Effect of Cold Rolling on Microstructure and Mechanical Properties of a Cast TiNbZr-Based Composite Reinforced with Borides

Abstract

1. Introduction

2. Materials and Methods

3. Results

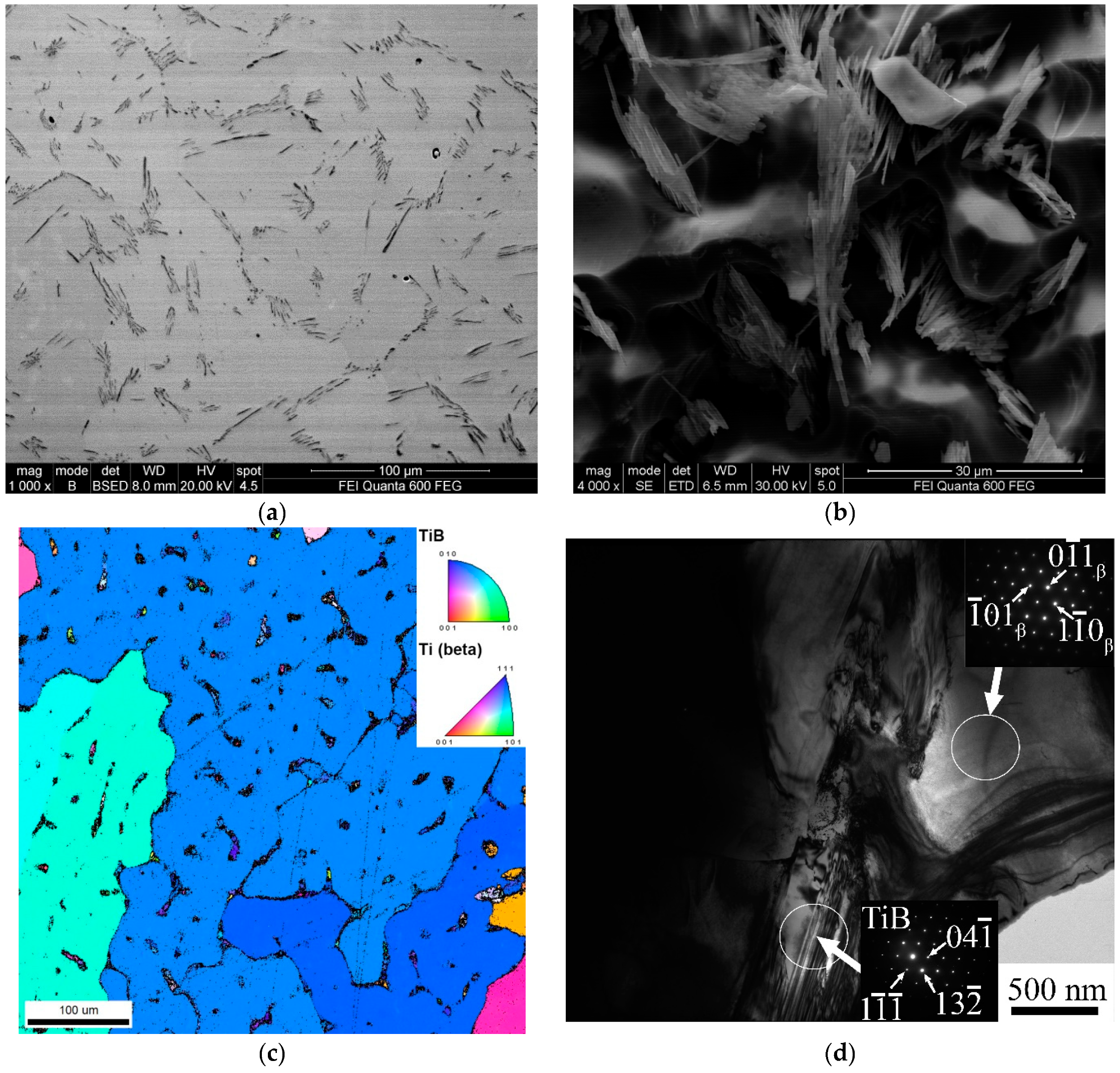

3.1. Initial Microstructure

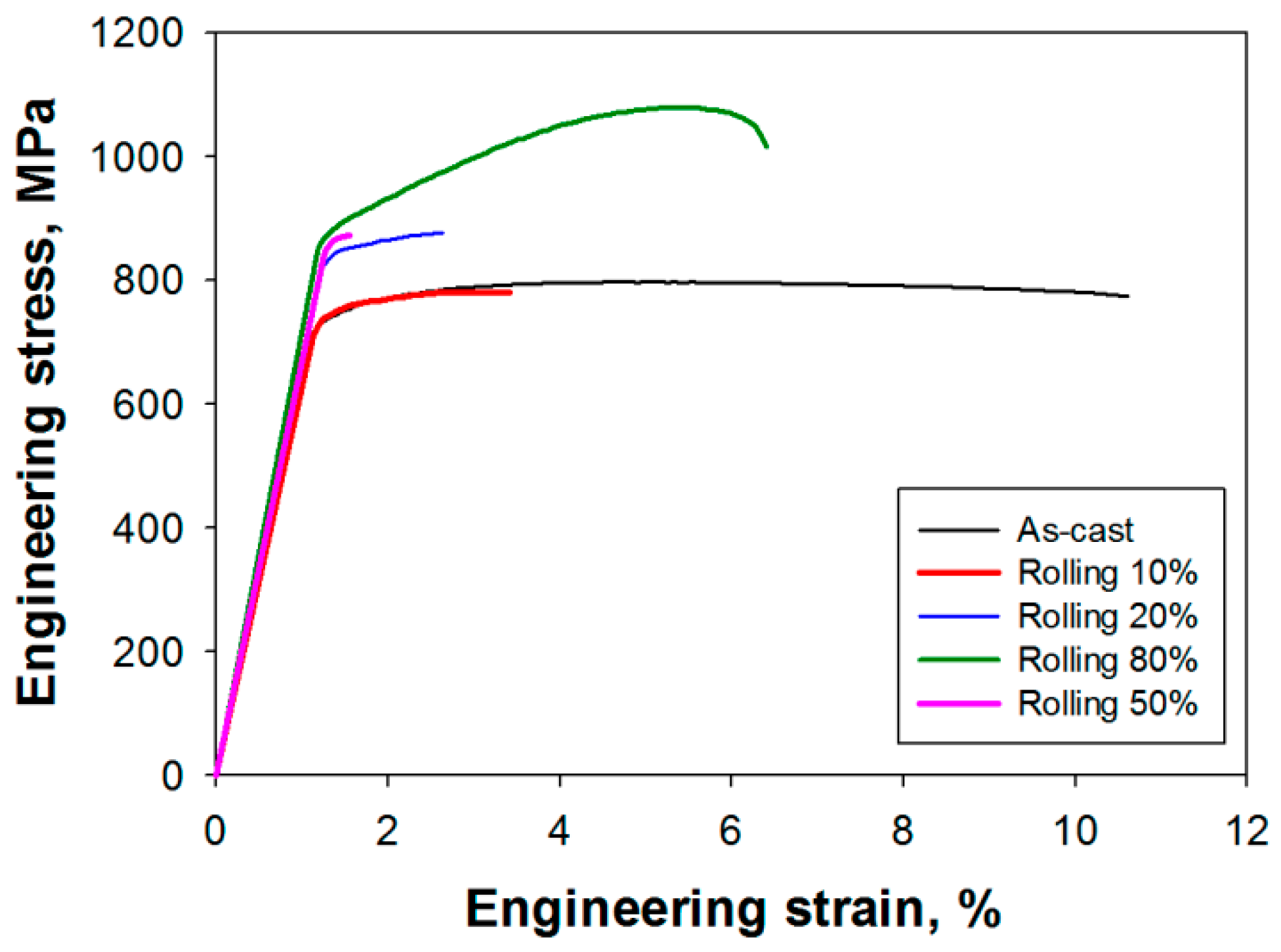

