Cold Formability of Twin-Roll Cast, Rolled and Annealed Mg Strips

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experimental Procedure

2.3. Material Characterisation

3. Results

Characterisation of the Initial AZ31 and ZAX210 Strips

4. Conclusions

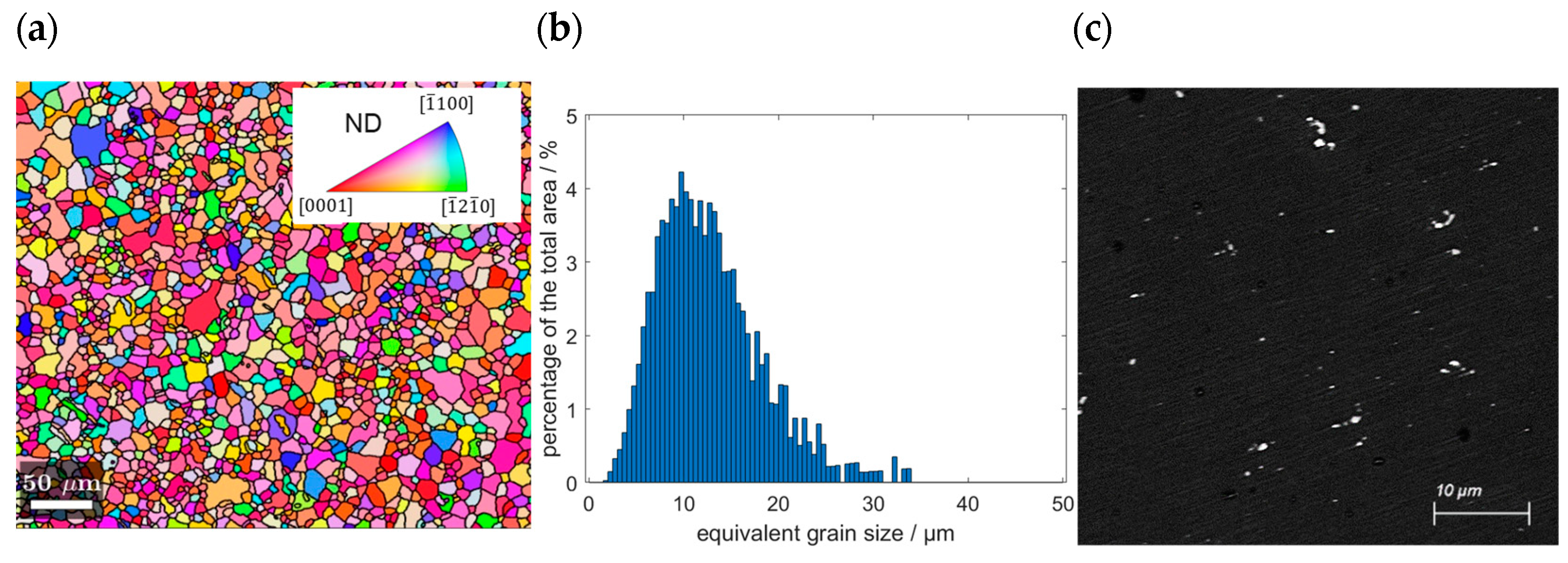

- Both alloys exhibited similar grain sizes, with AZ31 having an average value of 7.9 µm and ZAX210 having an average value of 8.9 µm. The microstructure of the AZ31 strips showed finely distributed Al8Mn5 particles in α-Mg, while the ZAX210 strips exhibited Mg2Ca, MgZn, and Ca2Mg6Zn3 phases in α-Mg.

- The influence of alloying elements on texture was evident in the IPFs and pole figures. The presence of calcium effectively weakened the intensity of the basal texture in ZAX210, whereas AZ31 exhibited a strong basal texture with a pronounced 〈0001〉 fibre parallel to the normal direction (ND). The mechanical properties, including tensile strength and total elongation, were evaluated for both alloys. ZAX210 demonstrated medium strengths with tensile strengths of about 240 MPa and excellent total elongation ranging from 28% to 32%, depending on the sampling direction. A comparison with AZ31 revealed higher strengths in AZ31 due to its higher aluminium content, but also a stronger directional dependence in mechanical properties attributed to its strong basal texture formed during hot rolling.

