Effect of Al5TiB Master Alloy with P on Microstructure and Mechanical Properties of AlSi7Mg Alloy

Abstract

:1. Introduction

- Modification [16,17,18], including, among others, with: calcium [19], sodium [20], sodium chloride [21,22], exothermic mixtures based on natrium [23,24], mischmetal [25], strontium [26,27], lithium [28], scandium and yttrium [29,30], antimony [31], titanium [32,33,34], boron [35], and modification with a homogeneous modifier with a composition similar to a worked alloy (or made from a worked alloy) [36];

2. Materials and Methods

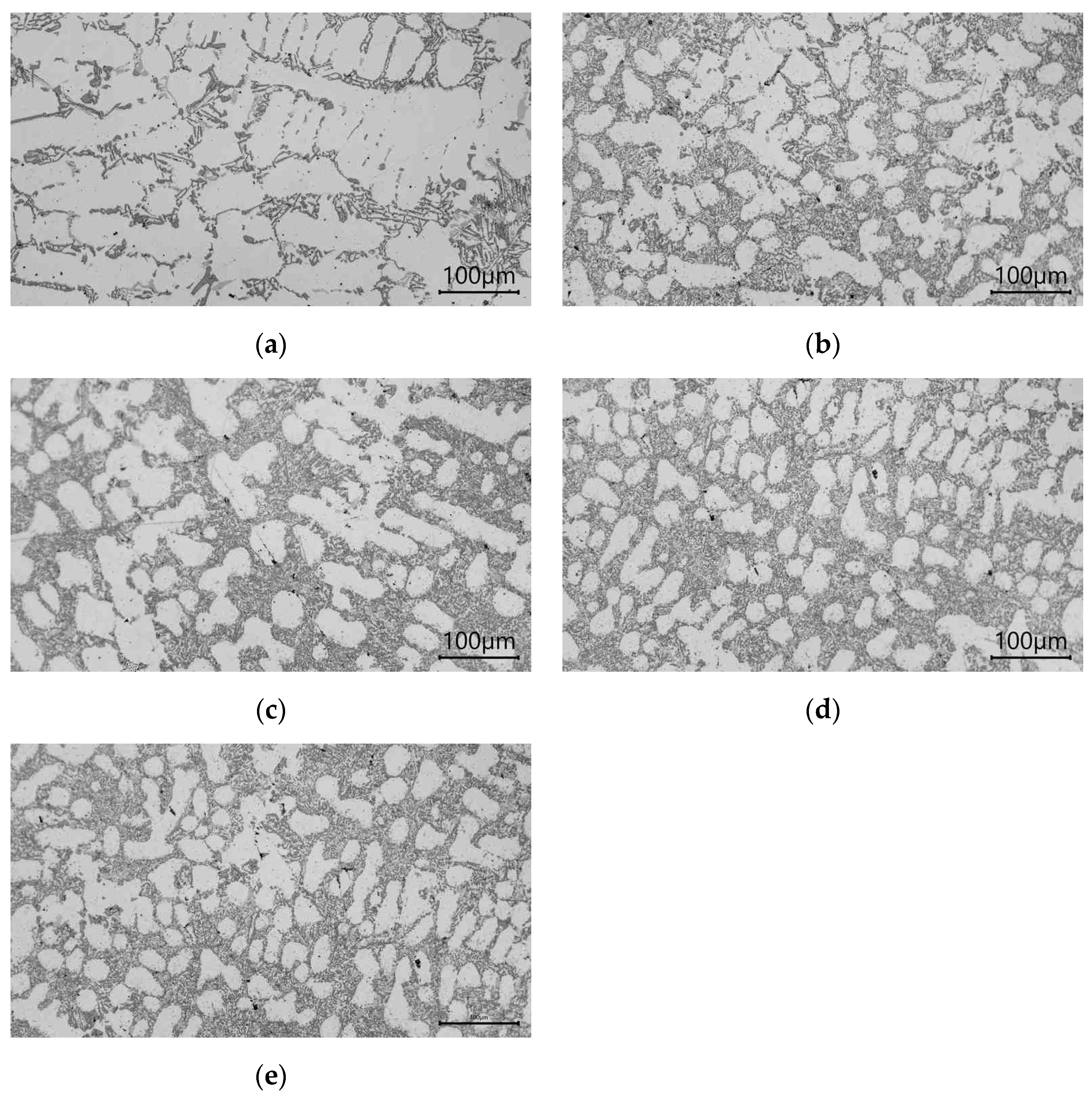

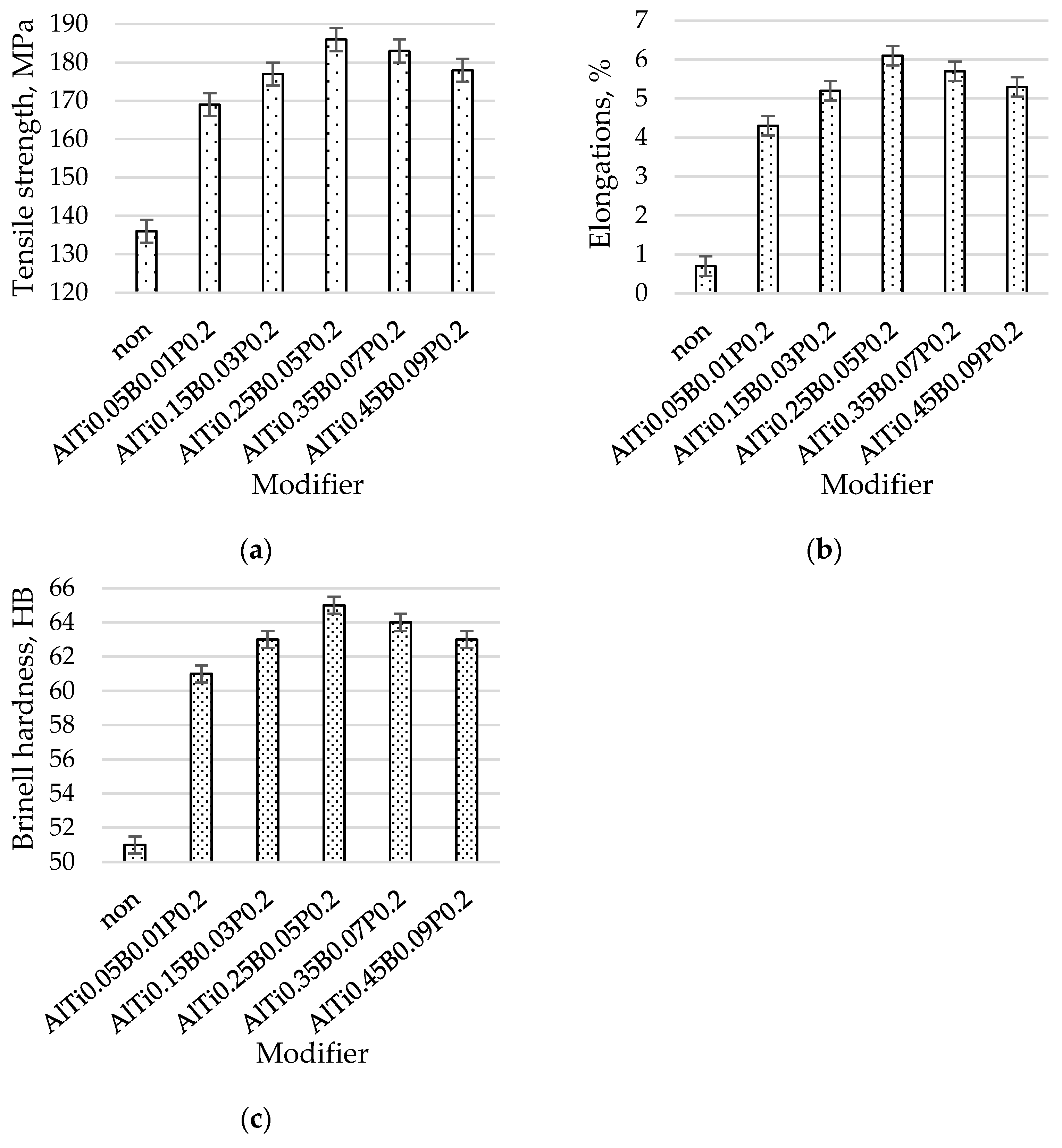

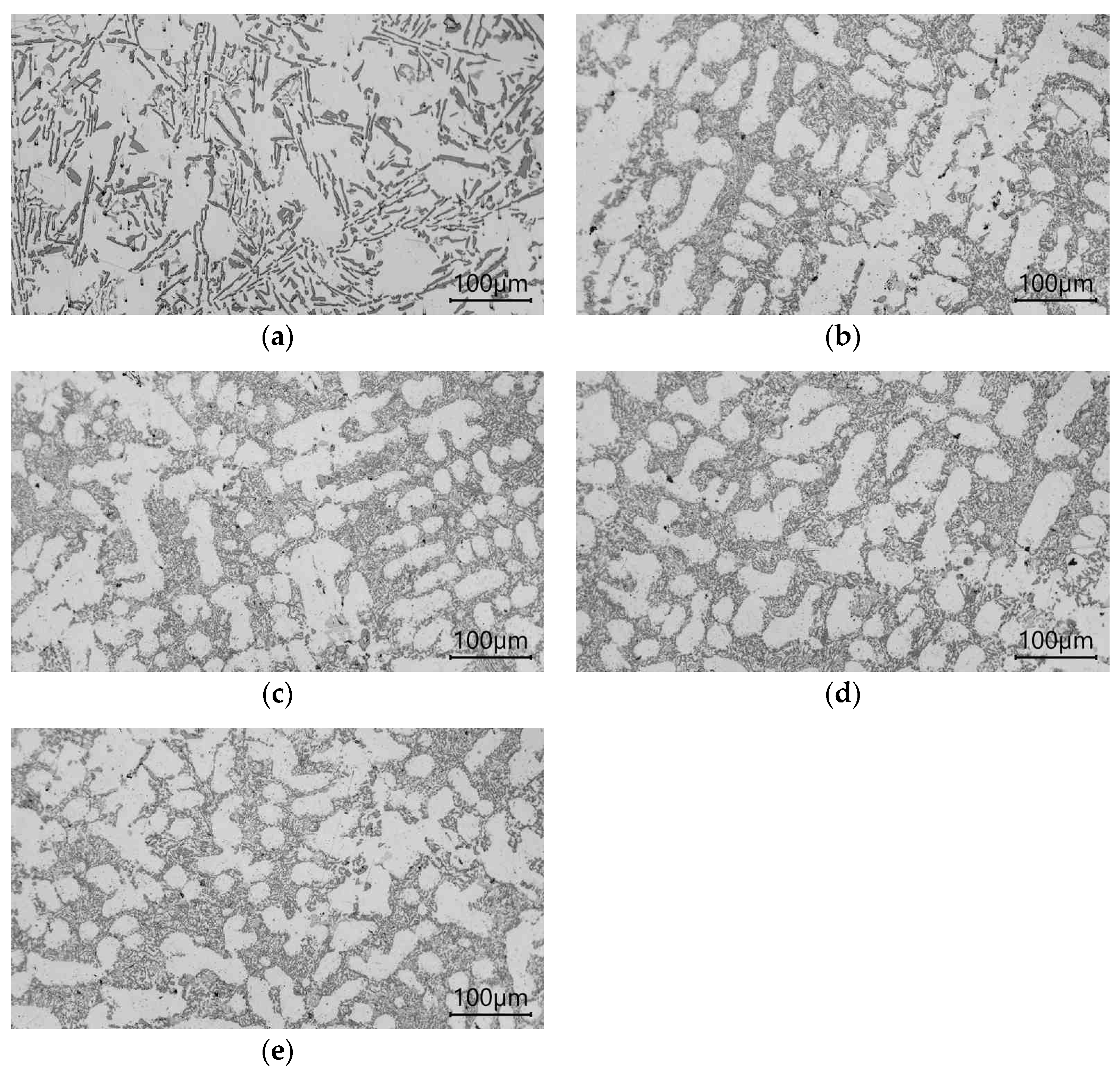

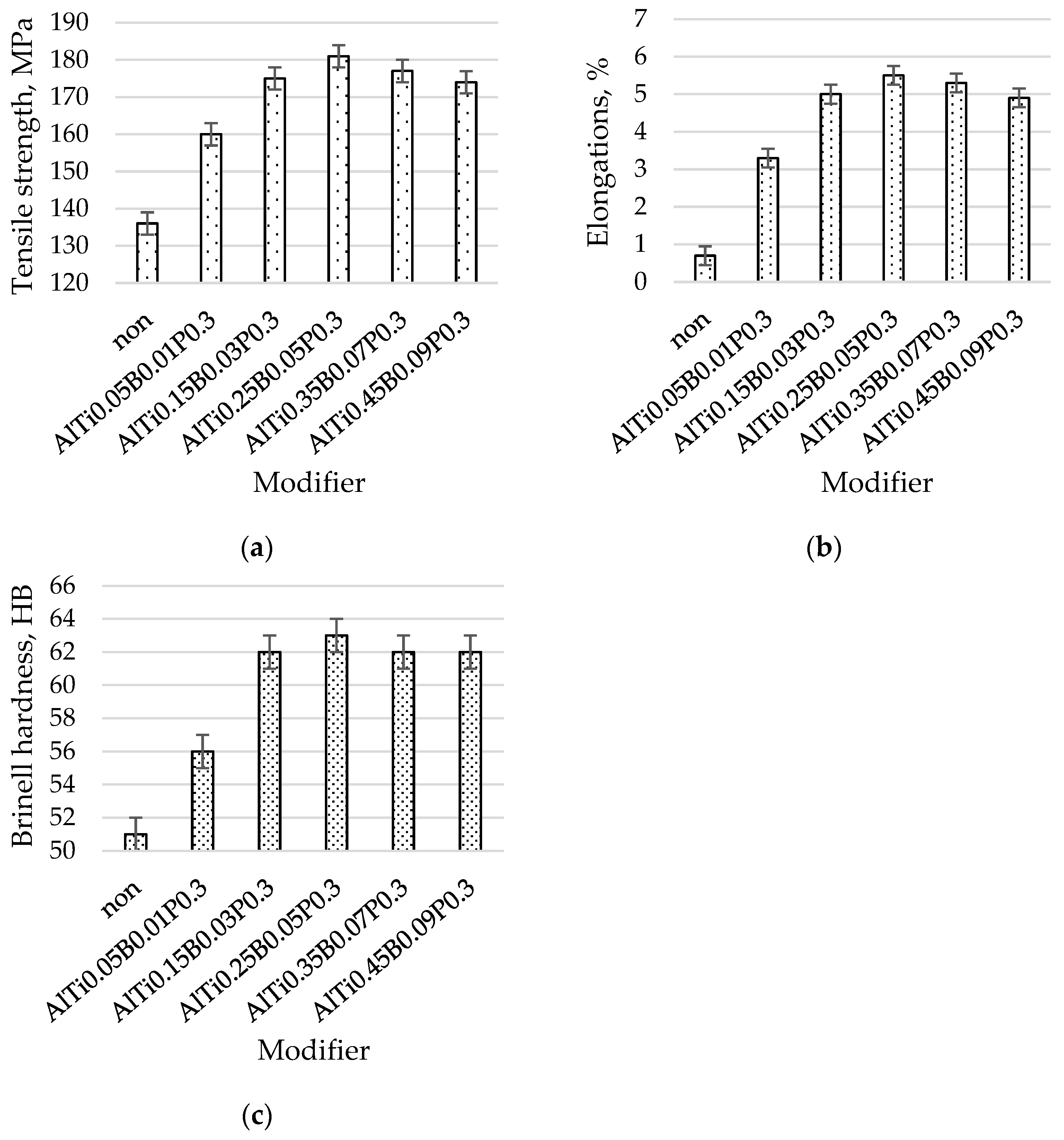

3. Results and Discussion

4. Conclusions

- By changing the content of titanium and boron (5:1 ratio) in the aluminum-based master alloy in the presence of phosphorus, it is possible to control the microstructure and mechanical properties of hypoeutectic silumin;

- Phosphorus in the master alloy, based on aluminum, titanium, and boron, affects the microstructure and mechanical properties of hypoeutectic silumin AlSi7Mg;

