The Influence of Hot Deformation on the Mechanical and Structural Properties of 42CrMo4 Steel

Abstract

:1. Introduction

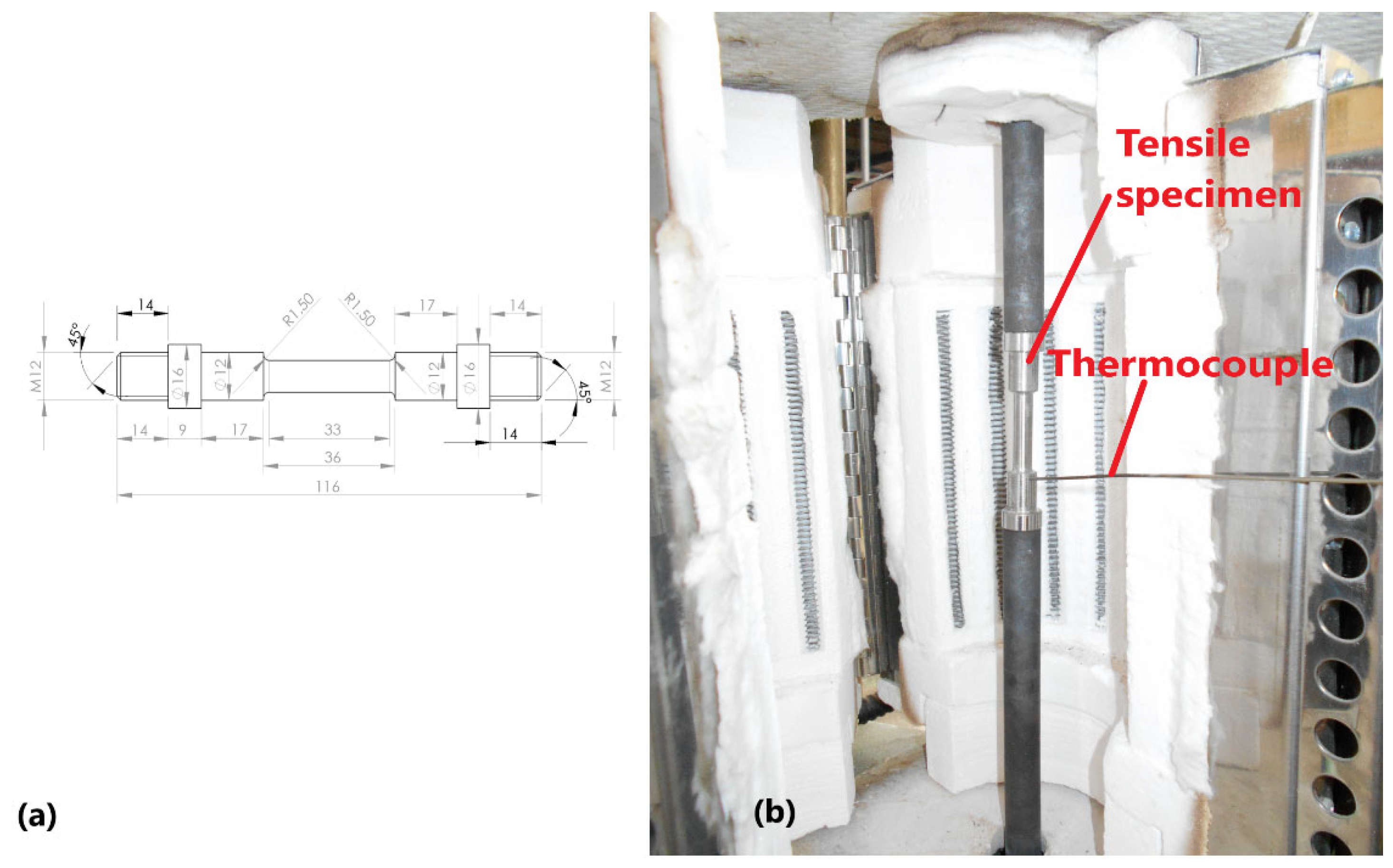

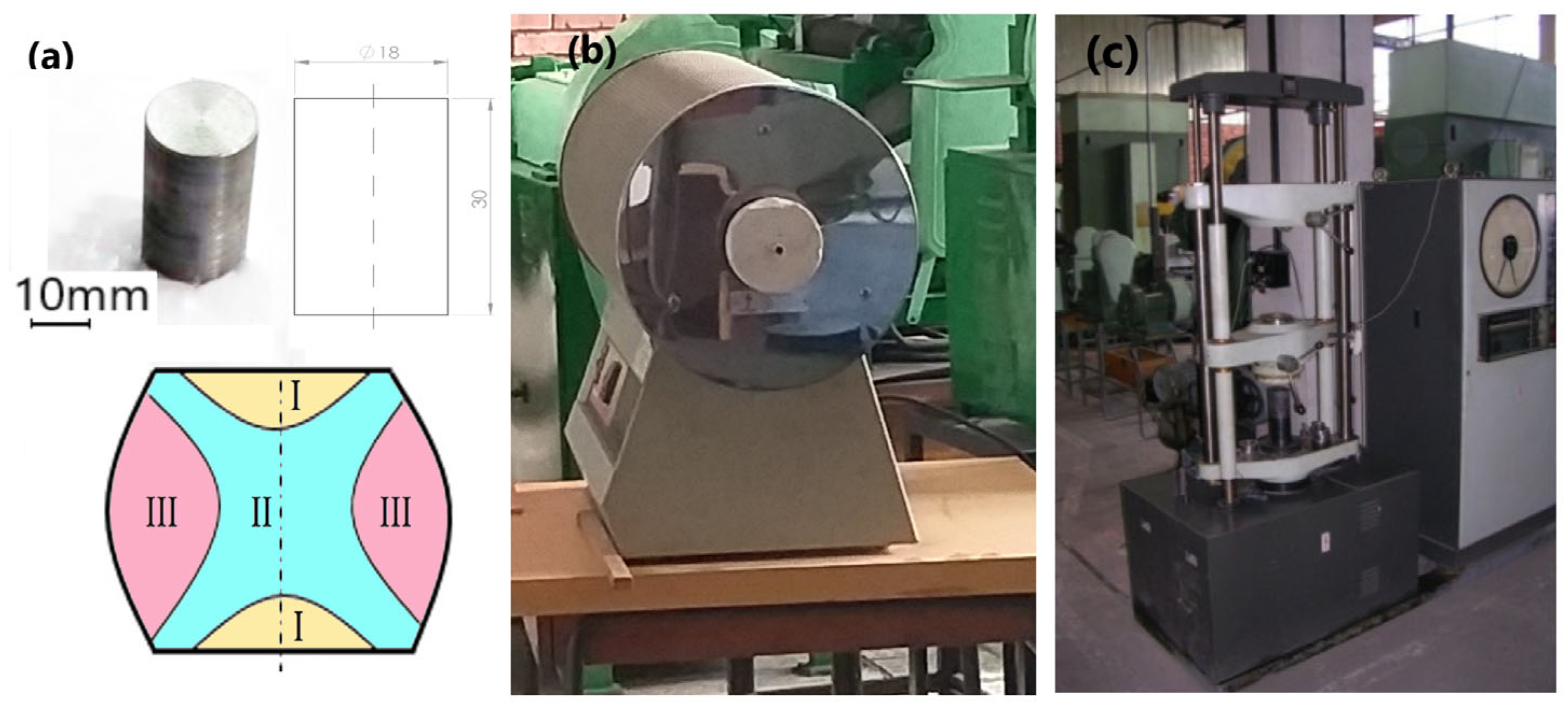

2. Experimental Details

3. Experimental Results

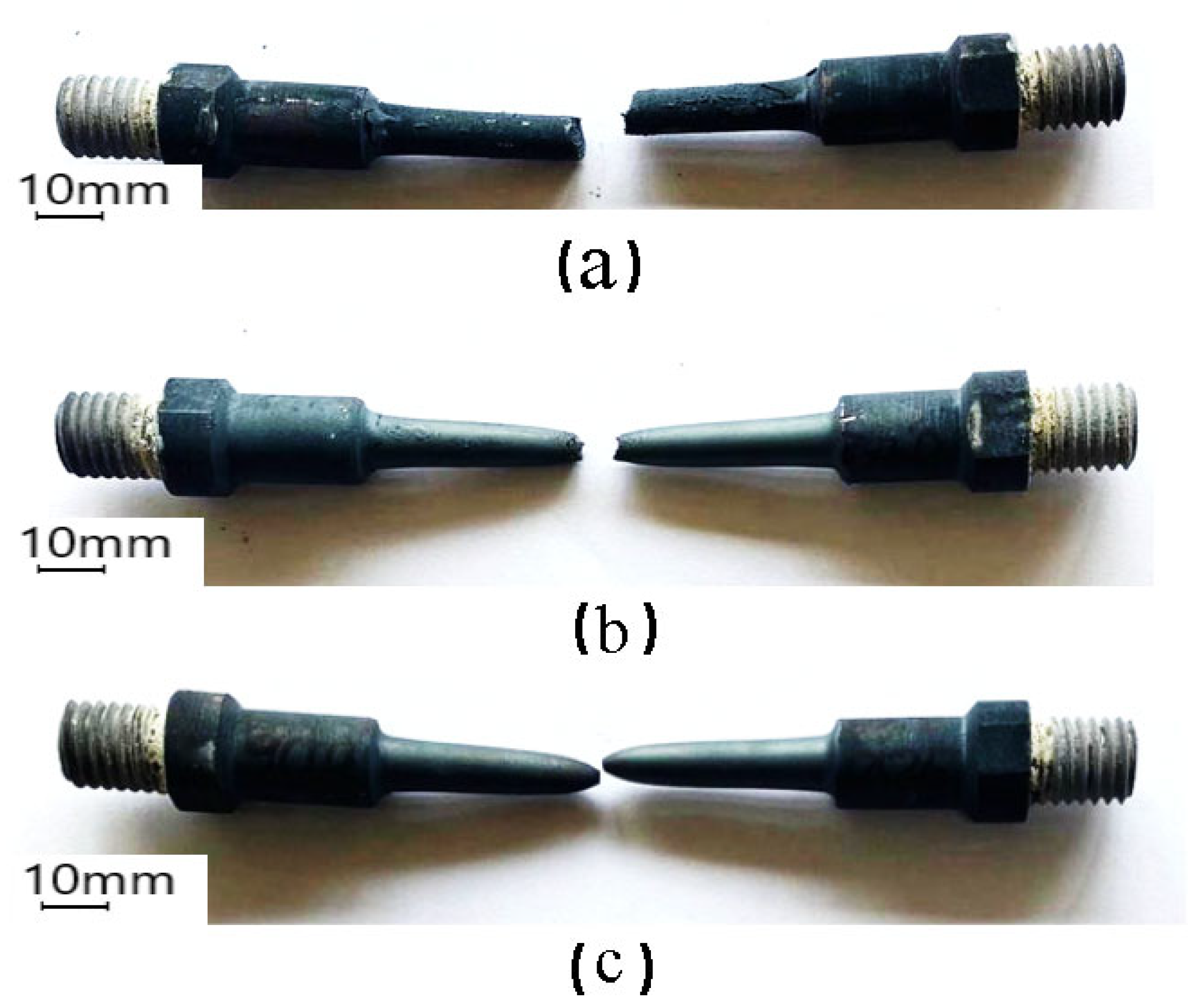

