Revisiting the Structural and Magnetic Properties of SmCo5/Sm2Co17 Interface from First-Principles Investigations

Abstract

1. Introduction

2. Calculation Details

3. Results

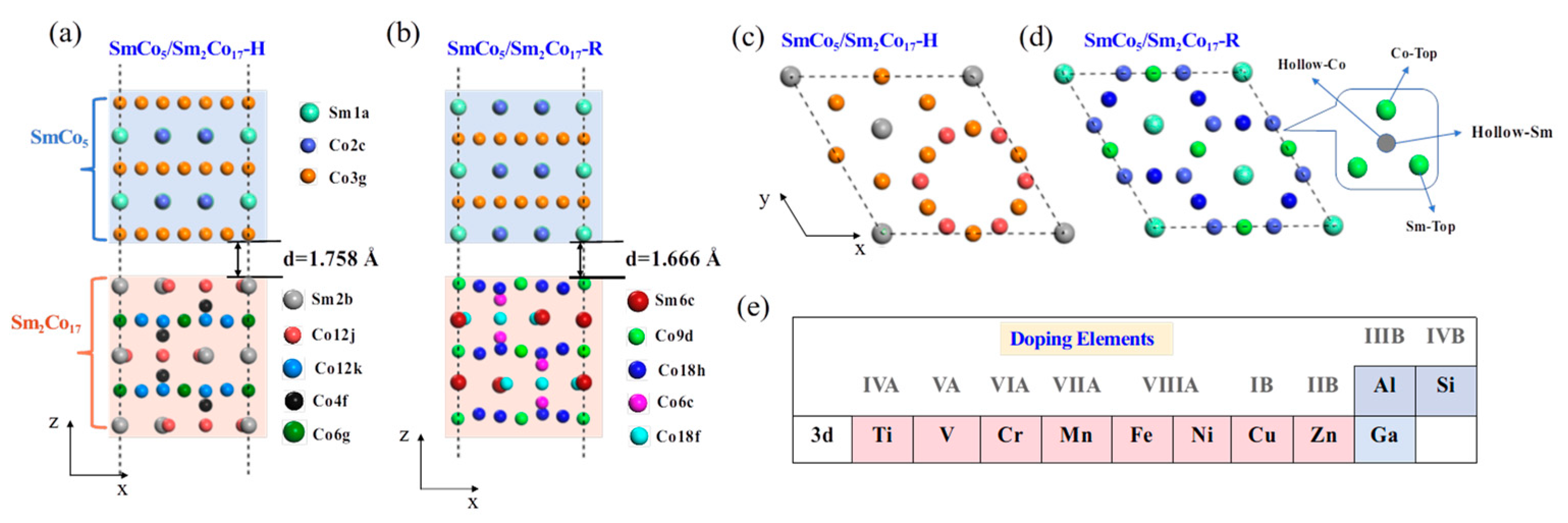

3.1. Interfacial Configurations of SmCo5/Sm2Co17 Structure

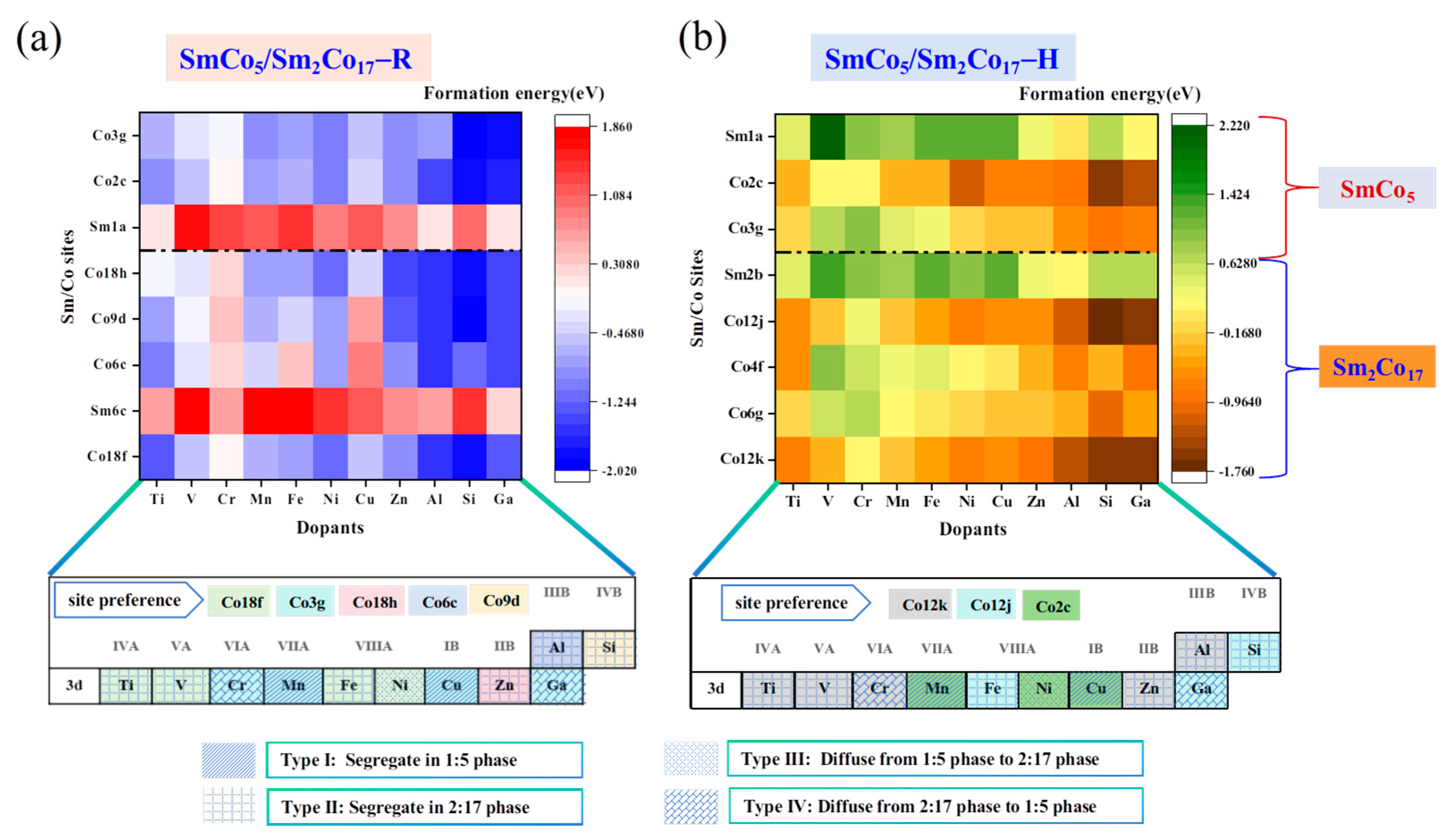

3.2. Thermodynamic Stability of Typical Elements-Doped 1:5/2:17H/R Interfaces

3.3. The Binding Strengths of Pristine and Doped 1:5/2:17H/R Interfaces

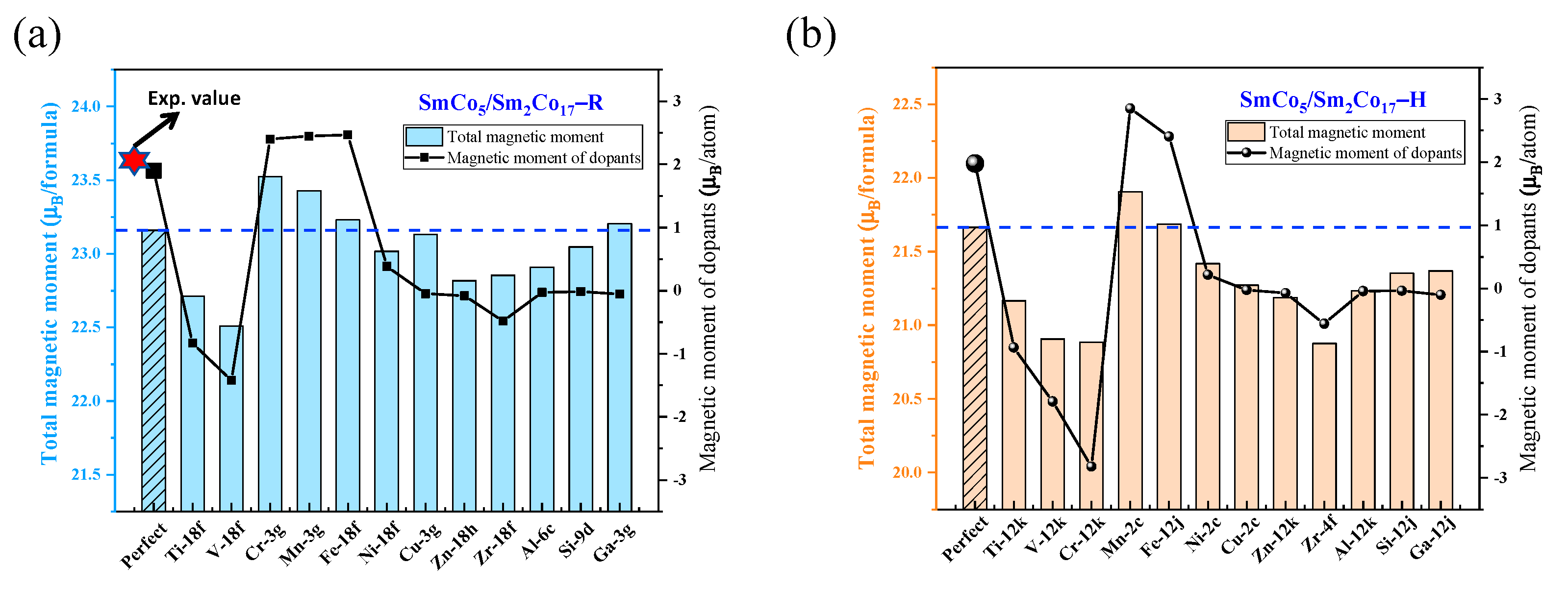

3.4. Magnetic Properties of Pristine and Doped 1:5/2:17H/R Interfaces

4. Discussion

5. Conclusions

- (1)

- The SmCo-Co (Co-SmCo) termination with hollow-Sm stacking is the most stable configuration for the 1:5/2:17R (1:5/2:17H) interface. This stacking mode easily forms the basal stacking faults gliding along the a/3 [] partial dislocations direction. The 1:5/2:17R and 1:5/2:17H interfaces exhibit completely opposite behaviors in terms of elemental doping. The doped 1:5/2:17H