Optimizing Wear Resistance and Tensile Strength of Nickel-Based Coatings through Tungsten Carbide Reinforcement

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

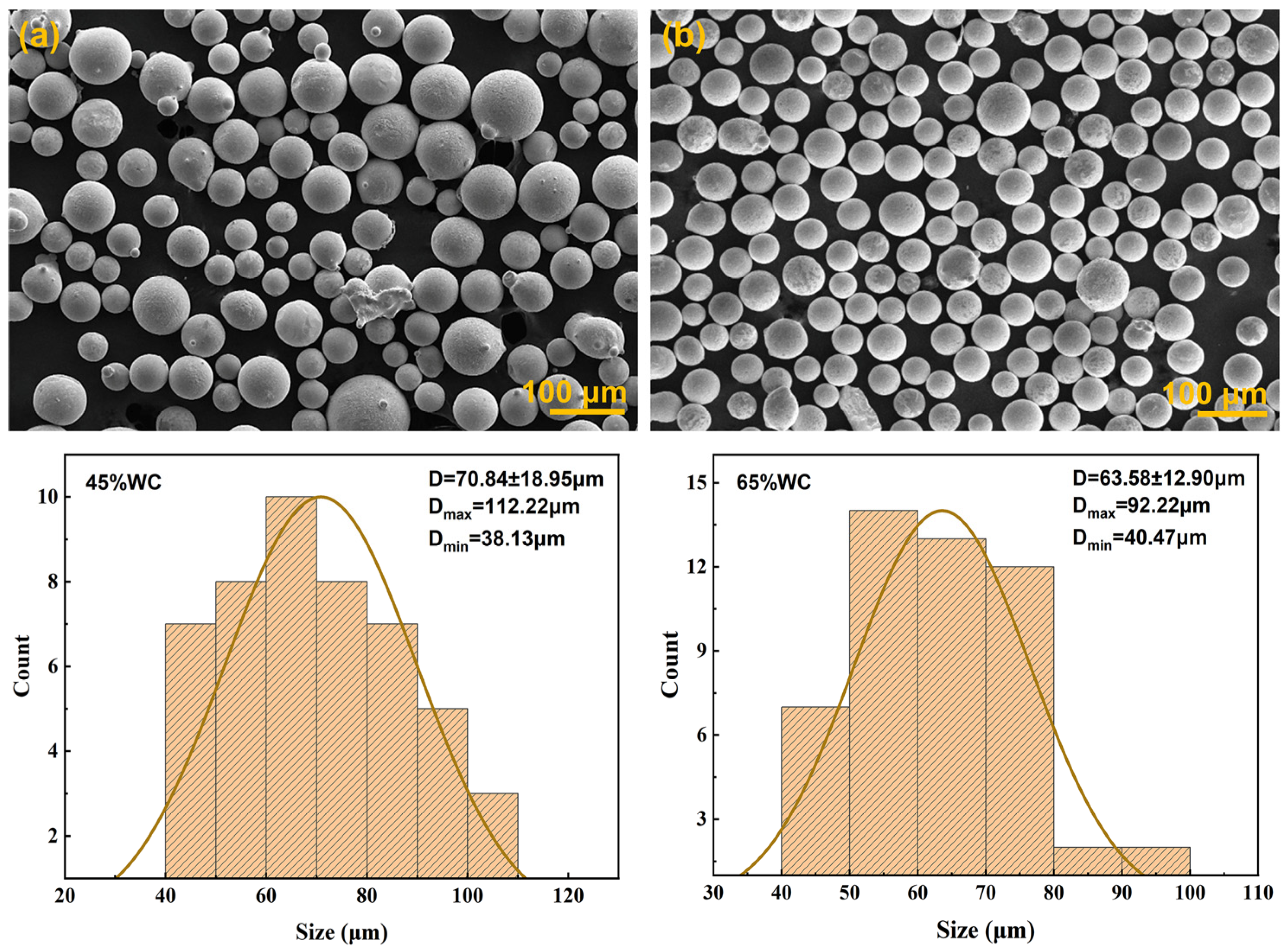

3.1. Microstructures of the Coatings

3.2. Phases of the Coatings

3.3. XPS Analyses of the Coatings

3.4. Hardness of the Coatings

3.5. Wear Resistance of the Coatings

3.5.1. Wear Behavior and 3D Morphological Analysis

3.5.2. Wear Morphological Analysis

3.6. Mechanical Properties of the Coatings

3.6.1. Tensile Curve Analysis

3.6.2. Fracture Morphological Analysis

3.6.3. In Situ Tensile Surface Structure Analysis

4. Conclusions

- With the increase in the WC content from 45% to 65%, the formation of carbides such as M7C3, M6C, and M23C6 increased significantly, while the formation of the γ-phase was inhibited significantly. XPS analysis further revealed that the changes in the WC and Cr7C3 phases were particularly prominent in the high-WC content coating, with the binding energies of Fe-C and Cr-C bonds increasing by 0.3 eV and 0.2 eV, respectively. Additionally, the charge transfer between WC and Ni substantially enhanced the bonding strength of the W-C bonds. This finding further confirmed that the stability of the Fe-C, Cr-C, and W-C bonds was significantly improved. These structural changes, together with particle and solid solution strengthening, resulted in an increase in hardness of 232 HV1.0 for the 65% WC coating compared with the 45% WC coating.

- The friction coefficient for the 65% WC coating was remarkably stable and remained low at 0.42, with a wear rate of 3.329 × 10−6 mm3 (N·m)−1, a reduction of 3.709 × 10−6 mm3 (N·m)−1 compared with the 45% WC coating. The 45% WC coating exhibited a greater wear width (an increase of approximately 16 μm), together with pronounced deep grooves and surface degradation, with the wear mechanisms being predominantly adhesive wear, abrasive wear, and oxidative wear. In contrast, the 65% WC coating exhibited less wear due to the presence of WC particles and hard particles, with the wear mechanism primarily driven by adhesive wear and minor oxidative wear.

