Ductile Fracture Prediction in Hole Hemming of Aluminum and Magnesium Sheets

Abstract

:1. Introduction

2. Experimental Tests

2.1. Material Properties

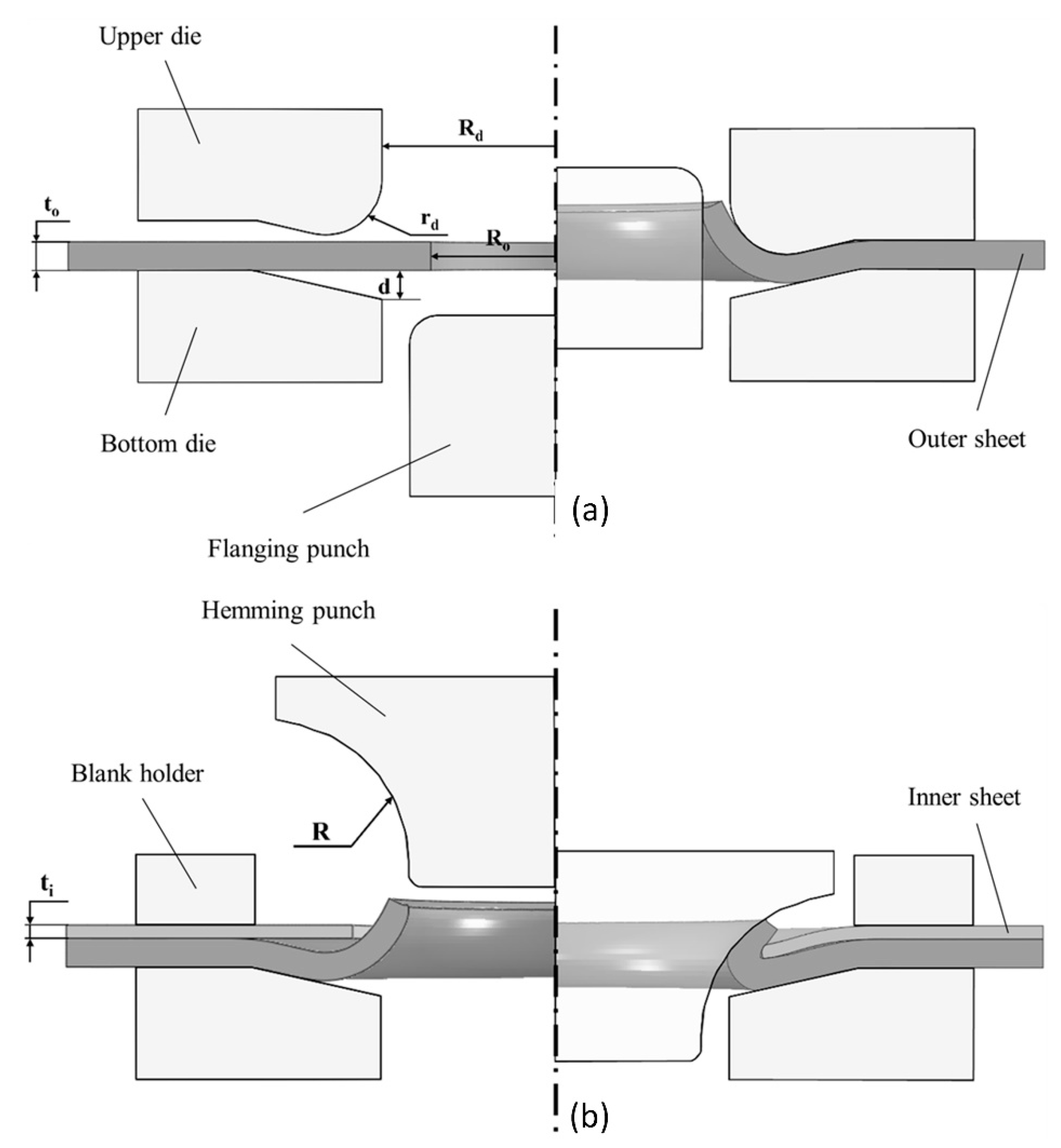

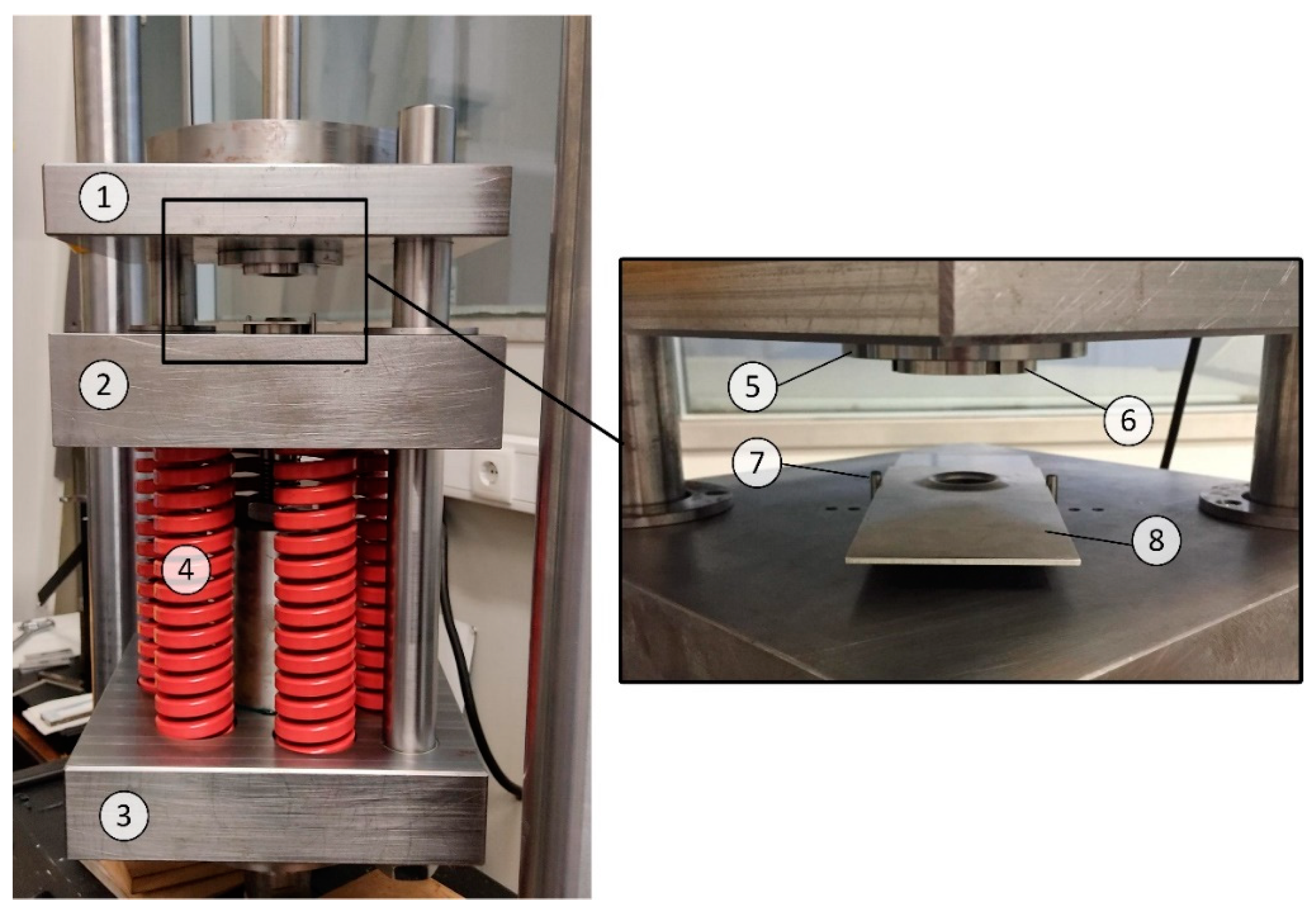

2.2. Hole Hemming

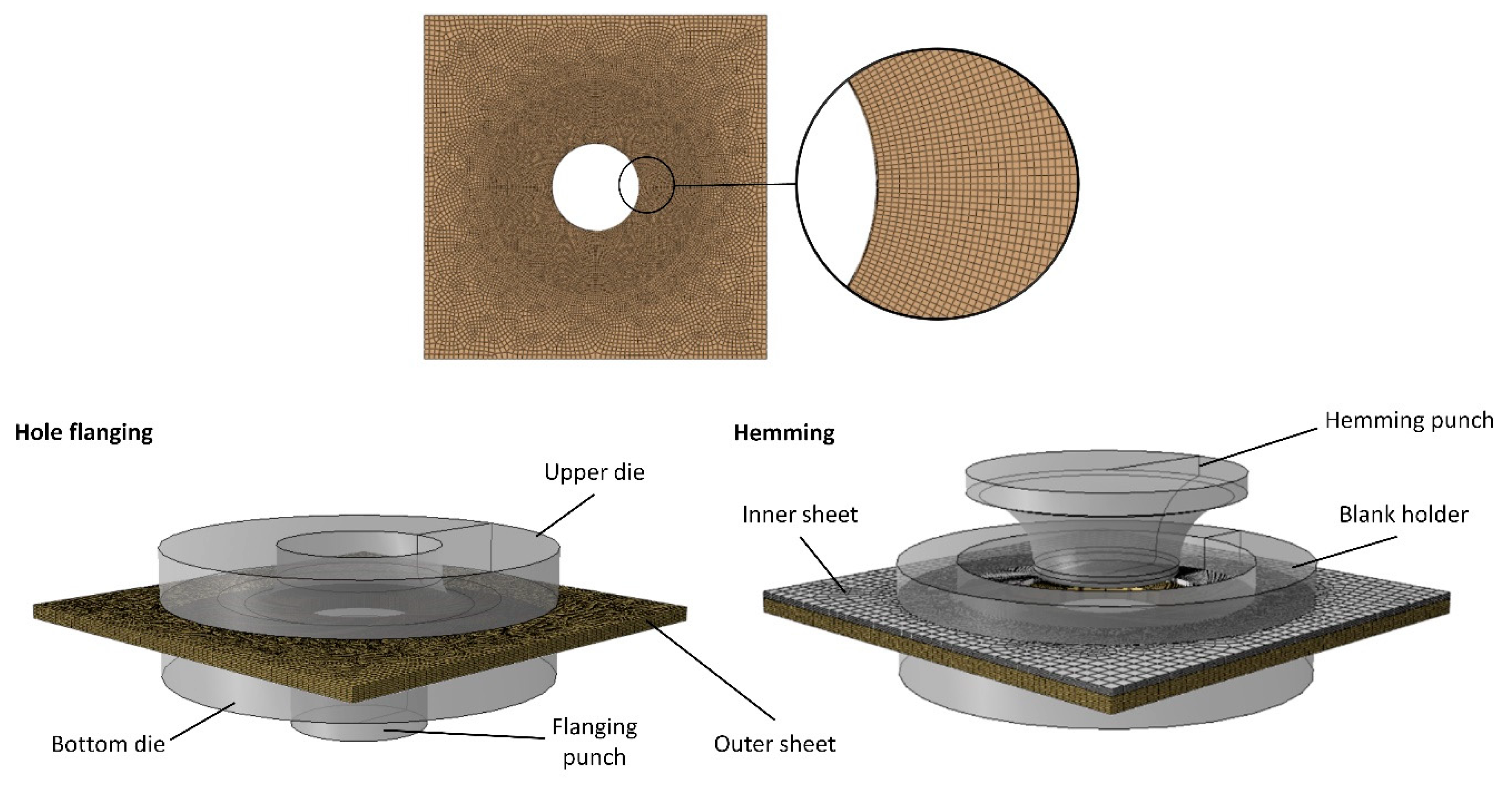

3. Finite Element Simulation

3.1. Tension Tests

3.2. Hole Hemming

4. Ductile Fracture Modelling

5. Results and Discussion

5.1. Fracture Envelope

5.2. Evaluation of Fracture Criteria

6. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kasaei, M.M.; Beygi, R.