Inclusion-Based Model: Calculating Tooth Root Bending Strength Considering Steel Cleanliness

Abstract

:1. Introduction

2. State of the Art

2.1. Influence of Steel Cleanliness on Fatigue Strength

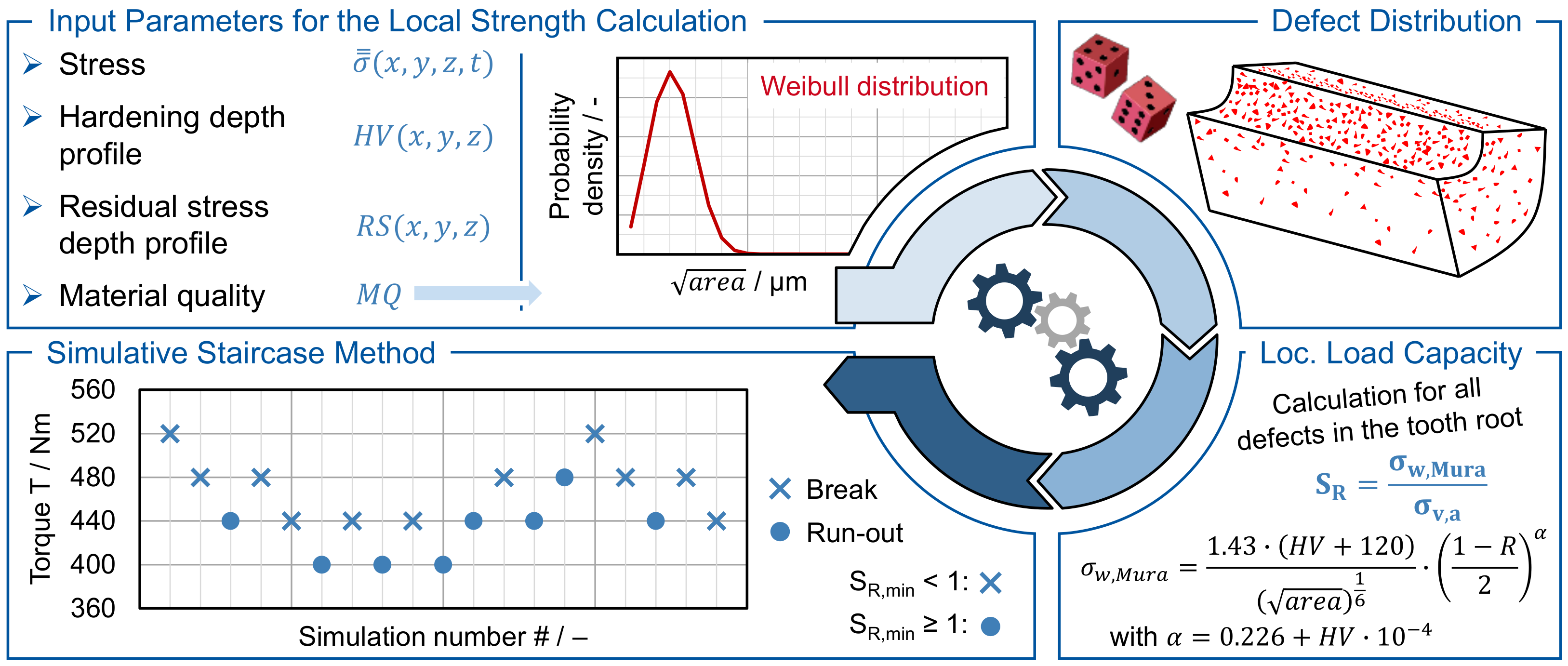

2.2. Calculation Procedure for Determining Tooth Root Bending Strength

3. Objective and Approach

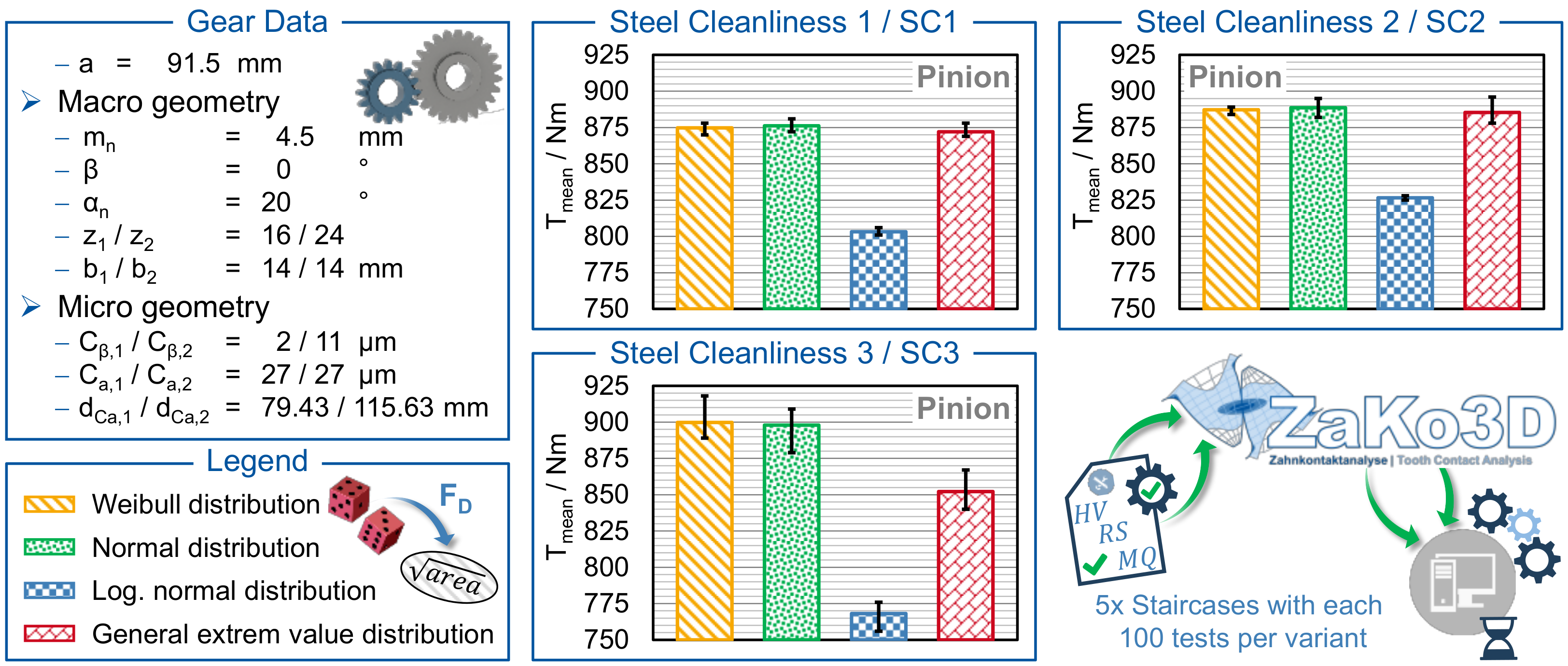

4. Test Gears

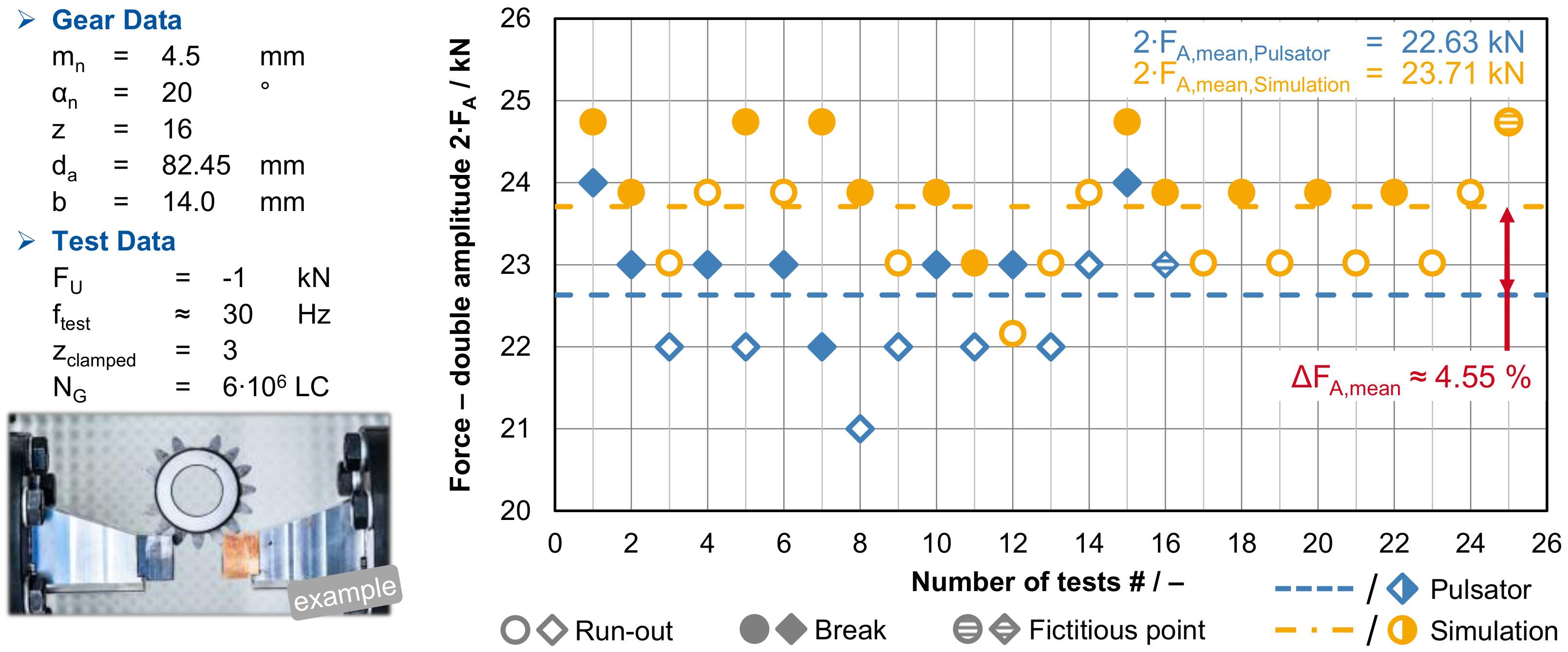

4.1. Macro and Micro Geometry

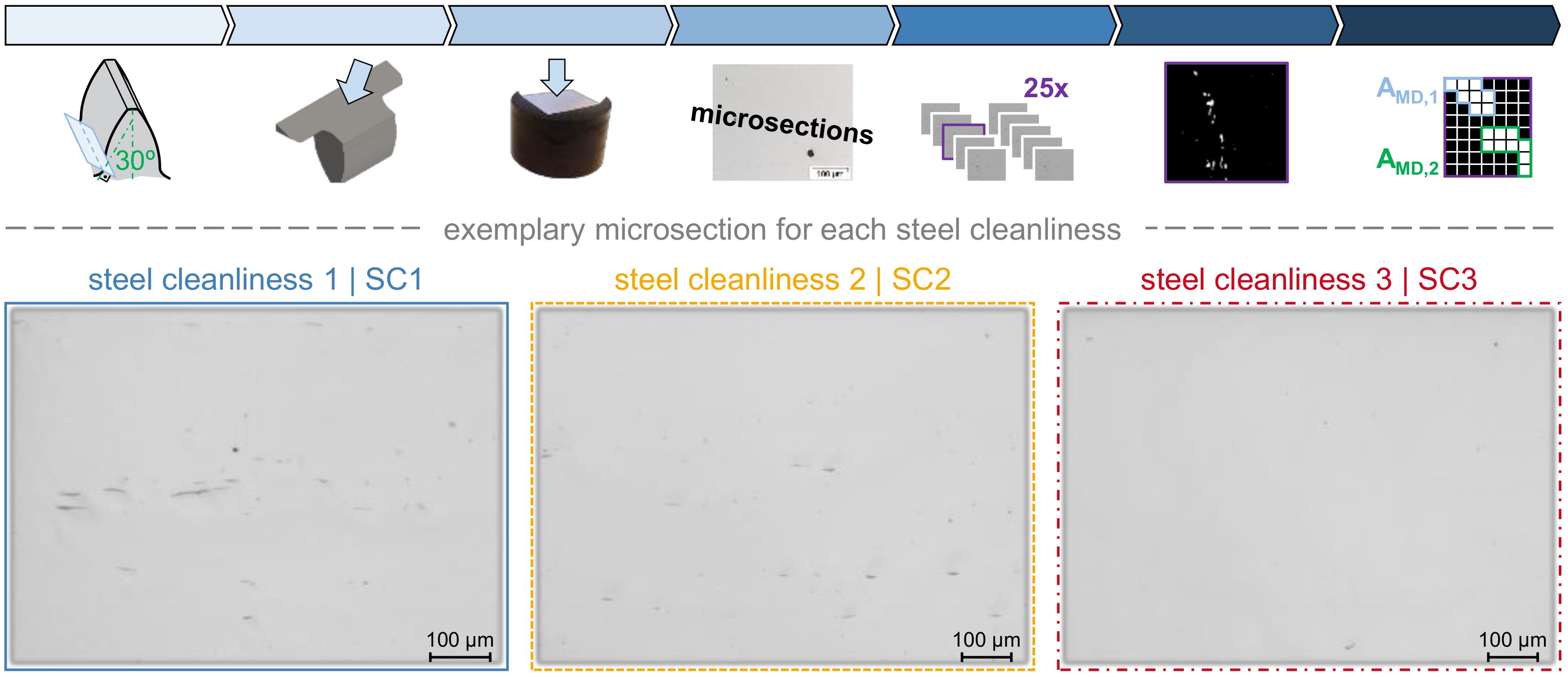

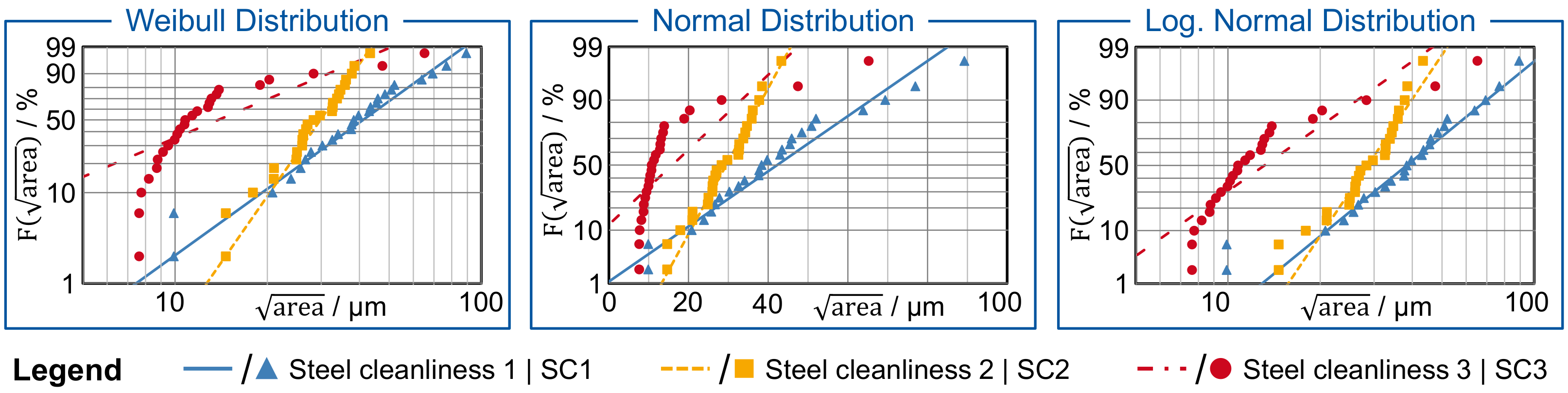

4.2. Material Analysis and Defect Distribution

5. Expansion of the Inclusion-Based Model

5.1. Implementation of Additional Distribution Functions

