Dynamic Recrystallization Nucleation Mechanism and Precipitation Behavior of Homogeneous Al-Zn-Mg-Cu Alloy during Hot Deformation

Abstract

:1. Introduction

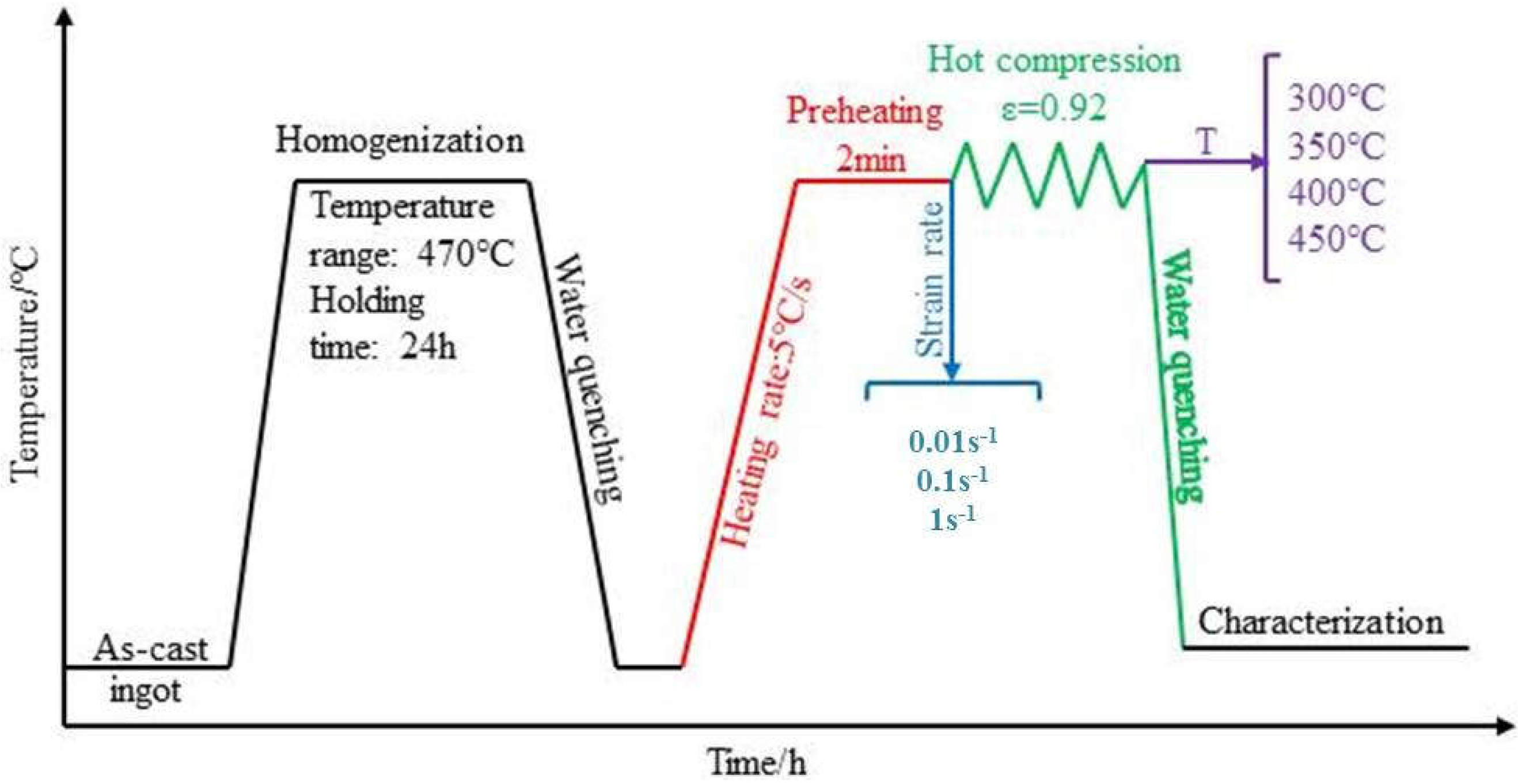

2. Material and Methods

3. Results and Discussion

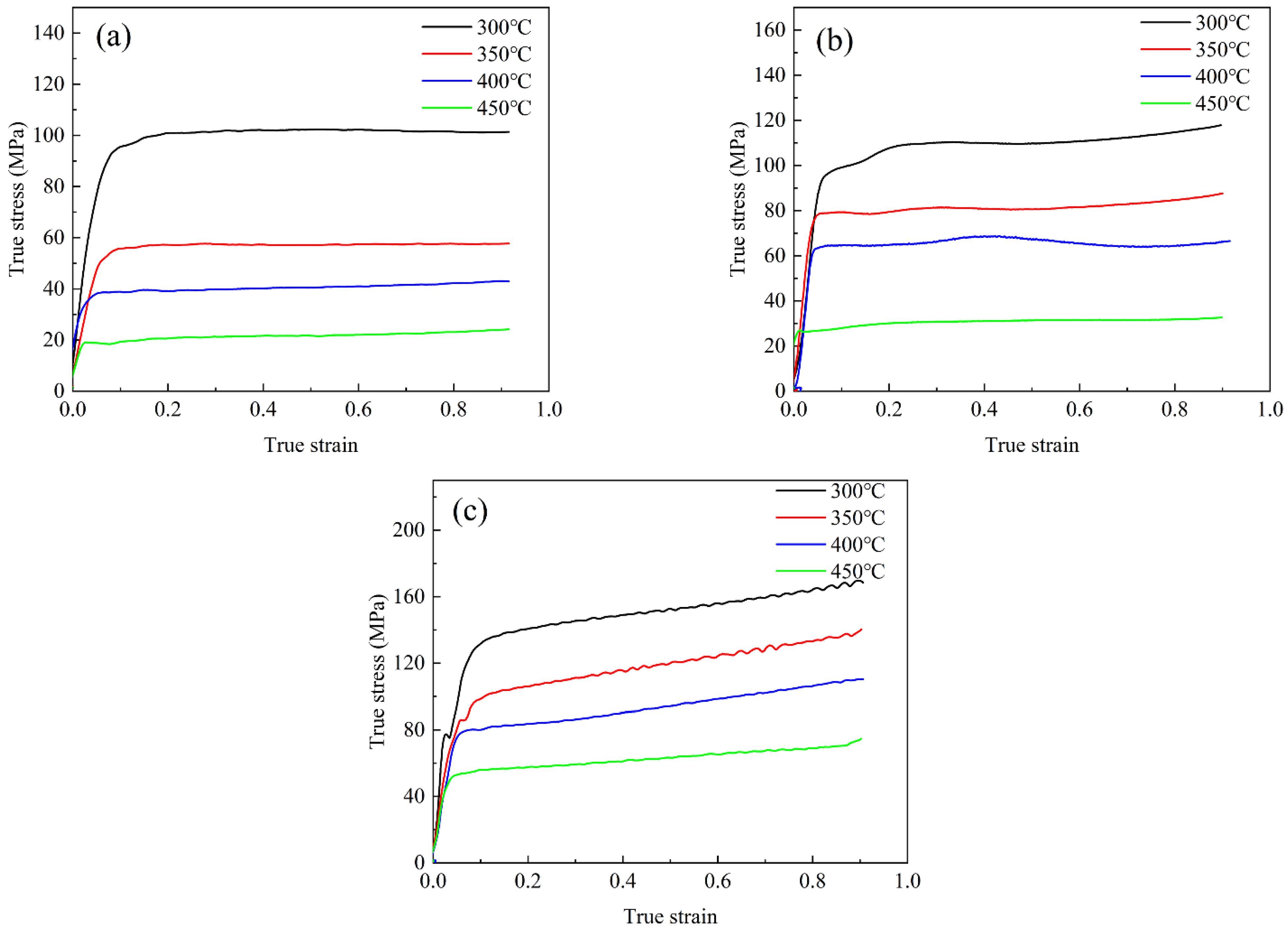

3.1. True Stress–Strain Curve

