Abstract

Utilizing spent refractory material (SRM), generated after the overhaul of aluminum electrolytic cells, as a raw material for producing Al-Si alloys presents an efficient approach towards achieving full resource utilization of SRM. However, a bottleneck restricting this technology has become the dissolution of SRM. Based on the heat and mass transfer mechanism, the shrinkage core model of SRM particle dissolution was established. The effects of alumina concentration, silica concentration, electrolyte superheat, particle temperature, and turbulent kinetic energy dissipation rate on the mass dissolution rate and dissolution time of SRM particles were investigated. Calculation results and experimental data were compared to confirm the accuracy of the established model. The results show that by maintaining low alumina and silica concentrations, increasing the electrolyte superheat and particle preheating temperature, and increasing the electrolyte turbulent kinetic energy dissipation rate, SRM particles can dissolve faster. The dissolution of agglomerated particles is greatly influenced by the turbulent kinetic energy dissipation rate and superheat. The present research provides promising guidance for practical application in predicting particle dissolution time, controlling process parameters, and accelerating the dissolution of SRM particles.

1. Introduction

Spent refractory material (SRM) generated after the overhaul of aluminum electrolytic cells is a hazardous waste, and its main components include alumina, silica, and fluoride salts [1]. On average, every tonne of primary aluminum produced generates 24~30 kg of spent pot lining, of which 50% is SRM [2,3]. From the global primary aluminum production of 69 million tonnes in 2022, approximately one million tonnes of SRM was generated. Large amounts of hazardous waste pose a significant threat to the environment. With the growing global concern for ecological preservation, it becomes imperative to reduce pollutant emissions from the aluminum electrolysis industry. To achieve this, the industry needs to focus on making SRM harmless, reducing it, and utilizing it as resources. This will pave the way for the aluminum industry’s greener and more sustainable development [4,5]. Therefore, the economical and effective recycling of SRM is an urgent issue facing the current aluminum electrolysis industry.

To achieve the harmless reduction in and high-value utilization of SRM, many scholars have conducted relevant research [6,7,8]. Liang et al. [9] used wet acid-free treatment technology to convert fluoride and cyanide in SRM into non-toxic products through leaching and chemical reactions. Renó et al. [10] and Ghenai et al. [11] utilized SRM as an input material for cement production and discovered that fluoride had several benefits in the cement manufacturing process. A lower cement kiln temperature, a lower melting point of raw materials, and a decrease in NOx and CO2 emissions were all achieved. However, the Na in SRM restricts its addition amount. Wang et al. [12] used high-temperature vacuum distillation to distil out toxic substances in SRM, and the remaining refractory materials could be recycled. Hu et al. [13] constructed a novel asphalt modifier using SRM as an additive and realized the high-value utilization of SRM.

Although there are various methods to dispose of SRM, achieving high-value recycling of large amounts of SRM is not common. Our previous work [14,15,16] proposed a process for recycling SRM through aluminum electrolytic cells to produce Al-Si alloys. The industrial application has been successfully demonstrated, providing a sustainable solution to SRM disposal and resource utilization in aluminum smelters. However, the current bottleneck of this technology is that the dissolution rate of SRM is relatively slow. As a result, the addition of SRM is not too large, which limits the Si content in the alloys. Additionally, the current efficiency is also slightly reduced. A detailed investigation of the dissolution mechanism and dissolution rate of SRM is therefore necessary.

Currently, the most studied topic is the dissolution of alumina in aluminum electrolytic cells, and there is little research on the dissolution of SRM. Alumina, being a major constituent of SRM, can serve as a reference for studying the dissolution of SRM. Thonstad et al. [17] suggested that the dissolution of alumina particles is governed by heat and mass transfer mechanisms. According to the mass transfer mechanism, Alarie et al. [18] designed a series of experiments to measure the alumina diffusivity in an electrolytic bath and obtained a general Sherwood number equation to predict the dissolution rate of alumina. Kovács et al. [19] investigated the dissolution of one cold alumina particle in a bath based on the heat and mass transfer mechanism. Our previous work [20,21] focused on the behavior of alumina agglomerates in an electrolyte. It was found that the particles took much longer to dissolve than to freeze. Taylor et al. [22] discovered through experiments that the dissolution of agglomerated particles is governed by the heat transfer, while the dissolution of dispersed small particles is governed by the mass transfer. The above-mentioned research on alumina dissolution provides a valuable reference for studying the dissolution process of SRM, but the effect of process conditions and parameters on the dissolution rate is neglected, which is the most concerning part of the production process.

In this work, a mass transfer model and a heat transfer model for the dissolution of SRM particles were established, which describe the diffusion migration control and surface reaction control, respectively. According to the established dissolution model, the effects of electrolyte superheat, alumina concentration, silica concentration, turbulent kinetic energy dissipation rate, and particle temperature on the dissolution rate of SRM particles were analyzed. The dissolution law of SRM obtained through theoretical analysis can provide theoretical guidance for subsequent electrolytic cell process parameter control and process design.

2. Modeling and Methods

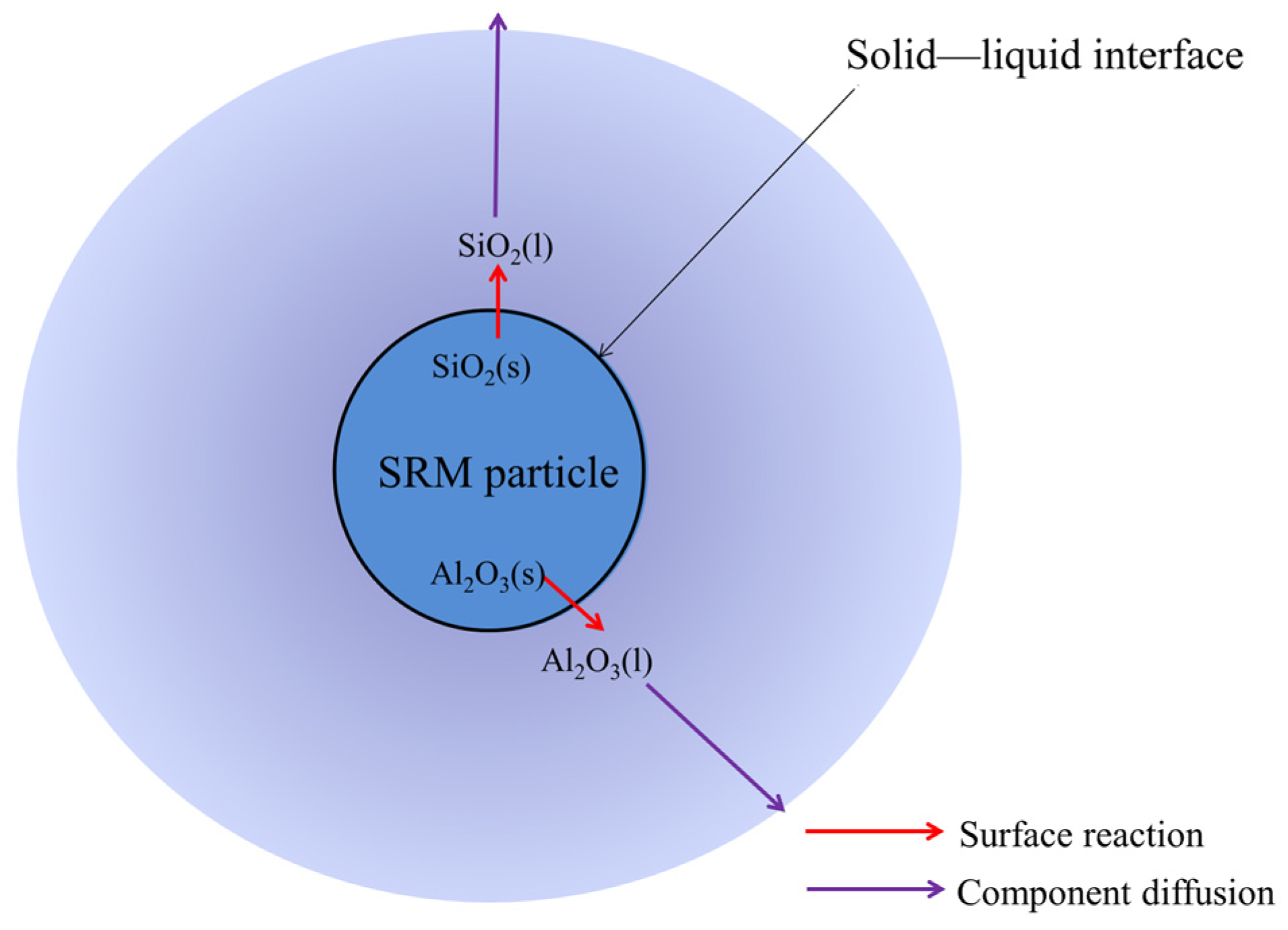

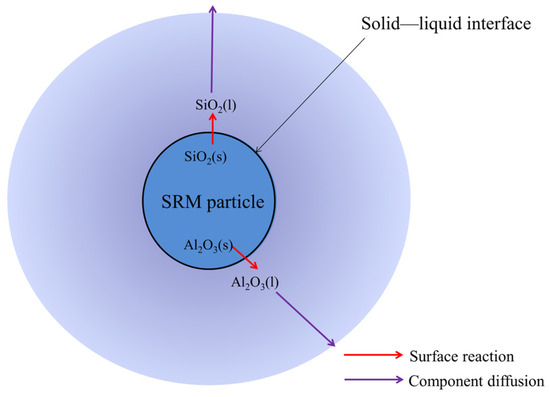

There are two processes involved in dissolving SRM particles: the surface reaction and the diffusion of the components, as shown in Figure 1. The slowest step of the surface reaction rate and diffusion rate is the rate-controlling step, and the dissolution rate depends on this rate-controlling step [23,24]. If the chemical reaction rate at a particle surface is greater than the diffusion rate, dissolution is governed by the mass transfer mechanism. Conversely, dissolution is governed by the heat transfer mechanism.

