Galvanic Corrosion of E690 Offshore Platform Steel in a Simulated Marine Thermocline

Abstract

1. Introduction

2. Experiment

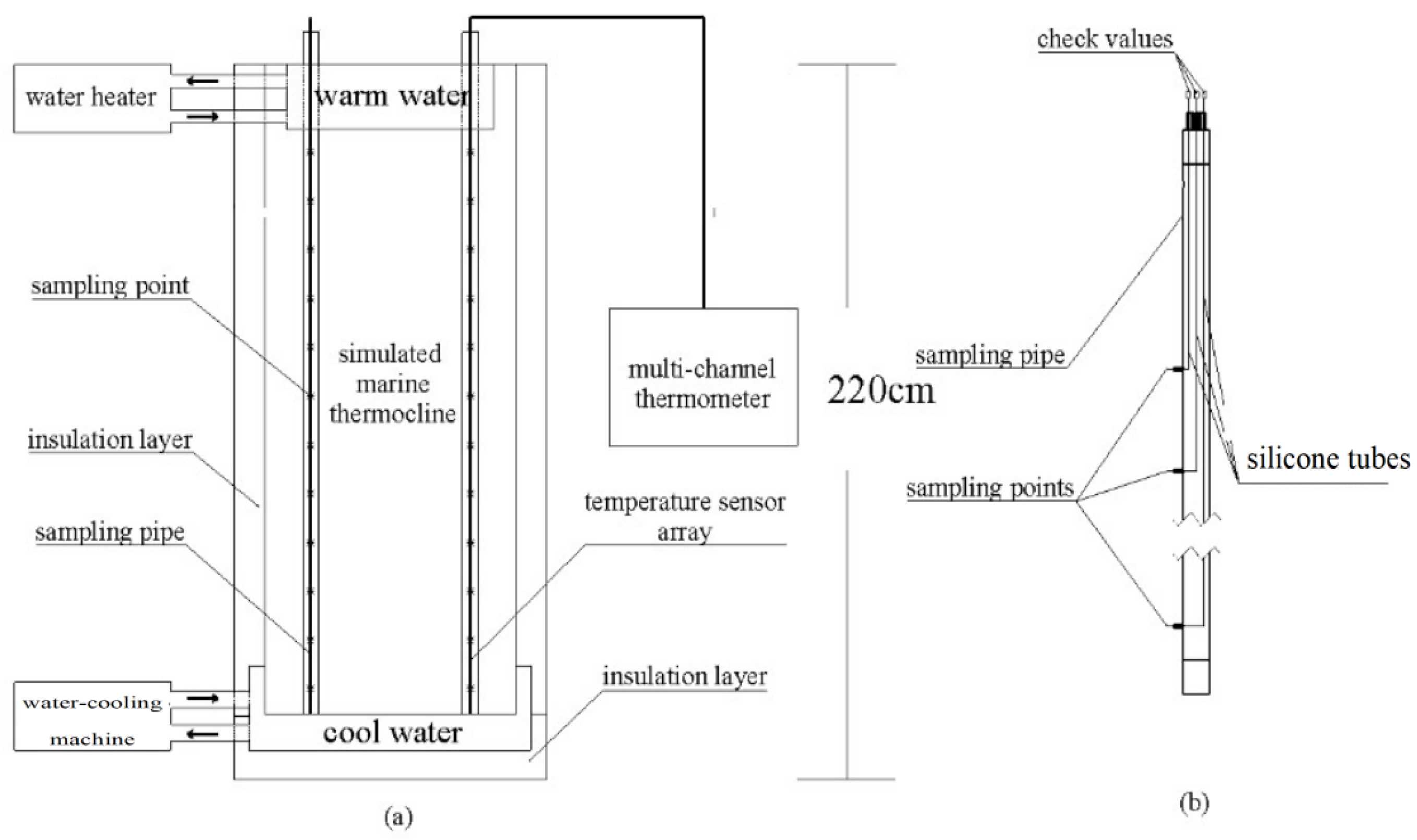

2.1. Simulated Marine Thermocline

2.1.1. Marine Thermocline Simulator

2.1.2. Measurement of Marine Thermocline Parameters