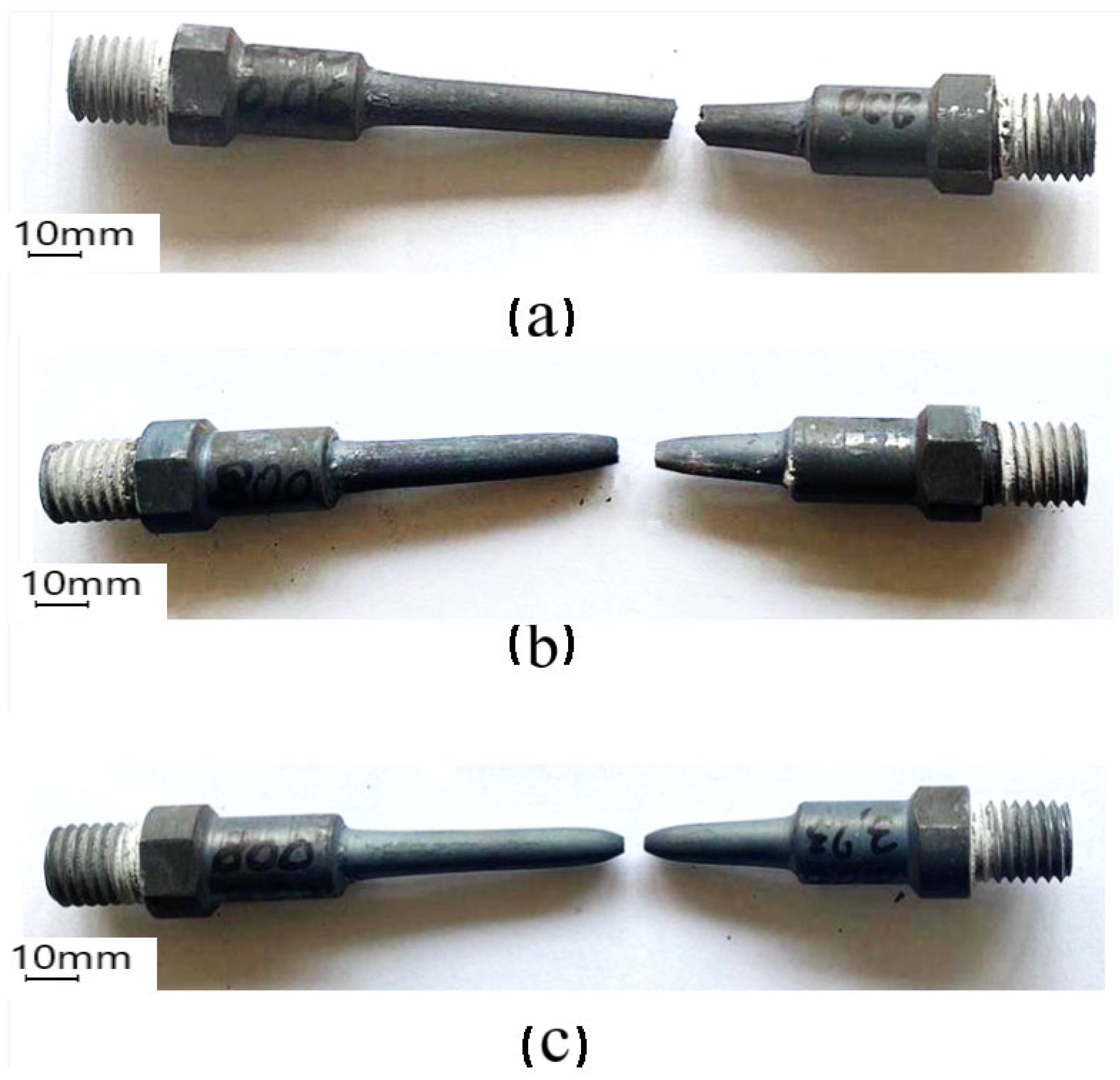

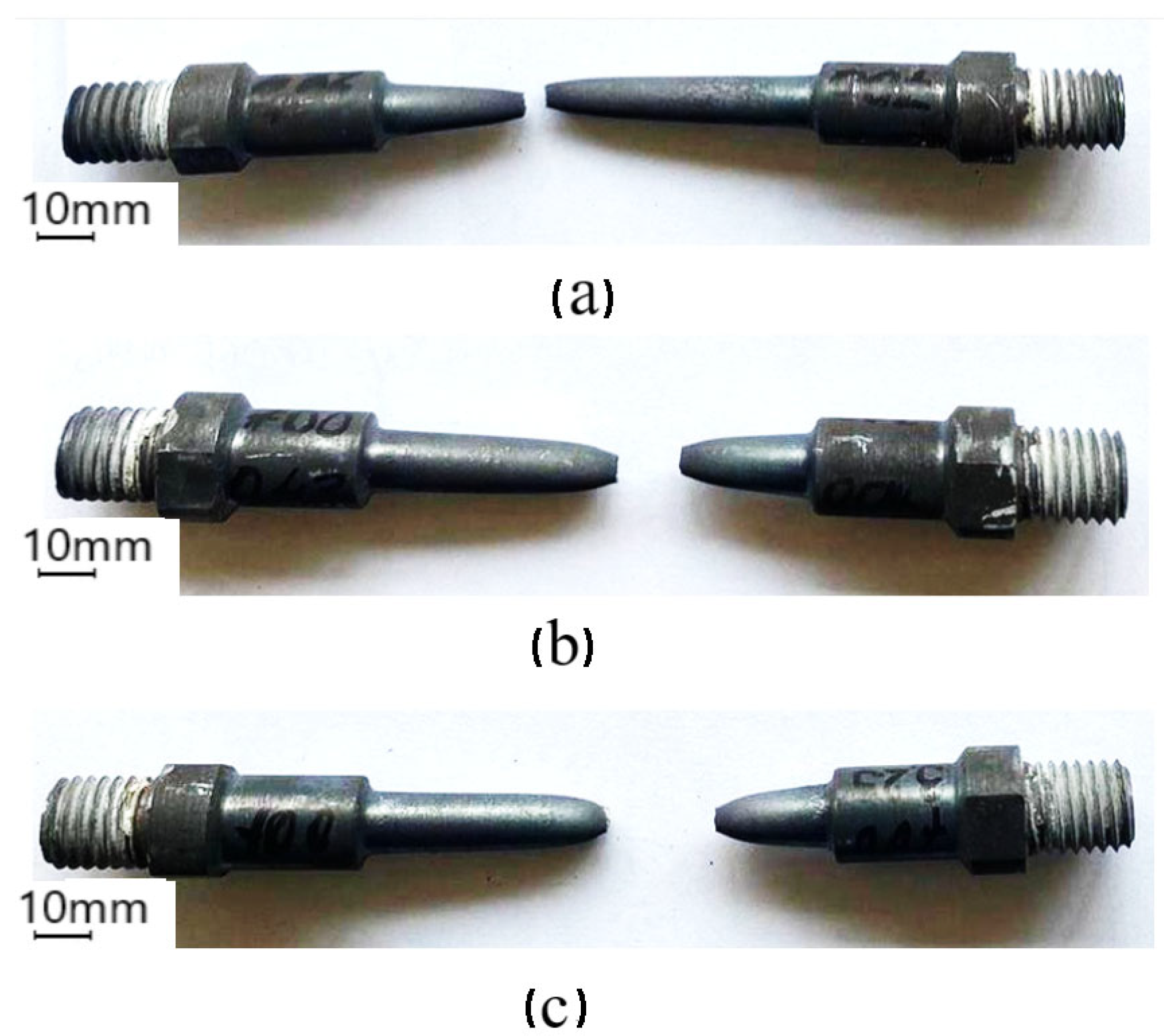

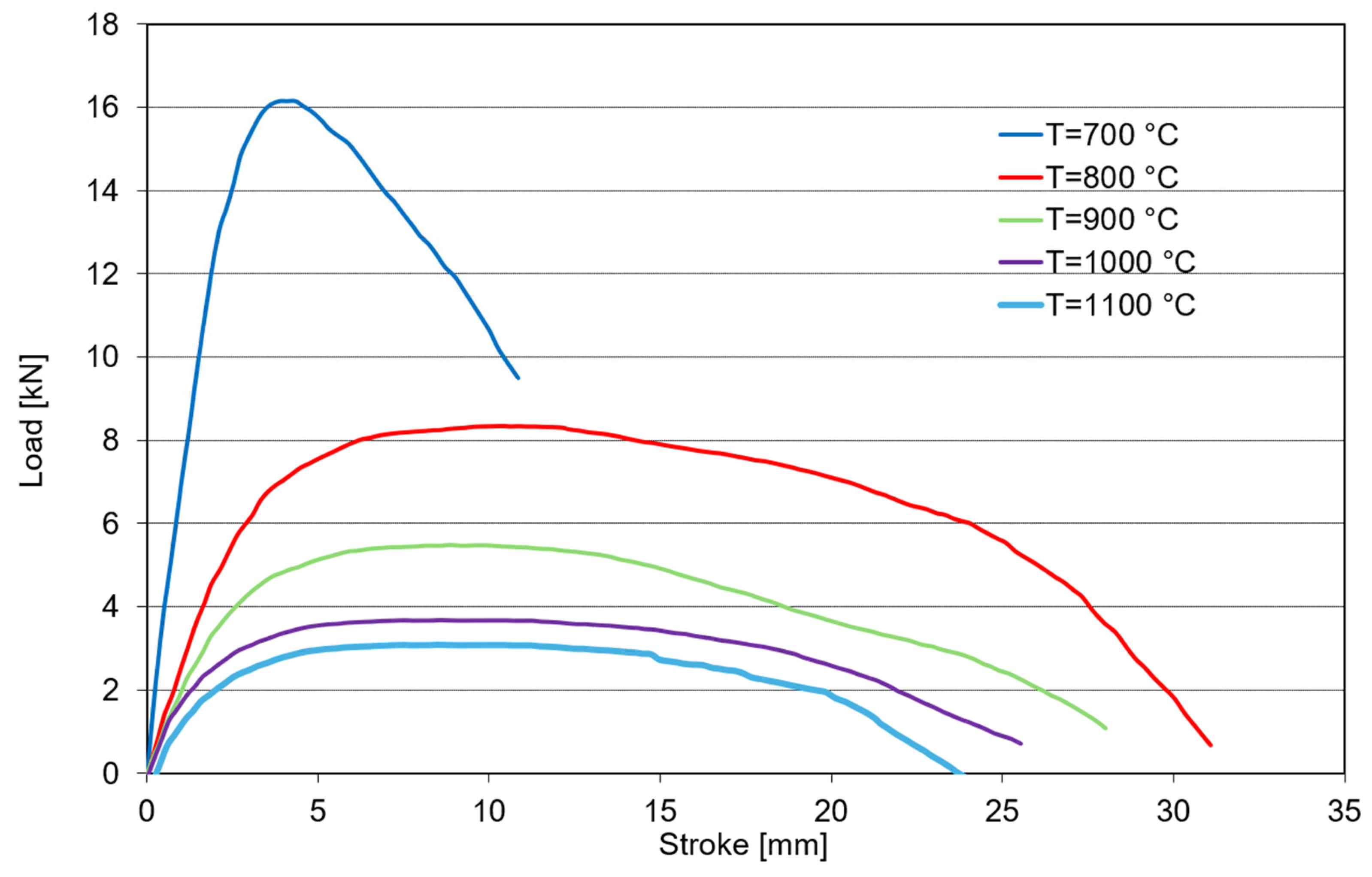

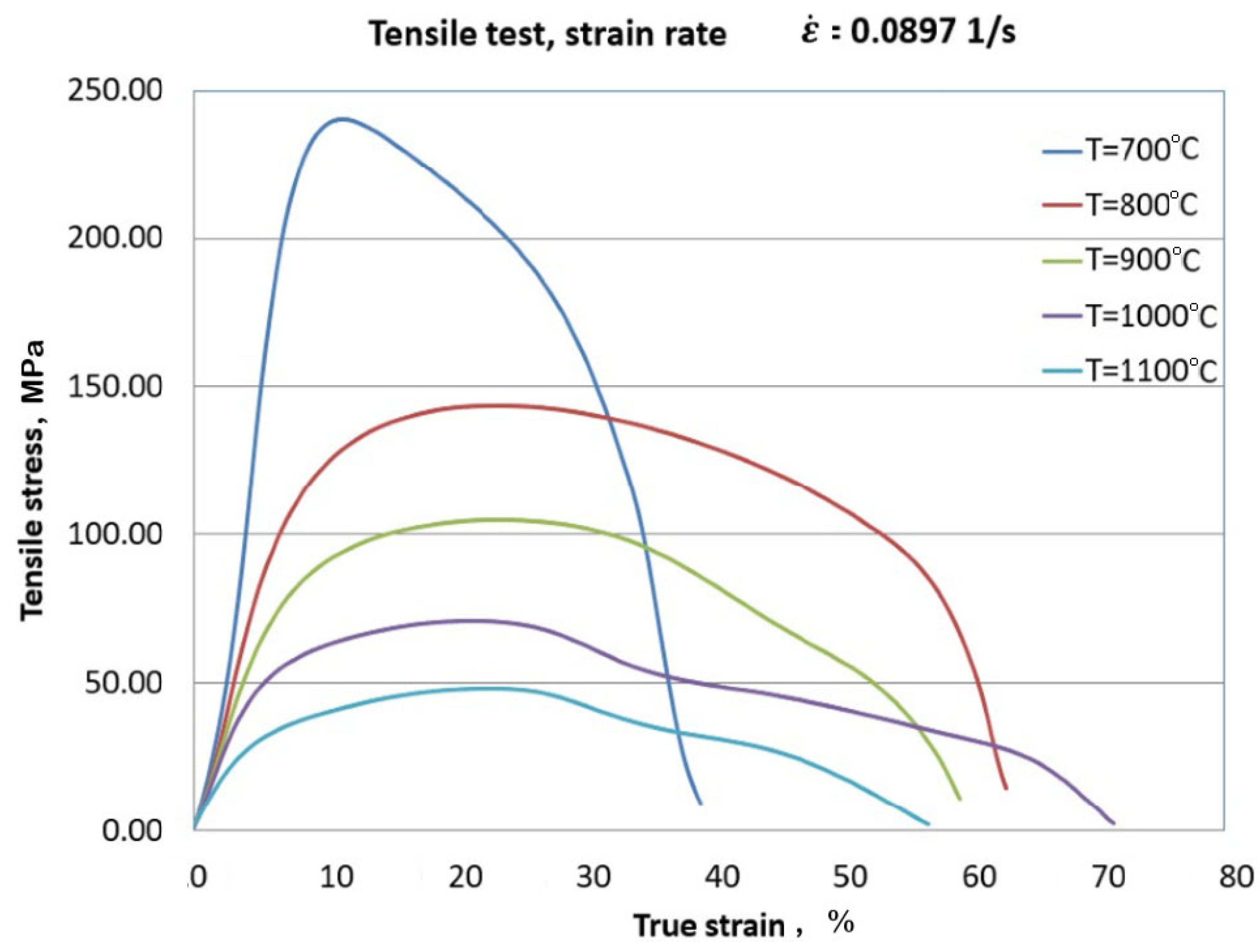

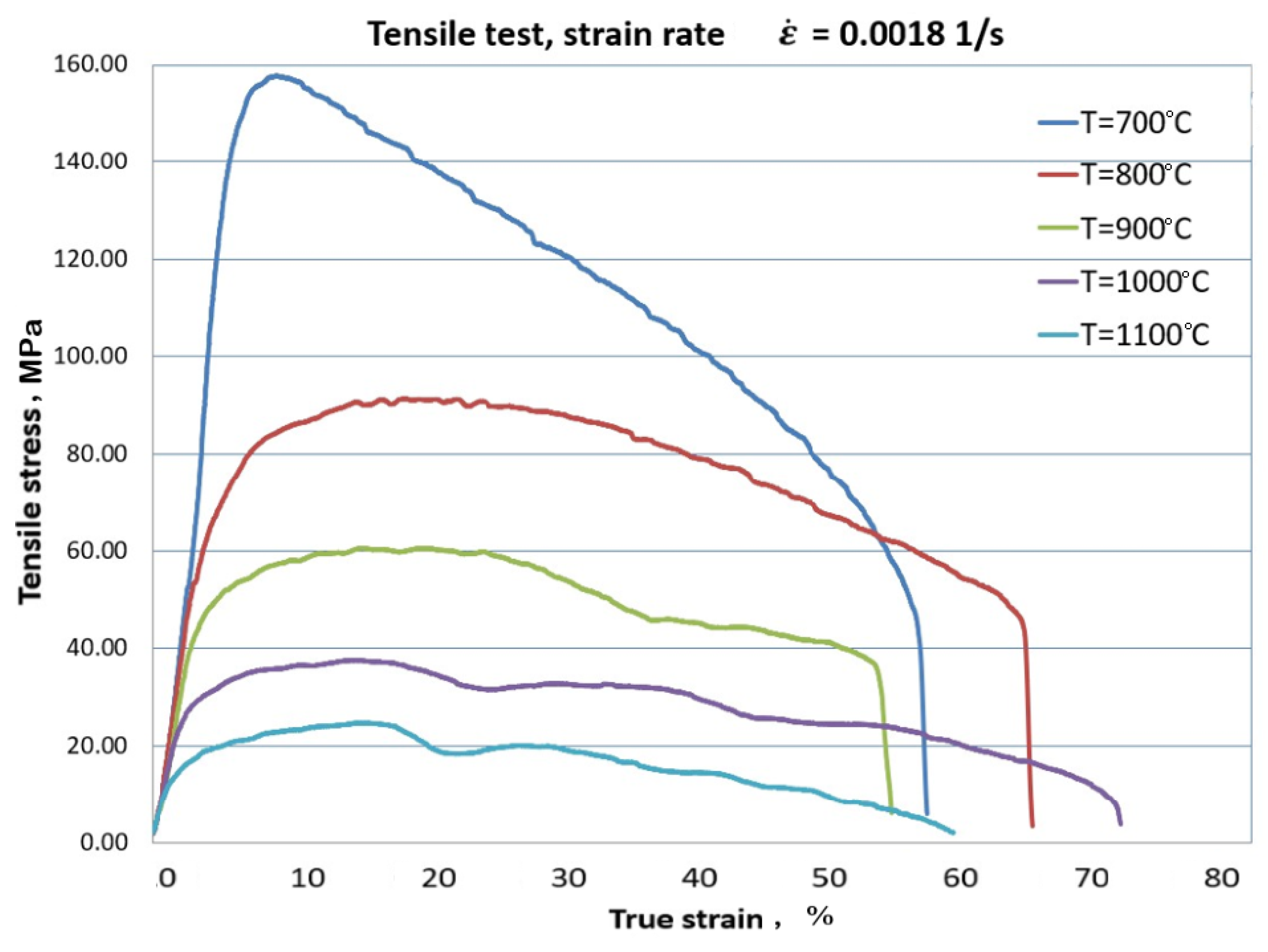

3.1. Hot Tensile Behaviour

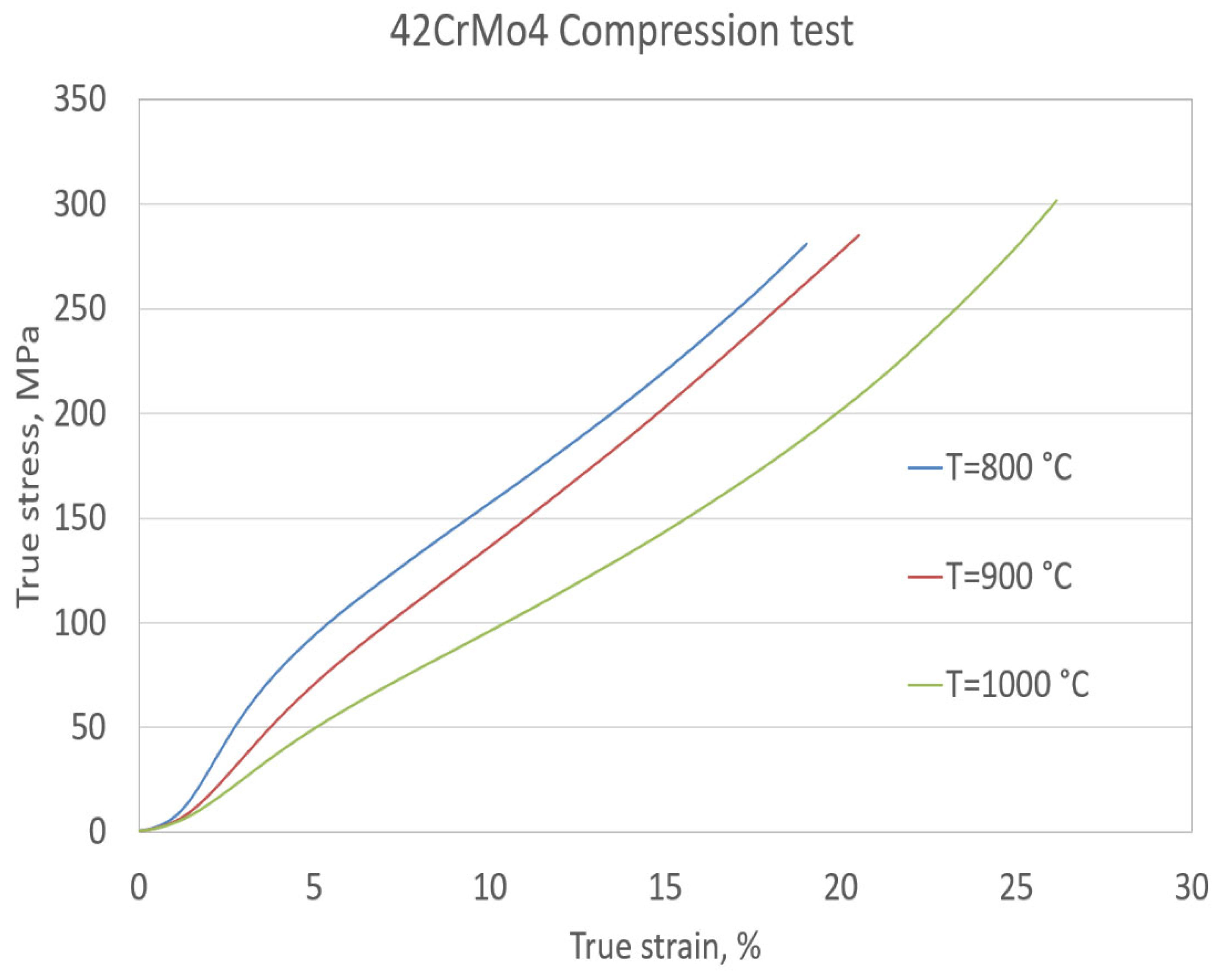