3.2. Mechanical Properties during Cold Rolling

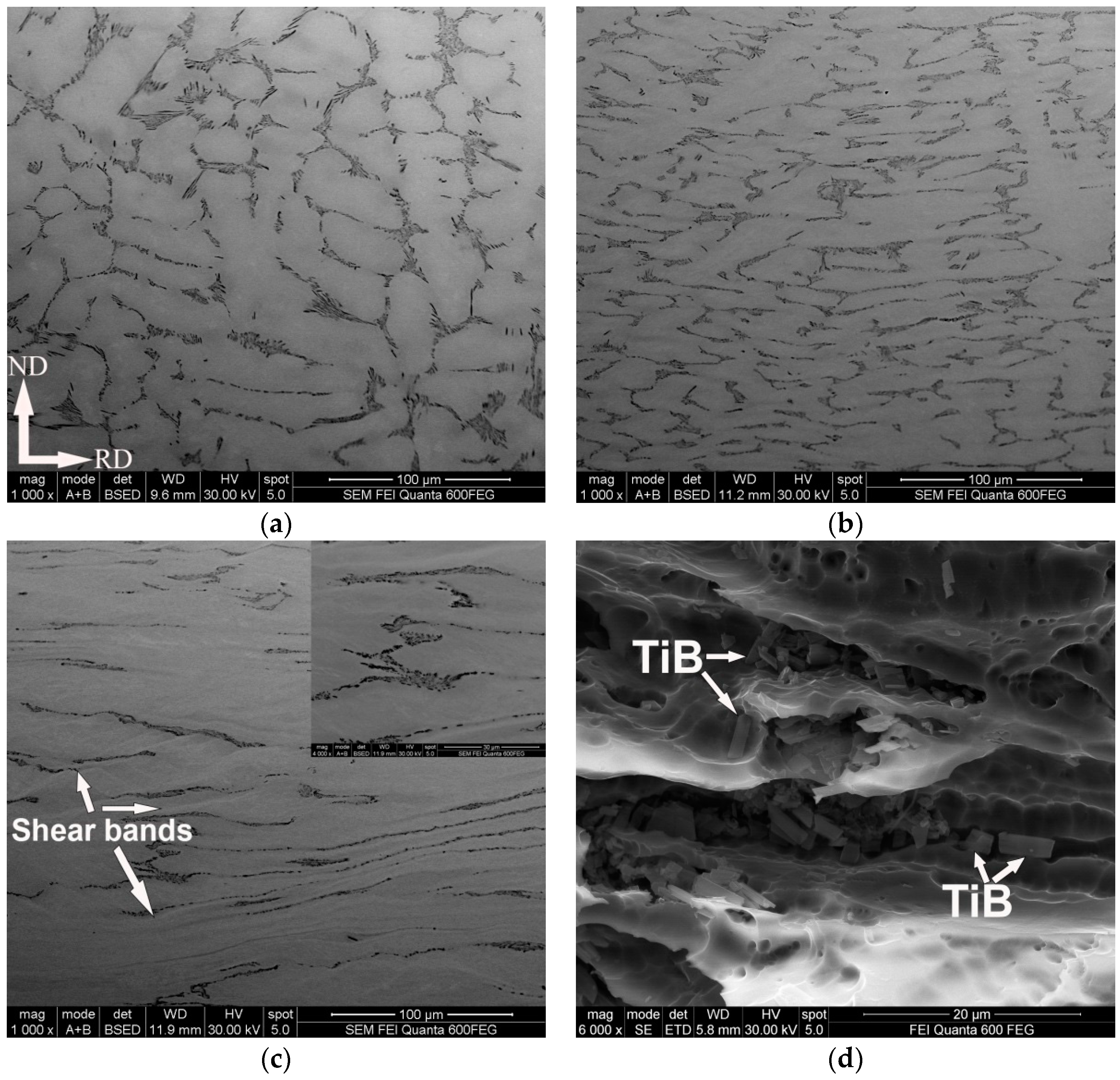

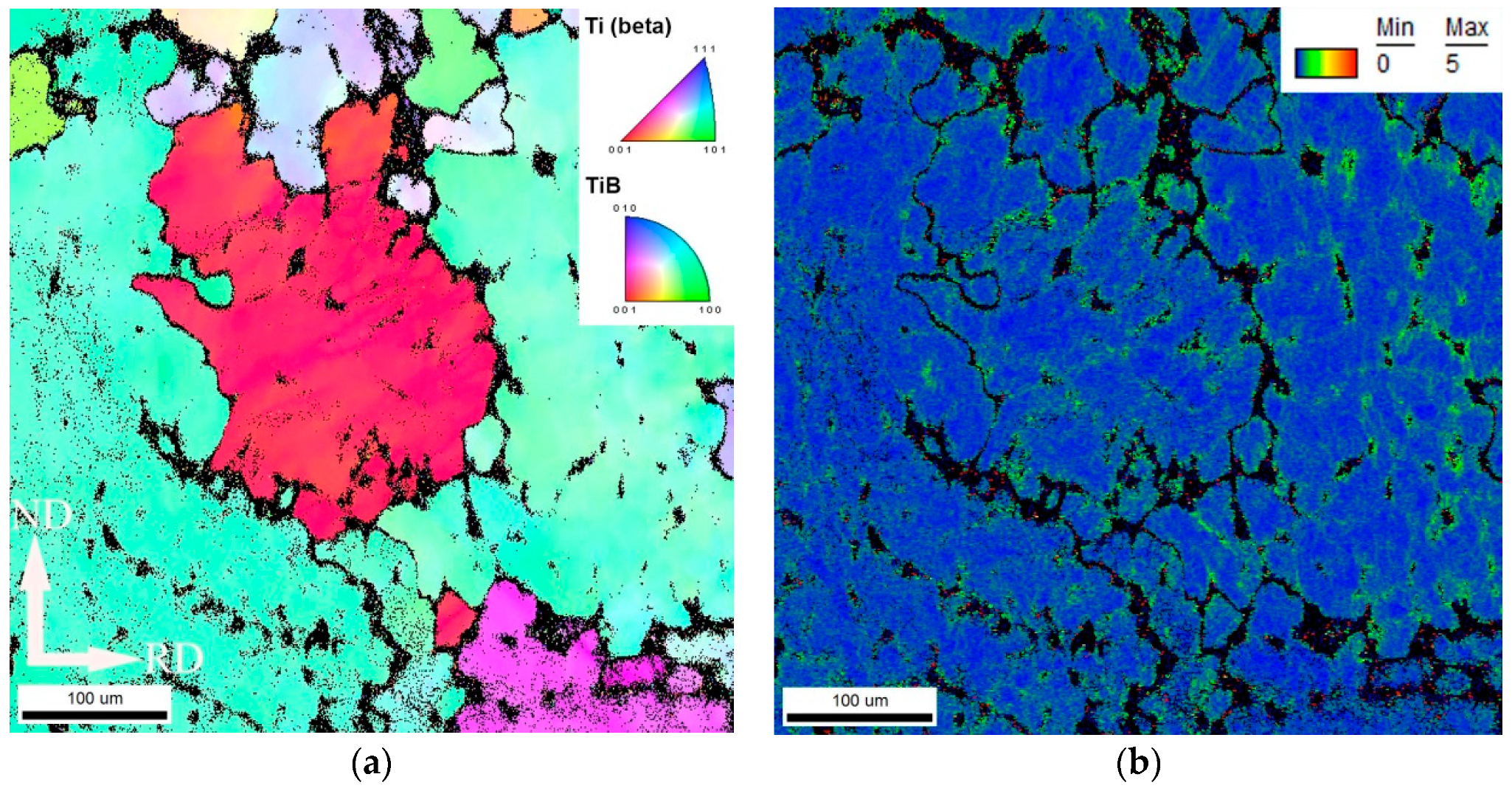

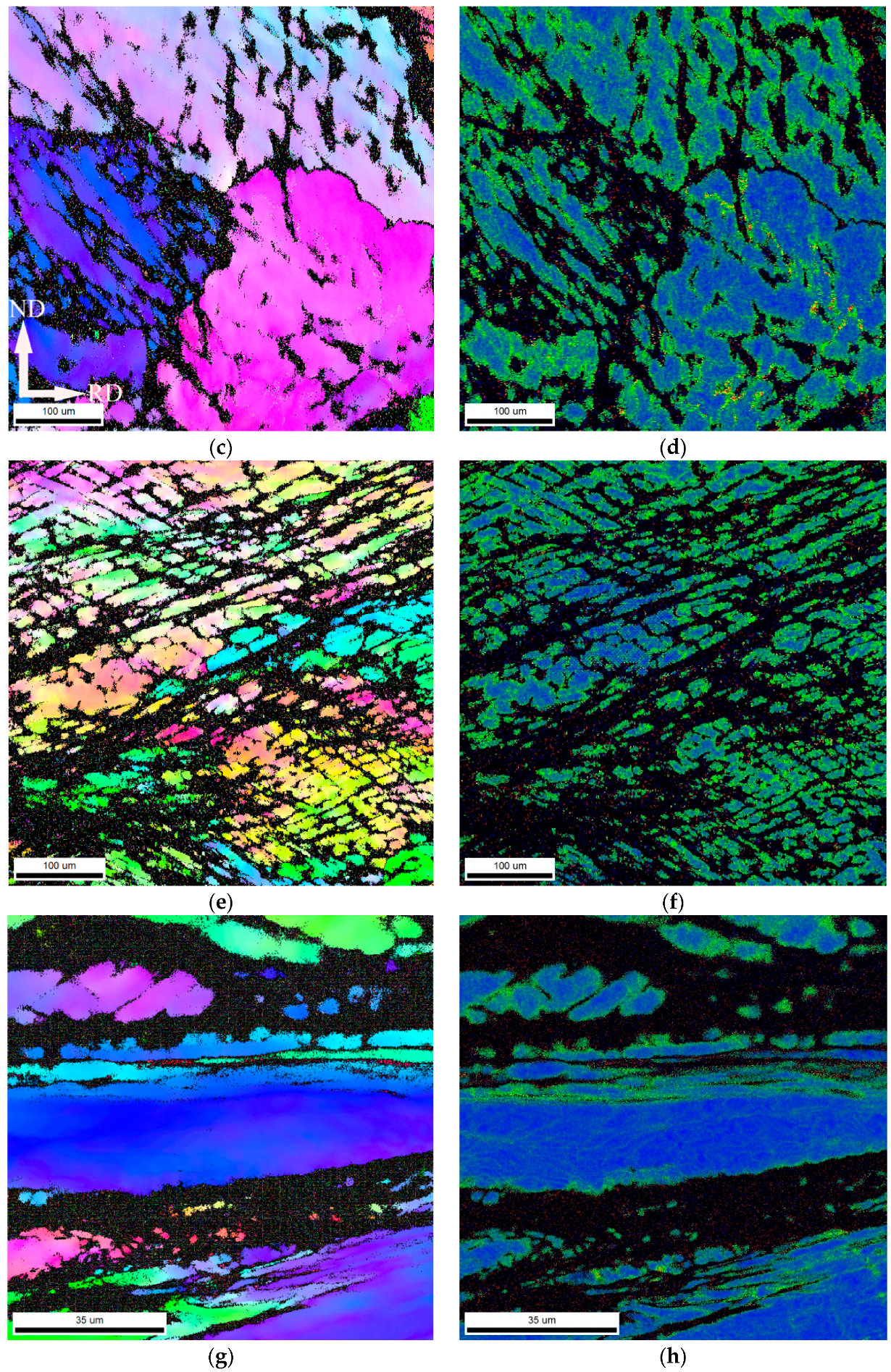

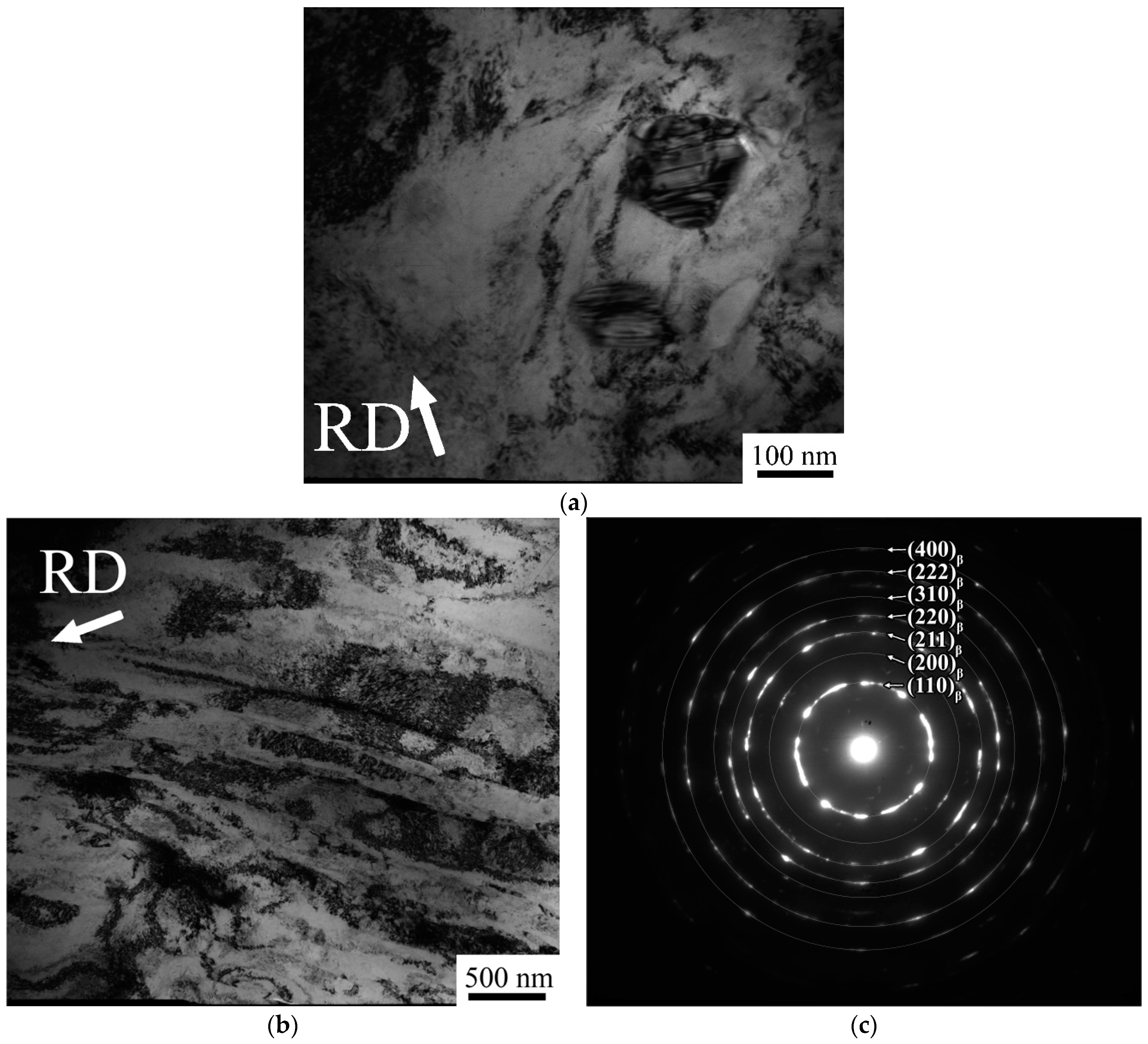

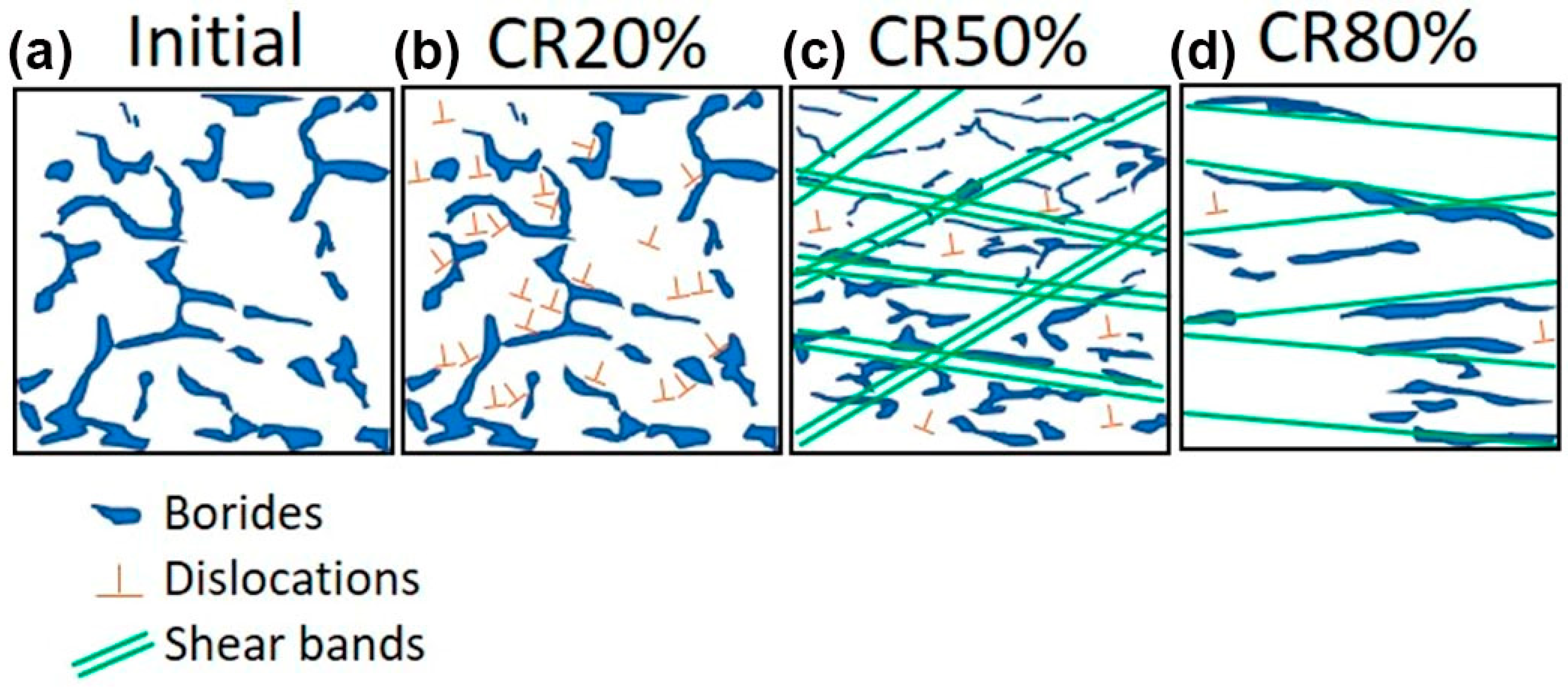

