Hot Deformation Behavior and Processing Maps of Vapor-Phase-Grown Carbon Nanofiber Reinforced 7075Al Composites

Abstract

:1. Introduction

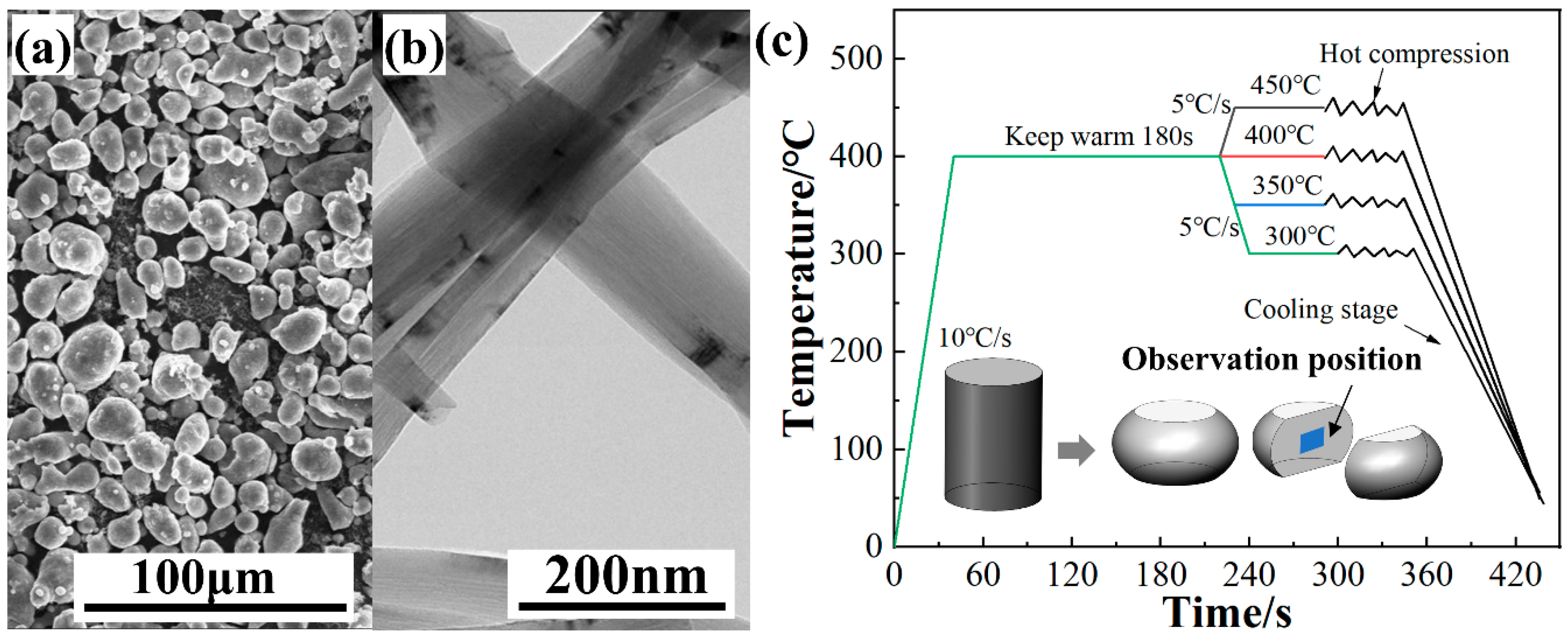

2. Materials and Methods

3. Results and Discussion