- It was shown that with the ratio of titanium to boron in the aluminum-based master alloy in the presence of phosphorus, the highest mechanical properties were achieved for the AlTi0.25B0.05P0.2 master alloy with the content of 0.25% titanium, 0.05% boron, and 0.2% phosphorus in relation to the weight of the modified hypoeutectic silumin.

Funding

Data Availability Statement

Conflicts of Interest

References

- Michna, S.; Lukac, I.; Ocenasek, V.; Koreny, R.; Drapala, J.; Schneider, H.; Miskufova, A. Encyclopaedia of Aluminium; Adin s.r.o. Presov: Prešov, Slovakia, 2005. (In Czech) [Google Scholar]

- Selejdak, J.; Ulewicz, R.; Ingaldi, M. The evaluation of the use of a device for producing metal elements applied in civil engineering. In Proceedings of the 23rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 21–23 May 2014; pp. 1882–1888. [Google Scholar]

- Koreček, D.; Solfronk, P.; Sobotka, J. Research of Mechanical Properties of the Aluminium Alloy Amag 6000 under the Plane Stress State Conditions. Manuf. Technol. 2022, 22, 709–712. [Google Scholar] [CrossRef]

- Dash, S.S.; Chen, D. A Review on Processing—Microstructure–Property Relationships of Al-Si Alloys: Recent Advances in Deformation Behavior. Metals 2023, 13, 609. [Google Scholar] [CrossRef]

- Šurdová, Z.; Kuchariková, L.; Tillová, E.; Pastierovičová, L.; Chalupová, M.; Uhríčik, M.; Mikolajčík, M. The Influence of Fe Content on Corrosion Resistance of secondary AlSi7Mg0.3 Cast Alloy with Increased Fe-content. Manuf. Technol. 2022, 22, 598–604. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Khorshidi, M.; Mohammadzadeh, R.; Khajeh, R.; Mofarrehi, M.; Javidani, M.; Chen, X.-G. Multipass Friction Stir Processing of Laser-Powder Bed Fusion AlSi10Mg: Microstructure and Mechanical Properties. Materials 2023, 16, 1559. [Google Scholar] [CrossRef]

- Józwik, J.; Ruggiero, A.; Leleń, M. Microscopic Analysis of the Surface Morphology of Multilayer Structures of the Aluminum Alloy—Silicon Type after Water Jet Cutting. Manuf. Technol. 2022, 22, 693–702. [Google Scholar]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidifications; TTP: Trasadingen, Switzerland, 1986. [Google Scholar]

- Flemings, M.C. Solidification Processing. Metall. Mater. Tran. 1974, 5, 2121–2134. [Google Scholar] [CrossRef]