interface along the c-axis is expanded by about 1.98~3.28%, while the 1:5/2:17R interface slightly shrinks by about −0.04~−0.87% along the c-axis. This great difference between doped 1:5/2:17R and 1:5/2:17H interfaces may induce the extra interfacial stress and facilitates the phase transformation from 2:17H to 2:17R.

- (2)

- The site preferences of the alloys in the 1:5/2:17H and 1:5/2:17R interfaces are categorized into four distinct types. The type I (Cu, Mn) and type IV (Ga) elements prefer to segregate at 1:5H in the 1:5/2:17 interfaces. Type II (Ti, V, Fe, Zn, Al, Si) and type III (Ni) tend to segregate at the 2:17 phase in the 1:5/2:17 interfaces.

- (3)

- The relationship between interface distances, interfacial binding strength, and elemental doping is complex, and there is no obvious relation for different alloy-doped 1:5/2:17H/R structures. Mn, Fe, and Ga doping are beneficial in improving the saturation magnetization strength in SmCo5/Sm2Co17-R magnets due to improving the Co-Co exchange interaction. This work provides a new insight to uncover the effect of elemental doping on SmCo5/Sm2Co17 cellular structures.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gopalan, R.; Ohkubo, T.; Hono, K. Identification of the cell boundary phase in the isothermally aged commercial Sm(Co0.725Fe0.1Cu0.12Zr0.04)7.4 sintered magnet. Scr. Mater. 2006, 54, 1345–1349. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, Z.; Li, M.; Lee, D.; Chen, R.J.; Liu, J.; Li, W.; Yan, A.R. Positive temperature coefficient of coercivity in Sm1−xDyx(Co0.695Fe0.2Cu0.08Zr0.025)7.2 magnets with spin-reorientation-transition cell boundary phases. Appl. Phys. Lett. 2015, 106, 052408. [Google Scholar] [CrossRef]

- Duerrschnabel, M.; Yi, M.; Uestuener, K.; Liesegang, M.; Katter, M.; Kleebe, H.-J.; Xu, B.; Gutfleisch, O.; Molina-Luna, L. Atomic structure and domain wall pinning in samarium-cobalt-based permanent magnets. Nat. Commun. 2017, 8, 54. [Google Scholar] [CrossRef]