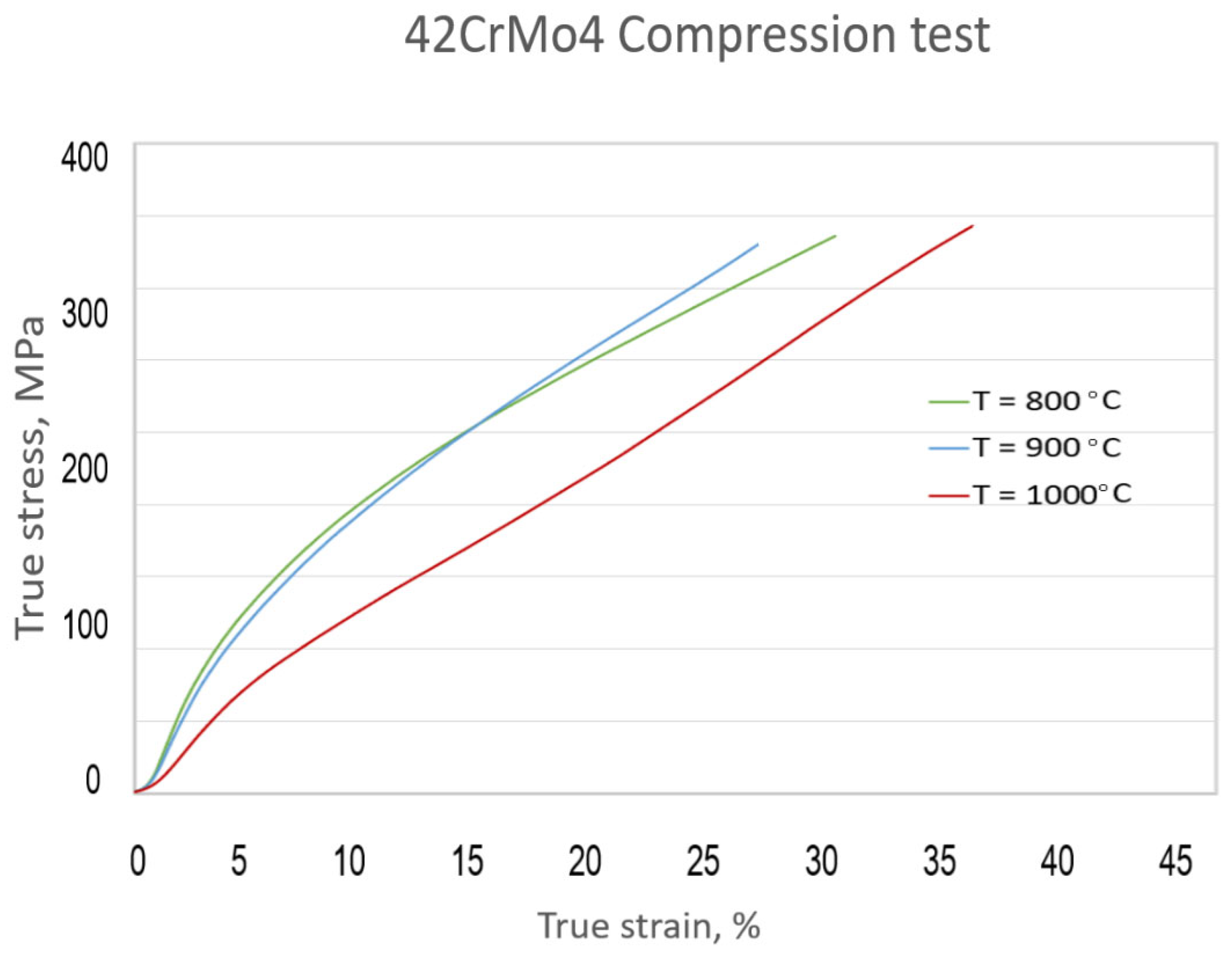

3.2. Compression Tests Behaviour

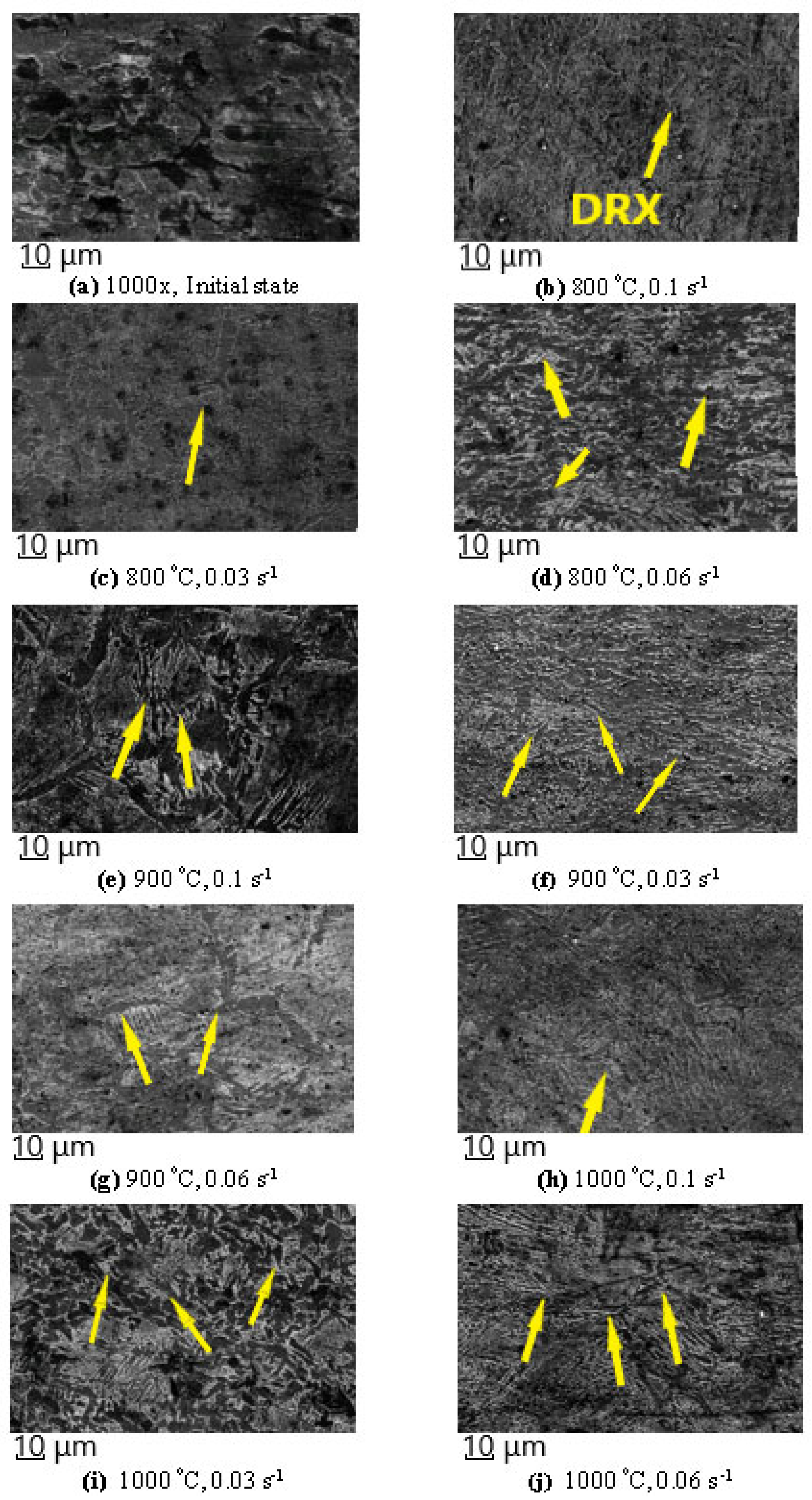

3.3. Microstructural Analysis

4. Conclusions

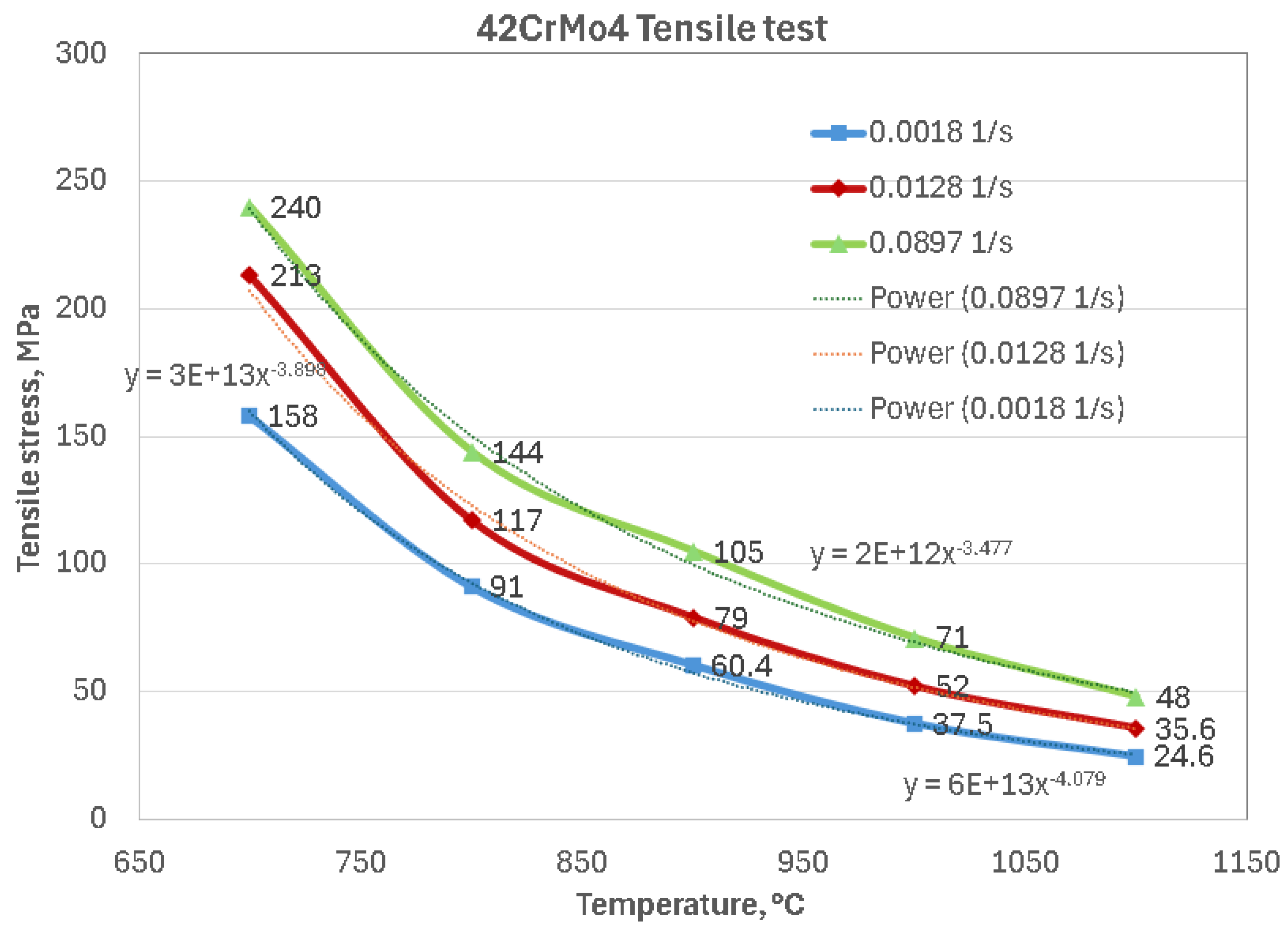

- Tensile stress significantly depends on temperature and strain rate. Yield stress increases with increasing strain rate and decreases with increasing temperature. As can be seen from Figure 10, the maximum tensile stress value is 240 MPa at the maximum strain rate of 0.0897 s−1, 213 MPa at 0.0128 s−1, and 158 MPa at 0.0018 s−1.

