Surface Polishing of an Inconel 625 Bar by a Super-Fast MAF Process for a Solenoid Valve Stem Used in a Hydrogen Tank

Abstract

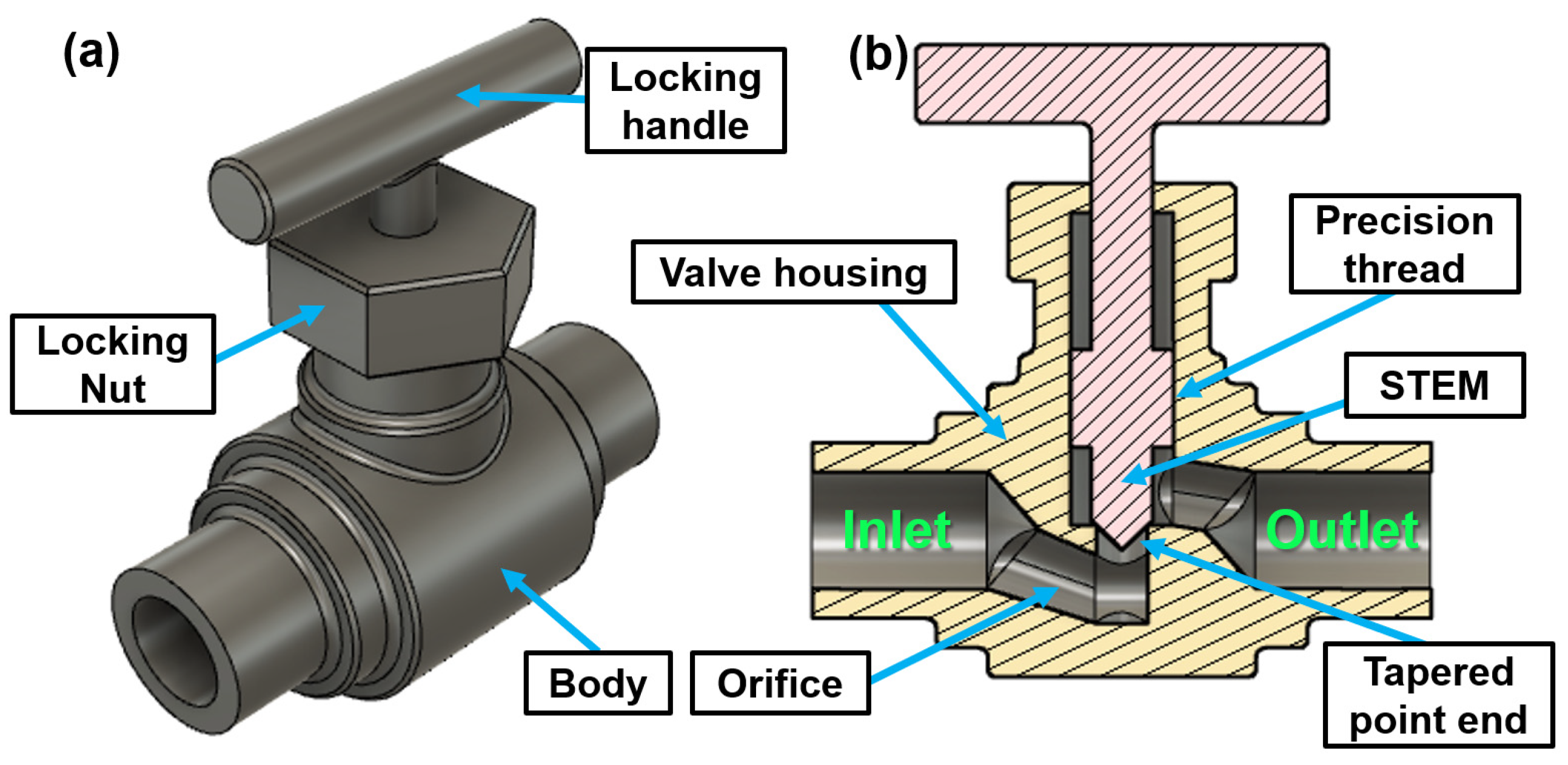

1. Introduction

2. Material Selection

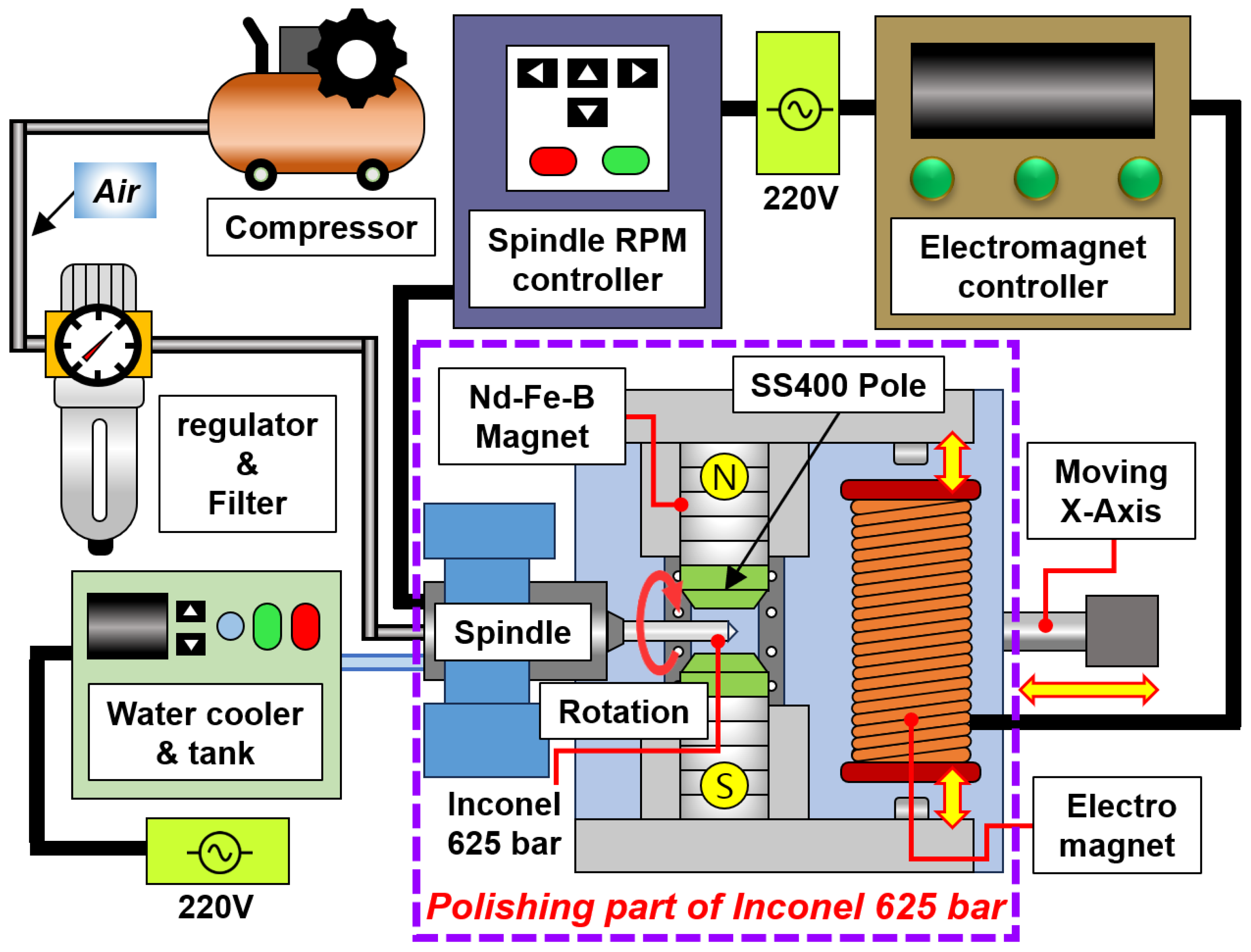

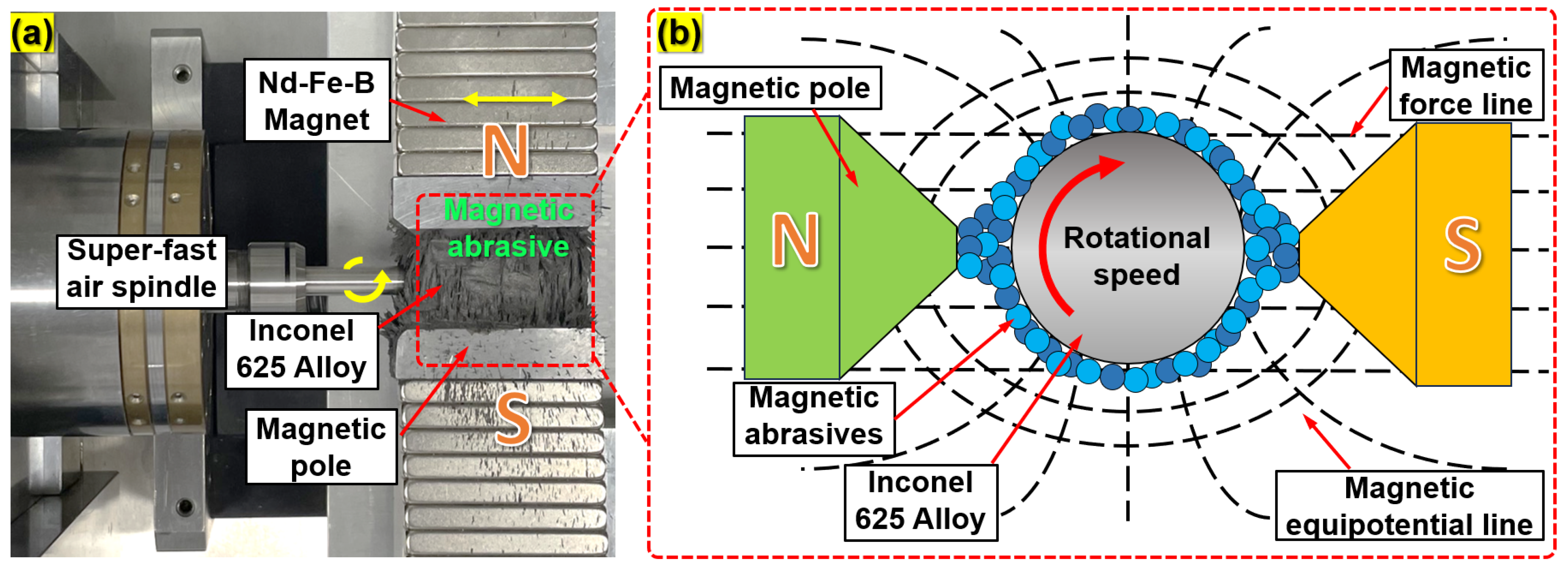

3. Experimental Setup and Polishing Principle of the Super-Fast MAF Process

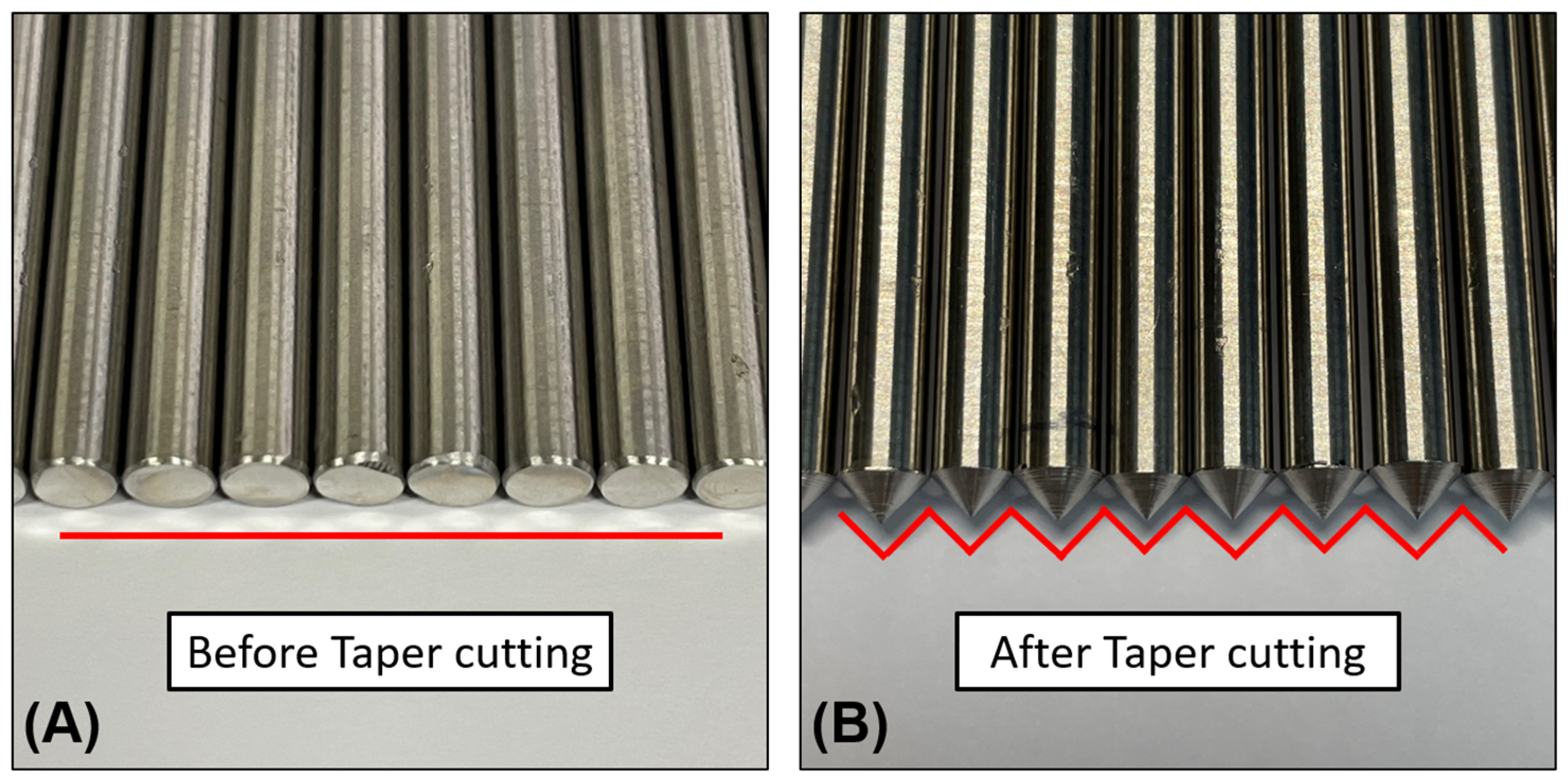

4. Experimental Method and Conditions

4.1. Experimental Conditions

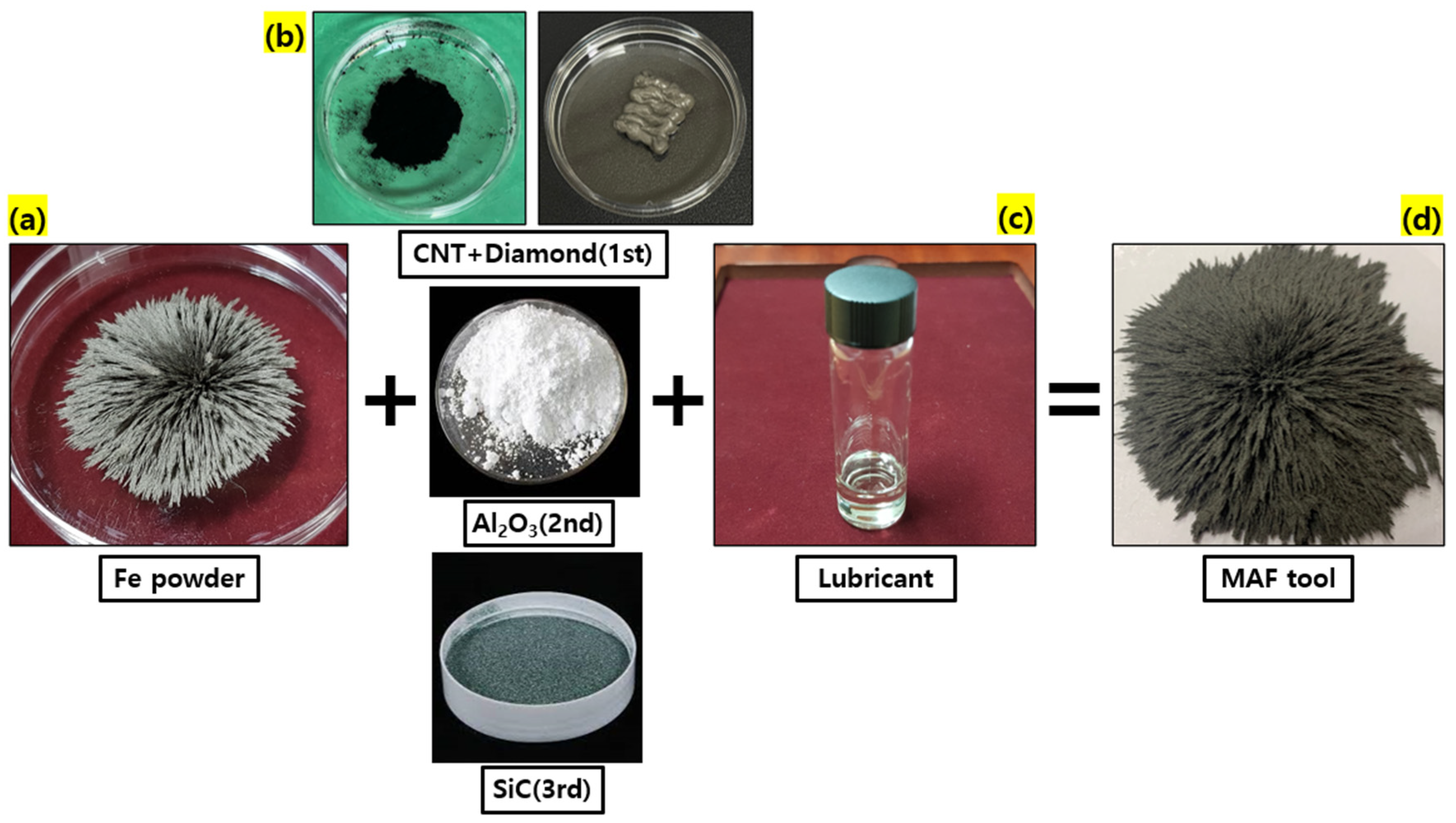

4.1.1. MAF Tools

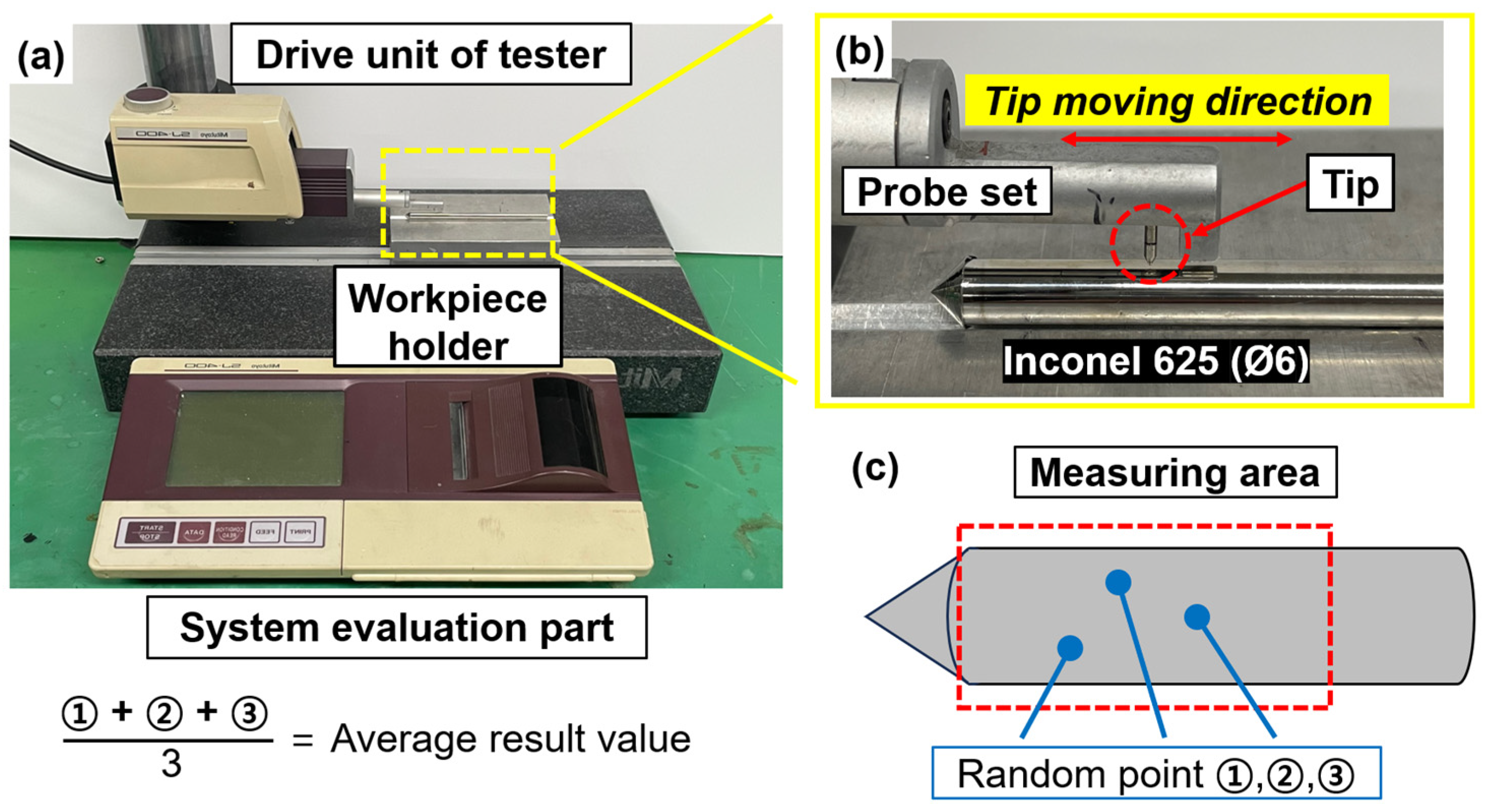

4.1.2. Measurements

5. Results and Discussion

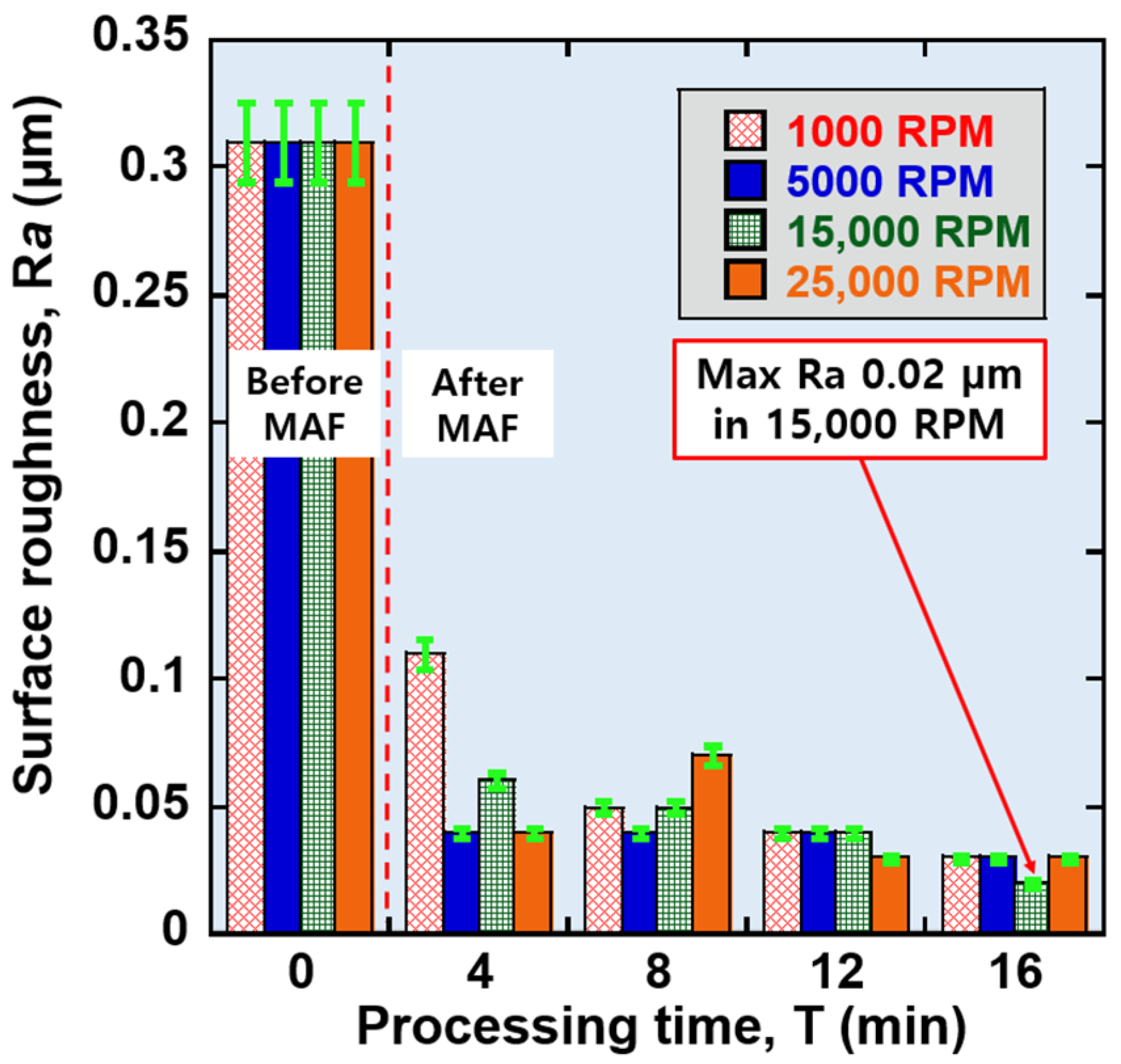

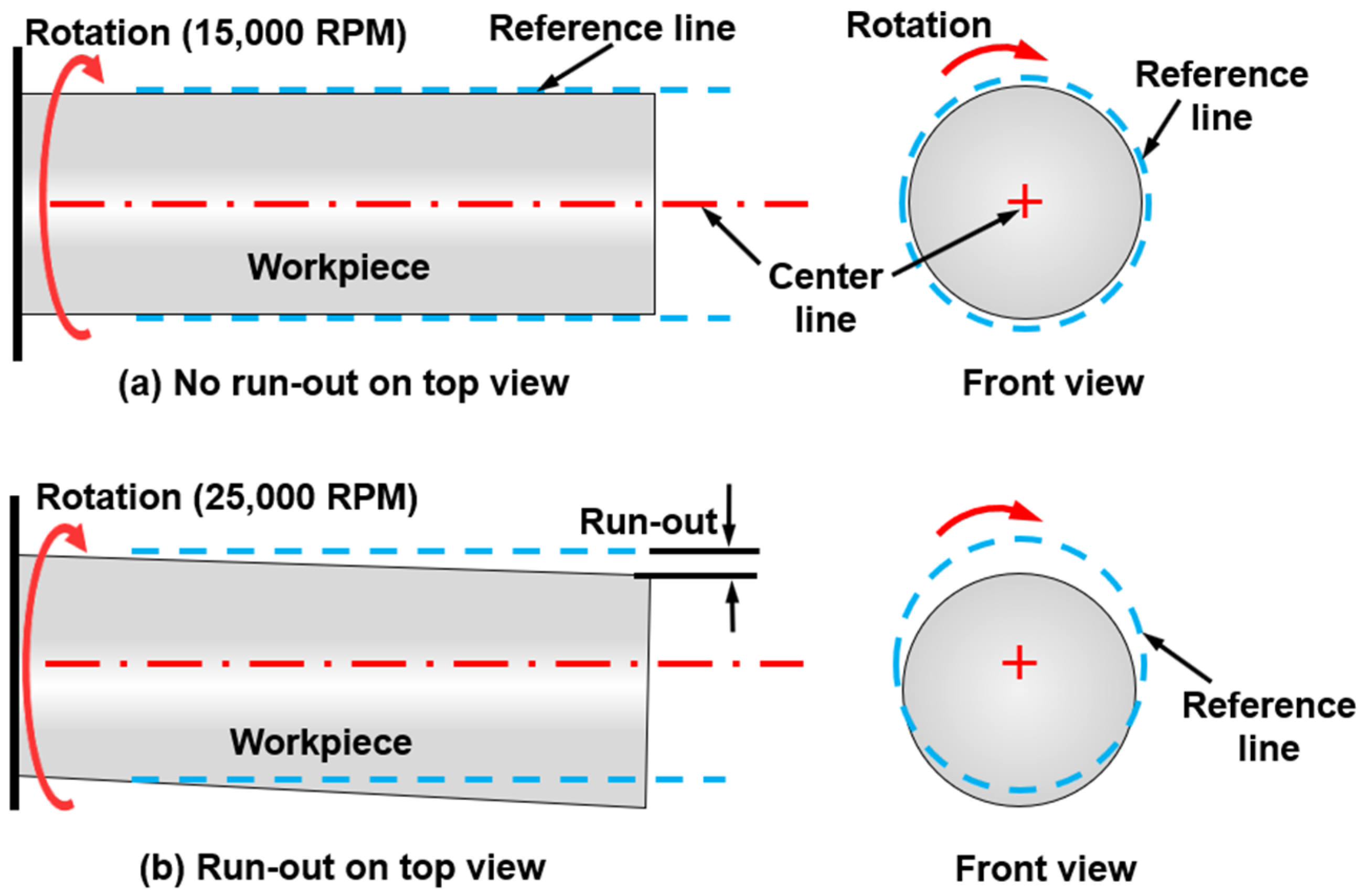

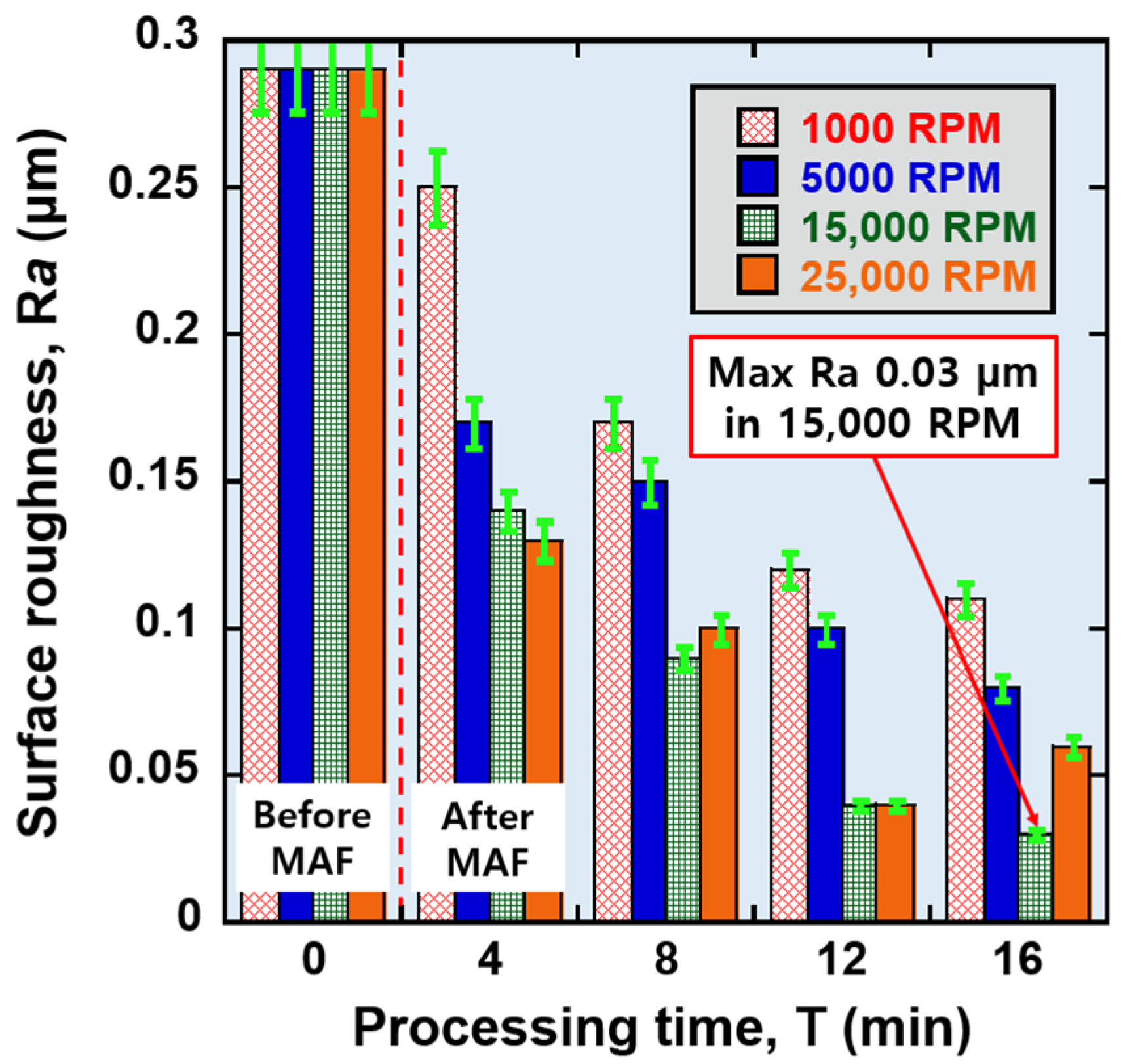

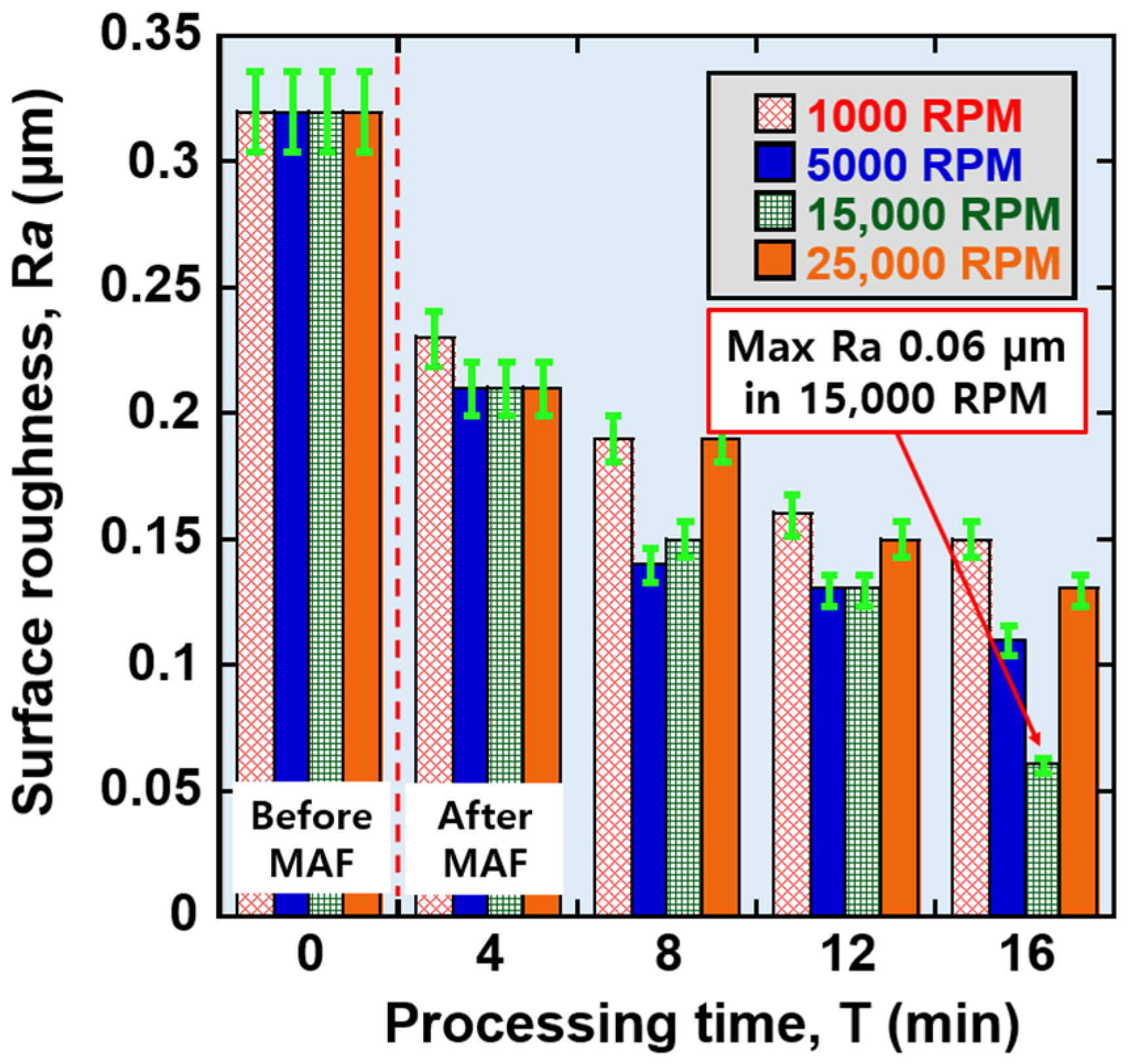

