Effect of Printing Orientation on the Mechanical Properties of 3D-Printed Cu–10Sn Alloys by Laser Powder Bed Fusion Technology

Abstract

:1. Introduction

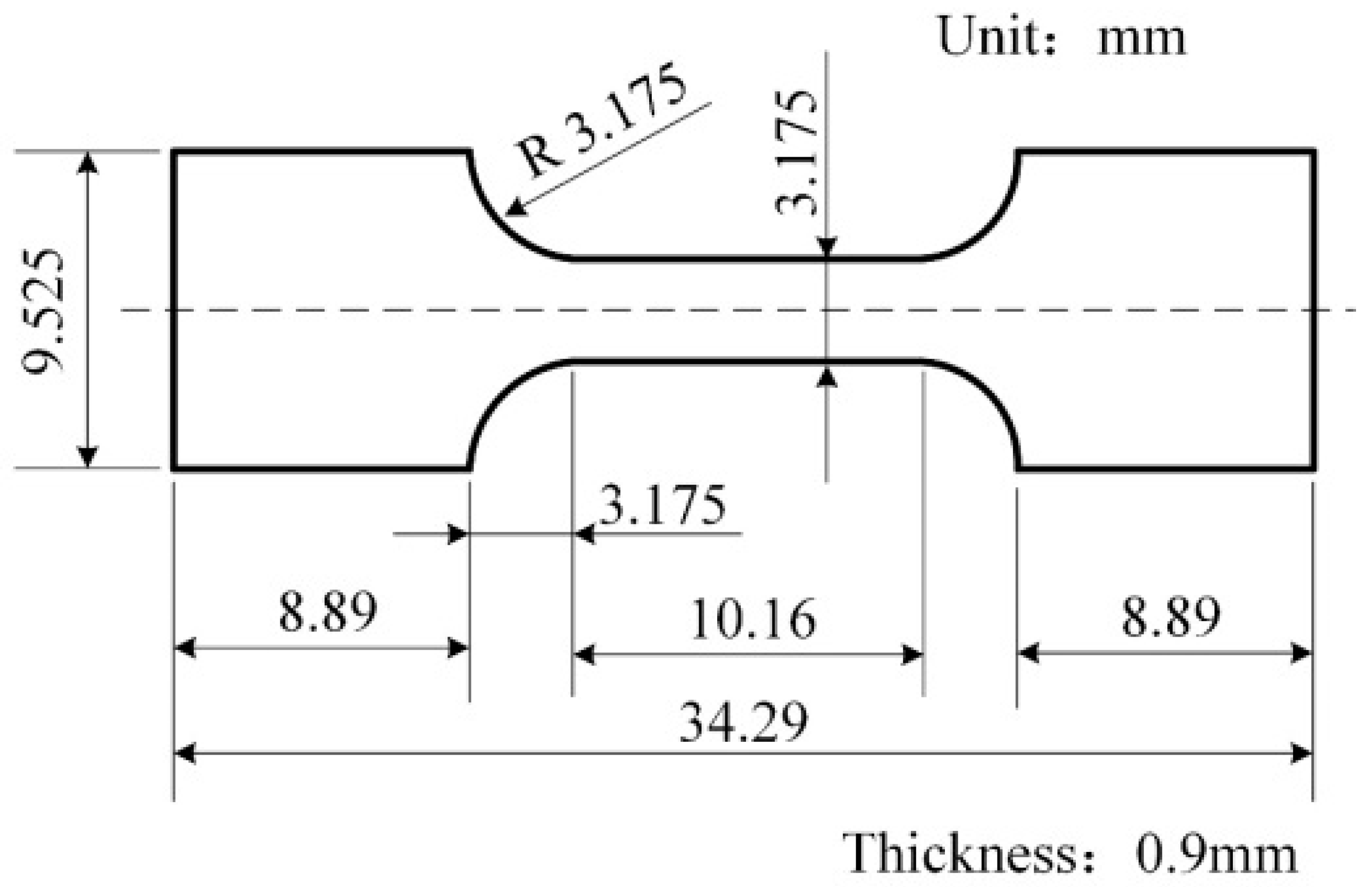

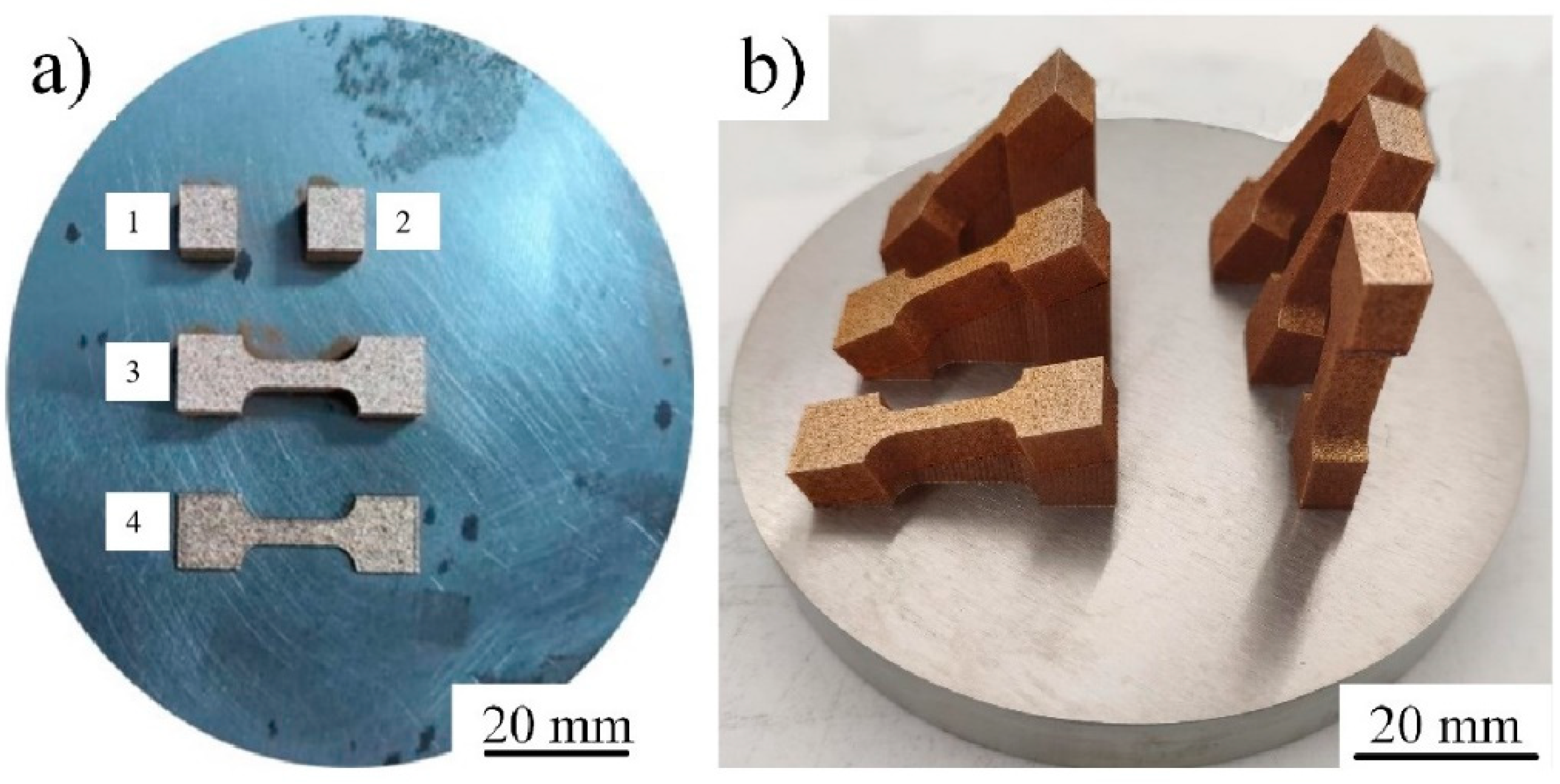

2. Materials and Methods

2.1. Materials

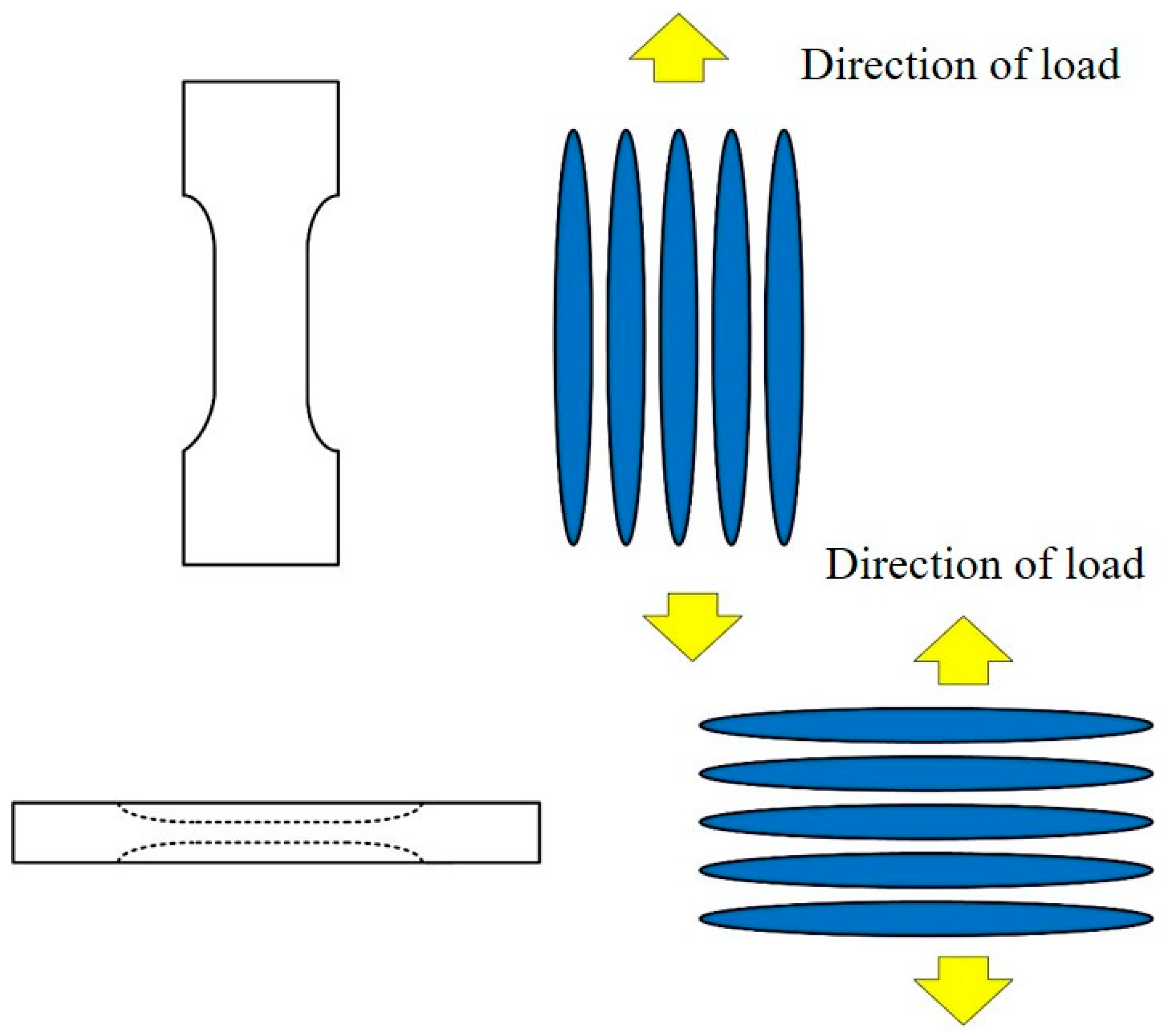

2.2. LPBF Process and Machine

2.3. Analysis