3.1. Effect of VGCNF on Mechanical Properties and Microstructure of Composites

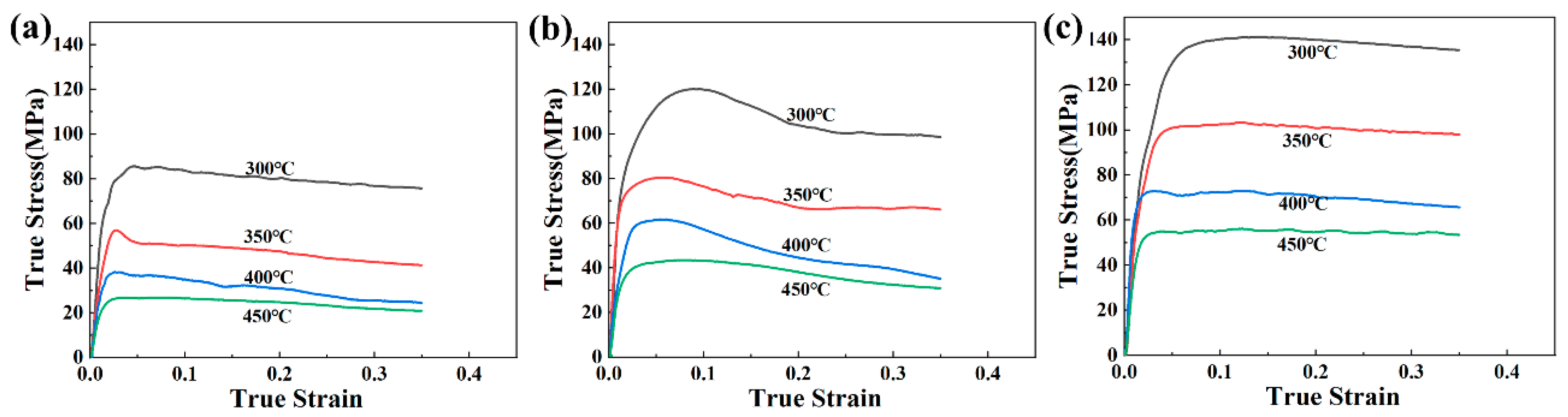

3.2. High Temperature Flow Behavior of VGCNF/7075Al

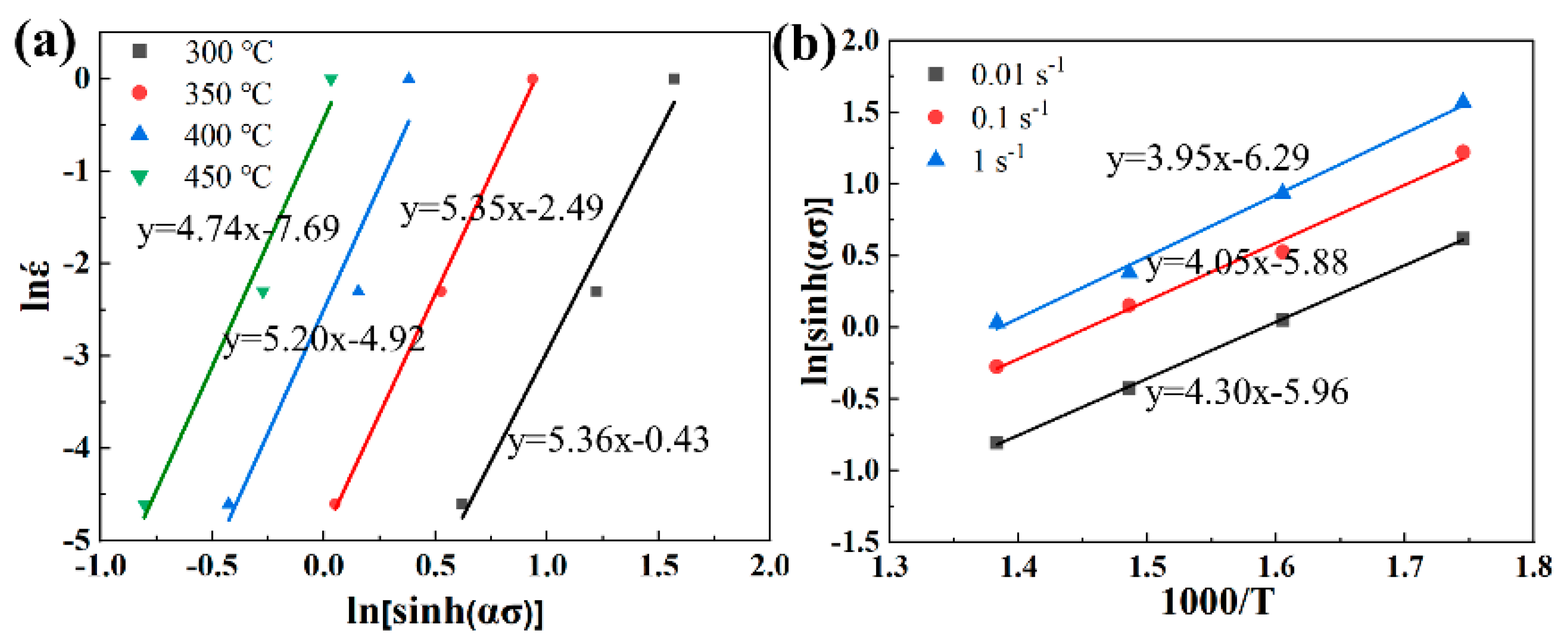

3.3. Constitutive Model and Hot Deformation Activation Energy of VGCNF/7075Al Composites