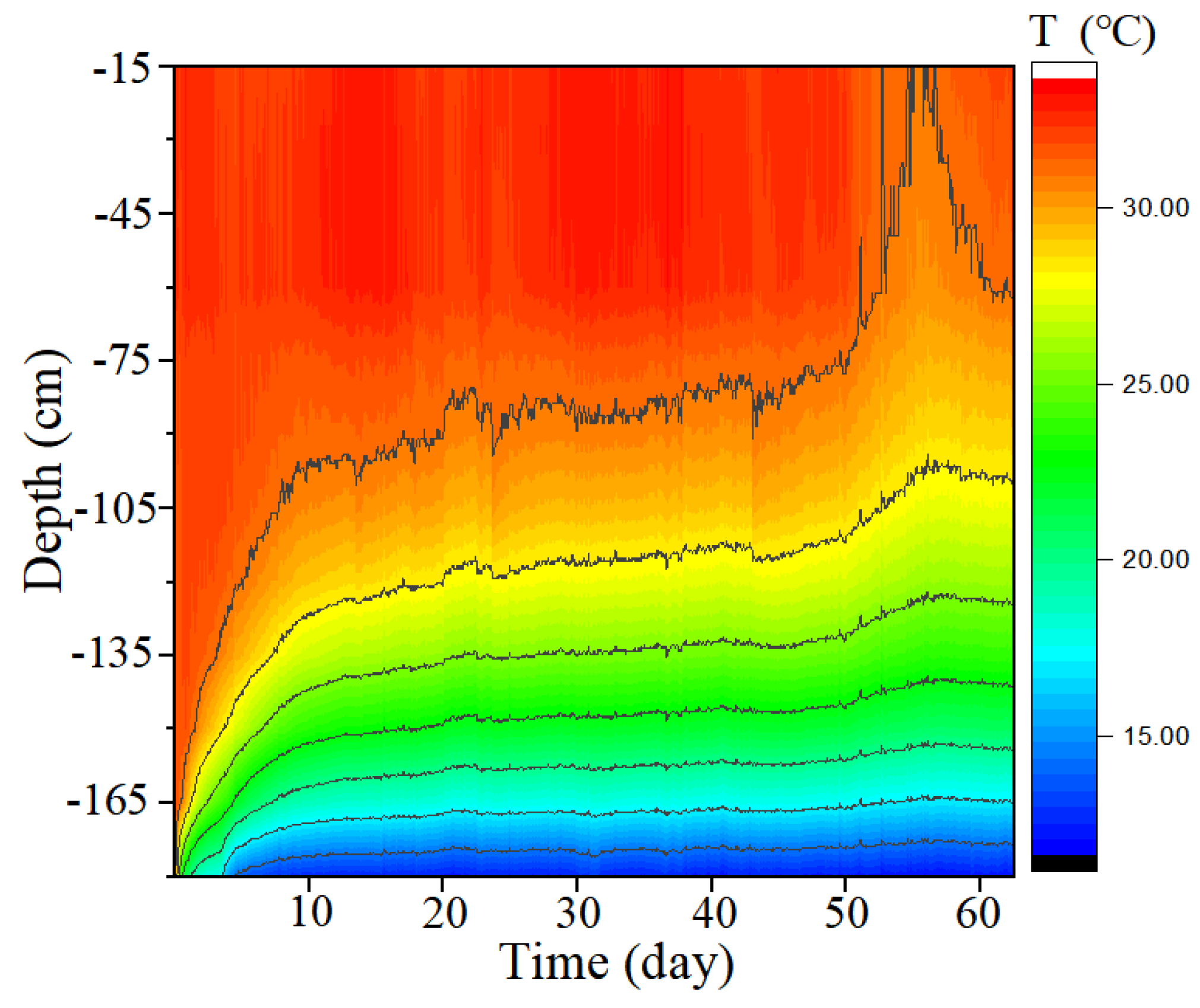

- Temperature measurementThe temperature measurement unit contained a multichannel thermometer and temperature sensor array. The temperature sensors were numbered 1 to 12 from the bottom to the top. The temperature data were collected every 10 min.