- Tenkamp, J.; Stern, F.; Walther, F. Uniform Fatigue Damage Tolerance Assessment for Additively Manufactured and Cast Al-Si Alloys: An Elastic-Plastic Fracture Mechanical Approach. Addit. Manuf. Lett. 2022, 3, 100054. [Google Scholar] [CrossRef]

- Magnin, P.; Mason, J.T.; Trivedi, R. Growth of irregular eutectics and the Al-Si system. Acta Metall. Et Mater. 1991, 39, 469–480. [Google Scholar] [CrossRef]

- Novak, M.; Naprstkova, N.; Ruzicka, L. New ways in aluminium alloys grinding. Key Eng. Mater. 2012, 496, 132–137. [Google Scholar] [CrossRef]

- Khalaf, A.A. Microstructure evolution of Al-Si hypoeutectic alloys prepared by controlled diffusion solidification. Int. J. Adv. Manuf. Technol. 2022, 120, 5003–5014. [Google Scholar] [CrossRef]

- Michna, Š.; Hren, I.; Cais, J.; Michnová, L. The research of the different properties and production parameters having influence on deep-drawing sheets made of AlMg3 alloy. Manuf. Technol. 2020, 20, 347–354. [Google Scholar] [CrossRef]

- Fang, L.; Fuxiao, Y.; Dazhi, Z.; Liang, Z. Microstructure and mechanical properties of an Al–12.7Si–0.7Mg alloy processed by extrusion and heat treatment. Mater. Sci. Eng. 2011, 528, 3786–3790. [Google Scholar]

