Experimental Investigation on Quasi-Freckle Phenomenon in Single-Crystal-Blade Castings of Superalloys

Abstract

1. Introduction

2. Experimental Materials and Methods

3. Experimental Results and Analysis

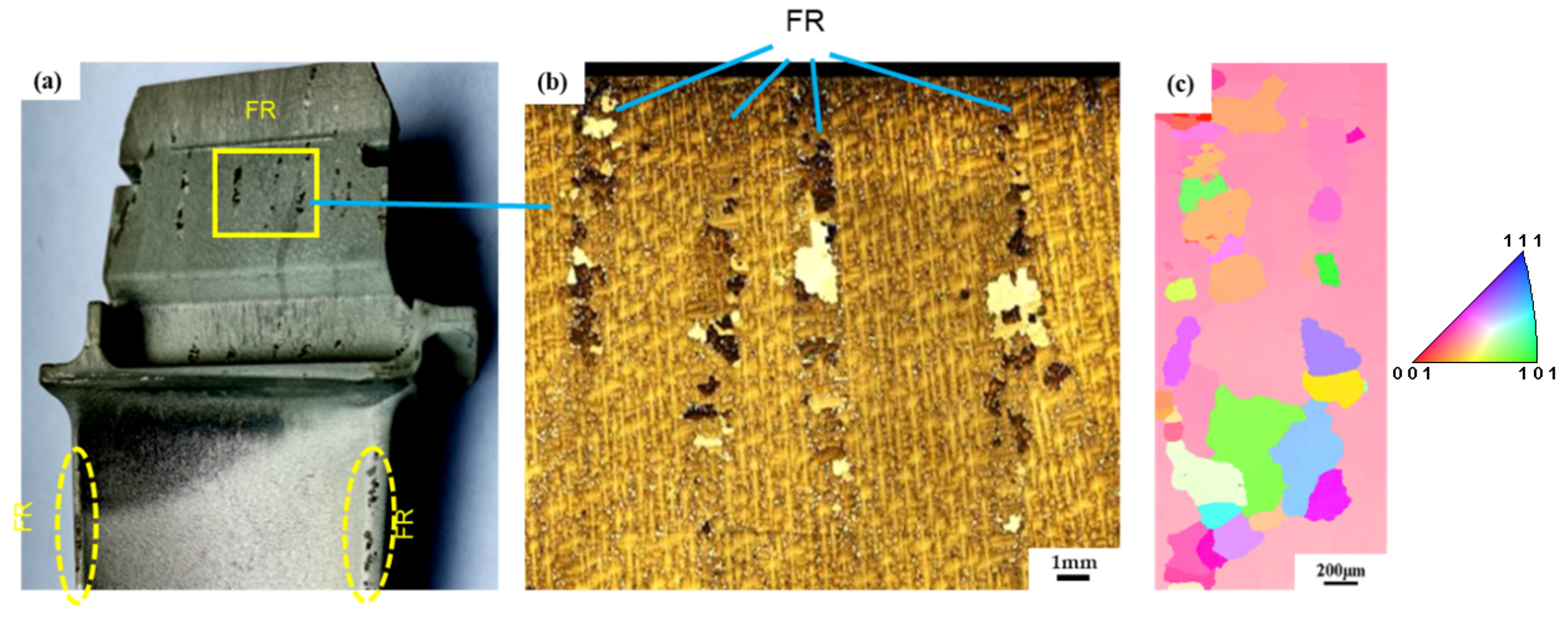

3.1. Typical Freckles (FR)

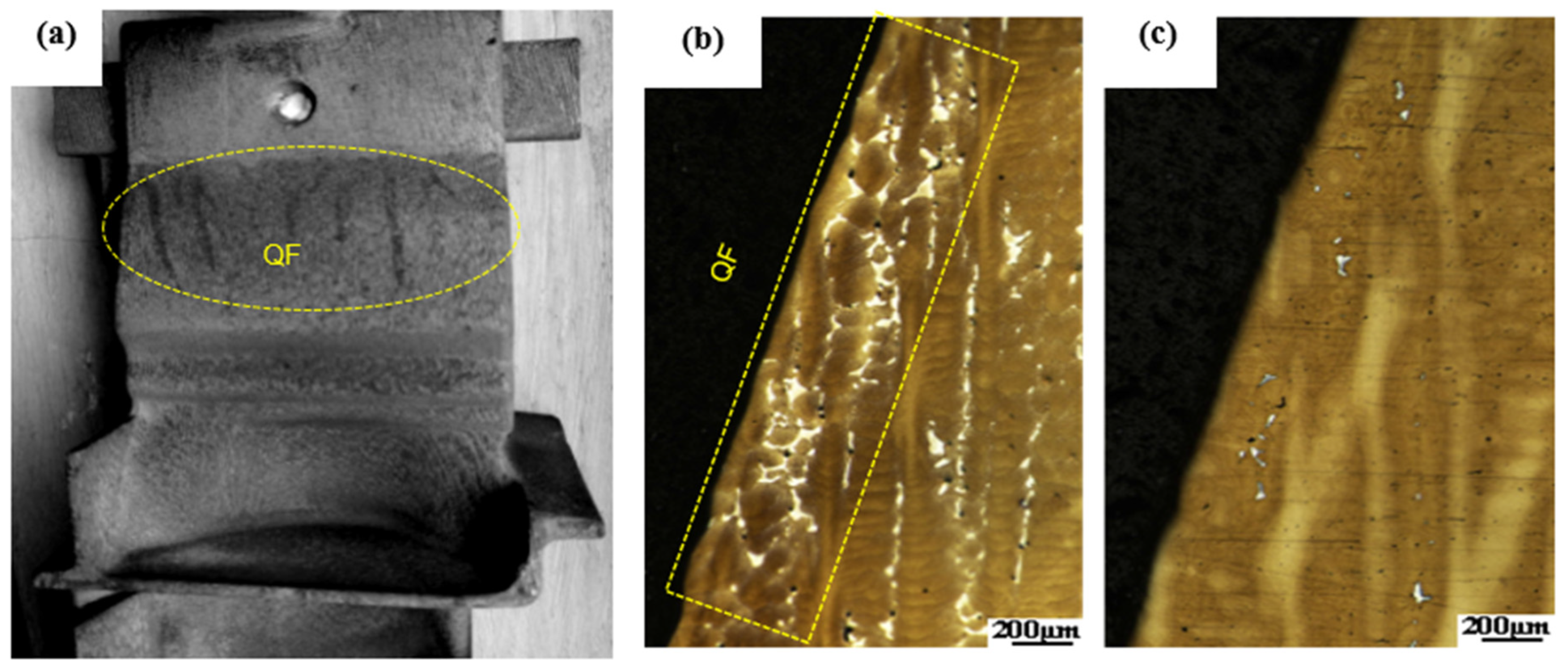

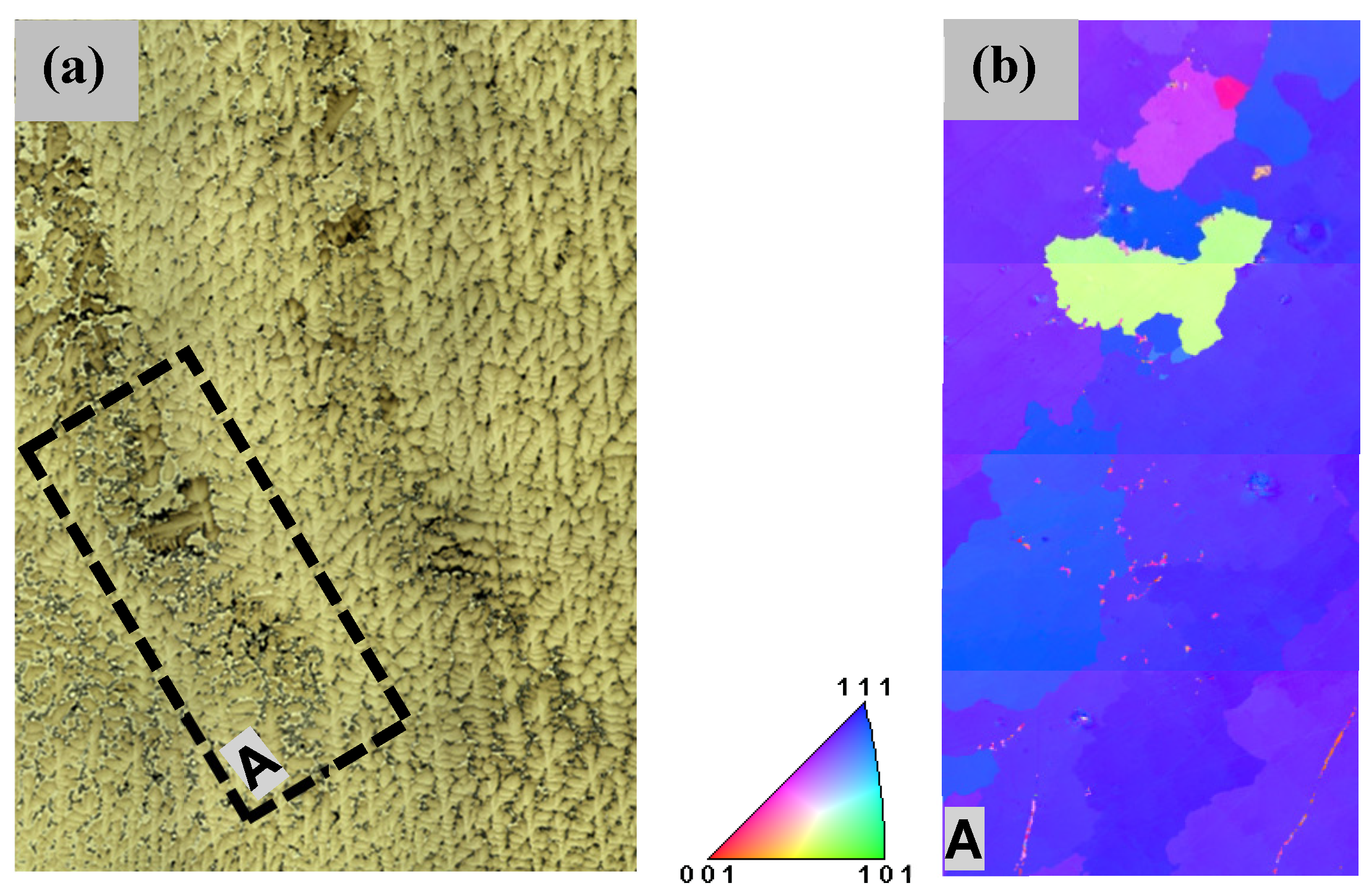

3.2. Typical Quasi-Freckles (QF)

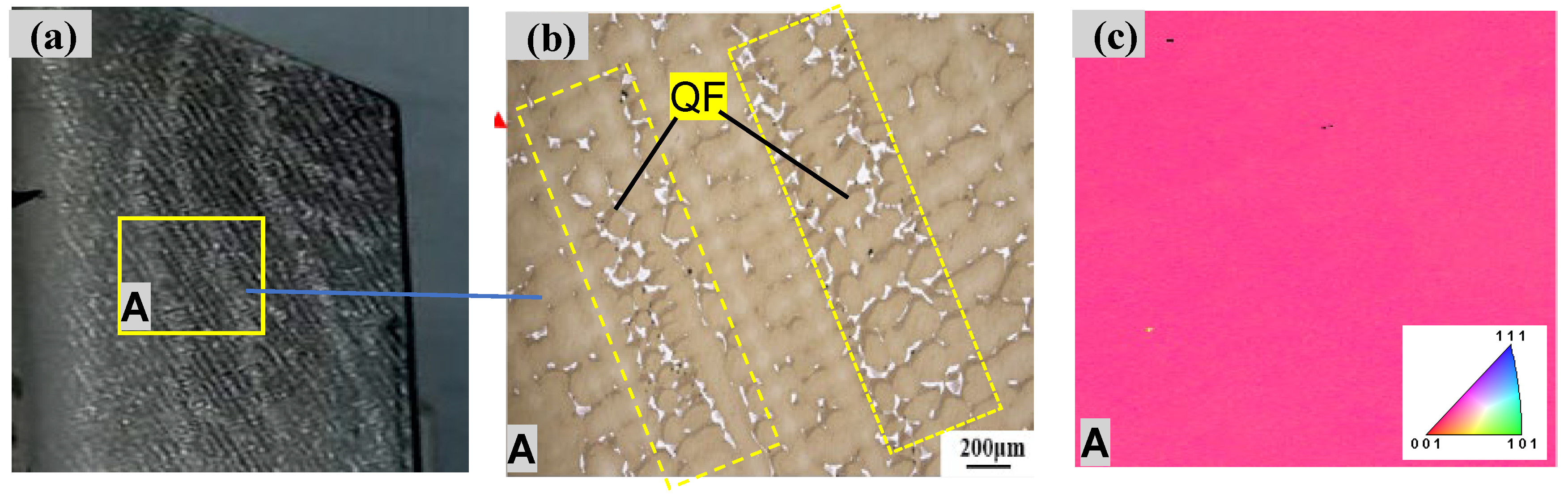