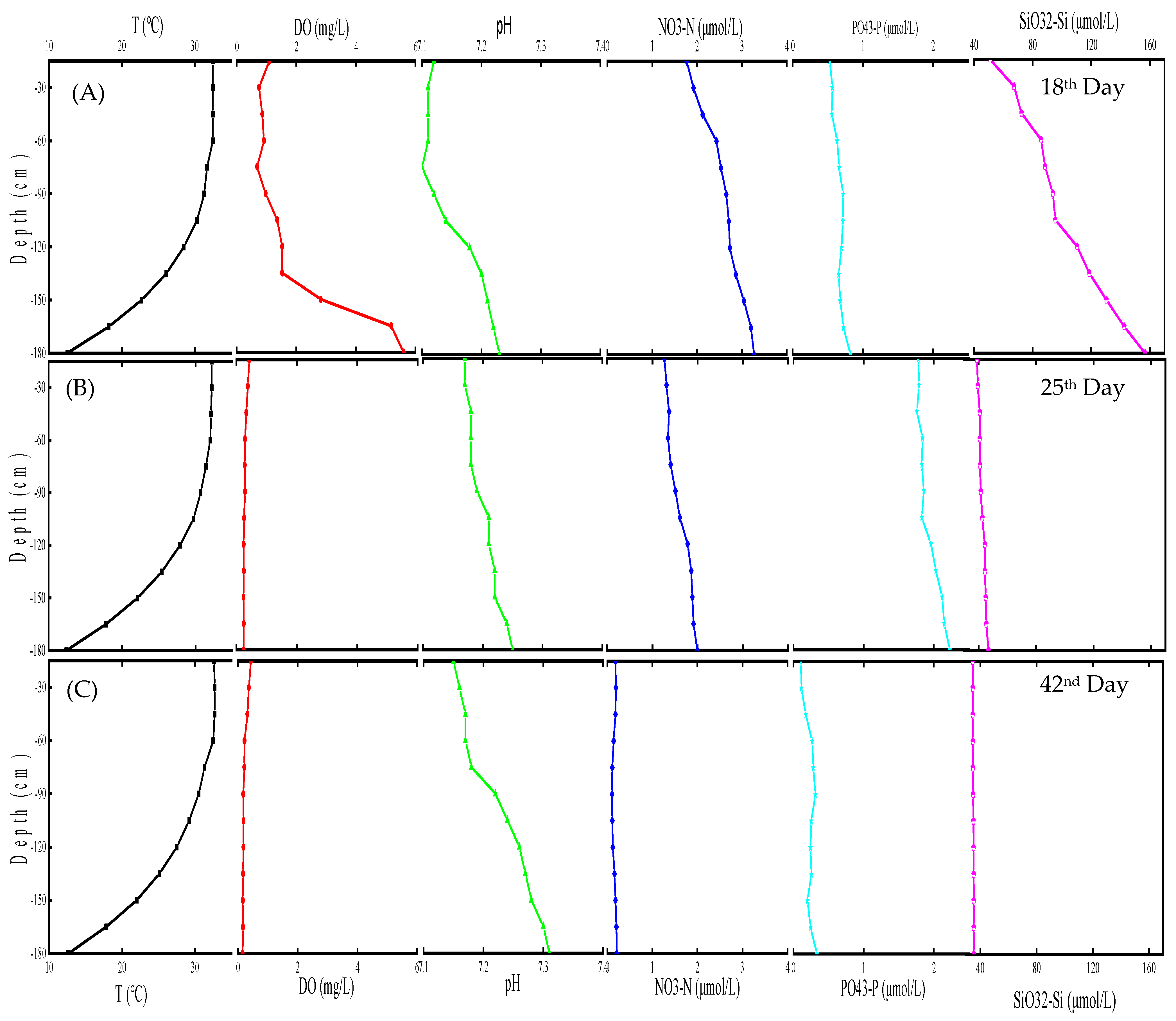

- pH measurementThe SMT lasted for 66 days. On the 18th, 25th, and 42nd days, seawater samples were taken through the sampling tube. The seawater sample’s pH was measured immediately by a pH meter with temperature compensation.