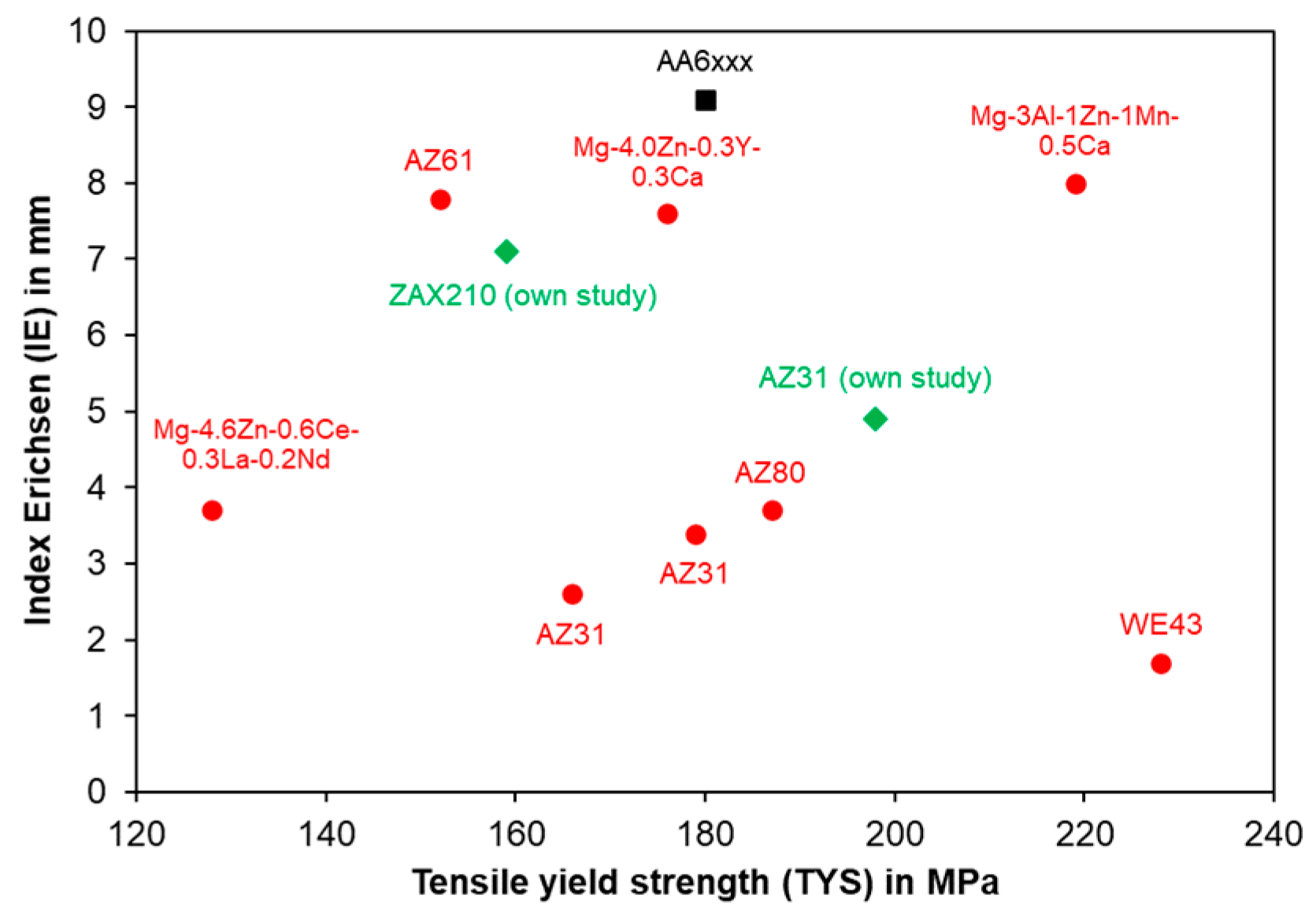

- The formability at room temperature of the alloys was assessed through Erichsen tests, with ZAX210 strips demonstrating significantly higher formability compared to AZ31. The texture softening in ZAX210, resulting from the weakening of basal texture intensity and the splitting of basal poles towards the rolling direction (RD), contributed to its enhanced formability. Recrystallisation at double and compression twins, along with the potential grain boundary segregation of calcium, were identified as mechanisms for the weakened texture in ZAX210 [33]. The ZAX210 alloy offers an outstanding combination of strength, ductility and formability, which is comparable to those of AA6xxx aluminium alloy sheets.

