Experimental and Crystal Plasticity Finite Element Investigations of Plastic Anisotropy in Additively Manufactured Ti6Al4V Alloy

Abstract

1. Introduction

2. Materials and Methods

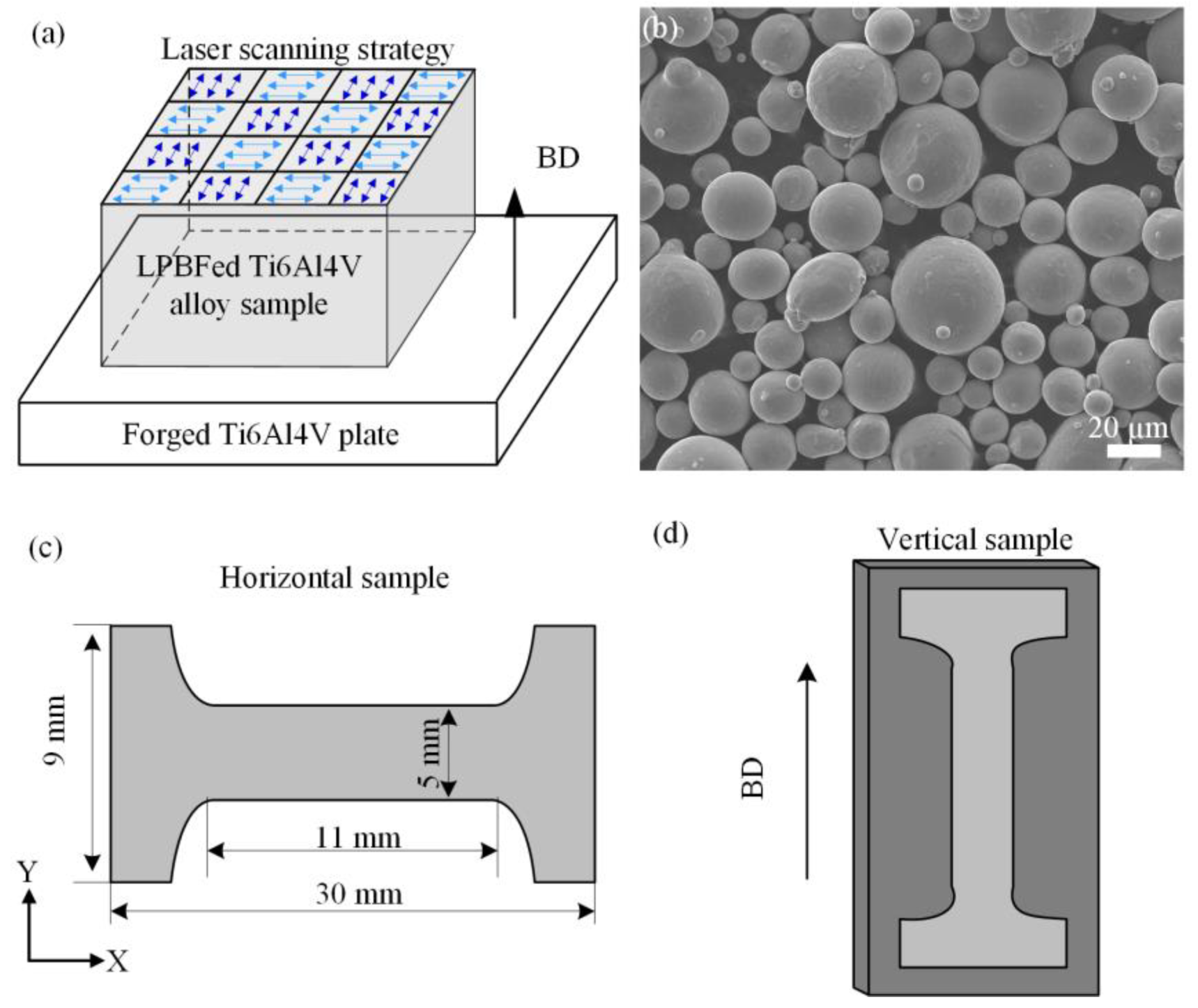

2.1. LPBF Process of Ti6Al4V Alloy

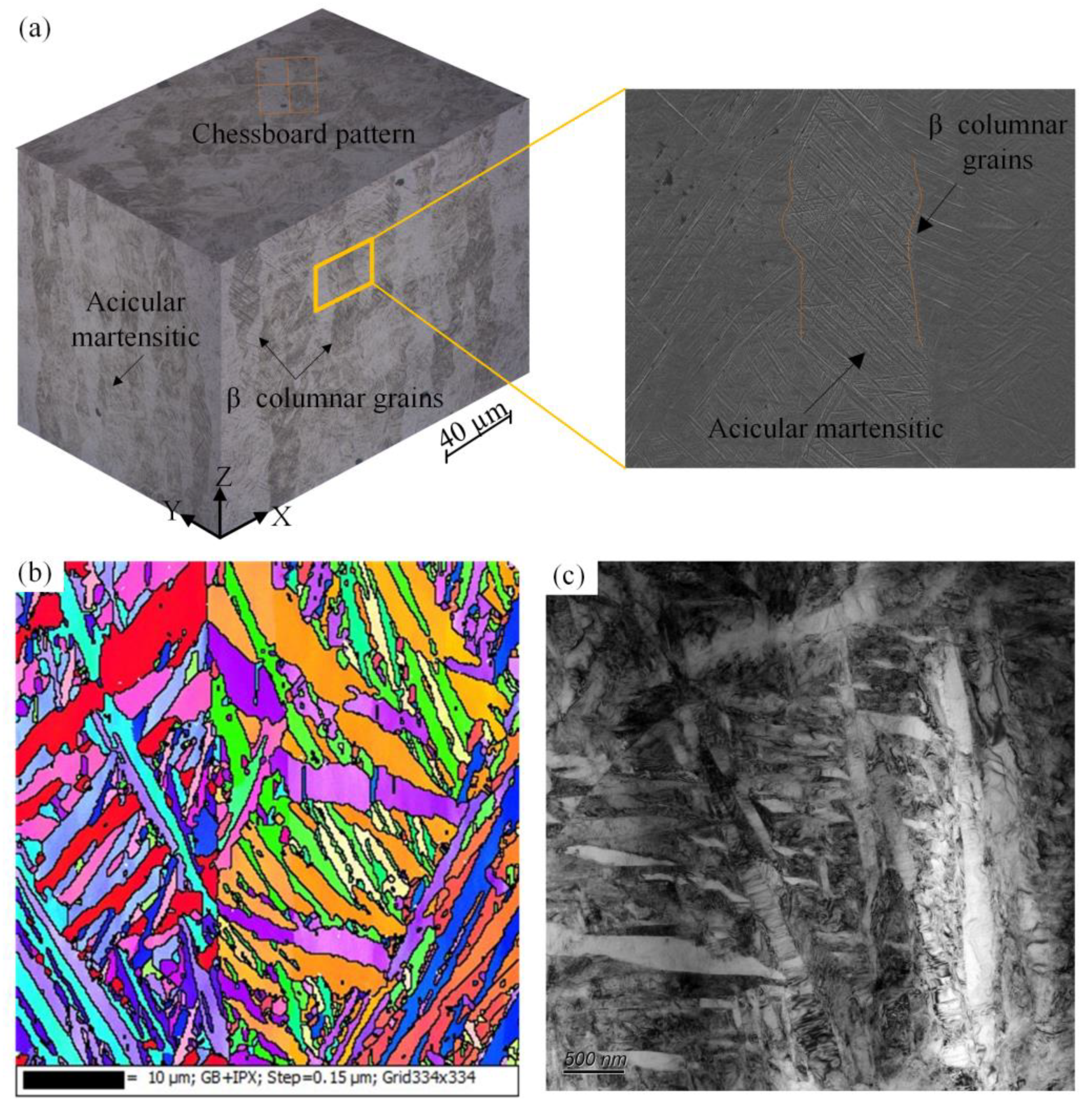

2.2. Microstructure of the LPBFed Ti6Al4V Sample

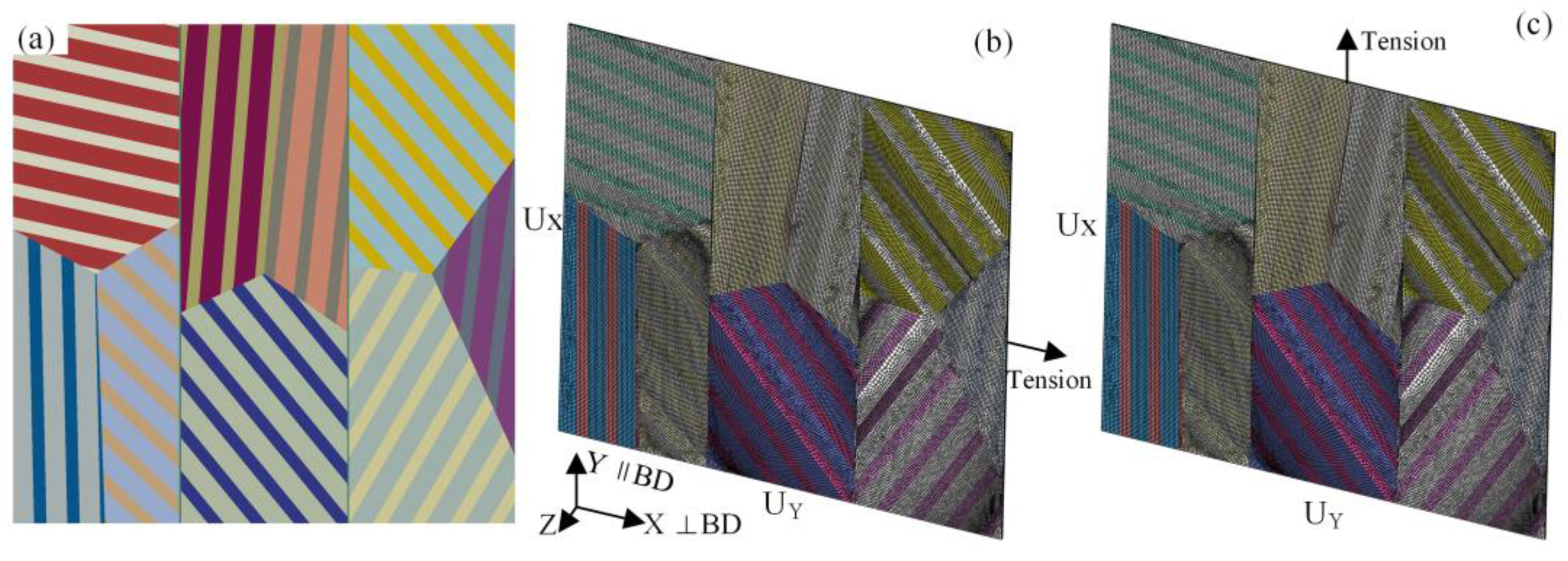

2.3. CPFE Modelling

3. Results and Discussion

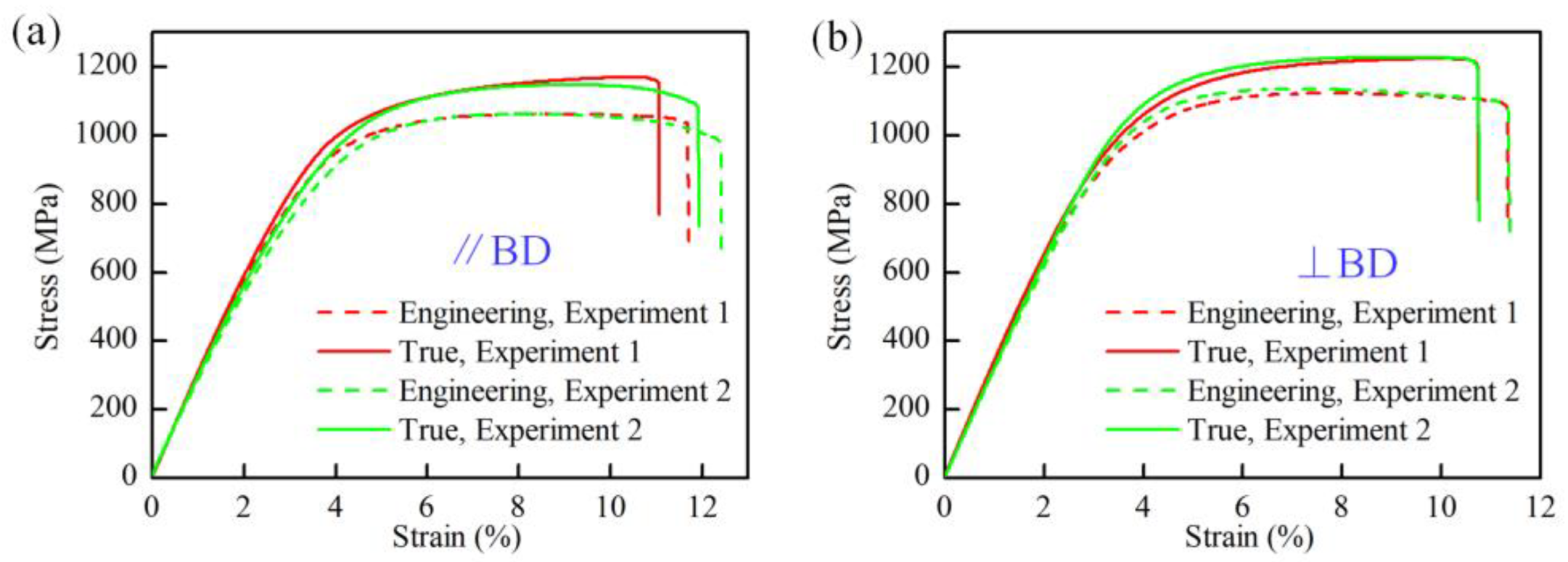

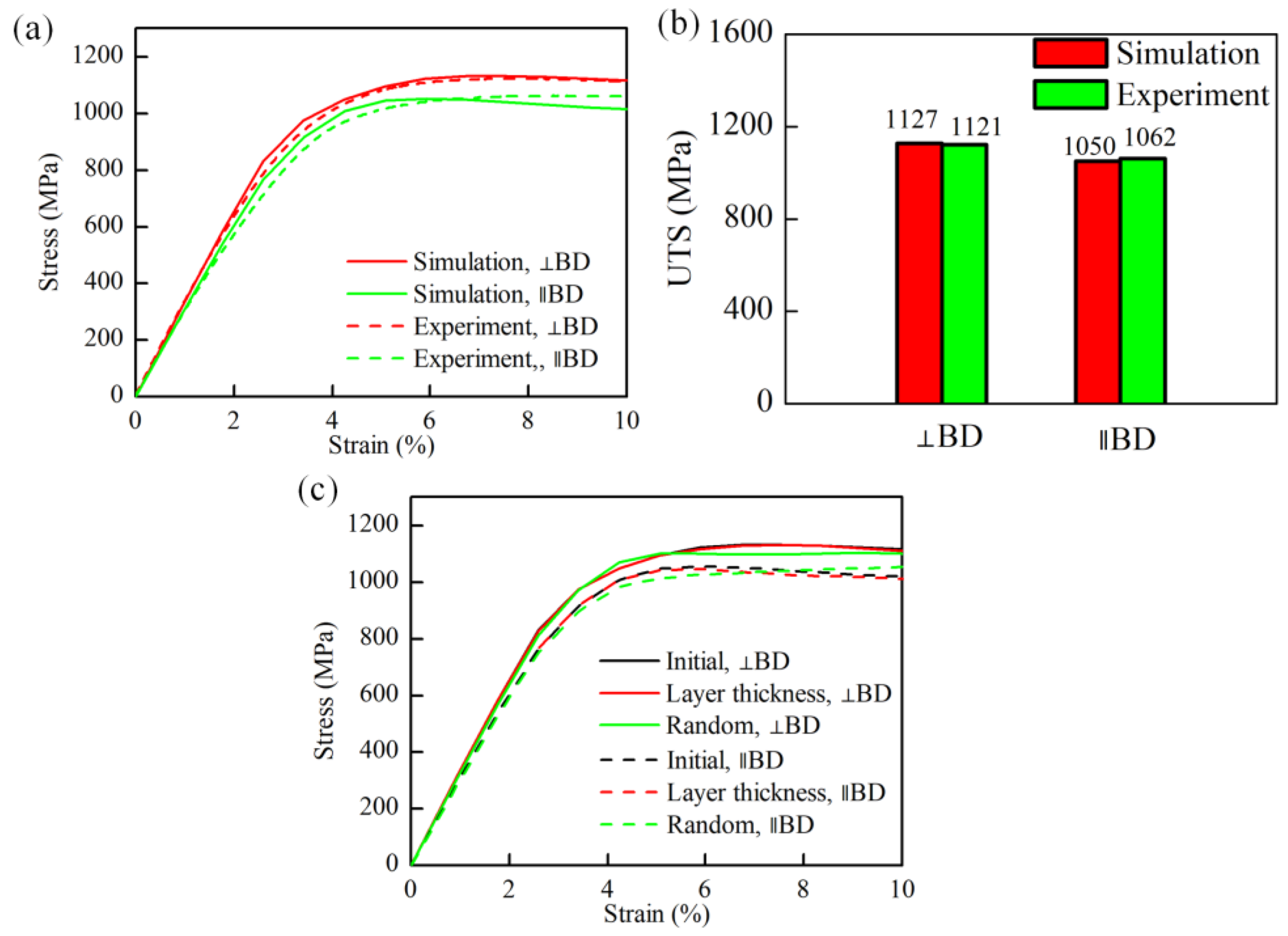

3.1. Anisotropic Mechanical Properties

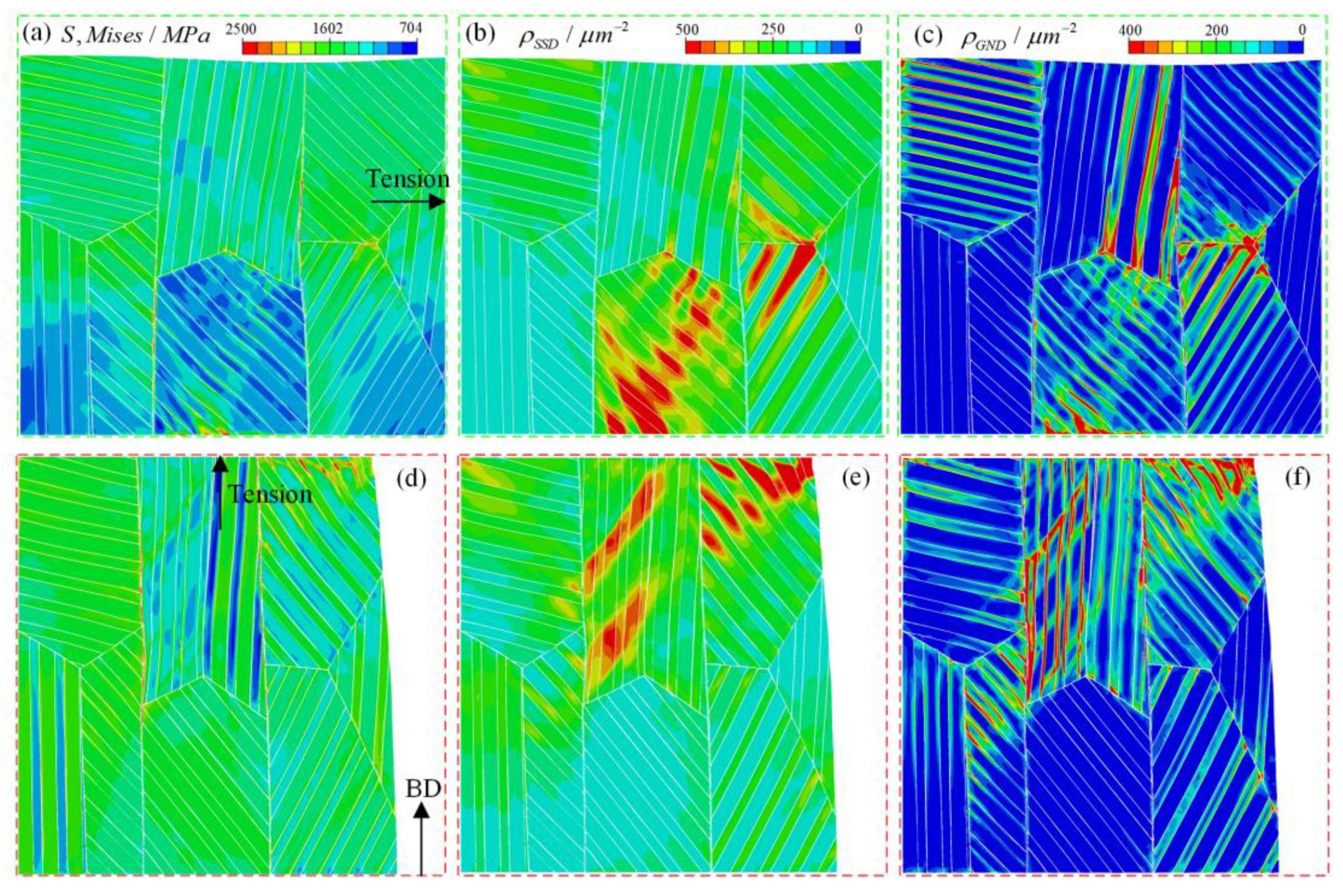

3.2. Effects of Columnar Grains

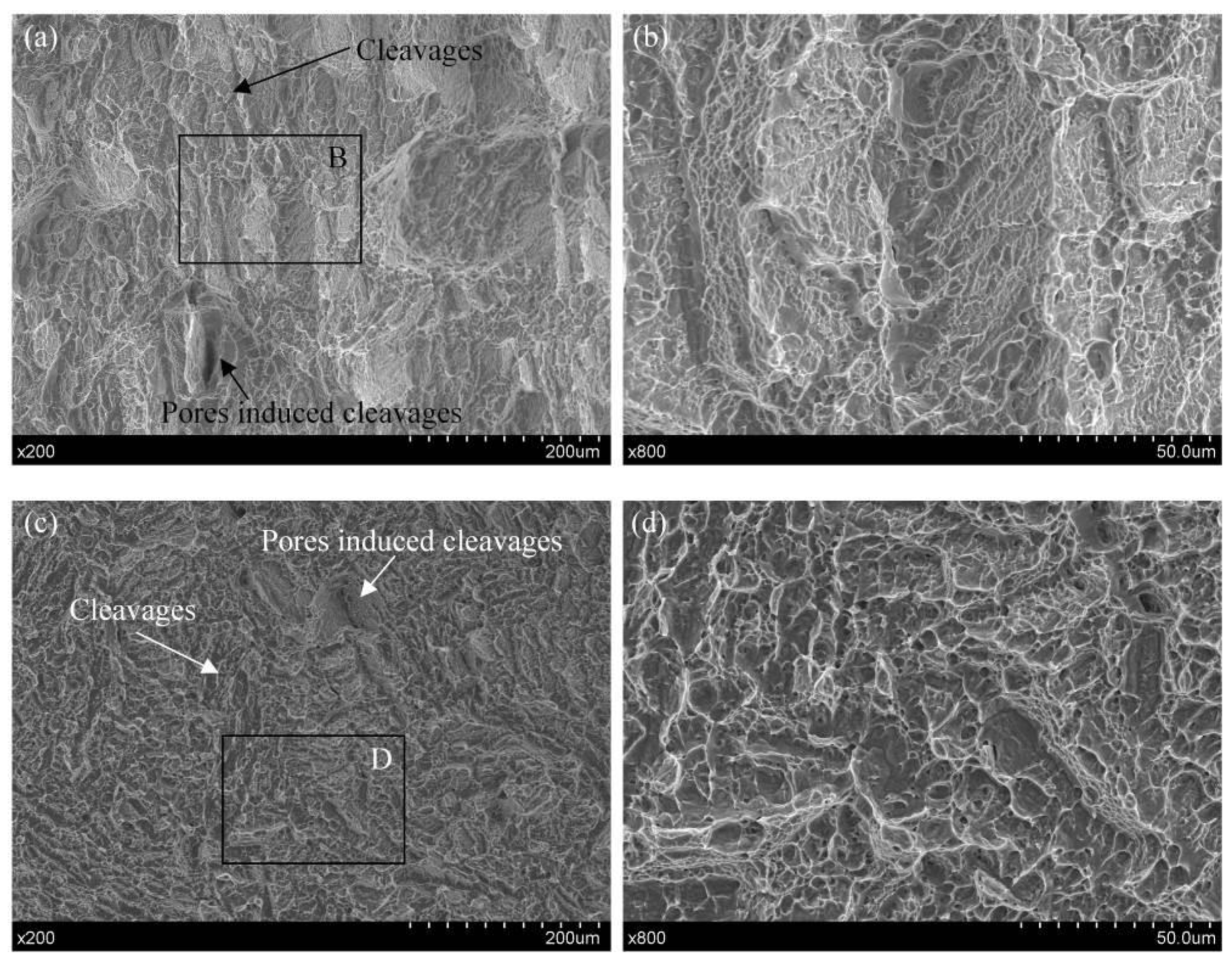

3.3. Fracture Morphology of Tensile Experiments

4. Conclusions

- (1)