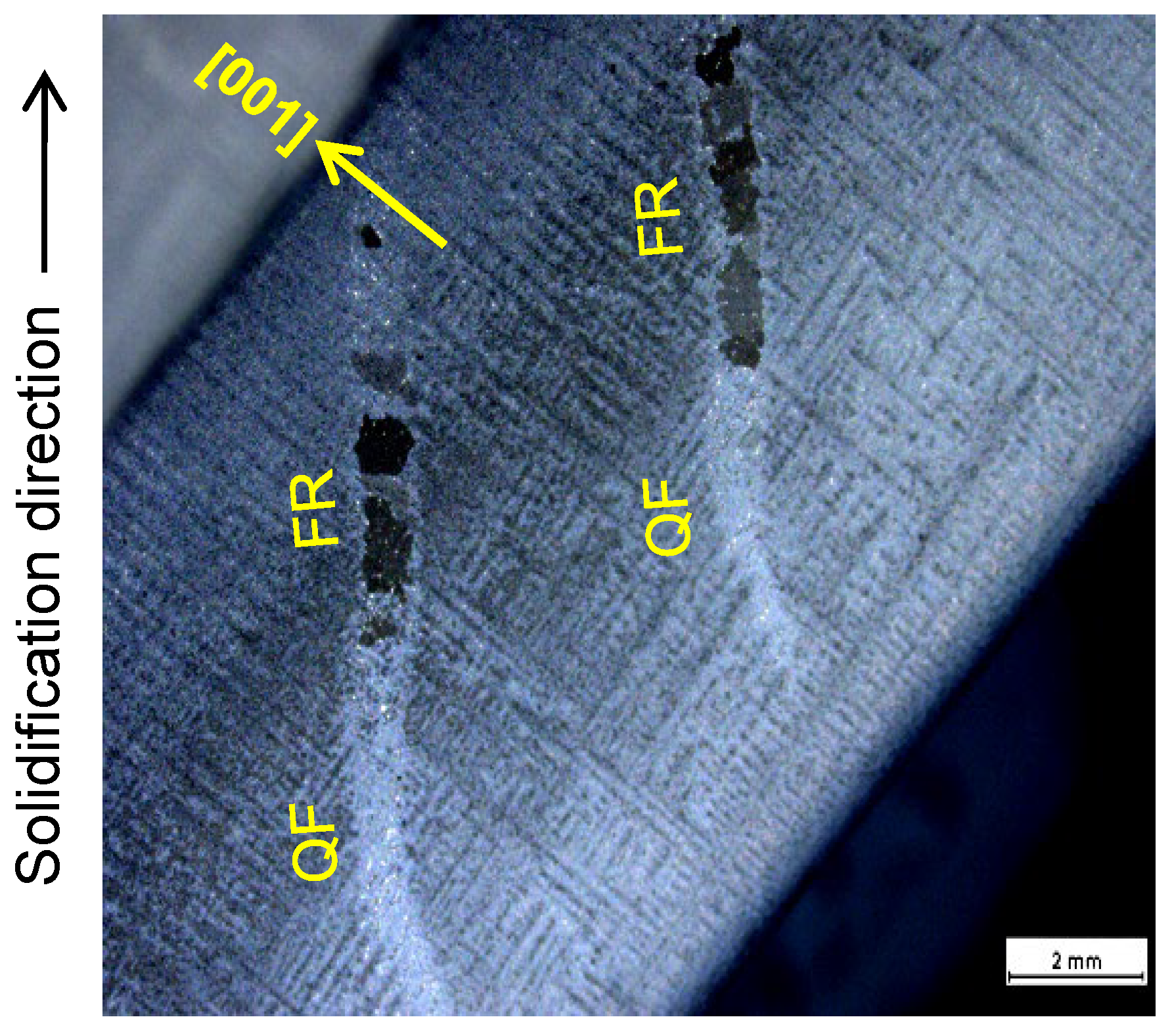

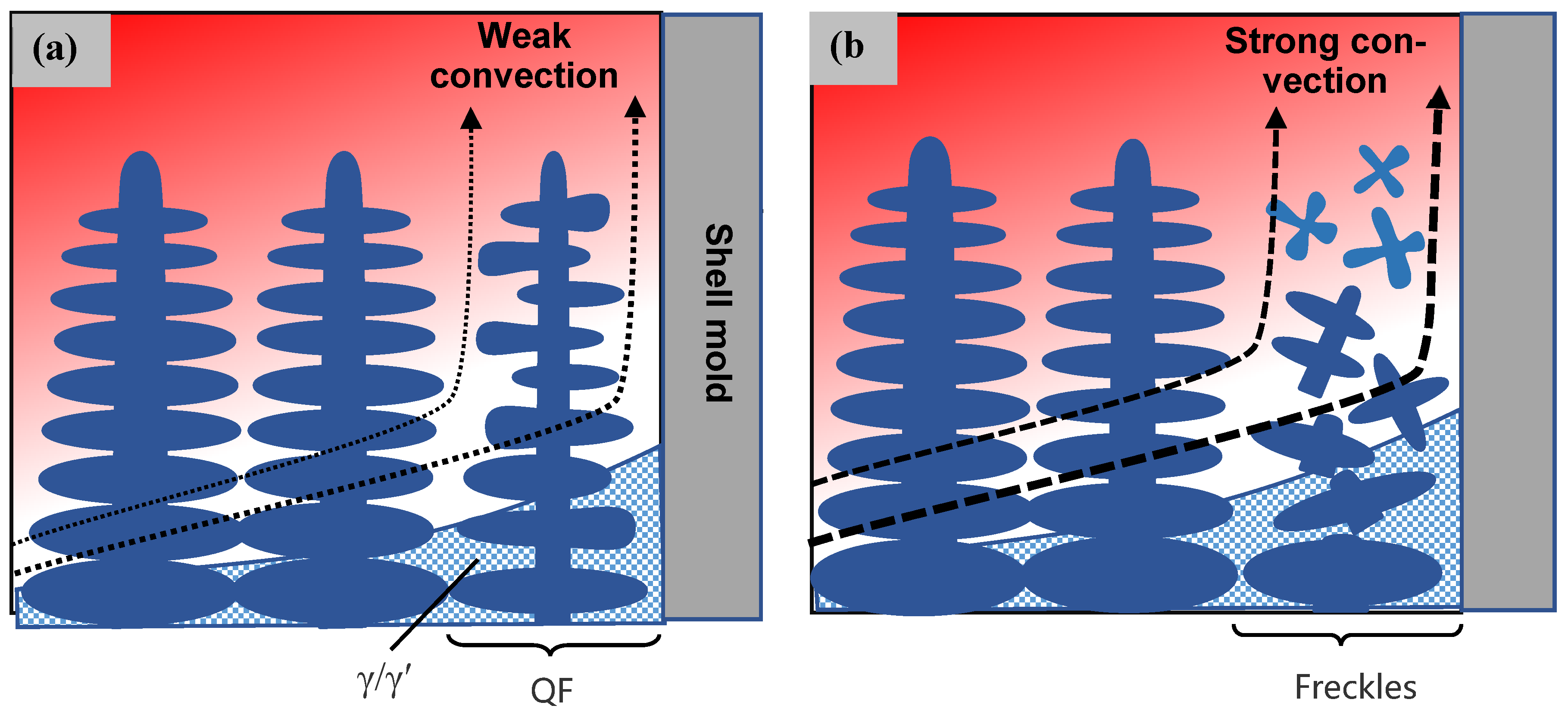

3.3. Mixed Freckles

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide; ASM International: Troit, MI, USA, 2002. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Versnyder, F.I.; Shank, M.E. The development of columnar grain and single crystal high temperature materials through directional solidification. Mater. Sci. Eng. 1970, 6, 213–247. [Google Scholar] [CrossRef]