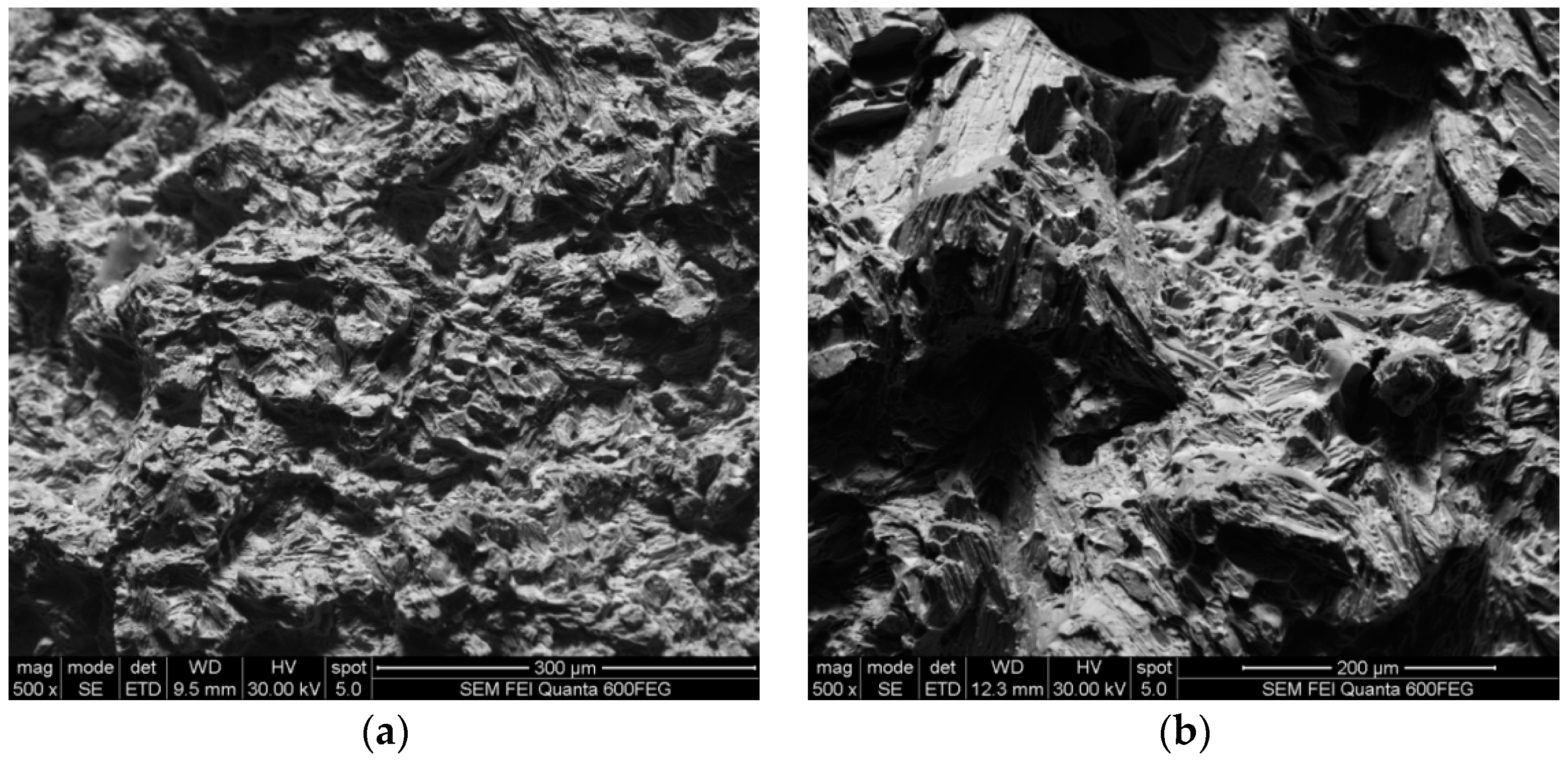

3.3. Microstructure Evolution during Cold Rolling

4. Discussion

5. Conclusions

- In the initial as-cast condition, the alloy had a network-like structure consisting of areas of the TiNbZr matrix (~500 µm size) surrounded by arrays of (Ti, Nb)B fibers. The (Ti, Nb)B fibers had a volume fraction of 2.5% and a transverse size of ~400 nm.

- Cold rolling resulted in a noticeable increase in strength by 17–35% in comparison with the as-cast condition. Deformation to a thickness strain of 80% led to growths in yield strength and ultimate tensile strength of the composite from 720 to 865 MPa and from 800 to 1080 MPa, respectively. Ductility of the alloy decreased from 10% in the as-cast condition to 0.3% after 50% CR; however further straining resulted in an increase in ductility to 5% after 80% of CR.