- Conventional tensile tests showed a negative correlation between the WC content and the internal stress and strain of the coatings. Due to the complex eutectic structure and abundant transitional layers, the 45% WC coating exhibited a maximum stress of 333 MPa and strain of 2.5%, which were 71% and 36% higher, respectively, than those of the 65% WC coating. The fracture morphology of the 45% WC coating showed a river-like structure and deep dimples, indicating a fracture mechanism combining ductile and quasi-cleavage properties. In contrast, the fracture of the 65% WC coating was relatively smooth with cracks extending along the W2C phase, indicating a typical brittle fracture mechanism.

- In situ tensile tests coupled with SEM observations revealed that in the 65% WC coating, the WC particles were denser, with weaker internal bonding, leading to a shorter fracture process of only 52 s. Conversely, the fracture time for the 45% WC coating extended to 72 s, with cracks originating in the WC aggregation area and propagating along the WC particles and decomposed hard phases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ramezani, M.; Mohd Ripin, Z.; Pasang, T.; Jiang, C.P. Surface engineering of metals: Techniques, characterizations and appli-cations. Metals 2023, 13, 1299. [Google Scholar] [CrossRef]

- Tian, J.Y.; Hu, Y.; Zhao, H.W.; Hu, Y.; Li, Y.; Zhou, S.L.; Cao, C.Y.; Zhang, L. The indentation and wear performance of hardfacing layers on H13 steel for use in high temperature application. AIP Adv. 2019, 9, 095304. [Google Scholar] [CrossRef]

- Sun, D.S.; Yang, Y.; Liu, Z.; Han, J.Y.; Ma, S.T.; Xu, B.; Yuan, M.Y. Study of design and microstructure properties of laser clad multiphase coupled nickel-based self-lubricating coatings. J. Mater. Eng. Perform. 2024, 33, 6314–6330. [Google Scholar] [CrossRef]

- Lisiecki, A.; Ślizak, D. Hybrid laser deposition of composite WC-Ni layers with forced local cryogenic cooling. Materials 2021, 14, 4312. [Google Scholar] [CrossRef]