- Pratt, D.C. Industrial casting of superalloys. Mater. Sci. Technol. 1986, 2, 426–435. [Google Scholar] [CrossRef]

- Quested, P.N.; Osgerby, S. Mechanical properties of conventionally cast, directionally solidified, and single-crystal superalloys. Mater. Sci. Technol. 1986, 2, 461–475. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Xie, G. Recent Progress in Research and Development of Nickel-Based Single Crystal Superalloys. Acta Metall. Sin. 2023, 59, 1109–1124. [Google Scholar]

- Yan, W.; Zhang, Y.; Chen, W.; Li, J. Characteristics and Formation Tendency of Freckle Segregation in Electroslag Remelted Bearing Steel. Metals 2020, 10, 246. [Google Scholar] [CrossRef]

- Giamei, A.F.; Kear, B.H. On the nature of freckles in nickel base superalloys. Metall. Trans. 1970, 1, 2185–2192. [Google Scholar] [CrossRef]

- Copley, S.M.; Giamei, A.F.; Johnson, S.M.; Hornbecker, M.F. The origin of freckles in unidirectionally solidified castings. Metall. Trans. 1970, 1, 2193–2204. [Google Scholar] [CrossRef]

- Auburtin, P.; Wang, T.; Cockcroft, S. A Mitchell. Freckle formation and freckle criterion in superalloy castings. Metall. Mater. Trans. B 2000, 31, 801–811. [Google Scholar] [CrossRef]

- Tin, S.; Pollock, T.M. Predicting freckle formation in single crystal Ni-base superalloys. J. Mater. Sci. 2004, 39, 7199–7205. [Google Scholar] [CrossRef]

- Ren, N.; Panwisawas, C.; Li, J.; Xia, M.; Dong, H.; Li, J. Solute enrichment induced dendritic fragmentation in directional solidification of nickel-based superalloys. Acta Mater. 2021, 215, 117043. [Google Scholar] [CrossRef]

- Ma, D. Effect of casting geometry on the freckle formation during single crystal solidification of superalloys. Rare Met. Mater. Eng. 2021, 50, 4357–4364. [Google Scholar]

