Evaluation of Austenitic Stainless Steel ER308 Coating on H13 Tool Steel by Robotic GMAW Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Heat Input Calculation

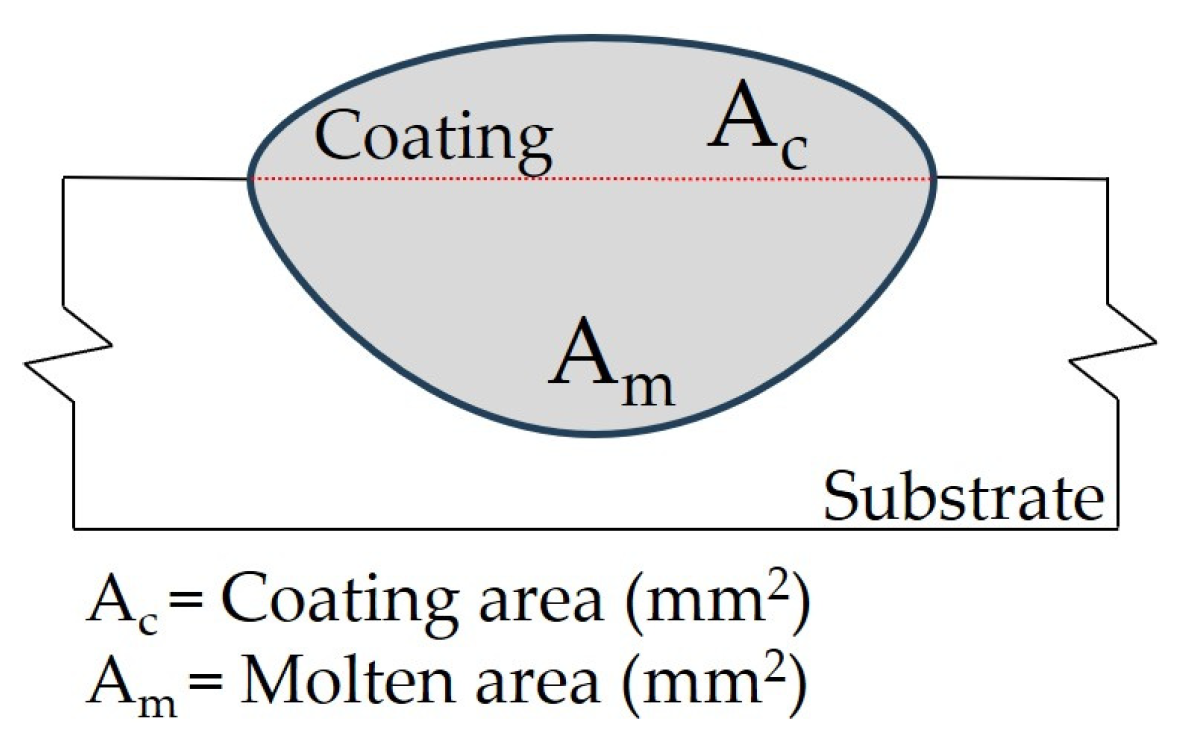

2.2. Dilution Percent Calculation

2.3. Macro- and Microstructural Characterization

2.4. Microhardness

2.5. Pin-on-Disk Test

3. Results and Discussion

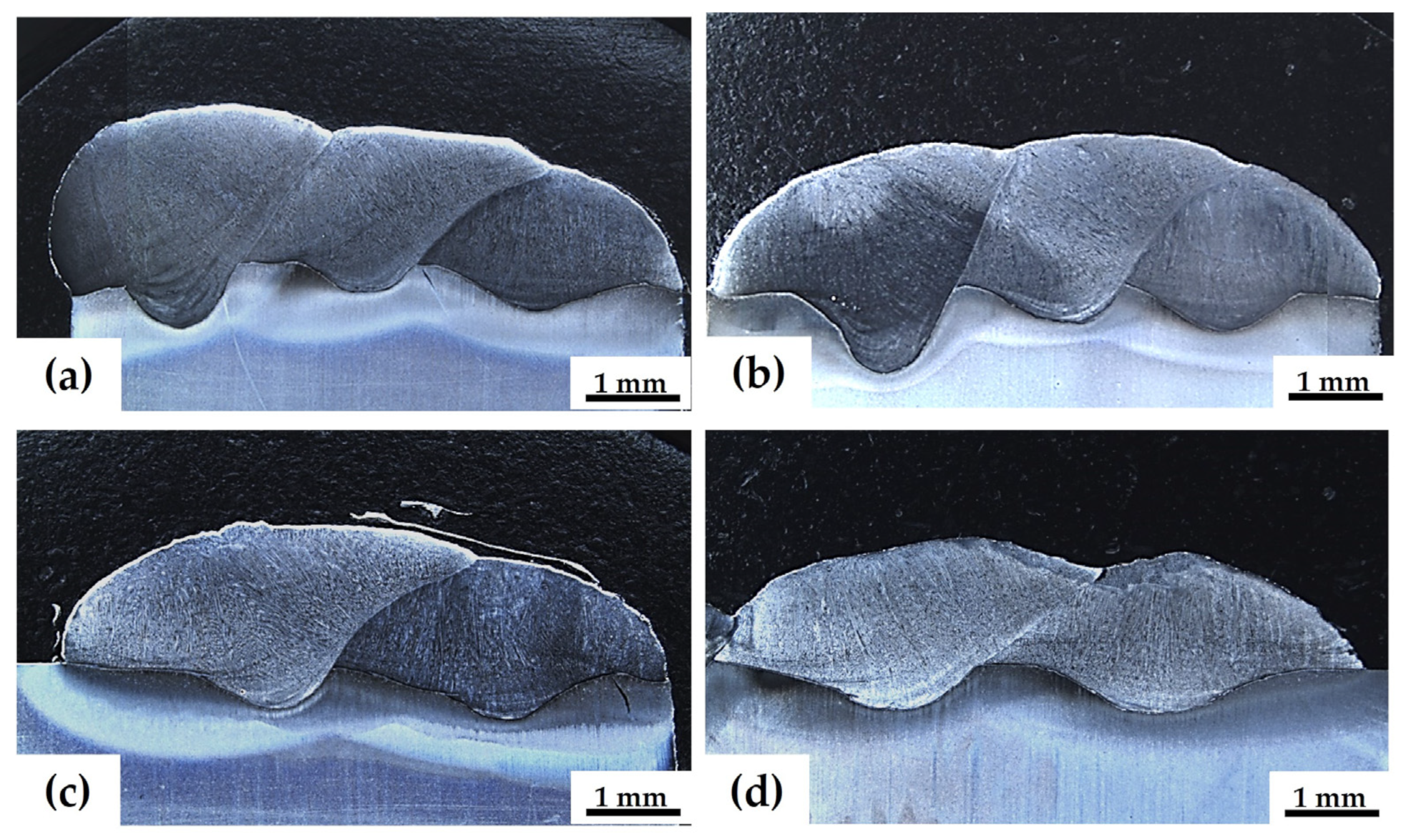

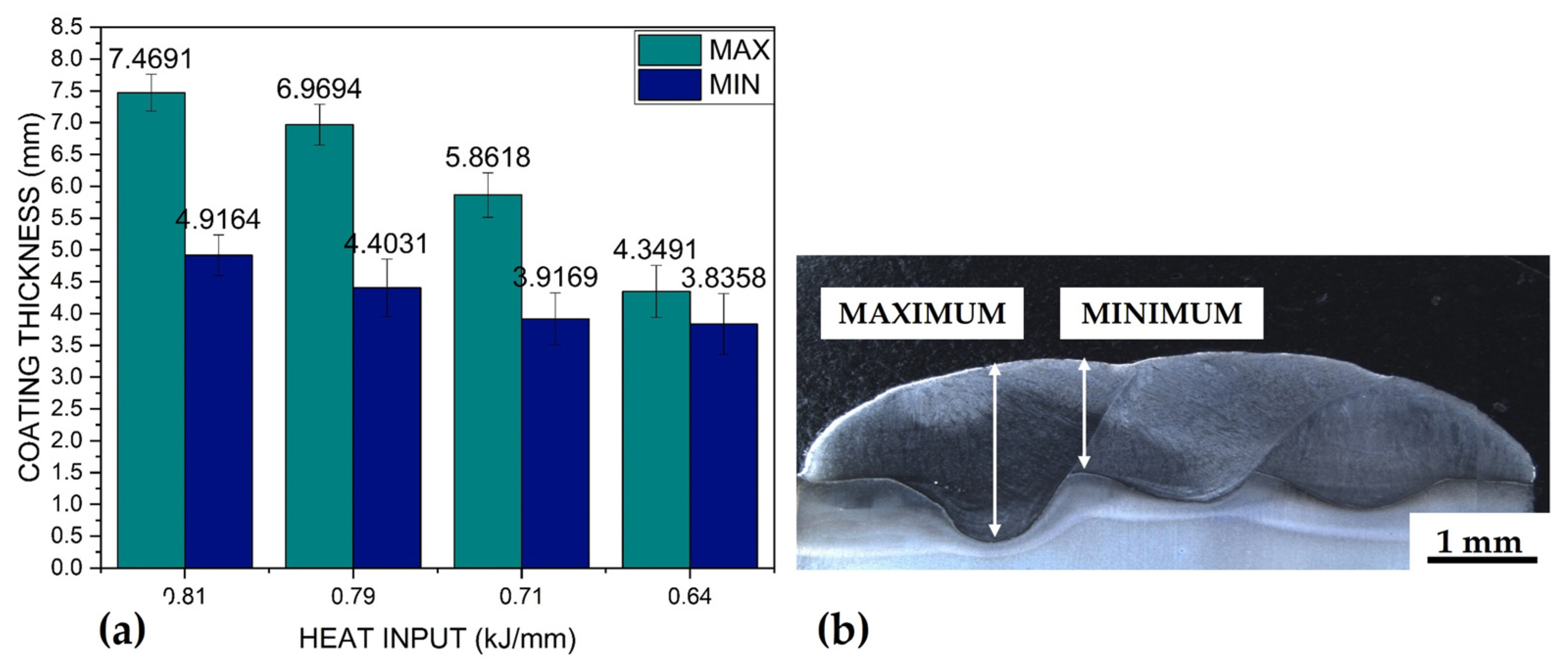

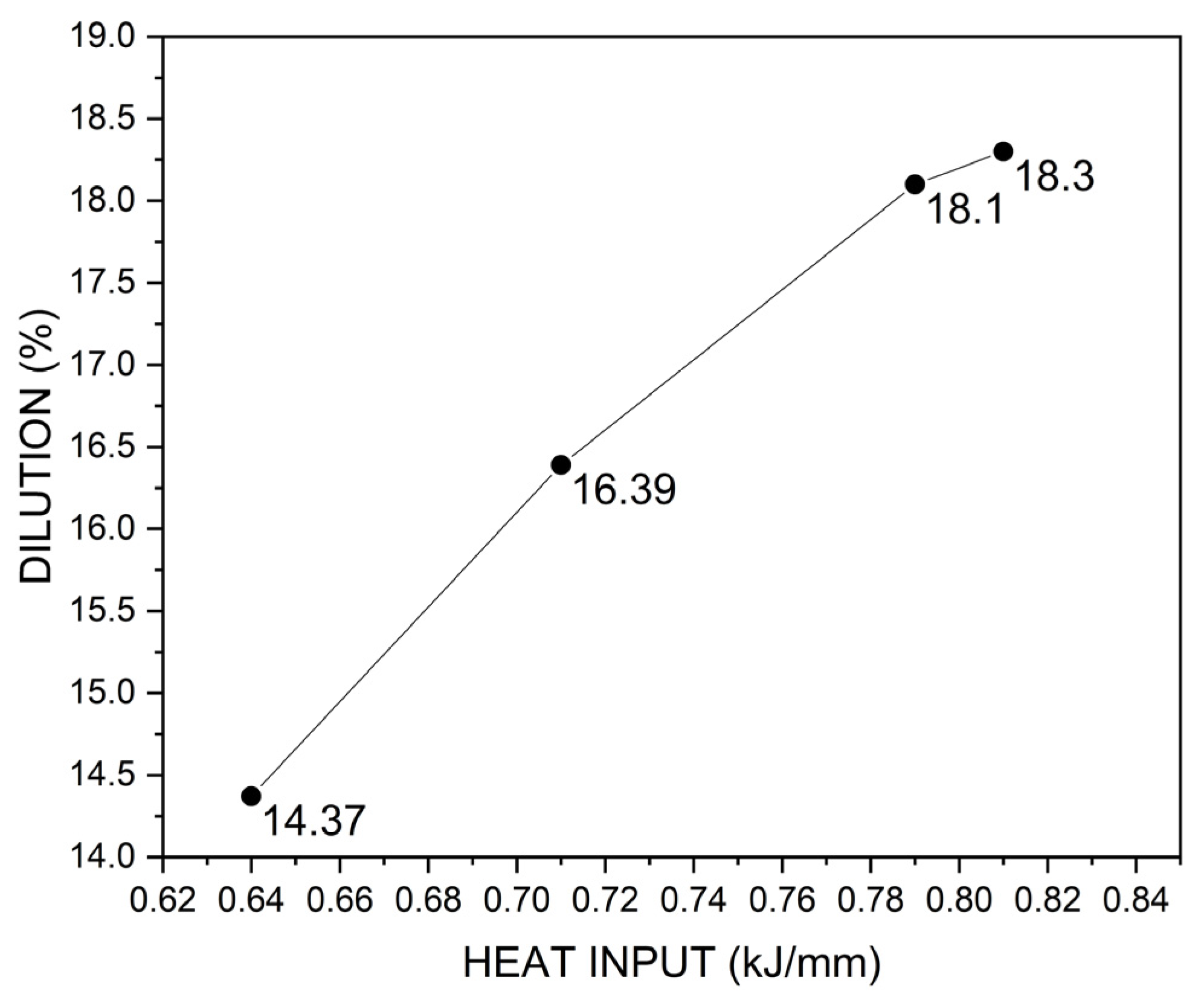

3.1. Macrostructure of Welds and Dilution Percentage

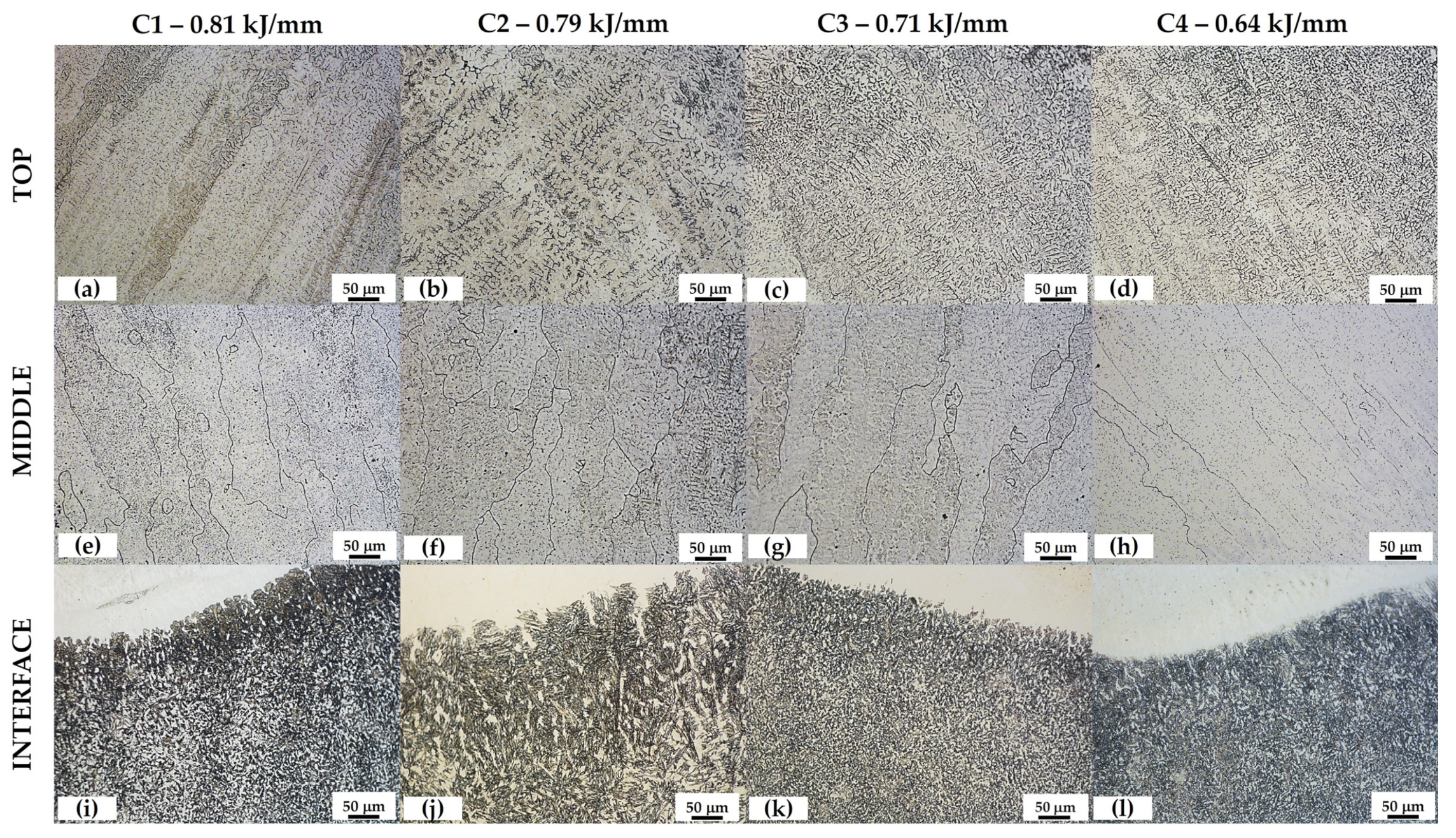

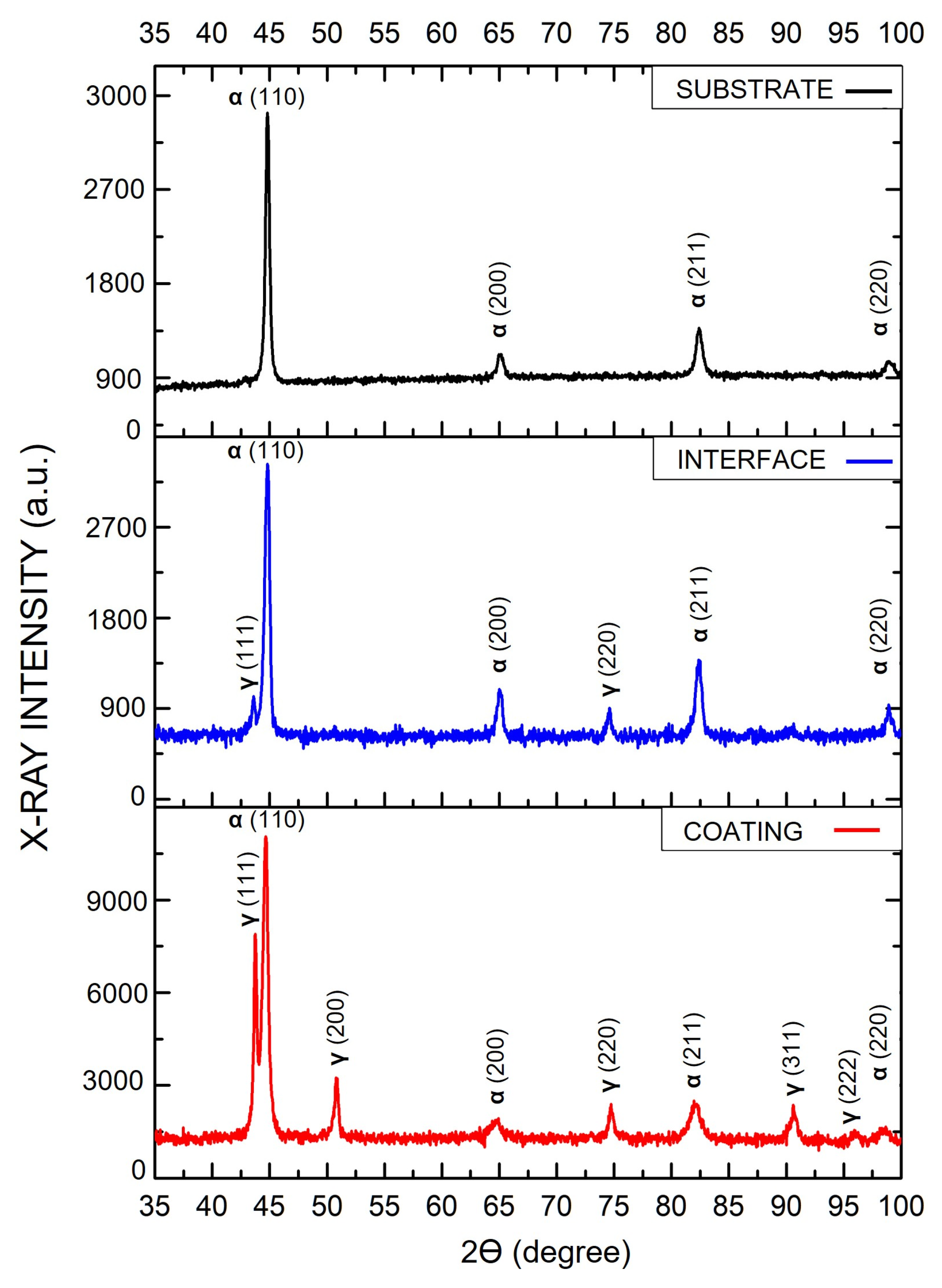

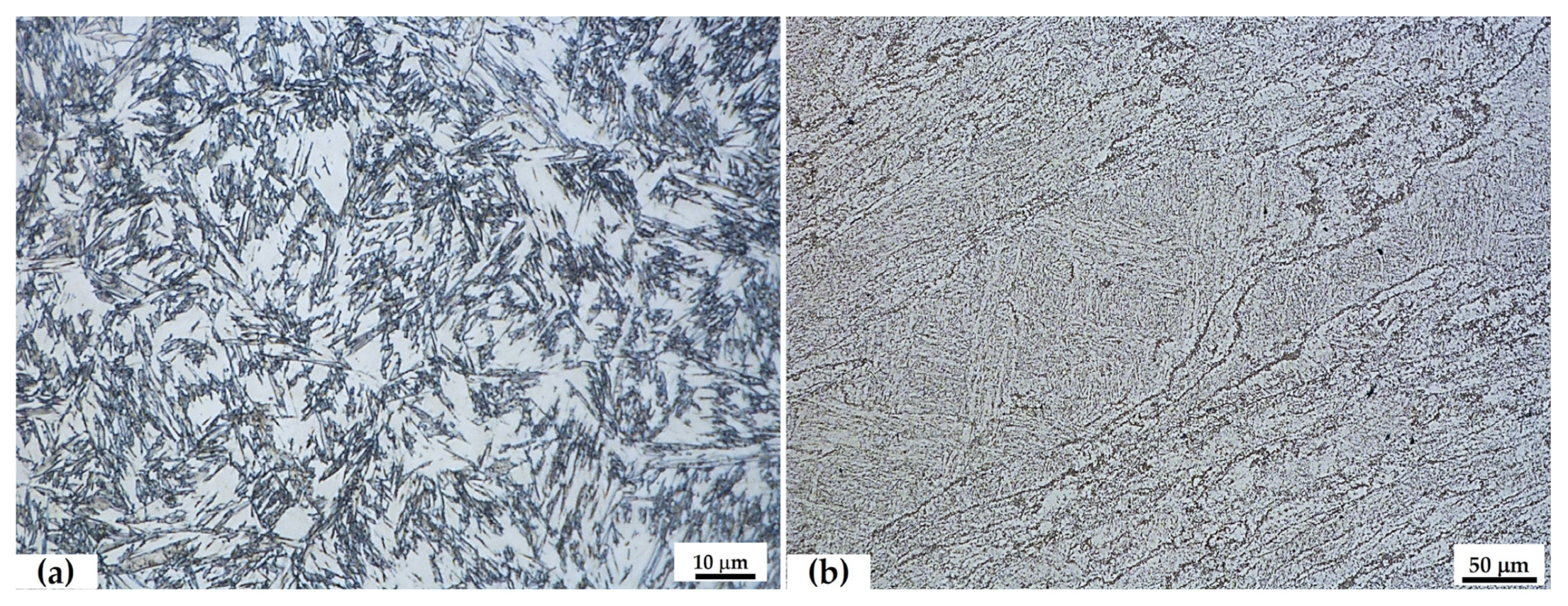