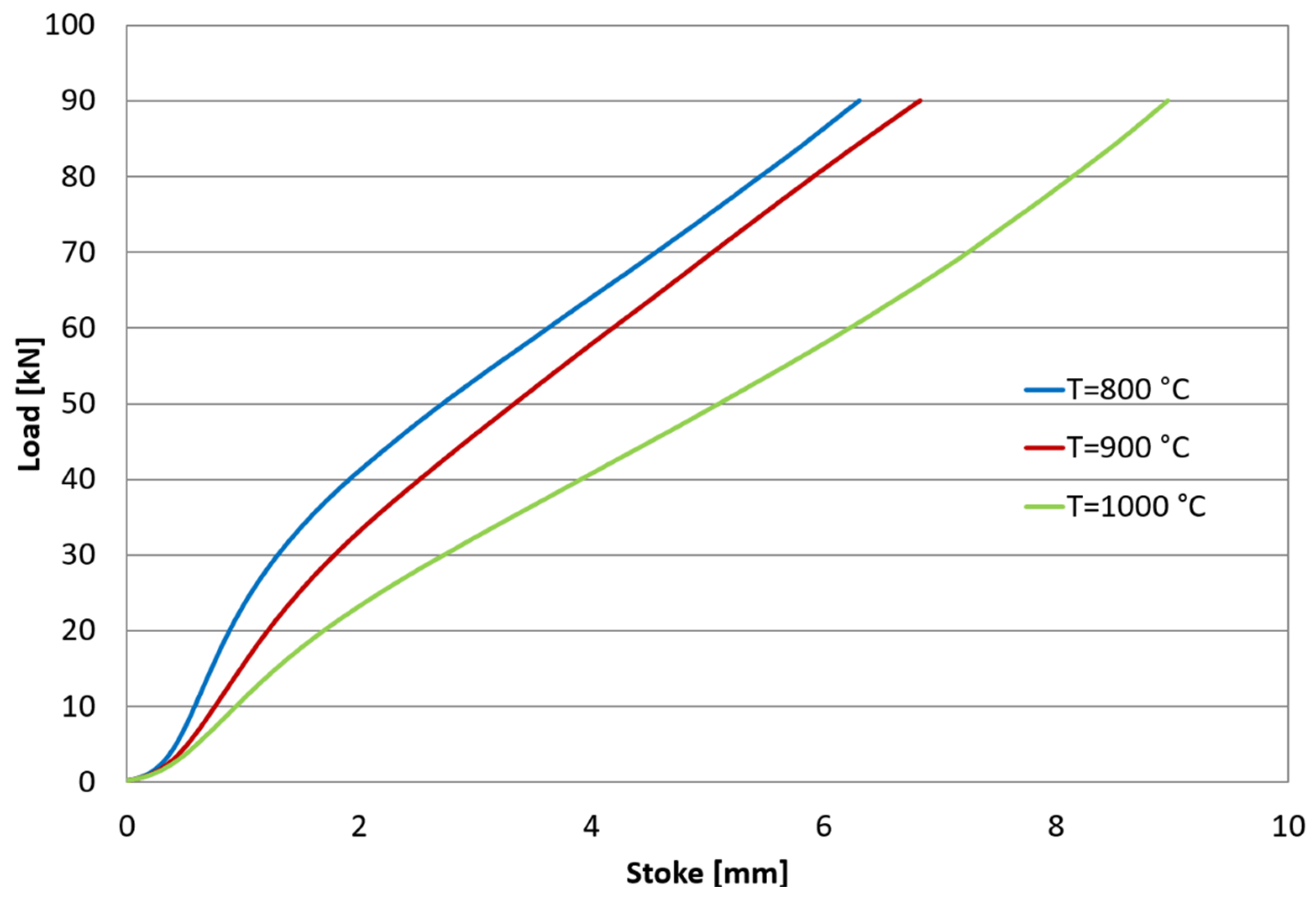

- The experimental curves show typical characteristics that demonstrate the presence of dynamic recrystallization at high temperatures and low strain rates. At the deformation temperature of 800 °C, 900 °C, 1000 °C, when the balance between hardening and dynamic recovery takes place, the flow curves show a steady phase in which the flow stress is approximately constant.

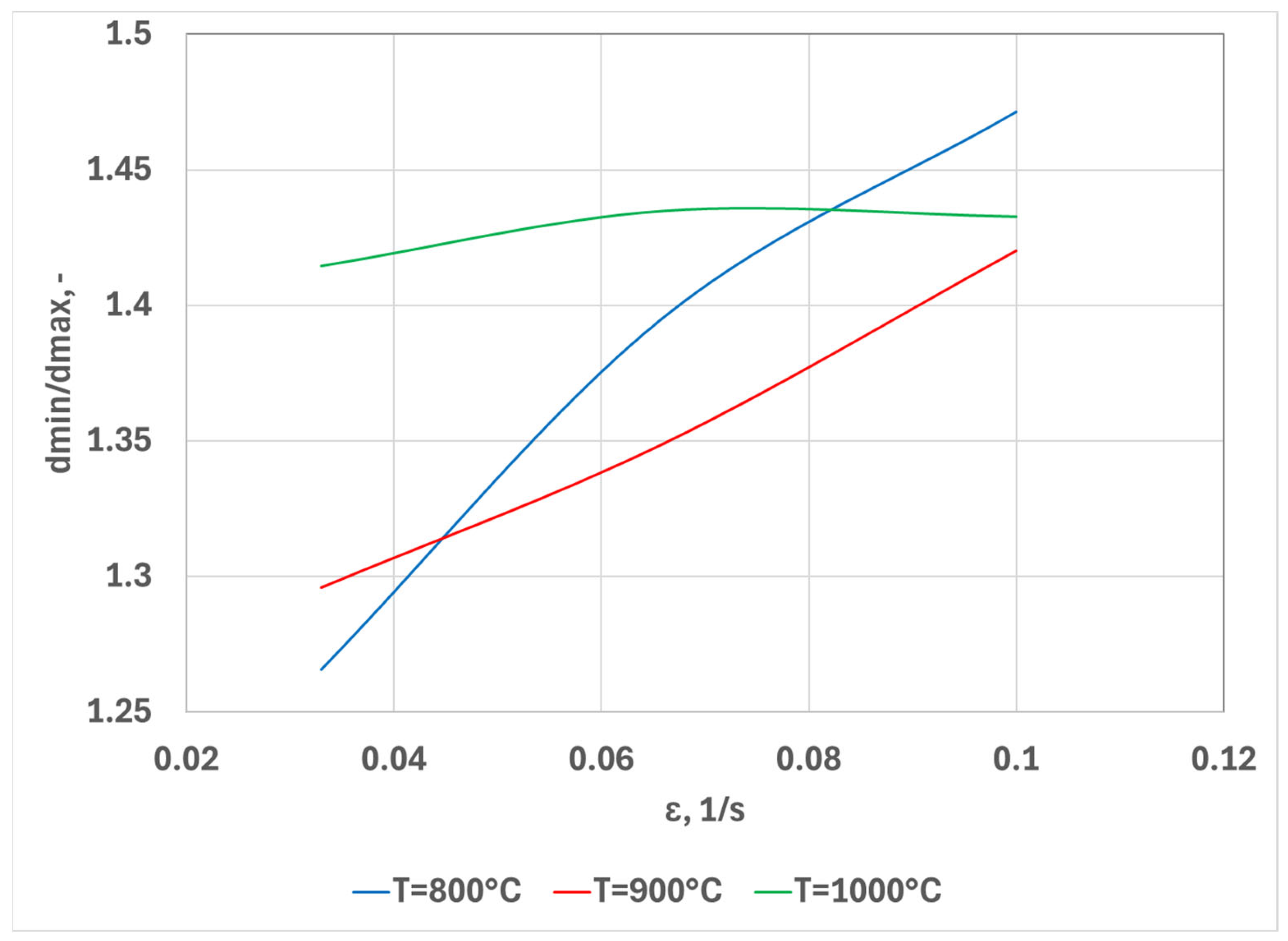

- In the compression tests, it was observed that once the strain rate increases, the true strain slightly increases, depending on temperature. The greatest non-uniformity of the deformations was observed for the temperature of 1000 °C. With increasing deformation speed, the non-uniformity of the deformations increases. The maximum true strain of 50% was obtained at a temperature of 1000 °C and a strain rate of 0.1 s−1. When reducing the strain rate, the true strain value decreases, as can be seen from Figure 16, Figure 17 and Figure 18.

- The deformations’ non-uniformity is significantly influenced by the temperature and the strain rate. With increasing temperature, the degree of non-uniformity increases. The greatest non-uniformity of the deformations is observed in the case of the temperature of 1000 °C. From Figure 17, it can be seen that by increasing the strain rate, the deformations’ non-uniformity also increases.