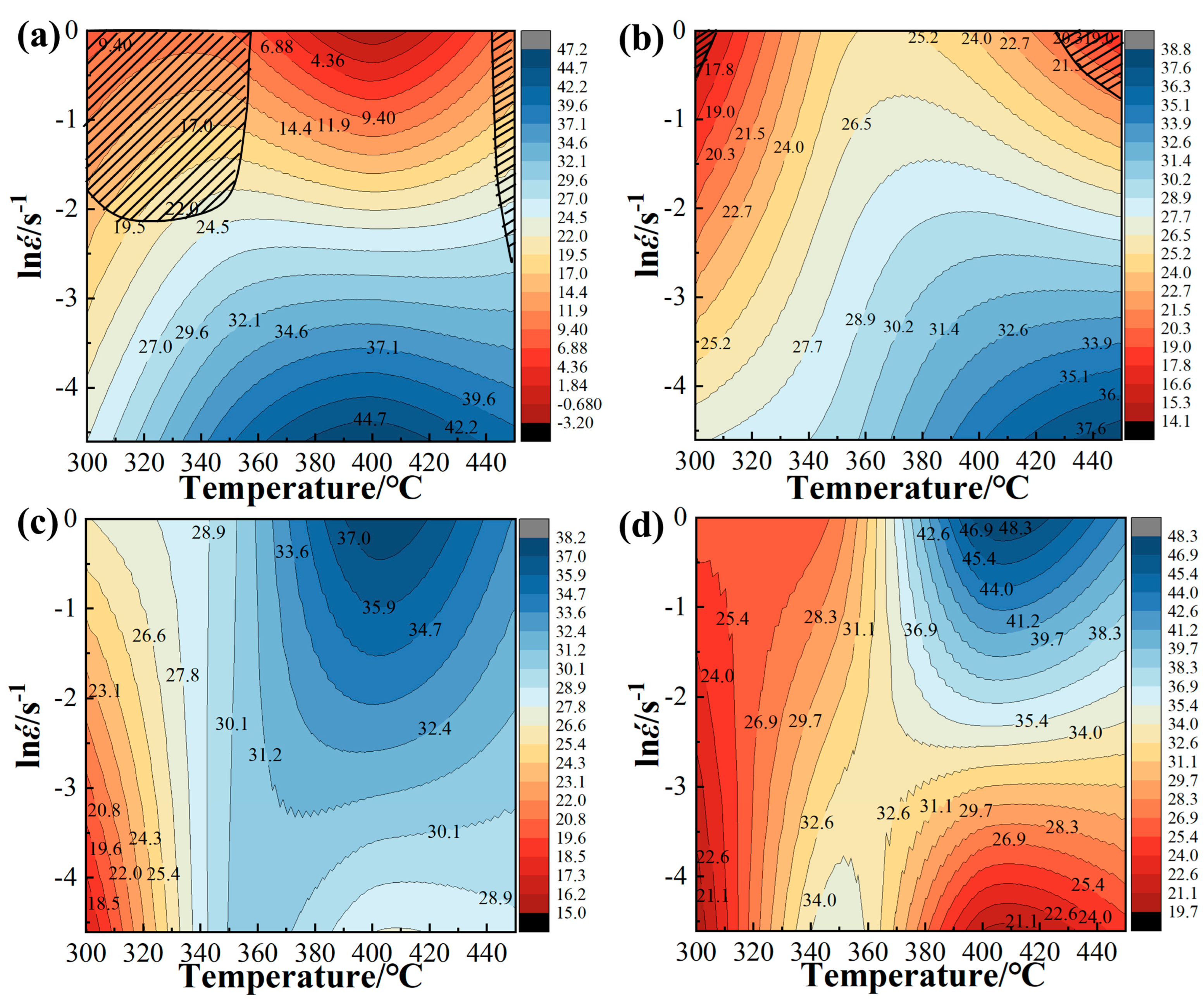

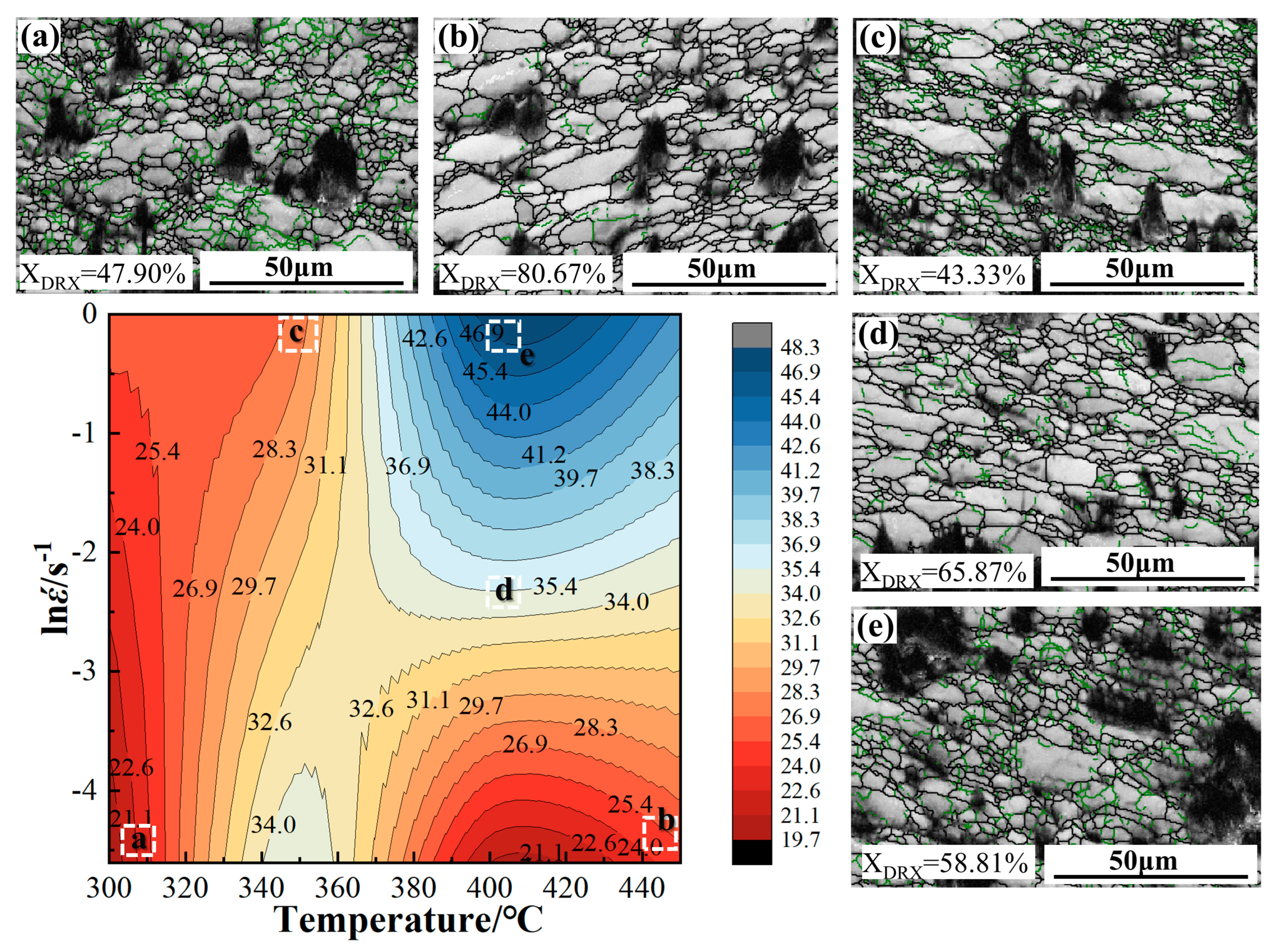

3.4. Hot Processing Map of VGCNF/7075Al Composites

3.5. Microstructure Evolution of VGCNF/7075Al Composites During Thermomechanical Eformation

4. Conclusions

- (1)

- The high-temperature flow behavior of VGCNF/7075Al could be described by a hyperbolic sine function with a characteristic stress constitutive equation:The activation energy for deformation of VGCNF/7075Al composites was 175.98 kJ/mol.