3.2. Microstructure and XRD Measurements

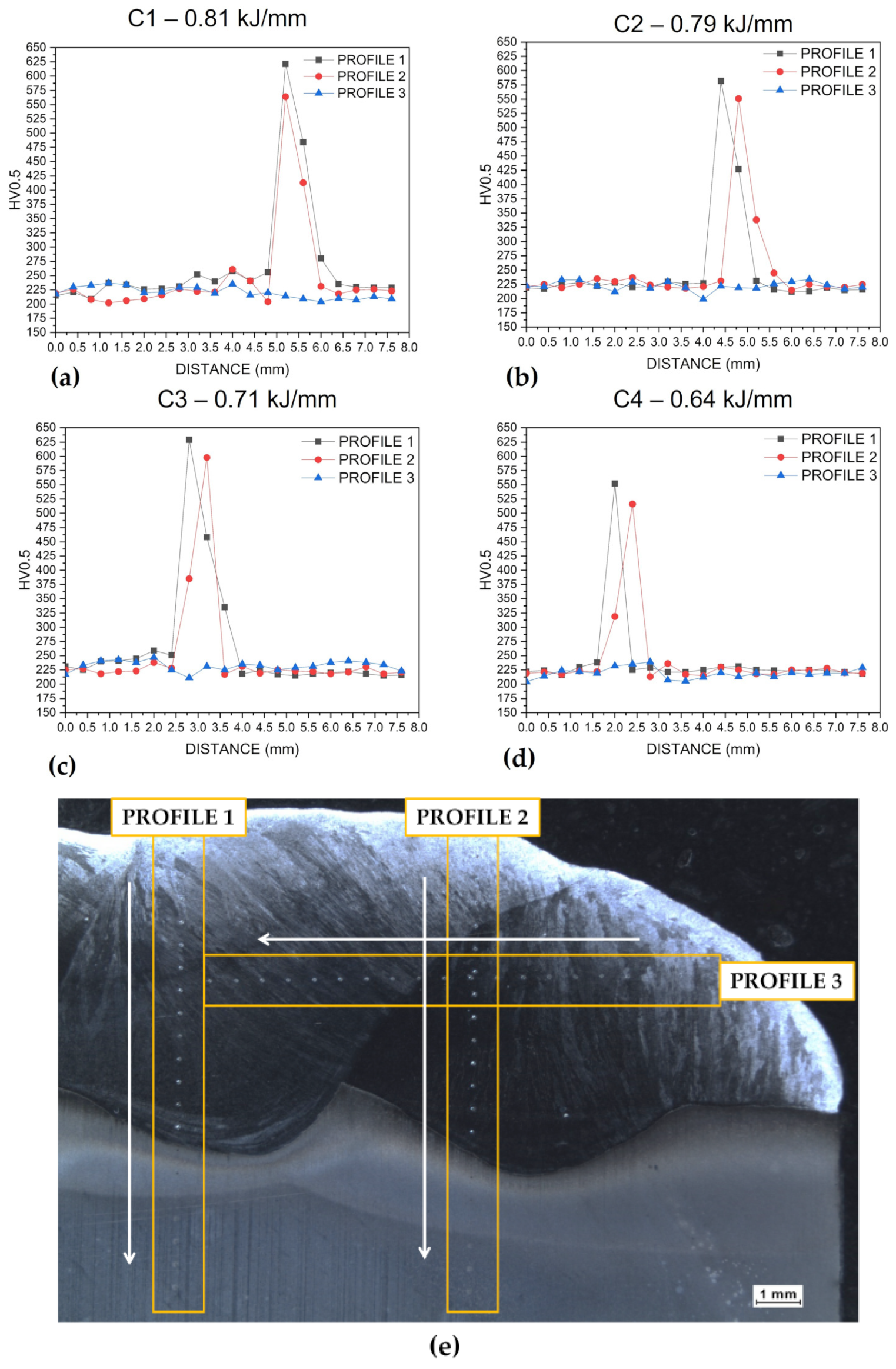

3.3. Microhardness Test

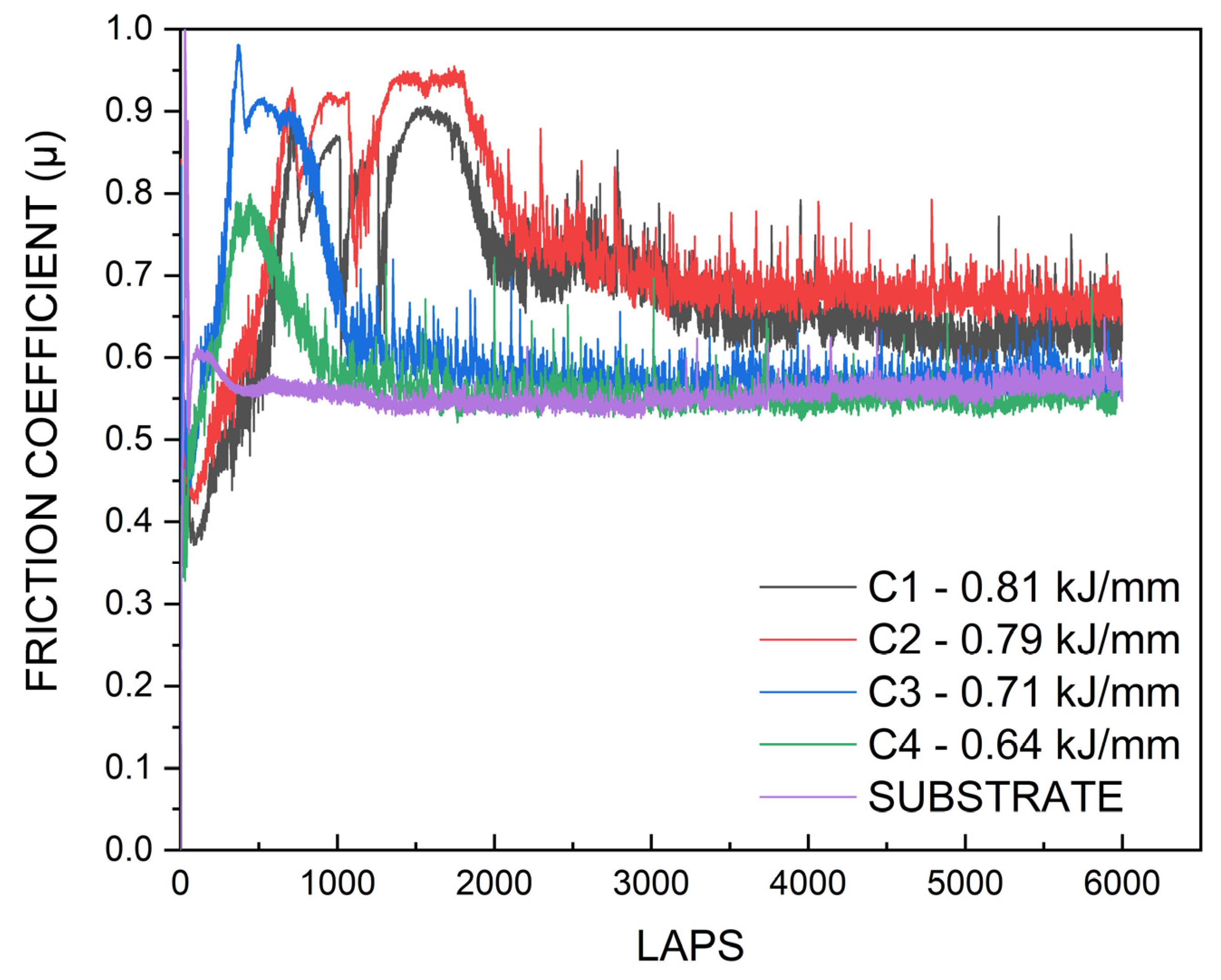

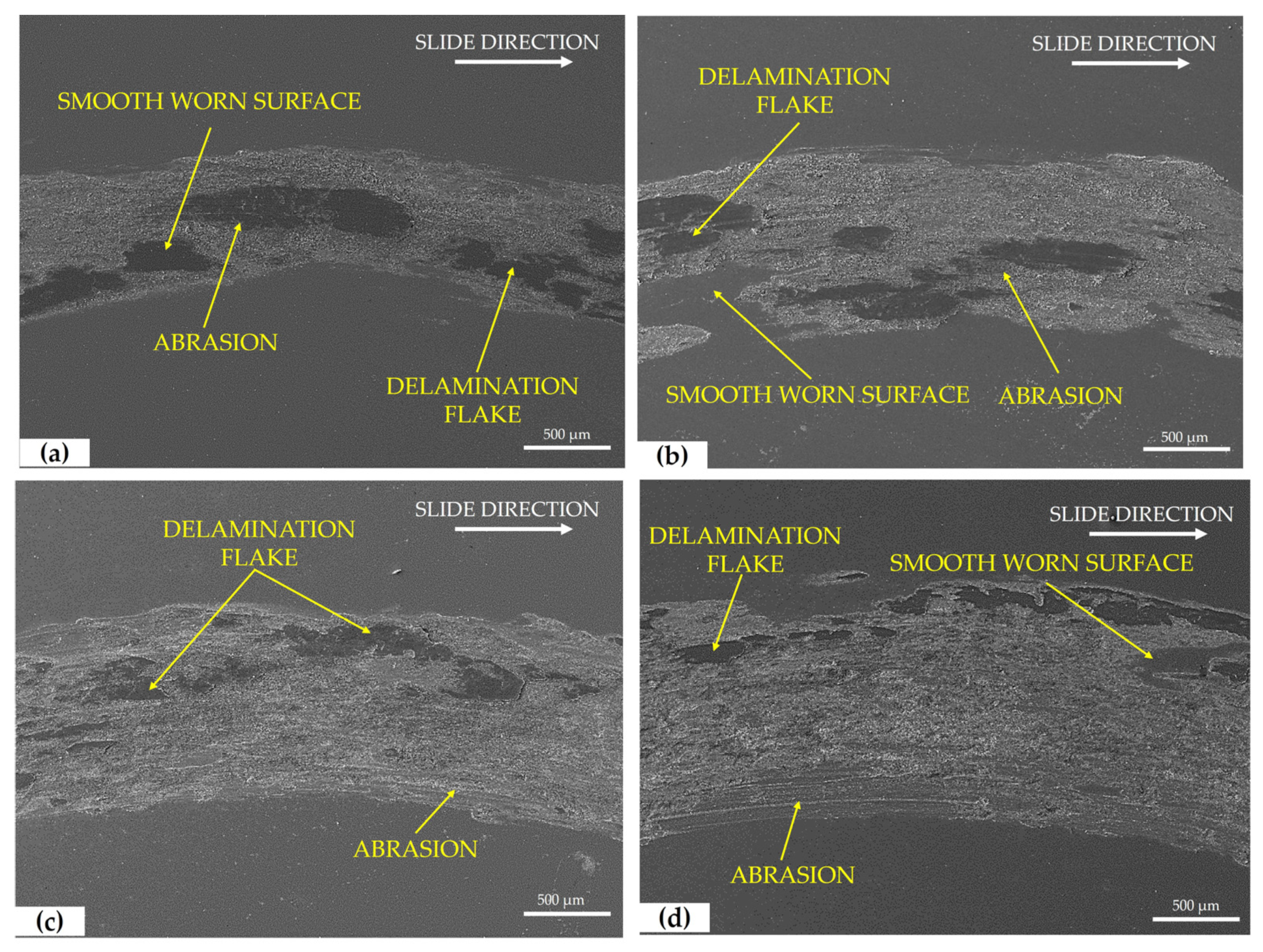

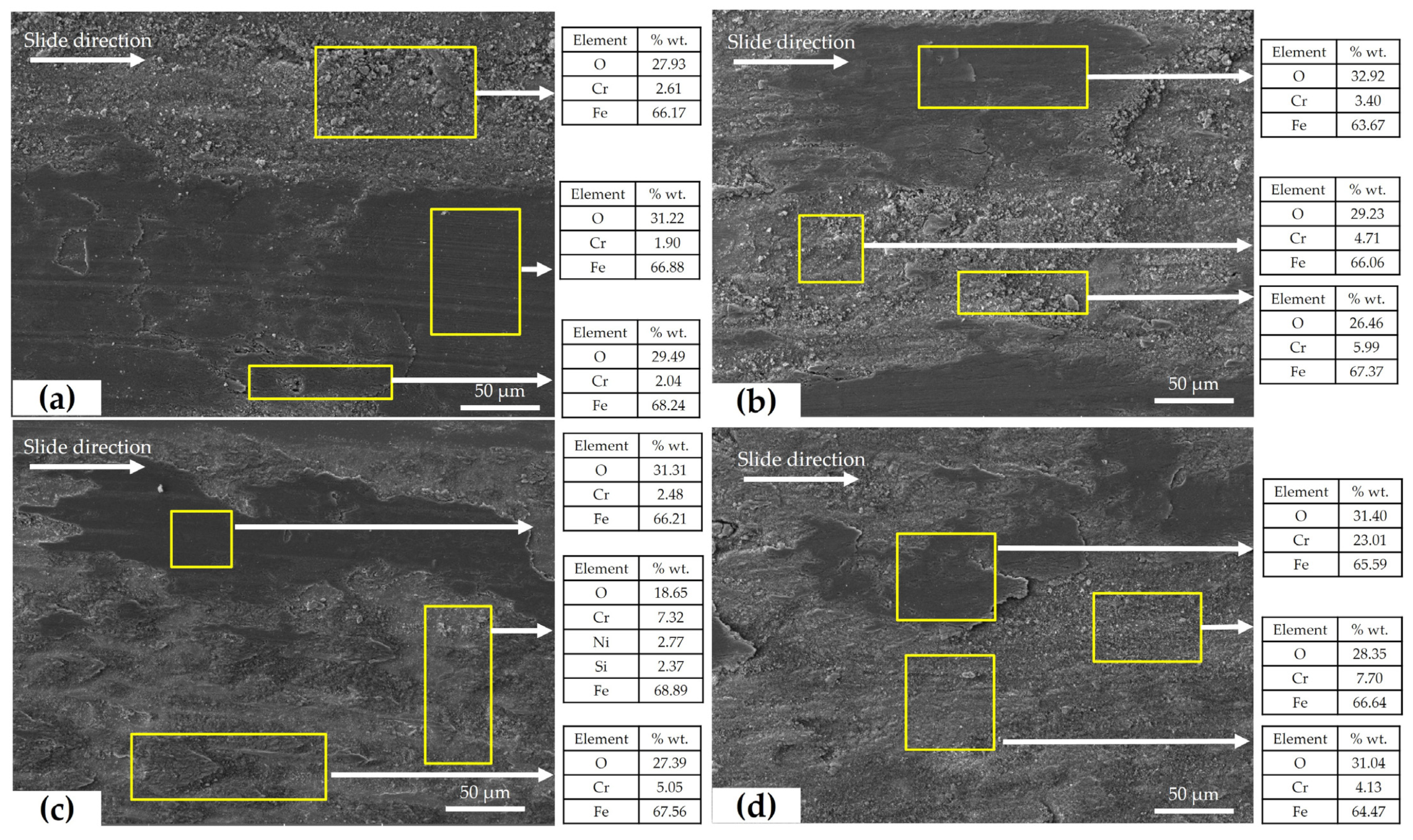

3.4. Wear Test

4. Conclusions

- No visible discontinuities such as pores, cracks, or lack of fusion were observed in any of the coatings.

- The thickness of the coating and its dilution are directly related to the heat input. For a high heat input (0.81 kJ/mm), the dilution percentage and the maximum coating thickness reach higher values (18.3% and 7.46 mm, respectively) compared to the values obtained with lower heat input 0.64 kJ/mm (14.3%—4.34 mm).