Figure 1.

Schematic diagram of SRM particle dissolution.

2.1. Mass Transfer Model

The electrolyte flow in an aluminum electrolytic cell is turbulent [25,26]. Assuming that the alumina and silica particles are spherical, the mass transfer process of alumina and silica particles in the electrolyte can be expressed by a dimensionless equation [27]:

where Sh is the Sherwood number, ; Rem is the modified Reynolds number, ; and Sc is the Schmidt number, . ds is the solid particle diameter, k is the mass transfer coefficient, εL is the turbulent kinetic energy dissipation rate, D is the diffusion coefficient, and νL is the kinematic viscosity of the electrolyte. k is expressed as follows:

Due to the concentration difference being the driving force for particle dissolution under the mass transfer mechanism, the mass dissolution rate can be expressed as follows [17,28]:

where ms is the particle mass, . csat is the saturation concentration and c is the local concentration. τ is time and ρp and ρL are the particle density and the electrolyte density, respectively.

By combining Equations (2) and (3), a shrinking core model in which particles dissolve under the mass transfer mechanisms can be derived:

2.2. Heat Transfer Model

According to the analogy of heat and mass transfer, the heat transfer process of alumina and silica particles can be expressed by a dimensionless equation:

where Nu is the Nusselt number, and λL is the thermal conductivity of the electrolyte. Pr is the Prandtl number, , cp,L is the specific heat capacity of the electrolyte, and h is the convective heat transfer coefficient between the agglomerate particle and the electrolyte.

Due to the superheat being the driving force for particle dissolution under the heat transfer mechanism, the mass dissolution rate of particles can be expressed as follows:

where cp is the specific heat capacity of the particle, which is a variable related to temperature. ΔHdiss is the heat absorbed by particle dissolution, which mainly includes particle dissolution enthalpy, water vapor vaporization enthalpy in particles, and component phase change enthalpy [29,30]. TL, Tp, and Tliq are the electrolyte temperature, agglomerate temperature, and liquidus temperature, respectively.

According to Equations (8) and (9), the shrinkage core model of particles under the heat transfer mechanism can be derived:

According to the specific heat capacity data of Al2O3 and SiO2 in NIST-JANAF [31], as shown in Table 1, the formulas for the specific heat capacity of Al2O3 and SiO2 are obtained through data fitting.

Table 1.

Specific heat capacity of Al2O3 and SiO2 at different temperatures.

The heat absorbed by alumina when it heats up can be expressed as follows:

The heat absorbed by silica when it heats up can be expressed as follows:

2.3. Calculation Conditions

The particle size of SRM particles is below 200 μm, and the particle size distribution is listed in Table 2 [15]. When SRM particles are fed into the electrolyte, the electrolyte temperature decreases as the particles absorb heat, which causes some poorly dispersed SRM particles to clump together and form agglomerates. The agglomerates typically form within the first 20 s, with the SRM in the agglomerates hardly dissolving during this period [20,32]. The particle size of these agglomerated particles is generally around 1~1.5 cm, and the particle size distribution is listed in Table 3. The mass of agglomerated particles in SRM particles accounts for approximately 84.1% [33,34]. The ratio of silica to alumina in SRM is approximately 9:16.

Table 2.

Particle size distribution of non-agglomerated SRM particles.

Table 3.

Particle size distribution of agglomerated SRM particles.

The physical parameters of the electrolyte, alumina, and silica particles are shown in Table 4. These values were obtained through experimental measurements, theoretical calculations, and relevant literature [17,34].

Table 4.

Initial physical parameters in calculation.

Based on the conclusions from Taylor’s experiment [22], the mass transfer model was used to calculate the dissolution of non-agglomerated particles, while the heat transfer model was used to calculate the dissolution of agglomerated particles.

3. Results and Discussion

3.1. Effect of Concentration on SRM Dissolution

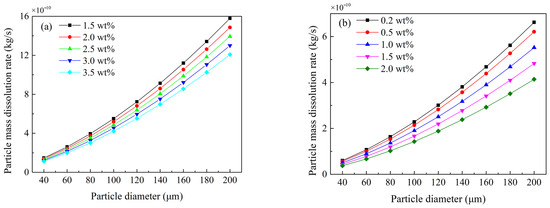

To avoid the anode effect and accelerate the dissolution of SRM, the alumina concentration is normally kept at 1.5~3.5 wt%, and the silica concentration is generally controlled at 0.2~1.5 wt%. When SRM is fed into the electrolyte, the SRM particles dissolve into the electrolyte, and the local alumina and silica concentrations in the electrolyte will increase. Changes in alumina and silica concentration affect the dissolution rate of the non-agglomerated SRM particles. The effects of alumina concentrations of 1.5, 2.0, 2.5, 3.0, and 3.5 wt% and silica concentrations of 0.2, 0.5, 1.0, 1.5, and 2.0 wt% on the dissolution process were investigated.