5.1. Surface Roughness with Rotational Speed

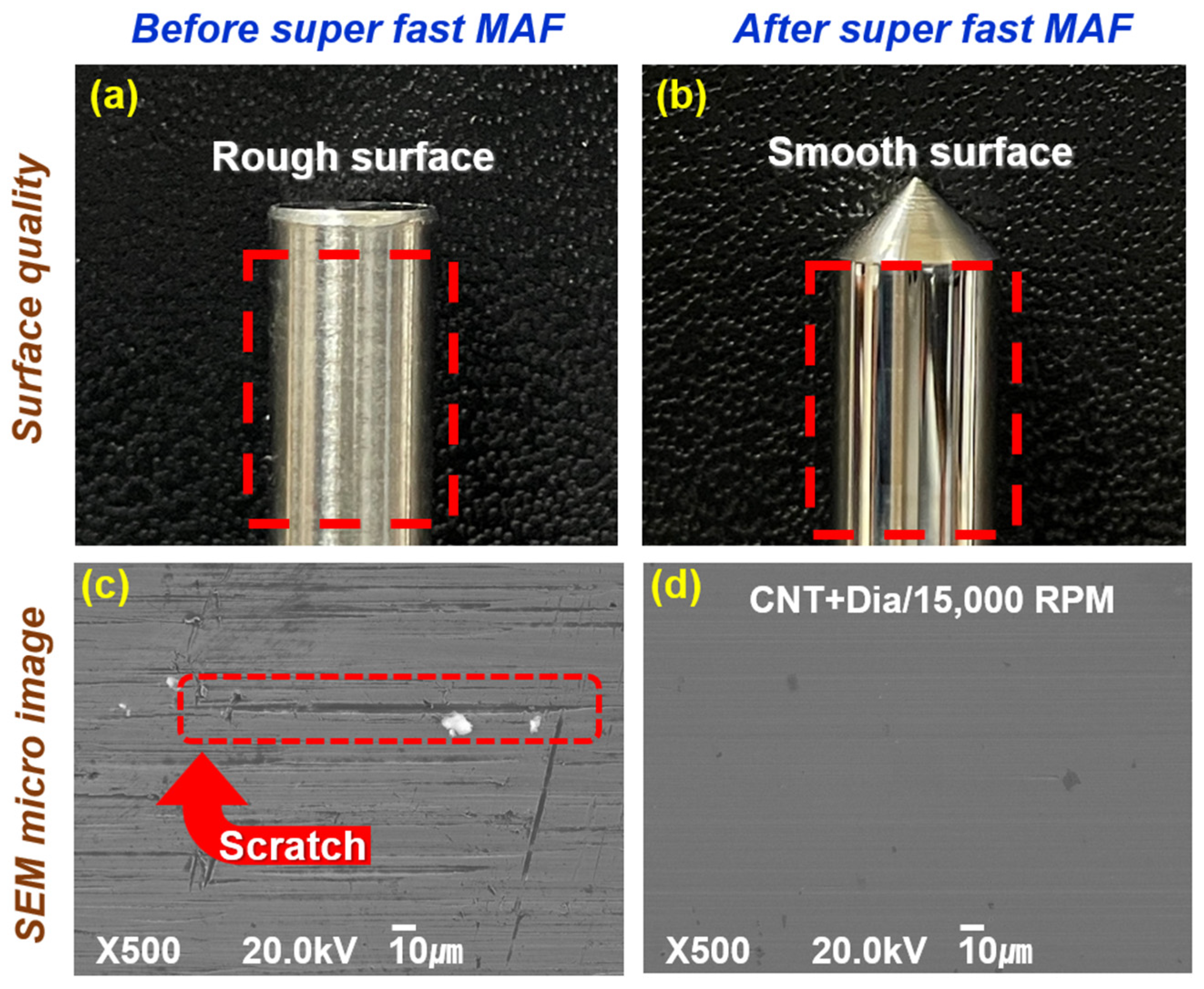

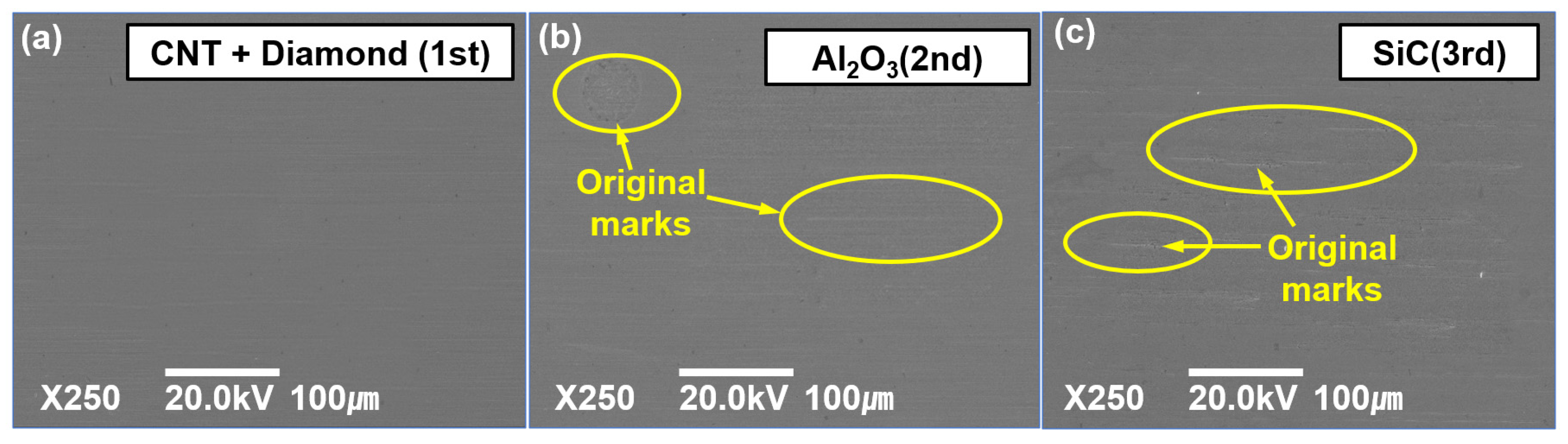

5.2. Surface Observation

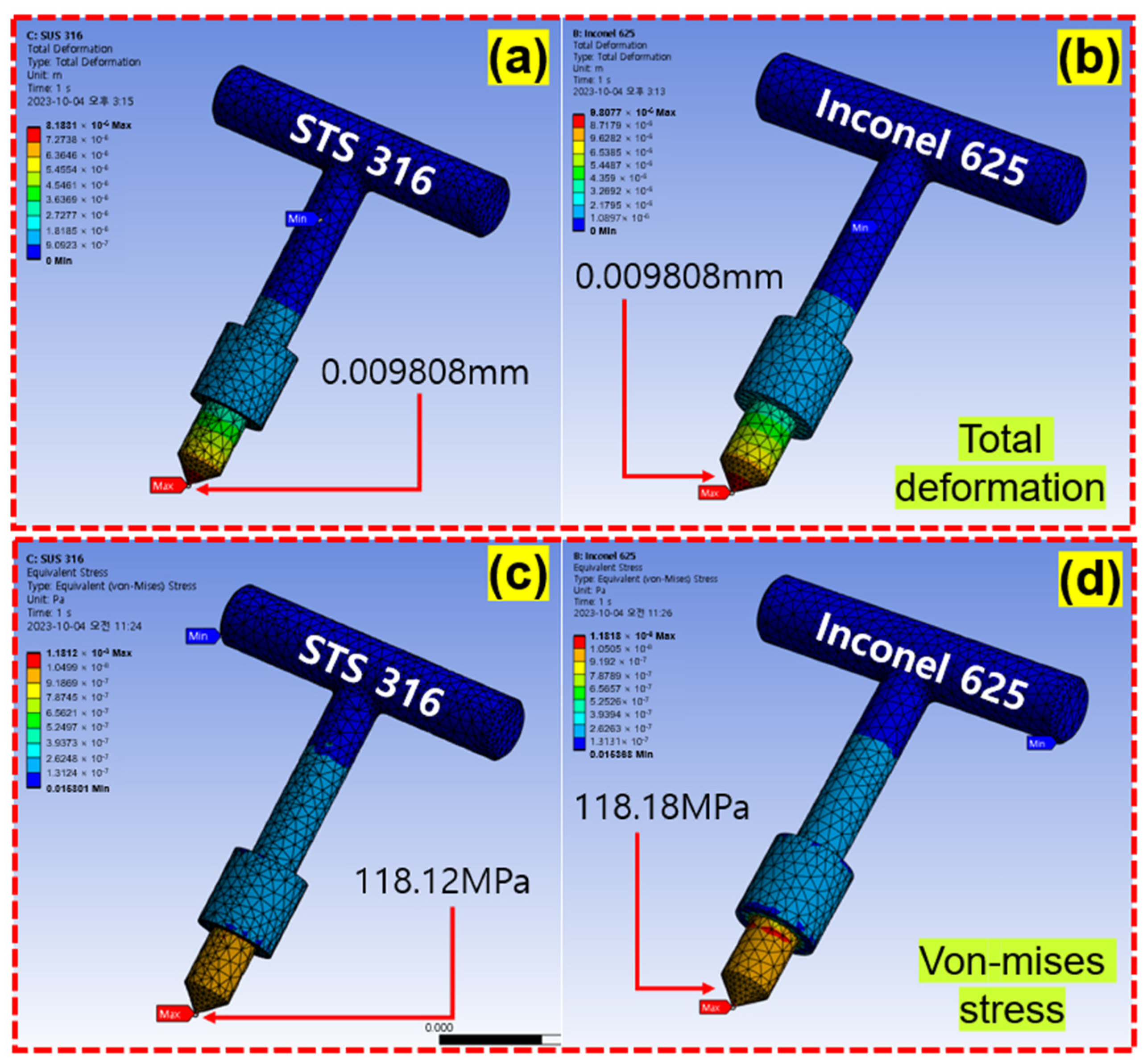

5.3. FEA Structural Analysis

6. Conclusions

- A super-fast MAF process is suitable for reducing the surface roughness Ra values of Inconel 625 bars effectively. Based on the results, the Ra values of Inconel 625 bars were successfully reduced from 0.31 μm to 0.02 μm, 0.03 μm, and 0.06 μm by the CNT + diamond paste, Al2O3, and SiC abrasives.

- The best results of reduction in surface roughness were obtained under optimal conditions such as rotational speed of Inconel 625 bars: 15,000 RPM; abrasive particles: CNT + diamond paste; and processing time: 12 min.