- In all samples, the coating mainly consists of austenite, with lathy ferrite at the top of the coating and columnar austenitic grains in the center. The interface shows the presence of austenite and quenched martensite.

- Microhardness tests revealed that the coating and the substrate have similar hardness values, which increase significantly at the interface, reaching a maximum of 625 HV due to the presence of martensite in this area.

- Samples with a higher heat input (0.81, 0.79 kJ/mm) exhibited greater wear resistance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, S.-H.; Tsai, B.-C.; Huang, K.-T.; Yang, C.-H. Investigation of the Wear and Corrosion Behaviors of CrN Films onto Oxynitriding-Treated AISI H13 Alloy Steel by the Direct Current Magnetron Sputtering Process. Thin Solid Films 2022, 758, 139434. [Google Scholar] [CrossRef]

- Kotarska, A.; Poloczek, T.; Janicki, D. Characterization of the Structure, Mechanical Properties and Erosive Resistance of the Laser Cladded Inconel 625-Based Coatings Reinforced by TiC Particles. Materials 2021, 14, 2225. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Carmona, J.M.; Mambuscay, C.L.; Ortega-Portilla, C.; Hurtado-Macias, A.; Piamba, J.F. TiNbN Hard Coating Deposited at Varied Substrate Temperature by Cathodic Arc: Tribological Performance under Simulated Cutting Conditions. Materials 2023, 16, 4531. [Google Scholar] [CrossRef] [PubMed]

- Grossi, E.; Baroni, E.; Aprile, A.; Fortini, A.; Zerbin, M.; Merlin, M. Tribological Behavior of Structural Steel with Different Surface Finishing and Treatments for a Novel Seismic Damper. Coatings 2023, 13, 135. [Google Scholar] [CrossRef]

- Di Schino, A.; Porcu, G.; Scoppio, L.; Longobardo, M.; Turconi, G.L. Metallurgical Design and Development of C125 Grade for Mild Sour Service Application. In Proceedings of the NACE CORROSION CONFERENCE SERIES, San Diego, CA, USA, 12–16 March 2006; pp. 061251–0612514. Available online: https://onepetro.org/NACECORR/proceedings-abstract/CORR06/All-CORR06/NACE-06125/118115 (accessed on 19 December 2023).

