Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

3.1. Microstructure

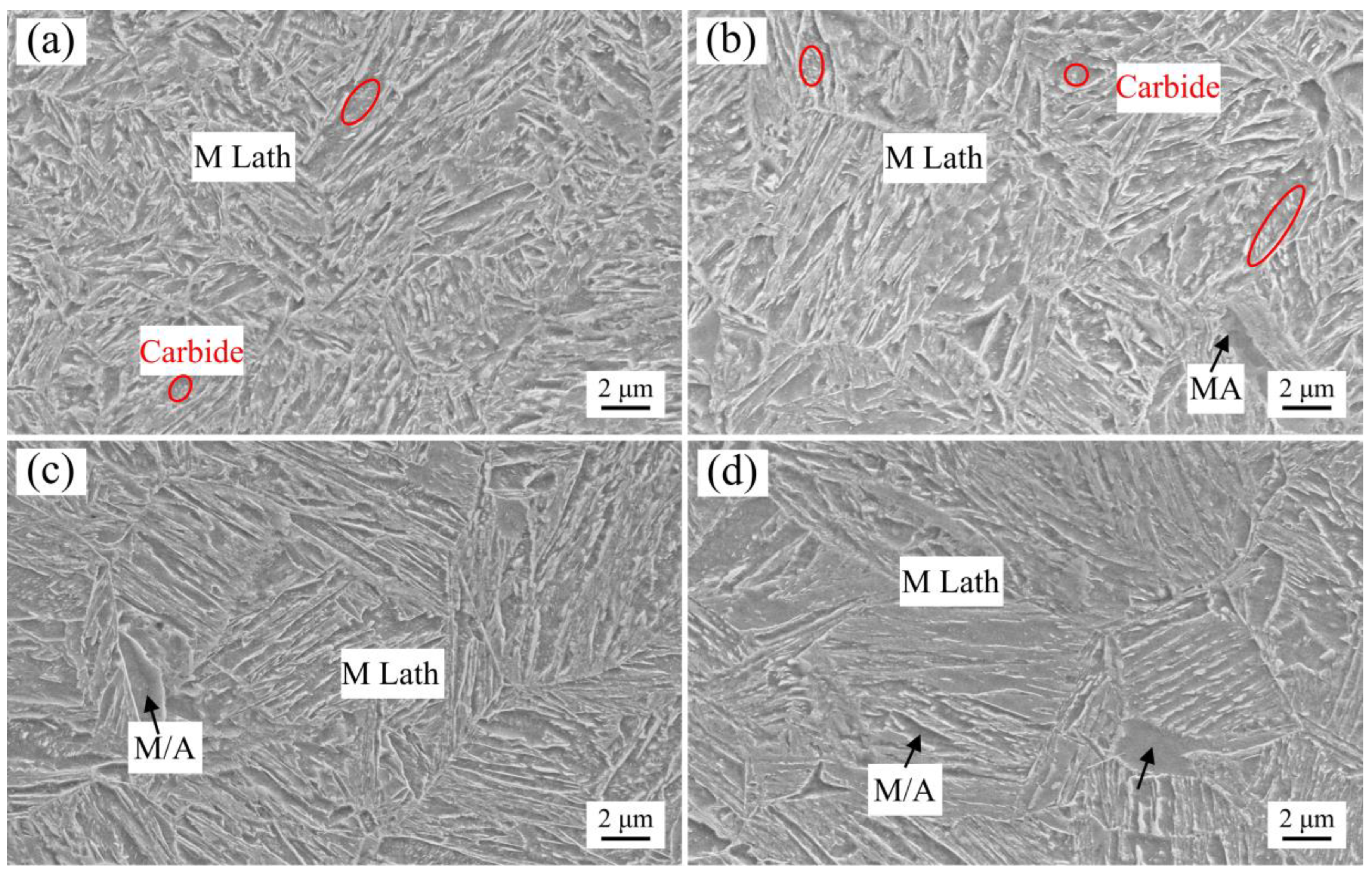

3.1.1. Effect of Austenitizing Temperature on Microstructure

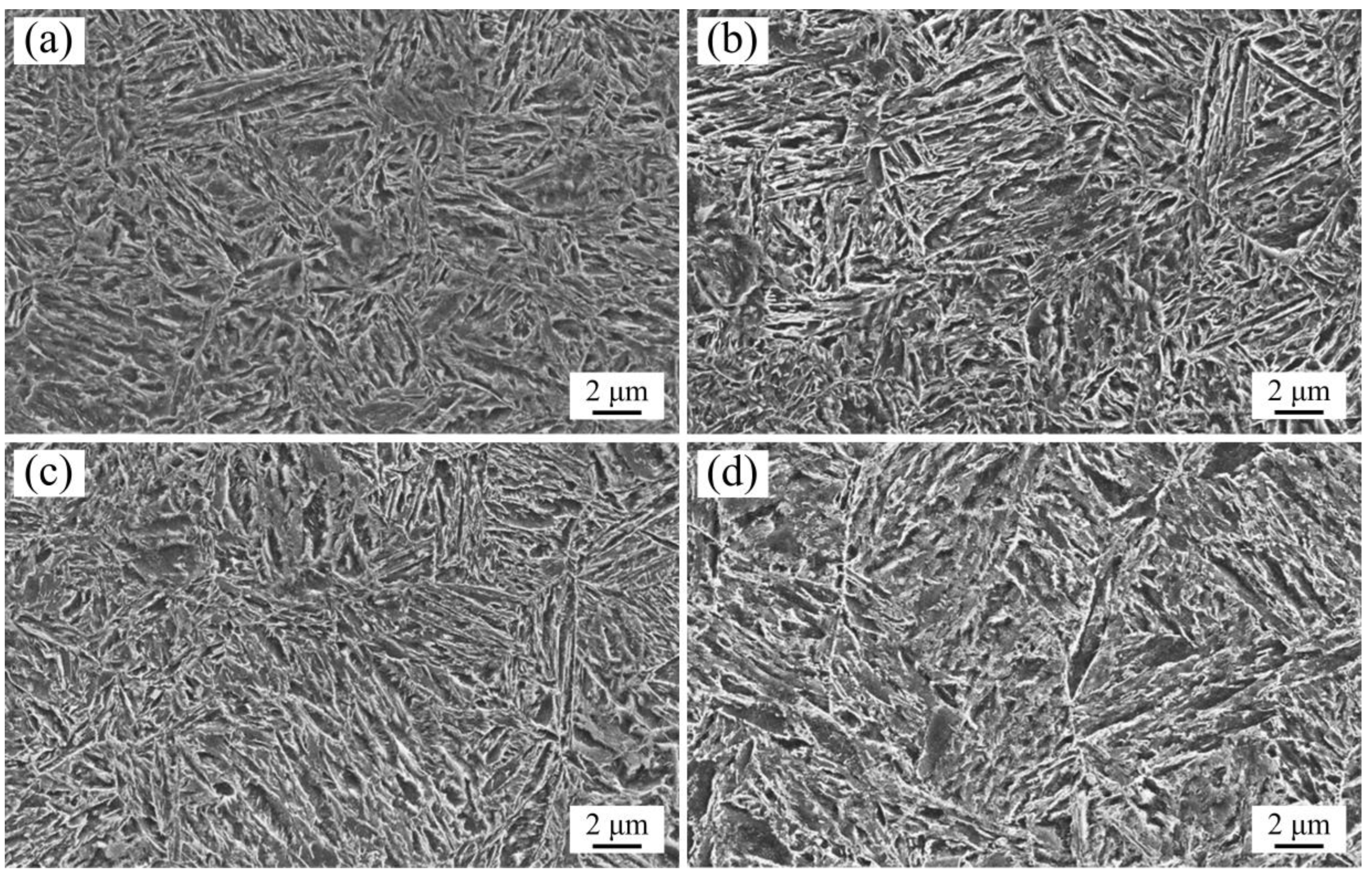

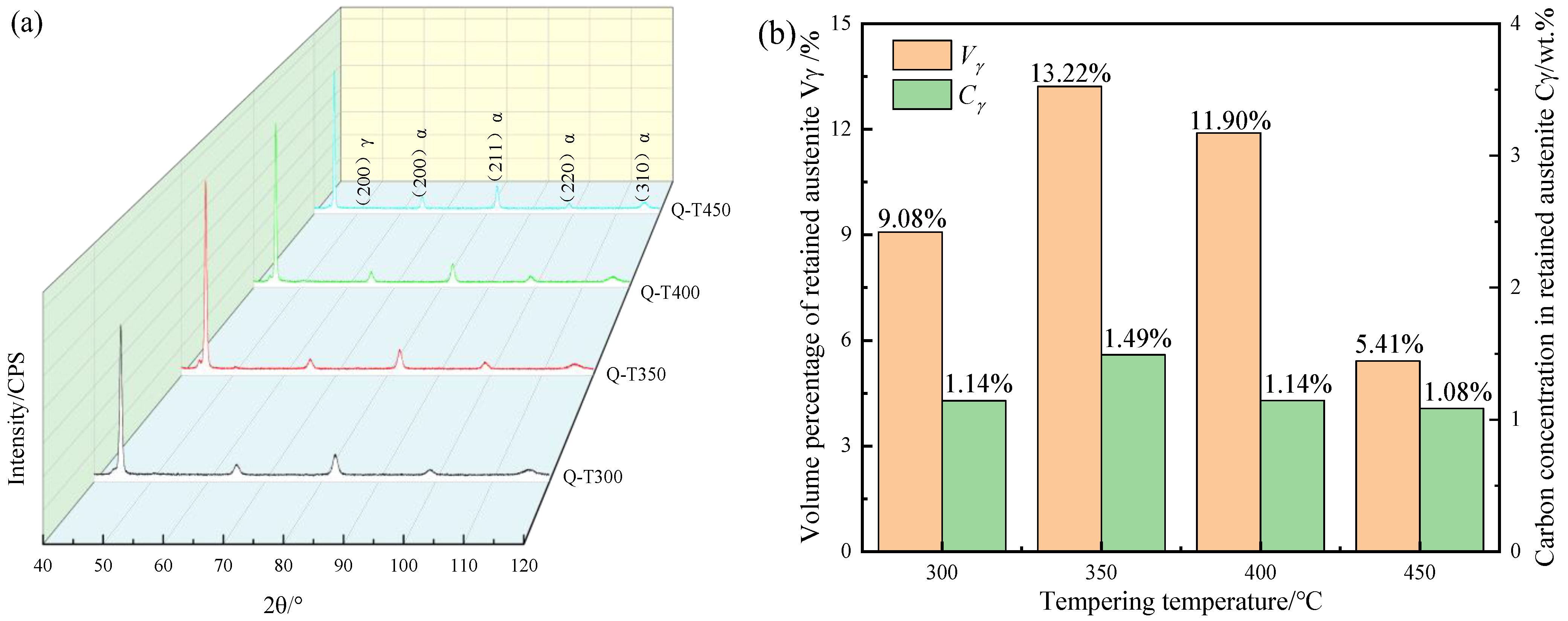

3.1.2. Effect of Tempering Temperature on Microstructure

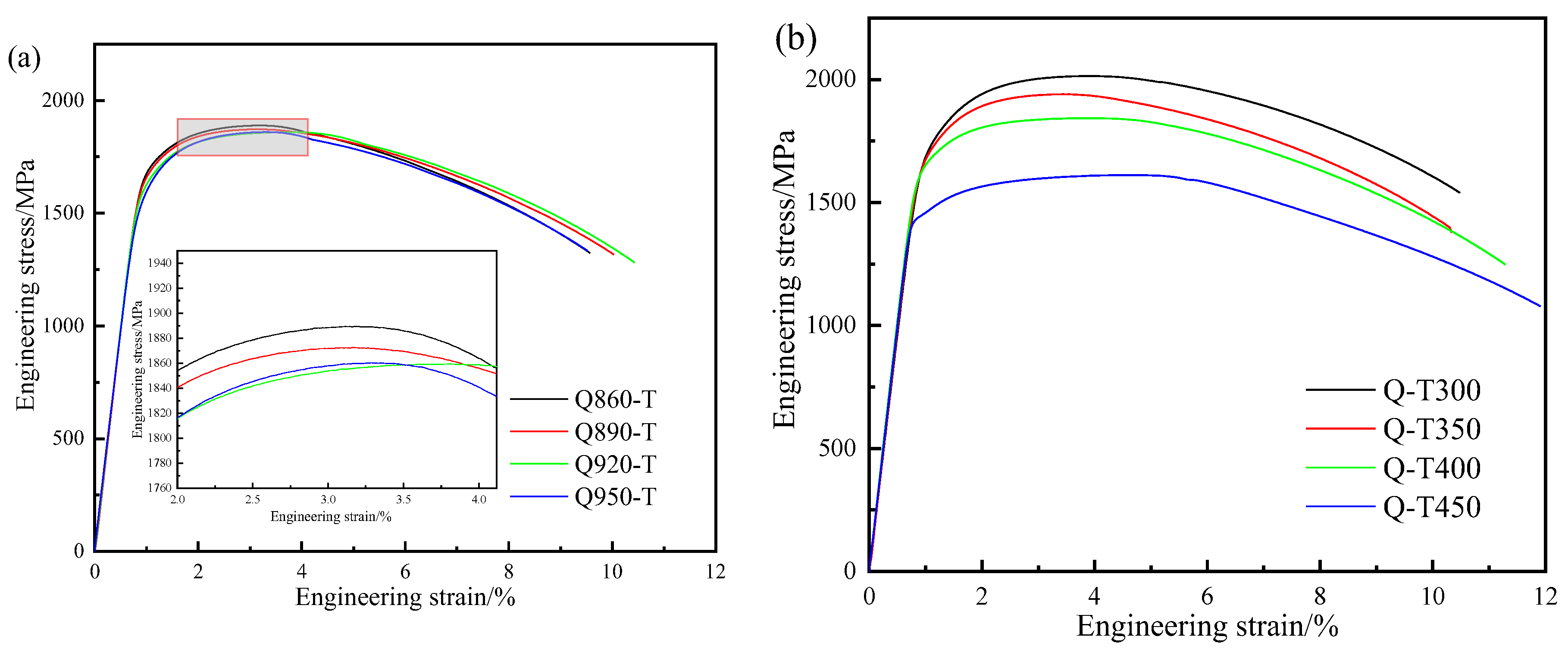

3.2. Mechanical Properties

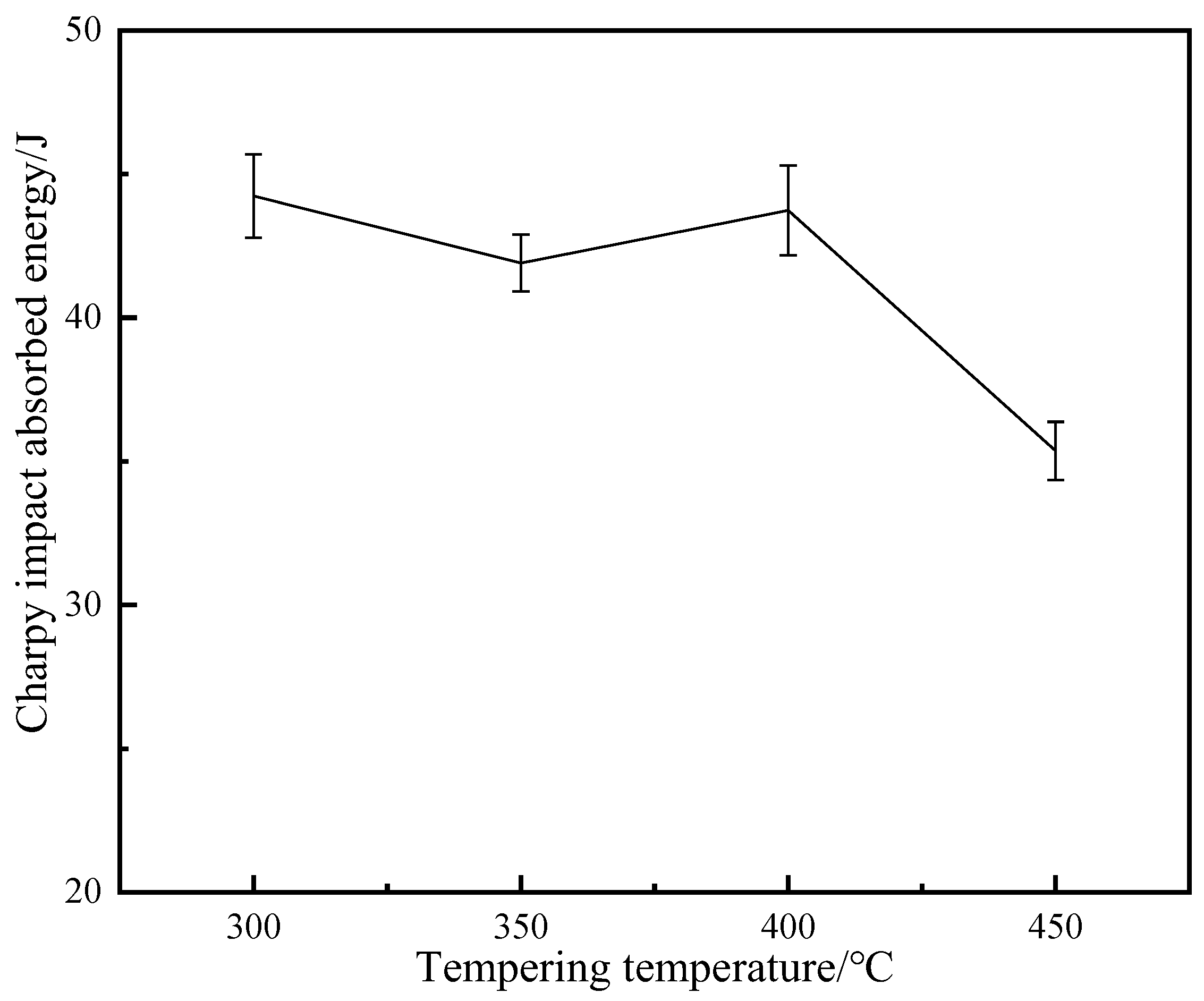

3.3. Impact Toughness

4. Discussion

5. Conclusions

- (1)

