Microstructure and Mechanical Properties Ultrasonic Assistance Laser Welded Joints of Beta Titanium Alloy with Multiple Vibrators

Abstract

1. Introduction

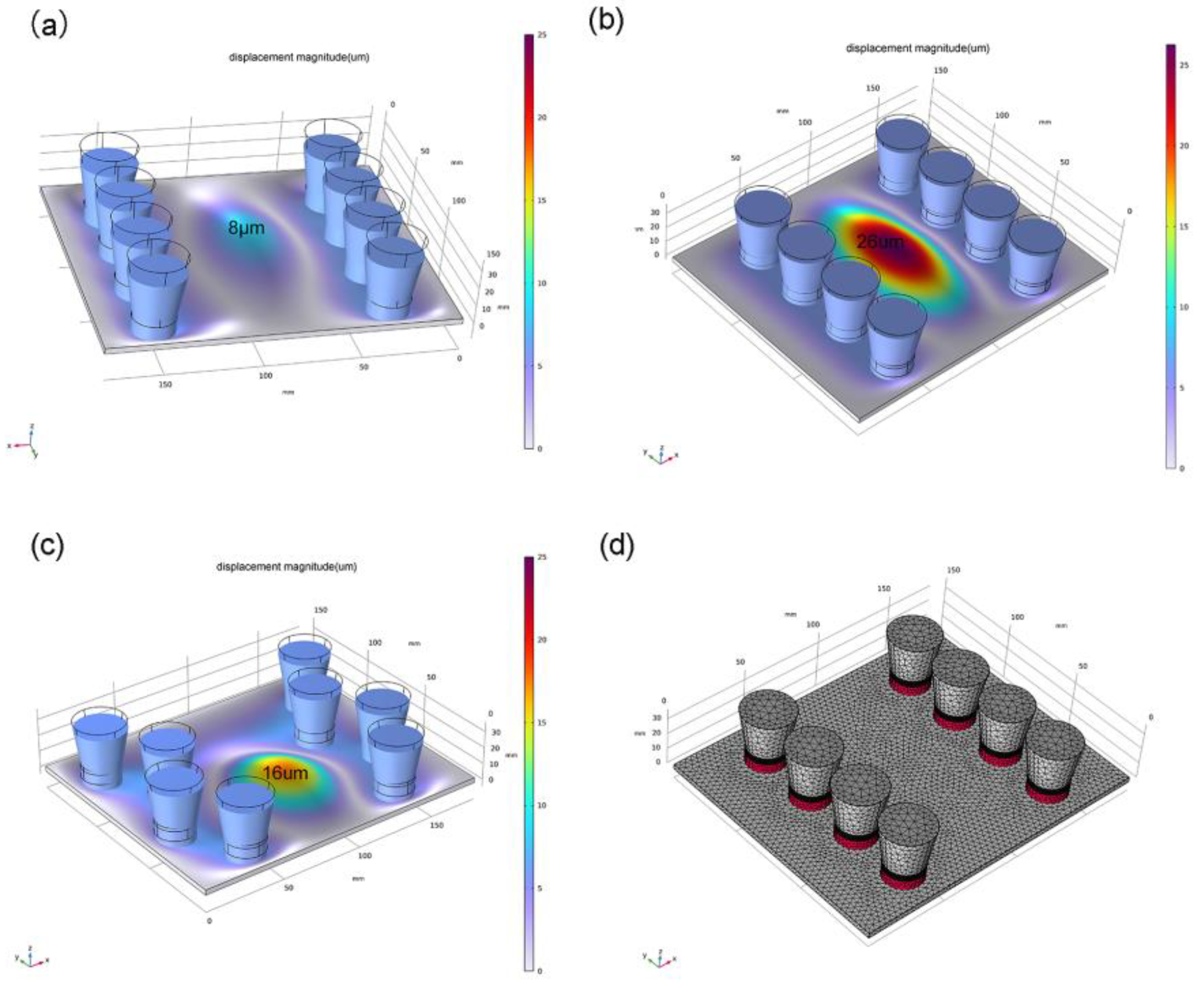

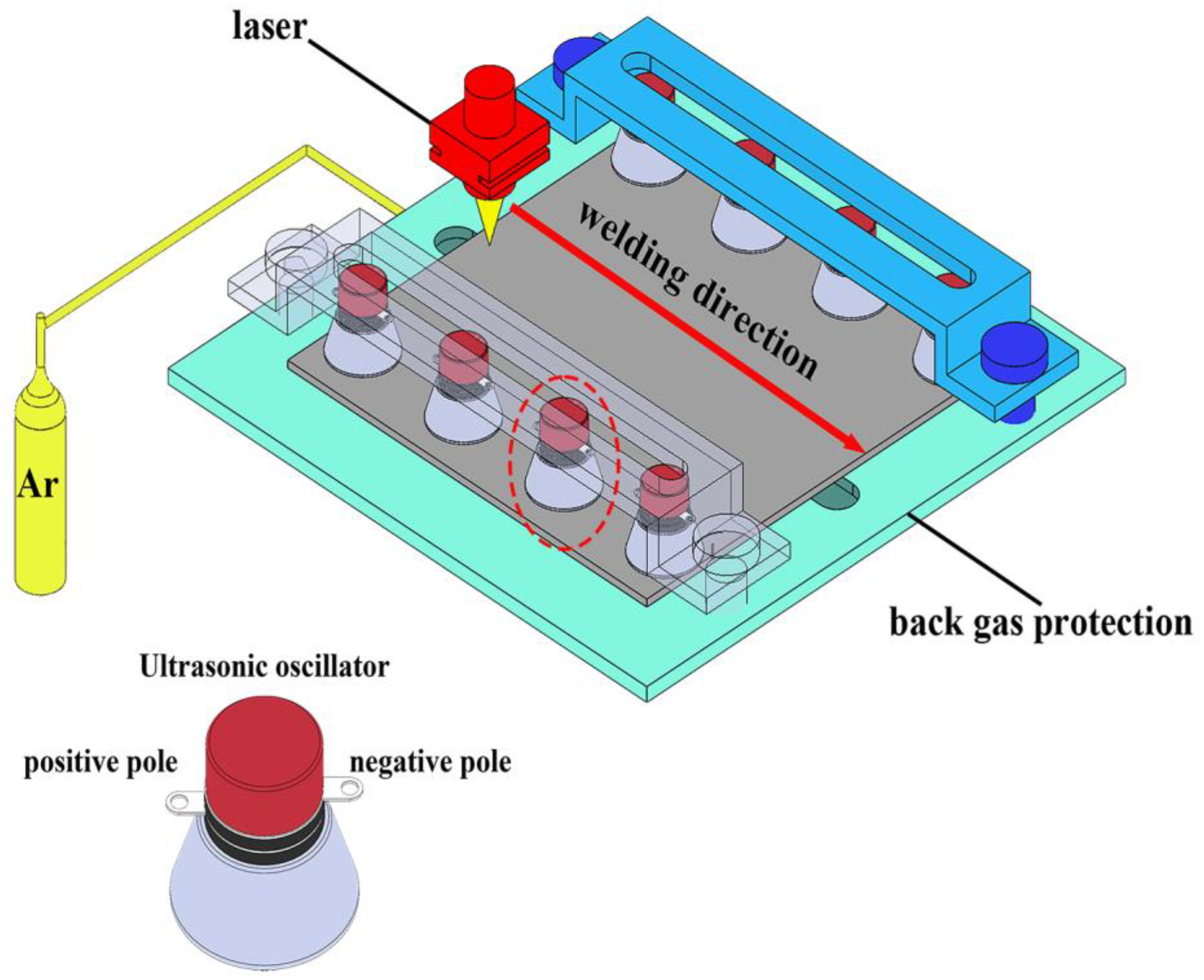

2. Materials and Methods

3. Results and Discussion

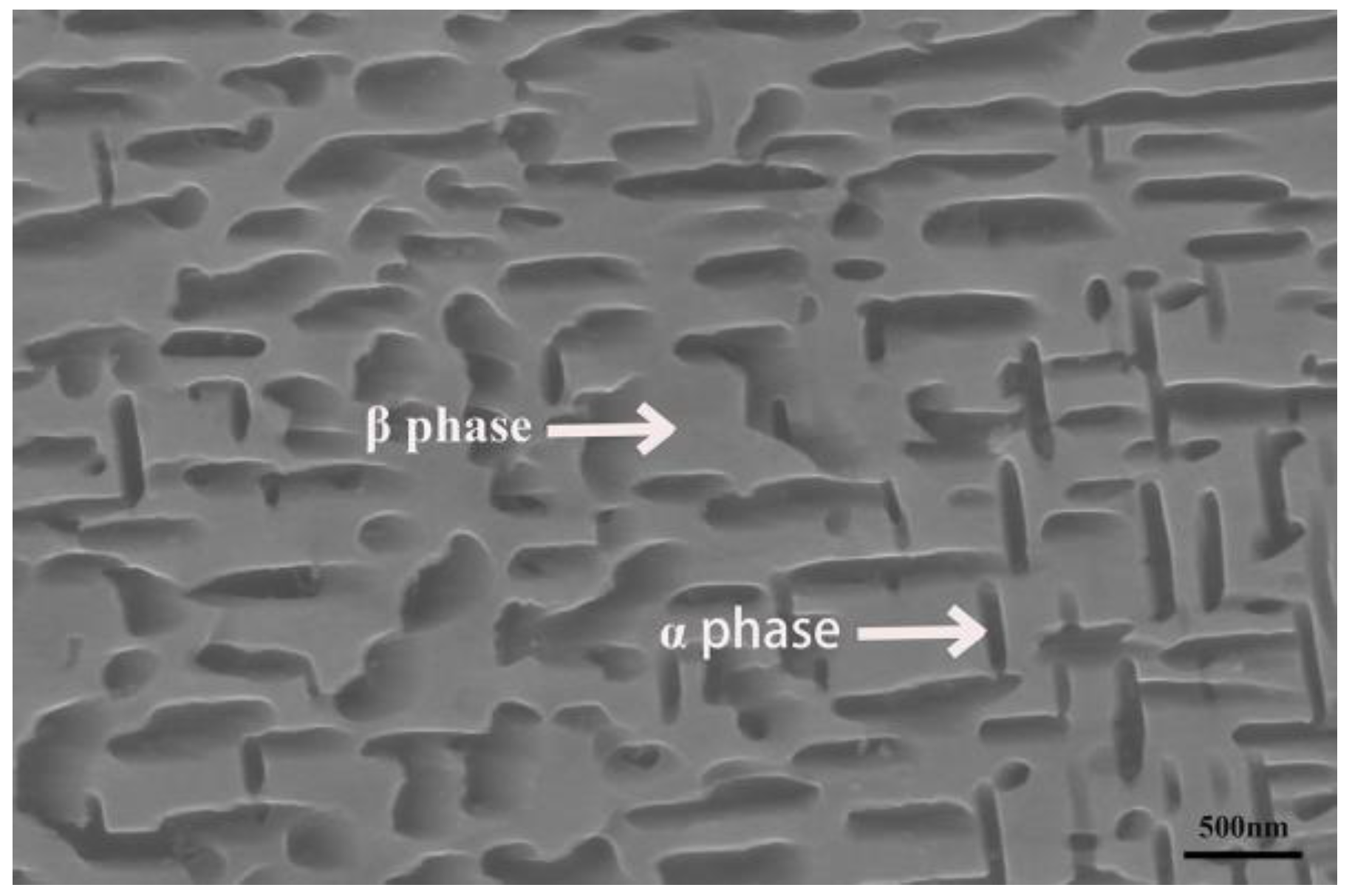

3.1. Microstructure

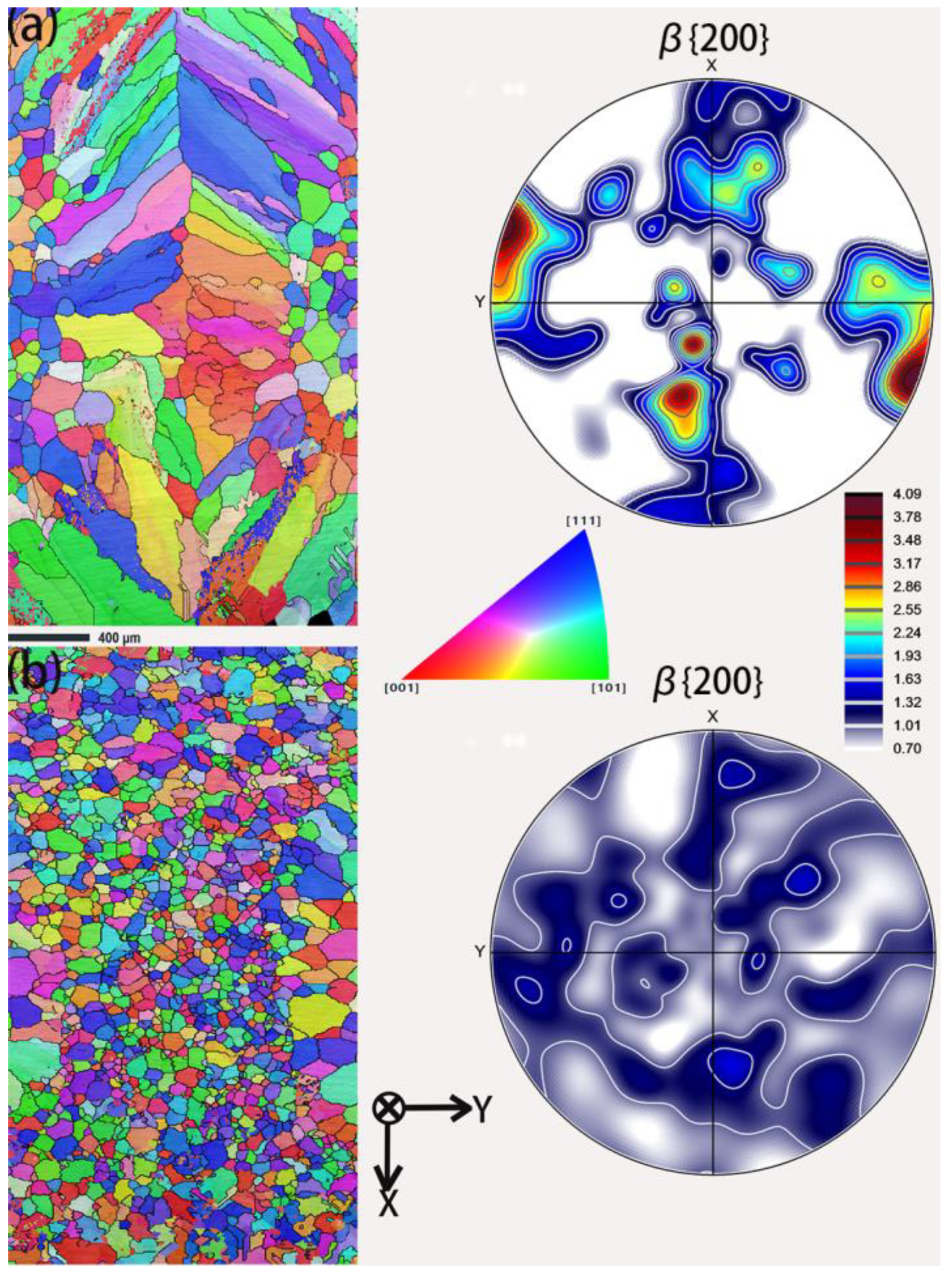