- Di Schino, A.; Valentini, L.; Kenny, J.M.; Gerbig, Y.; Ahmed, I.; Haefke, H. Wear resistance of a high-nitrogen austenitic stainless steel coated with nitrogenated amorphous carbon films. Surf. Coat. Technol. 2002, 161, 224–231. [Google Scholar] [CrossRef]

- Stornelli, G.; Gaggiotti, M.; Mancini, S.; Napoli, G.; Rocchi, C.; Tirasso, C.; Di Schino, A. Recrystallization and Grain Growth of AISI 904L Super-Austenitic Stainless Steel: A Multivariate Regression Approach. Metals 2022, 12, 200. [Google Scholar] [CrossRef]

- Ranjan, R.; Kumar Das, A. Protection from Corrosion and Wear by Different Weld Cladding Techniques: A Review. Mater. Today Proc. 2022, 57, 1687–1693. [Google Scholar] [CrossRef]

- Liu, T.; Chang, M.; Cheng, X.; Zeng, X.; Shao, H.; Liu, F. Characteristics of WC Reinforced Ni-Based Alloy Coatings Prepared by PTA + PMI Method. Surf. Coat. Technol. 2020, 383, 125232. [Google Scholar] [CrossRef]

- Magarò, P.; Marino, A.L.; Di Schino, A.; Furgiuele, F.; Maletta, C.; Pileggi, R.; Sgambitterra, E.; Testani, C.; Tului, M. Effect of Process Parameters on the Properties of Stellite-6 Coatings Deposited by Cold Gas Dynamic Spray. Surf. Coat. Technol. 2019, 377, 124934. [Google Scholar] [CrossRef]

- Aslam, M.; Sahoo, C.K. Development of Hard and Wear-Resistant SiC-AISI304 Stainless Steel Clad Layer on Low Carbon Steel by GMAW Process. Mater. Today Commun. 2023, 36, 106444. [Google Scholar] [CrossRef]

- Kumar, V.; Ranjan Sahu, D.; Mandal, A. Parametric Study and Optimization of GMAW Based AM Process for Multi-Layer Bead Deposition. Mater. Today Proc. 2022, 62, 255–261. [Google Scholar] [CrossRef]

- Di Schino, A.; Kenny, J.M.; Barteri, M. High temperature resistance of a high nitrogen and low nickel austenitic stainless steel. J. Mat. Sci. Lett. 2003, 22, 691–693. [Google Scholar] [CrossRef]

- Di Schino, A.; Kenny, J.M.; Salvatori, I.; Abbruzzese, G. Modelling primary recrystallization and grain growth in a low nickel austenitic stainless steel. J. Mater. Sci. 2001, 36, 593–601. [Google Scholar] [CrossRef]

- Kang, K.; Kawahito, Y.; Gao, M.; Zeng, X. Effects of Laser-Arc Distance on Corrosion Behavior of Single-Pass Hybrid Welded Stainless Clad Steel Plate. Mater. Des. 2017, 123, 80–88. [Google Scholar] [CrossRef]

- Li, C.; Qin, G.; Tang, Y.; Zhang, B.; Lin, S.; Geng, P. Microstructures and Mechanical Properties of Stainless Steel Clad Plate Joint with Diverse Filler Metals. J. Mater. Res. Technol. 2020, 9, 2522–2534. [Google Scholar] [CrossRef]

- Vlasov, I.V.; Gordienko, A.I.; Eremin, A.V.; Semenchuk, V.M.; Kuznetsova, A.E. Structure and Mechanical Behavior of Heat-Resistant Steel Manufactured by Multilayer Arc Deposition. Metals 2023, 13, 1375. [Google Scholar] [CrossRef]

- Valiente Bermejo, M.A.; Eyzop, D.; Hurtig, K.; Karlsson, L. Welding of Large Thickness Super Duplex Stainless Steel: Microstructure and Properties. Metals 2021, 11, 1184. [Google Scholar] [CrossRef]

- Singh Singhal, T.; Kumar Jain, J. GMAW Cladding on Metals to Impart Anti-Corrosiveness: Machine, Processes and Materials. Mater. Today Proc. 2020, 26, 2432–2441. [Google Scholar] [CrossRef]

- Zhu, L.; Cui, Y.; Cao, J.; Tian, R.; Cai, Y.; Xu, C.; Han, J.; Tian, Y. Effect of TIG Remelting on Microstructure, Corrosion and Wear Resistance of Coating on Surface of 4Cr5MoSiV1 (AISI H13). Surf. Coat. Technol. 2021, 405, 126547. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, S.; Cui, X.; Zhang, C.; Liu, Y.; Zhang, J. Tribological and Cavitation Erosion Behaviors of Nickel-Based and Iron-Based Coatings Deposited on AISI 304 Stainless Steel by Cold Metal Transfer. J. Mater. Res. Technol. 2020, 9, 6665–6681. [Google Scholar] [CrossRef]

- Rajeev, G.P.; Kamaraj, M.; Bakshi, S.R. Comparison of Microstructure, Dilution and Wear Behavior of Stellite 21 Hardfacing on H13 Steel Using Cold Metal Transfer and Plasma Transferred Arc Welding Processes. Surf. Coat. Technol. 2019, 375, 383–394. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, H.; You, M.; Li, Z.; Zhang, Y. Improving Wear Resistance and Friction Stability of FeNi Matrix Coating by In-Situ Multi-Carbide WC-TiC via PTA Metallurgical Reaction. Surf. Coat. Technol. 2019, 378, 124957. [Google Scholar] [CrossRef]

- Morales, C.; Fortini, A.; Soffritti, C.; Merlin, M. Effect of Post-Fabrication Heat Treatments on the Microstructure of WC-12Co Direct Energy Depositions. Coatings 2023, 13, 1459. [Google Scholar] [CrossRef]

- Hao, J.; Niu, Q.; Ji, H.; Liu, H. Effect of Ultrasonic Rolling on the Organization and Properties of a High-Speed Laser Cladding IN 718 Superalloy Coating. Crystals 2023, 13, 1214. [Google Scholar] [CrossRef]

- Bailey, N.S.; Katinas, C.; Shin, Y.C. Laser Direct Deposition of AISI H13 Tool Steel Powder with Numerical Modeling of Solid Phase Transformation, Hardness, and Residual Stresses. J. Mater. Process. Technol. 2017, 247, 223–233. [Google Scholar] [CrossRef]

- Lizzul, L.; Sorgato, M.; Bertolini, R.; Ghiotti, A.; Bruschi, S.; Fabbro, F.; Rech, S. On the Influence of Laser Cladding Parameters and Number of Deposited Layers on As-Built and Machined AISI H13 Tool Steel Multilayered Claddings. CIRP J. Manuf. Sci. Technol. 2021, 35, 361–370. [Google Scholar] [CrossRef]

- Le, V.T.; Mai, D.S. Microstructural and Mechanical Characteristics of 308L Stainless Steel Manufactured by Gas Metal Arc Welding-Based Additive Manufacturing. Mater. Lett. 2020, 271, 127791. [Google Scholar] [CrossRef]

- Miranda-Pérez, A.F.; Rodríguez-Vargas, B.R.; Calliari, I.; Pezzato, L. Corrosion Resistance of GMAW Duplex Stainless Steels Welds. Materials 2023, 16, 1847. [Google Scholar] [CrossRef]

- Stinson, H.; Ward, R.; Quinn, J.; McGarrigle, C. Comparison of Properties and Bead Geometry in MIG and CMT Single Layer Samples for WAAM Applications. Metals 2021, 11, 1530. [Google Scholar] [CrossRef]

- Amushahi, M.H.; Ashrafizadeh, F.; Shamanian, M. Characterization of Boride-Rich Hardfacing on Carbon Steel by Arc Spray and GMAW Processes. Surf. Coat. Technol. 2010, 204, 2723–2728. [Google Scholar] [CrossRef]