- The optimal heat treatment process is oil quenching at 890 °C for 40 min, followed by tempering at 400 °C for 60 min, and then water cooling. Under such processing conditions, this spring steel has high strength and high plasticity. Its tensile strength reaches 1865 MPa, its yield strength is 1662 MPa, its elongation is 11.5%, its area shrinkage is 51.5%, and its impact toughness reaches 43.7 J.

- (2)

- After quenching, the microstructure of this spring steel is mainly composed of lath martensite and a small amount of retained austenite. As the austenitizing temperature increases, the size of martensite laths increases, and the amount of martensite and M/A increase, which is the main reason for the decrease in strength. After tempering, this spring steel mainly undergoes martensite recovery, resulting in a reduction in dislocation density. This is the main reason for the decrease in strength caused by an increase in tempering temperature.

- (3)

- In different tempering temperature ranges, the atomic diffusion capabilities in steel are different, causing the amount of retained austenite to first increase, and then decrease. At 450 °C, the steel exhibits tempered martensitic brittleness due to the massive decomposition of retained austenite and the precipitation of carbides.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Senuma, T.; Okayasu, M.; Mohrbacher, H. Microstructural Control and Alloy Design for Improving the Resistance to Delayed Fracture of Ultrahigh-Strength Automotive Steel Sheets. Metals 2023, 13, 1368. [Google Scholar] [CrossRef]

- Yuan, L.; You, X.; Liu, Z.; Zhang, J.; Hu, F.; Wang, K.; Chen, H.; Yang, Z.; Zhang, C. A new Nb-Si-added 2100 MPa ultra-strong spring steel designed under the guidance of a strength model. J. Mater. Sci. 2023, 58, 5933–5950. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, L.; Liu, Y. Heredity in the Microstructure and Mechanical Properties of Hot-rolled Spring Steel Wire 60S12MnA during Heat Treatment Process. J. Mater. Sci. Technol. 2013, 29, 82–88. [Google Scholar] [CrossRef]