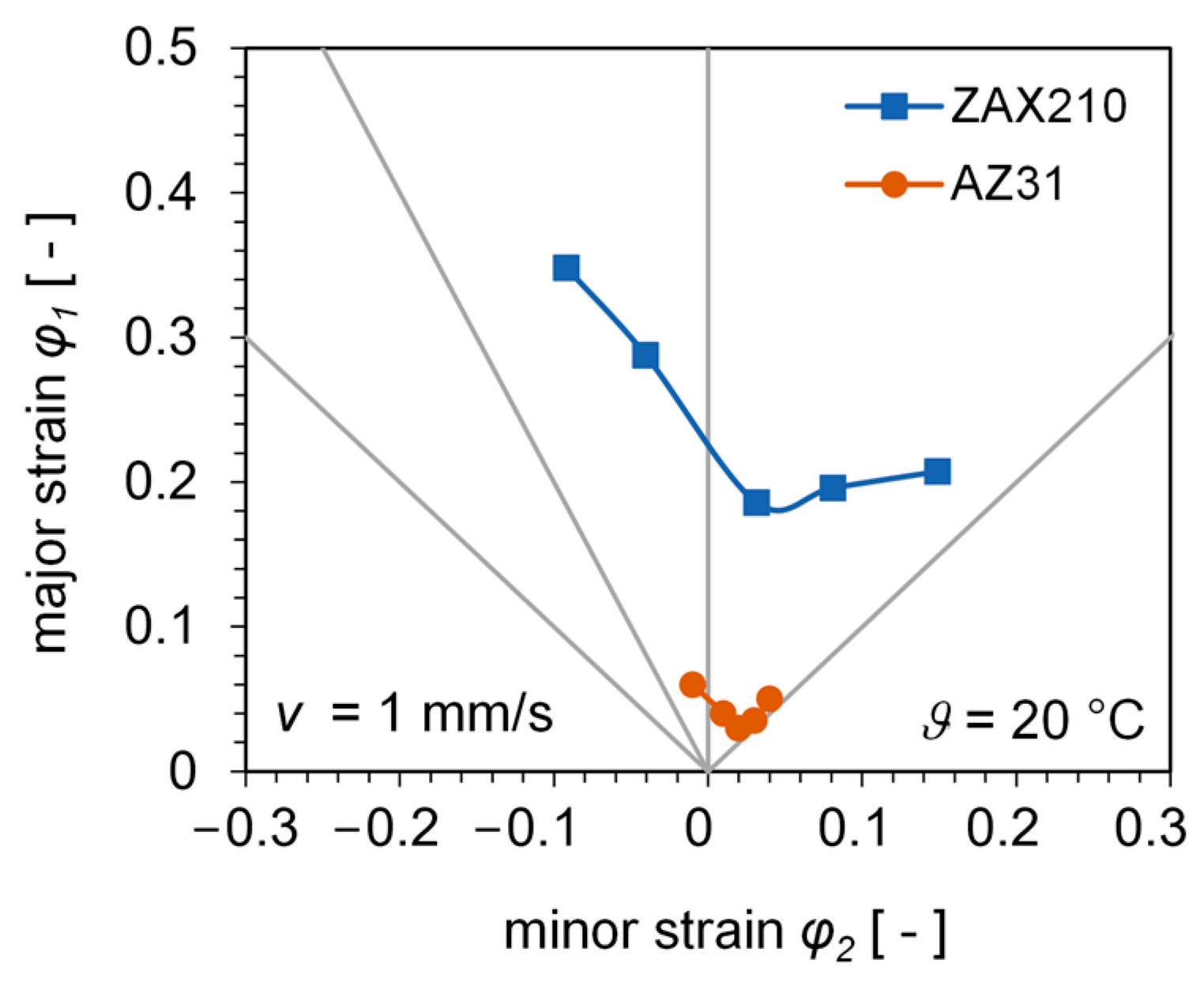

- Forming limit strains were determined using the Nakajima test, indicating that ZAX210 exhibited higher forming limit values compared to AZ31. The ZAX210 strip demonstrated higher forming changes on the left side of the forming limit curve (FLC), allowing for deeper forming operations at room temperature. The forming capacity of ZAX210 is comparable to a ZE10 alloy, which contains rare earth elements, due to the weakened textures achieved after rolling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.; Jiang, B.; Chen, D.; Jin, Z.; Zhao, L.; Yang, Q.; Huang, G.; Pan, F. Strategies for enhancing the room-temperature stretch formability of magnesium alloy sheets: A review. J. Mater. Sci. 2021, 56, 12965–12998. [Google Scholar] [CrossRef]

- Bian, M.; Huang, X.; Chino, Y. Substantial improvement in cold formability of concentrated Mg-Al-Zn-Ca alloy sheet by high temperature final rolling. Acta Mater. 2021, 220, 117328. [Google Scholar] [CrossRef]

- Krajňák, T.; Minárik, P.; Stráský, J.; Máthis, K.; Janeček, M. Mechanical properties of ultrane-grained AX41 magnesium alloy at room and elevated temperatures. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 731, 438–445. [Google Scholar] [CrossRef]

- Mendis, C.; Bae, J.; Kim, N.; Hono, K. Microstructures and tensile properties of a twin roll cast and heat-treated mg-2.4Zn-0.1Ag-0.1Ca-0.1Zr alloy. Scr. Mater. 2011, 64, 335–338. [Google Scholar] [CrossRef]

- Hänzi, A.C.; Sologubenko, A.S.; Gunde, P.; Schinhammer, M.; Uggowitzer, P.J. Design considerations for achieving simultaneously high-strength and highly ductile magnesium alloys. Philos. Mag. Lett. 2012, 92, 417–427. [Google Scholar] [CrossRef]

- Chai, Y.; Jiang, B.; Song, J.; Wang, Q.; Gao, H.; Liu, B.; Huang, G.; Zhang, D.; Pan, F. Improvement of mechanical properties and reduction of yield asymmetry of extruded mg-sn-zn alloy trough Ca addition. J. Alloys Compd. 2019, 782, 1076–1086. [Google Scholar] [CrossRef]