- According to the surface and SEM images of Inconel 625 bars before and after the super-fast MAF process, the rough parts (such as scratches and unevenness) were completely removed from the surface of Inconel 625 bars, and the surface condition after polishing was achieved to a super-smooth surface level (Ra: 0.02 μm).

- FEA structural analysis results showed suitable strain (0.009808 mm), equivalent stress (118.18 MPa), and safety factor (4.6539) of the Inconel 625 bar, indicating that Inconel 625 is suitable for use as a valve material for hydrogen tanks.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, Y.; Zhang, C.; Jia, Q.; Birgersson, E.; Han, M.; Zhang, P. Novel closed anode pressure-swing system for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2020, 45, 17727–17735. [Google Scholar] [CrossRef]

- Das, L.M.; Gulati, R.; Gupta, P.K. A comparative evaluation of the performance characteristics of a spark ignition engine using hydrogen and compressed natural gas as alternative fuels. Int. J. Hydrogen Energy 2000, 25, 783–793. [Google Scholar] [CrossRef]

- Matsuoka, S.; Yamabe, J.; Matsunaga, H. Criteria for determining hydrogen compatibility and the mechanisms for hydrogen-assisted, surface crack growth in austenitic stainless steels. Eng. Fract. Mech. 2016, 153, 103–127. [Google Scholar] [CrossRef]

- Lee, H.J.; Ahn, J.; Kim, H.-Y. Design of a Solenoid Actuator for a Cylinder Valve in a Fuel Cell Vehicle. Appl. Sci. 2016, 6, 288. [Google Scholar] [CrossRef]