- Li, J.F.; Zhu, Z.C.; Peng, Y.X.; Shen, G. Phase evolution and wear resistance of in-situ synthesized (Cr, W)23C6-WC composite ceramics reinforced Fe-based composite coatings produced by laser cladding. Vacuum 2021, 190, 110242. [Google Scholar] [CrossRef]

- Zhang, K.; Ju, H.C.; Xing, F.; Wang, W.; Li, Q.; Yu, X.F.; Liu, W.J. Microstructure and properties of composite coatings by laser cladding Inconel 625 and reinforced WC particles on non-magnetic steel. Opt. Laser Technol. 2023, 163, 109321. [Google Scholar] [CrossRef]

- Hu, Y.J.; Wang, Z.X.; Pang, M. Effect of WC content on laser cladding Ni-based coating on the surface of stainless steel. Mater. Today Commun. 2022, 31, 103357. [Google Scholar] [CrossRef]

- Zhou, S.F.; Zeng, X.Y.; Hu, Q.W.; Huang, Y.J. Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization. Appl. Surf. Sci. 2008, 255, 1646–1653. [Google Scholar] [CrossRef]

- Liu, S.L.; Zheng, X.P. Microstructure and properties of AC-HVAF sprayed Ni60/WC composite coating. J. Alloy Compd. 2009, 480, 254–258. [Google Scholar] [CrossRef]

- Ma, Q.S.; Li, Y.J.; Wang, J.; Liu, K. Investigation on cored-eutectic structure in Ni60/WC composite coatings fabricated by wide-band laser cladding. J. Alloy Compd. 2015, 645, 151–157. [Google Scholar] [CrossRef]

- Boonyongmaneerat, Y.; Saengkiettiyut, K.; Saenapitak, S.; Sangsuk, S. Effects of WC addition on structure and hardness of electrodeposited Ni–W. Surf. Coat. Technol. 2009, 203, 3590–3594. [Google Scholar] [CrossRef]

- Bartkowski, D.; Młynarczak, A.; Piasecki, A.; Dudziak, B.; Gościański, M.; Bartkowska, A. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt. Laser Technol. 2015, 68, 191–201. [Google Scholar] [CrossRef]

- Li, W.Y.; Yang, X.F.; Xiao, J.P.; Hou, Q.M. Effect of WC mass fraction on the microstructure and friction properties of WC/Ni60 laser cladding layer of brake discs. Ceram. Int. 2021, 47, 28754–28763. [Google Scholar] [CrossRef]

- Li, X.N.; Zhang, S.Y.; Liu, W.; Pang, X.T.; Tong, Y.G.; Zhang, M.J.; Zhang, J.; Wang, K.M. Effect of WC content on the wear and corrosion properties of oscillating laser-cladding-produced nickel-based coating. Coatings 2023, 13, 1614. [Google Scholar] [CrossRef]

- Wang, H.T.; Chen, X.; Bai, X.B.; Ji, G.C.; Dong, Z.X.; Yi, D.L. Microstructure and properties of cold sprayed multimodal WC–17Co deposits. Int. J. Refract. Met. H. 2014, 45, 196–203. [Google Scholar] [CrossRef]

- Huang, J.H.; He, J.C.; Li, Z.J.; Shen, L.; Chen, L.; Chang, F.; Dai, P.Q.; Tang, Q.H. Effect of WC addition on microstructure and properties of powder metallurgy CoCrNi medium entropy alloy. Mater. Today Commun. 2023, 36, 106435. [Google Scholar] [CrossRef]

- Yue, K.; Wang, L.; Xu, Z.; Cheng, C.L.; Wang, Y.Q.; Fan, Y.; Xu, J.; Wang, Z.J.; Chen, Z. Effect of WC content on the microstructure and wear resistance of laser cladding AlCoCrFeNiTi0.5 high-entropy alloy coatings. Ceram. Int. 2024, S0272884224034163. [Google Scholar] [CrossRef]