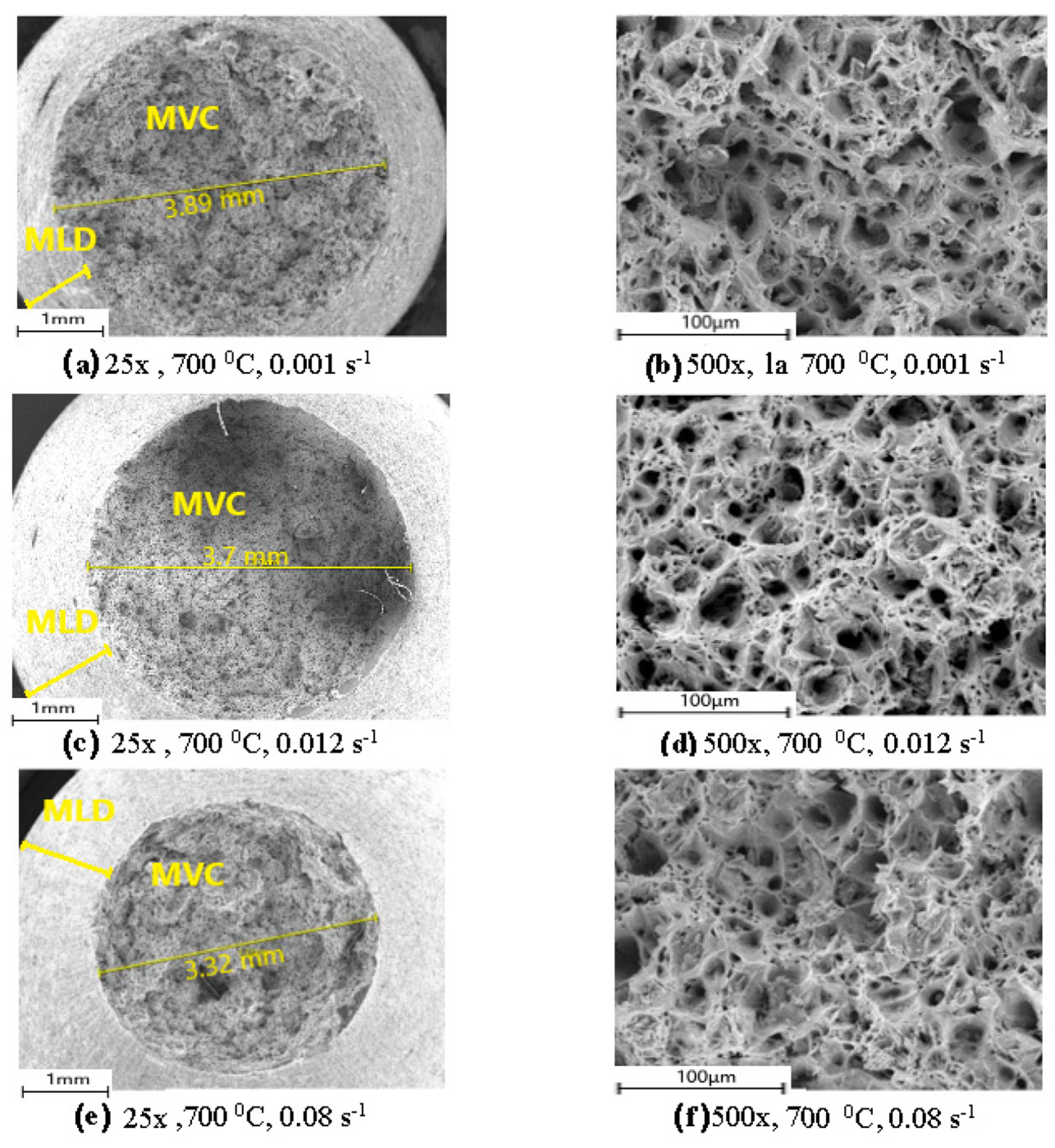

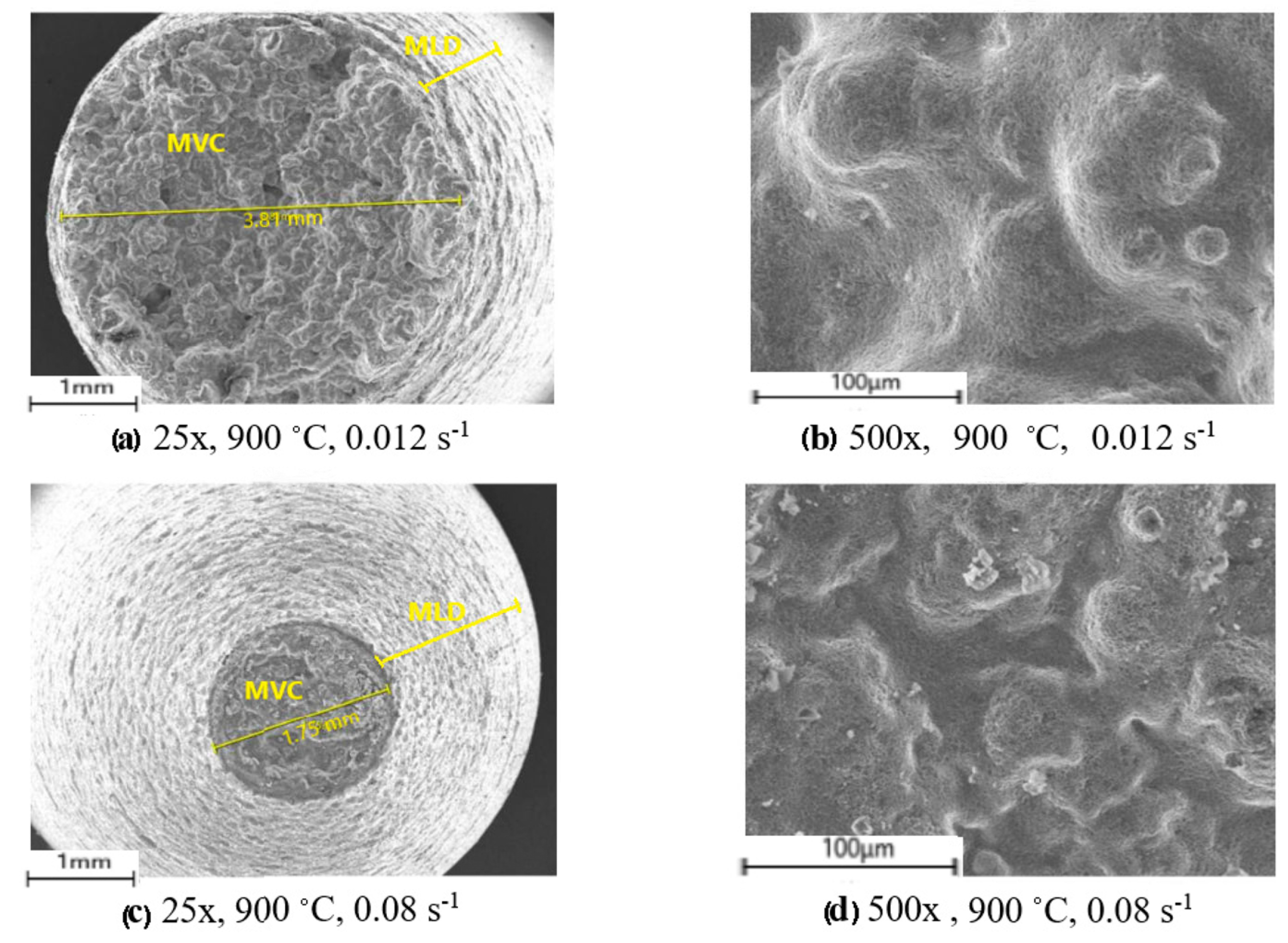

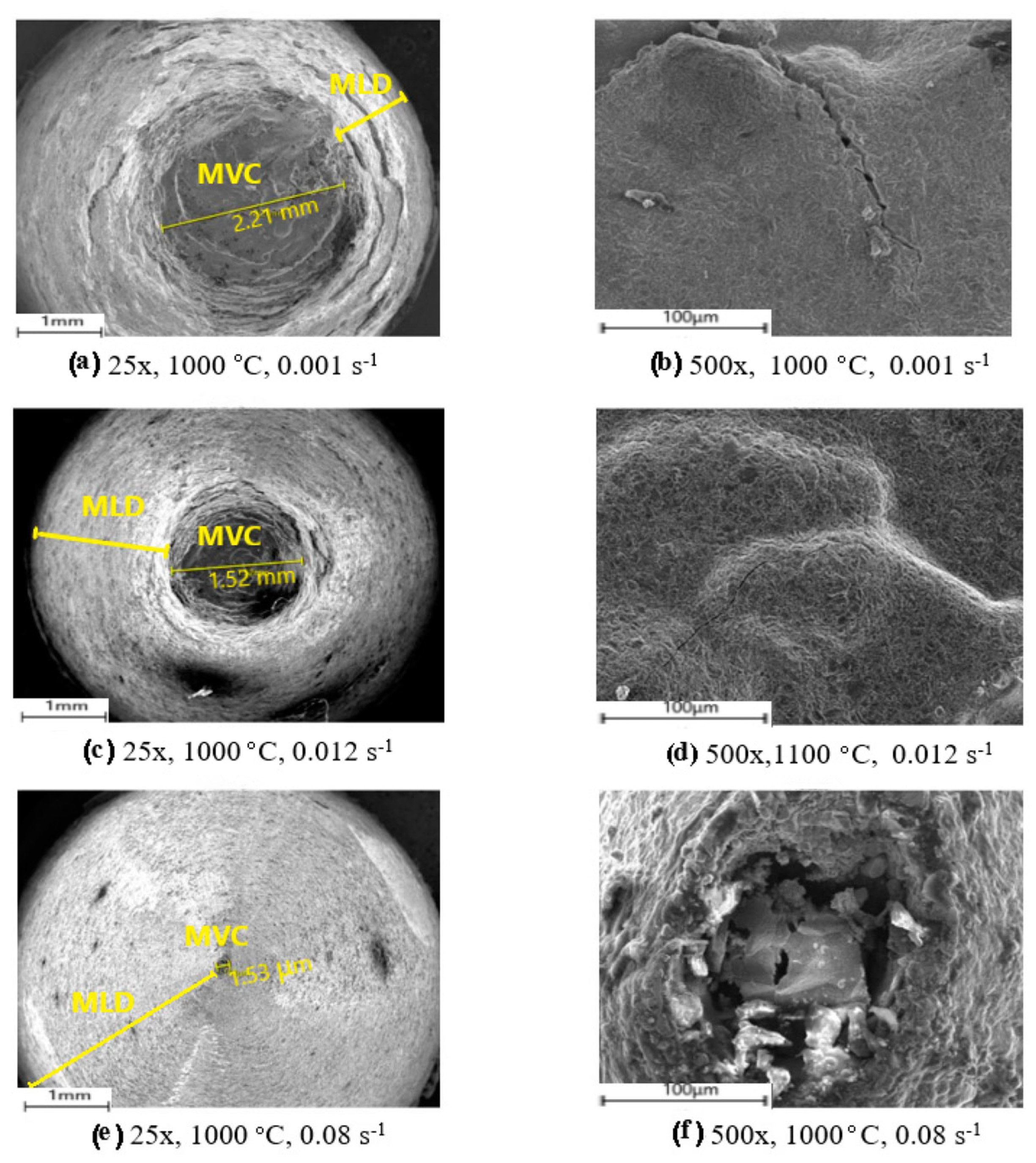

- The scanning electron microscopy investigations demonstrate the influence of temperature and strain rate on the formability and structural change of the material.

- For all the presented deformation conditions, the formation of fractures through the ductile fracture mechanism resulted from localized necking and the coalescence of microvoids.