5.2. Sensitivity Analysis of Defect Distribution Functions

6. Application of Expanded Inclusion-Based Model

7. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kratzer, D.; Koller, P.; Tobie, T.; Stahl, K. Investigation of the effects of surface roughness and shot peening on the tooth root bending strength of case-carburized gears. J. Mech. Sci. Technol. 2022, 36, 731–740. [Google Scholar] [CrossRef]

- Hellenbrand, G.; Steinbacher, M.; Brecher, C.; Fechte-Heinen, R. Turbohochtemperaturstahl: FVV Nr. 1386|Zwischenbericht (ZB). In Proceedings of the FVV Transfer + Networking Event March 2023, Würzburg, Germany, 30 March 2023; FVV e.V.: Frankfurt am Main, Germany, 2023; pp. 614–645. [Google Scholar]

- Kamjou, L.; Ölund, P.; Claesson, E.; Fagerlund, J.; Wicks, G.; Wennmo, M.; Hansson, H. Innovative Steel Design and Gear Machining of Advanced Engineering Steel. Gear Technol. 2016, 33, 82–87. [Google Scholar]

- ISO 6336-1; Calculation of Load Capacity of Spur and Helical Gears—Part 1: Basic Principles, Introduction and General Influence Factors, 3rd ed. ISO Copyright Office: Geneva, Switzerland, 2019.

- ISO 6336-5; Calculation of Load Capacity of Spur and Helical Gears—Part 5: Strength and Quality of Materials, 3rd ed. ISO Copyright Office: Geneva, Switzerland, 2016.