- Luo, K.X.; He, J.Y.; Ma, H.; Wang, C.; Lu, J.; Li, C.; Peng, Y.D.; Wu, N.; Luo, F.H. Dissolution behaviour of WC particles and evolution of precipitated phases in the plasma transfer arc Ni-based composite coating reinforced by 30 wt.% WC particles. Ceram. Int. 2024, 50, 35065–35078. [Google Scholar] [CrossRef]

- Kleykamp, H. Thermodynamic studies on chromium carbides by the electromotive force (Emf) method. J. Alloy Compd. 2001, 321, 138–145. [Google Scholar] [CrossRef]

- Wu, P.; Du, H.M.; Chen, X.L.; Li, Z.Q.; Bai, H.L.; Jiang, E.Y. Influence of WC particle behavior on the wear resistance properties of Ni–WC composite coatings. Wear 2004, 257, 142–147. [Google Scholar] [CrossRef]

- Guo, C.; Chen, J.M.; Zhou, J.S.; Zhao, J.R.; Wang, L.Q.; Yu, Y.J.; Zhou, H.D. Effects of WC-Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating. Surf. Coat. Technol. 2012, 206, 2064–2071. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Hida, M.; Sakakibara, A.; Takemoto, Y. Effect of WC addition on microstructures of laser melted Ni-based alloy powder. Surf. Coat. Technol. 2003, 169–170, 384–387. [Google Scholar] [CrossRef]

- Shen, X.H.; He, X.P.; Gao, L.Y.; Su, G.S.; Xu, C.H.; Xu, N. Study on crack behavior of laser cladding ceramic-metal composite coating with high content of WC. Ceram. Int. 2022, 48, 17460–17470. [Google Scholar] [CrossRef]

- Tan, N.; Hu, Z.Y.; Zhou, Y.J.; Li, Y.; Lu, B.W.; Hu, D.C.; Liu, Y.; Li, Q. Effect of WC particle size on the microstructure and tribological properties of high-speed laser cladding Ni/WC composite coatings. Mater. Today Commun. 2024, 39, 109066. [Google Scholar] [CrossRef]

- He, B. Effect of WC Content on microstructure and properties of WC/316L laser coatings. Ferroelectrics 2023, 608, 1–12. [Google Scholar] [CrossRef]

- Bao, C.G.; Gao, Y.M.; Xing, J.D.; Zhang, G.S. Wear behavior of plasma sprayed Ni-WC composite coatings. KEM 2007, 336–338, 1731–1733. [Google Scholar] [CrossRef]

- Yan, X.C.; Huang, C.J.; Chen, C.Y.; Bolot, R.; Dembinski, L.; Huang, R.Z.; Ma, W.Y.; Liao, H.L.; Liu, M. Additive manufacturing of WC reinforced maraging steel 300 composites by cold spraying and selective laser melting. Surf. Coat. Technol. 2019, 371, 161–171. [Google Scholar] [CrossRef]

- Bello, Z.A.; Kang, M.; Ndumia, J.N.; Geng, C.; Jibril, A.N.; Liu, J. Microstructure and properties of WC-reinforced AlCoCrFeNiSi high entropy alloy coatings prepared via high-velocity arc spraying. Mater. Today Commun. 2024, 40, 109705. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Li, M.; Chi, J.; Wang, S.F.; Yang, S.; Yang, J.; Wei, Y.J. Effect of Ti on microstructure characteristics, carbide precipi-tation mechanism and tribological behavior of different WC types reinforced Ni-based gradient coating. Surf. Coat. Technol. 2019, 374, 645–655. [Google Scholar] [CrossRef]

- Baturin, A.; Lotkov, A.; Grishkov, V.; Rodionov, I.; Kudiiarov, V. Effect of hydrogen redistribution during aging on the structure and phase state of nanocrystalline and coarse-grained TiNi alloys. J. Alloy Compd. 2018, 751, 359–363. [Google Scholar] [CrossRef]

- Petrushin, N.; Hvatzkiy, K.; Link, T.; Epishin, A.; Nolze, G.; Gerstein, G. A single-crystal Co-base superalloy strengthened by γ′ precipitates: Structure and mechanical properties. Adv. Eng. Mater. 2015, 17, 755–760. [Google Scholar] [CrossRef]