- Measurement of DO and nutrient contentsThe DO and nutrient (nitrate, phosphate, and silicate) contents of the seawater samples were determined using a chemical method [27] on the 18th, 25th, and 42nd days. The Wenkler method was employed for the analytical determination of DO in seawater. The method utilized for the analysis of nitrate in the seawater involved zinc sheet reduction followed by neethylenediamine spectrophotometry. The analyses of both the phosphates and silicates were conducted using molybdate amine chromogenic spectrophotometry.

2.2. Material

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Als | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 0.20 | 1.00 | 0.0058 | 0.0014 | 0.99 | 1.45 | 0.0091 | 0.37 | 0.03 | 0.036 | Bal. |

2.3. Corrosion Research Method

2.3.1. Measurement of RCWBE Galvanic Currents

2.3.2. Measurement of Instantaneous Icorr and Ecorr

2.3.3. Corrosion Morphology Observation

2.3.4. Weight Loss Measurement

3. Results and Discussion

3.1. Characterization of the Simulated Marine Thermocline

3.1.1. Temperature Variation in the Simulated Marine Thermocline

3.1.2. Component Variation in the Simulated Marine Thermocline

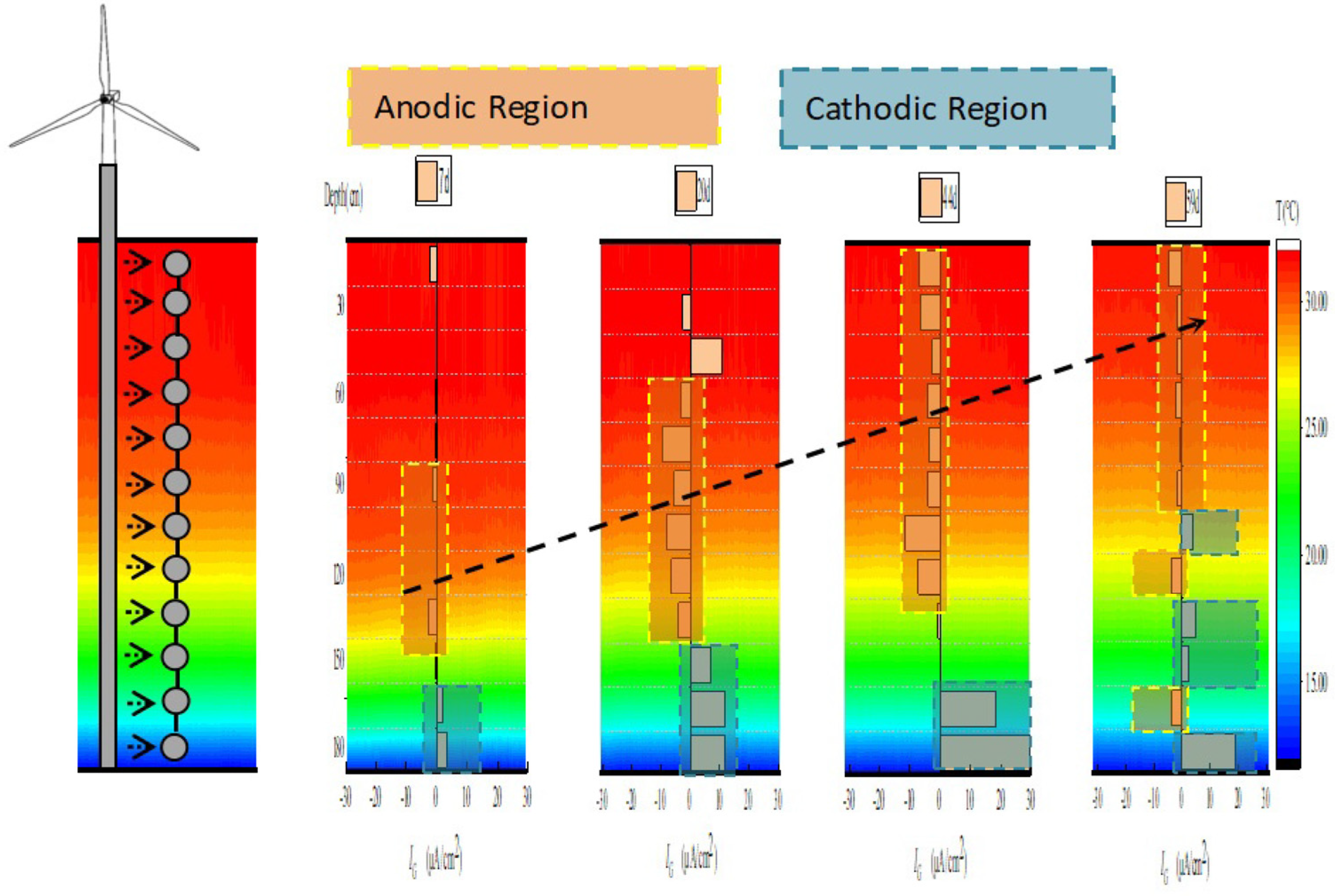

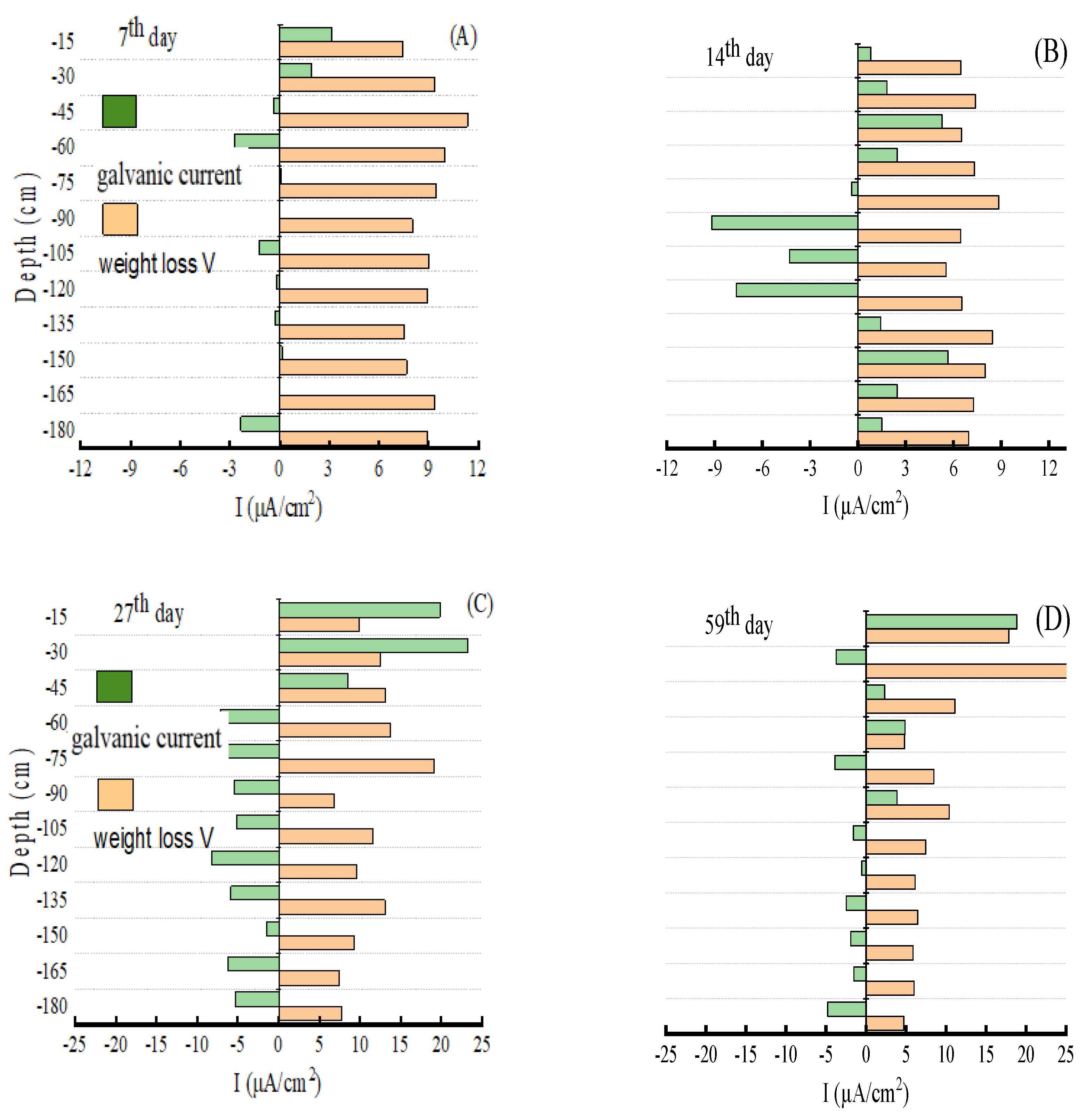

3.2. Galvanic Corrosion of E690 Offshore Platform Steel in a Simulated Marine Thermocline