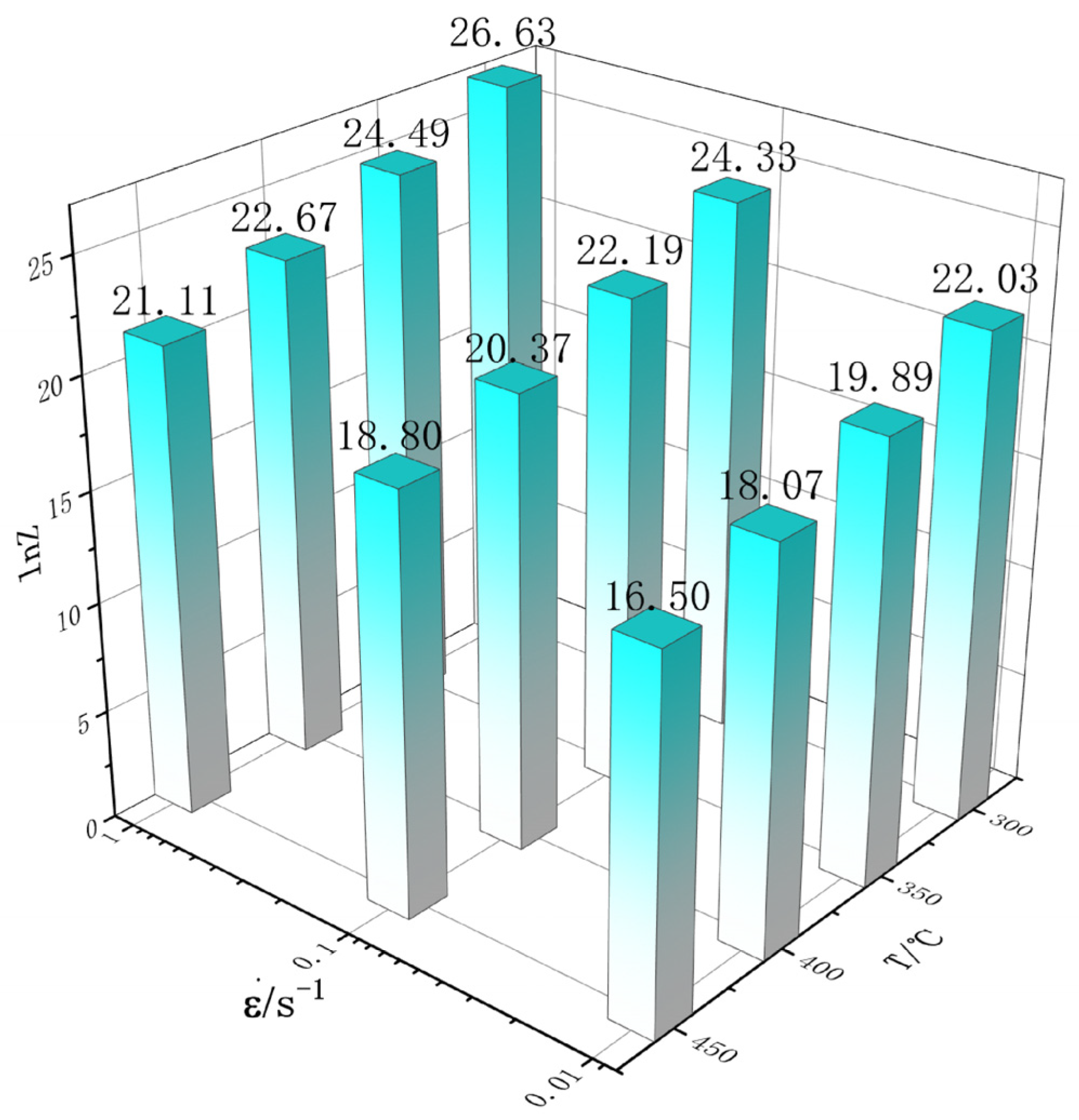

3.2. Constitutive Equation

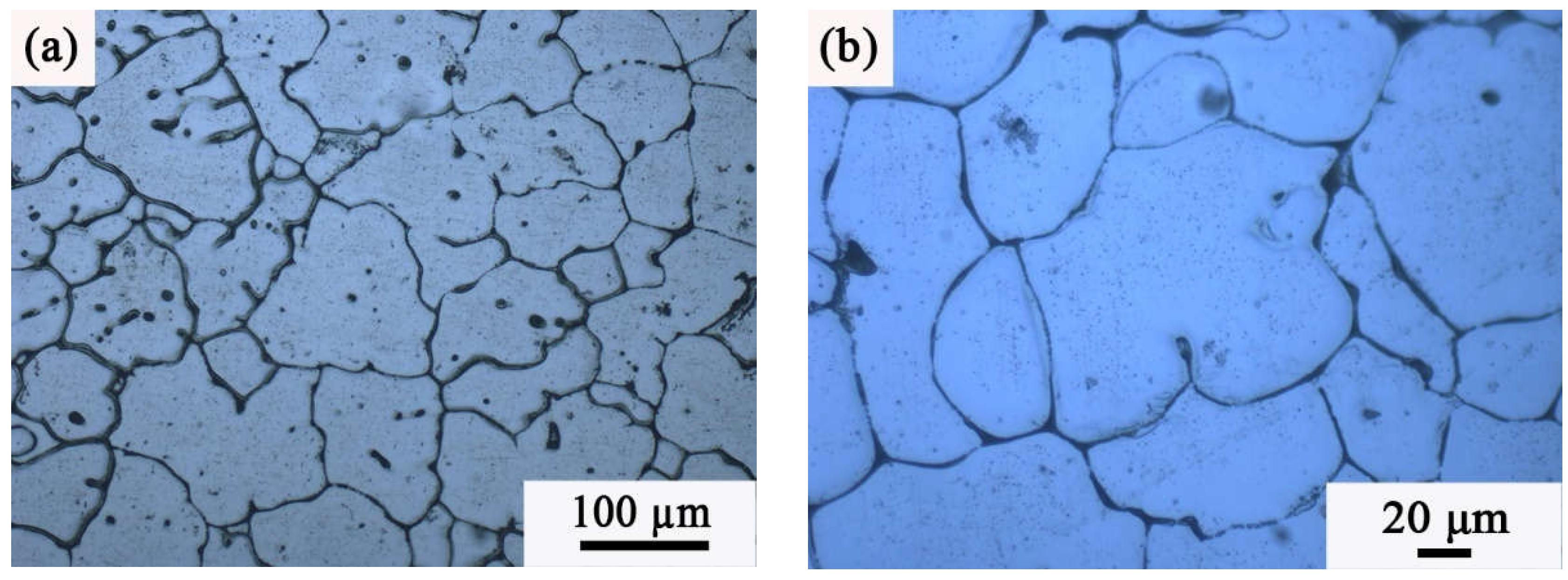

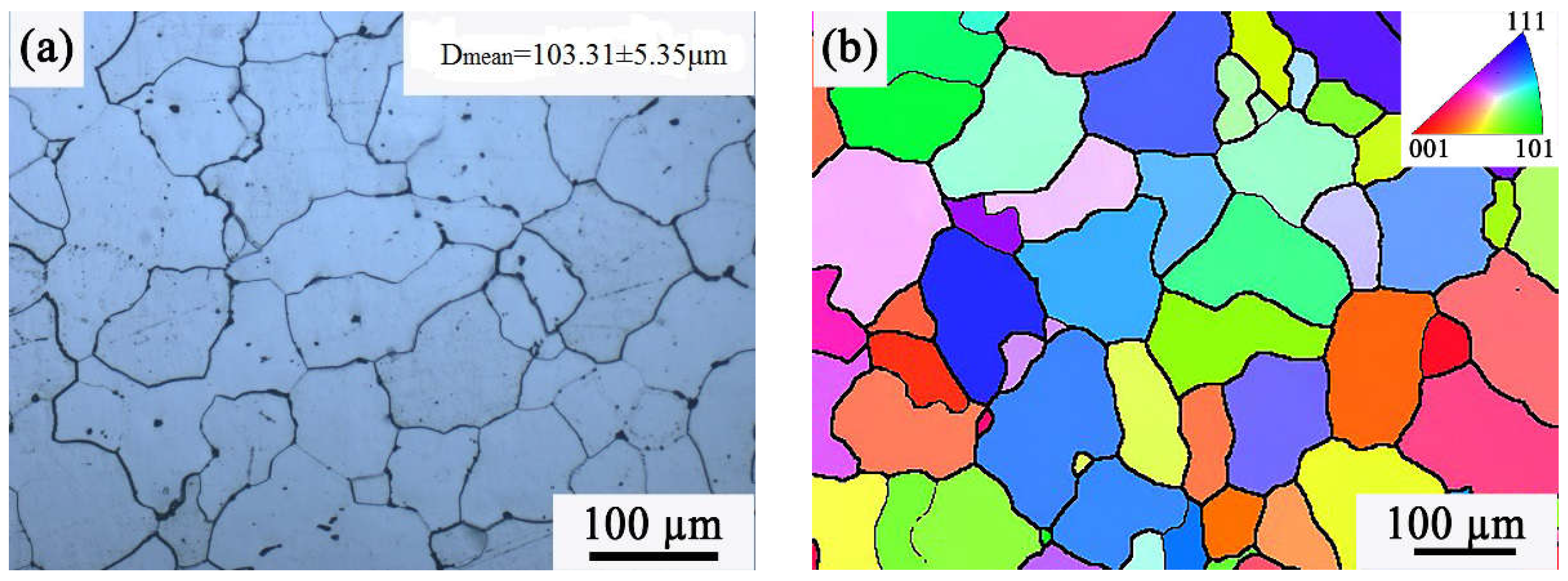

3.3. Homogenization Treatment

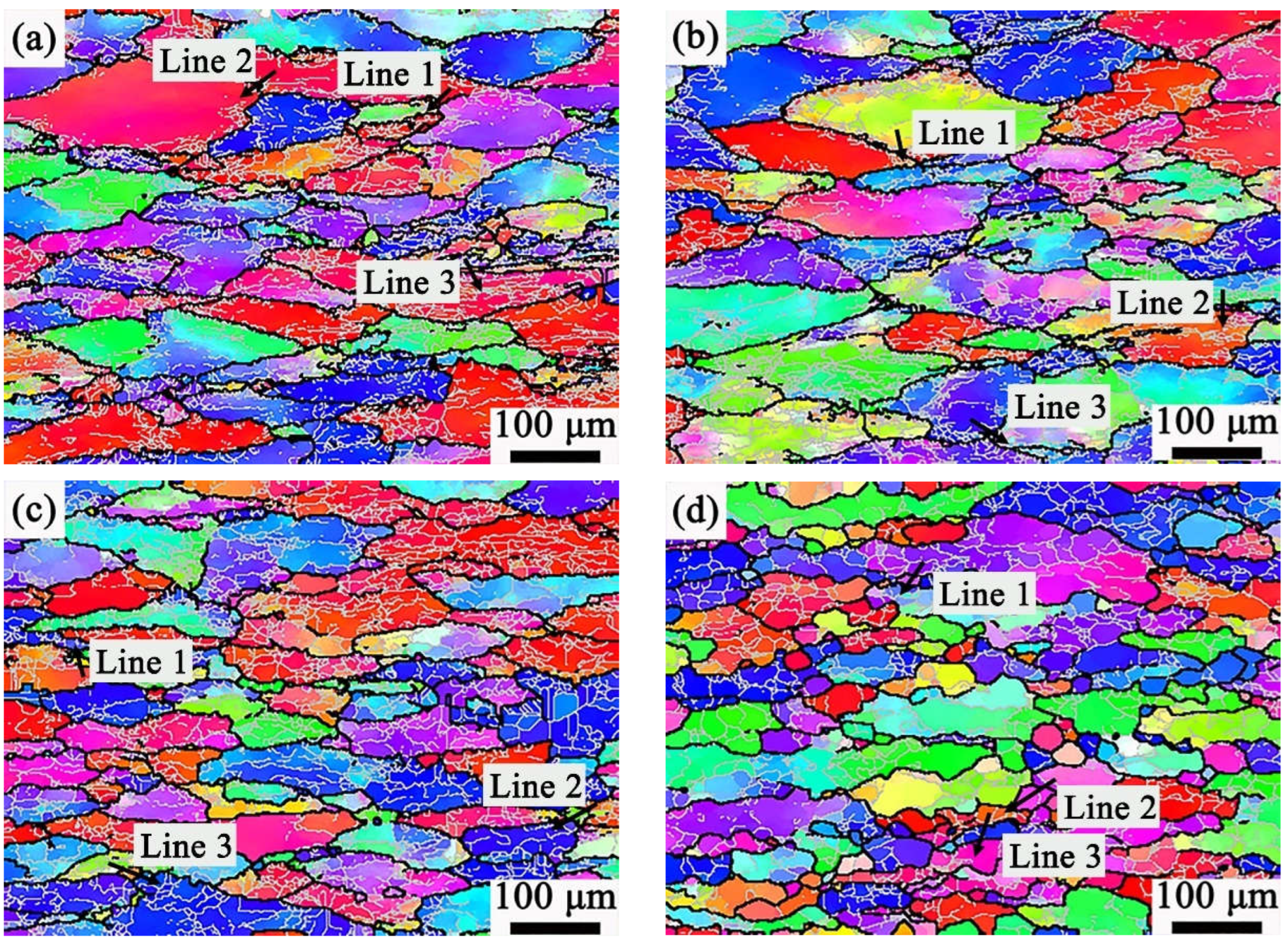

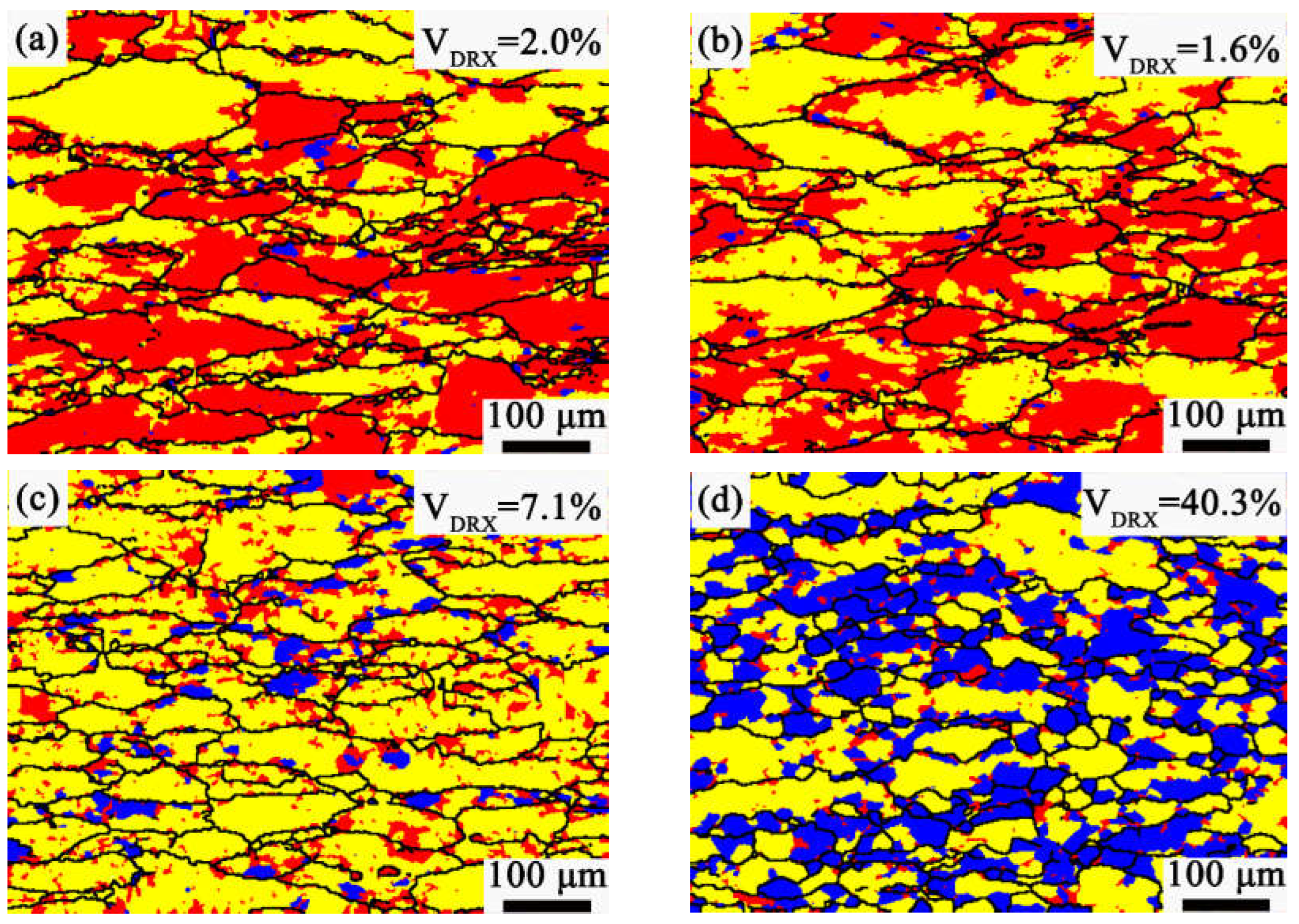

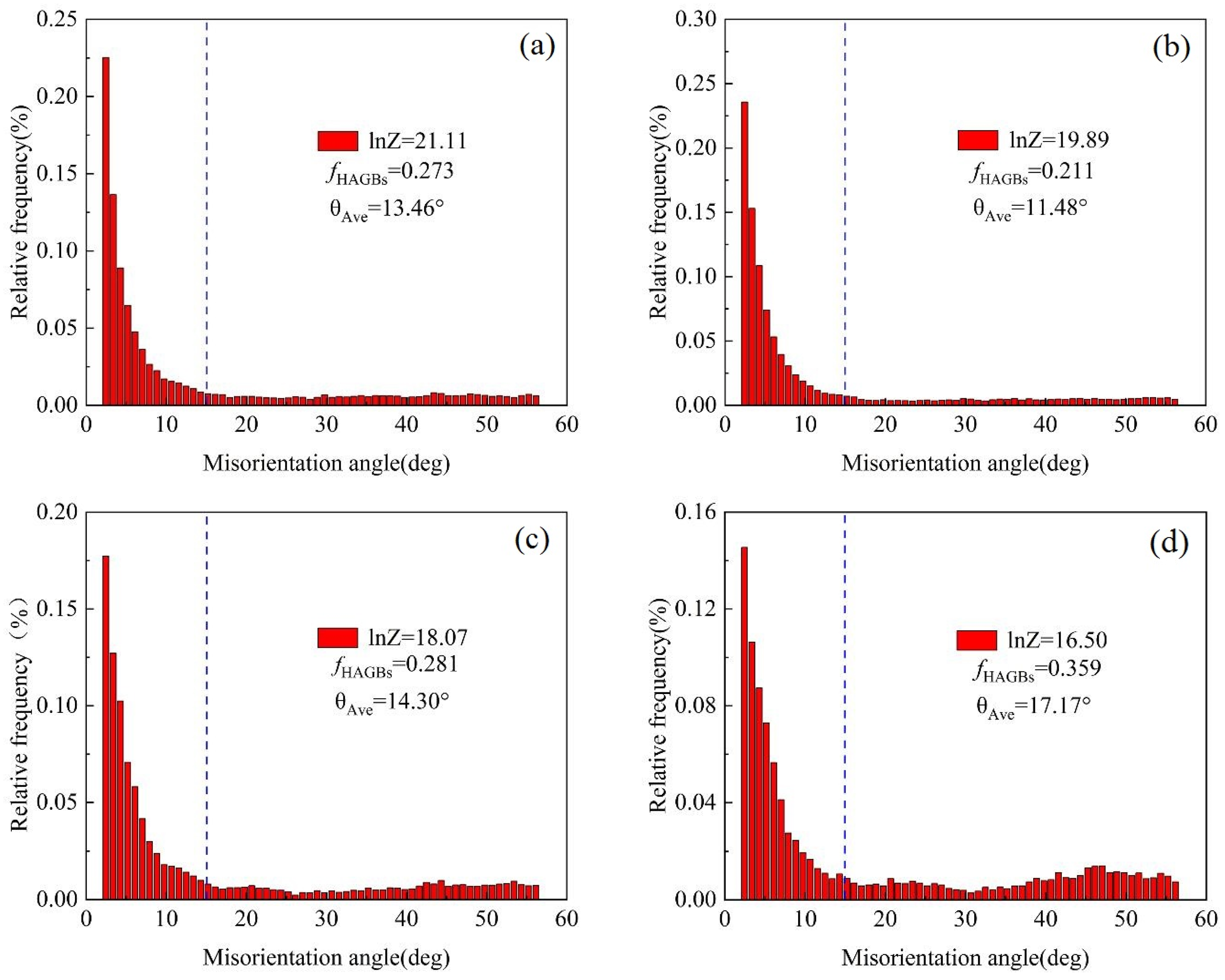

3.4. Effect of Z Parameter on Dynamic Recrystallization

3.5. Dislocation Microstructure

3.6. Precipitation Behavior

4. Conclusions

- (1)

- According to the flow stress curve, the peak value and steady value of stress decrease gradually with the increase in deformation temperature and the decrease in strain rate. The hot deformation constitutive relation of the alloy is obtained by fitting the relevant numerical values. The hot deformation activation energy of the alloy is 126.9 kJ/mol, and the constitutive equation is as follows:

- (2)

- When the Z value is high, the softening mechanism of 7075 aluminum alloy is dynamic recovery. The main recrystallization mechanism of the alloy is DDRX at a relatively high Z value. However, at a lower Z value, the main recrystallization mechanism of the alloy is CDRX, and these experimental conditions are helpful to obtaining more uniformly refined grains.

- (3)