- Kammer, C. Magnesium Taschenbuch; Aluminium-Verlag: Düsseldorf, Germany, 2000. [Google Scholar]

- Bian, M.; Huang, X.; Chino, Y. A combined experimental and numerical study on room temperature formable magnesium-silver-calcium alloys. J. Alloys Compd. 2020, 834, 155017. [Google Scholar] [CrossRef]

- Jo, S.; Bohlen, J.; Kurz, G. Individual Contribution of Zn and Ca on Age-Hardenability and Formability of Zn-Based Magnesium Alloy Sheet. Materials 2022, 15, 5239. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Watazu, A.; Shigematsu, I.; Saito, N. Improvement of formability of Mg-Al-Zn alloy sheet at low temperatures using differential speed rolling. J. Alloys Compd. 2009, 470, 263–268. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Chino, Y.; Mabuchi, M. Texture and strecht formability of AZ61 and AM60 magnesium alloy sheets processed by high-temperature rolling. J. Alloys Compd. 2015, 632, 94–102. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Saito, N. Microstructure and mechanical properties of AZ80 magnesium alloy sheet processed by differential speed rolling. Mater. Sci. Eng. A 2009, 508, 226–233. [Google Scholar] [CrossRef]

- Trang, T.T.T.; Zhang, J.H.; Kim, J.H.; Zargaran, A.; Hwang, J.H.; Suh, B.-C.; Kim, N.J. Designing a magnesium alloy with hight strength and high formability. Nat. Commun. 2018, 9, 2522. [Google Scholar] [CrossRef] [PubMed]

- Chino, Y.; Mabuchi, M. Enhanced strech formability of Mg-Al-Zn alloy sheets rolled at high temperatuer (723 K). Scirpta Mater. 2009, 60, 447–450. [Google Scholar] [CrossRef]

- Suh, B.-C.; Shim, M.-S.; Shin, K.; Kim, N.J. Current issues in magenium sheet alloys: Where do we go from here? Scr. Mater. 2014, 84–85, 1–6. [Google Scholar] [CrossRef]