3.2. β-Phase Orientation

3.3. Effect of Ultrasonic Amplitude on the Grain Morphology of Joint Β

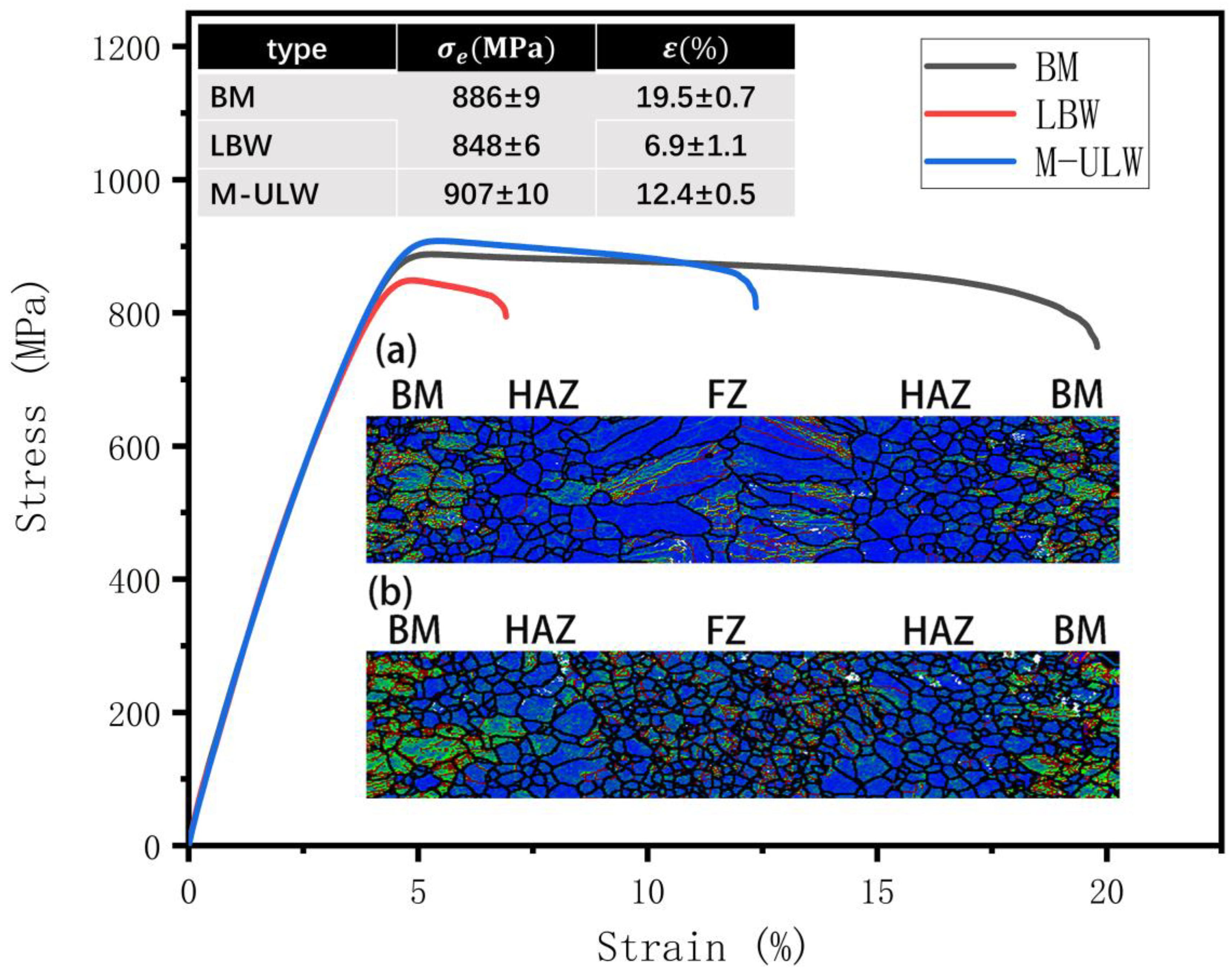

3.4. Mechanical Properties and Analysis

4. Conclusions

- Multiple vibrator ultrasonic assistance welding of beta titanium alloys at a laser power of 2.4 kW and a spot diameter of 0.5 mm resulted in defect-free welded joints.

- The introduction of ultrasonic vibration changed the temperature gradient in the molten pool, but the resulting temperature change was not sufficient to change the phase composition of the weld.

- The significant reduction of the weld width after the introduction of ultrasonic vibrations is attributed to the fact that the introduction of ultrasonic vibrations promotes forced convection in the molten pool. The difference between the surface of the weld and the surface of the base metal is mainly due to the recrystallization of the β grain and remelting of the α phase under the action of temperature, whereas the difference in the surface at different amplitudes is due to the difference in the content of grain boundaries.

- Based on the cavitation effect produced by ultrasonic vibration in the molten pool, the average grain size of the β phase in the weld decreases with the increase of the ultrasonic amplitude, but it is not a linear relationship, and uniformly distributed fine grains are obtained at an amplitude of 20 μm, and the grains in the weld are not further refined when the amplitude is increased to 25 μm.