- Zhou, S.F.; Dai, X.Q. Laser induction hybrid rapid cladding of WC particles reinforced NiCrBSi composite coatings. Appl. Surf. Sci. 2010, 256, 4708–4714. [Google Scholar] [CrossRef]

- Liu, F.F.; Liaw, P.K.; Zhang, Y. Recent progress with BCC-structured high-entropy alloys. Metals 2022, 12, 501. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Shi, C.B.; Li, J.H. Evolution of eutectic carbide during M7C3 /M23C6 in situ transformation in martensitic stainless steel. Steel Res. Int. 2022, 93, 2200231. [Google Scholar] [CrossRef]

- Ma, Q.; Lu, B.W.; Zhang, Y.M.; Wang, Y.L.; Yan, X.C.; Liu, M.; Zhao, G.R. Crack-free 60 wt.% WC reinforced FeCoNiCr high-entropy alloy composite coating fabricated by laser cladding. Mater. Lett. 2022, 324, 132667. [Google Scholar] [CrossRef]

- Wei, Y.; Wei, X.S.; Chen, B.; Zuo, J.Y.; Ma, T.C.; Shen, J. Parameter optimization for tungsten carbide/Ni-based composite coating deposited by plasma transferred arc hardfacing. Trans. Nonferrous Met. Soc. 2018, 28, 2511–2519. [Google Scholar] [CrossRef]

- Genga, R.M.; Akdogan, G.; Polese, C.; Garrett, J.C.; Cornish, L.A. Abrasion wear, thermal shock and impact resistance of WC-cemented carbides produced by PECS and LPS. Int. J. Refract. Met. Hard Mater 2015, 49, 133–142. [Google Scholar] [CrossRef]

- Kaçmaz, D.; Kalkavan, F.; Yazıcı, S.; Demirural, A.; Baykara, T. Processing, sintering and performance of WC-Co-near-nano TiC metal matrix composites. RDMS. 2019, 9, 1012–1018. [Google Scholar] [CrossRef]

- Detroye, M.; Reniers, F.; Buess-Herman, C.; Vereecken, J. AES–XPS study of chromium carbides and chromium iron carbides. Appl. Surf. Sci. 1999, 144–145, 78–82. [Google Scholar] [CrossRef]

- Li, J.; Liu, C.Y.; Zhao, B.G.; Lin, Y.Q.; Deng, Z.J. Structures and properties of Fe-C particles prepared by AC arc discharge. J. Magn. Magn. Mater. 1999, 195, 470–475. [Google Scholar] [CrossRef]

- Furlan, A.; Jansson, U.; Lu, J.; Hultman, L.; Magnuson, M. Structure and bonding in amorphous iron carbide thin films. J. Phys. Condens. Matter. 2015, 27, 045002. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Zhao, Y.W.; Xiang, N. Photocatalytic activity and microstructure of micro-Arc oxidized TiO2: Cr3+ com-posite coatings. Mater. Technol. 2018, 33, 592–602. [Google Scholar] [CrossRef]

- Lynch, B.; Wang, Z.; Ma, L.; Paschalidou, E.M.; Wiame, F.; Maurice, V.; Marcus, P. Passivation-induced Cr and Mo enrichments of 316L stainless steel surfaces and effects of controlled pre-oxidation. J. Electrochem. Soc. 2020, 167, 141509. [Google Scholar] [CrossRef]

- Håkansson, K.L.; Johansson, H.I.P.; Johansson, L.I. High-resolution core-level study of hexagonal WC (0001). Phys. Rev. B 1994, 49, 2035–2039. [Google Scholar] [CrossRef]

- Sivkov, D.; Nekipelov, S.; Petrova, O.; Vinogradov, A.; Mingaleva, A.; Isaenko, S.; Makarov, P.; Ob’edkov, A.; Kaverin, B.; Gusev, S.; et al. Studies of buried layers and interfaces of tungsten carbide coatings on the MWCNT surface by XPS and NEXAFS spec-troscopy. Appl. Sci. 2020, 10, 4736. [Google Scholar] [CrossRef]