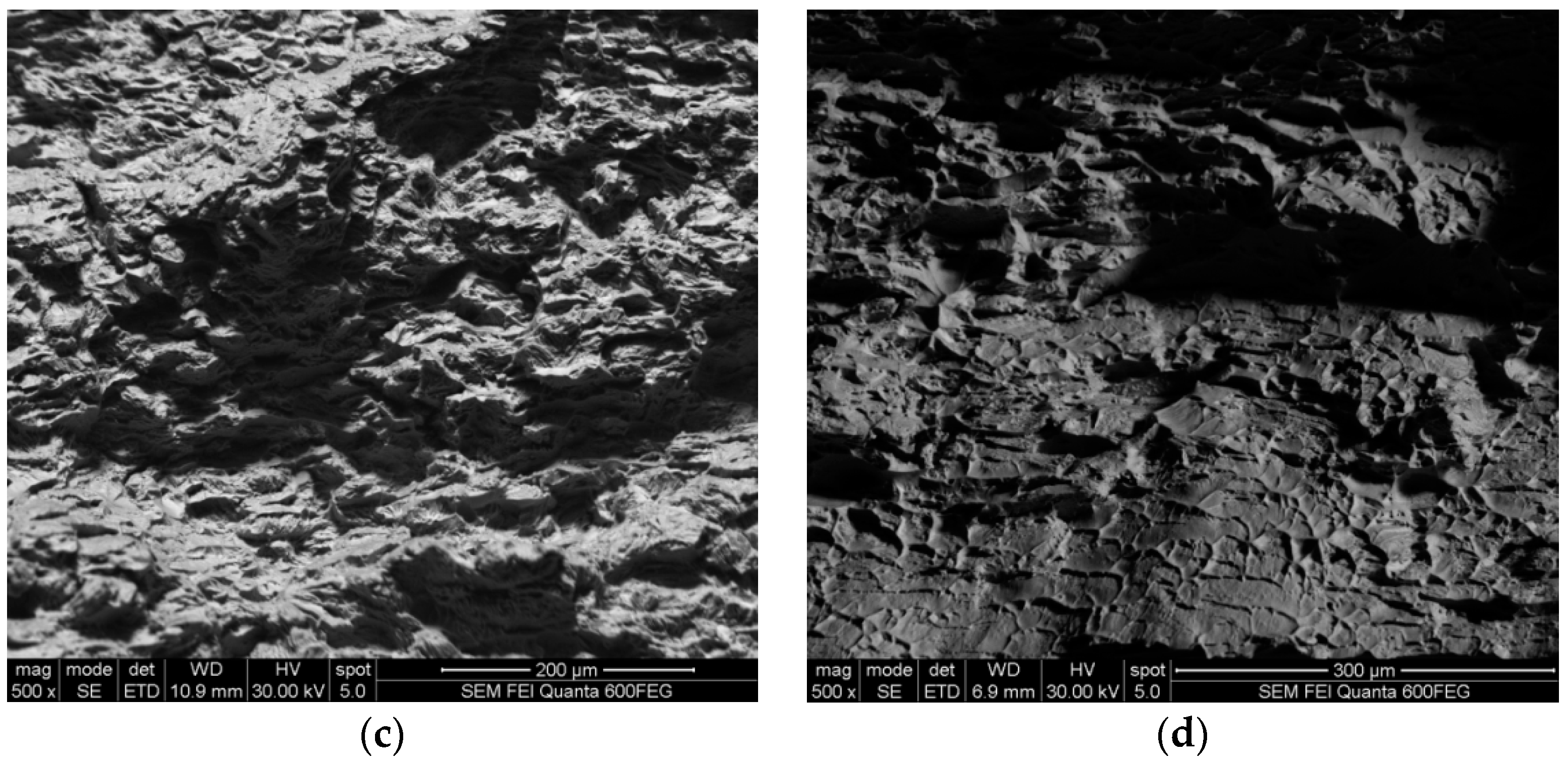

- The microstructure of the composite after CR to 10 or 20% of thickness reduction did not change noticeably in comparison with the as-cast condition. Rolling to 50% resulted in the development of shear deformation, and the formation of a network consisting of crossing shear bands declined mainly ~45° from the rolling plane. Further deformation until 80% of thickness reduction resulted in the formation of a lamellar-like microstructure, in which the refined (Ti, Nb)B layers separated the TiNbZr laths. After deformation to 80%, the TiB fibers of practically equiaxed particles, with a length to diameter ratio of ~2, were transformed.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, L.C.; Chen, L.Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Okazaki, Y. A new Ti-15Zr-4Nb-4Ta alloy for medical applications. Curr. Opin. Solid State Mater. Sci. 2001, 5, 45–53. [Google Scholar] [CrossRef]

- Flaten, T.P. Aluminium as a risk factor in Alzheimer’s disease, with emphasis on drinking water. Brain Res. Bull. 2001, 55, 187–196. [Google Scholar] [CrossRef]

- Lima, P.D.; Vasconcellos, M.C.; Montenegro, R.C.; Bahia, M.O.; Costa, E.T.; Antunes, L.M. Genotoxic effects of aluminum, iron and manganese in human cells and experimental systems: A review of the literature. Hum. Exp. Toxicol. 2011, 30, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Ozan, S.; Lin, J.; Li, Y.; Ipek, R.; Wen, C. Development of Ti–Nb–Zr alloys with high elastic admissible strain for temporary orthopedic devices. Acta Biomater. 2015, 20, 176–187. [Google Scholar] [CrossRef]

- Laheurte, P.; Prima, F.; Eberhardt, A.; Gloriant, T.; Wary, M.; Patoor, E. Mechanical properties of low modulus β titanium alloys designed from the electronic approach. J. Mech. Behav. Biomed. Mater. 2010, 3, 565–573. [Google Scholar] [CrossRef]

- Black, J. Biological Performance of Materials, Fundamentals of Biocompatibility; CRC Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Huiskes, R.; Weinans, H.; Vanrietbergen, B. The relationship between stress shielding and bone-resorption around total hip stems and the effects of flexible materials. Clin. Orthop. Relat. Res. 1992, 274, 124–134. [Google Scholar] [CrossRef]

- Senkov, O.N.; Rao, S.; Chaput, K.J.; Woodward, C. Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys. Acta Mater. 2018, 151, 201–215. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, S.; Liu, Q.; Hu, L.; Zhao, X. A β-type TiNbZr alloy with low modulus and high strength for biomedical applications. Prog. Nat. Sci. Mater. Int. 2014, 24, 157–162. [Google Scholar] [CrossRef]