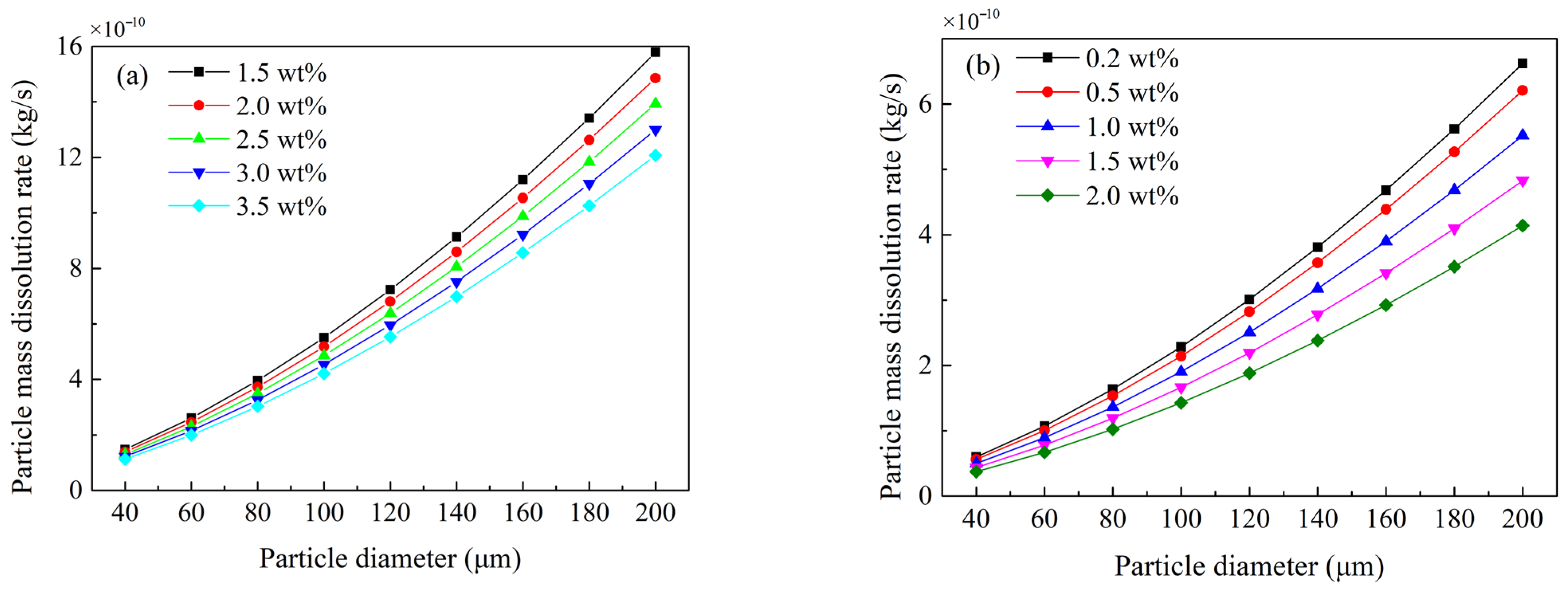

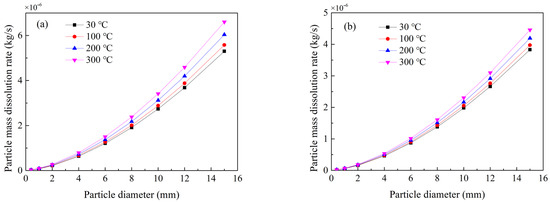

Figure 2 shows the effect of concentration on the mass dissolution rate of non-agglomerated SRM particles. The figure shows that for the same alumina or silica concentration, the mass dissolution rate of alumina or silica particles increases rapidly with increasing particle size. For the same particle size, the dissolution rate of non-agglomerated SRM particles decreases with the increasing concentration. This is because a high concentration leads to a reduction in the concentration difference, which limits the mass diffusion rate of alumina and silica in the electrolyte, resulting in a reduction in the mass dissolution rate of the particles. Therefore, maintaining a low concentration of alumina and silica in the electrolyte contributes to the rapid dissolution of SRM particles. Comparing Figure 2a and Figure 2b shows that the dissolution rate of the alumina particles is faster than that of the silica particles, which is consistent with previous literature [1,15].

Figure 2.

Effect of concentration on the mass dissolution rate of non-agglomerated SRM particles: (a) alumina particles; (b) silica particles.

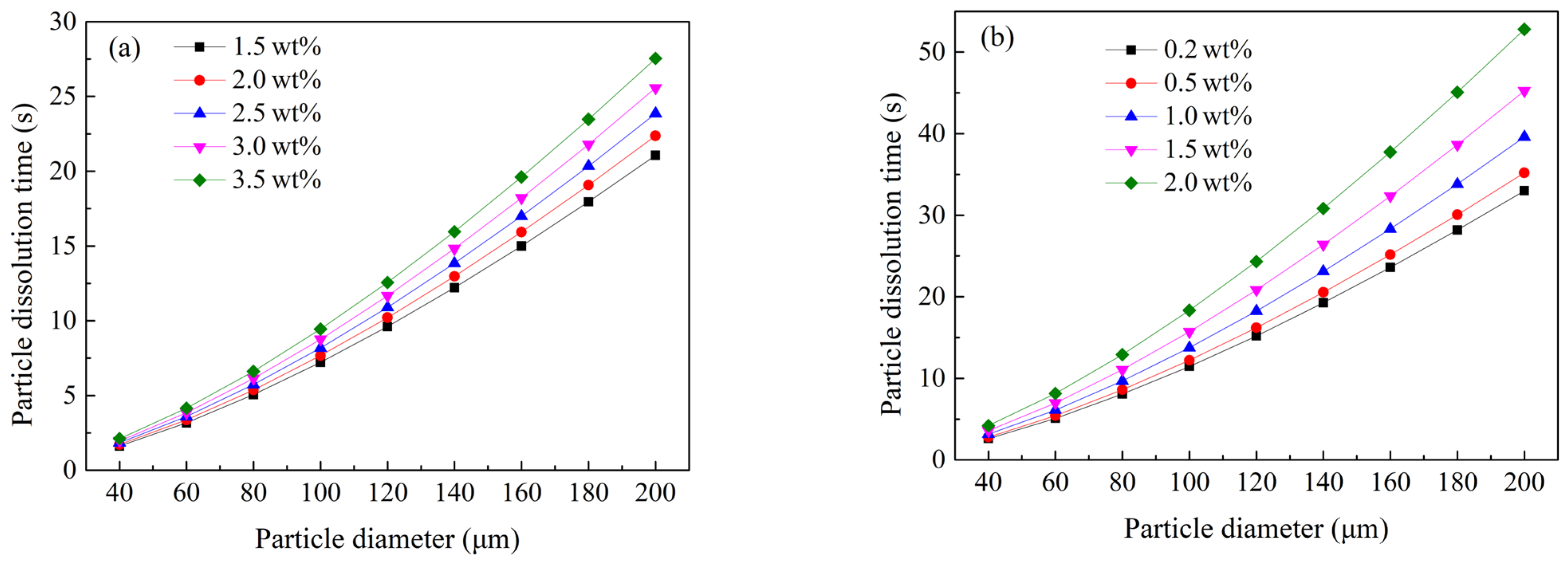

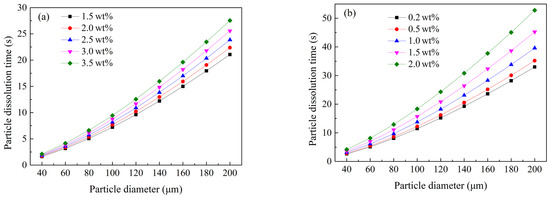

Figure 3 illustrates the influence of concentration on the dissolution time of non-agglomerated SRM particles. With consistent particle size, reducing the concentration of alumina or silica surrounding the SRM particles leads to a significant reduction in the dissolution time of the alumina and silica particles. Within the concentration range shown in the figure, non-agglomerated alumina particles can be completely dissolved within 28 s, which is much smaller than 53 s for silica particles.

Figure 3.

Effect of concentration on the dissolution time of non-agglomerated SRM particles: (a) alumina particles; (b) silica particles.

In summary, the concentration of alumina and silica around non-agglomerated particles affects their dissolution rate, with higher concentrations leading to slower dissolution rates and longer dissolution times. Maintaining a lower concentration of alumina and silica and accelerating the dispersion and transport of the particles to areas with lower concentrations contributes not only to the rapid dissolution of the particles, but also to the timely replenishment of the alumina and silica consumed by the electrolysis.