- The intricate LPBF process engenders the development of columnar grains that align themselves along the build direction, concomitant with the presence of distinctive lath structures.

- (2)

- Rigorous tensile examinations underscore a marked discrepancy in strength between the material’s behavior perpendicular and parallel to the build direction. The augmented strength exhibited orthogonal to the build direction, compared to its in-line counterpart, manifests in tandem with the strain distribution profiles unveiled by DIC experiments and an analysis of the fracture surfaces, corroborating the pivotal role played by inherent microstructural attributes in dictating the material’s tensile attributes.

- (3)

- A meticulously formulated finite element model that accurately encapsulates columnar grains and laths has been meticulously developed, bearing apt testimony to its fidelity in replicating plastic responses akin to those unveiled through experimental uniaxial tension tests.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jared, B.H.; Aguilo, M.A.; Beghini, L.L.; Boyce, B.L.; Clark, B.W.; Cook, A.; Kaehr, B.J.; Robbins, J. Additive manufacturing: Toward holistic design. Scr. Mater. 2017, 135, 141147. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Pasang, T.; Kirchner, A.; Jehring, U.; Aziziderouei, M.; Tao, Y.; Jiang, C.P.; Wang, J.C.; Aisyah, I.S. Microstructure and mechanical properties of welded additively manufactured stainless steels SS316L. Met. Mater. Int. 2019, 25, 1278–1286. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, B.; Wu, S.; Liu, W. Anisotropic tension-compression asymmetry in SLM 316L stainless steel. Int. J. Mech. Sci. 2023, 246, 108139. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.; Mukherjee, T.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2017, 92, 112–224. [Google Scholar] [CrossRef]