- Chen, T.; Xue, S.; Wang, B.; Zhai, P.; Long, W. Study on Short-Circuiting GMAW Pool Behavior and Microstructure of the Weld with Different Waveform Control Methods. Metals 2019, 9, 1326. [Google Scholar] [CrossRef]

- Das, S.; Vora, J.J.; Patel, V.; Li, W.; Andersson, J.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Experimental Investigation on Welding of 2.25 Cr-1.0 Mo Steel with Regulated Metal Deposition and GMAW Technique Incorporating Metal-Cored Wires. J. Mater. Res. Technol. 2021, 15, 1007–1016. [Google Scholar] [CrossRef]

- Chhabra, P.; Kaur, M.; Singh, S. High Temperature Tribological Performance of Atmospheric Plasma Sprayed Cr3C2-NiCr Coating on H13 Tool Steel. Mater. Today Proc. 2020, 33, 1518–1530. [Google Scholar] [CrossRef]

- Telasang, G.; Dutta Majumdar, J.; Padmanabham, G.; Manna, I. Wear and Corrosion Behavior of Laser Surface Engineered AISI H13 Hot Working Tool Steel. Surf. Coat. Technol. 2015, 261, 69–78. [Google Scholar] [CrossRef]

- Hadidi, H.; Saminathan, R.; Zouli, N. Enhancement of Diffusive Oxidation Resistance and Topographical Corrosion Resistance of Hot Work Tool Steels by Nickel Multifunctional Coatings. J. Mater. Res. Technol. 2024, 28, 1227–1232. [Google Scholar] [CrossRef]

- Calvo-García, E.; Valverde-Pérez, S.; Riveiro, A.; Álvarez, D.; Román, M.; Magdalena, C.; Badaoui, A.; Moreira, P.; Comesaña, R. An Experimental Analysis of the High-Cycle Fatigue Fracture of H13 Hot Forging Tool Steels. Materials 2022, 15, 7411. [Google Scholar] [CrossRef] [PubMed]

- Shinde, T.; Pruncu, C.; Dhokey, N.B.; Parau, A.C.; Vladescu, A. Effect of Deep Cryogenic Treatment on Corrosion Behavior of AISI H13 Die Steel. Materials 2021, 14, 7863. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Wang, K.; Dong, X.; Yang, L.; Ebrahimi, M.; Jiang, H.; Wang, Q.; Ding, W. Review on Corrosion Resistance of Mild Steels in Liquid Aluminum. J. Mater. Sci. Technol. 2021, 71, 12–22. [Google Scholar] [CrossRef]

- Lou, D.C.; Akselsen, O.M.; Onsøien, M.I.; Solberg, J.K.; Berget, J. Surface Modification of Steel and Cast Iron to Improve Corrosion Resistance in Molten Aluminium. Surf. Coat. Technol. 2006, 200, 5282–5288. [Google Scholar] [CrossRef]

- Chen, G.; Xue, L.; Wang, J.; Tang, Z.; Li, X.; Dong, H. Investigation of Surface Modifications for Combating the Molten Aluminum Corrosion of AISI H13 Steel. Corros. Sci. 2020, 174, 108836. [Google Scholar] [CrossRef]

- Ostolaza, M.; Arrizubieta, J.I.; Lamikiz, A.; Cortina, M. Functionally Graded AISI 316L and AISI H13 Manufactured by L-DED for Die and Mould Applications. Appl. Sci. 2021, 11, 771. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- De Oliveira, U.; Ocelík, V.; De Hosson, J.T.M. Analysis of Coaxial Laser Cladding Processing Conditions. Surf. Coat. Technol. 2005, 197, 127–136. [Google Scholar] [CrossRef]

- Davis, J.R. Hardfacing, Weld Cladding, and Dissimilar Metal Joining. In Welding, Brazing, and Soldering; ASM International: Tokyo, Japan, 1993; pp. 789–829. [Google Scholar]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; ISBN 978-0-471-47379-4. [Google Scholar]

- Arsić, D.; Lazić, V.; Mitrović, S.; Džunić, D.; Aleksandrović, S.; Djordjević, M.; Nedeljković, B. Tribological Behavior of Four Types of Filler Metals for Hard Facing under Dry Conditions. Ind. Lubr. Tribol. 2016, 68, 729–736. [Google Scholar] [CrossRef]

- ASTM G99; ASTM E384 International Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus G99–17. ASTM International: Conshohocken, PA, USA, 2022.

- Luchtenberg, P.; de Campos, P.T.; Soares, P.; Laurindo, C.A.H.; Maranho, O.; Torres, R.D. Effect of Welding Energy on the Corrosion and Tribological Properties of Duplex Stainless Steel Weld Overlay Deposited by GMAW/CMT Process. Surf. Coat. Technol. 2019, 375, 688–693. [Google Scholar] [CrossRef]

- Chen, L.; Tan, H.; Wang, Z.; Li, J.; Jiang, Y. Influence of Cooling Rate on Microstructure Evolution and Pitting Corrosion Resistance in the Simulated Heat-Affected Zone of 2304 Duplex Stainless Steels. Corros. Sci. 2012, 58, 168–174. [Google Scholar] [CrossRef]

- Rodriguez, B.R.; Miranda, A.; Gonzalez, D.; Praga, R.; Hurtado, E. Maintenance of the Austenite/Ferrite Ratio Balance in GTAW DSS Joints Through Process Parameters Optimization. Materials 2020, 13, 780. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, X.; Yu, K.; Lei, Z.; Chen, Y.; Wu, S.; Li, Z. Improving Fusion Zone Microstructure Inhomogeneity in Dissimilar-Metal Welding by Laser Welding with Oscillation. Mater. Lett. 2019, 2019, 126995. [Google Scholar] [CrossRef]

- Bunaziv, I.; Ren, X.; Hagen, A.B.; Hovig, E.W.; Jevremovic, I.; Gulbrandsen-Dahl, S. Laser Beam Remelting of Stainless Steel Plate for Cladding and Comparison with Conventional CMT Process. Int. J. Adv. Manuf. Technol. 2023, 127, 911–934. [Google Scholar] [CrossRef]

- Wu, D.; An, Q.; Zhao, G.; Zhang, Y.; Zou, Y. Corrosion Resistance of Stainless Steel Layer Prepared by Twin-Wire Indirect Arc Surfacing Welding. Vacuum 2020, 177, 109348. [Google Scholar] [CrossRef]

- Li, S.; Eliniyaz, Z.; Zhang, L.; Sun, F.; Shen, Y.; Shan, A. Microstructural Evolution of Delta Ferrite in SAVE12 Steel under Heat Treatment and Short-Term Creep. Mater. Charact. 2012, 73, 144–152. [Google Scholar] [CrossRef]

- Kim, Y.-G.; Lee, D.J.; Byun, J.; Jung, K.H.; Kim, J.; Lee, H.; Taek Shin, Y.; Kim, S.; Lee, H.W. The Effect of Sigma Phases Formation Depending on Cr/Ni Equivalent Ratio in AISI 316L Weldments. Mater. Des. 2011, 32, 330–336. [Google Scholar] [CrossRef]

- Fu, J.W.; Yang, Y.S.; Guo, J.J.; Ma, J.C.; Tong, W.H. Microstructure Formation in Rapidly Solidified AISI 304 Stainless Steel Strip. Ironmak. Steelmak. 2009, 36, 230–233. [Google Scholar] [CrossRef]

- Lee, D.J.; Byun, J.C.; Sung, J.H.; Lee, H.W. The Dependence of Crack Properties on the Cr/Ni Equivalent Ratio in AISI 304L Austenitic Stainless Steel Weld Metals. Mater. Sci. Eng. A 2009, 513–514, 154–159. [Google Scholar] [CrossRef]

- Tate, S.B.; Liu, S. Solidification Behaviour of Laser Welded Type 21Cr–6Ni–9Mn Stainless Steel. Sci. Technol. Weld. Join. 2014, 19, 310–317. [Google Scholar] [CrossRef]

- Weidong, H. Microstructure Evolution of 316L Stainless Steel During Laser Rapid Forming. Acta Metall. Sin. 2006, 42, 361–368. Available online: https://www.ams.org.cn/EN/abstract/abstract5556.shtml (accessed on 19 December 2023).