- Dahle, A.K.; Nogita, K.; Mcdonald, S.D.; Dinnis, C.; Lu, L. Eutectic modification and microstructure development in Al–Si Alloys. Mater. Sci. Eng. 2005, 413–414, 243–248. [Google Scholar] [CrossRef]

- Martinovsky, M.; Madl, J. The effect of different modifiers on cutting temperature in turning of AlSi7Mg0.3 alloy. Manuf. Technol. 2018, 18, 950–953. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Wang, J.L.; Zhang, Q.L.; Zhang, S.P.; Shi, Q.N.; Qi, H.R. Research on Grain Refinement Mechanism of 6061 Aluminum. Alloy Processed by Combined SPD Methods of ECAP and MAC. Materials 2018, 11, 1246. [Google Scholar] [CrossRef]

- Naprstkova, N.; Kraus, P.; Stancekova, D. Calcium and its using for modification of AlSi7Mg0.3 alloy from view of final microstructure and hardness. Proc. Eng. Rural. Dev. 2018, 17, 2003–2008. [Google Scholar]

- Lipiński, T.; Szabracki, P. Mechanical Properties of AlSi9Mg Alloy with a Sodium Modifier. Solid State Phenom. 2015, 223, 78–86. [Google Scholar] [CrossRef]

- Nova, I.; Frana, K.; Sobotka, I.; Solfronk, P.; Korecek, D.; Novakova, I. Production of porous aluminium using sodium chloride. Manuf. Technol. 2019, 19, 817–822. [Google Scholar] [CrossRef]

- Nová, I.; Fraňa, K.; Lipiński, T. Monitoring of the interaction of aluminum alloy and sodium chloride as the basis for ecological production of expanded aluminum. Phys. Met. Metallogr. 2021, 122, 1288–1300. [Google Scholar] [CrossRef]

- Lipinski, T.; Szabracki, P. Modification of the hypo-eutectic Al-Si alloys with an exothermic modifier. Arch. Metall. Mater. 2013, 58, 453–458. [Google Scholar] [CrossRef]

- Lipiński, T. Use Properties of the AlSi9Mg Alloy with Exothermical Modifier. Manuf. Technol. 2011, 11, 44–49. [Google Scholar]

- El Sebaie, O.; Samuel, A.M.; Samuel, F.H.; Doty, H.W. The effects of mischmetal, cooling rate and heat treatment on the eutectic Si particle characteristics of A319.1, A356.2 and A413.1 Al–Si casting alloys. Mater. Sci. Eng. 2008, 480, 342–355. [Google Scholar] [CrossRef]

- Liao, H.; Sun, Y.; Sun, G. Effect of Al-5Ti-1B on the microstructure of near-eutectic Al-13.0%Si alloys modified with Sr. J. Mater. Sci. 2002, 37, 3489–3495. [Google Scholar] [CrossRef]

- Hren, I.; Svobodova, J. Fractographic analysis of strontium-modified Al-Si alloys. Manuf. Technol. 2018, 18, 900–905. [Google Scholar] [CrossRef]

- Lei, W.B.; Liu, X.T.; Wang, W.M.; Sun, Q.; Xu, Y.Z.; Cui, J.Z. On the influences of Li on the microstructure and properties of hypoeutectic Al-7Si alloy. J. Alloys Compd. 2017, 729, 703–709. [Google Scholar] [CrossRef]

- Konovalov, S.V.; Zagulyaev, D.V.; Ivanov, Y.F.; Gromov, V.E. Effect of yttrium oxide modification of Al-Si alloy on microhardness and microstructure of surface layers. Metalurgija 2018, 57, 253–256. [Google Scholar]

- Zupanič, F.; Žist, S.; Albu, M.; Letofsky-Papst, I.; Burja, J.; Vončina, M.; Bončina, T. Dispersoids in Al-Mg-Si Alloy AA 6086 Modified by Sc and Y. Materials 2023, 16, 2949. [Google Scholar] [CrossRef]

- Xiufang, B.; Weimin, W.; Jingyu, Q. Liquid structure of Al-12.5% Si alloy modified by antimony. Mater. Charact. 2001, 46, 25–29. [Google Scholar] [CrossRef]

- Wang, Q.; Kang, N.; Mansori, M.; Yu, T.; Hadrouz, M.; Huang, X.; Lin, X. Effect of Ti on the microstructure and wear behavior of a selective laser melted Al-Cu-Mg-Si alloy. Wear 2023, 523, 204790. [Google Scholar] [CrossRef]

- Wu, Y.N.; Zhang, J.F.; Liao, H.C.; Li, G.Y.; Wu, Y.P. Development of high performance near eutectic Al-Si-Mg alloy profile by micro alloying with Ti. J. Alloys Compd. 2016, 660, 141–147. [Google Scholar] [CrossRef]

- Zhang, S.; Yi, W.; Zhong, J.; Gao, J.; Lu, Z.; Zhang, L. Computer Alloy Design of Ti Modified Al-Si-Mg-Sr Casting Alloys for Achieving Simultaneous Enhancement in Strength and Ductility. Materials 2023, 16, 306. [Google Scholar] [CrossRef] [PubMed]

