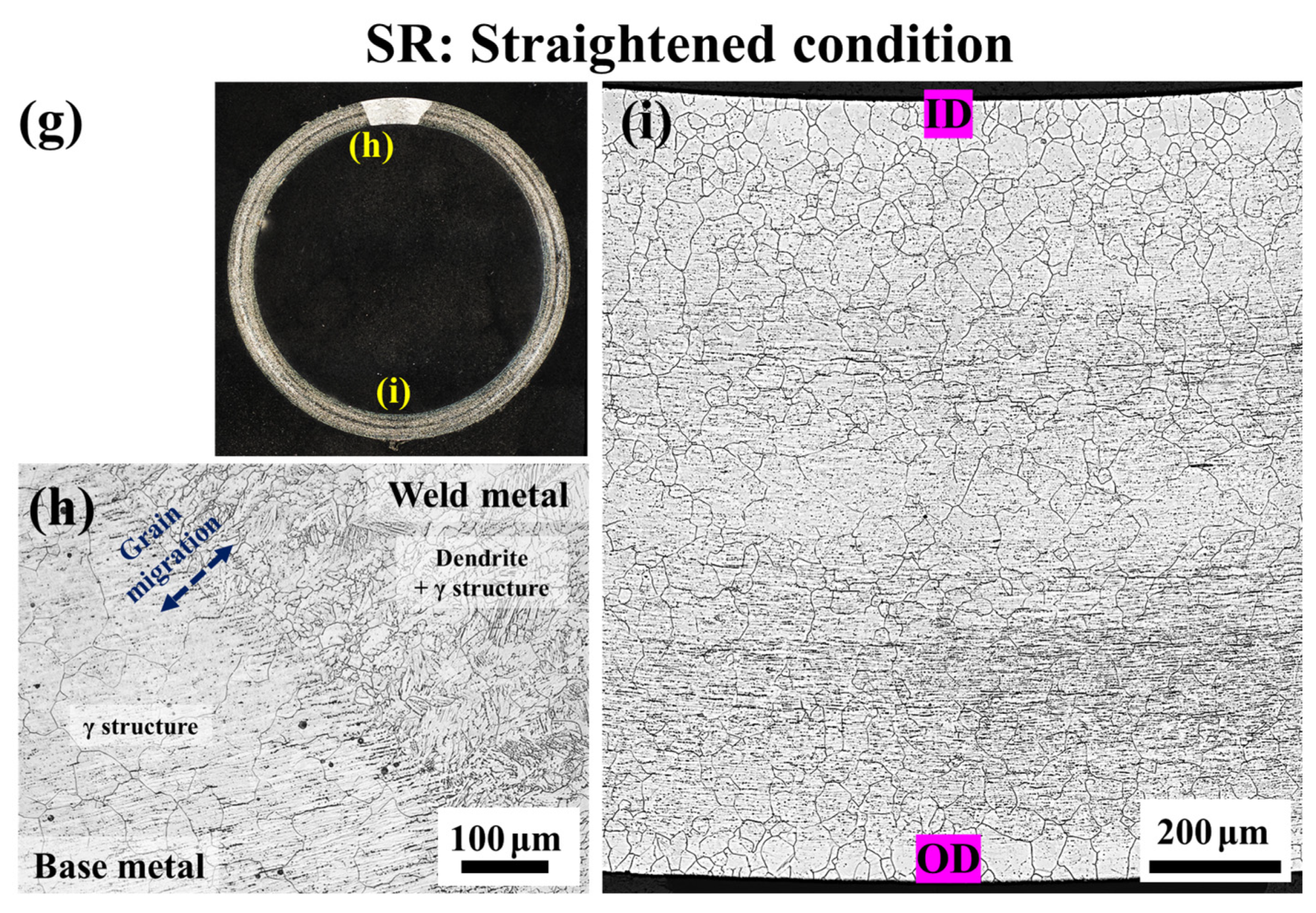

3.2. Residual Stress Measurement Using Split-Ring Test

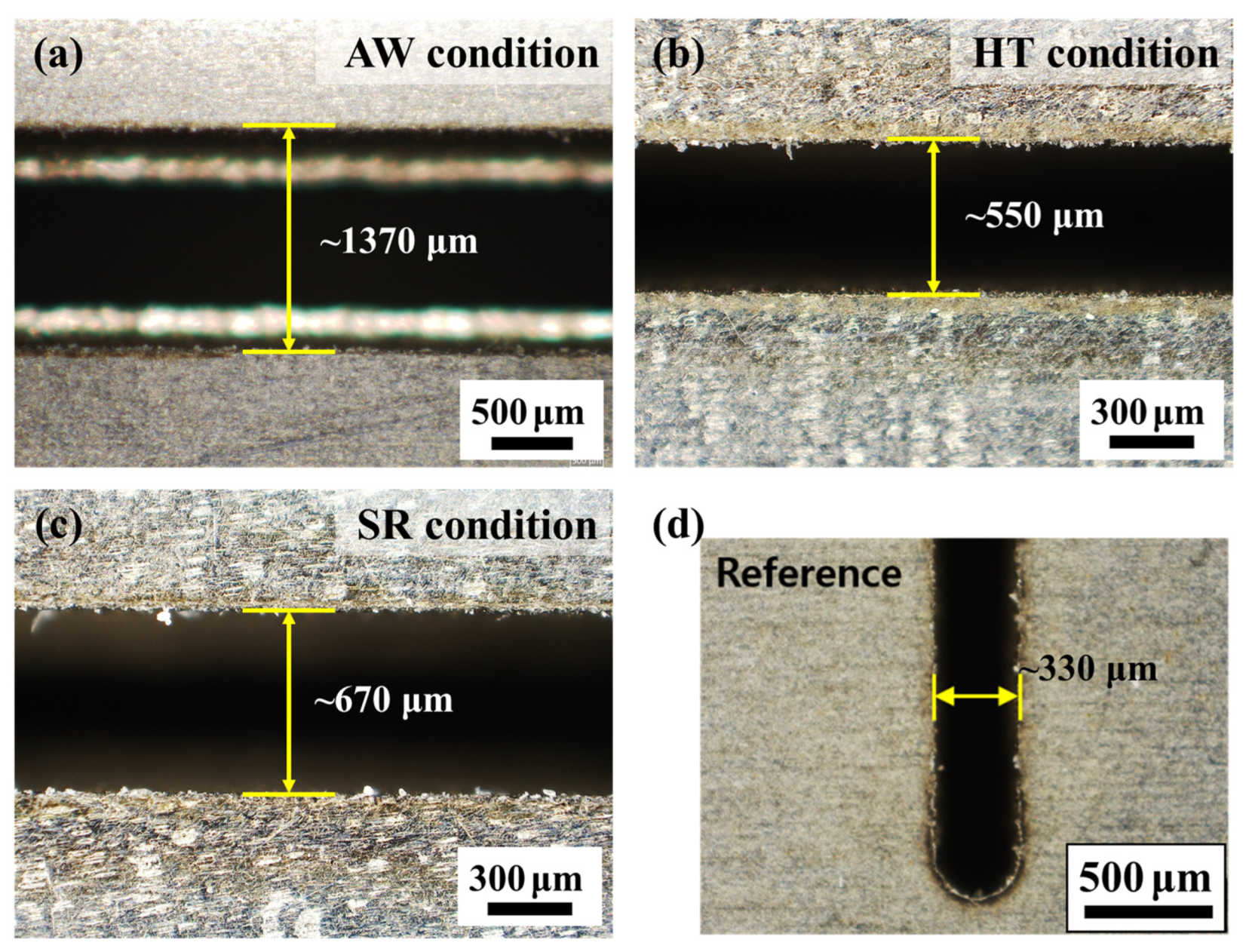

3.3. Micro-Hardness Measurements

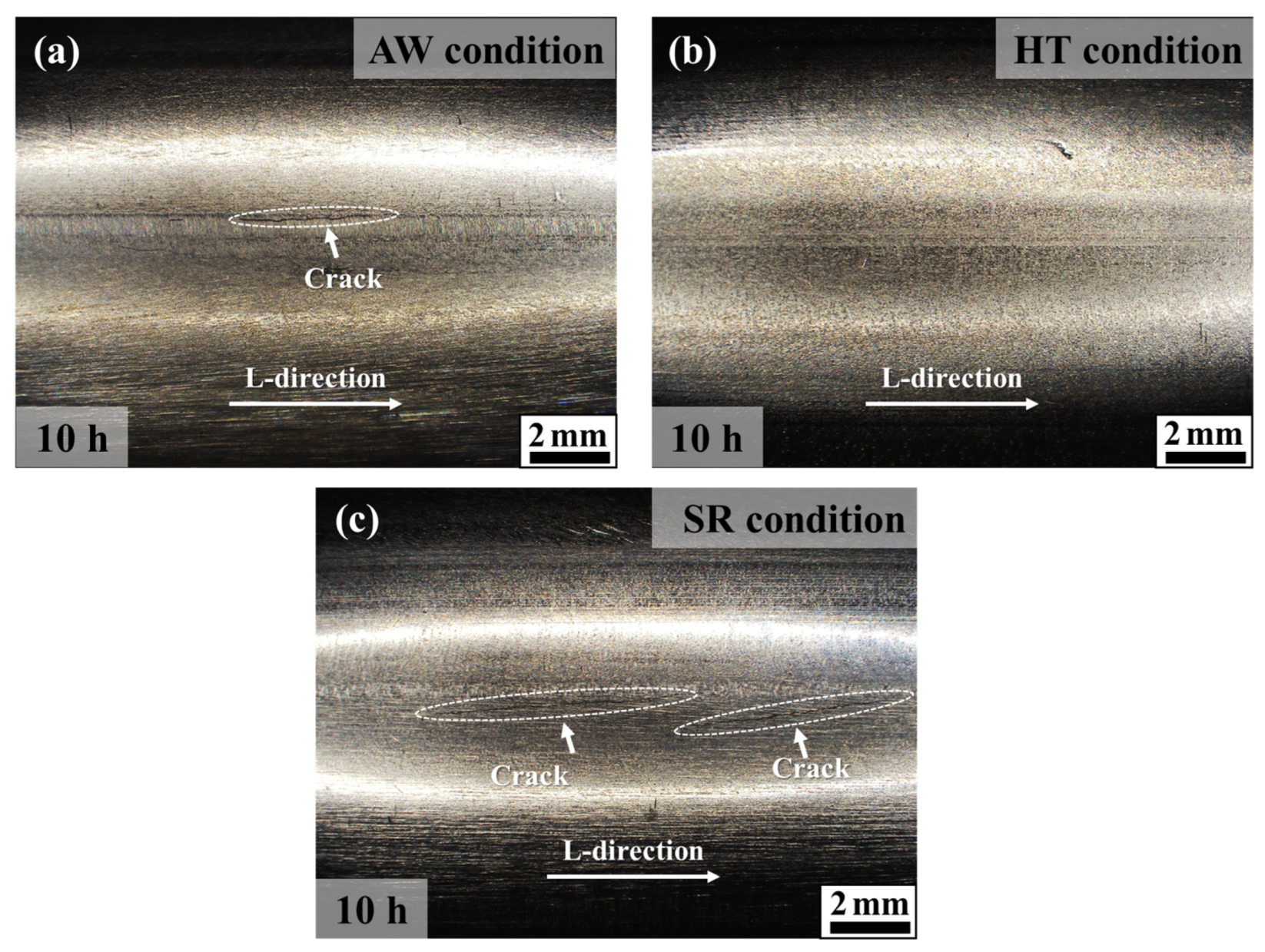

3.4. Evolution of SCC Resistance Depending on the TMP Condition

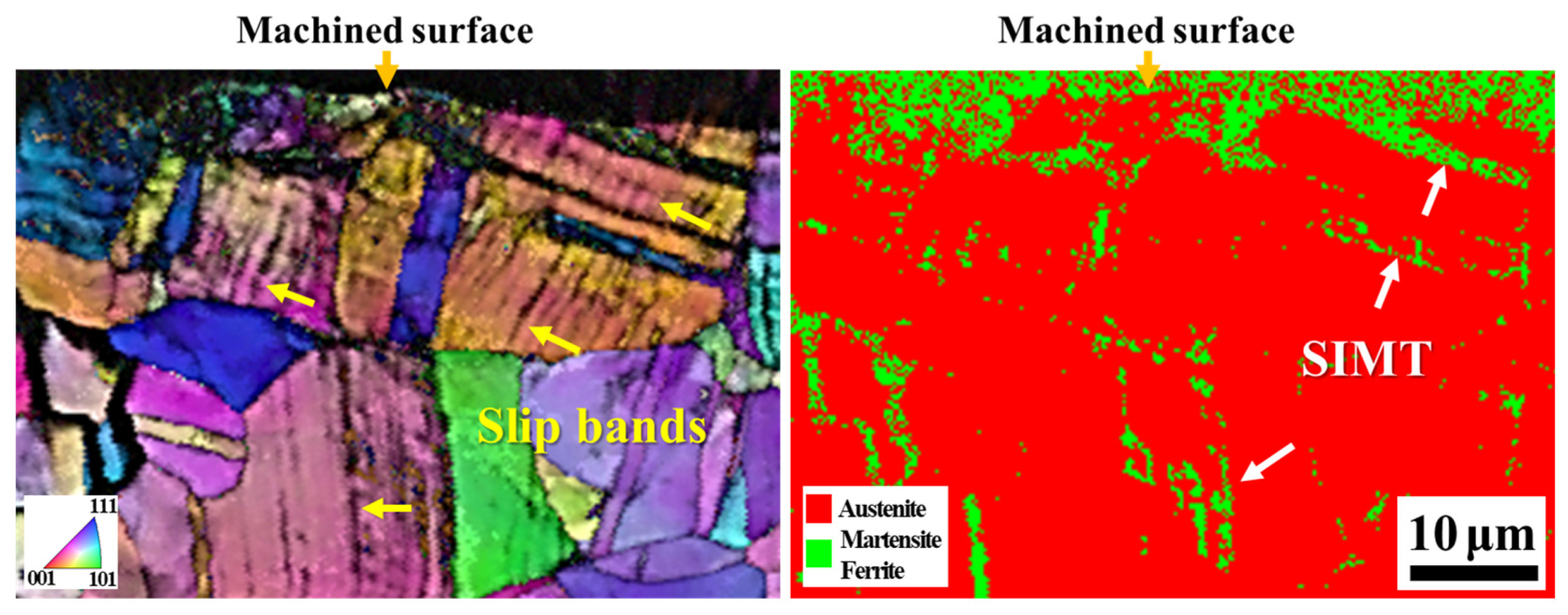

3.5. Effect of Residual Stress and Martensite on SCC Mode

4. Conclusions

- Microstructural changes such as an increase in grain size and grain migration were observed in the HT tube compared with the AW tube. These changes can lead to a significant reduction in hardness and residual stress. Meanwhile, the SR tube exhibited microstructures and mechanical properties similar to those of the HT tube but had slightly higher residual stress and a slight increase in hardness on the outer surface. This could be attributed to surface hardening resulting from the straightening process during manufacturing.