- Li, K.; Li, D.; Liu, D.; Pei, G.; Sun, L. Microstructure Evolution and Mechanical Properties of Multiple-Layer Laser Cladding Coating of 308L Stainless Steel. Appl. Surf. Sci. 2015, 340, 143–150. [Google Scholar] [CrossRef]

- Li, D.; Lu, S.; Li, D.; Li, Y. Investigation of the microstructure and impact properties of the high nitrogen stainless steel weld. Acta Metall. Sin. 2013, 49, 129. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, J.; Li, X. Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing. Metals 2023, 13, 1484. [Google Scholar] [CrossRef]

- Wang, Y.; Sebeck, K.; Tess, M.; Gingrich, E.; Feng, Z.; Haynes, J.A.; Lance, M.J.; Muralidharan, G.; Marchel, R.; Kirste, T.; et al. Interfacial Microstructure and Mechanical Properties of Rotary Inertia Friction Welded Dissimilar 422 Martensitic Stainless Steel to 4140 Low Alloy Steel Joints. Mater. Sci. Eng. A 2023, 885, 145607. [Google Scholar] [CrossRef]

- Hamada, A.; Ghosh, S.; Ali, M.; Jaskari, M.; Järvenpää, A. Studying the Strengthening Mechanisms and Mechanical Properties of Dissimilar Laser-Welded Butt Joints of Medium-Mn Stainless Steel and Automotive High-Strength Carbon Steel. Mater. Sci. Eng. A 2022, 856, 143936. [Google Scholar] [CrossRef]

- Ansari, R.; Movahedi, M.; Pouranvari, M. Microstructural Features and Mechanical Behavior of Duplex Stainless Steel/Low Carbon Steel Friction Stir Dissimilar Weld. J. Mater. Res. Technol. 2023, 25, 5352–5371. [Google Scholar] [CrossRef]

- Kattire, P.; Paul, S.; Singh, R.; Yan, W. Experimental Characterization of Laser Cladding of CPM 9V on H13 Tool Steel for Die Repair Applications. J. Manuf. Process. 2015, 20, 492–499. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Sun, G.; Deng, D. Modeling of Welding Residual Stress in a Dissimilar Metal Butt-Welded Joint between P92 Ferritic Steel and SUS304 Austenitic Stainless Steel. J. Mater. Res. Technol. 2023, 23, 4938–4954. [Google Scholar] [CrossRef]

- Guan, H.; Chai, L.; Wang, Y.; Xiang, K.; Wu, L.; Pan, H.; Yang, M.; Teng, C.; Zhang, W. Microstructure and Hardness of NbTiZr and NbTaTiZr Refractory Medium-Entropy Alloy Coatings on Zr Alloy by Laser Cladding. Appl. Surf. Sci. 2021, 549, 149338. [Google Scholar] [CrossRef]

- Li, X.; Jiang, P.; Nie, M.; Liu, Z.; Liu, M.; Qiu, Y.; Chen, Z.; Zhang, Z. Enhanced Strength-Ductility Synergy of Laser Additive Manufactured Stainless Steel/Ni-Based Superalloy Dissimilar Materials Characterized by Bionic Mechanical Interlocking Structures. J. Mater. Res. Technol. 2023, 26, 4770–4783. [Google Scholar] [CrossRef]

- Wang, X.; Lei, L.; Yu, H. A Review on Microstructural Features and Mechanical Properties of Wheels/Rails Cladded by Laser Cladding. Micromachines 2021, 12, 152. [Google Scholar] [CrossRef] [PubMed]

- Di Schino, A.; Testani, C. Corrosion Behavior and Mechanical Properties of AISI 316 Stainless Steel Clad Q235 Plate. Metals 2020, 10, 552. [Google Scholar] [CrossRef]

- Zhang, M.; Li, M.; Chi, J.; Wang, S.; Ren, L.; Fang, M. Microstructure and Tribology Properties of In-Situ MC(M:Ti,Nb) Coatings Prepared via PTA Technology. Vacuum 2019, 160, 264–271. [Google Scholar] [CrossRef]

- Luiz, V.D.; dos Santos, A.J.; Câmara, M.A.; Rodrigues, P.C.d.M. Influence of Different Contact Conditions on Friction Properties of AISI 430 Steel Sheet with Deep Drawing Quality. Coatings 2023, 13, 771. [Google Scholar] [CrossRef]

- Zhao, C.; Xing, X.; Guo, J.; Shi, Z.; Zhou, Y.; Ren, X.; Yang, Q. Microstructure and Wear Resistance of (Nb,Ti)C Carbide Reinforced Fe Matrix Coating with Different Ti Contents and Interfacial Properties of (Nb,Ti)C/α-Fe. Appl. Surf. Sci. 2019, 494, 600–609. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Gershman, I.S.; Endrino, J.L. Accelerated Tribo-Films Formation in Complex Adaptive Surface-Engineered Systems under the Extreme Tribological Conditions of Ultra-High-Performance Machining. Lubricants 2023, 11, 221. [Google Scholar] [CrossRef]

- Morales, C.; Merlin, M.; Fortini, A.; Fortunato, A. Direct Energy Depositions of a 17-4 PH Stainless Steel: Geometrical and Microstructural Characterizations. Coatings 2023, 13, 636. [Google Scholar] [CrossRef]

- Ferreira Filho, D.; Souza, D.; Gonçalves Júnior, J.L.; Reis, R.P.; Da Silva Junior, W.M.; Tavares, A.F. Influence of Substrate on the Tribological Behavior of Inconel 625 GMAW Overlays. Coatings 2023, 13, 1454. [Google Scholar] [CrossRef]

| Material | Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Cu | Mn | Mo | Ni | Si | V | Al | Fe | |

| H13 | 0.45 | 4.95 | 0.071 | 0.39 | 1.26 | 0.16 | 0.93 | 0.47 | 0.05 | Bal. |

| ER308 | 0.11 | 16.80 | 0.14 | 0.48 | 0.23 | 11.49 | 0.59 | 0.17 | 0.07 | Bal. |

| Material | Mechanical Properties | ||||

|---|---|---|---|---|---|

| Hardness (HRC) | Tensile Strength Ultimate (MPa) | Tensile Strength Yield (MPa) | Modulus of Elasticity (GPa) | Elongation after Fracture (%) | |

| H13 | 25–28 | 1100 | 820 | 215 | 9.0 |

| ER308 | - | >600 | - | - | >30.0 |

| Designation | Welding Parameters | ||||

|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Welding Speed (mm/s) | Wire Feed Speed (mm/s) | Heat Input (kJ/mm) | |

| C1 | 254.3 | 20.0 | 5 | 5 | 0.813 |

| C2 | 252.0 | 19.8 | 0.798 | ||

| C3 | 229.5 | 19.6 | 0.719 | ||

| C4 | 208.3 | 19.4 | 0.646 | ||

| Electrode extension: 10 mm Arc length: 1 mm | |||||

| Parameters | Value |

|---|---|

| Normal force | 3 N |

| Rotating speed | 10 cm/s |

| Test radius | 4.5 mm |

| Sliding distance | 170 m |

| Sphere radius | 3 mm |

| Environment | Air |

| Temperature nominal | 28 °C |

| Specimen dimensions | 1 mm × 1 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernandez-Flores, J.E.; Rodriguez-Vargas, B.R.; Stornelli, G.; Pérez, A.F.M.; García-Vázquez, F.d.J.; Gómez-Casas, J.; Di Schino, A. Evaluation of Austenitic Stainless Steel ER308 Coating on H13 Tool Steel by Robotic GMAW Process. Metals 2024, 14, 43. https://doi.org/10.3390/met14010043

Hernandez-Flores JE, Rodriguez-Vargas BR, Stornelli G, Pérez AFM, García-Vázquez FdJ, Gómez-Casas J, Di Schino A. Evaluation of Austenitic Stainless Steel ER308 Coating on H13 Tool Steel by Robotic GMAW Process. Metals. 2024; 14(1):43. https://doi.org/10.3390/met14010043

Chicago/Turabian StyleHernandez-Flores, Jorge Eduardo, Bryan Ramiro Rodriguez-Vargas, Giulia Stornelli, Argelia Fabiola Miranda Pérez, Felipe de Jesús García-Vázquez, Josué Gómez-Casas, and Andrea Di Schino. 2024. "Evaluation of Austenitic Stainless Steel ER308 Coating on H13 Tool Steel by Robotic GMAW Process" Metals 14, no. 1: 43. https://doi.org/10.3390/met14010043

APA StyleHernandez-Flores, J. E., Rodriguez-Vargas, B. R., Stornelli, G., Pérez, A. F. M., García-Vázquez, F. d. J., Gómez-Casas, J., & Di Schino, A. (2024). Evaluation of Austenitic Stainless Steel ER308 Coating on H13 Tool Steel by Robotic GMAW Process. Metals, 14(1), 43. https://doi.org/10.3390/met14010043