- Liu, L.F.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength-ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Chua, C.K. Simultaneously enhanced strength and ductility for 3D-printed stainless steel 316L by selective laser melting. NPG Asia Mater. 2018, 10, 127–136. [Google Scholar] [CrossRef]

- Xia, M.; Gu, D.; Yu, G.; Dai, D.; Chen, H.; Shi, Q. Porosity evolution and its thermo-dynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tool Manuf. 2017, 116, 96–106. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- DW, D.W.B.; Adams, D.P.; Balogh, L.; Carpenter, J.S.; Clausen, B.; King, G.; Reedlunn, B.; Palmer, T.A.; Maguire, M.C.; Vogel, S.C. In situ neutron diffraction study of the influence of microstructure on the mechanical response of additively manufactured 304L stainless steel. Metall. Mater. Trans. A 2017, 48, 6055–6069. [Google Scholar]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An experimental investigation into additive manufacturing-induced residual stresses in 316L stainless steel. Metall. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Agnew, S.R.; Fitz-Gerald, J.M.; Moore, W.R.; Newman, T.A. High strength and ductility of additively manufactured 316L stainless steel explained. Metall. Mater. Trans. A 2018, 49, 3011–3027. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater. Design. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Kramer, S.L.B.; Jones, A.; Mostafa, A.; Ravaji, B. The third Sandia fracture challenge: Predictions of ductile fracture in additively manufactured metal. Int. J. Frac. 2019, 218, 5–61. [Google Scholar] [CrossRef]

- Garlea, E.; Choo, H.; Sluss, C.C.; Koehler, M.R.; Bridges, R.L.; Xiao, X.; Ren, Y.; Jared, B.H. Variation of elastic mechanical properties with texture, porosity, and defect characteristics in laser powder bed fusion 316L stainless steel. Mater. Sci. Eng. A 2019, 763, 138032. [Google Scholar] [CrossRef]

- Wilson-Heid, A.E.; Qin, S.; Beese, A.M. Multiaxial plasticity and fracture behavior of stainless steel 316L by laser powder bed fusion: Experiments and computational modelling. Acta Mater. 2020, 199, 578–592. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, S.; Shi, G.; Xie, W.; Geng, Y.; Wang, Z. A study on a hybrid SERS substrates based on arrayed gold nanoparticle/graphene/copper cone cavities fabricated by a conical tip indentation. J. Mater. Res. Technol. 2022, 22, 1558–1571. [Google Scholar] [CrossRef]