- Song, D.; Shin, J.; Lee, Y.; Kwon, Y.; Lim, J.; Kim, E.-J.; Oh, S.; Kim, M.; Cho, E. Thin nickel layer with embedded WC nano-particles for efficient oxygen evolution. ACS Appl. Energy Mater. 2019, 2, 3452–3460. [Google Scholar] [CrossRef]

- Li, Y.L.; Song, P.; Wang, W.Q.; Lei, M.; Li, X.W. Microstructure and wear resistance of a Ni-WC composite coating on titanium grade 2 obtained by electroplating and electron beam remelting. Mater. Charact. 2020, 170, 110674. [Google Scholar] [CrossRef]

- Wu, H.Y.; Dong, Y.P.; Li, X.W.; Li, Y.L.; Yan, M. First principle calculations and low cost SLM processing of Ti-TiB composite materials. Mater. Sci. Eng. A 2021, 803, 140711. [Google Scholar] [CrossRef]

- Li, Y.L.; Wu, Y.Y.; Wang, W.Q.; Lei, M.; Li, X.W. Microstructure and mechanical properties of the Ni-B-Ti composite coating on TA2 prepared by pre-plating and laser remelting. Surf. Coat. Technol. 2021, 405, 126567. [Google Scholar] [CrossRef]

- Wu, Z.L.; Wang, W.Q.; Li, X.W.; Yan, M.; Li, Y.L. Microstructure and mechanical properties of Ti-6Al-4V prepared by nickel preplating and electron beam surface remelting. J. Mater. Process. Technol. 2019, 271, 420–428. [Google Scholar] [CrossRef]

- Ren, S.; Li, J.; Fang, Q.; Feng, H. Effect of solid solution addition on the dislocation emission in aluminum alloys. Acta Mech. 2020, 231, 4537–4545. [Google Scholar] [CrossRef]

- Melendez, N.M.; McDonald, A.G. Development of WC-Based metal matrix composite coatings using low-pressure cold gas dynamic spraying. Surf. Coat. Technol. 2013, 214, 101–109. [Google Scholar] [CrossRef]

- Chen, G.D.; Liu, X.B.; Zhang, F.Z.; Li, M.X.; Zhang, S.H. Refractory ceramic WC reinforced Co matrix composite coatings on IN718 superalloy: Microstructure, wear mechanisms and surface energy. Tribol. Int. 2024, 194, 109516. [Google Scholar] [CrossRef]

- Ma, L.T.; Zhao, D.C.; Wang, Y.H.; Wang, K.B.; Huang, J.; Jin, X.Y.; Kong, D.C.; Wang, M.L.; Yamaguchi, T.; Wang, H.W. Optimized wear behaviors and related wear mechanisms of medium entropy alloy-based composite coatings. J. Mater. Res. Technol. 2024, 29, 12–27. [Google Scholar] [CrossRef]

- Wang, Z.H.; Liu, Y.W.; Liu, K.; Wang, B.X. Mechanical properties and microstructure of spark plasma sintered WC-8 wt.%Co-VC-cBN ultrafine grained cemented carbide. Ceram. Int. 2019, 45, 23658–23665. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.P.; Kung, H.; Hoagland, R.G.; Embury, J.D. Dislocation models for strengthening in nanostructured metallic multilayers. MRS Proc. 2000, 634, B4.2.1. [Google Scholar] [CrossRef]

- Yao, Y.Z.; Huang, Y.H.; Chen, B.; Tan, C.W.; Su, Y.; Feng, J.C. Influence of processing parameters and heat treatment on the mechanical properties of 18Ni300 manufactured by laser based directed energy deposition. Opt. Laser Technol. 2018, 105, 171–179. [Google Scholar] [CrossRef]

- Liu, W.; Sha, J.B. Failure mode transition of Nb phase from cleavage to dimple/tear in Nb-16Si-based alloys prepared via spark plasma sintering. Mater. Des. 2016, 111, 301–311. [Google Scholar] [CrossRef]