3. Results and Discussion

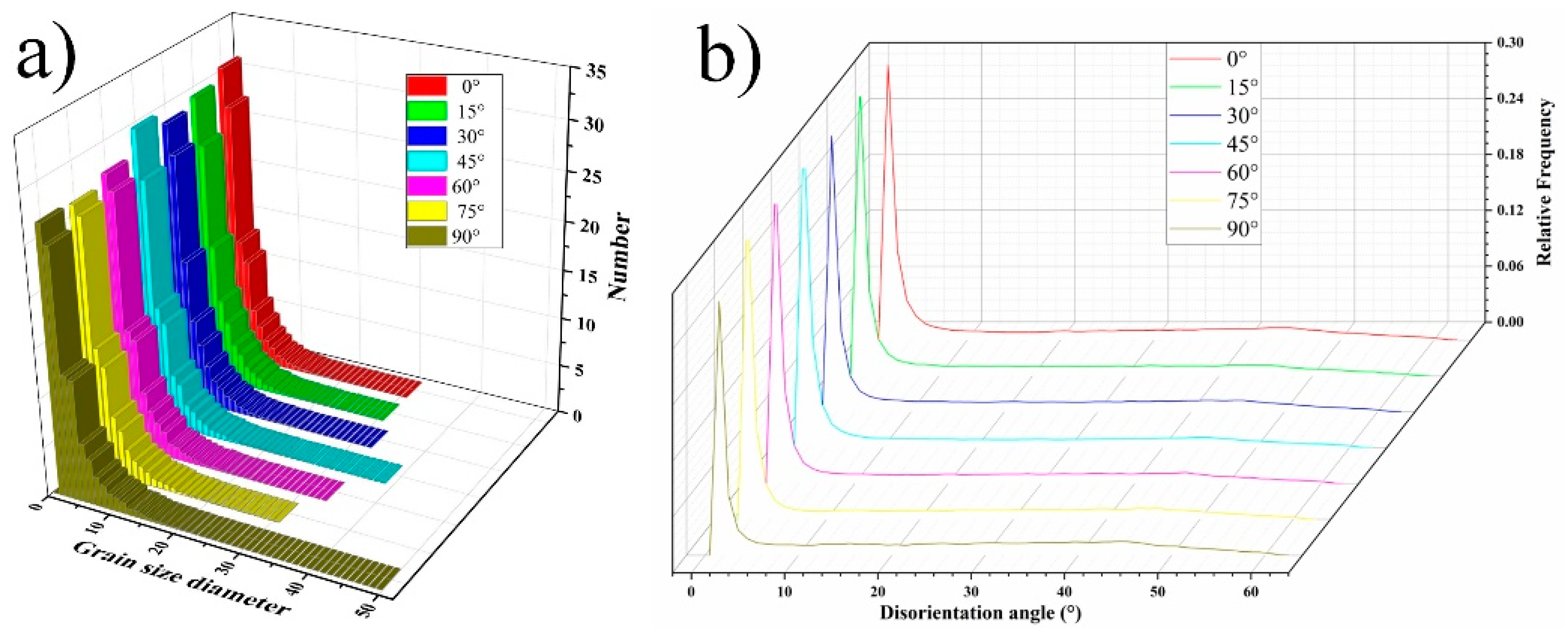

3.1. Phase and Microstructures

3.2. Mechanical Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karthik, M.; Abhinav, J.; Shankar, K. Morphological and mechanical behaviour of Cu–Sn alloys—A review. Met. Mater. Int. 2021, 27, 1915–1946. [Google Scholar] [CrossRef]

- Manu, K.; Jezierski, J.; Ganesh, M.; Shankar, K.; Narayanan, S. Titanium in cast Cu-Sn alloys—A review. Materials 2021, 14, 4587. [Google Scholar] [CrossRef]

- Kannojia, H.; Dixit, P. A review of intermetallic compound growth and void formation in electrodeposited Cu–Sn Layers for microsystems packaging. J. Mater. Sci.-Mater. Electron. 2021, 32, 6742–6777. [Google Scholar] [CrossRef]

- Walsh, F.; Low, C. A review of developments in the electrodeposition of tin-copper alloys. Surf. Coat. Technol. 2016, 304, 246–262. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, D.; Jiang, J.; Fu, G.; Zhang, P. Processing optimisation, mechanical properties and microstructural evolution during selective laser melting of Cu-15Sn high-tin bronze. Mater. Sci. Eng. A 2018, 721, 125–134. [Google Scholar] [CrossRef]