- Ye, J.; Cui, J.; Hua, Z.; Xie, J.; Peng, W.; Wang, W. Study on the high-pressure hydrogen gas flow characteristics of the needle valve with different spool shapes. Int. J. Hydrogen Energy 2023, 48, 11370–11381. [Google Scholar] [CrossRef]

- Kim, R.-W.; Hwang, K.-H.; Kim, S.-R.; Lee, J.-H. Investigation of Ultra-High Pressure Gas Control System for Hydrogen Vehicles. Energies 2020, 13, 2446. [Google Scholar] [CrossRef]

- Ariyadi, H.M.; Jeong, J.; Saito, K. Computational analysis of hydrogen flow and aerodynamic noise emission in a solenoid valve during fast-charging to fuel cell automobiles. J. Energy Storage 2022, 45, 103661. [Google Scholar] [CrossRef]

- Ye, J.; Zhao, Z.; Zheng, J.; Salem, S.; Yu, J.; Cui, J.; Jiao, X. Transient Flow Characteristic of High-Pressure Hydrogen Gas in Check Valve during the Opening Process. Energies 2020, 13, 4222. [Google Scholar] [CrossRef]

- Takaki, S.; Nanba, S.; Imakawa, K.; Macadre, A.; Yamabe, J.; Matsunaga, H.; Matsuoka, S. Determination of hydrogen compatibility for solution-treated austenitic stainless steels based on a newly proposed nickel-equivalent equation. Int. J. Hydrogen Energy 2016, 41, 15095–15100. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, M.; Rong, L. Overview of hydrogen-resistant alloys for high-pressure hydrogen environment: On the hydrogen energy structural materials. Clean Energy 2023, 7, 99–115. [Google Scholar] [CrossRef]

- Hicks, P.; Altstetter, C. Internal hydrogen effects on tensile properties of iron-and nickel-base superalloys. Metall. Trans. A 1990, 21, 365–372. [Google Scholar] [CrossRef]

- Hicks, P.; Altstetter, C. Hydrogen-enhanced cracking of superalloys. Metall. Trans. A 1992, 23, 237–249. [Google Scholar] [CrossRef]

- Cheung, C.F.; Wang, C.J.; Cao, Z.C.; Ho, L.T.; Liu, M.Y. Development of a multi-jet polishing process for inner surface finishing. Precis. Eng. 2018, 52, 112–121. [Google Scholar] [CrossRef]

- Nagdeve, L.; Dhakar, K.; Kumar, H. Development of novel finishing tool into Magnetic Abrasive Finishing process of Aluminum 6061. Mater. Manuf. Process. 2020, 35, 1129–1134. [Google Scholar] [CrossRef]

- Barman, A.; Das, M.J. Simulation and experimental investigation of finishing forces in magnetic field assisted finishing process. Mater. Manuf. Process. 2018, 33, 1223–1232. [Google Scholar] [CrossRef]

- Heng, L.; Kim, Y.; Mun, S. Review of Superfinishing by the Magnetic Abrasive Finishing Process. High Speed Mach. 2017, 3, 42–55. [Google Scholar] [CrossRef]