3.2. Effect of Electrolyte Superheat on SRM Dissolution

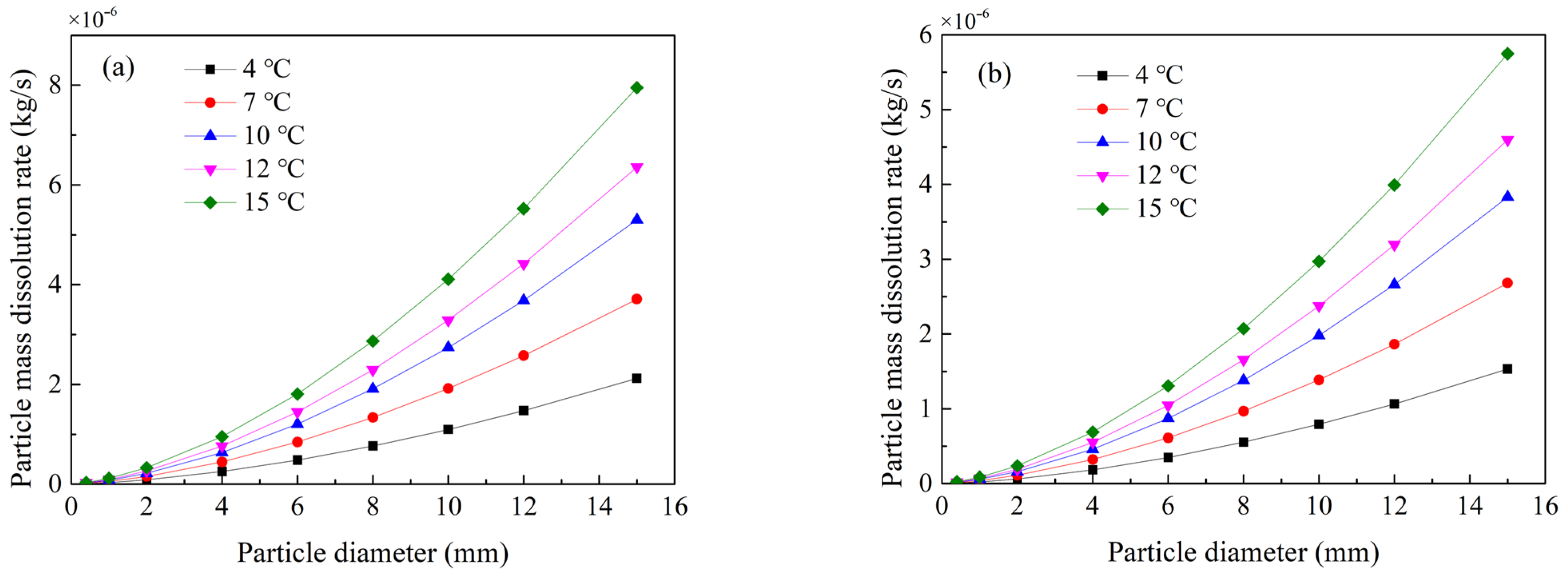

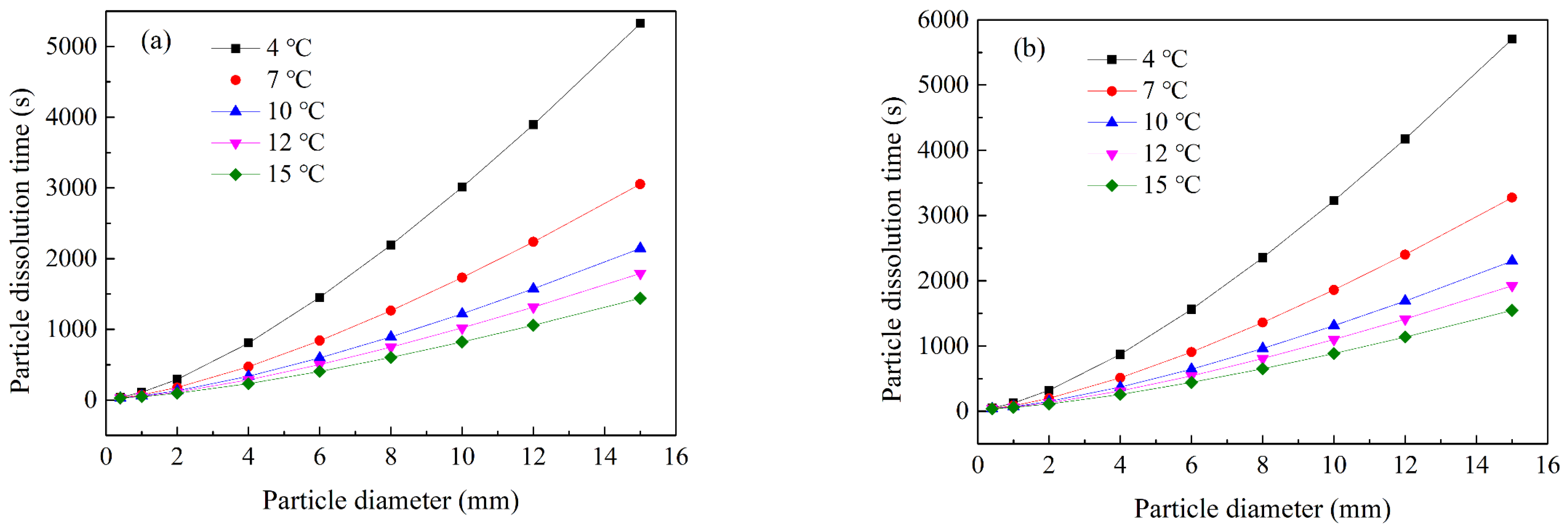

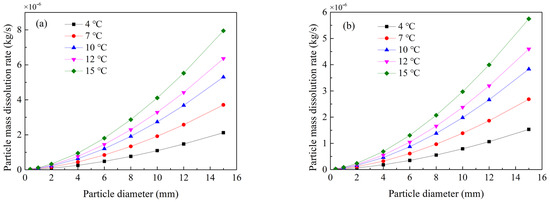

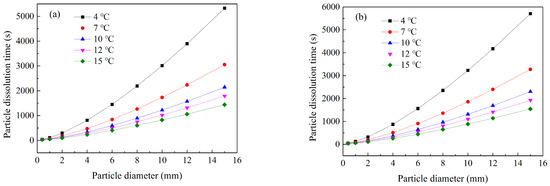

The superheat of the electrolyte is generally controlled at 8~15 °C. The temperature of the electrolyte decreases and superheat reduces when SRM is fed into the electrolyte, attributed to particle dissolution and heat absorption. The dissolution of agglomerated SRM particles is governed by the heat transfer, that is, affected by the superheat. To reveal the influence of different superheats on the dissolution of agglomerated SRM particles, the effects of superheats of 4, 7, 10, 12, and 15 °C on the particle dissolution rate and dissolution time were studied, respectively. The results are illustrated in Figure 4 and Figure 5.

Figure 4.

Effect of superheat on the mass dissolution rate of agglomerated SRM particles: (a) alumina particles; (b) silica particles.

Figure 5.

Effect of superheat on the dissolution time of agglomerated SRM particles: (a) alumina particles; (b) silica particles.

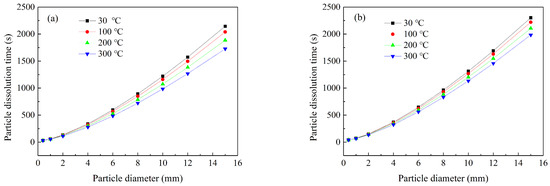

Figure 4 shows that the mass dissolution rate of the agglomerated SRM particles increases exponentially with increasing particle size at the same superheat. The higher the superheat, the larger the gradient of particle dissolution rate with particle size. This is because, with an increase in particle size, the surface area of the particles participating in the reaction also increases, leading to a higher dissolution rate. Therefore, it is important to disperse the SRM particles well in the electrolyte to minimize particle agglomeration, which results in a larger total reaction area that is more conducive to particle dissolution. Additionally, for particles of the same size, the dissolution rate increases significantly with an increase in superheat. The increase in superheat accelerates the dissolution of SRM particles.

Figure 5 shows that for the same particle size, the time needed for particle dissolution increases significantly with decreasing superheat. Similarly, when the superheat is the same, the time needed for particle dissolution increases exponentially with the increase in particle size. This explains why SRM must be broken into fine particles, as it encourages its dissolution in the electrolyte and prevents larger particles from dissolving slowly and forming sediment at the bottom of the cell. Comparing Figure 5a and Figure 5b, it is evident that the time required for the dissolution of silica in SRM is longer than that of alumina when the particle size is the same. Alumina and silica particles with a particle size less than 1 mm can be fully dissolved within a feeding cycle of 144 s. However, in the case of large agglomerated particles, which are around 1cm in size, if the electrolyte has low superheat, then the time taken for these particles to dissolve will be longer, which can be up to 3000 s. This may lead to sediment formation. To prevent this from happening, it is important to ensure the fluidity of the particles, so they can be quickly dispersed and avoid aggregation after being fed. This helps to reduce the formation of large agglomerates and excessive sediment.