- Maddin, R. The history of the evolution and development of metal. In Proceedings of the Forum for International Conference on the Beginning of the Use of Metals and Alloys (BUMA-IV), Shimane, Japan, 16–17 January 1996. [Google Scholar]

- Chiavari, C.; Colledan, A.; Frignani, A.; Brunoro, G. Corrosion evaluation of traditional and new bronzes for artistic castings. Mater. Chem. Phys. 2006, 95, 252–259. [Google Scholar] [CrossRef]

- Tavakoli, A.; Liu, R.; Wu, X. Improved mechanical and tribological properties of tin–bronze journal bearing materials with newly developed tribaloy alloy additive. Mater. Sci. Eng. A 2008, 489, 389–402. [Google Scholar] [CrossRef]

- Korkmaz, M.; Gupta, M.; Robak, G. Development of lattice structure with selective laser melting process: A state of the art on properties, future trends and challenges. J. Manuf. Process. 2022, 81, 1040–1063. [Google Scholar] [CrossRef]

- Sajjad, U.; Rehman, T.; Ali, M.; Park, C.; Yan, W. Manufacturing and potential applications of lattice structures in thermal systems: A comprehensive review of recent advances. Int. J. Heat Mass Transf. 2022, 198, 123352. [Google Scholar] [CrossRef]

- Zhao, M.; Ji, B.; Zhang, D.; Li, H.; Zhou, H. Design and mechanical performances of a novel functionally graded sheet-based lattice structure. Addit. Manuf. 2022, 52, 102676. [Google Scholar] [CrossRef]

- Zhao, M.; Li, X.; Zhang, D.; Zhai, W. TPMS-based interpenetrating lattice structures: Design, mechanical properties and multiscale optimization. Int. J. Mech. Sci. 2023, 244, 108092. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Ding, D.; Tang, H.; Qiu, L.; Luo, X.; Shi, G. Strengthening and toughening strategies for tin bronze alloy through fabricating in-situ nanostructured grains. Mater. Des. 2015, 66, 60–66. [Google Scholar] [CrossRef]

- Yang, P.; He, D.; Lu, S.; Chen, S.; Oleksandr, D.; Guo, X. Influence of surface micro-oxidation on the formability of pure copper powders by selective laser melting. J. Mater. Res. Technol. 2024, 28, 4350–4357. [Google Scholar] [CrossRef]

- Tümer, E.; Erbil, H. Extrusion-based 3D printing applications of PLA composites: A review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Horn, T.; Harrysson, O. Overview of current additive manufacturing technologies and selected applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, Y.; Chen, X. The development situation of selective laser melting metal powder based on 3D printing, Applied Mechanics and Materials. Appl. Mech. Mater. 2014, 518, 12–18. [Google Scholar] [CrossRef]

- Chen, L.; Liang, S.; Liu, Y.; Zhang, L. Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges. Mater. Sci. Eng. R Rep. 2021, 146, 100648. [Google Scholar] [CrossRef]

- Ventura, A.; Wade, C.; Pawlikowski, G.; Bayes, M.; Watanabe, M.; Misiolek, W. Mechanical properties and microstructural characterization of Cu-4.3 Pct Sn fabricated by selective laser melting. Metall. Mater. Trans. A 2017, 48, 178–187. [Google Scholar] [CrossRef]

- Yang, P.; He, D.; Wang, Z.; Tan, Z.; Fu, H.; Shao, W.; Guo, X. Investigation of selective laser melting process for Cu-5Sn alloy on surface roughness, microstructure and mechanical property. Rapid Prototyp. J. 2021, 28, 10–20. [Google Scholar] [CrossRef]

- Loh, L.; Chua, C.; Yeong, W.; Song, J.; Mapar, M.; Sing, S.; Liu, Z.; Zhang, D. Numerical investigation and an effective modelling on the Selective Laser Melting (SLM) process with aluminium alloy 6061. Int. J. Heat Mass Transf. 2015, 80, 288–300. [Google Scholar] [CrossRef]

- Yang, P.; Guo, X.; He, D.; Shao, W.; Tan, Z.; Fu, h.; Zhang, X. Microstructure Twinning and Mechanical Properties of Laser Melted Cu-10Sn Alloy for High Strength and Plasticity. J. Mater. Eng. Perform. 2022, 31, 2624–2632. [Google Scholar] [CrossRef]