- (2)

- A dynamic material model was used to make the processing maps for VGCNF/7075Al composites. These maps showed two main flow destabilization zones at strains of 0.05, 0.15, 0.25, and 0.35. These zones were primarily found in the low-temperature, high-strain-rate region and the high-temperature, high-strain-rate region at strains of 0.05–0.15. As the strain increased, the area of the destabilization zone decreased.

- (3)

- At a strain of 0.35, VGCNF/7075Al composites achieved a maximum power dissipation efficiency of 48.30%. Following the principle of selecting high power dissipation efficiency within the safety zone, the optimal thermomechanical deformation parameters for strains of 0.05 to 0.15 were 400–450 °C and 0.01–0.1 s−1. For strains of 0.25 to 0.35, the optimal thermomechanical deformation parameters were 380–430 °C and 0.01–1 s−1.

- (4)

- The flow stress in VGCNF/7075Al composites decreased with increasing deformation temperature and increased with increasing strain rate. During thermomechanical deformation, these composites demonstrated clear, dynamic softening characteristics. The primary softening mechanism was attributed to DRX, while DRV and DRX contributed together at high strain rates.

- (5)

- Incorporating VGCNFs into the composites promoted DRX. The addition of VGCNFs resulted in higher dislocation densities and greater orientation deviations in the matrix during deformation. These higher dislocation densities in the deformation zones near VGCNFs served as stored energy that drove DRX process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xia, Y.; Kuang, Z.; Sun, Y.; Zhu, P.; Ju, B.; Chen, G.; Yang, W.; Wu, G. Hot Deformation Behavior of Recycled-Be/2024Al Composites Prepared by Pressure Infiltration Method. J. Mater. Res. Technol. 2024, 32, 2780–2791. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent Progress in Aluminum Metal Matrix Composites: A Review on Processing, Mechanical and Wear Properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent Developments in Advanced Aircraft Aluminium Alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- El-Sabbagh, A.; Soliman, M.; Taha, M.; Palkowski, H. Hot Rolling Behaviour of Stir-Cast Al 6061 and Al 6082 Alloys—SiC Fine Particulates Reinforced Composites. J. Mater. Process. Technol. 2012, 212, 497–508. [Google Scholar] [CrossRef]

- Xie, K.; Cai, B.; Zhang, G.; Shi, Y.; Li, M.; Huang, H.; Huang, J.; Zhou, W.; Liu, Z. High-Strength Al Matrix Composites Reinforced with Uniformly Dispersed Nanodiamonds. J. Alloys Compd. 2022, 898, 162917. [Google Scholar] [CrossRef]

- Sahoo, B.N.; Panigrahi, S.K. Deformation Behavior and Processing Map Development of AZ91 Mg Alloy with and without Addition of Hybrid In-Situ TiC+TiB2 Reinforcement. J. Alloys Compd. 2019, 776, 865–882. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Fu, L.; Shao, P.; Zhou, Y.; Zhu, P.; Su, H.; Wu, G. Hot Deformation Behavior and Microstructure Evolution of Flaky Ti3AlC2 Particles Reinforced Pure Al Composite. J. Alloys Compd. 2022, 927, 167118. [Google Scholar] [CrossRef]

- Ma, Z.; Zhou, M.; Li, H.; Jing, K.; Zhang, J.; Tian, B.; Zhang, Y.; Li, X.; Hu, H.; Volinsky, A.A. Effects of Y2O3 on the Hot Deformation Behavior and Microstructure Evolution of Al2O3-Cu/35Cr3TiB2 Electrical Contact Composites. Mater. Charact. 2024, 215, 114120. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, Z.; Chen, X.-G. Hot Deformation and Processing Maps of Al-15%B4C Composites Containing Sc and Zr. J. Mater. Eng. Perform 2017, 26, 1673–1684. [Google Scholar] [CrossRef]

- Cai, J.; Wang, K.; Zhai, P.; Li, F.; Yang, J. A Modified Johnson-Cook Constitutive Equation to Predict Hot Deformation Behavior of Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2014, 24, 32–44. Available online: https://link.springer.com/article/10.1007/s11665-014-1243-x (accessed on 30 April 2024). [CrossRef]