- Geng, Y.; Harrison, N. Functionally graded bimodal Ti6Al4V fabricated by powder bed fusion additive manufacturing: Crystal plasticity finite element modelling. Mater. Sci. Eng. A 2020, 773, 138736. [Google Scholar] [CrossRef]

- Bronkhorst, C.; Mayeur, J.; Livescu, V.; Pokharel, R.; Brown, D.; Gray, G. Structural representation of additively manufactured 316L austenitic stainless steel. Int. J. Plast. 2019, 118, 70–86. [Google Scholar] [CrossRef]

- Goh, C.-H.; Neu, R.W.; McDowell, D.L. Crystallographic plasticity in fretting of Ti–6Al–4V. Int. J. Plast. 2003, 19, 1627–1650. [Google Scholar] [CrossRef]

- Mayeur, J.R.; McDowell, D.L. A three-dimensional crystal plasticity model for duplex Ti–6Al–4V. Int. J. Plast. 2007, 23, 1457–1485. [Google Scholar] [CrossRef]

- Venkatramani, G.; Ghosh, S.; Mills, M. A size-dependent crystal plasticity finite-element model for creep and load shedding in polycrystalline titanium alloys. Acta Mater. 2007, 55, 3971–3986. [Google Scholar] [CrossRef]

- Chatterjee, K.; Echlin, M.P.; Kasemer, M.; Callahan, P.G.; Pollock, T.M.; Dawson, P. Prediction of tensile stiffness and strength of Ti–6Al–4V using instantiated volume elements and crystal plasticity. Acta Mater. 2018, 157, 21–32. [Google Scholar] [CrossRef]

- Thomas, J.; Groeber, M.; Ghosh, S. Image-based crystal plasticity FE framework for microstructure dependent properties of Ti–6Al–4V alloys. Mater. Sci. Eng. A 2012, 553, 164–175. [Google Scholar] [CrossRef]

- Venkatramani, G.; Kirane, K.; Ghosh, S. Microstructural parameters affecting creep induced load shedding in Ti-6242 by a size dependent crystal plasticity FE model. Int. J. Plast. 2008, 28, 428–454. [Google Scholar] [CrossRef]

- Somlo, K.; Frodal, B.; Funch, C.; Poulios, K.; Winther, G.; Hopperstad, O.; Børvik, T.; Niordson, C. Anisotropic yield surfaces of additively manufactured metals simulated with crystal plasticity. Eur. J. Mech. A 2022, 94, 104506. [Google Scholar] [CrossRef]

- Sun, X.; Choi, K.S.; Liu, W.N.; Khaleel, M.A. Predicting failure modes and ductility of dual phase steels using plastic strain localization. Int. J. Plast. 2009, 25, 1888–1909. [Google Scholar] [CrossRef]

- Azhari, F.; Wallbrink, C.; Sterjovski, Z.; Crawford, B.R.; Menzel, A.; Agiu, D.; Wang, C.H.; Chaffer, G.S. Predicting the complete tensile properties of additively manufactured Ti-6Al-4V by integrating three-dimensional microstructure statistics with a crystal plasticity model. Int. J. Plast. 2022, 148, 103127. [Google Scholar] [CrossRef]

- Wang, X.; Cazes, F.; Li, J.; Hocini, A.; Ameyama, K.; Dirras, G. A 3D crystal plasticity model of monotonic and cyclic simple shear deformation for commercial-purity polycrystalline Ti with a harmonic structure. Mech. Mater. 2019, 128, 117–128. [Google Scholar] [CrossRef]

- Zhao, N.; Roy, A.; Wang, W.; Zhao, L.; Silberschmidt, V.V. Coupling crystal plasticity and continuum damage mechanics for creep assessment in Cr-based power-plant steel. Mech. Mater. 2019, 130, 29–38. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.Y.; Zhang, Y.Q.; Zhu, X.M.; Sun, D. Texture evolution and inhomogeneous deformation of polycrystalline Cu based on crystal plasticity finite element method and particle swarm optimization algorithm. J. Cent. South Univ. 2017, 24, 2747–2756. [Google Scholar] [CrossRef]

- Liu, W.; Chen, B.K.; Pang, Y. Numerical investigation of evolution of earing, anisotropic yield and plastic potentials in cold rolled FCC aluminium alloy based on the crystallographic texture measurements. Eur. J. Mech. A/Solids 2019, 75, 41–55. [Google Scholar] [CrossRef]

- Lu, J.Z.; Lu, H.F.; Xu, X.; Yao, J.H.; Cai, J.; Luo, K.Y. High-performance integrated additive manufacturing with laser shock peening-induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components. Int. J. Mach. Tool Manufact. 2020, 148, 103475. [Google Scholar] [CrossRef]