- Yang, P.; He, D.; Shao, W.; Tan, Z.; Guo, X.; Lu, S.; Anton, K. Study of the microstructure and mechanical properties of Cu–Sn alloys formed by selective laser melting with different Sn contents. J. Mater. Res. Technol. 2023, 24, 5476–5485. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.; Humbeeck, J.V. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Donoghue, J.; Antonysamy, A.; Martina, F.; Colegrove, P.; Williams, S.; Prangnell, P. The effectiveness of combining rolling deformation with Wire–Arc Additive Manufacture on β-grain refinement and texture modification in Ti–6Al–4V. Mater. Charact. 2016, 114, 103–114. [Google Scholar] [CrossRef]

- Bacchewar, P.; Singhal, S.; Pandey, P. Statistical modelling and optimization of surface roughness in the selective laser sintering process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 35–52. [Google Scholar] [CrossRef]

- Antonysamy, A. Microstructure, Texture and Mechanical Property Evolution during Additive Manufacturing of Ti6Al4V Alloy for Aerospace Applications. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and mechanical properties of additive manufactured copper alloy. Mater. Lett. 2016, 15, 38–41. [Google Scholar] [CrossRef]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Z.; Liu, J.; Wang, L.; Zhu, S.; Yang, G.; Gong, S.; Wang, Q.; Yang, R. Deformation behaviors of as-built and hot isostatically pressed Ti-6Al-4V alloys fabricated via electron beam rapid manufacturing. J. Mater. Sci. Technol. 2019, 35, 2552–2558. [Google Scholar] [CrossRef]

- Lu, J.; Chang, L.; Wang, J.; Sang, L.; Wu, S.; Zhang, Y. In-situ investigation of the anisotropic mechanical properties of laser direct metal deposition Ti6Al4V alloy. Mater. Sci. Eng. A 2018, 712, 199–205. [Google Scholar] [CrossRef]

- Ren, M.; Lin, X.; Fu, X.; Tan, H.; Chen, J.; Huang, D. Microstructure and deformation behavior of Ti-6Al-4V alloy by high-power laser solid forming. Acta Mater. 2017, 132, 82–95. [Google Scholar] [CrossRef]

- Carroll, E.; Palmer, A.; Beese, M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