- Yuying, W.; Xiangfa, L.; Xiufang, B. Effect of boron on the microstructure of near-eutectic Al–Si alloys. Mater. Charact. 2007, 58, 205–209. [Google Scholar] [CrossRef]

- Lipiński, T. Modification of Al-Si alloys with the use of a homogenous modifiers. Arch. Metall. Mater. 2008, 53, 193–197. [Google Scholar]

- Zhang, X.; Yan, L.; Li, Z.; Li, X.; Gao, G.; Yan, H.; Wen, K.; Zhang, Y.; Xiong, B. Effects of Cu Addition on Age Hardening Behavior and Mechanical Properties of High-Strength Al-1.2Mg-1.2Si Alloy. Materials 2023, 16, 3126. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Chen, J.; Li, Y.; Luo, T. Enhancing the Strength and Toughness of A356.2-0.15Fe Aluminum Alloy by Trace Mn and Mg Co-Addition. Metals 2023, 13, 1451. [Google Scholar] [CrossRef]

- Wang, H.; He, L.; Zhang, Q.; Yuan, Y. Influence of Ni Contents on Microstructure and Mechanical Performance of AlSi10Mg Alloy by Selective Laser Melting. Materials 2023, 16, 4679. [Google Scholar] [CrossRef]

- Ourdjini, A.; Yilmaz, F.; Hamed, Q.S.; Elliott, R. Microstructure and mechanical properties of directionally solidified Al-Si eutectic alloys with and without antimony. Mater. Sci. Technol. 1992, 8, 764–776. [Google Scholar] [CrossRef]

- Pierantoni, M.; Gremaud, M.; Magnin, P.; Stoll, D.; Kurz, W. The coupled zone of rapidly solidified Al-Si alloys in laser treatment. Acta Metall. Et Mater. 1992, 40, 1637–1644. [Google Scholar] [CrossRef]

- Li, S.M.; Quan, Q.R.; .Li, X.; Fu, H.Z. Increasing the growth velocity of coupled eutectics in directional solidification of off-eutectic alloys. J. Cryst. Growth 2011, 314, 279–284. [Google Scholar] [CrossRef]

- Wołczyński, W.; Cupryś, R.; Major, B. Averge intrelanellar spacing in oriented eutectic growth of irregular structure. Arch. Metall. 1998, 43, 309–320. [Google Scholar]

- Yang, J.; Oliveira, J.P.; Li, Y.; Tan, C.; Gao, C.; Zhao, Y.; Yu, Z. Laser techniques for dissimilar joining of aluminum alloys to steels: A critical review. J. Mater. Process. Technol. 2022, 301, 117443. [Google Scholar] [CrossRef]

- Zaguliaev, D.; Konovalov, S.; Ivanov, Y.; Gromov, V. Effect of electron-plasma alloying on structure and mechanical properties of Al-Si alloy. Appl. Surf. Sci. 2019, 498, 143767. [Google Scholar] [CrossRef]

- Lipinski, T. Effect of combinative cooled addition of strontium and aluminium on mechanical properties AlSi12 alloy. J. Achiev. Mater. Manuf. Eng. 2017, 83, 5–11. [Google Scholar] [CrossRef]

- Pastircák, R.; Bruna, M.; Matejka, M.; Bolibruchová, D. Effect of Input Parameters on the Structure and Properties of Castings Obtained via Crystallization under Pressure. Metals 2023, 13, 1424. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, T. Effect of Standing Time after Mixing on the Mixture Microstructure of an Al-Si Alloy during Controlled Diffusion Solidification with Simultaneous Mixing. Metals 2023, 13, 733. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Huang, Y. Improving Precipitation in Cryogenic Rolling 6016 Aluminum Alloys during Aging Treatment. Materials 2023, 16, 3336. [Google Scholar] [CrossRef]

- Di Egidio, G.; Martini, C.; Börjesson, J.; Ghassemali, E.; Ceschini, L.; Morri, A. Influence of Microstructure on Fracture Mechanisms of the Heat-Treated AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion. Materials 2023, 16, 2006. [Google Scholar] [CrossRef]

- Lipiński, T.; Bramowicz, M.; Szabracki, P. The Microstructure and Mechanical Properties of Al-7%SiMg Alloy Treated with an Exothermic Modifier Containing Na and B. Solid State Phenom. 2013, 203–204, 250–253. [Google Scholar] [CrossRef]

- Gebril, M.A.; Omar, M.Z.; Mohamed, I.F.; Othman, N.K.; Irfan, O.M. Microstructure Refinement by a Combination of Heat Treatment and Thixoforming Process Followed by Severe Plastic Deformation and Their Effects on Al-Si Alloy Hardness. Metals 2022, 12, 1972. [Google Scholar] [CrossRef]

- Nogita, K.; Knuutinen, A.; McDonald, S.D.; Dahle, A.K. Mechanisms of eutectic solidification in Al–Si alloys modified with Ba, Ca, Y and Yb. J. Light Met. 2001, 1, 219–228. [Google Scholar] [CrossRef]