- Jiang, M.; Wu, Y.; Nie, J.; Chen, Y.; Fan, Y.; Liu, X.; Zhao, Y. Revealing the Ultra-High High-Temperature Compressive Mechanical Properties and Deformation Mechanism of a Heterostructured AlNp/Al Nanocomposite. Mater. Sci. Eng. A 2023, 878, 145199. [Google Scholar] [CrossRef]

- Ma, K.; Liu, Z.Y.; Zhang, X.X.; Xiao, B.L.; Ma, Z.Y. Hot Deformation Behavior and Microstructure Evolution of Carbon Nanotube/7055Al Composite. J. Alloys Compd. 2021, 854, 157275. [Google Scholar] [CrossRef]

- Li, B.; Pan, Q.; Zhang, Z.; Li, C. Characterization of Flow Behavior and Microstructural Evolution of Al–Zn–Mg–Sc–Zr Alloy Using Processing Maps. Mater. Sci. Eng. A 2012, 556, 844–848. [Google Scholar] [CrossRef]

- Lakshmi, A.A.; Rao, C.S.; Gangadhar, J.; Srinivasu, C.; Singh, S.K. Review of Processing Maps and Development of Qualitative Processing Maps. Mater. Today Proc. 2017, 4, 946–956. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K. Processing Maps: A Status Report. J. Mater. Eng. Perform. 2003, 12, 638–645. [Google Scholar] [CrossRef]

- Chen, X.-M.; Lin, Y.C.; Wen, D.-X.; Zhang, J.-L.; He, M. Dynamic Recrystallization Behavior of a Typical Nickel-Based Superalloy during Hot Deformation. Mater. Des. 2014, 57, 568–577. [Google Scholar] [CrossRef]

- Jamir, M.R.M.; Majid, M.S.A.; Khasri, A. 8—Natural Lightweight Hybrid Composites for Aircraft Structural Applications. In Sustainable Composites for Aerospace Applications; Jawaid, M., Thariq, M., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2018; pp. 155–170. ISBN 978-0-08-102131-6. [Google Scholar]

- McQueen, H.J.; Ryan, N.D. Constitutive Analysis in Hot Working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Li, H.; Wang, H.; Zeng, M.; Liang, X.; Liu, H. Forming Behavior and Workability of 6061/B4CP Composite during Hot Deformation. Compos. Sci. Technol. 2011, 71, 925–930. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. An Experimental Study of the Recrystallization Mechanism during Hot Deformation of Aluminium. Mater. Sci. Eng. A 2000, 283, 274–288. [Google Scholar] [CrossRef]

- Cerri, E.; Spigarelli, S.; Evangelista, E.; Cavaliere, P. Hot Deformation and Processing Maps of a Particulate-Reinforced 6061 + 20% Al2O3 Composite. Mater. Sci. Eng. A 2002, 324, 157–161. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, G.A.; Wu, Y.; Mathon, M.H.; Borbely, A.; Chen, D.; Ji, G.; Wang, M.L.; Zhong, S.Y.; Wang, H.W. Multi-Scale Study of Microstructure Evolution in Hot Extruded Nano-Sized TiB2 Particle Reinforced Aluminum Composites. Mater. Des. 2017, 116, 577–590. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Y.; Zhang, K.; Li, X.; Ma, M.; Shi, G.; Yuan, J.; Zhang, H. Microstructure and Hot Deformation Behavior of the Mg–8 Wt.% Sn–1.5 Wt.% Al Alloy. Materials 2021, 14, 2050. [Google Scholar] [CrossRef]

- Liu, M.; Shan, Z.; Li, X.; Zang, Y. Hot Tensile Deformation Behavior and Microstructure Evolution of 7075 Aluminum Alloy Sheet. J. Mater. Res. Technol. 2023, 24, 724–736. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Cui, Z.; Chen, Z.; Chen, D. Compressive Response and Microstructural Evolution of In-Situ TiB2 Particle-Reinforced 7075 Aluminum Matrix Composite. Trans. Nonferrous Met. Soc. China 2021, 31, 1235–1248. [Google Scholar] [CrossRef]