- AGMA 908-B89; Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth. American Gear Manufacturers Association: Alexandria, VA, USA, 1989.

- Hertter, T. Rechnerischer Festigkeitsnachweis der Ermüdungstragfähigkeit Vergüteter und Einsatzgehärteter Stirnräder. Ph.D. Thesis, TU München, München, Germany, 2003. [Google Scholar]

- Henser, J. Berechnung der Zahnfußtragfähigkeit von Beveloidverzahnungen. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2015. [Google Scholar]

- Fuchs, D. Einfluss Mikroskopischer Fehlstellen auf die Zahnfußtragfähigkeit. Ph.D. Thesis, TU München, München, Germany, 2023. [Google Scholar]

- Trippe, M.; Löpenhaus, C.; Brecher, C.; Kamjou, L.; Löthman, E. Tooth Root Testing of Steels with High Cleanliness. Gear Solut. 2020, 18, 29–36. [Google Scholar]

- Bretl, N.; Schurer, S.; Tobie, T.; Stahl, K.; Höhn, B.-R. Investigations on Tooth Root Bending Strength of Case Hardened Gears in the Range of High Cycle Fatigue. Therm. Process. 2014, 3, 52–59. [Google Scholar]

- Fuchs, D.; Schurer, S.; Tobie, T.; Stahl, K. On the determination of the bending fatigue strength in and above the very high cycle fatigue regim of shot-peened gears. Forsch. Ingenieurwesen 2022, 86, 81–92. [Google Scholar] [CrossRef]

- ISO 6336-3; Calculation of Load Capacity of Spur and Helical Gears—Part 3: Calculation of Tooth Bending Strength, 3rd ed. ISO copyright Office: Geneva, Switzerland, 2019.