- Baufeld, B.; Biest, O.V.D.; Dillien, S. Texture and crystal orientation in Ti-6Al-4V builds fabricated by shaped metal deposition. Metall. Mater. Trans. A 2010, 41, 1917–1927. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Rice, J. Inelastic constitutive relations for solids: An internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 1971, 19, 433–455. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Lu, J. Effects of crystallographic orientations and grain boundaries on nanoscratching behaviour of unique bi-crystal Cu. Wear 2022, 498, 204313. [Google Scholar] [CrossRef]

- Kalidindi, S.R. Incorporation of deformation twinning in crystal plasticity models. J. Mech. Phys. Solids 1998, 46, 267–290. [Google Scholar] [CrossRef]

- Ma, A.; Hartmaier, A. On the influence of isotropic and kinematic hardening caused by strain gradients on the deformation behaviour of polycrystals. Philos. Mag. 2014, 94, 125–140. [Google Scholar] [CrossRef]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Kapoor, K.; Ravi, P.; Noraas, R.; Park, J.-S.; Venkatesh, V.; Sangid, M.D. Modeling Ti–6Al–4V using crystal plasticity, calibrated with multi-scale experiments, to understand the effect of the orientation and morphology of the α and β phases on time dependent cyclic loading. J. Mech. Phys. Solids 2021, 146, 104192. [Google Scholar] [CrossRef]

- Waheed, S.; Zheng, Z.; Balint, D.S.; Dunne, F.P.E. Microstructural effects on strain rate and dwell sensitivity in dual-phase titanium alloys. Acta Mater. 2019, 162, 136–148. [Google Scholar] [CrossRef]

- Cai, W.; Song, Q.; Ji, H.; Liu, Z. Dual-phase morphology distribution effects on mechanical behaviors of Ti6Al4V via pseudorandom crystal plasticity modeling. J. Mater. Res. Technol. 2022, 17, 2897–2912. [Google Scholar] [CrossRef]

- Xie, Z.; Dai, Y.; Ou, X.; Ni, S.; Song, M. Effects of selective laser melting build orientations on the microstructure and tensile performance of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2020, 776, 139001. [Google Scholar] [CrossRef]

- Sabban, R.; Bahl, S.; Chatterjee, K.; Suwas, S. Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 2019, 1, 239–254. [Google Scholar] [CrossRef]

| Process | Energy Source | Deposition Parameters | Scanning Strategy | |||||

|---|---|---|---|---|---|---|---|---|

| LPBF | Type | Wavelength [nm] | Power [W] | Spot diameter [μm] | Scanning speed [mm/s] | Hatch distance [μm] | Layer thickness [μm] | Bidirectional with 90° rotation in each layer |

| Pulsed laser | 400 | 280 | 100 | 1200 | 140 | 30 | ||

| Parameter | α Phase | β Phase |

|---|---|---|

| Elastic constants (GPa) | C11 = 89.0 C12 = 39.0 C44 = 24.0 C13 = 42.0 C33 = 126.0 | C11 = 68.250 C12 = 53.000 C44 = 30.390 |

| (μm2) | 5.71 × 10−2 | 5.71 × 10−2 |

| (Hz) | 8.75 × 1012 | 8.75 × 1012 |

| (nm) | 0.295 | 0.286 |

| 0.4247 | 0.3340 | |

| (JK−1) | 1.38 × 1023 | 1.38 × 1023 |

| (K) | 293 | 293 |

| (nm3) | 1.22b3 | 2.10 × 10−3b3 |

| (MPa) | Basal: 397.95 Prism: 574.21 Pyramidal: 778.0 | 370.60 |

| (GPa) | 40.0 | 54.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Xu, M.; Liu, X.; Lin, Q.; Huang, X.; Zhang, H. Experimental and Crystal Plasticity Finite Element Investigations of Plastic Anisotropy in Additively Manufactured Ti6Al4V Alloy. Metals 2024, 14, 130. https://doi.org/10.3390/met14010130

Wang Z, Xu M, Liu X, Lin Q, Huang X, Zhang H. Experimental and Crystal Plasticity Finite Element Investigations of Plastic Anisotropy in Additively Manufactured Ti6Al4V Alloy. Metals. 2024; 14(1):130. https://doi.org/10.3390/met14010130

Chicago/Turabian StyleWang, Zhanfeng, Mengyu Xu, Xiao Liu, Qing Lin, Xiaoxuan Huang, and Hongmei Zhang. 2024. "Experimental and Crystal Plasticity Finite Element Investigations of Plastic Anisotropy in Additively Manufactured Ti6Al4V Alloy" Metals 14, no. 1: 130. https://doi.org/10.3390/met14010130

APA StyleWang, Z., Xu, M., Liu, X., Lin, Q., Huang, X., & Zhang, H. (2024). Experimental and Crystal Plasticity Finite Element Investigations of Plastic Anisotropy in Additively Manufactured Ti6Al4V Alloy. Metals, 14(1), 130. https://doi.org/10.3390/met14010130