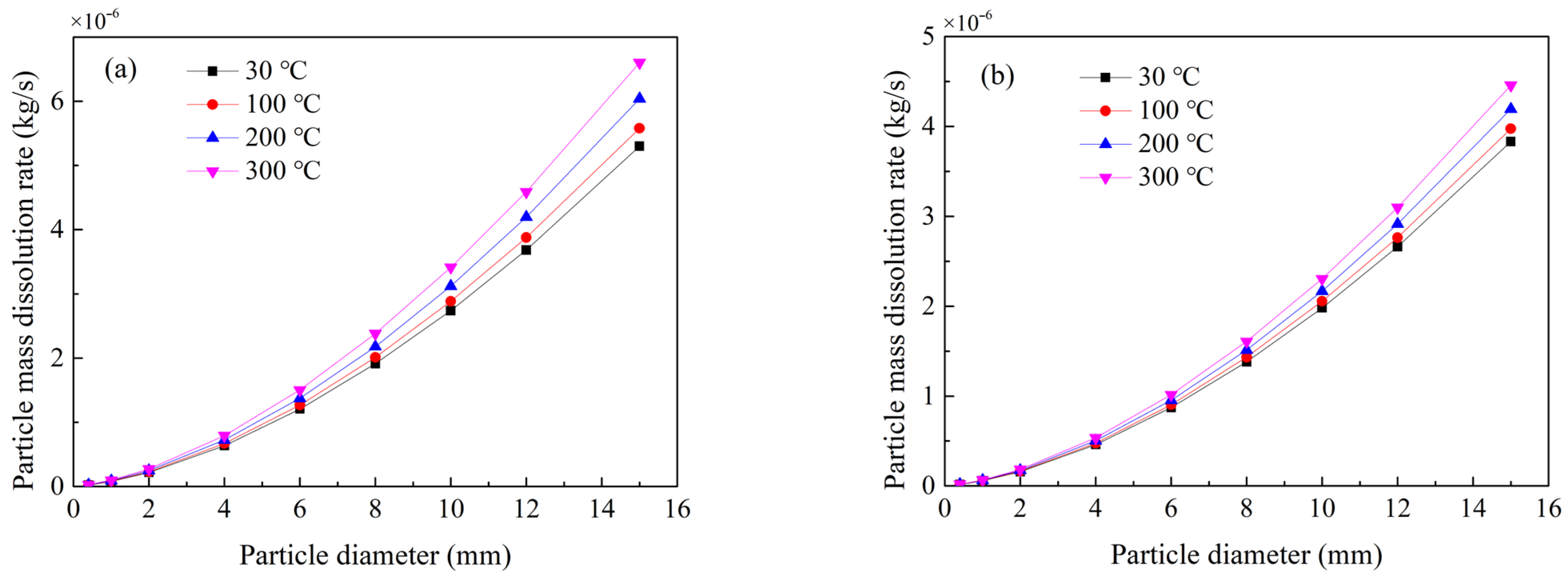

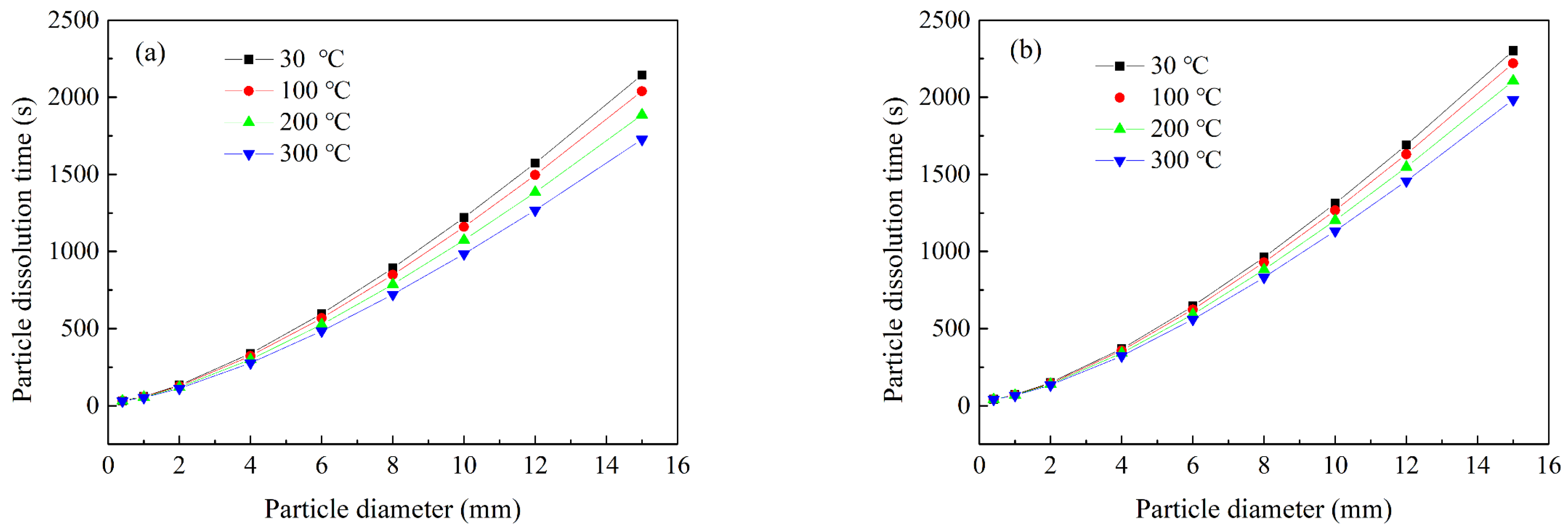

3.3. Effect of Particle Temperature on SRM Dissolution

To determine whether preheating of SRM particles is required, the effects of SRM particle temperatures on the particle dissolution process at 30 °C, 100 °C, 200 °C, and 300 °C were studied, respectively. The results are presented in Figure 6 and Figure 7. The figures show that the dissolution rate of the particles increases slightly with increasing temperature of the SRM particles and the dissolution time is shortened. For instance, for a 1 cm SRM particle, when the particle temperature increases from 30 °C to 300 °C, the dissolution time reduces by approximately 300 s. The difference in dissolution time for SRM particles with smaller particle sizes is even smaller. Preheating of the SRM particles has little effect on dissolution time. However, the dissolution time of a 1 cm SRM particle can be shortened by 2300 s when the electrolyte superheat increases from 4 °C to 15 °C. Therefore, increasing the temperature of SRM particles can help speed up the particle dissolution rate and shorten the dissolution time, but the effect is not significant. Compared to preheating SRM particles, increasing the superheat of the electrolyte is more effective in dissolving SRM particles. If there is waste heat that can be used to heat the SRM, the SRM particles can be preheated. There is no need to expend fuel specifically to preheat SRM particles.

Figure 6.

Effect of particle temperature on the mass dissolution rate of agglomerated SRM particles: (a) alumina particles; (b) silica particles.

Figure 7.

Effect of particle temperature on the dissolution time of agglomerated SRM particles: (a) alumina particles; (b) silica particles.