- Xu, L.; Chen, L.; Sun, W. Effects of Soaking and Tempering Temperature on Microstructure and Mechanical Properties of 65Si2MnWE Spring Steel. Vacuum 2018, 154, 322–332. [Google Scholar] [CrossRef]

- Cruz, J.A., Jr.; Rodrigues, T.F.M.; Viana, V.D.C.; Abreu, H.; Santos, D.B. Influence of Temperature and Time of Austempering Treatment on Mechanical Properties of SAE 9254 Commercial Steel. Steel Res. Int. 2012, 83, 22–31. [Google Scholar] [CrossRef]

- Dai, Q.; Jin, L.; Chen, W.; Wu, J.; Fang, Z.; Yang, T.; Ma, R.; Li, K. High-performance reality of 55SiCrV spring steel processed by the rapid-induction heat treatment. Mater. Sci. Technol. 2023, 39, 1267–1277. [Google Scholar] [CrossRef]

- Zurnadzhy, V.; Efremenko, V.; Wu, K.; Azarkhov, A.; Chabak, Y.; Greshta, V.; Isayev, O.; Pomazkov, M. Effects of stress relief tempering on microstructure and tensile/impact behavior of quenched and partitioned commercial spring steel. Mater. Sci. Eng. A 2019, 745, 307–318. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Tong, Q.; Wang, L. Effects of Temperature and Oxygen Concentration on the Characteristics of Decarburization of 55SiCr Spring Steel. ISIJ Int. 2014, 54, 1920–1926. [Google Scholar] [CrossRef]

- Barani, A.A.; Li, F.; Romano, P.; Ponge, D.; Raabe, D. Design of High-Strength Steels by Microalloying and Thermomechanical Treatment. Mater. Sci. Eng. A 2007, 463, 138–146. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Y.; Zhou, L.; Jiang, C.; Xiao, J. Forming Condition and Control Strategy of Ferrite Decarburization in 60Si2MnA Spring Steel Wires for Automotive Suspensions. Int. J. Miner. Metall. Mater. 2012, 19, 116–121. [Google Scholar] [CrossRef]

- Ma, X.; Huang, Z.; Yao, Z.; Jiang, Z.; Zhao, B. Strengthening Mechanisms of Microalloying Spring Steel. In Proceedings of the 2018 China Symposium on Sustainable Steelmaking Technology (CSST2018), Tianjin, China, 25–27 October 2018. [Google Scholar]

- Chen, K.; Jiang, Z.; Liu, F.; Yu, J.; Li, Y.; Gong, W.; Chen, C. Effect of quenching and tempering temperature on microstructure and tensile properties of microalloyed ultra-high strength suspension spring steel. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. 2019, 766, 138272. [Google Scholar] [CrossRef]

- Wang, S.; Xi, X.; Zhao, Y.; Chen, L. Microstructures and Mechanical Properties of an Ultrahigh-Strength and Ductile Medium-Carbon High-Silicon Spring Steel. Steel Res. Int. 2023, 94, 2200149. [Google Scholar] [CrossRef]

- Chen, W.; Gao, P.; Wang, S.; Zhao, X.; Zhao, Z. Strengthening Mechanisms of Nb and V Microalloying High Strength Hot-Stamped Steel. Mater. Sci. Eng. A 2020, 797, 140115. [Google Scholar] [CrossRef]

- Xia, B.; Zhang, P.; Wang, B.; Zhu, Y.K.; Li, X.W.; Zhang, Z.F. A simultaneous improvement of the strength and plasticity of spring steels by replacing Mo with Si. Mater. Sci. Eng. A. 2021, 820, 141516. [Google Scholar] [CrossRef]

- Xia, B.; Wang, B.; Zhang, P.; Li, X.; Zhang, Z. The effect of tempering temperature on the microstructure and impact properties of high-strength spring steel. J. Mater. Res. 2023, 37, 341–352. [Google Scholar]

- Jiang, B.; Mei, Z.; Zhou, L.; Zhang, C.; Liu, Y. Microstructure Evolution, Fracture and Hardening Mechanisms of Quenched and Tempered Steel for Large Sized Bearing Rings at Elevated Quenching Temperatures. Met. Mater. Int. 2016, 22, 572–578. [Google Scholar] [CrossRef]