- Lipiński, T. Effect of Modifier Form on Mechanical Properties of Hypoeutectic Silumin. Materials 2023, 16, 5250. [Google Scholar] [CrossRef] [PubMed]

- Knuutinen, A.; Nogita, K.; McDonald, S.D.; Dahle, A.K. Modification of Al–Si alloys with Ba, Ca, Y and Yb. J. Light Met. 2001, 1, 229–240. [Google Scholar] [CrossRef]

- Tang, T.; Lai, H.; Sheng, Z.; Gan, C.; Xing, P.; Luo, X. Effect of tin addition on the distribution of phosphorus and metallic impurities in Si–Al alloys. J. Cryst. Growth 2016, 453, 13–19. [Google Scholar] [CrossRef]

- Lipiński, T. Modification of Al-11% Si Alloy with Cl—Based Modifier. Manuf. Technol. 2015, 15, 581–587. [Google Scholar] [CrossRef]

- Ludwig, T.H.; Schaffer, P.L.; Arnberg, L. Influence of phosphorus on the nucleation of eutectic silicon in Al–Si alloys. Metall. Mater. Trans. 2013, 44, 5796–5805. [Google Scholar] [CrossRef]

- Wang, T.; Fu, H.; Chen, Z.; Xu, J.; Zhu, J.; Cao, F.; Li, T. A novel fading-resistant Al–3Ti–3B grain refiner for Al–Si alloys. J. Alloys Compd. 2012, 511, 45–49. [Google Scholar] [CrossRef]

- Grobner, J.; Mirkovic, D.; Schmid-Fetzer, R. Thermodynamic aspects of grain refinement of Al–Si alloys using Ti and B. Mater. Sci. Eng. 2005, 395, 10–21. [Google Scholar] [CrossRef]

- Lipiński, T. Effect of Sr, Ti and B additions as powder and a preliminary alloy with Al on microstructure and tensile strength AlSi9Mg alloy. Manuf. Technol. 2019, 19, 807–812. [Google Scholar] [CrossRef]

- Li, J.G.; Zhang, B.Q.; Wang, L.; Yang, W.Y.; Ma, H.T. Combined effect and its mechanism of Al-3wt.%Ti-4wt.%B and Al-10wt.%Sr master alloy on microstructures of Al-Si-Cu alloy. Mater. Sci. Eng. 2002, 328, 169–176. [Google Scholar] [CrossRef]

- Lipiński, T. Double modification of AlSi9Mg alloy with boron, titanium and strontium. Arch. Metall. Mater. 2015, 60, 2415–2419. [Google Scholar] [CrossRef]

- Xua, J.; Li, Y.; Maa, K.; Fub, Y.; Guoc, E.; Chenc, Z.; Gud, Q.; Hane, Y.; Wangc, T.; Li, Q. In-situ observation of grain refinement dynamics of hypoeutectic Al-Si alloy inoculated by Al-Ti-Nb-B alloy. Scr. Mater. 2020, 187, 142–147. [Google Scholar] [CrossRef]

- Kakhidze, N.; Valikhov, V.; Selikhovkin, M.; Khrustalyov, A.; Zhukov, I.; Vasiliev, S.; Vorozhtsov, A. Effects of ErF3 Particles on the Structure and Physicomechanical Properties of A359 Alloy. Metals 2023, 13, 1463. [Google Scholar] [CrossRef]

- Lu, L.; Dahle, A.K. Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al–Si foundry alloys. Mater. Sci. Eng. 2006, 435–436, 288–296. [Google Scholar] [CrossRef]

- Meng, C.; Su, C.; Liu, Z.; Liao, D.; Rong, X.; Li, Y.; Tang, H.; Wang, J. Synergistic Effect of RE (La, Er, Y, Ce) and Al-5Ti-B on the Microstructure and Mechanical Properties of 6111Aluminum Alloy. Metals 2023, 13, 606. [Google Scholar] [CrossRef]

- Prasada Rao, A.K.; Das, K.; Murty, B.S.; Chakraborty, M. Al–Ti–C–Sr master alloy—A melt inoculant for simultaneous grain refinement and modification of hypoeutectic Al–Si alloys. J. Alloys Compd. 2009, 480, L49–L51. [Google Scholar]

- Sofyan, B.T.; Kharistal, D.J.; Trijati, L.; Purba, K.; Susanto, R.E. Grain refinement of AA333 aluminium cast alloy by Al–Ti granulated flux. Mater. Des. 2010, 31, S36–S43. [Google Scholar] [CrossRef]

- Nogita, K.; Dahle, A.K. Effects of boron on eutectic modification of hypoeutectic Al–Si alloys. Scr. Mater. 2003, 48, 307–313. [Google Scholar] [CrossRef]

- Kori, S.A.; Murty, B.S.; Chakraborty, M. Development of an efficient grain refiner for Al–7Si alloy and its modification with strontium. Mater. Sci. Eng. 2000, 283, 94–104. [Google Scholar] [CrossRef]

- Shu, D.; Sun, B.; Mi, J.; Grant, P.S. A quantitative study of solute diffusion field effects on heterogeneous nucleation and the grain size of alloys. Acta Mater. 2011, 59, 2135–2144. [Google Scholar] [CrossRef]