- Wu, Z.; Ahmad, R.; Yin, B.; Sandlöbes, S.; Curtin, W.A. Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science 2018, 359, 447–452. [Google Scholar] [CrossRef]

- Park, S.; Jung, H.C.; Shin, K.S. Deformation Behavior of Twin Roll Cast Mg-Zn-X-Ca Alloys for Enhanced Room-Temperature Formability. Mater. Sci. Eng. A 2017, 679, 329–339. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, G.; Liu, C.-M.; Zuo, L. Effects of different tempers on precipitation hardening of 6000 series aluminium alloys. Trans. Nonferrous Met. Soc. China 2007, 17, 122–127. [Google Scholar] [CrossRef]

- Zhang, H.; Ren, S.; Li, X.; Wang, L.; Fan, J.; Chen, S.; Zhu, L.; Meng, F.; Tong, Y.; Roven, H.J.; et al. Dramatically enhanced stamping formability of Mg-3Al-1Zn alloy by weakening (0001) basal texture. J. Mater. Res. Technol. 2020, 9, 14742–14753. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Hamad, K.; Kim, J. A Further Improvement in the Room-Temperature Formability of Magnesium Alloy Sheets by Pre-Stretching. Materials 2020, 13, 2633. [Google Scholar] [CrossRef]

- Bian, M.; Huang, X.; Chino, Y. Towards Improving Cold Formability of a Concentrated Mg-Al-Zn-Ca Alloy Sheet. In Magnesium Technology; Springer International Publishing: Cham, Switzerland, 2022; pp. 227–231. [Google Scholar] [CrossRef]

- Han, X.-Z.; Hu, L.; Jia, D.-Y.; Chen, J.-M.; Zhou, T.; Jiang, S.-Y.; Tian, Z. Role of unusual double-peak texture in significantly enhancing cold rolling formability of AZ31 magnesium alloy sheet. Trans. Nonferrous Met. Soc. China 2023, 33, 2351–2364. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Y.; Geng, L.; Lu, C. Effects of calcium on texture and mechanical properties of hot-extruded Mg-Zn-Ca alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2012, 539, 56–60. [Google Scholar] [CrossRef]

- Chino, Y.; Ueda, T.; Otomatsu, Y.; Sassa, K.; Huang, X.; Suzuki, K.; Mabuchi, M. Effects of Ca on tensile properties and stretch formability at room temperature in Mg-Zn and Mg-Al alloys. Mater. Trans. 2011, 52, 1477–1482. [Google Scholar] [CrossRef]

- Griffiths, D. Explaining texture weakening and improved formability in magnesium rare earth alloys. Mater. Sci. Technol. 2015, 31, 10–24. [Google Scholar] [CrossRef]

- Ullmann, M.; Kittner, K.; Henseler, T.; Stöcker, A.; Prahl, U.; Kawalla, R. Development of new alloy systems and innovative processing technologies for the production of magnesium flat products with excellent property profile. Procedia Manuf. 2019, 27, 203–208. [Google Scholar] [CrossRef]

- Neh, K.; Ullmann, M.; Oswald, M.; Berge, F.; Kawalla, R. Twin ro ll casting and strip rolling of several magnesium alloys. Mater. Today Proc. 2015, 2, S45–S52. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX–Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- DIN EN ISO 6892-1; Metallische Werkstoffe—Zugversuch—Teil1: Prüfverfahren bei Raumtemperatur. Deutsches Institut für Normung: Berlin, Germany, 2019.

- DIN 50125; Prüfung metallischer Werkstoffe—Zugproben. Deutsches Institut für Normung: Berlin, Germany, 2022.

- DIN EN ISO 20482; Metallische Werkstoffe—Bleche und Bänder—Tiefungsversuch nach Erichsen. Deutsches Institut für Normung: Berlin, Germany, 2013.

- ISO 12004-2; Metallischer Werkstoffe—Bestimmung der Grenzformänderungskurven für Bleche und Bänder—Bestimmung von Grenzformänderungskurven im Labor. Deutsches Institut für Normung: Berlin, Germany, 2021.