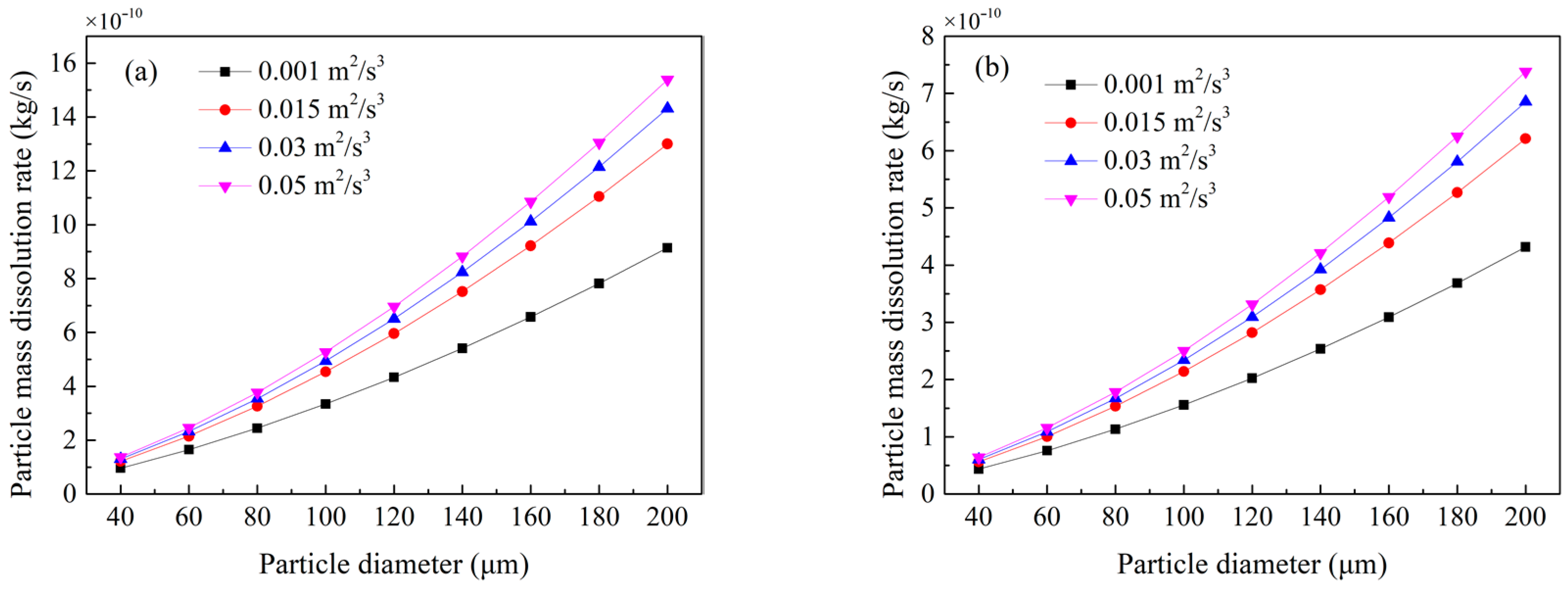

3.4. Effect of Turbulent Kinetic Energy Dissipation Rate on SRM Dissolution

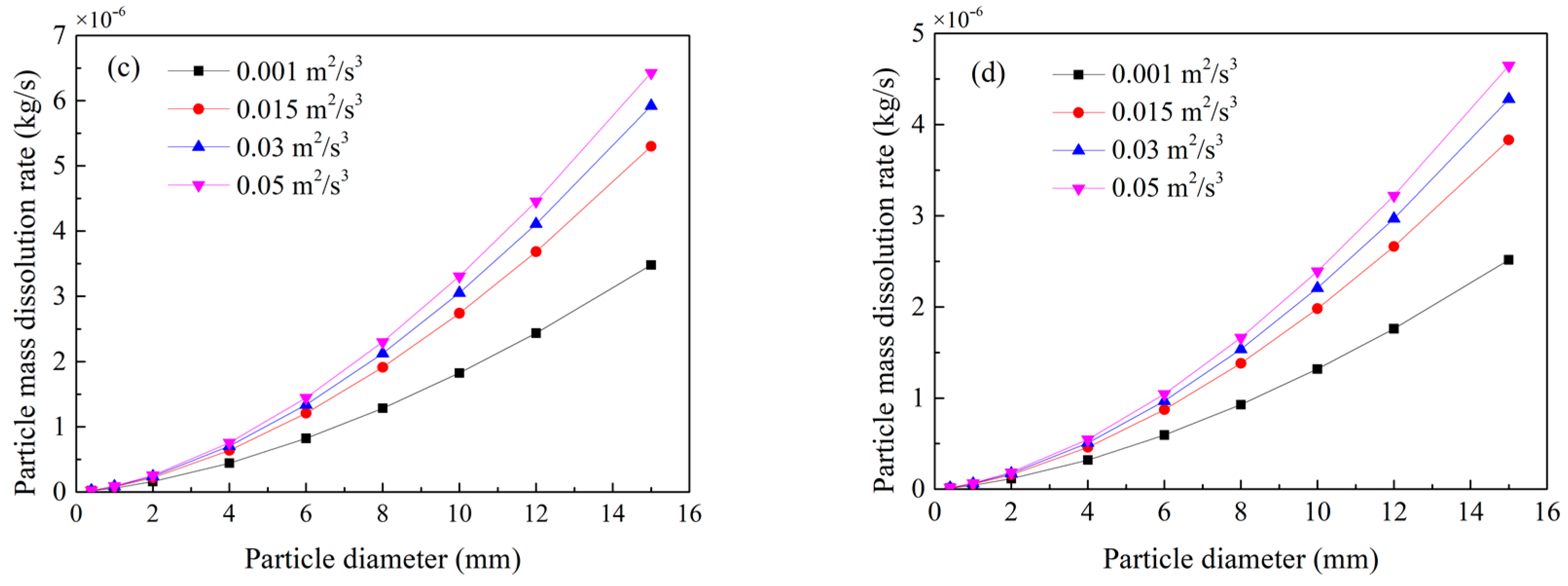

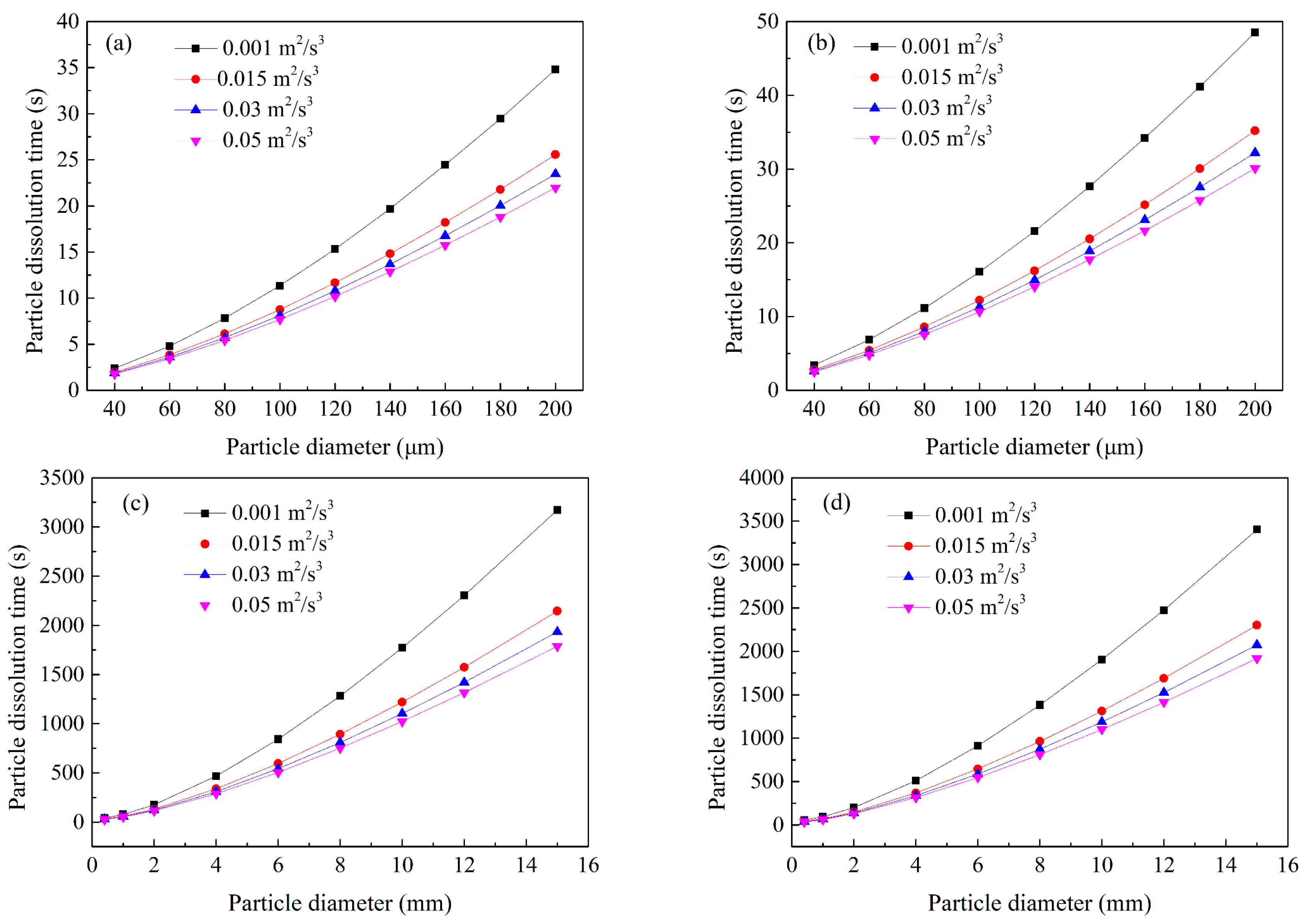

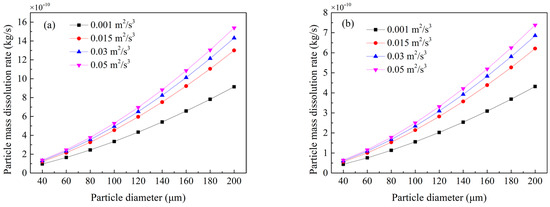

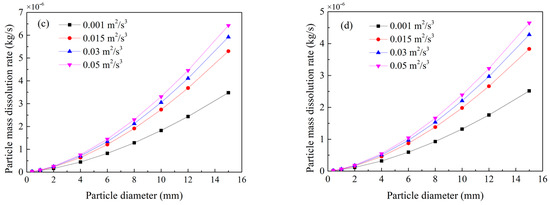

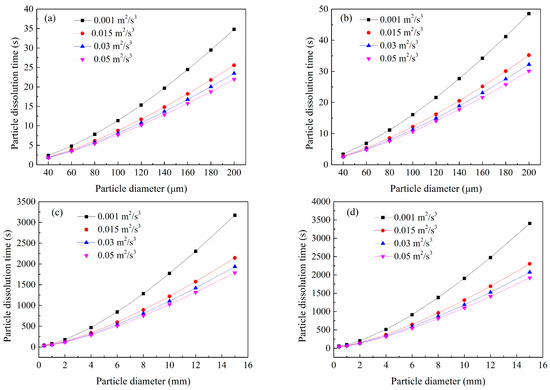

The electrolyte flow in the aluminum electrolytic cell is turbulent. Especially at the feeding hole, the bubbles escape and drive the electrolyte to stir up and down, making the electrolyte flow more turbulent and increasing the turbulent kinetic energy dissipation rate. Turbulence has a significant influence on the dissolution of SRM particles, as it contributes to particle dispersion, heat transfer, and mass transfer. To investigate the influence of the turbulent kinetic energy dissipation rate of the electrolyte on the dissolution of SRM particles, the dissolution was studied at different turbulent kinetic energy dissipation rates, namely 0.001 m2/s3, 0.015 m2/s3, 0.03 m2/s3, and 0.05 m2/s3. The results are presented in Figure 8 and Figure 9.

Figure 8.

Effect of turbulent kinetic energy dissipation rate on the mass dissolution rate of SRM particles: (a) non-agglomerated alumina particles; (b) non-agglomerated silica particles; (c) agglomerated alumina particles; and (d) agglomerated silica particles.

Figure 9.

Effect of turbulent kinetic energy dissipation rate on the dissolution time of SRM particles: (a) non-agglomerated alumina particles; (b) non-agglomerated silica particles; (c) agglomerated alumina particles; (d) agglomerated silica particles.