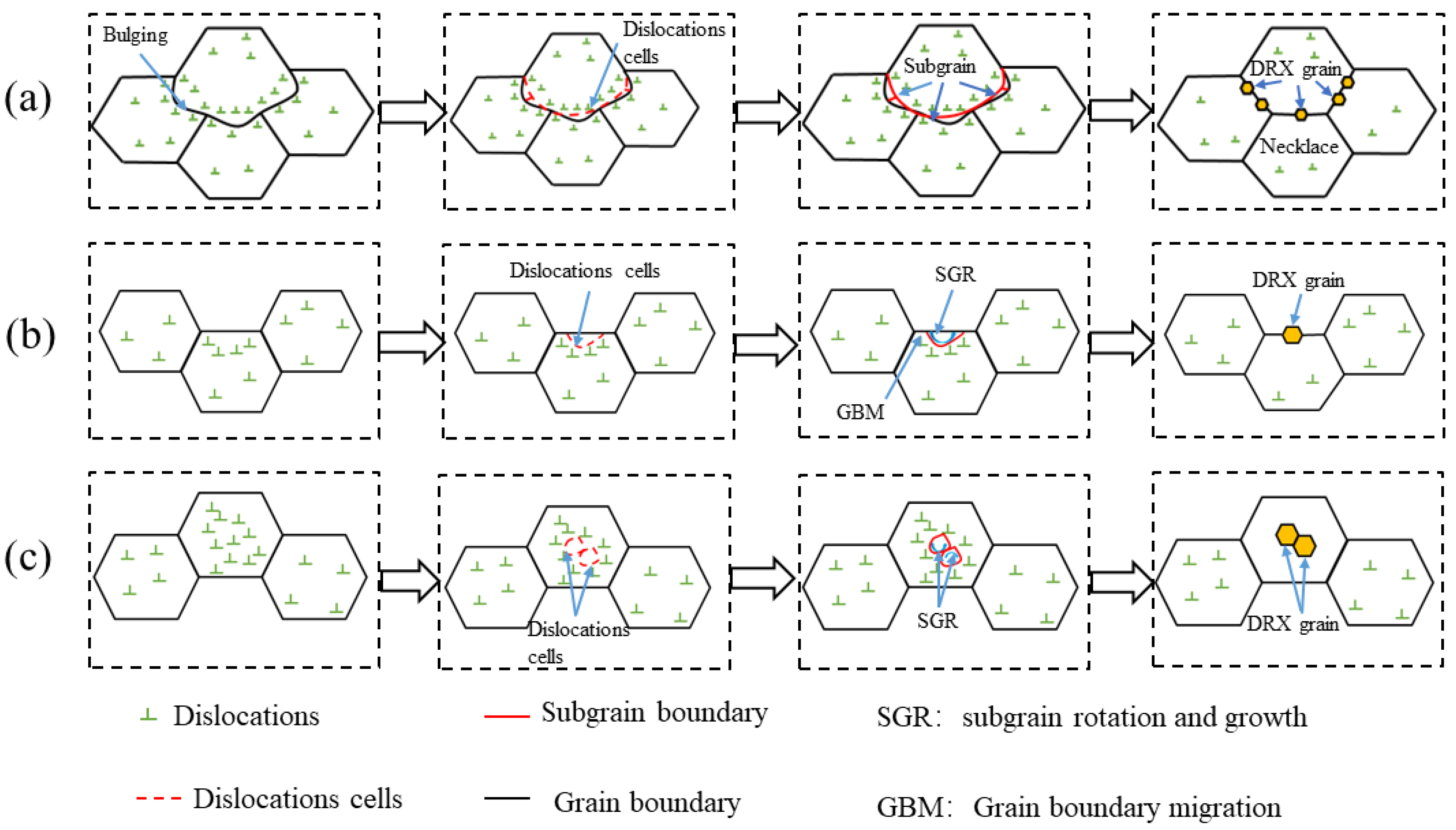

- There are four different recrystallization mechanisms in AlZn5.5Mg2.56Cu1.26 alloys, among which DDRX is mainly produced by grain boundary bulge, subgrain rotation, and grain boundary migration; CDRX is mainly produced by subgrain rotation and grain boundary migration within grains and at grain boundaries; and GDRX is produced by the pinch breaking of original grains.

- (4)

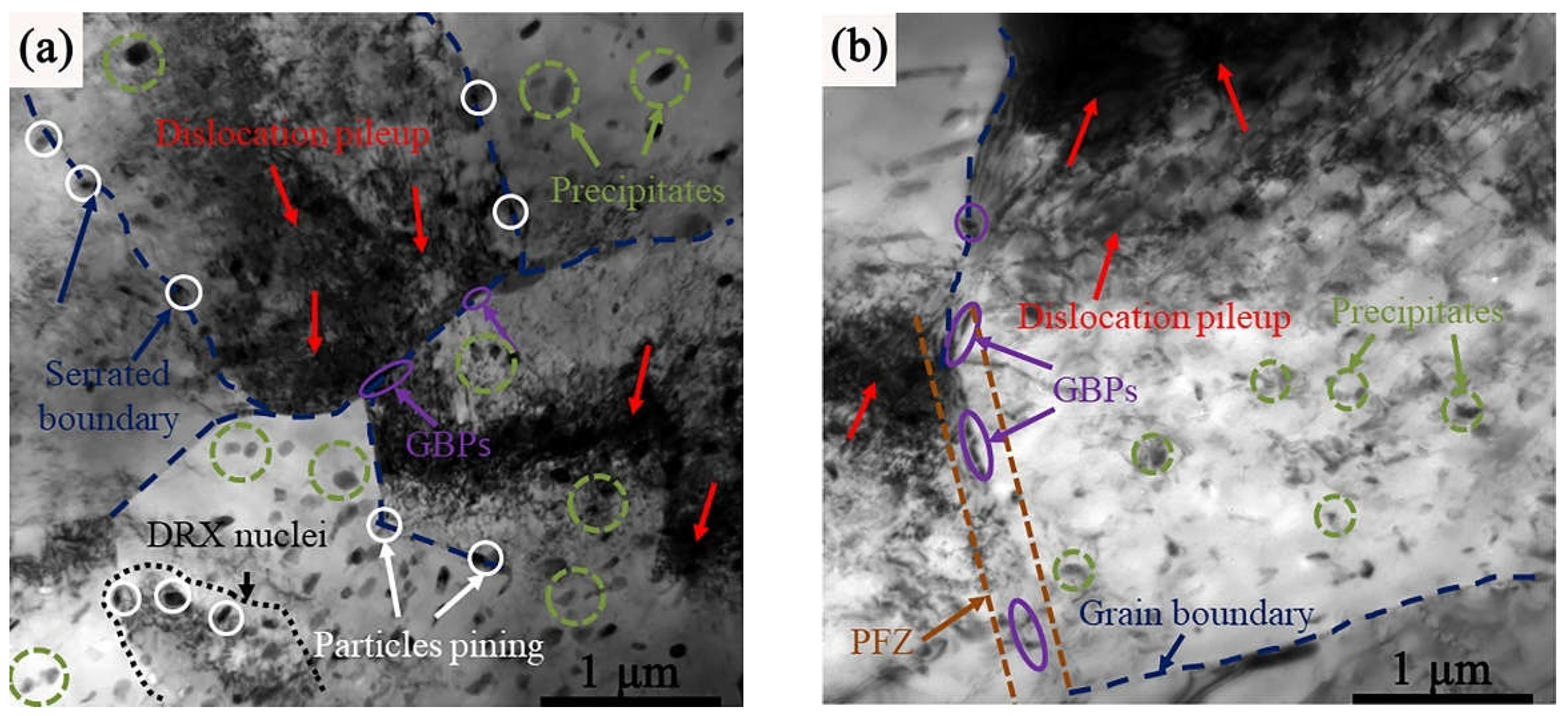

- Higher Z parameters can promote dynamic precipitation during hot compression. The dislocation density of the alloy decreases with the decrease in the Z value. Precipitates in the alloy inhibit the nucleation and growth of dynamic recrystallization by hindering dislocation movement and grain boundary migration, and the greater the Z value, the more obvious the influence is.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Zang, C.; Xiao, W.; Fu, Y.; Ma, C. Enhanced properties and homogeneity of Al-Zn-Mg-Cu alloy thick plate by non-isothermal aging. J. Alloys Compd. 2023, 952, 170023. [Google Scholar] [CrossRef]