- TG cracks were found to initiate on the surfaces of AW and SR tubes, which exhibited elevated levels of residual stress and hardness. These regions can be inferred to possess inherent residual stress values that are higher than the critical stress required for crack initiation. Furthermore, the formation of SIMT and slip bands, induced by the TMP, were identified as factors contributing to SCC susceptibility.

- In summary, varying the TMP condition can lead to variations in the magnitudes of residual stresses and the distribution of slightly different hardness values based on the depth direction, which can be associated with microstructural features. As a result of this, cracks can show multiple SCC modes in cases where residual stress occurs near the surface, while straight TG cracking can be the dominant SCC mode when high levels of residual stress and SIMT occur along the overall matrix.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.J.; Hsiang Hsieh, I. Using an IR lamp to perform DNA amplifications on an oscillatory thermocycler. Appl. Therm. Eng. 2016, 106, 1–12. [Google Scholar] [CrossRef]

- Chang, L.; Volpe, L.; Wang, Y.L.; Burke, M.G.; Maurotto, A.; Tice, D.; Lozano-Perez, S.; Scenini, F. Effect of machining on stress corrosion crack initiation in warm-forged type 304L stainless steel in high temperature water. Acta Mater. 2019, 165, 203–214. [Google Scholar] [CrossRef]

- Mayuzumi, M.; Arai, T.; Hide, K. Chloride Induced Stress Corrosion Cracking of Type 304 and 304L Stainless Steels in Air. Zair.-Kankyo 2003, 52, 166–170. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, K.; Hu, Y.; Wang, S.; Wang, X. Effect of machining-induced surface residual stress on initiation of stress corrosion cracking in 316 austenitic stainless steel. Corros. Sci. 2016, 108, 173–184. [Google Scholar] [CrossRef]

- Fujii, T.; Tohgo, K.; Kenmochi, A.; Shimamura, Y. Experimental and numerical investigation of stress corrosion cracking of sensitized type 304 stainless steel under high-temperature and high-purity water. Corros. Sci. 2015, 97, 139–149. [Google Scholar] [CrossRef]

- Bosch, R.W.; Vankeerberghen, M.; Gérard, R.; Somville, F. Crack initiation testing of thimble tube material under PWR conditions to determine a stress threshold for IASCC. J. Nucl. Mater. 2015, 461, 112–121. [Google Scholar] [CrossRef]

- Chang, L.; Burke, M.G.; Scenini, F. Understanding the effect of surface finish on stress corrosion crack initiation in warm-forged stainless steel 304L in high-temperature water. Scr. Mater. 2019, 164, 1–5. [Google Scholar] [CrossRef]