3.3. Driver of E690 Offshore Platform Steel Galvanic Corrosion in the SMT

3.4. Proportion of Galvanic Corrosion in E690 Offshore Platform Steel Corrosion

4. Conclusions

- (1)

- The SMT showed a stable multilayer structure. The variations in temperature, DO, pH, and nutrient concentration in the SMT were similar to those seen in a natural marine thermocline.

- (2)

- Galvanic corrosion occurred after the intrusion of E690 steel into the marine thermocline. Primary anodic regions were located in the area with the fastest temperature variation, and the anodic regions were intermixed with the cathodic region in the lower part of the stable marine thermocline.

- (3)

- The driver of galvanic corrosion of E690 steel in the marine thermocline was the of the E690 steel at various depths. The continuous reduction in Ecorr with depth contributed to large-scale galvanic corrosion, and the oscillation variation of Ecorr with depth was the reason for small-scale galvanic corrosion.

- (4)

- The Ecorr values of the E690 steel were influenced by the temperature, pH, and DO in the marine thermocline, in the following order: DO >> T > pH.

- (5)

- There were at least two forms of E690 steel corrosion in the marine thermocline: galvanic corrosion and seawater corrosion. The proportion of galvanic corrosion in the average corrosion rate could increase up to approximately 80% in the anodic region. There were many deep corrosion pits in the long-term and stable anodic region of galvanic corrosion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lynne, D.T.; Pickard, G.L. Typical Distributions of Water Characteristics. In Descriptive Physical Oceanography: An Introduction, 6th ed.; Elsevier: London, UK, 2011; pp. 67–110. [Google Scholar]

- Tang, Z.; Li, T. Remote and local controls on dissolved oxygen in the Western Tropical Pacific thermocline during the last 700 kyr. Palaeogeogr. Palaeocl. 2024, 638, 112015. [Google Scholar] [CrossRef]

- Zhang, M.; Shu, Q. Spatiotemporal propagating decadal signal of ocean heat content and thermocline depth identified in the tropical Pacific. Sci. Total Environ. 2022, 838, 155972. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.; Oh, S. Acoustic characterization of fish and macroplankton communities in the Seychelles-Chagos thermocline ridge of the southwest Indian ocean. Deep-Sea Res. Part II 2024, 213, 105356. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F. A review on defects in steel offshore structures and developed strengthening techniques. Structures 2019, 20, 635–657. [Google Scholar] [CrossRef]