- Atkinson, H.; Burke, K.; Vaneetveld, G. Recrystallisation in the semi-solid state in 7075 aluminium alloy. Mater. Sci. Eng. A 2008, 490, 266–276. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shaeri, M.; Naseri, R.; Gode, C. Equal channel angular extrusion for tube configuration of Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2018, 731, 569–576. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. Effect of deformation induced precipitation on grain refinement and improvement of mechanical properties AA 7055 aluminum alloy. Mater. Charact. 2017, 130, 123–134. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.; Liu, S.; Deng, Y. Constitutive equation and hot deformation behavior of homogenized Al–7.68Zn–2.12Mg–1.98Cu–0.12Zr alloy during compression at elevated temperature. Mater. Sci. Eng. A 2014, 608, 63–72. [Google Scholar] [CrossRef]

- Li, J.; Wu, X.; Cao, L.; Liao, B.; Wang, Y.; Liu, Q. Hot deformation and dynamic recrystallization in Al-Mg-Si alloy. Mater. Charact. 2021, 173, 110976. [Google Scholar] [CrossRef]

- Zhao, J.; Deng, Y.; Tang, J. Grain refining with DDRX by isothermal MDF of Al-Zn-Mg-Cu alloy. J. Mater. Res. Technol. 2020, 9, 8001–8012. [Google Scholar] [CrossRef]

- Liu, S.; Pan, Q.; Li, M.; Wang, X.; He, X.; Li, X.; Peng, Z.; Lai, J. Microstructure evolution and physical-based diffusion constitutive analysis of Al-Mg-Si alloy during hot deformation. Mater. Des. 2019, 184, 108181. [Google Scholar] [CrossRef]

- Lu, D.-D.; Li, J.-F.; Guo, Y.-J.; Wang, G.; Wu, R.; Ma, P.-C.; Chen, Y.-L.; Zhang, X.-H.; You, W.; Zhang, R.-F. T1 precipitate bands and particle stimulated nucleation in 2195 Al-Cu-Li alloy during hot deformation. J. Alloys Compd. 2022, 909, 164716. [Google Scholar] [CrossRef]

- Lee, S.-H.; Jung, J.-G.; Baik, S.-I.; Park, S.H.; Kim, M.-S.; Lee, Y.-K.; Euh, K. Effects of Ti addition on the microstructure and mechanical properties of Al–Zn–Mg–Cu–Zr alloy. Mater. Sci. Eng. A 2021, 801, 140437. [Google Scholar] [CrossRef]

- Berg, L.; Gjønnes, J.; Hansen, V.; Li, X.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L. GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Chung, T.-F.; Yang, Y.-L.; Shiojiri, M.; Hsiao, C.-N.; Li, W.-C.; Tsao, C.-S.; Shi, Z.; Lin, J.; Yang, J.-R. An atomic scale structural investigation of nanometre-sized η precipitates in the 7050 aluminium alloy. Acta Mater. 2019, 174, 351–368. [Google Scholar] [CrossRef]

- Li, Q.; Qin, J.; Jiang, D.; Yi, D.; Wang, B. Precipitate coarsening and mechanical properties in 6082 aluminium alloy during long-term thermal exposure. J. Alloys Compd. 2022, 909, 164819. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, C.; Meng, Z.; Cheng, Z.; Chen, L.; Zhao, G. Precipitation behavior and its effect on the dynamic recrystallization of a novel extruded Al-Cu-Li alloy. Mater. Des. 2022, 223, 111135. [Google Scholar] [CrossRef]

- Long, S.; Wu, D.-X.; Wang, S.-Y.; Jiang, Y.-P.; Xia, R.-Z.; Li, S.-S.; Zhou, Y.-T.; Peng, P.; Dai, Q.-W. An optimized constitutive model and microstructure characterization of a homogenized Al-Cu-Li alloy during hot deformation. J. Alloys Compd. 2022, 929, 167290. [Google Scholar] [CrossRef]

- Kassner, M.; Barrabes, S. New developments in geometric dynamic recrystallization. Mater. Sci. Eng. A 2005, 410–411, 152–155. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Q.; Xiong, S.; Liu, L. Prediction on hot deformation behavior of spray formed ultra-high strength aluminum alloy—A comparative study using constitutive models. J. Alloys Compd. 2018, 735, 1931–1942. [Google Scholar] [CrossRef]

- Yan, J.; Pan, Q.; Li, B.; Huang, Z.; Liu, Z.; Yin, Z. Research on the hot deformation behavior of Al–6.2Zn–0.70Mg–0.3Mn–0.17Zr alloy using processing map. J. Alloys Compd. 2015, 632, 549–557. [Google Scholar] [CrossRef]

- Tang, J.; Wang, J.; Teng, J.; Wang, G.; Fu, D.; Zhang, H.; Jiang, F. Effect of Zn content on the dynamic softening of Al–Zn–Mg–Cu alloys during hot compression deformation. Vacuum 2021, 184, 109941. [Google Scholar] [CrossRef]

- Sun, Y.; Pan, Q.; Huang, Z.; Wang, W.; Wang, X.; Li, M.; Lai, J. Evolutions of diffusion activation energy and Zener–Hollomon parameter of ultra-high strength Al-Zn-Mg-Cu-Zr alloy during hot compression. Prog. Nat. Sci. 2018, 28, 635–646. [Google Scholar] [CrossRef]