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. A review on mechanical and metallurgical joining by plastic deformation. Discov. Mech. Eng. 2023, 2, 5. [Google Scholar] [CrossRef]

- Guilleaume, C.; Brosius, A. Cross-rolling process for manufacturing lightweight hybrid components. J. Adv. Join. Process. 2021, 3, 100063. [Google Scholar] [CrossRef]

- Lipman, T.E.; Maier, P. Advanced materials supply considerations for electric vehicle applications. MRS Bull. 2021, 46, 1164–1175. [Google Scholar] [CrossRef]

- Wischer, C.; Wiens, E.; Homberg, W. Joining with versatile joining elements formed by friction spinning. J. Adv. Join. Process. 2021, 3, 100060. [Google Scholar] [CrossRef]

- Viswanadhapalli, B.; Bupesh Raja, V. Application of magnesium alloys in automotive industry-a review. Emerg. Trends Comput. Expert Technol. 2020, 35, 519–531. [Google Scholar]

- Shah, L.H.; Othman, N.H.; Gerlich, A. Review of research progress on aluminium–magnesium dissimilar friction stir welding. Sci. Technol. Weld. Join. 2018, 23, 256–270. [Google Scholar] [CrossRef]

- Han, S.; Li, Z.; Wang, Z.; Li, Y. Review on joining processes of magnesium alloy sheets. Int. J. Adv. Manuf. Technol. 2022, 118, 2787–2803. [Google Scholar] [CrossRef]