- Klocke, F.; Brecher, C. Zahnrad-und Getriebetechnik: Auslegung—Herstellung—Untersuchung—Simulation, 2nd ed.; Carl Hanser: München, Germany, 2024; ISBN 978-3-446-46975-4. [Google Scholar]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, 2nd ed.; Elsevier Ltd.: London, UK, 2019. [Google Scholar]

- Hück, M. Auswertung von Stichproben normalverteilter, quantitativer Merkmalsgrößen. Mater. Und Werkst. 1994, 25, 20–29. [Google Scholar] [CrossRef]

- Schurer, S. Einfluss Nichtmetallischer Einschlüsse in Hochreinen Werkstoffen auf die Zahnfußtragfähigkeit. Ph.D. Thesis, TU München, München, Germany, 2016. [Google Scholar]

- Fuchs, D.; Tobie, T.; Stahl, K. Challenges in determination of microscopic degree of cleanliness in ultra-clean gear steels. J. Iron Steel Res. Int. 2022, 29, 1583–1600. [Google Scholar] [CrossRef]

- Murakami, Y.; Toriyama, T.; Coudert, E.M. Instructions for a New Method of Inclusion Rating and Correlations with Fatigue Limit. J. Test. Eval. 1994, 22, 318–326. [Google Scholar] [CrossRef]

- Brecher, C.; Löpenhaus, C.; Pollaschek, J. Automated Defect Size Determination for Gear Tooth Root Bending Strength Simulation. WIT Trans. Eng. Sci. 2017, 116, 87–97. [Google Scholar]

- Hedderich, J.; Sachs, L. Angewandte Statistik: Methodensammlung mit R, 17th ed.; Springer Spektrum: Berlin, Germany, 2020. [Google Scholar]

- Zenner, H.; Mauch, H. (Eds.) Statistische Methoden zur Beurteilung von Bauteillebensdauer und Zuverlässigkeit und ihre Beispielhafte Anwendung auf Zahnräder; Research Association for Drive Technology: Frankfurt am Main, Germany, 1999. [Google Scholar]

- Goergen, F. Analogieversuch zur Erzeugung von Zahnflankenbrüchen an Stirnrädern. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2023. [Google Scholar]

- Ahmad, M.I.; Sinclair, C.D.; Spurr, B.D. Assessment of Flood Frequency Models Using Empirical Distribution Function Statistics. Water Resour. Res. 1988, 24, 1323–1328. [Google Scholar] [CrossRef]

| Parameters | SC1 | SC2 | SC3 | ||

|---|---|---|---|---|---|

| Defect reference count | ND,ref | Defect reference count acc. To [HENS15; BREC17] | 0.021 | 0.0011 | 0.0005 |

| Weibull distribution (WBD) | T | Scale parameter | 47.65 | 32.12 | 17.82 |

| k | Shape parameter | 2.48 | 4.95 | 1.45 | |

| Normal distribution (ND) | μ | Location parameter | 42.23 | 29.46 | 15.90 |

| σ | Scale parameter | 18.40 | 6.95 | 13.55 | |

| Log-normal distribution (LND) | μ | Location parameter | 3.65 | 3.35 | 2.58 |

| σ | Scale parameter | 0.47 | 0.26 | 0.54 | |

| General extreme value distribution (GEV) | μ | Location parameter | 34.41 | 27.28 | 9.97 |

| σ | Scale parameter | 14.96 | 7.03 | 2.73 | |

| ξ | Shape parameter | −0.06 | −0.35 | 0.75 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eggert, C.; Mevissen, D.; Westphal, C.; Brecher, C. Inclusion-Based Model: Calculating Tooth Root Bending Strength Considering Steel Cleanliness. Metals 2024, 14, 1349. https://doi.org/10.3390/met14121349

Eggert C, Mevissen D, Westphal C, Brecher C. Inclusion-Based Model: Calculating Tooth Root Bending Strength Considering Steel Cleanliness. Metals. 2024; 14(12):1349. https://doi.org/10.3390/met14121349

Chicago/Turabian StyleEggert, Christian, Dieter Mevissen, Christian Westphal, and Christian Brecher. 2024. "Inclusion-Based Model: Calculating Tooth Root Bending Strength Considering Steel Cleanliness" Metals 14, no. 12: 1349. https://doi.org/10.3390/met14121349

APA StyleEggert, C., Mevissen, D., Westphal, C., & Brecher, C. (2024). Inclusion-Based Model: Calculating Tooth Root Bending Strength Considering Steel Cleanliness. Metals, 14(12), 1349. https://doi.org/10.3390/met14121349