- Kittner, K.; Ullmann, M.; Prahl, U. Microstructural andTextural Investigation of an Mg-Zn-Al-Ca Alloy after Hot PlaneStrain Compression. Materials 2022, 15, 7499. [Google Scholar] [CrossRef]

- Nienaber, M.; Bohlen, J.; Victoria-Hernández, J.; Yi, S.; Kainer, K.U.; Letzig, D. Cold Formabiliy of Extruded Magnesium Bands. In Magnesium Technology; Springer International Publishing: Cham, Switzerland, 2020; pp. 329–334. [Google Scholar] [CrossRef]

- Stutz, L. Das Umformverhalten von Magnesiumblechen der Legierungen AZ31 und ZE10. Ph.D. Dissertation, Technische Universität Berlin, Berlin, Germany, 2015. [Google Scholar]

| Alloys (Wt%) | Processing Condition | TYS (MPa) | TE (%) | IE (mm) | References |

|---|---|---|---|---|---|

| AZ31 | Hot rolling, annealing | 166 | 23 | 2.6 | [10] |

| AZ61 | Extrusion, hot rolling, annealing | 152 | 24 | 7.8 | [11] |

| AZ80 | Extrusion, hot rolling, annealing | 187 | 24 | 3.7 | [12] |

| Mg-3Al-1Zn-1Mn-0.5Ca | Twin-roll casting, hot rolling, annealing | 219 | 16 | 8.0 | [13] |

| AZ31 | Hot rolling, annealing | 179 | 22 | 3.4 | [14] |

| WE43 | Hot rolling, annealing | 228 | 15 | 1.7 | [15] |

| Mg-4.6Zn-0.6Ce-0.3La-0.2Nd | Hot rolling, T4 | 128 | 12 | 3.7 | [16] |

| Mg-4.0Zn-0.3Y-0.3Ca | Twin-roll casting, hot rolling, annealing | 176 | 26 | 7.6 | [17] |

| AA6xxx | T4, naturally aged | 180 | 27 | 9.1 | [18] |

| Alloy | Mg | Zn | Al | Ca | Mn | Cu | Fe | Ni | Si | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| ZAX210 | Bal. | 2.29 | 0.92 | <0.24 | 0.04 | 0.001 | 0.005 | 0.001 | 0.022 | <0.020 |

| AZ31 | Bal. | 0.85 | 2.92 | 0 | 0.32 | 0.001 | 0.005 | 0.001 | 0.021 | <0.004 |

| Strips | Direction | TYS (MPa) | UTS (MPa) | TE (%) | UTS/YS | I.E. | |

|---|---|---|---|---|---|---|---|

| AZ31 | RD | 198 ± 5 | 280 ± 6 | 24 ± 2 | 1.4 | 4.9 ± 0.2 |  |

| 45° | 195 ± 6 | 276 ± 6 | 22 ± 2 | 1.4 | |||

| TD | 189 ± 5 | 273 ± 5 | 18 ± 1 | 1.4 | |||

| ZAX210 | RD | 159 ± 3 | 248 ± 4 | 30 ± 2 | 1.6 | 7.1 ± 0.3 |  |

| 45° | 145 ± 3 | 238 ± 3 | 32 ± 2 | 1.6 | |||

| TD | 136 ± 3 | 242 ± 4 | 28 ± 3 | 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullmann, M.; Kittner, K.; Prahl, U. Cold Formability of Twin-Roll Cast, Rolled and Annealed Mg Strips. Metals 2024, 14, 121. https://doi.org/10.3390/met14010121

Ullmann M, Kittner K, Prahl U. Cold Formability of Twin-Roll Cast, Rolled and Annealed Mg Strips. Metals. 2024; 14(1):121. https://doi.org/10.3390/met14010121

Chicago/Turabian StyleUllmann, Madlen, Kristina Kittner, and Ulrich Prahl. 2024. "Cold Formability of Twin-Roll Cast, Rolled and Annealed Mg Strips" Metals 14, no. 1: 121. https://doi.org/10.3390/met14010121

APA StyleUllmann, M., Kittner, K., & Prahl, U. (2024). Cold Formability of Twin-Roll Cast, Rolled and Annealed Mg Strips. Metals, 14(1), 121. https://doi.org/10.3390/met14010121