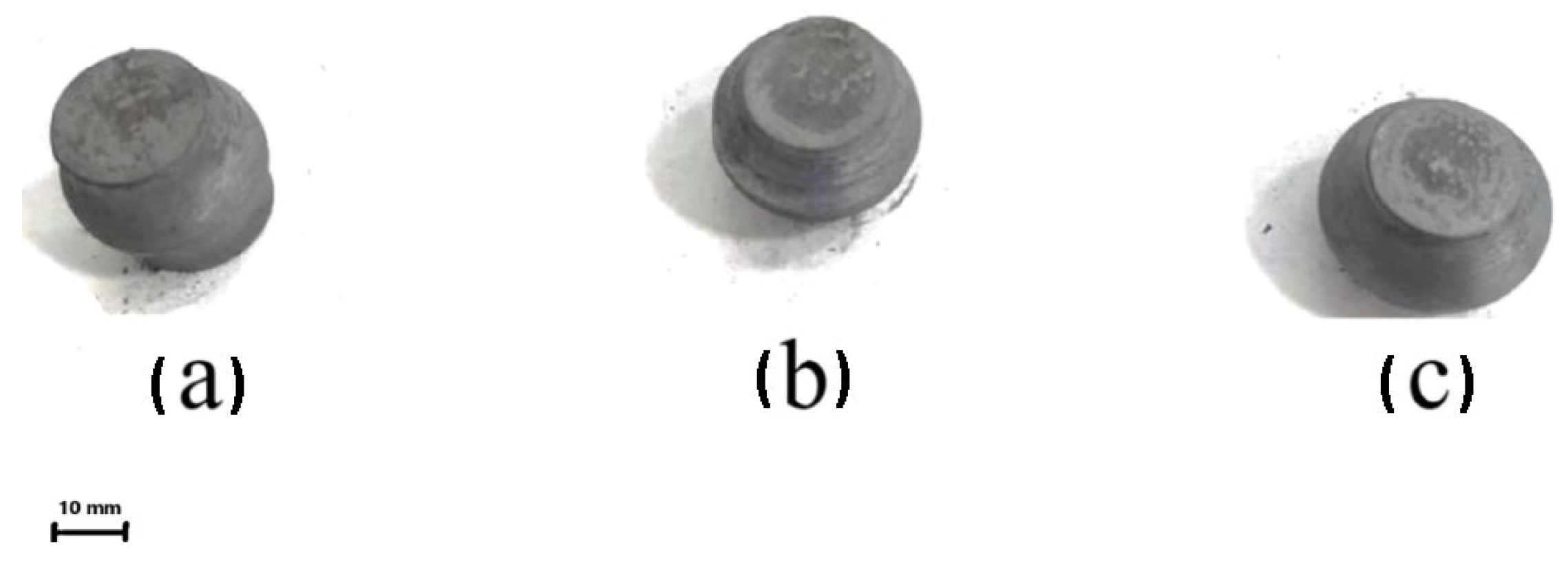

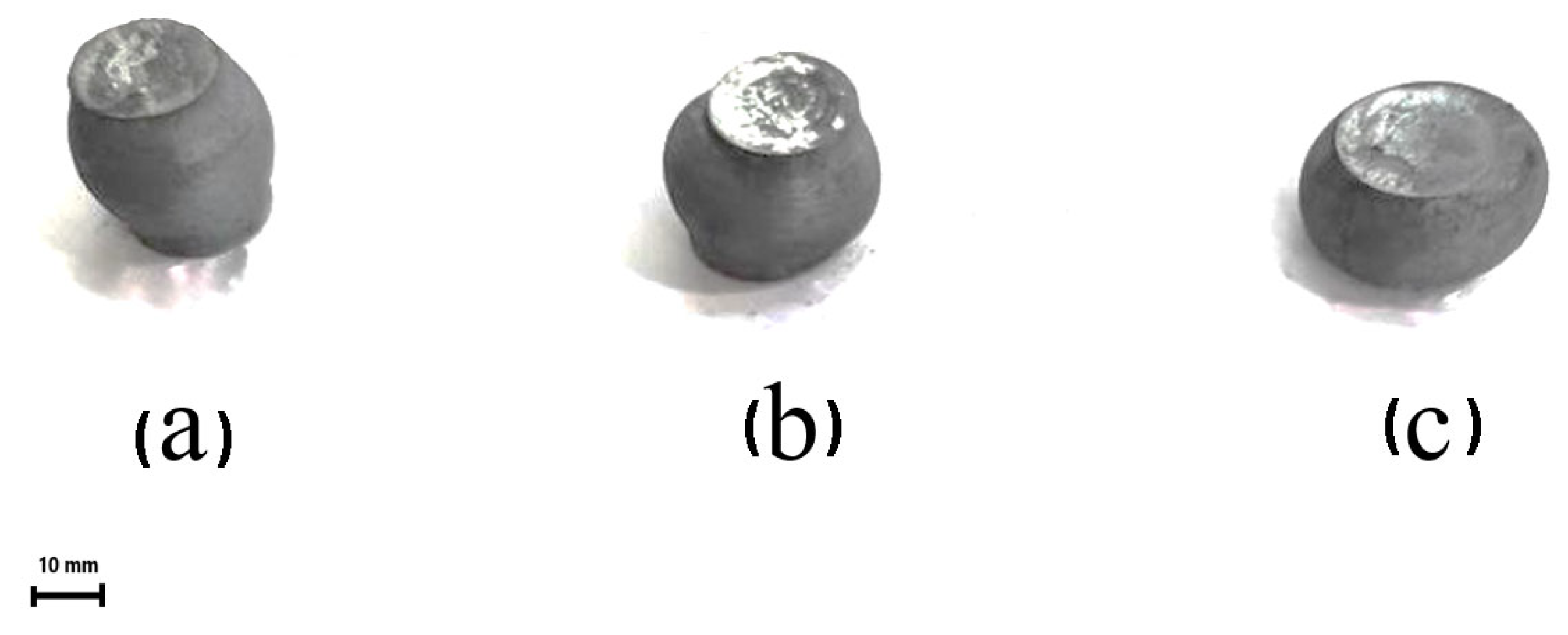

- The SEM images showed classic cup-and-cone fracture surfaces at low (25×) and high magnification (500×). These were observed at different temperatures (700 °C, Figure 20; 900 °C, Figure 21; 1000 °C, Figure 22). Images for different strain rates ((a,b) 0.001 s−1; (c,d) 0.012 s−1; (e,f) 0.08 s−1) are presented in Figure 20 and Figure 22, while Figure 21 shows images for 900 °C at strain rates of 0.001 s−1 and 0.08 s−1 (a–d).

- An advanced detached embrittlement was present in the peripheral region at a temperature of 1000 °C under conditions of low strain rate (0.001 s−1).

- In the temperature range 700–800 °C, the structure of 42CrMo4 steel changes from BCC to FCC, which explains the change in the curves in Figure 17. The temperature at which the complete austenitic transformation occurs is close to 800 °C.

- DRX evolution was influenced by increasing deformation temperature and decreasing strain rate. The quantity of dynamically recrystallized grains increases at higher temperatures and lower strain rates.

- By increasing the deformation temperature and reducing the strain rate, the fracture behaviour of 42CrMo4 steel can be improved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| T | deformation temperature [°C]; |

| strain rate [s−1]; | |

| elongation [-]; | |

| l0 | initial length of the specimen [mm]; |

| l1 | final length of the specimen [mm]; |

| d0 | initial diameter of the specimen [mm]; |

| d1 | final diameter of the specimen [mm]; |

| dr | diameter of the specimen in the fracture area [mm]; |

| longitudinal strains [%]; | |

| transversal strains [%]; | |

| V | deformation speed [mm/s]; |

| h0 | initial height of the specimen [mm]; |

| h1 | final height of the specimen [mm]; |

| dmin | minimum diameter of the deformed specimen [mm]; |

| dmax | maximum diameter of the deformed specimen [mm]. |

References

- Bilbao, O.; Loizaga, I.; Alonso, J.; Girot, F.; Torregaray, A. 42CrMo4 steel flow behavior characterization for high temperature closed dies hot forging in automotive components applications. Heliyon 2023, 9, E22256. [Google Scholar] [CrossRef] [PubMed]

- Imdad, A.; Arniella, V.; Zafra, A.; Belzunce, J. Tensile behaviour of 42CrMo4 steel submitted to annealed, normalized, and quench and tempering heat treatments with in-situ hydrogen charging. Int. J. Hydrogen Energy 2024, 5, 270–280. [Google Scholar] [CrossRef]

- Zheng, J.; Feng, Y.; Zhao, Y.; Chen, L. High-Temperature Cyclic Oxidation Behavior and Microstructure Evolution of W- and Ce-Containing 18Cr-Mo Type Ferritic Stainless Steel. Materials 2024, 17, 2230. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, Q.; Wang, Q.; Li, C.; Li, K. Effect of Boron on Microstructures and Low-Temperature Impact Toughness of Medium-Carbon CrMo Alloy Steels with Different Quenching Temperatures. Processes 2024, 12, 852. [Google Scholar] [CrossRef]

- Wang, H.; Zhai, Y.; Zhou, L.; Zhang, Z. Study on Laser Surface Hardening Behavior of 42CrMo Press Brake Die. Coatings 2021, 11, 997. [Google Scholar] [CrossRef]

- Cristea, A.F.; Ninacs, R.; Haragâş, S. Studies regarding the kinematic and functioning of unconventional worm Gear. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2022, 65, 437–442. [Google Scholar]

- Sas-Boca, I.M.; Frunza, D.; Popa, F.; Ilutiu-Varvara, D.A.; Tintelecan, M.C. Influence of Temperature and Strain Rate on Microstructure and Fracture Mechanism of Mild Steel. Procedia Manuf. 2020, 46, 891–898. [Google Scholar] [CrossRef]

- Ilhan, E.; Findik, F.; Aslanlar, S. An investigation of the factors affecting the design of drum dryers. Mater. Des. 2003, 24, 503–507. [Google Scholar] [CrossRef]

- Bronis, M.; Miko, E.; Nowakowski, L. Analyzing the Effects of the Kinematic System on the Quality of Holes Drilled in 42CrMo4 + QT Steel. Materials 2021, 14, 4046. [Google Scholar] [CrossRef]

- González-Pociño, A.; Asensio-Lozano, J.; Álvarez-Antolín, F.; García-Diez, A. Evaluation of Hardness, Sliding Wear and Strength of a Hypoeutectic White Iron with 25%Cr after Heat Treatments. Metals 2021, 11, 947. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Microstructural evolution in 42CrMo steel during compression at elevated temperatures. Mater. Lett. 2008, 62, 2136–2139. [Google Scholar] [CrossRef]

- Arun, S.; Thakare, A.S.; Butee, S.P.; Kamble, K.R. Improvement in Mechanical Properties of 42CrMo4 Steel Through Novel Thermomechanical Processing Treatment. Metallogr. Microstruct. Anal. 2020, 9, 759–773. [Google Scholar] [CrossRef]

- Miokovic, T.; Schulze, V.; Vohringer, O.; Lohe, D. Prediction of phase transformations during laser surface hardening of AISI 4140 including the effects of inhomogeneous austenite formation. Mater. Sci. Eng. A 2006, 435, 547–555. [Google Scholar] [CrossRef]

- Nikitin, I.; Besel, M. Correlation between residual stress and plastic strain amplitude during low cycle fatigue of mechanically surface treated austenitic stainless steel AISI 304 and ferritic–pearlitic steel SAE 1045. Mater. Sci. Eng. A 2008, 491, 297–303. [Google Scholar] [CrossRef]

- Pop, M.; Frunza, D.; Popa, F.; Neag, A. Aspects Regarding the Hot Fracture Behavior of 42CrMo4 Alloy. Roum. J. Phys. 2017, 62, 1–13. [Google Scholar]

- Pop, M.; Neag, A.; Frunza, D.; Popa, F. Thermomechanical study on 42CrMo4 steel formability. Acta Tech. Napoc. Appl. Math. Mech. 2019, 62, 287–294. [Google Scholar]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Krupp, U.; Giertler, A. Surface or Internal Fatigue Crack Initiation during VHCF of Tempered Martensitic and Bainitic Steels: Microstructure and Frequency/Strain Rate Dependency. Metals 2022, 12, 1815. [Google Scholar] [CrossRef]

- Totik, Y.; Sadeler, R.; Kaymaz, I. Hot workability of AISI 4140 steel with hot torsion test. J. Mech. Behav. Mater. 2002, 13, 65–72. [Google Scholar]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Effect of temperature and strain rate on the compressive deformation behavior of 42CrMo steel. J. Mater. Process Technol. 2008, 205, 308–315. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhang, J.; Zhong, J. Application of neural networks to predict the elevated temperature flow behavior of a low alloy steel. Comput. Mater. Sci. 2008, 43, 752–758. [Google Scholar] [CrossRef]

- Quan, G.Z.; Zhao, L.; Chen, T.; Wang, Y.; Mao, Y.P.; Lv, W.Q.; Zhou, J. Identification for the optimal working parameters of as-extruded 42CrMo high-strength steel from a large range of strain, strain rate and temperature. Mater. Sci. Eng. A 2012, 538, 364–373. [Google Scholar] [CrossRef]

- Quan, G.Z.; Wang, Y.; Liu, Y.Y.; Zhou, J. Effect of Temperatures and Strain Rates on the Average Size of Grains Refined by Dynamic Recrystallization for as-extruded 42CrMo Steel. Mater. Res. 2013, 16, 1092–1105. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, Z.; Yu, W.; Wang, G.; Zhou, J.; Cai, Q. Deformation Behavior and Constitutive Equation of 42CrMo Steel at High Temperature. Metals 2021, 11, 1614. [Google Scholar] [CrossRef]

- Szala, M.; Winiarski, G.; Wójcik, Ł.; Bulzak, T. Effect of Annealing Time and Temperature Parameters on the Microstructure, Hardness, and Strain-Hardening Coefficients of 42CrMo4 Steel. Materials 2020, 13, 2022. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.S.; Lin, Y.C.; Ma, X.S. The kinetics of dynamic recrystallization of 42CrMo steel. Mater. Sci. Eng. A 2012, 556, 260–266. [Google Scholar] [CrossRef]

- Yang, D.; Chen, W.; Zhou, R.; Wang, S.; Ma, Y.; Zan, X.; Peng, L. Microstructure evolution of dynamic recrystallizatin of 42CrMo steel during multi-stage forging by FEM. App Mech. Mater. 2012, 217, 415–418. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Study of Static Recrystallization Kinetics in a Low Alloy Steel. Comput. Mater. Sci. 2008, 44, 316–321. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Study of Metadynamic Recrystallization Behaviors in a Low Alloy Steel. J. Mater. Process. Technol. 2009, 209, 2477–2482. [Google Scholar] [CrossRef]