The figures shows that both types of particles experience an increase in their dissolution rates and a reduction in the dissolution time as the turbulent kinetic energy dissipation rate increases. This demonstrates that an increase in the turbulent kinetic energy dissipation rate contributes to the rapid dissolution of particles. For agglomerated particles, such as 1 cm agglomerated particles, when the turbulent kinetic energy dissipation rate increases from the lowest 0.001 m2/s3 to the largest 0.05 m2/s3, the dissolution time decreases by around 800 s. The turbulent kinetic energy dissipation rate has a major influence on the dissolution of agglomerated particles. During the field tests, it was also found that alumina dissolves faster when the feeding hole is located at the intersection of the anode gap and the center channel. This is due to the fact that the electrolyte in this area is violently stirred up by the bubbles and the turbulent kinetic energy dissipation rate is higher, which is conducive to the dissolution and dispersion of the particles. Therefore, by adjusting the anode structure and the process parameters, appropriately increasing the turbulence intensity and turbulent kinetic energy dissipation rate of the electrolyte will contribute to the rapid dissolution of SRM.

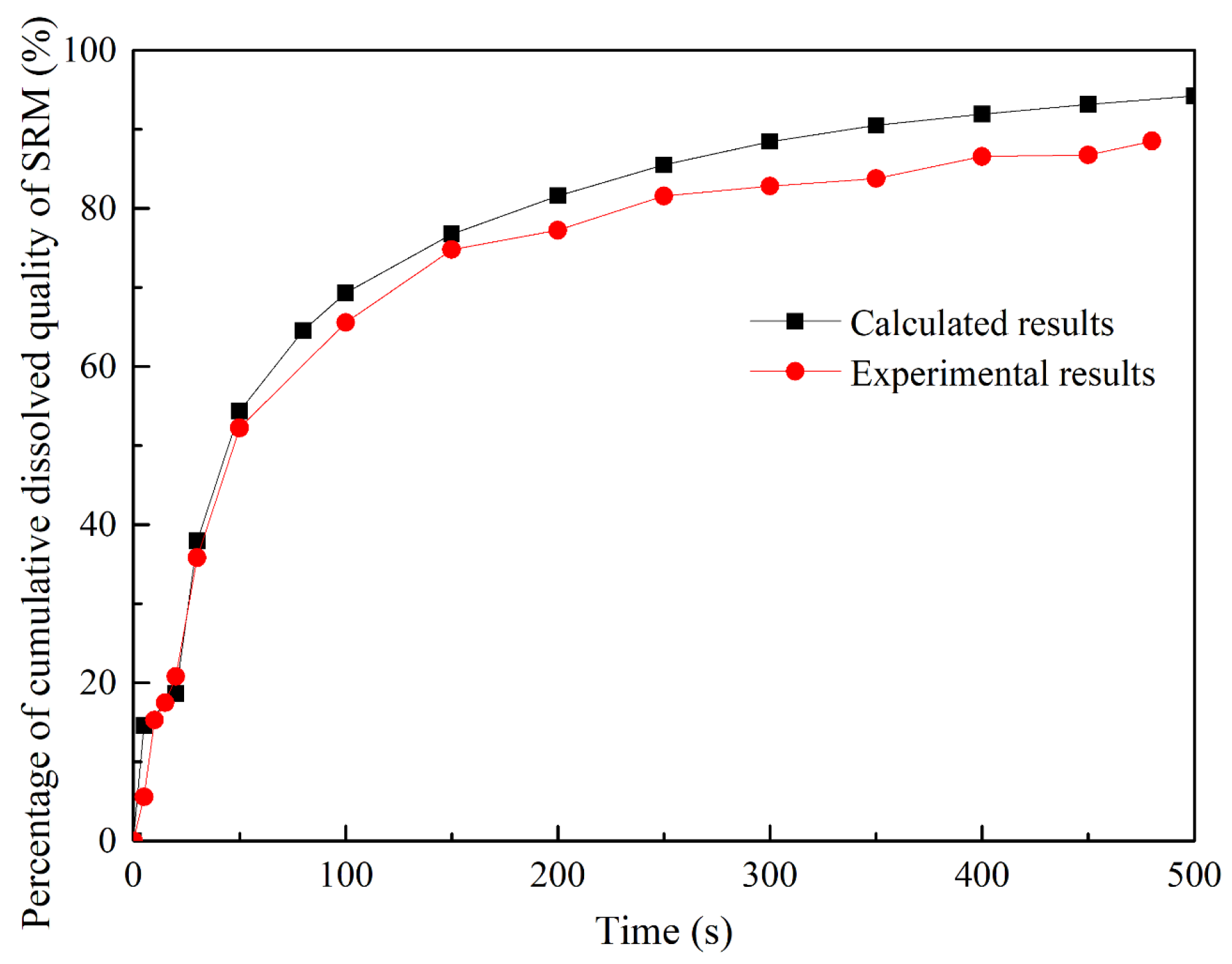

3.5. Model Validation

To check the accuracy of the model, the data from the literature and the experiment are compared with the calculated results of the model established in this work. The dissolution time of a non-agglomerated alumina particle is compared with the results from the literature, as shown in Table 5. The comparison shows that the calculated dissolution time of alumina is basically consistent with the literature data, indicating that the proposed model is suitable for calculating the dissolution process of non-agglomerated particles.

Table 5.

Comparison of calculated alumina dissolution time with the literature data.

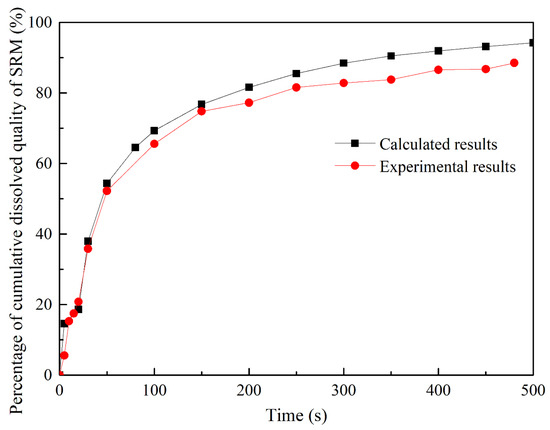

The comparison of the percentage of cumulative dissolved quantity between the calculated and experimental results is illustrated in Figure 10. It can be seen that the results obtained by calculations and experiments are in good agreement, with an error within 10%, suggesting that the model established is reliable when calculating the dissolution of SRM particles. The calculated results are slightly larger than the experimental data. This is mainly due to the reduction in dissolution rate caused by the decrease in temperature and the increase in concentration during the dissolution process.

Figure 10.

The comparison between the calculated and experimental results.

4. Conclusions

A mass transfer model and a heat transfer model for the dissolution of SRM particles were established. Based on the established dissolution model, the effects of electrolyte superheat, alumina concentration, silica concentration, turbulent kinetic energy dissipation rate, and particle temperature on the dissolution rate and dissolution time of SRM particles were investigated. The established model was verified and the dissolution law of SRM particles in the electrolyte was theoretically analyzed and explained. The main conclusions are listed below:

- (1)

- Non-agglomerated SRM particles can dissolve within 50 s, and as the concentration decreases, the mass dissolution rate increases and the time required for complete dissolution is shorter. For example, when the silica concentration in the electrolyte is reduced to 0.2 wt%, the time required for the complete dissolution of non-agglomerated SRM particles is reduced to 33 s. On the premise that no anode effect occurs, the alumina and silica concentrations should be kept as low as possible.

- (2)

- By increasing the particle temperature and the electrolyte superheat, the mass dissolution rate of the agglomerated SRM particles can be accelerated and the dissolution time shortened. However, increasing the electrolyte superheat has a greater effect on accelerating the dissolution of agglomerated SRM particles than increasing the particle temperature. In practical applications, the electrolyte temperature can be increased accordingly.

- (3)

- Regardless of whether the SRM particles are non-agglomerated or agglomerated, increasing the turbulent kinetic energy dissipation rate can increase the mass dissolution rate and shorten the dissolution time. The tilted anode can be used to allow more bubbles to escape from the feeding point and increase the turbulent kinetic energy dissipation rate of the electrolyte, thereby accelerating the dispersion and dissolution of the SRM particles.