- Hao, C.L.; Yang, C.Y.; Liu, P.; Luan, Y.K.; Sang, B.G. Effects of rare earth elements on inclusions, microstructure and impact toughness of spring steel. J. Iron Steel Res. Int. 2023. [Google Scholar] [CrossRef]

- Jiang, B.; Wu, M.; Zhang, M.; Zhao, F.; Zhao, Z.; Liu, Y. Microstructural Characterization, Strengthening and Toughening Mechanisms of a Quenched and Tempered Steel: Effect of Heat Treatment Parameters. Mater. Sci. Eng. A 2017, 707, 306–314. [Google Scholar] [CrossRef]

- Chen, K.; Jiang, Z.; Liu, F.; Li, H.; Ma, X.; Zhao, B.; Kang, C.; Li, Y. Enhanced Mechanical Properties by Retained Austenite in Medium-Carbon Si-Rich Microalloyed Steel Treated by Quenching-Tempering, Austempering and Austempering-Tempering Processes. Mater. Sci. Eng. A 2020, 790, 139742. [Google Scholar] [CrossRef]

- Ito, A.; Fuse, T.; Torizuka, S. Effect of Dislocation Behavior on High Strength and High Ductility of Low Carbon-2%Si-5%Mn Fresh Martensitic Steel. Tetsu-to-Hagané 2022, 108, 877–890. [Google Scholar] [CrossRef]

- Zhang, L.; Gong, D.; Li, Y.; Wang, X.; Ren, X.; Wang, E. Effect of Quenching Conditions on the Microstructure and Mechanical Properties of 51CrV4 Spring Steel. Metals 2018, 8, 1056. [Google Scholar] [CrossRef]

- Stornelli, G.; Tselikova, A.; Gattia, D.M.; Mortello, M.; Schmidt, R.; Sgambetterra, M.; Testani, C.; Zucca, G.; Di Schino, A. Influence of Vanadium Micro-Alloying on the Microstructure of Structural High Strength Steels Welded Joints. Materials 2023, 16, 2897. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, Z.; Guo, K.; Guan, Y.; Yuan, L.; Wang, Q. Effect of Nb Content on the Microstructure and Impact Toughness of High-Strength Pipeline Steel. Metals 2024, 14, 42. [Google Scholar] [CrossRef]

- Cui, J.; Zhu, W.; Chen, Z.; Chen, L. Effect of Simulated Cooling Time on Microstructure and Toughness of CGHAZ in Novel High-Strength Low-Carbon Construction Steel. Sci. Technol. Weld. Join. 2020, 25, 169–177. [Google Scholar] [CrossRef]

- Dai, X.; Chen, Y.-F.; Wang, P.; Zhang, L.; Yang, B.; Chen, L.-S. Mechanical and fatigue properties of SA508-IV steel used for nuclear reactor pressure vessels. J. Iron Steel Res. Int. 2022, 29, 1312–1321. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Wang, P.; Li, D.; Li, Y. Effect of a modified quenching on impact toughness of 52,100 bearing steels. J. Mater. Sci. Technol. 2023, 160, 96–108. [Google Scholar] [CrossRef]

- Trzaska, J.; Dobrzański, L.A. Modelling of CCT diagrams for engineering and constructional steels. J. Mater. Process. Technol. 2007, 192–193, 504–510. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, X.; Wei, J.; Luo, R. Characterization of Carbide Precipitation during Tempering for Quenched Dievar Steel. Materials 2022, 15, 6448. [Google Scholar] [CrossRef]

- Van Dijk, N.; Butt, A.; Zhao, L.; Sietsma, J.; Offerman, S.; Wright, J.; van der Zwaag, S. Thermal Stability of Retained Austenite in TRIP Steels Studied by Synchrotron X-Ray Diffraction during Cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Xi, X.; Wang, J.; Li, X.; Chen, L.; Wang, Z. The Role of Intercritical Annealing in Enhancing Low-Temperature Toughness of Fe-C-Mn-Ni-Cu Structural Steel. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 2019, 50, 2912–2921. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Zhu, K.; Wang, C.; Xu, W. An integral transformation model for the combined calculation of key martensitic transformation temperatures and martensite fraction. Mater. Des. 2022, 219, 110768. [Google Scholar] [CrossRef]