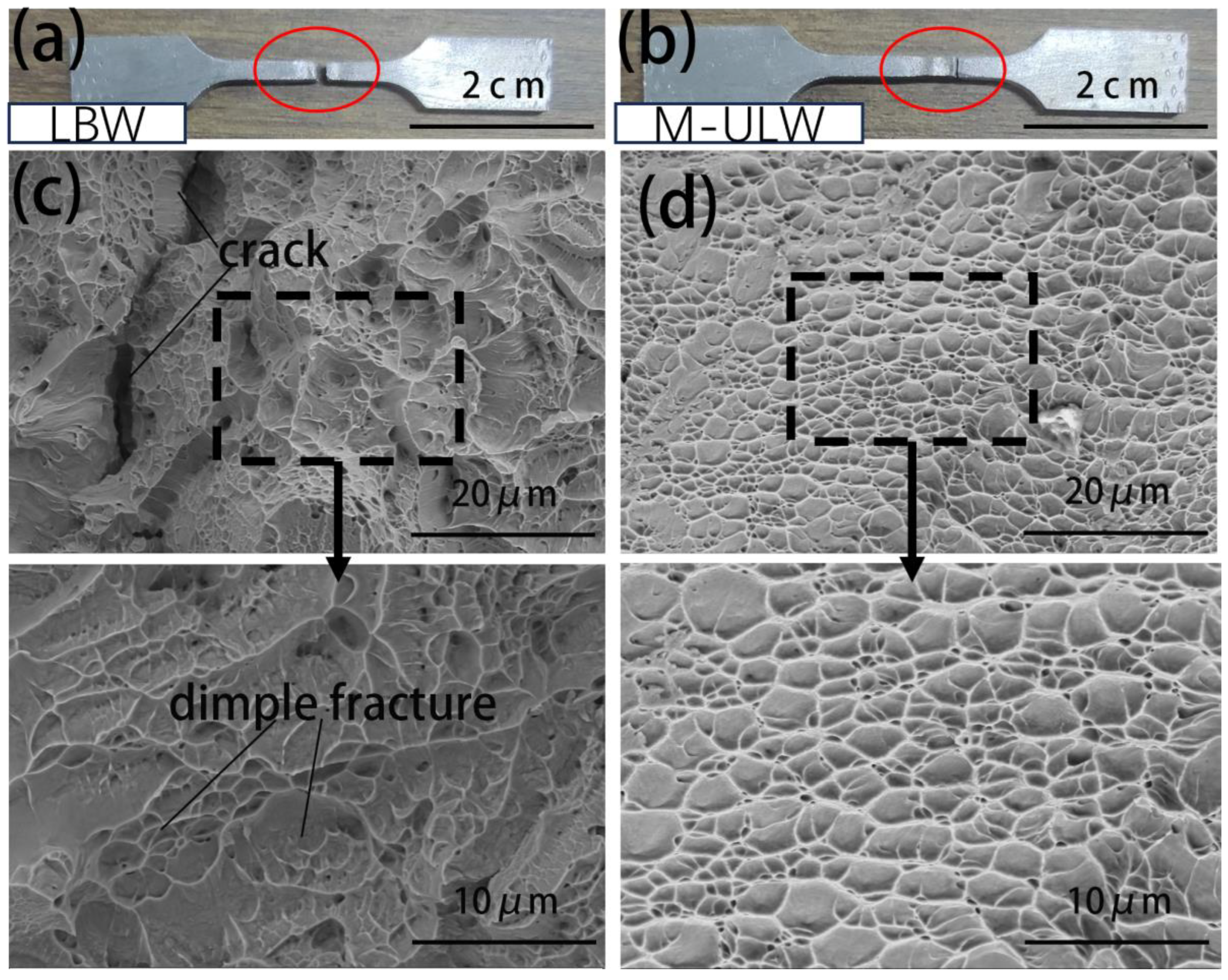

- After the introduction of ultrasonic vibration, the plasticity and strength of the joints are improved, which is due to the strengthening effect caused by grain refinement, and at the same time, the ultrasonic vibration causes the proliferation of dislocation in the joints, and the weakening of structural anisotropy caused by the weakening of weaving in the {200} direction, so that the joints in the tensile process obtain a better resistance to deformation.

- The improvement of joint performance makes the fracture location of the tensile specimen change from the middle of the weld in the LBW joint to the vicinity of the connection between the welded joint and the heat-affected zone.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Balachandran, S.; Kumar, S.; Banerjee, D. On recrystallization of the α and β phases in titanium alloys. Acta Mater. 2017, 131, 423–434. [Google Scholar] [CrossRef]

- Balachandran, S.; Kashiwar, A.; Choudhury, A.; Banerjee, D.; Shi, R.; Wang, Y. On variant distribution and coarsening behavior of the α phase in a metastable β titanium alloy. Acta Mater. 2016, 106, 374–387. [Google Scholar] [CrossRef]

- van Bohemen, S.; Kamp, A.; Petrov, R.; Kestens, L.; Sietsma, J. Nucleation and variant selection of secondary α plates in a β Ti alloy. Acta Mater. 2008, 56, 5907–5914. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Ye, Q.; Yang, X.; Ma, T.; Vairis, A. Linear friction welding of a beta titanium alloy: Experimental investigations on microstructure evolution and mechanical properties. Sci. Technol. Weld. Join. 2020, 25, 625–636. [Google Scholar] [CrossRef]