Author Contributions

Conceptualization, X.H. and W.H.; methodology, W.H.; software, X.H.; validation, W.H. and W.L.; formal analysis, X.H. and W.H.; investigation, X.H.; data curation, M.L. and H.L.; writing—original draft preparation, X.H. and W.H.; writing—review and editing, W.L.; supervision, W.L., M.L. and H.L.; funding acquisition, W.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Research Program of Shanxi Province (202203021222028), National Natural Science Foundation of China (62205311), and Innovation Key Talent Team of Solar Energy Utilization Technology in Shanxi Province (202204051002023).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Author Wei Liu was employed by Shenyang Aluminium & Magnesium Engineering & Research Institute Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, J.; Lu, X.; Meng, F.; Li, H. Dissolution behavior of overhaul slag from aluminum reduction cell in a cryolite-based molten salt system. Energy Rep. 2023, 9, 118–127. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, B.; Hong, S.; Huang, H.; Liu, F.; Sohn, H.Y. Recovery of copper and cobalt from converter slags via reduction–sulfurization smelting using spent pot lining as the reductant. ACS Sustain. Chem. Eng. 2021, 9, 4234–4246. [Google Scholar] [CrossRef]

- Miksa, D.; Homsak, M.; Samec, N. Spent potlining utilisation possibilities. Waste Manag. Res. 2003, 21, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, P.; Bu, X.; Chelgani, S.C.; Kong, Y.; Liang, X. Resource utilization strategies for spent pot lining: A review of the current state. Sep. Purif. Technol. 2022, 300, 121816. [Google Scholar] [CrossRef]

- Li, J.; Tu, H.; Li, X.; Chen, Y.; Zhou, T.; Li, Z.; Zhao, Z.; Liu, Y. Resourceful modification mechanism of modified electrolytic aluminum spent refractory material and its long-term safety performance assessment. Constr. Build. Mater. 2024, 418, 135254. [Google Scholar] [CrossRef]

- Li, N.; Gao, L.; Chattopadhyay, K. Experimental Study on the Collecting Agent for Spent Potlining Flotation Index Optimization; Tomsett, A., Ed.; Light Metals: Warrendale, PA, USA, 2020; pp. 1243–1250. [Google Scholar]

- Robshaw, T.J.; Bonser, K.; Coxhill, G.; Dawson, R.; Ogden, M.D. Development of a combined leaching and ion-exchange system for valorisation of spent potlining waste. Waste Biomass Valorization 2020, 11, 5467–5481. [Google Scholar] [CrossRef]

- Tropenauer, B.; Klinar, D.; Golob, J. Improved understanding of Sodium hydroxide concentration role and kinetic model of cryolite reactive extraction in cathode Spent Pot Linings. Pol. J. Chem. Technol. 2021, 23, 37–44. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, J.; Lu, Z.; Liu, Z.; Liu, P. Research on Wet Acid-Free Treatment Technology for SPL; Perander, L., Ed.; Light Metals: Warrendale, PA, USA, 2021; pp. 467–473. [Google Scholar]

- Renó, M.L.G.; Torres, F.M.; Silva, R.J.d.; Santos, J.J.C.S.; Melo, M.d.L.N.M. Exergy analyses in cement production applying waste fuel and mineralizer. Energy Convers. Manag. 2013, 75, 98–104. [Google Scholar] [CrossRef]

- Ghenai, C.; Inayat, A.; Shanableh, A.; Al-Sarairah, E.; Janajreh, I. Combustion and emissions analysis of Spent Pot lining (SPL) as alternative fuel in cement industry. Sci. Total Environ. 2019, 684, 519–526. [Google Scholar] [CrossRef]

- Wang, Y.; Huan, S.; Di, Y.; Peng, J. The harmless of spent refractory in aluminum electrolysis cells and summary of its treatment. Conserv. Util. Min. Resour. 2019, 39, 42–47. [Google Scholar]

- Tu, H.; Li, X.; Muhammad, Y.; Jin, X.; Lin, H.; Pei, R.; Zhao, Z.; Li, J. Feasibility of reuse of modified electrolytic aluminium spent refractory material in asphalt and assessment of its environmental stability. J. Clean. Prod. 2023, 389, 136072. [Google Scholar] [CrossRef]

- Hou, W.; Li, M.; Li, H. Industrial experimental research on co-processing of spent refractory materials in aluminum electrolytic cell. J. Cent. South Univ. 2023, 54, 587–594. [Google Scholar]

- Hou, W.; Li, H.; Li, M.; Cheng, B. Recycling of spent refractory materials to produce Al-Si master alloys via the aluminum reduction cell. J. Clean. Prod. 2021, 289, 125162. [Google Scholar] [CrossRef]

- Hou, W.; Wang, J.; Li, H. Theoretical investigation of thermodynamic properties of the Al–Si–Fe ternary alloy. ACS Omega 2024, 9, 6316–6324. [Google Scholar] [CrossRef] [PubMed]

- Thonstad, J.; Solheim, A.; Rolseth, S.; Skar, O. The Dissolution of Alumina in Cryolite Melts; Boxall, G., Ed.; Light Metals: Warrendale, PA, USA, 1988; pp. 105–111. [Google Scholar]

- Alarie, J.; Kiss, L.I.; Dion, L.; Guérard, S.; Bilodeau, J.-F.; Santerre, R. Determination of the alumina diffusivity and dissolution rate for alumina samples immersed in a cryolitic bath. Materialia 2023, 32, 101901. [Google Scholar] [CrossRef]

- Kovács, A.; Breward, C.J.W.; Einarsrud, K.E.; Halvorsen, S.A.; Nordgård-Hansen, E.; Manger, E.; Münch, A.; Oliver, J.M. A heat and mass transfer problem for the dissolution of an alumina particle in a cryolite bath. Int. J. Heat Mass Transfer 2020, 162, 120232. [Google Scholar] [CrossRef]

- Wang, J.; Li, M.; Cheng, B.; Li, H. Modelling the formation and dissolution behavior of alumina agglomerate in the cryolite. Particuology 2024, 86, 211–222. [Google Scholar] [CrossRef]

- Li, M.; Wang, J.; Hou, W.; Cheng, B.; Li, H. Mathematical model of the dissolution process of alumina particles in the Hall-Héroult process. Int. Commun. Heat Mass Transfer 2021, 128, 105627. [Google Scholar] [CrossRef]

- Taylor, M.P.; Welch, B.J.; McKibbin, R. Effect of convective heat transfer and phase change on the stability of aluminium smelting cells. AIChE J. 1986, 32, 1459–1465. [Google Scholar] [CrossRef]

- Hou, W.; Li, H.; Li, M.; Cheng, B.; Feng, Y. Effects of electrolysis process parameters on alumina dissolution and their optimization. Trans. Nonferrous Met. Soc. China 2020, 30, 3390–3403. [Google Scholar] [CrossRef]

- Li, S.; Li, M.; Hou, W.; Li, H.; Cheng, B. Simulation of alumina dissolution and temperature response under different feeding quantities in aluminum reduction cell. J. Cent. South Univ. 2019, 26, 2119–2128. [Google Scholar] [CrossRef]

- Feng, Y.; Schwarz, M.P.; Yang, W.; Cooksey, M. Two-phase CFD model of the bubble-driven flow in the molten electrolyte layer of a Hall–Héroult aluminum cell. Metall. Mater. Trans. B 2015, 46, 1959–1981. [Google Scholar] [CrossRef]

- Hou, W.; Sun, K.; Sun, S.; Li, M. Numerical investigation of electro-thermal field distribution law of busbar under different operating conditions. Metals 2023, 13, 1361. [Google Scholar] [CrossRef]

- Armenante, P.M.; Kirwan, D.J. Mass transfer to microparticles in agitated systems. Chem. Eng. Sci. 1989, 44, 2781–2796. [Google Scholar] [CrossRef]

- Cao, H.; Amador, C.; Jia, X.; Li, Y.; Ding, Y. A modelling framework for bulk particles dissolving in turbulent regime. Chem. Eng. Res. Des. 2016, 114, 108–118. [Google Scholar] [CrossRef]

- Solheim, A.; Skybakmoen, E. Mass- and Heat Transfer during Dissolution of Alumina; Tomsett, A., Ed.; Light Metals: Warrendale, PA, USA, 2020; pp. 664–671. [Google Scholar]

- Berezin, A.I.; Isaeva, L.A.; Belolipetsky, V.M.; Piskazhova, T.V.; Sinelnikov, V.V. A Model of Dissolution and Heating of Alumina Charged by Point-Feeding System in “Virtual Cell” Program; Kvande, H., Ed.; Light Metals: Warrendale, PA, USA, 2005; pp. 151–154. [Google Scholar]

- NIST-JANAF Thermochemical Tables. Available online: https://kinetics.nist.gov (accessed on 15 December 2022).

- Walker, D.I. Alumina in Aluminum Smelting and Its Behaviour after Addition to Cryolite-Based Electrolytes. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 1993. [Google Scholar]

- Østbø, N.P. Evolution of Alpha Phase Alumina in Agglomerates upon Addition to Cryolitic Melts. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2002. [Google Scholar]

- Hou, W. Theoretical and Application Study on Co-Processing Spent Refractory Materials in the Aluminum Reduction Cell. Ph.D. Thesis, Central South University, Changsha, China, 2021. [Google Scholar]

- Lillebuen, B.; Bugge, M.; Hlie, H. Alumina Dissolution and Current Efficiency in Hall-Heroult Cells; Bearne, G., Ed.; Light Metals: Warrendale, PA, USA, 2009; pp. 389–394. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).