- Lin, Y.C.; Liu, Y.X.; Liu, G.; Chen, M.S.; Huang, Y.C. Prediction of Ductile Fracture Behaviors for 42CrMo Steel at Elevated Temperatures. JMEPEG 2015, 24, 221–228. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhao, S.D.; Fan, S.Q.; Zhong, B. Plastic Properties and Constitutive Equations of 42CrMo Steel During Warm Forming Process. Mater. Sci. Technol. 2014, 30, 645–652. [Google Scholar] [CrossRef]

- Huang, Y.C.; Lin, Y.C.; Deng, J.; Liu, G.; Chen, M.S. Hot tensile deformation behaviors and constitutive model of 42CrMo steel. Mater. Des. 2014, 53, 349–356. [Google Scholar] [CrossRef]

- Mžourek, M.; Papuga, J.; Nesládek, M.; Matušů, M.; Čapek, J.; Mára, V. Fatigue Damage Analysis On 42CrMo4+QT Via Critical Volume Approach. Procedia Struct. Integr. 2022, 42, 457–464. [Google Scholar] [CrossRef]

- Zhu, Z.; Lu, Y.; Xie, Q.; Li, D.; Gao, N. Mechanical properties and dynamic constitutive model of 42CrMo steel. Mater. Des. 2017, 119, 171–179. [Google Scholar] [CrossRef]

- Kim, S.I.; Lee, Y.; Byon, S.M. Study on constitutive relation of AISI4140 steel subject to large strain at elevated temperatures. J. Mater. Process. Technol. 2003, 140, 84–89. [Google Scholar] [CrossRef]

- Sheng, Z.Q.; Shivpuri, R. Modeling flow stress of magnesium alloys at elevated temperature. Mater. Sci. Eng. A 2006, 419, 202–208. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, Z.; Li, D.; Xie, Q. Constitutive model of 42CrMo steel under a wide range of strain rates based on crystal plasticity theory. Mater. Sci. Eng. A 2017, 679, 215–222. [Google Scholar] [CrossRef]

- Kimm, J.S.; Bergmann, J.A.; Woste, F.; Pohl, F.; Wiederkehr, P.; Theisen, W. Deformation behavior of 42CrMo4 over a wide range of temperatures and strain rates in Split-Hopkinson pressure bar tests. Mater. Sci. Eng. A 2021, 826, 141953. [Google Scholar] [CrossRef]

- Jonšta, P.; Jonšta, Z.; Brožová, S.; Ingaldi, M.; Pietraszek, J.; Klimecka-Tatar, D. The Effect of Rare Earth Metals Alloying on the Internal Quality of Industrially Produced Heavy Steel Forgings. Materials 2021, 14, 5160. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, M.-C.; Tian, Y.; Zhang, J.; Wang, Z.; Zhao, Y.-C.; Peng, L. Simultaneous Enhancement of Strength and Sulfide Stress Cracking Resistance of Hot-Rolled Pressure Vessel Steel Q345 via a Quenching and Tempering Treatment. Materials 2024, 17, 1636. [Google Scholar] [CrossRef]

- Ferreira, A.A.; Darabi, R.; Sousa, J.P.; Cruz, J.M.; Reis, A.R.; Vieira, M.F. Optimization of Direct Laser Deposition of a Martensitic Steel Powder (Metco 42C) on 42CrMo4 Steel. Metals 2021, 11, 672. [Google Scholar] [CrossRef]

- Mirzaee, M.; Keshmiri, H.; Ebrahimi, G.R.; Momeni, A. Dynamic recrystallization and precipitation in low carbon low alloy steel 26NiCrMoV 14-5. Mater. Sci. Eng. A 2012, 551, 25–31. [Google Scholar] [CrossRef]

- Arniella, V.; Zafra, A.; Álvarez, G.; Belzunce, J.; Rodríguez, C. Comparative study of embrittlement of quenched and tempered steels in hydrogen environments. Int. J. Hydrogen Energy 2022, 47, 17056–17068. [Google Scholar] [CrossRef]

- Andreatta, F.; Zanocco, M.; Virgilio, S.; Machetta, P.; Silvonen, A.; Lanzutti, A.; Fedrizzi, L. Localized attack at inclusions in 42CrMo4 QT steel. Electrochim. Acta 2023, 462, 142754. [Google Scholar] [CrossRef]

- Peral, L.B.; Díaz, A.; Arniella, V.; Belzunce, J.; Alegre, J.M.; Cuesta, I.I. Influence of hydrogen on the hydraulic fracture behavior of a 42CrMo4 steel welds: Effect of the prior austenite grain size. Eng. Fract. Mech. 2023, 289, 109414. [Google Scholar] [CrossRef]

- Polášek, M.; Krbata, M.; Eckert, M.; Mikuš, P.; Cíger, R. Contact Fatigue Resistance of Gun Barrel Steels. Procedia Struct. Integr. 2023, 43, 306–311. [Google Scholar] [CrossRef]

- EN 10083-3: 2006; Steels for Quenching and Tempering. Technical Delivery Conditions for Alloy Steels. DIN Deutsches Institut für Normung: Berlin, Germany, 2006.

- Dieter, G.; Kuhn, H.; Semiatin, S. Handbook of Workability and Process Design; ASM International: Materials Park, OH, USA, 2003; pp. 47–56. [Google Scholar]

- Edward, G.H.; Ashby, M.F. Intergranular Fracture During Powder-Law Creep. Acta Metall. 1979, 27, 1505–1518. [Google Scholar] [CrossRef]

- Chokshi, A.H. The Development of Cavity Growth Maps for Superplastic Materials. J. Mater. Sci. 1986, 21, 2073–2082. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.38–0.45 | Max 0.4 | 0.6–0.9 | Max 0.025 | Max 0.035 | 0.9–1.2 | 0.15–0.3 |

| Crt No. | Material | l0 [mm] | d0 [mm] | l1 [mm] | d1 [mm] | dr [mm] | εl [%] | [%] | V [m/s] | [s−1] | T [°C] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 42CrMo4 | 36 | 8 | 59.6 | 5.1 | 6.3 | 0.655556 | 0.363 | 0.066 | 0.001833 | 1000 |

| 2 | 42CrMo4 | 36 | 8 | 57.0 | 5.0 | 6.5 | 0.583333 | 0.375 | 0.066 | 0.001833 | 950 |

| 3 | 42CrMo4 | 36 | 8 | 56.7 | 4.3 | 6.5 | 0.575000 | 0.463 | 0.066 | 0.001833 | 900 |

| 4 | 42CrMo4 | 36 | 8 | 56.3 | 3.9 | 6.3 | 0.563889 | 0.513 | 0.066 | 0.001833 | 850 |

| 5 | 42CrMo4 | 36 | 8 | 56.0 | 2.9 | 6.8 | 0.555556 | 0.638 | 0.066 | 0.001833 | 800 |

| 6 | 42CrMo4 | 36 | 8 | 49.9 | 3.4 | 5.5 | 0.386111 | 0.575 | 0.066 | 0.001833 | 750 |

| 7 | 42CrMo4 | 36 | 8 | 42.2 | 2.3 | 7.5 | 0.172222 | 0.713 | 0.066 | 0.001833 | 700 |

| 8 | 42CrMo4 | 36 | 8 | 61.2 | 3.9 | 6.7 | 0.700000 | 0.513 | 0.462 | 0.012833 | 1000 |

| 9 | 42CrMo4 | 36 | 8 | 53.7 | 3.0 | 6.1 | 0.491667 | 0.625 | 0.462 | 0.012833 | 900 |

| 10 | 42CrMo4 | 36 | 8 | 50.0 | 2.8 | 5.8 | 0.388889 | 0.650 | 0.462 | 0.012833 | 800 |

| 11 | 42CrMo4 | 36 | 8 | 48.0 | 2.6 | 5.6 | 0.333333 | 0.675 | 0.462 | 0.012833 | 700 |

| 12 | 42CrMo4 | 36 | 8 | 63.5 | 5.5 | 6.4 | 0.763889 | 0.313 | 3.230 | 0.089722 | 1000 |

| 13 | 42CrMo4 | 36 | 8 | 63.1 | 3.0 | 6.0 | 0.752778 | 0.625 | 3.230 | 0.089722 | 900 |

| 14 | 42CrMo4 | 36 | 8 | 59.7 | 2.6 | 6.1 | 0.658333 | 0.675 | 3.230 | 0.089722 | 800 |

| 15 | 42CrMo4 | 36 | 8 | 43.5 | 2.2 | 7.5 | 0.208333 | 0.725 | 3.230 | 0.089722 | 700 |

| Crt. No. | Material | T [°C] | d0 [mm] | h0 [mm] | V [m/s] | dmin [mm] | dmax [mm] | h1 [mm] | εh [%] | εd [%] | [-] | [s−1] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 42CrMo4 | 800 | 18 | 30 | 0.003 | 18.35 | 27 | 17.1 | 0.43 | 0.5 | 1.47139 | 0.1 |

| 2. | 42CrMo4 | 800 | 18 | 30 | 0.002 | 18.2 | 25.4 | 19.2 | 0.36 | 0.41 | 1.395604 | 0.066 |

| 3. | 42CrMo4 | 800 | 18 | 30 | 0.001 | 18.25 | 23.1 | 23.2 | 0.22 | 0.28 | 1.265753 | 0.033 |

| Crt. No. | Material | T [°C] | d0 [mm] | h0 [mm] | V [m/s] | dmin [mm] | dmax [mm] | h1 [mm] | εh [%] | εd [%] | [-] | [s−1] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 42CrMo4 | 900 | 18 | 30 | 0.003 | 19.5 | 27.7 | 15.7 | 0.47 | 0.53 | 1.420 | 0.1 |

| 2. | 42CrMo4 | 900 | 18 | 30 | 0.002 | 20.6 | 27.8 | 18.1 | 0.39 | 0.54 | 1.349 | 0.066 |

| 3. | 42CrMo4 | 900 | 18 | 30 | 0.001 | 23.3 | 30.2 | 21.9 | 0.27 | 0.67 | 1.296 | 0.033 |

| Crt. No. | Material | T [°C] | d0 [mm] | h0 [mm] | V [m/s] | dmin [mm] | dmax [mm] | h1 [mm] | εh [%] | εd [%] | [-] | [s−1] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 42CrMo4 | 1000 | 18 | 30 | 0.003 | 20.8 | 30 | 13.1 | 0.56 | 0.66 | 1.43269 | 0.1 |

| 2. | 42CrMo4 | 1000 | 18 | 30 | 0.002 | 18.4 | 26.4 | 18.3 | 0.39 | 0.46 | 1.43478 | 0.066 |

| 3. | 42CrMo4 | 1000 | 18 | 30 | 0.001 | 18.45 | 26.1 | 21.1 | 0.29 | 0.45 | 1.41463 | 0.033 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pop, M.; Sas-Boca, I.-M.; Frunză, D.; Popa, F.; Neag, A. The Influence of Hot Deformation on the Mechanical and Structural Properties of 42CrMo4 Steel. Metals 2024, 14, 647. https://doi.org/10.3390/met14060647

Pop M, Sas-Boca I-M, Frunză D, Popa F, Neag A. The Influence of Hot Deformation on the Mechanical and Structural Properties of 42CrMo4 Steel. Metals. 2024; 14(6):647. https://doi.org/10.3390/met14060647

Chicago/Turabian StylePop, Mariana, Ioana-Monica Sas-Boca, Dan Frunză, Florin Popa, and Adriana Neag. 2024. "The Influence of Hot Deformation on the Mechanical and Structural Properties of 42CrMo4 Steel" Metals 14, no. 6: 647. https://doi.org/10.3390/met14060647