- Rho, J.Y.; Tsui, T.Y.; Pharr, G.M. Elastic properties of human cortical and trabecular lamellar bone measured by nanoindentation. Biomaterials 1997, 18, 1325–1330. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Hanawa, T.; Hiromoto, S.; Asami, K.; Okuno, O.; Asaoka, K. Surface oxide films on titanium alloys regenerated in Hanks’ solution. Mater. Trans. 2002, 43, 3000–3004. [Google Scholar] [CrossRef]

- Mishchenko, O.; Ovchynnykov, O.; Kapustian, O.; Pogorielov, M. New Zr-Ti-Nb Alloy for Medical Application: Development, Chemical and Mechanical Properties, and Biocompatibility. Materials 2020, 13, 1306. [Google Scholar] [CrossRef]

- Aguilar Maya, A.E.; Grana, D.R.; Hazarabedian, A.; Kokubu, G.A.; Luppo, M.I.; Vigna, G. Zr–Ti–Nb porous alloys for biomedical application. Mater. Sci. Eng. C 2012, 32, 321–329. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Shetty, R.; Hegde, A.; Shetty SV, U.K.; Nayak, R.; Naik, N.; Nayak, M. Processing and Mechanical Characterisation of Titanium Metal Matrix Composites: A Literature Review. J. Compos. Sci. 2022, 6, 388. [Google Scholar] [CrossRef]

- Morsi, K. Review: Titanium–titanium boride composites. J. Mater. Sci. 2019, 54, 6753–6771. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Kolesnikov, A.; Stepanov, N.; Zherebtsov, S. Deformation behavior and microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature compression tests. Mater. Des. 2016, 112, 17–26. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Sokolovsky, V.; Stepanov, N.; Popov, A.; Boldin, M.; Zherebtsov, S. Evolution of microstructure and mechanical properties of Ti/TiB metal-matrix composite during isothermal multiaxial forging. J. Alloys Compd. 2019, 770, 840–848. [Google Scholar] [CrossRef]

- Huang, L.; An, Q.; Geng, L.; Wang, S.; Jiang, S.; Cui, X.; Zhang, R.; Sun, F.; Jiao, Y.; Chen, X.; et al. Multiscale Architecture and Superior High-Temperature Performance of Discontinuously Reinforced Titanium Matrix Composites. Adv. Mater. 2021, 33, 2000688. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Klimova, M.; Moskovskikh, D.; Stepanov, N.; Salishchev, G. Mechanical behavior and microstructure evolution of a Ti-15Mo/TiB titanium–matrix composite during hot deformation. Metals 2019, 9, 1175. [Google Scholar] [CrossRef]

- Samuel, S.; Nag, S.; Scharf, T.W.; Banerjee, R. Wear resistance of laser-deposited boride reinforced Ti-Nb-Zr-Ta alloy composites for orthopedic implants. Mater. Sci. Eng. C 2008, 28, 414–420. [Google Scholar] [CrossRef]