- Xu, C.; Wang, H.; Liu, B.; Xu, H.; Zhang, T.; Liu, J.; Jiang, C. Correlation between ordered solid solution and cellular structure of Sm2Co17 type magnets with high iron content. J. Magn. Magn. Mater. 2021, 519, 167477. [Google Scholar] [CrossRef]

- Goll, D.; Kronmüller, H.; Stadelmaier, H.H. Micromagnetism and the microstructure of high-temperature permanent magnets. J. Appl. Phys. 2004, 96, 6534–6545. [Google Scholar] [CrossRef]

- Xiong, X.Y.; Ohkubo, T.; Koyama, T.; Ohashi, K.; Tawara, Y.; Hono, K. The microstructure of sintered Sm(Co0.72Fe0.20Cu0.055Zr0.025)7.5 permanent magnet studied by atom probe. Acta Mater. 2004, 52, 737–748. [Google Scholar] [CrossRef]

- Xu, C.; Wang, H.; Zhang, T.L.; Popov, A.; Gopalan, R.; Jiang, C.B. Correlation of microstructure and magnetic properties in Sm(CoFe0.1Cu0.1Zr0.033)6.93 magnets solution-treated at different temperatures. Rare Met. 2019, 38, 20–28. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, D.T.; Yue, M.; Wang, Y.Q.; Shang, Z.F.; Wu, D.; Liang, J.M. In-situ observation of magnetization reversal process of Sm(Co,Cu,Fe,Zr)z magnets with different Fe contents. Rare Met. 2020, 39, 250–255. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Thielsch, J.; Fischbacher, J.; Ohkubo, T.; Schrefl, T.; Gutfleisch, O.; Hono, K. Correlation of microchemistry of cell boundary phase and interface structure to the coercivity of Sm(Co0.784Fe0.100Cu0.088Zr0.028)7.19 sintered magnets. Acta Mater. 2017, 126, 1–10. [Google Scholar] [CrossRef]

- Song, X.; Zhou, X.; Yuan, T.; Wang, J.; Yue, M.; Ma, T. Role of nanoscale interfacial defects on magnetic properties of the 2:17-type Sm–Co permanent magnets. J. Alloys Compd. 2020, 816, 152620. [Google Scholar] [CrossRef]

- Yang, L.; Zuo, S.; Guan, C.; Liu, Z.; Hu, M.; Kang, D.; Zhao, M.; Liu, B.; Liu, J.; Peng, Y.; et al. Effect of interfacial stress on microchemistry and coercivity in 2:17-type SmCo sintered magnets. Acta Mater. 2024, 264, 119580. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Xu, H.; Liu, J.; Jiang, C. Atomic-Scale Transition Zones Determined Coercivity in Samarium-Cobalt Based Permanent Magnets. Adv. Funct. Mater. 2023, 33, 2304711. [Google Scholar] [CrossRef]

- Das, B.; Choudhary, R.; Skomski, R.; Balasubramanian, B.; Pathak, A.K.; Paudyal, D.; Sellmyer, D.J. Anisotropy and orbital moment in Sm-Co permanent magnets. Phys. Rev. B 2019, 100, 024419. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Xu, C.; Liu, X.; Zhang, Q.; Zhang, T.; Stamenov, P.; Coey, J.M.D.; Jiang, C. First-principles study of site preferences for Fe in Sm(CoFeCuZr)z permanent magnets. Phys. Rev. Mater. 2020, 4, 044406. [Google Scholar] [CrossRef]

- Sabirianov, R.F.; Kashyap, A.; Skomski, R.; Jaswal, S.S.; Sellmyer, D.J. First principles study of transition-metal substitutions in Sm–Co permanent magnets. Appl. Phys. Lett. 2004, 85, 2286–2288. [Google Scholar] [CrossRef]

- Zhu, S.; Ge, Y.; Li, L.; Du, Y. Chemical segregation mechanism and magnetic properties of Sm2Co17-based permanent magnets: Experimental investigation and first-principles calculations. J. Alloys Compd. 2023, 960, 170899. [Google Scholar] [CrossRef]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Perdew, Burke, and Ernzerhof Reply. Phys. Rev. Lett. 1998, 80, 891. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865. [Google Scholar] [CrossRef]