- Beygi, R.; Pouraliakbar, H.; Torabi, K.; Eisaabadi, B.G.; Fallah, V.; Kim, S.K.; Shi, R.; da Silva, L.F.M. The inhibitory effect of stir zone liquefaction and eutectic-phase formation on the growth of γ/β intermetallics during dissimilar FSW of Al/Mg alloys. J. Manuf. Process. 2021, 70, 152–162. [Google Scholar] [CrossRef]

- Li, Y.; Qin, F.; Liu, C.; Wu, Z. A Review: Effect of Friction Stir Welding on Microstructure and Mechanical Properties of Magnesium Alloys. Metals 2017, 7, 524. [Google Scholar] [CrossRef]

- Liu, L. Welding and Joining of Magnesium Alloys; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Meschut, G.; Merklein, M.; Brosius, A.; Drummer, D.; Fratini, L.; Füssel, U.; Gude, M.; Homberg, W.; Martins, P.A.F.; Bobbert, M.; et al. Review on mechanical joining by plastic deformation. J. Adv. Join. Process. 2022, 5, 100113. [Google Scholar] [CrossRef]

- Neugebauer, R.; Kraus, C.; Dietrich, S. Advances in mechanical joining of magnesium. CIRP Ann. 2008, 57, 283–286. [Google Scholar] [CrossRef]

- Domitner, J.; Silvayeh, Z.; Predan, J.; Auer, P.; Stippich, J.; Enzinger, N.; Gubeljak, N. Load-bearing capacity of hybrid riv-bonded aluminum-magnesium joints at quasi-static and cyclic loadings. J. Manuf. Process. 2023, 87, 133–140. [Google Scholar] [CrossRef]

- Neugebauer, R.; Dietrich, S.; Kraus, C. Dieless clinching and dieless rivet-clinching of magnesium. Key Eng. Mater. 2007, 34, 693–698. [Google Scholar] [CrossRef]

- Li, Y.; Wei, Z.; Wang, Z.; Li, Y. Friction Self-Piercing Riveting of Aluminum Alloy AA6061-T6 to Magnesium Alloy AZ31B. J. Manuf. Sci. Eng. 2013, 135, 061007. [Google Scholar] [CrossRef]

- Kasaei, M.M.; da Silva, L.F. Joining sheets made from dissimilar materials by hole hemming. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 1321–1332. [Google Scholar] [CrossRef]

- Pereira, J.A.C.; Kasaei, M.M.; Carbas, R.J.C.; Marques, E.A.S.; Lim, H.; da Silva, L.F.M. Joining magnesium and aluminum alloy sheets by a novel hole hemming process. Thin-Walled Struct. 2023, 187, 110758. [Google Scholar] [CrossRef]

- Haran-Nogueira, A.; Kasaei, M.M.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Kim, S.K.; da Silva, L.F.M. Development of hybrid bonded-hole hemmed joints: Process design and joint characterization. J. Manuf. Process. 2023, 95, 479–491. [Google Scholar] [CrossRef]

- Haran-Nogueira, A.; Kasaei, M.M.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Failure analysis of hybrid bonded-hole hemmed joints for dissimilar materials. Thin-Walled Struct. 2023, 189, 110907. [Google Scholar] [CrossRef]

- Badparva, H.; Naeini, H.M.; Kasaei, M.M.; Asl, Y.D.; Abbaszadeh, B.; da Silva, L.F.M. Deformation length in flexible roll forming. Int. J. Adv. Manuf. Technol. 2023, 125, 1229–1238. [Google Scholar] [CrossRef]

- Conceição, A.G.C.; Kasaei, M.M.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. A flexible tool for joining dissimilar materials by the novel hole hemming process. Mech. Based Des. Struct. Mach. 2023, 1–29. [Google Scholar] [CrossRef]

- Kasaei, M.M.; Oliveira, M.C. Influence of the contact with friction on the deformation behavior of advanced high strength steels in the Nakajima test. J. Strain Anal. Eng. Des. 2022, 57, 193–207. [Google Scholar] [CrossRef]

- Khademi, M.; Naeini, H.M.; Mirnia, M.J.; Kasaei, M.M.; da Silva, L.F. Fracture prediction of AA6061-T6 sheet in bending process using Gurson–Tvergaard–Needleman model. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 1–14. [Google Scholar] [CrossRef]

- Talebi-Ghadikolaee, H.; Naeini, H.M.; Mirnia, M.J.; Mirzai, M.A.; Gorji, H.; Alexandrov, S. Fracture analysis on U-bending of AA6061 aluminum alloy sheet using phenomenological ductile fracture criteria. Thin-Walled Struct. 2020, 148, 106566. [Google Scholar] [CrossRef]