- Tan, C.; Hu, J.; Shi, Q.; Khanlari, K.; Xie, H.W.; Liu, X. Enhanced hardness and toughness in WC/W2C-Ni-Cu composites fabricated by selective laser melting. Int. J. Refract. Met. Hard Mater. 2022, 105, 105805. [Google Scholar] [CrossRef]

- Domitner, J.; Silvayeh, Z.; Buzolin, R.H.; Krisam, S.; Achterhold, K.; Povoden-Karadeniz, E.; Sommitsch, C.; Mayr, P. Microstructure characterization of nickel matrix composite reinforced with tungsten carbide particles and produced by laser cladding. Adv. Eng. Mater. 2022, 24, 2200463. [Google Scholar] [CrossRef]

- Dong, R.F.; Li, J.S.; Zhang, T.B.; Hu, R.; Kou, H.C. Elements segregation and phase precipitation behavior at grain boundary in a Ni-Cr-W based superalloy. Mater. Charact. 2016, 122, 189–196. [Google Scholar] [CrossRef]

- Qin, J.Y.; Hui, J.Q.; Dong, W.W.; Bai, Y.F.; Fan, J.H.; Ding, H.; Zhu, S.G. Preparation of high-performance WC–MgO composites by spark plasma sintering. Adv. Eng. Master. 2022, 24, 2200625. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Mo | P | S | Fe |

|---|---|---|---|---|---|---|---|

| 0.39 | 0.56 | 0.19 | 0.11 | 0.15 | ≤0.015 | ≤0.015 | Base |

| Label | W | C | Si | Cr | Fe | B | Ni |

|---|---|---|---|---|---|---|---|

| 45% WC | 43.14 | 2.16 | 2.22 | 8.44 | 1.84 | 1.67 | Bal |

| 65% WC | 62.32 | 2.8 | 1.42 | 5.37 | 1.23 | 1.06 | Bal |

| Area | W | Cr | C | Fe | Ni |

|---|---|---|---|---|---|

| A | 35.85 | 15.79 | 17.85 | 5.20 | 25.31 |

| B | 0.57 | 4.45 | 9.63 | 50.38 | 34.97 |

| C | - | 4.74 | 9.97 | 22.53 | 62.76 |

| D | 49.02 | 14.64 | 10.02 | 4.09 | 20.23 |

| E | 43.52 | 10.84 | 20.32 | 8.98 | 16.34 |

| F | - | 6.60 | 19.78 | 10.00 | 63.62 |

| Area | W | C | Cr | Fe | Ni |

|---|---|---|---|---|---|

| A | - | 4.23 | 20.40 | 22.64 | 52.73 |

| B | 74.70 | 23.88 | 0.10 | 0.24 | 1.08 |

| C | 69.16 | 25.20 | 1.16 | 0.95 | 3.53 |

| D | 53.65 | 7.36 | 13.31 | 4.23 | 21.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Li, S.; Zhang, C.; Zhang, S.; Ai, X.; Xie, Z. Optimizing Wear Resistance and Tensile Strength of Nickel-Based Coatings through Tungsten Carbide Reinforcement. Metals 2024, 14, 1097. https://doi.org/10.3390/met14101097

Zhang L, Li S, Zhang C, Zhang S, Ai X, Xie Z. Optimizing Wear Resistance and Tensile Strength of Nickel-Based Coatings through Tungsten Carbide Reinforcement. Metals. 2024; 14(10):1097. https://doi.org/10.3390/met14101097

Chicago/Turabian StyleZhang, Li, Shengli Li, Chunlin Zhang, Shihan Zhang, Xingang Ai, and Zhiwen Xie. 2024. "Optimizing Wear Resistance and Tensile Strength of Nickel-Based Coatings through Tungsten Carbide Reinforcement" Metals 14, no. 10: 1097. https://doi.org/10.3390/met14101097

APA StyleZhang, L., Li, S., Zhang, C., Zhang, S., Ai, X., & Xie, Z. (2024). Optimizing Wear Resistance and Tensile Strength of Nickel-Based Coatings through Tungsten Carbide Reinforcement. Metals, 14(10), 1097. https://doi.org/10.3390/met14101097