- Liu, H.; Fujii, H. Microstructural and mechanical properties of a beta-type titanium alloy joint fabricated by friction stir welding. Mater. Sci. Eng. A 2018, 711, 140–148. [Google Scholar] [CrossRef]

- Guo, Z.; Ma, T.; Yang, X.; Tao, J.; Li, J.; Li, W.; Vairis, A. In-situ investigation on dislocation slip concentrated fracture mechanism of linear friction welded dissimilar Ti17(α+β)/Ti17(β) titanium alloy joint. Mater. Sci. Eng. A 2023, 872, 144991. [Google Scholar] [CrossRef]

- Tal-Gutelmacher, E.; Eliezer, D.; Boellinghaus, T. Hydrogen Behavior in GTA Welded Ti-6Al-4V and Beta-21S Aerospace Applic-Ative Titanium Alloys; Beijing International Materials Week: Beijing, China, 2006; pp. 1413–1420. [Google Scholar]

- Liu, X.; Graff, K.F. Ultrasonic metal forming: Materials. Power Ultrason. 2023, 243–275. [Google Scholar] [CrossRef]

- Buddery, A.; Wang, G.; Yu, Z.; Dargusch, M.; Nabulsi, S. Microstructure Characterization of Laser Welded near-β titanium Al-loy ‘TLM’ under Different Process Conditions. In Proceedings of the 7th Pacific Rim International Conference on Advanced Materials and Processing, Cairns, Australia, 2–6 August 2010; pp. 2146–2149. [Google Scholar]

- Anis, A.L.; Talari, M.K.; Babu, N.K.; Ismail, M.H.; Ram, G.J.; Arif, I.A.M. Grain refinement of Ti-15V-3Cr-3Sn-3Al metastable β titanium alloy welds using boron-modified fillers. J. Alloys Compd. 2018, 749, 320–328. [Google Scholar] [CrossRef]

- Lu, J.; Lu, H.; Xu, X.; Yao, J.; Cai, J.; Luo, K. High-performance integrated additive manufacturing with laser shock peening–induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components. Int. J. Mach. Tools Manuf. 2020, 148, 103475. [Google Scholar] [CrossRef]

- Ramirez, A.; Qian, M.; Davis, B.; Wilks, T.; StJohn, D. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys. Scr. Mater. 2008, 59, 19–22. [Google Scholar] [CrossRef]

- Shu, D.; Sun, B.; Mi, J.; Grant, P.S. A High-Speed Imaging and Modeling Study of Dendrite Fragmentation Caused by Ultrasonic Cavitation. Met. Mater. Trans. A 2012, 43, 3755–3766. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W. Ultrasonic vibration-assisted (UV-A) manufacturing processes: State of the art and future perspectives. J. Manuf. Process. 2020, 51, 174–190. [Google Scholar] [CrossRef]

- Zhang, K.; He, C.; Liu, D.; Yan, C.; Niu, H.; Yang, Z.; Bao, Y. Effect of heat input on microstructure and tensile properties of laser welded Ti–3Al–6Mo–2Fe–2Zr alloy joint. J. Mater. Res. Technol. 2022, 17, 1652–1661. [Google Scholar] [CrossRef]

- Zhaoxin, D.; Guolong, L.; Xiaoming, C.; Huimin, L.; Jun, C. Effect of Pre-aging on Microstructure and Mechanical Properties of Ti-3.5Al-5Mo-6V-3Cr-2Sn-0.5Fe Alloy. Rare Met. Mater. Eng. 2019, 48, 1904–1908. [Google Scholar]

- Zhang, S.; Wang, Q.; Cheng, X.; Han, J.; Zhang, W.; Zhang, C.; Wu, J. Static Recrystallization Behavior and Texture Evolution during Annealing in a Cold Rolling Beta Titanium Alloy Sheet. Metals 2022, 12, 899. [Google Scholar] [CrossRef]

- Du, Z.; Xiao, S.; Liu, J.; Lv, S.; Xu, L.; Kong, F.; Chen, Y. Hot Deformation Behavior of Ti-3.5Al-5Mo-6V-3Cr-2Sn-0.5Fe Alloy in α + β Field. Metals 2015, 5, 216–227. [Google Scholar] [CrossRef]