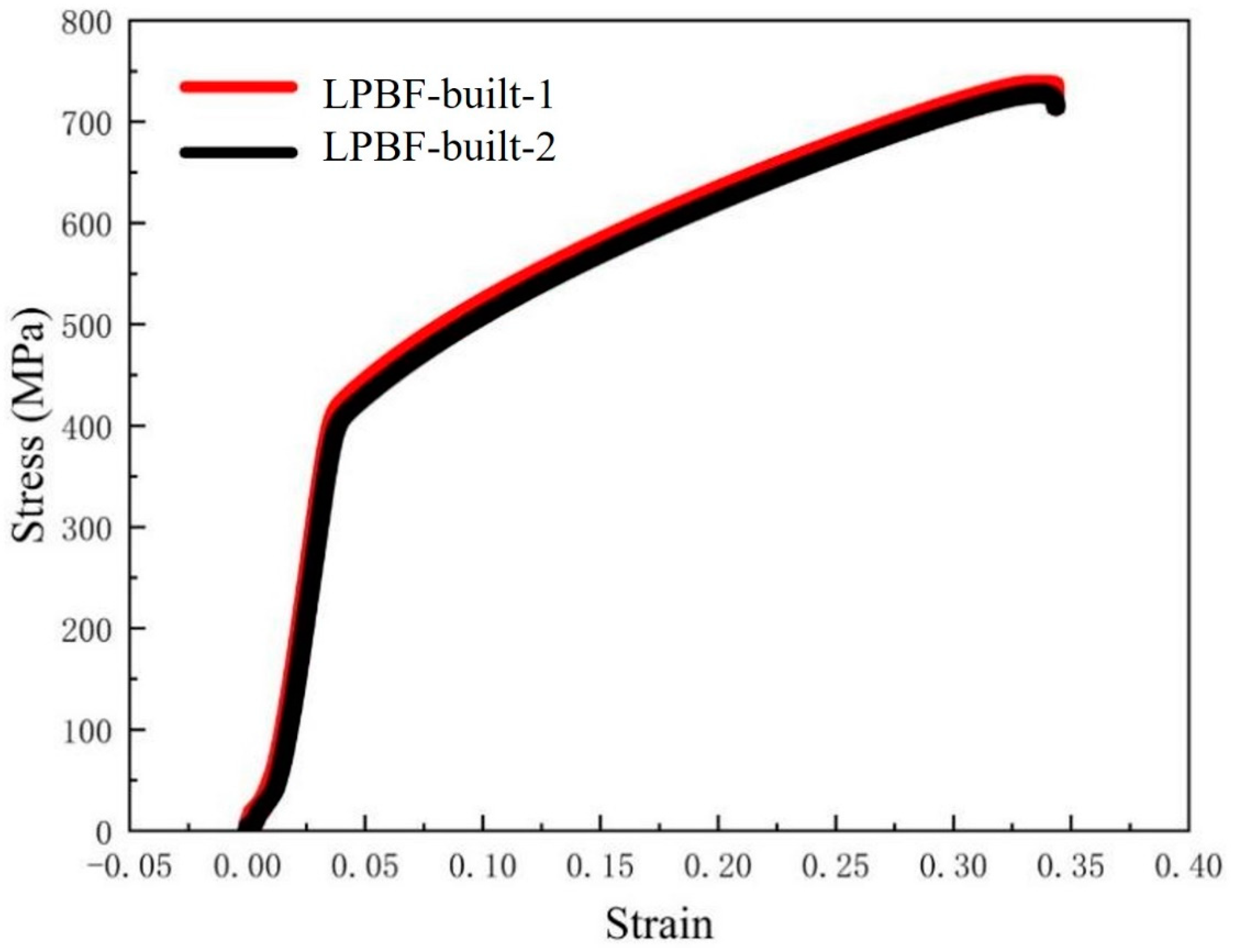

| Specimen | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| LPBF-built-1 | 376 2 | 742 2 | 33 0.5 |

| LPBF-built-2 | 374 2 | 736 2 | 33 0.5 |

| Specimen | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 0° | 386 3 | 723.17 3 | 33 0.5 |

| 15 | 391 5 | 700.12 5 | 28 0.5 |

| 30° | 390 2 | 696.56 2 | 26 0.5 |

| 45° | 341 3 | 605.85 3 | 19 0.5 |

| 60° | 355 2 | 636.94 2 | 23 0.5 |

| 75° | 376 3 | 622.67 3 | 21 0.5 |

| 90° | 379 2 | 557.96 2 | 12 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, P.; He, D.; Guo, X.; Lu, S.; Chen, S.; Shang, F.; Oleksandr, D.; Chen, L. Effect of Printing Orientation on the Mechanical Properties of 3D-Printed Cu–10Sn Alloys by Laser Powder Bed Fusion Technology. Metals 2024, 14, 660. https://doi.org/10.3390/met14060660

Yang P, He D, Guo X, Lu S, Chen S, Shang F, Oleksandr D, Chen L. Effect of Printing Orientation on the Mechanical Properties of 3D-Printed Cu–10Sn Alloys by Laser Powder Bed Fusion Technology. Metals. 2024; 14(6):660. https://doi.org/10.3390/met14060660

Chicago/Turabian StyleYang, Peng, Dingyong He, Xingye Guo, Sheng Lu, Shujin Chen, Fanmin Shang, Dubovyy Oleksandr, and Liangyu Chen. 2024. "Effect of Printing Orientation on the Mechanical Properties of 3D-Printed Cu–10Sn Alloys by Laser Powder Bed Fusion Technology" Metals 14, no. 6: 660. https://doi.org/10.3390/met14060660

APA StyleYang, P., He, D., Guo, X., Lu, S., Chen, S., Shang, F., Oleksandr, D., & Chen, L. (2024). Effect of Printing Orientation on the Mechanical Properties of 3D-Printed Cu–10Sn Alloys by Laser Powder Bed Fusion Technology. Metals, 14(6), 660. https://doi.org/10.3390/met14060660