- Jiao, A.; Quan, H.; Li, Z.; Chen, Y. Study of magnetic abrasive finishing in seal ring groove surface operations. Int. J. Adv. Manuf. Technol. 2016, 85, 1195–1205. [Google Scholar] [CrossRef]

- Xu, J.; Zou, Y.J. Development of a new magnetic abrasive finishing process with renewable abrasive particles using the circulatory system. Precis. Eng. 2021, 72, 417–425. [Google Scholar] [CrossRef]

- Singh, M.; Singh, A.K. Magnetorheological finishing of variable diametric external surface of the tapered cylindrical workpieces for functionality improvement. J. Manuf. Process. 2021, 61, 153–172. [Google Scholar] [CrossRef]

- Singh, M.; Singh, A.K. Magnetorheological finishing of copper cylindrical roller for its improved performance in printing machine. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 103–115. [Google Scholar] [CrossRef]

- Rana, A.S.; Bedi, T.S.; Grover, V. Fine-finishing of stepped cylindrical workpiece using magnetorheological finishing process. Mater. Today Proc. 2021, 41, 886–892. [Google Scholar] [CrossRef]

- Nguyen, D.N.; Chau, N.L.; Dao, T.-P.; Prakash, C.; Singh, S. Experimental study on polishing process of cylindrical roller bearings. Meas. Control 2019, 52, 1272–1281. [Google Scholar] [CrossRef]

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Buddaraju, K.M.; Sastry, G.R.K.; Kosaraju, S. A review on turning of Inconel alloys. Mater. Today Proc. 2021, 44, 2645–2652. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Parida, A.K.; Maity, K. Comparison the machinability of Inconel 718, Inconel 625 and Monel 400 in hot turning operation. Eng. Sci. Technol. Int. J. 2018, 21, 364–370. [Google Scholar] [CrossRef]

- Yun, H.; Han, B.; Chen, Y.; Liao, M. Internal finishing process of alumina ceramic tubes by ultrasonic-assisted magnetic abrasive finishing. Int. J. Adv. Manuf. Technol. 2016, 85, 727–734. [Google Scholar] [CrossRef]

- Singh, G.; Kumar, H.; Kansal, H.K.; Srivastava, A.J. Effects of chemically assisted magnetic abrasive finishing process parameters on material removal of Inconel 625 tubes. Procedia Manuf. 2020, 48, 466–473. [Google Scholar] [CrossRef]

- Liu, J.; Zou, Y. Study on Elucidation of the Roundness Improvement Mechanism of the Internal Magnetic Abrasive Finishing Process Using a Magnetic Machining Tool. J. Manuf. Mater. Process. 2023, 7, 49. [Google Scholar] [CrossRef]

- Xie, H.; Zou, Y.; Dong, C.; Wu, J. Study on the magnetic abrasive finishing process using alternating magnetic field: Investigation of mechanism and applied to aluminum alloy plate. Int. J. Adv. Manuf. Technol. 2019, 102, 1509–1520. [Google Scholar] [CrossRef]

- Kausar, A.; Ilyas, H.; Siddiq, M. Current Research Status and Application of Polymer/Carbon Nanofiller Buckypaper: A Review. Polym. Plast. Technol. Eng. 2017, 56, 1780–1800. [Google Scholar] [CrossRef]

- Heng, L.; Yang, G.E.; Wang, R.; Kim, M.S.; Mun, S.D. Effect of carbon nano tube (CNT) particles in magnetic abrasive finishing of Mg alloy bars. J. Mech. Sci. Technol. 2015, 29, 5325–5333. [Google Scholar] [CrossRef]

- Abubakr, M.; Hegab, H.; Osman, T.A.; Elharouni, F.; Kishawy, H.A.; Esawi, A.M.K. Carbon Nanotube–Based Nanofluids. In Handbook of Carbon Nanotubes; Abraham, J., Thomas, S., Kalarikkal, N., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1501–1532. [Google Scholar] [CrossRef]

- Postek, E.; Sadowski, T. Impact model of the Al2O3/ZrO2 composite by peridynamics. Compos. Struct. 2021, 271, 114071. [Google Scholar] [CrossRef]

| Al | Cr | Fe | Mo | Nb | Ti | Ni |

|---|---|---|---|---|---|---|

| 0.16 | 21.5 | 4.6 | 8.7 | 3.32 | 0.18 | Base |

| Young’s Modulus (MPa) | Yield Strength (MPa) | Density (kg/m3) | Poisson’s Ratio |

|---|---|---|---|

| 2.1 × 105 | 516 | 7.8 × 10−9 | 0.28 |

| Parameter | Value |

|---|---|

| Workpiece | Inconel 625 bar (dimension: ∅6 × 100 mm) |

| Rotational speed (RPM) | 1000, 5000, 15,000, 25,000 |

| Magnetic abrasive (g) | Fe powder: 9.0 g (#200) (i) CNT: 0.05 g (0.04 µm) + diamond paste: 1 g (1 µm) (ii) Al2O3: 0.7 g (0.05 µm) (iii) SiC: 2.0 g (#320) |

| Lubricant (g) | Light oil: 0.5 g |

| Processing time (min) | 0, 4, 8, 12, 16 |

| Pole shape | Trapezoid |

| Pole material | SS400 steel |

| Amplitude (mm) | 1 |

| Magnet size (mm) | 30 × 20 × 10 |

| Magnetic flux density (mT) | 550 |

| Mechanical Properties | CNT Abrasive Particles | Diamond Abrasive in Paste | Alumina Oxide (Al2O3) | Silicon Carbide (SiC) |

|---|---|---|---|---|

| Density (Mg/m3) | 1.6 | 3.44 | 3 | 4.36 |

| Thermal conductivity (W/mK) | 1800~6600 | 350 | 30 | 70~110 |

| Strength (GPa) | 20~50 | 4.0 | 1.5 | 2.9 |

| Young’s modulus (GPa) | 1200 | 1050 | 215–413 | 90 |

| Tensile strength (MPa) | 150,000 | 2800 | 69 | 240 |

| Elastic modulus (GPa) | 600~1200 | 1050 | 380 | 210 |

| Total Deformation (mm) | Maximum | Average |

|---|---|---|

| STS 316 | 0.008183 | 0.001085 |

| Inconel 625 | 0.009808 | 0.001295 |

| Von Mises Stress (MPa) | Maximum | Average | Safety Factor |

|---|---|---|---|

| STS 316 | 118.12 | 4.8463 | 4.6563 |

| Inconel 625 | 118.18 | 4.8539 | 4.6539 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-J.; Heng, L.; Mun, S.-D. Surface Polishing of an Inconel 625 Bar by a Super-Fast MAF Process for a Solenoid Valve Stem Used in a Hydrogen Tank. Metals 2024, 14, 242. https://doi.org/10.3390/met14020242

Kim H-J, Heng L, Mun S-D. Surface Polishing of an Inconel 625 Bar by a Super-Fast MAF Process for a Solenoid Valve Stem Used in a Hydrogen Tank. Metals. 2024; 14(2):242. https://doi.org/10.3390/met14020242

Chicago/Turabian StyleKim, Hwi-Joong, Lida Heng, and Sang-Don Mun. 2024. "Surface Polishing of an Inconel 625 Bar by a Super-Fast MAF Process for a Solenoid Valve Stem Used in a Hydrogen Tank" Metals 14, no. 2: 242. https://doi.org/10.3390/met14020242

APA StyleKim, H.-J., Heng, L., & Mun, S.-D. (2024). Surface Polishing of an Inconel 625 Bar by a Super-Fast MAF Process for a Solenoid Valve Stem Used in a Hydrogen Tank. Metals, 14(2), 242. https://doi.org/10.3390/met14020242