- Qiao, J.; Wu, C.; Li, Y. Numerical and experimental investigation of keyholing process in ultrasonic vibration assisted plasma arc welding. J. Manuf. Process. 2020, 50, 603–613. [Google Scholar] [CrossRef]

- Mohammed, S.M.; Paul, T.; John, D.; Zhang, C.; Agarwal, A. Understanding the role of ultrasonic cavitation assisted casting of boron nitride nanotube-reinforced aluminum matrix composite. J. Mater. Res. Technol. 2023, 25, 2405–2418. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Q.; Hu, Q.; Liu, J.; Yu, B.; Yang, R. Effect of β (110) texture intensity on α-variant selection and microstructure morphology during β→α phase transformation in near α titanium alloy. Acta Mater. 2017, 126, 372–382. [Google Scholar] [CrossRef]

- Cayron, C.; Artaud, B.; Briottet, L. Reconstruction of parent grains from EBSD data. Mater. Charact. 2006, 57, 386–401. [Google Scholar] [CrossRef]

- Ye, Q.; Li, X.; Tayyebi, M.; Assari, A.H.; Polkowska, A.; Lech, S.; Polkowski, W.; Tayebi, M. Effect of heat treatment parameters on microstructure evolution, tensile strength, wear resistance, and fracture behavior of Ni–Ti multilayered composites produced by cross-accumulative roll bonding. Arch. Civ. Mech. Eng. 2022, 23, 27. [Google Scholar] [CrossRef]

- Liu, S.; Tayyebi, M.; Assari, A.H.; Polkowska, A.; Lech, S.; Polkowski, W. Microstructure, Texture and Tensile Properties of Nickel/Titanium Laminated Composites Produced by Cross Accumulative Roll Bonding Process. Met. Mater. Int. 2023, 29, 3630–3644. [Google Scholar] [CrossRef]

- Wei, X.; Li, X.; Zhang, L.; Lv, Q. Effect of in-situ ultrasonic impact treatment on flow and solidification behavior of laser metal deposition: By finite element simulation. Int. J. Heat Mass Transf. 2022, 192, 122914. [Google Scholar] [CrossRef]

- Jia, H.; Cao, L.; Fu, S.; Wen, H.; Ma, G. Numerical simulation and experiment for the dynamic behavior of molten pool in ultrasonic-assisted MIG welding. Int. J. Heat Mass Transf. 2023, 215, 124469. [Google Scholar] [CrossRef]

- Zuo, Z.; Haowei, M.; Yarigarravesh, M.; Assari, A.H.; Tayyebi, M.; Tayebi, M.; Hamawandi, B. Microstructure, Fractography, and Mechanical Properties of Hardox 500 Steel TIG-Welded Joints by Using Different Filler Weld Wires. Materials 2022, 15, 8196. [Google Scholar] [CrossRef]

| Element | Ti | Al | Mo | V | Cr | Sn | Fe |

|---|---|---|---|---|---|---|---|

| wt.% | 79.40 | 3.78 | 5.26 | 5.79 | 2.64 | 2.51 | 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Dong, P.; Chai, F.; Gao, L.; Zhang, S.; Zhang, C. Microstructure and Mechanical Properties Ultrasonic Assistance Laser Welded Joints of Beta Titanium Alloy with Multiple Vibrators. Metals 2024, 14, 422. https://doi.org/10.3390/met14040422

Wang S, Dong P, Chai F, Gao L, Zhang S, Zhang C. Microstructure and Mechanical Properties Ultrasonic Assistance Laser Welded Joints of Beta Titanium Alloy with Multiple Vibrators. Metals. 2024; 14(4):422. https://doi.org/10.3390/met14040422

Chicago/Turabian StyleWang, Shiyu, Peng Dong, Fei Chai, Linshan Gao, Shuzhi Zhang, and Changjiang Zhang. 2024. "Microstructure and Mechanical Properties Ultrasonic Assistance Laser Welded Joints of Beta Titanium Alloy with Multiple Vibrators" Metals 14, no. 4: 422. https://doi.org/10.3390/met14040422

APA StyleWang, S., Dong, P., Chai, F., Gao, L., Zhang, S., & Zhang, C. (2024). Microstructure and Mechanical Properties Ultrasonic Assistance Laser Welded Joints of Beta Titanium Alloy with Multiple Vibrators. Metals, 14(4), 422. https://doi.org/10.3390/met14040422