- Lu, Z.; Shoji, T.; Meng, F.; Qiu, Y.; Dan, T.; Xue, H. Effects of water chemistry and loading conditions on stress corrosion cracking of cold-rolled 316NG stainless steel in high temperature water. Corros. Sci. 2011, 53, 247–262. [Google Scholar] [CrossRef]

- Chen, J.; Yang, N.; Nishihara, H. Special issue in honor of Koichi Aoki Preface. J. Electroanal. Chem. 2016, 779, 1–6. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, J. Effect of temperature and loading mode on environmentally assisted crack growth of a forged 316L SS in oxygenated high-temperature water. Corros. Sci. 2014, 87, 278–287. [Google Scholar] [CrossRef]

- Yaguchi, S.; Yonezawa, T. Intergranular Stress Corrosion Cracking growth perpendicular to fatigue pre-cracks in T–L oriented compact tension specimens in simulated Pressurized Water Reactor primary water. Corros. Sci. 2014, 86, 326–336. [Google Scholar] [CrossRef]

- Han, Y.; Mei, J.; Peng, Q.; Han, E.-H.; Ke, W. Effect of electropolishing on corrosion of nuclear grade 316L stainless steel in deaerated high temperature water. Corros. Sci. 2016, 112, 625–634. [Google Scholar] [CrossRef]

- Acharyya, S.G.; Khandelwal, A.; Kain, V.; Kumar, A.; Samajdar, I. Surface working of 304L stainless steel: Impact on microstructure, electrochemical behavior and SCC resistance. Mater. Charact. 2012, 72, 68–76. [Google Scholar] [CrossRef]

- Turnbull, A.; Mingard, K.; Lord, J.D.; Roebuck, B.; Tice, D.R.; Mottershead, K.J.; Fairweather, N.D.; Bradbury, A.K. Sensitivity of stress corrosion cracking of stainless steel to surface machining and grinding procedure. Corros. Sci. 2011, 53, 3398–3415. [Google Scholar] [CrossRef]

- Ghosh, S.; Rana, V.P.S.; Kain, V.; Mittal, V.; Baveja, S.K. Role of residual stresses induced by industrial fabrication on stress corrosion cracking susceptibility of austenitic stainless steel. Mater. Des. 2011, 32, 3823–3831. [Google Scholar] [CrossRef]

- Ben Rhouma, A.; Braham, C.; Fitzpatrick, M.E.; Lédion, J.; Sidhom, H. Effects of surface preparation on pitting resistance, residual stress, and stress corrosion cracking in austenitic stainless steels. J. Mater. Eng. Perform. 2001, 10, 507–514. [Google Scholar] [CrossRef]

- Park, J.W.; Ferracane, J.L. Measuring the residual stress in dental composites using a ring slitting method. Dent. Mater. 2005, 21, 882–889. [Google Scholar] [CrossRef]

- Seif, M.; Short, S. Determination of residual stresses in thin-walled composite cylinders. Exp. Tech. 2002, 26, 43–46. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, X.; Wang, S.; Wu, H.; Yang, C.; Hu, Y.; Fang, K.; Jiang, H. Combined effects of machining-induced residual stress and external load on SCC initiation and early propagation of 316 stainless steel in high temperature high pressure water. Corros. Sci. 2021, 190, 109644. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, X.; Hu, Y.; Wang, S. Predictive modelling of microstructure changes, micro-hardness and residual stress in machining of 304 austenitic stainless steel. Int. J. Mach. Tools Manuf. 2018, 130–131, 36–48. [Google Scholar] [CrossRef]

- Nakano, J.; Nemoto, Y.; Tsukada, T.; Uchimoto, T. SCC susceptibility of cold-worked stainless steel with minor element additions. J. Nucl. Mater. 2011, 417, 883–886. [Google Scholar] [CrossRef]

- Hou, Z.; Xiu, S.; Sun, C.; Zou, X.; Yao, Y. Enhancing the surface integrity and SCC resistance of 304 austenitic stainless steel by pre-stress grinding. J. Mater. Res. Technol. 2023, 25, 2890–2902. [Google Scholar] [CrossRef]

- Motoyashiki, Y.; Brückner-Foit, A.; Sugeta, A. Microstructural influence on small fatigue cracks in a ferritic–martensitic steel. Eng. Fract. Mech. 2008, 75, 768–778. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Song, X.; Liang, T. Microstructure and high-temperature deformation behavior of dissimilar superalloy welded joint of DD407/IN718. Acta Met. Sin. 2019, 55, 1221–1230. [Google Scholar]