- Zheng, Z.; Chang, Z. Mitigating deepwater jacket offshore platform vibration under wave and earthquake loadings utilizing nonlinear energy sinks. Ocean Eng. 2023, 283, 115096. [Google Scholar] [CrossRef]

- Morales, Y.; Samanta, P. Water management for Power-to-X offshore platforms: An underestimated item. Sci. Rep. 2023, 13, 12286. [Google Scholar] [CrossRef] [PubMed]

- Ben, N.; Vytyaz, O.Y. Mechanical properties of steel for floating offshore platforms under static and cyclic loading. Mater. Sci. 2024, 59, 152–157. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z. Effect of cathodic potential on stress corrosion cracking behavior of different heat-affected zone microstructures of E690 steel in artificial seawater. J. Mater. Sci. Technol. 2021, 64, 141–152. [Google Scholar] [CrossRef]

- Liu, Z.; Hao, W. Fundamental investigation of stress corrosion cracking of E690 steel in simulated marine thin electrolyte layer. Corros. Sci. 2019, 148, 388–396. [Google Scholar] [CrossRef]

- Ma, H.C.; Fan, Y. Effect of pre-strain on the electrochemical and stress corrosion cracking behavior of E690 steel in simulated marine atmosphere. Ocean Eng. 2019, 182, 188–195. [Google Scholar] [CrossRef]

- Ma, H.C.; Liu, Z.Y. Stress corrosion cracking of E690 steel as a welded joint in a simulated marine atmosphere containing sulphur dioxide. Corros. Sci. 2015, 100, 627–641. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, L. Corrosion evolution and stress corrosion cracking of E690 steel for marine construction in artificial seawater under potentiostatic anodic polarization. Constr. Build. Mater. 2020, 238, 117763. [Google Scholar] [CrossRef]

- Li, G.; Li, Y. Evaluation of the impact of chloride ion concentration on stress corrosion cracking in E690 steel under low pH conditions. Int. J. Electrochem. Sci. 2023, 18, 100375. [Google Scholar] [CrossRef]

- Tian, H.; Wang, X. Electrochemical corrosion, hydrogen permeation and stress corrosion cracking behavior of E690 steel in thiosulfate-containing artificial seawater. Corros. Sci. 2018, 144, 145–162. [Google Scholar] [CrossRef]

- Ma, H.; Liu, Z. Comparative study of the SCC behavior of E690 steel and simulated HAZ microstructures in a SO2-polluted marine atmosphere. Mater. Sci. Eng. A 2016, 650, 93–101. [Google Scholar] [CrossRef]

- Ma, H.; Du, C. Effect of SO2 content on SCC behavior of E690 high-strength steel in SO2-polluted marine atmosphere. Ocean Eng. 2018, 164, 256–262. [Google Scholar] [CrossRef]

- Ma, H.; Chen, L. Effect of prior austenite grain boundaries on corrosion fatigue behaviors of E690 high strength low alloy steel in simulated marine atmosphere. Mater. Sci. Eng. A 2020, 773, 138884. [Google Scholar] [CrossRef]

- Ma, H.; Liu, Z. Effect of cathodic potentials on the SCC behavior of E690 steel in simulated seawater. Mater. Sci. Eng. A 2015, 642, 22–31. [Google Scholar] [CrossRef]

- Gardiner, C.P.; Melchers, R.E. Corrosion analysis of bulk carriers, Part I: Operational parameters influencing corrosion rates. Mar. Struct. 2003, 16, 547–566. [Google Scholar] [CrossRef]

- Wei, H.; Tang, Y. Corrosion behavior and microstructure analysis of butt welds of Q690 high strength steel in simulated marine environment. J. Build. Eng. 2024, 84, 108509. [Google Scholar] [CrossRef]

- Tian, H.; Cui, Z. Corrosion evolution and stress corrosion cracking behavior of a low carbon bainite steel in the marine environments: Effect of the marine zones. Corros. Sci. 2022, 206, 110490. [Google Scholar] [CrossRef]