- Nag, S.; Samuel, S.; Puthucode, A.; Banerjee, R. Characterization of novel borides in Ti-Nb-Zr-Ta + 2B metal-matrix composites. Mater. Charact. 2009, 60, 106–113. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Dhara, S.; Chakraborty, M. Influence of in situ TiB reinforcements and role of heat treatment on mechanical properties and biocompatibility of β Ti-alloys. J. Mech. Behav. Biomed. Mater. 2012, 10, 1–12. [Google Scholar] [CrossRef]

- Ozerov, M.; Sokolovsky, V.; Nadezhdin, S.; Zubareva, E.; Zherebtsova, N.; Stepanov, N.; Huang, L.; Zherebtsov, S. Microstructure and mechanical properties of medium-entropy TiNbZr alloy-based composites, reinforced with boride particles. J. Alloys Compd. 2023, 938, 168512. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q.; Rao, J. Growth mechanism of in situ TiB whiskers in spark plasma sintered TiB/Ti metal matrix composites. Cryst. Growth Des. 2006, 6, 1626–1630. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Teliovych, R.V.; Ivanchenko, V.G.; Tamirisakandala, S.; Miracle, D.B. Processing, Microstructure, Texture, and Tensile Properties of the Ti-6Al-4V-1.55B Eutectic Alloy. Metall. Mater. Trans. A 2008, 39, 402–416. [Google Scholar] [CrossRef]

- Gaisin, A.; Imayev, V.M.; Imayev, R.M. Effect of hot forging on microstructure and mechanical properties of near α titanium alloy/TiB composites produced by casting. J. Alloys Compd. 2017, 723, 385–394. [Google Scholar] [CrossRef]

- Ozerov, M.; Sokolovsky, V.; Stepanov, N.; Zherebtsov, S. Microstructure and tensile properties of TiNbZr alloy-based metal-matrix composites, reinforced with borides. AIP Conf. Proc. 2023, 2899, 020109. [Google Scholar]

- Eleti, R.R.; Stepanov, N.; Yurchenko, N.; Zherebtsov, S.; Maresca, F. Cross-kink unpinning controls the medium- to high-temperature strength of body-centered cubic NbTiZr medium-entropy alloy. Scr. Mater. 2022, 209, 114367. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Maurya, P.; Kota, Т.; Gibmeier, J.; Wanner, A.; Roy, S. Review on study of internal load transfer in metal matrix composites using diffraction techniques. Mater. Sci. Eng. A 2022, 840, 142973. [Google Scholar] [CrossRef]

- Jia, N.; Roters, F.; Eisenlohr, P.; Raabe, D.; Zhao, X. Simulation of shear banding in heterophase co-deformation: Example of plane strain compressed Cu–Ag and Cu–Nb metal matrix composites. Acta Mater. 2013, 61, 4591–4606. [Google Scholar] [CrossRef]

- Sauvage, X.; Renaud, L.; Deconihout, B.; Blavette, D.; Ping, D.H.; Hono, K. Solid state amorphization in cold drawn Cu/Nb wires. Acta Mater. 2001, 49, 389–394. [Google Scholar] [CrossRef]

- Ohsaki, S.; Kato, S.; Tsuji, N.; Ohkubo, T.; Hono, K. Bulk mechanical alloying of Cu–Ag and Cu/Zr two-phase microstructures by accumulative roll-bonding process. Acta Mater. 2007, 55, 2885–2895. [Google Scholar] [CrossRef]

- Raabe, D.; Mattissen, D. Microstructure and mechanical properties of a cast and wire-drawn ternary Cu–Ag–Nb in situ composite. Acta Mater. 1998, 46, 5973–5984. [Google Scholar] [CrossRef]

| Condition | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation, % |

|---|---|---|---|

| As-cast | 720 ± 5 | 800 ± 7 | 10 ± 0.5 |

| CR 10% | 730 ± 8 | 800 ± 8 | 3 ± 0.3 |

| CR 20% | 830 ± 9 | 880 ± 10 | 1 ± 0.2 |

| CR 50% | 850 ± 8 | - | 0.3 ± 0.05 |

| CR 80% | 865 ± 12 | 1080 ± 15 | 5 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozerov, M.; Sokolovsky, V.; Yurchenko, N.; Astakhov, I.; Povolyaeva, E.; Plekhov, O.; Tagirov, D.; Stepanov, N.; Zherebtsov, S. Effect of Cold Rolling on Microstructure and Mechanical Properties of a Cast TiNbZr-Based Composite Reinforced with Borides. Metals 2024, 14, 104. https://doi.org/10.3390/met14010104

Ozerov M, Sokolovsky V, Yurchenko N, Astakhov I, Povolyaeva E, Plekhov O, Tagirov D, Stepanov N, Zherebtsov S. Effect of Cold Rolling on Microstructure and Mechanical Properties of a Cast TiNbZr-Based Composite Reinforced with Borides. Metals. 2024; 14(1):104. https://doi.org/10.3390/met14010104

Chicago/Turabian StyleOzerov, Maxim, Vitaly Sokolovsky, Nikita Yurchenko, Ilya Astakhov, Elizaveta Povolyaeva, Oleg Plekhov, Damir Tagirov, Nikita Stepanov, and Sergey Zherebtsov. 2024. "Effect of Cold Rolling on Microstructure and Mechanical Properties of a Cast TiNbZr-Based Composite Reinforced with Borides" Metals 14, no. 1: 104. https://doi.org/10.3390/met14010104

APA StyleOzerov, M., Sokolovsky, V., Yurchenko, N., Astakhov, I., Povolyaeva, E., Plekhov, O., Tagirov, D., Stepanov, N., & Zherebtsov, S. (2024). Effect of Cold Rolling on Microstructure and Mechanical Properties of a Cast TiNbZr-Based Composite Reinforced with Borides. Metals, 14(1), 104. https://doi.org/10.3390/met14010104