- Ding, W.; Liu, X.; Zhao, X.; Chen, T.; Zhang, H.; Cheng, Y.; Shi, H. Hot Deformation Behavior and Microstructure Evolution of 6063 Aluminum Alloy Modified by Rare Earth Y and Al-Ti-B Master Alloy. Materials 2020, 13, 4244. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Jiang, J.; Wang, Y.; Liu, Y.; Huang, M. Hot deformation behavior and microstructure evolution of hot-extruded 6A02 aluminum alloy. Mater. Charact. 2022, 188, 111908. [Google Scholar] [CrossRef]

- Wang, Q.; He, X.; Deng, Y.; Zhao, J.; Guo, X. Experimental study of grain structures evolution and constitutive model of isothermal deformed 2A14 aluminum alloy. J. Mater. Res. Technol. 2021, 12, 2348–2367. [Google Scholar] [CrossRef]

- Sellars, C.; McTegart, W. On the mechanism of hot deformation. Acta Met. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Tang, H.; Liu, T.; Li, Z.; Jiang, H.; Wang, K.; Ebrahimi, M.; Ding, W. Hot deformation constitutive model and processing maps of homogenized Al–5Mg–3Zn–1Cu alloy. J. Mater. Res. Technol. 2021, 14, 324–339. [Google Scholar] [CrossRef]

- Khomutov, M.G.; Pozdniakov, A.V.; Churyumov, A.Y.; Barkov, R.Y.; Solonin, A.N.; Glavatskikh, M.V. Flow Stress Modelling and 3D Processing Maps of Al4.5Zn4.5Mg1Cu0.12Zr Alloy with Different Scandium Contents. Appl. Sci. 2021, 11, 4587. [Google Scholar] [CrossRef]

- Hu, H.; Zhen, L.; Yang, L.; Shao, W.; Zhang, B. Deformation behavior and microstructure evolution of 7050 aluminum alloy during high temperature deformation. Mater. Sci. Eng. A 2008, 488, 64–71. [Google Scholar] [CrossRef]

- Xu, C.; Huang, J.; Jiang, F.; Jiang, Y. Dynamic recrystallization and precipitation behavior of a novel Sc, Zr alloyed Al-Zn-Mg-Cu alloy during hot deformation. Mater. Charact. 2022, 183, 111629. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Yang, X.; Chu, Z.; Li, Y.; Qin, F. Flow Behavior and Microstructure Characterization of 7085 Aluminum Alloy Under Various Deformation Conditions. Met. Mater. Trans. A 2021, 52, 4865–4876. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, Y.; Huang, S.; Mao, X.; He, H.; Tang, J.; Guo, W.; Dong, F. Dynamic recrystallization mechanisms of 2195 aluminum alloy during medium/high temperature compression deformation. Mater. Sci. Eng. A 2021, 804, 140650. [Google Scholar] [CrossRef]

- Zhang, M.; Li, C.; Zhang, Y.; Liu, S.; Jiang, J.; Tang, J.; Ye, L.; Zhang, X. Effect of hot deformation on microstructure and quenching-induced precipitation behavior of Al-Zn-Mg-Cu alloy. Mater. Charact. 2021, 172, 110861. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Wang, M.; Sun, C.; Fu, M.; Liu, Z.; Qian, L. Study on the dynamic recrystallization mechanisms of Inconel 740 superalloy during hot deformation. J. Alloys Compd. 2020, 820, 153325. [Google Scholar] [CrossRef]

- Yaghoobi, M.; Voyiadjis, G.Z. The effects of temperature and strain rate in fcc and bcc metals during extreme deformation rates. Acta Mater. 2018, 151, 1–10. [Google Scholar] [CrossRef]

- Hunter, A.; Preston, D.L. Analytic model of dislocation density evolution in fcc polycrystals accounting for dislocation generation, storage, and dynamic recovery mechanisms. Int. J. Plast. 2022, 151, 103178. [Google Scholar] [CrossRef]

- Hutchinson, C.; de Geuser, F.; Chen, Y.; Deschamps, A. Quantitative measurements of dynamic precipitation during fatigue of an Al–Zn–Mg–(Cu) alloy using small-angle X-ray scattering. Acta Mater. 2014, 74, 96–109. [Google Scholar] [CrossRef]

- Wang, S.-S.; Jiang, J.-T.; Fan, G.-H.; Panindre, A.; Frankel, G.; Zhen, L. Accelerated precipitation and growth of phases in an Al-Zn-Mg-Cu alloy processed by surface abrasion. Acta Mater. 2017, 131, 233–245. [Google Scholar] [CrossRef]

- Santos-Güemes, R.; Bellón, B.; Esteban-Manzanares, G.; Segurado, J.; Capolungo, L.; Llorca, J. Multiscale modelling of precipitation hardening in Al–Cu alloys: Dislocation dynamics simulations and experimental validation. Acta Mater. 2020, 188, 475–485. [Google Scholar] [CrossRef]

- Robson, J. A new model for prediction of dispersoid precipitation in aluminium alloys containing zirconium and scandium. Acta Mater. 2004, 52, 1409–1421. [Google Scholar] [CrossRef]

- Shi, C.; Chen, X.-G. Effect of Zr addition on hot deformation behavior and microstructural evolution of AA7150 aluminum alloy. Mater. Sci. Eng. A 2014, 596, 183–193. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mg | Cr | Zn | Ti | Zr | Al |

|---|---|---|---|---|---|---|---|---|

| 0.078 | 0.130 | 1.62 | 2.56 | 0.23 | 5.50 | 0.10 | 0.033 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Cao, K.; Fang, Y.; Li, Y.; Qin, F. Dynamic Recrystallization Nucleation Mechanism and Precipitation Behavior of Homogeneous Al-Zn-Mg-Cu Alloy during Hot Deformation. Metals 2024, 14, 449. https://doi.org/10.3390/met14040449

Zhao X, Cao K, Fang Y, Li Y, Qin F. Dynamic Recrystallization Nucleation Mechanism and Precipitation Behavior of Homogeneous Al-Zn-Mg-Cu Alloy during Hot Deformation. Metals. 2024; 14(4):449. https://doi.org/10.3390/met14040449

Chicago/Turabian StyleZhao, Xiaodong, Kefan Cao, Yueping Fang, Yajie Li, and Fengming Qin. 2024. "Dynamic Recrystallization Nucleation Mechanism and Precipitation Behavior of Homogeneous Al-Zn-Mg-Cu Alloy during Hot Deformation" Metals 14, no. 4: 449. https://doi.org/10.3390/met14040449