- Melchers, R.E.; Jeffrey, R. Corrosion of long vertical steel strips in the marine tidal zone and implications for ALWC. Corros. Sci. 2012, 65, 26–36. [Google Scholar] [CrossRef]

- Qian, R.; Li, Q. Atmospheric chloride-induced corrosion of steel-reinforced concrete beam exposed to real marine-environment for 7 years. Ocean Eng. 2023, 286, 115675. [Google Scholar] [CrossRef]

- Wall, H.; Wadsö, L. Corrosion rate measurements in steel sheet pile walls in a marine environment. Mar. Struct. 2013, 33, 21–32. [Google Scholar] [CrossRef]

- Edwards, E.C.; Holcombe, A. Trends in floating offshore wind platforms: A review of early-stage devices. Renew. Sustain. Energ Rev. 2024, 194, 114271. [Google Scholar] [CrossRef]

- GB/T 12763.4-2007; Code for Marine Surveys Part 4 Investigation of Seawater Chemical Elements. China Standard Press: Beijing, China, 2008.

- Deng, P.; Li, Z. Vertical galvanic corrosion of pipeline steel in simulated marine thermocline. Ocean Eng. 2020, 217, 107584. [Google Scholar] [CrossRef]

- Hu, J.; Deng, P. The vertical Non-uniform corrosion of Reinforced concrete exposed to the marine environments. Constr. Build. Mater. 2018, 183, 180–188. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Chen, J.F. Deepening of the thermocline increases primary production in winter vs. summer in the northern South China Sea. Deep.-Sea Res. Part I 2023, 201, 104163. [Google Scholar] [CrossRef]

| Depth (cm) | Time | ||||

|---|---|---|---|---|---|

| 7th Day | 20th Day | 27th Day | 44th Day | 59th Day | |

| 15 |  |  |  |  |  |

| 45 |  |  |  |  |  |

| 75 |  |  |  |  |  |

| 105 |  |  |  |  |  |

| 135 |  |  |  |  |  |

| 165 |  |  |  |  |  |

| 180 |  |  |  |  |  |

| Depth (cm) | Time | ||||

|---|---|---|---|---|---|

| 7th Day | 20th Day | 27th Day | 44th Day | 59th Day | |

| 15 |  |  |  |  |  |

| 45 |  |  |  |  |  |

| 75 |  |  |  |  |  |

| 105 |  |  |  |  |  |

| 135 |  |  |  |  |  |

| 165 |  |  |  |  |  |

| 180 |  |  |  |  |  |

| Depth (cm) | Time | ||||

|---|---|---|---|---|---|

| 7th Day | 20th Day | 27th Day | 44th Day | 59th Day | |

| 15 |  |  |  |  |  |

| 45 |  |  |  |  |  |

| 75 |  |  |  |  |  |

| 105 |  |  |  |  |  |

| 135 |  |  |  |  |  |

| 165 |  |  |  |  |  |

| 180 |  |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Lin, G.; Deng, P.; Li, Z.; Tian, Y. Galvanic Corrosion of E690 Offshore Platform Steel in a Simulated Marine Thermocline. Metals 2024, 14, 287. https://doi.org/10.3390/met14030287

Hu J, Lin G, Deng P, Li Z, Tian Y. Galvanic Corrosion of E690 Offshore Platform Steel in a Simulated Marine Thermocline. Metals. 2024; 14(3):287. https://doi.org/10.3390/met14030287

Chicago/Turabian StyleHu, Jiezhen, Guodong Lin, Peichang Deng, Ziyun Li, and Yuwan Tian. 2024. "Galvanic Corrosion of E690 Offshore Platform Steel in a Simulated Marine Thermocline" Metals 14, no. 3: 287. https://doi.org/10.3390/met14030287

APA StyleHu, J., Lin, G., Deng, P., Li, Z., & Tian, Y. (2024). Galvanic Corrosion of E690 Offshore Platform Steel in a Simulated Marine Thermocline. Metals, 14(3), 287. https://doi.org/10.3390/met14030287