- Huang, C.C.; Qi, L.; Chen, J.; Guan, R.; Ojo, O.A.; Wang, Z.G. Effect of TiC Nanoparticles on the Hot Deformation Behavior of AA7075 Aluminum Alloy. Mater. Charact. 2021, 181, 111508. [Google Scholar] [CrossRef]

- Che, B.; Lu, L.; Kang, W.; Luo, J.; Ma, M.; Liu, L. Hot Deformation Behavior and Processing Map of a New Type Mg-6Zn-1Gd-1Er Alloy. J. Alloys Compd. 2021, 862, 158700. [Google Scholar] [CrossRef]

- Cavaliere, P.; Cerri, E.; Leo, P. Hot Deformation and Processing Maps of a Particulate Reinforced 2618/Al2O3/20p Metal Matrix Composite. Compos. Sci. Technol. 2004, 64, 1287–1291. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, M.; Xie, X.; Dong, J.; Lin, F.; Zhao, S. Hot Deformation Characteristics and Processing Map Analysis of a New Designed Nickel-Based Alloy for 700 °C A-USC Power Plant. J. Alloys Compd. 2016, 656, 119–131. [Google Scholar] [CrossRef]

- Li, Y.-L.; Wang, W.-X.; Zhou, J.; Chen, H.-S. Hot Deformation Behaviors and Processing Maps of B4C/Al6061 Neutron Absorber Composites. Mater. Charact. 2017, 124, 107–116. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242. Metall. Mater. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Shao, J.C.; Xiao, B.L.; Wang, Q.Z.; Ma, Z.Y.; Liu, Y.; Yang, K. Constitutive Flow Behavior and Hot Workability of Powder Metallurgy Processed 20 Vol.%SiCP/2024Al Composite. Mater. Sci. Eng. A 2010, 527, 7865–7872. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The Role of Annealing Twins during Recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Choi, H.-N.; Choi, J.-W.; Kang, H.; Fujii, H.; Lee, S.-J. Effect of Stacking-Fault Energy on Dynamic Recrystallization, Textural Evolution, and Strengthening Mechanism of Fe−Mn Based Twinning-Induced Plasticity (TWIP) Steels during Friction-Stir Welding. J. Adv. Join. Process. 2024, 10, 100236. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A Review of Dynamic Recrystallization Phenomena in Metallic Materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Subramanya Sarma, V. A Study on Microstructural Evolution and Dynamic Recrystallization During Isothermal Deformation of a Ti-Modified Austenitic Stainless Steel. Met. Mater Trans. A 2011, 42, 1062–1072. [Google Scholar] [CrossRef]

- Shiming, H.; Jingpei, X.; Aiqin, W.; Wenyan, W.; Jiwen, L. Hot Deformation Behavior and Processing Map of SiCp/2024Al Composite. Rare Met. Mater. Eng. 2014, 43, 2912–2916. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, M.; Xu, Z.; Wu, J.; Motozuka, S.; Tian, C.; Gu, J.; Yu, J. Hot Deformation Behavior and Processing Maps of Vapor-Phase-Grown Carbon Nanofiber Reinforced 7075Al Composites. Metals 2024, 14, 1245. https://doi.org/10.3390/met14111245

Zhu M, Xu Z, Wu J, Motozuka S, Tian C, Gu J, Yu J. Hot Deformation Behavior and Processing Maps of Vapor-Phase-Grown Carbon Nanofiber Reinforced 7075Al Composites. Metals. 2024; 14(11):1245. https://doi.org/10.3390/met14111245

Chicago/Turabian StyleZhu, Mengying, Zhefeng Xu, Junhua Wu, Satoshi Motozuka, Caili Tian, Jianglong Gu, and Jinku Yu. 2024. "Hot Deformation Behavior and Processing Maps of Vapor-Phase-Grown Carbon Nanofiber Reinforced 7075Al Composites" Metals 14, no. 11: 1245. https://doi.org/10.3390/met14111245

APA StyleZhu, M., Xu, Z., Wu, J., Motozuka, S., Tian, C., Gu, J., & Yu, J. (2024). Hot Deformation Behavior and Processing Maps of Vapor-Phase-Grown Carbon Nanofiber Reinforced 7075Al Composites. Metals, 14(11), 1245. https://doi.org/10.3390/met14111245