- Górny, Z. Foundry Alloys of Non-Ferrous Metals. Odlewnicze Stopy Metali Nieżelaznych; WNT: Warsaw, Poland, 1992. (In Polish) [Google Scholar]

- Murty, B.S.; Kori, S.A.; Venkateswarlu, K.; Bhat, R.R.; Chakraborty, M. Manufacture of Al–Ti–B master alloys by the reaction of complex halide salts with molten aluminium. J. Mater. Process. Technol. 1999, 89–90, 152–158. [Google Scholar] [CrossRef]

- Romankiewicz, F. Research on the modification of the AlSi7Mg alloy with additions of AlTi5B1 and AlSr10. Badania nad modyfikacją stopu AlSi7Mg dodatkami AlTi5B1 i AlSr10. In Proceedings of the II Konferencja—Zjawiska Powierzchniowe w Procesach Odlewniczych, Poznań, Kołobrzeg; 1994; pp. 93–103. (In Polish). [Google Scholar]

- Wen, Y.; Wu, Y.; Wu, Y.; Gao, T.; Wei, Z.; Liu, X. Effect of Al-5Ti-0.25C-0.25B and Al-5Ti-1B Master Alloys on the Microstructure and Mechanical Properties of Al-9.5Si-1.5Cu-0.8Mn-0.6Mg Alloy. Materials 2023, 16, 1246. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 6892-1:2019; Metallic Materials—Tensile Testing Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 6506-1:2014; Metallic Materials—Brinell Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2014.

- Wang, S.; Fu, M.; Li, L.; Wang, J.; Su, X. Microstructure and mechanical properties of Al–Si eutectic alloy modified with Al–3P master alloy. J. Mater. Process. Technol. 2018, 255, 105–109. [Google Scholar] [CrossRef]

- Nogita, K.; Mcdonald, S.D.; Tsujimoto, K.; Yasuda, K.; Dahle, A.K. Aluminium phosphide as a eutectic grain nucleus in hypoeutectic Al–Si alloys. J. Electron. Microsc. 2004, 53, 361–369. [Google Scholar] [CrossRef] [PubMed]

| Chemical Element | Si wt. % | Mg wt. % | Mn wt. % | Fe wt. % | Cu wt. % | Ni wt. % | Ti wt. % | B wt. % | Al wt. % |

|---|---|---|---|---|---|---|---|---|---|

| Average contents | 7.24 | 0.30 | 0.26 | 0.13 | 0.10 | 0.006 | 0.00 | 0.00 | bal. |

| Plan Point | Chemical Element | |||

|---|---|---|---|---|

| Ti wt. % | B wt. % | P wt. % | Al wt. % | |

| non | 0 | 0 | 0 | 0 |

| AlTi0.05B0.01P0.1 | 0.05 | 0.01 | 0.1 | Bal. |

| AlTi0.15B0.03P0.1 | 0.15 | 0.03 | 0.1 | Bal. |

| AlTi0.25B0.05P0.1 | 0.25 | 0.05 | 0.1 | Bal. |

| AlTi0.35B0.07P0.1 | 0.35 | 0.07 | 0.1 | Bal. |

| AlTi0.45B0.09P0.1 | 0.45 | 0.09 | 0.1 | Bal. |

| AlTi0.05B0.01P0.2 | 0.05 | 0.01 | 0.2 | Bal. |

| AlTi0.15B0.03P0.2 | 0.15 | 0.03 | 0.2 | Bal. |

| AlTi0.25B0.05P0.2 | 0.25 | 0.05 | 0.2 | Bal. |

| AlTi0.35B0.07P0.2 | 0.35 | 0.07 | 0.2 | Bal. |

| AlTi0.45B0.09P0.2 | 0.45 | 0.09 | 0.2 | Bal. |

| AlTi0.05B0.01P0.3 | 0.05 | 0.01 | 0.3 | Bal. |

| AlTi0.15B0.03P0.3 | 0.15 | 0.03 | 0.3 | Bal. |

| AlTi0.25B0.05P0.3 | 0.25 | 0.05 | 0.3 | Bal. |

| AlTi0.35B0.07P0.3 | 0.35 | 0.07 | 0.3 | Bal. |

| AlTi0.45B0.09P0.3 | 0.45 | 0.09 | 0.3 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lipiński, T. Effect of Al5TiB Master Alloy with P on Microstructure and Mechanical Properties of AlSi7Mg Alloy. Metals 2023, 13, 1560. https://doi.org/10.3390/met13091560

Lipiński T. Effect of Al5TiB Master Alloy with P on Microstructure and Mechanical Properties of AlSi7Mg Alloy. Metals. 2023; 13(9):1560. https://doi.org/10.3390/met13091560

Chicago/Turabian StyleLipiński, Tomasz. 2023. "Effect of Al5TiB Master Alloy with P on Microstructure and Mechanical Properties of AlSi7Mg Alloy" Metals 13, no. 9: 1560. https://doi.org/10.3390/met13091560

APA StyleLipiński, T. (2023). Effect of Al5TiB Master Alloy with P on Microstructure and Mechanical Properties of AlSi7Mg Alloy. Metals, 13(9), 1560. https://doi.org/10.3390/met13091560