- Liu, G.; Liu, K.; Zhang, M.; Ning, J.; Feng, Y. Effect of cold rolling reduction ratio on microstructure and mechanical properties of Fe–10Mn–4Al–0.4C steel containing δ ferrite. Mater. Sci. Eng. A 2023, 867, 144715. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Song, M.; Yang, H.; Song, K.; Guo, P.; Huang, W. Effect of tempering temperature on microstructure and mechanical properties of laser solid formed 300M steel. J. Alloys Compd. 2016, 689, 225–232. [Google Scholar] [CrossRef]

- Kim, B.; Celada, C.; San Martin, D.; Sourmail, T.; Rivera-Diaz-del-Castillo, P.E.J. The Effect of Silicon on the Nanoprecipitation of Cementite. Acta Mater. 2013, 61, 6983–6992. [Google Scholar] [CrossRef]

- Kozeschnik, E.; Bhadeshia, H.K.D.H. Influence of Silicon on Cementite Precipitation in Steels. Mater. Sci. Technol. 2008, 24, 343–347. [Google Scholar] [CrossRef]

- Dong, J.; Zhou, X.; Liu, Y.; Li, C.; Liu, C.; Guo, Q. Carbide precipitation in Nb-V-Ti microalloyed ultra-high strength steel during tempering. Mater. Sci. Eng. A 2017, 683, 215–226. [Google Scholar] [CrossRef]

- Toji, Y.; Miyamoto, G.; Raabe, D. Carbon Partitioning during Quenching and Partitioning Heat Treatment Accompanied by Carbide Precipitation. Acta Mater. 2015, 86, 137–147. [Google Scholar] [CrossRef]

- Zhou, C.; Ye, Q.B.; Hu, J.; Zhao, T.; Gao, X.H.; Wang, Z.D. Ultra-high-strength multi-alloyed steel with enhanced cryogenic toughness using thermally stable retained austenite. Mater. Sci. Eng. A 2022, 831, 142356. [Google Scholar] [CrossRef]

| C | Si | Mn + Cr + Ni | Ti + Nb + V | Al | S | P | Fe |

|---|---|---|---|---|---|---|---|

| 0.38 | 1.47 | 2.20 | 0.16 | 0.048 | 0.0045 | 0.0033 | Bal. |

| Sample | YS (MPa) | TS (MPa) | TEL (%) | RA (%) |

|---|---|---|---|---|

| Q860-T | 1700 | 1888 | 10.1 | 49.7 |

| Q890-T | 1662 | 1865 | 11.1 | 51.5 |

| Q920-T | 1635 | 1862 | 10.4 | 51.5 |

| Q950-T | 1633 | 1858 | 10.0 | 51.1 |

| Q-T300 | 1735 | 2020 | 10.8 | 47.1 |

| Q-T350 | 1713 | 1953 | 10.3 | 48.2 |

| Q-T400 | 1662 | 1865 | 11.5 | 51.5 |

| Q-T450 | 1635 | 1861 | 12.7 | 51.1 |

| Sample | Q-T300 | Q-T350 | Q-T400 | Q-T450 |

|---|---|---|---|---|

| ρ (m−2) | 6.26 × 1015 | 5.23 × 1015 | 4.23 × 1015 | 3.29 × 1015 |

| σp (MPa) | 1177.5 | 1076.1 | 967.8 | 853.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, F.; Zheng, J.; Zhang, J.; Zhao, Y.; Chen, L. Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness. Metals 2024, 14, 180. https://doi.org/10.3390/met14020180

Shi F, Zheng J, Zhang J, Zhao Y, Chen L. Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness. Metals. 2024; 14(2):180. https://doi.org/10.3390/met14020180

Chicago/Turabian StyleShi, Fang, Jian Zheng, Jie Zhang, Yang Zhao, and Liqing Chen. 2024. "Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness" Metals 14, no. 2: 180. https://doi.org/10.3390/met14020180

APA StyleShi, F., Zheng, J., Zhang, J., Zhao, Y., & Chen, L. (2024). Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness. Metals, 14(2), 180. https://doi.org/10.3390/met14020180