- Zhang, Y.; Jia, Y.; Zhou, J.; Yin, Y.; Ji, X.; Shen, X.; Li, W. Effect of withdrawal rate on freckle formation of large-size directional solidified nickel-based superalloy blades. J. Mater. Res. Technol. 2024, 30, 1518–1530. [Google Scholar] [CrossRef]

- Han, D.; Jiang, W.; Xiao, J.; Li, K.; Lu, Y.; Lou, L. Influence of Geometric Structure and Feeding Behavior of Casting on Freckle Formation during Directional Solidification of a Ni-Based Single-Crystal Superalloy. Cryst. Res. Technol. 2021, 56, 2000197. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Liu, S.; Wang, X.; Yang, W. Effects of Withdrawal Velocity and Casting Geometry on Freckle Formation of Nickel-Based Single Crystal Superalloys. Metall. Mater. Trans. A 2023, 54, 1223–1235. [Google Scholar] [CrossRef]

- Ma, D.; Zhao, Y.; Xu, W. Freckle formation affected by geometry features of single crystal superalloy castings. Res. Dev. Mater. Sci. 2021, 15, 1749–1752. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Liu, S.; Zhao, J.; Wang, X.; Yang, W. Investigation on freckle formation of nickel-based single crystal superalloy specimens with suddenly reduced cross section. J. Alloys Compd. 2022, 918, 165631. [Google Scholar] [CrossRef]

- Pustal, B.; Wittenzellner, T.; Behnken, H.; Böttger, B.; Bührig-Polaczek, A. Experimental Analysis and Simulation of Freckle Formation at Different Edge Angles During Directional Solidification of Ni-Base Superalloys. Metall. Mater. Trans. B 2024, 55, 2732–2738. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, F. A novel prediction model of the freckle defects for single-crystal superalloy blades. J. Phys. Conf. Ser. 2024, 2686, 012013. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, F.; Ma, D.; Yang, Q.; Xu, W.; Zhao, Y.; Li, D. Freckle prediction model incorporating geometrical effects for Ni-based single-crystal superalloy components. Acta Mater. 2024, 266, 119702. [Google Scholar] [CrossRef]

| Cr | Co | W | Mo | Al | Ti | Ta | Re | Hf | Ni | |

|---|---|---|---|---|---|---|---|---|---|---|

| DD419 | 6.44 | 9.57 | 6.38 | 0.61 | 5.60 | 1.02 | 6.47 | 2.94 | 0.11 | Bal. |

| CMSX-4 | 6.50 | 9.00 | 6.00 | 0.60 | 5.60 | 1.00 | 6.50 | 3.00 | 0.10 | Bal. |

| WZ30 | 3.50 | 6.00 | 6.50 | 0.40 | 5.80 | 0.15 | 8.00 | 4.95 | - | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, D.; Li, L.; Zhao, Y.; Deng, Y.; Cheng, B.; Xu, F. Experimental Investigation on Quasi-Freckle Phenomenon in Single-Crystal-Blade Castings of Superalloys. Metals 2024, 14, 1129. https://doi.org/10.3390/met14101129

Ma D, Li L, Zhao Y, Deng Y, Cheng B, Xu F. Experimental Investigation on Quasi-Freckle Phenomenon in Single-Crystal-Blade Castings of Superalloys. Metals. 2024; 14(10):1129. https://doi.org/10.3390/met14101129

Chicago/Turabian StyleMa, Dexin, Lv Li, Yunxing Zhao, Yangpi Deng, Bowen Cheng, and Fuze Xu. 2024. "Experimental Investigation on Quasi-Freckle Phenomenon in Single-Crystal-Blade Castings of Superalloys" Metals 14, no. 10: 1129. https://doi.org/10.3390/met14101129

APA StyleMa, D., Li, L., Zhao, Y., Deng, Y., Cheng, B., & Xu, F. (2024). Experimental Investigation on Quasi-Freckle Phenomenon in Single-Crystal-Blade Castings of Superalloys. Metals, 14(10), 1129. https://doi.org/10.3390/met14101129