- Grimme, S.; Antony, J.; Ehrlich, S.; Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 2010, 132, 154104. [Google Scholar] [CrossRef] [PubMed]

- Giaremis, S.; Katsikas, G.; Sempros, G.; Gjoka, M.; Sarafidis, C.; Kioseoglou, J. Ab initio, artificial neural network predictions and experimental synthesis of mischmetal alloying in Sm–Co permanent magnets. Nanoscale 2022, 14, 5824–5839. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Ma, T.; Zhou, X.; Ye, F.; Yuan, T.; Wang, J.; Yue, M.; Liu, F.; Ren, X. Atomic scale understanding of the defects process in concurrent recrystallization and precipitation of Sm-Co-Fe-Cu-Zr alloys. Acta Mater. 2021, 202, 290–301. [Google Scholar] [CrossRef]

- Rabenberg, L.; Mishra, R.K.; Thomas, G. Development of the cellular microstructure in the Sm Co7.4-type magnets. In Proceedings of the Sixth International Workshop on Rare Earth-Cobalt Permanent Magnets and Their Applications, Vienna, Austria, 31 August–2 September 1982; p. 892. [Google Scholar]

- Song, X.; Huang, D.; Jia, W.; Liu, Y.; Gao, J.; Ren, Y.; Ma, T. In-situ high-energy X-ray diffraction study of the early-stage decomposition in 2:17-type Sm-Co-based permanent magnets. Acta Mater. 2023, 244, 118580. [Google Scholar] [CrossRef]

- Christensen, M.; Dudiy, S.; Wahnström, G. First-principles simulations of metal-ceramic interface adhesion: Co/WC versus Co/TiC. Phys. Rev. B 2002, 65, 045408. [Google Scholar] [CrossRef]

- Hin, C.; Bréchet, Y.; Maugis, P.; Soisson, F. Kinetics of heterogeneous dislocation precipitation of NbC in alpha-iron. Acta Mater. 2008, 56, 5535–5543. [Google Scholar] [CrossRef]

- Schäfer, C.; Mohles, V.; Gottstein, G. Modeling of non-isothermal annealing: Interaction of recrystallization, recovery, and precipitation. Acta Mater. 2011, 59, 6574–6587. [Google Scholar] [CrossRef]

- Brener, E.A.; Temkin, D.E. Theory of diffusional growth in cellular precipitation. Acta Mater. 1999, 47, 3759–3765. [Google Scholar] [CrossRef]

- Perkins, R.; Gaiffi, S.; Menth, A. Permanent magnet properties of Sm2(Co,Fe)17. IEEE Trans. Magn. 1975, 11, 1431–1433. [Google Scholar] [CrossRef]

- Andreev, A.V.; Zadvorkin, S.M. Thermal expansion and spontaneous magnetostriction of RCo5 intermetallic compounds. Phys. B 1991, 172, 517–525. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Cheng, H.; Cheng, S.; Fang, Y.; Zhu, M.; Su, H.; Li, W. Revisiting the Structural and Magnetic Properties of SmCo5/Sm2Co17 Interface from First-Principles Investigations. Metals 2024, 14, 1356. https://doi.org/10.3390/met14121356

Sun X, Cheng H, Cheng S, Fang Y, Zhu M, Su H, Li W. Revisiting the Structural and Magnetic Properties of SmCo5/Sm2Co17 Interface from First-Principles Investigations. Metals. 2024; 14(12):1356. https://doi.org/10.3390/met14121356

Chicago/Turabian StyleSun, Xu, Haixia Cheng, Songqi Cheng, Yikun Fang, Minggang Zhu, Hang Su, and Wei Li. 2024. "Revisiting the Structural and Magnetic Properties of SmCo5/Sm2Co17 Interface from First-Principles Investigations" Metals 14, no. 12: 1356. https://doi.org/10.3390/met14121356

APA StyleSun, X., Cheng, H., Cheng, S., Fang, Y., Zhu, M., Su, H., & Li, W. (2024). Revisiting the Structural and Magnetic Properties of SmCo5/Sm2Co17 Interface from First-Principles Investigations. Metals, 14(12), 1356. https://doi.org/10.3390/met14121356