- Nielsen, C.V.; Martins, P.A.F. Chapter 2—Formability. In Metal Forming; Nielsen, C.V., Martins, P.A.F., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 7–107. [Google Scholar]

- Heyser, P.; Petker, R.; Meschut, G. Development of a numerical simulation model for self-piercing riveting of additive manufactured AlSi10Mg. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 1826–1835. [Google Scholar] [CrossRef]

- Wiesenmayer, S.; Merklein, M. Potential of shear-clinching technology for joining of three sheets. J. Adv. Join. Process. 2021, 3, 100043. [Google Scholar] [CrossRef]

- Barimani-Varandi, A.; Aghchai, A.J.; Lambiase, F. Failure behavior in electrically-assisted mechanical clinching joints. J. Manuf. Process. 2021, 68, 1683–1693. [Google Scholar] [CrossRef]

- Martins, P.A.F.; Bay, N.; Tekkaya, A.E.; Atkins, A.G. Characterization of fracture loci in metal forming. Int. J. Mech. Sci. 2014, 83, 112–123. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. Application of extended Mohr–Coulomb criterion to ductile fracture. Int. J. Fract. 2010, 161, 1–20. [Google Scholar] [CrossRef]

- Isik, K.; Silva, M.B.; Tekkaya, A.E.; Martins, P.A.F. Formability limits by fracture in sheet metal forming. J. Mater. Process. Technol. 2014, 214, 1557–1565. [Google Scholar] [CrossRef]

| Material | Young’s Modulus [GPa] | Yield Stress [MPa] | Ultimate Tensile Stress [MPa] | Elongation at Failure [%] | Lankford Coefficient, r | Normal Anisotropy | ||

|---|---|---|---|---|---|---|---|---|

| 0° | 45° | 90° | ||||||

| AA 6082-T4 | 70 | 173 | 278 | 24.5 | 0.54 | 0.55 | 0.66 | 0.58 |

| AZ31 | 44 | 142 | 259 | 16.6 | 0.68 | 1.24 | 1.77 | 1.23 |

| Material | [MPa] | [MPa] | [MPa] | ||||

|---|---|---|---|---|---|---|---|

| AA6082-T4 | 501 | 0.233 | 0.64 | 0.0077 | 174 | 173 | 13.1 |

| AZ31 | 455 | 0.214 | - | - | - | - | - |

| Material | ||||||

|---|---|---|---|---|---|---|

| AA6082-T4 | 0.63 | 0.63 | 0.37 | 1.36 | 1.5 | 1.5 |

| AZ31 | 0.23 | 0.59 | 0.41 | 1.44 | 1.5 | 1.5 |

| Parameter | Overlap | |||||||

|---|---|---|---|---|---|---|---|---|

| Value [mm] | 70 × 70 | 12.5 | 8.5 | 14.5 | 4 | 2 | 4 | 10 |

| Criterion | Calibration Tests | ||

|---|---|---|---|

| Plane Strain | Uniaxial Tension | Shear | |

| McClintock | 0.218 | 0.226 | - |

| Rice–Tracey | 0.916 | 1.041 | 0.568 |

| Normalized Cockroft–Latham | 0.479 | 0.611 | 0.342 |

| Brozzo | 0.509 | 0.614 | 0.381 |

| MMC | = 0.981 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasaei, M.M.; Pereira, J.A.C.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Ductile Fracture Prediction in Hole Hemming of Aluminum and Magnesium Sheets. Metals 2023, 13, 1559. https://doi.org/10.3390/met13091559

Kasaei MM, Pereira JAC, Carbas RJC, Marques EAS, da Silva LFM. Ductile Fracture Prediction in Hole Hemming of Aluminum and Magnesium Sheets. Metals. 2023; 13(9):1559. https://doi.org/10.3390/met13091559

Chicago/Turabian StyleKasaei, Mohammad Mehdi, José A. C. Pereira, Ricardo J. C. Carbas, Eduardo A. S. Marques, and Lucas F. M. da Silva. 2023. "Ductile Fracture Prediction in Hole Hemming of Aluminum and Magnesium Sheets" Metals 13, no. 9: 1559. https://doi.org/10.3390/met13091559

APA StyleKasaei, M. M., Pereira, J. A. C., Carbas, R. J. C., Marques, E. A. S., & da Silva, L. F. M. (2023). Ductile Fracture Prediction in Hole Hemming of Aluminum and Magnesium Sheets. Metals, 13(9), 1559. https://doi.org/10.3390/met13091559