- Stringfellow, R.; Parks, D.; Olson, G. A constitutive model for transformation plasticity accompanying strain-induced martensitic transformations in metastable austenitic steels. Acta Metall. Mater. 1992, 40, 1703–1716. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. Kinetics of nucleation strain-induced martensitic. Metall. Mater. Trans. A 1975, 6, 791. [Google Scholar] [CrossRef]

- Han, H.N.; Lee, C.G.; Oh, C.-S.; Lee, T.-H.; Kim, S.-J. A model for deformation behavior and mechanically induced martensitic transformation of metastable austenitic steel. Acta Mater. 2004, 52, 5203–5214. [Google Scholar] [CrossRef]

- Shen, Y.; Li, X.; Sun, X.; Wang, Y.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng. A 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Zhou, N.; Lin Peng, R.; Pettersson, R.; Schönning, M. Residual stress in stainless steels after surface grinding and its effect on chloride induced SCC. In Proceedings of the International Conference on Residual Stresses, Sydney, Australia, 3–7 July 2016; pp. 289–294. [Google Scholar]

- Ghosh, S.; Kain, V. Microstructural changes in AISI 304L stainless steel due to surface machining: Effect on its susceptibility to chloride stress corrosion cracking. J. Nucl. Mater. 2010, 403, 62–67. [Google Scholar] [CrossRef]

- Okamura, Y.; Sakashita, A.; Fukuda, T.; Yamashita, H.; Futami, T. Latest SCC issues of core shroud and recirculation piping in Japanese BWRs. In Proceedings of the SMIRT 17: 17. International Conference on Structural Mechanics in Reactor Technology, Prague, Czech Republic, 17–22 August 2003. [Google Scholar]

- Ohaeri, E.; Eduok, U.; Szpunar, J. Hydrogen related degradation in pipeline steel: A review. Int. J. Hydrog. Energy 2018, 43, 14584–14617. [Google Scholar] [CrossRef]

| TMP Condition | Thermo-Mechanical Processing | Grain Size (μm) | Grain Migration between the Weld and Base Metals | ||

|---|---|---|---|---|---|

| Welding | Heat Treatment Temperature | Straightening | |||

| AW | ○ | - | - | 22 ± 4 | × |

| HT | ○ | 1050 °C | - | 68 ± 23 | ○ |

| SR | ○ | 1050 °C | ○ | 71 ± 21 | ○ |

| TMP Condition | (GPa) | (mm) | (mm) | (mm) | (mm) | Splitting Distance (μm) | Splitting Distance Except Wire Width (μm) | Residual Stress (MPa) | |

|---|---|---|---|---|---|---|---|---|---|

| AW | −7664.8 | 190 | 6.75 | 7.95 | 7.35 | 1043 | 1373 ± 47 | 1043 | 1219 |

| HT | −1609.4 | 190 | 6.75 | 7.95 | 7.35 | 219 | 549 ± 7 | 219 | 256 |

| SR | −2461.9 | 190 | 6.75 | 7.95 | 7.35 | 335 | 665 ± 34 | 335 | 391 |

| TMP Condition | Exposure Time | |||

|---|---|---|---|---|

| 2.5 h | 5 h | 7.5 h | 10 h | |

| AW tubes | - | Observation of cracking | Observation of cracking | Observation of cracking |

| HT tubes | - | - | - | - |

| SR tubes | - | - | - | ○ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.H. Effect of Thermo-Mechanical Processing on Initiation and Propagation of Stress Corrosion Cracking in 304L Austenitic Stainless Steel. Metals 2023, 13, 1458. https://doi.org/10.3390/met13081458

Shin JH. Effect of Thermo-Mechanical Processing on Initiation and Propagation of Stress Corrosion Cracking in 304L Austenitic Stainless Steel. Metals. 2023; 13(8):1458. https://doi.org/10.3390/met13081458

Chicago/Turabian StyleShin, Ji Ho. 2023. "Effect of Thermo-Mechanical Processing on Initiation and Propagation of Stress Corrosion Cracking in 304L Austenitic Stainless Steel" Metals 13, no. 8: 1458. https://doi.org/10.3390/met13081458

APA StyleShin, J. H. (2023). Effect of Thermo-Mechanical Processing on Initiation and Propagation of Stress Corrosion Cracking in 304L Austenitic Stainless Steel. Metals, 13(8), 1458. https://doi.org/10.3390/met13081458