Optimization of Mechanical Properties of High-Manganese Steel for LNG Storage Tanks: A Comprehensive Review of Alloying Element Effects

Abstract

:1. Introduction

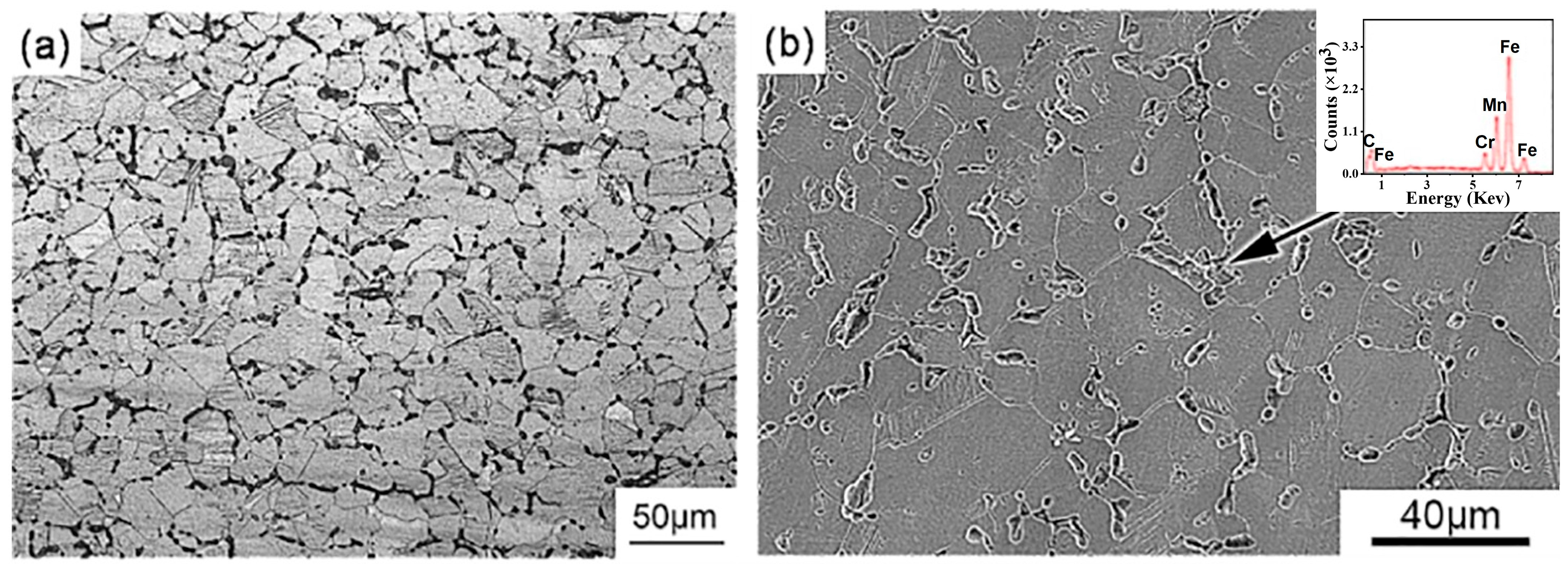

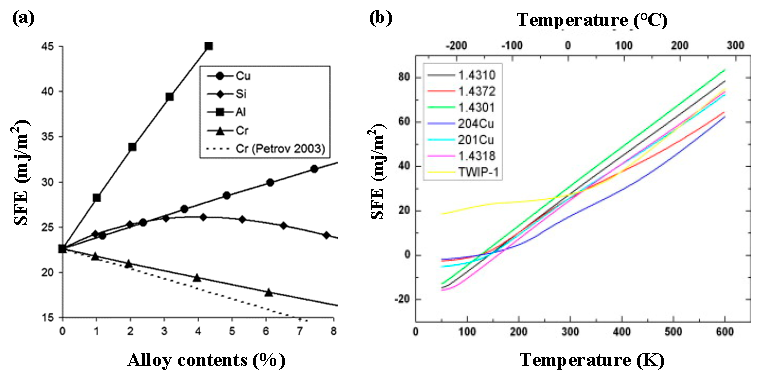

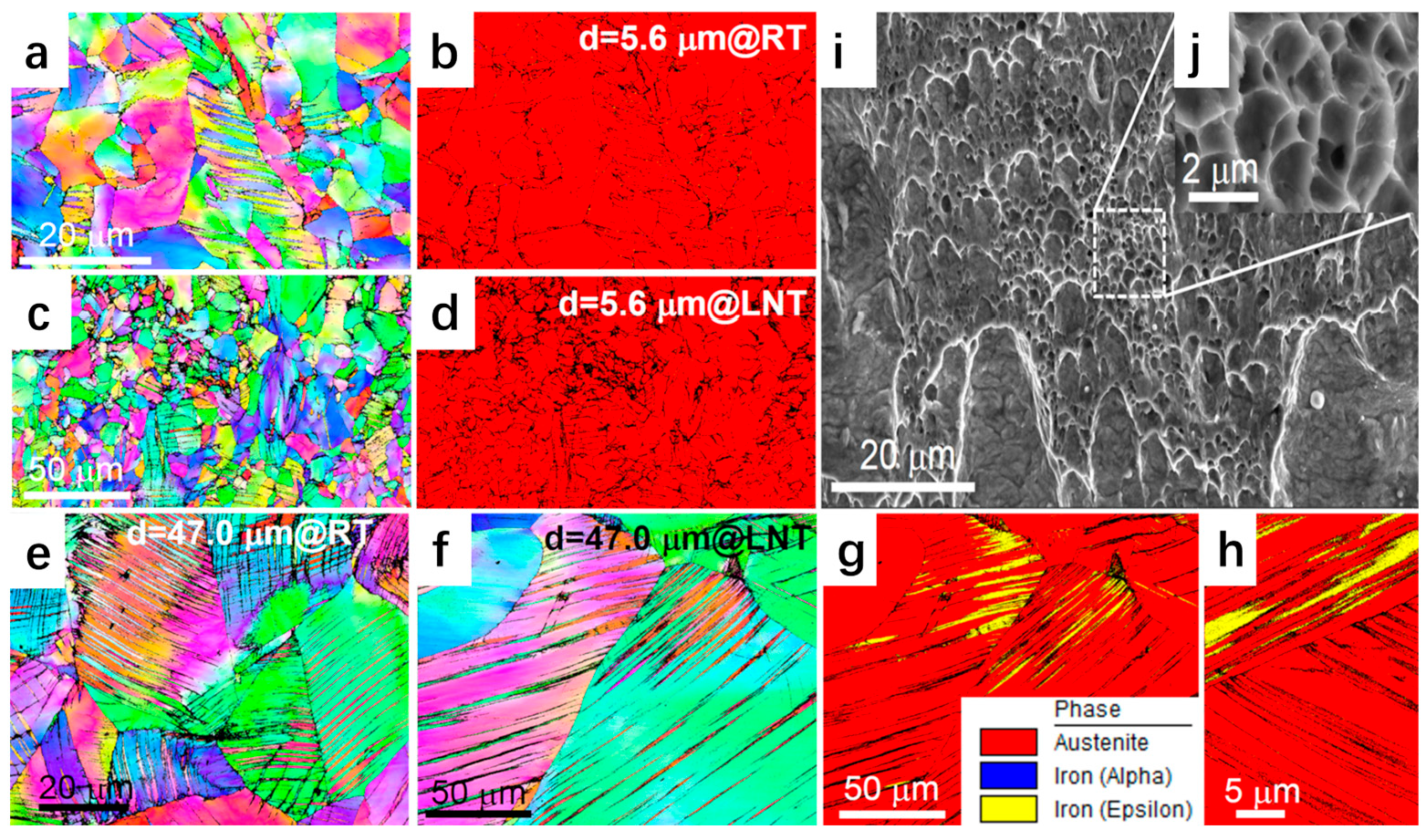

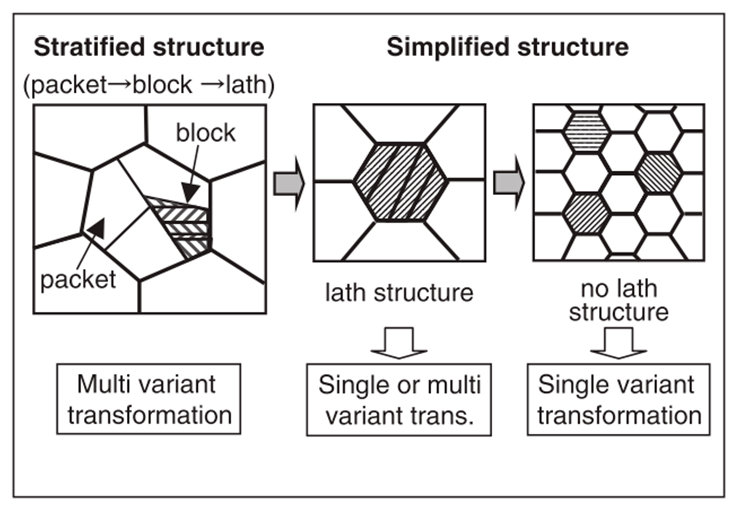

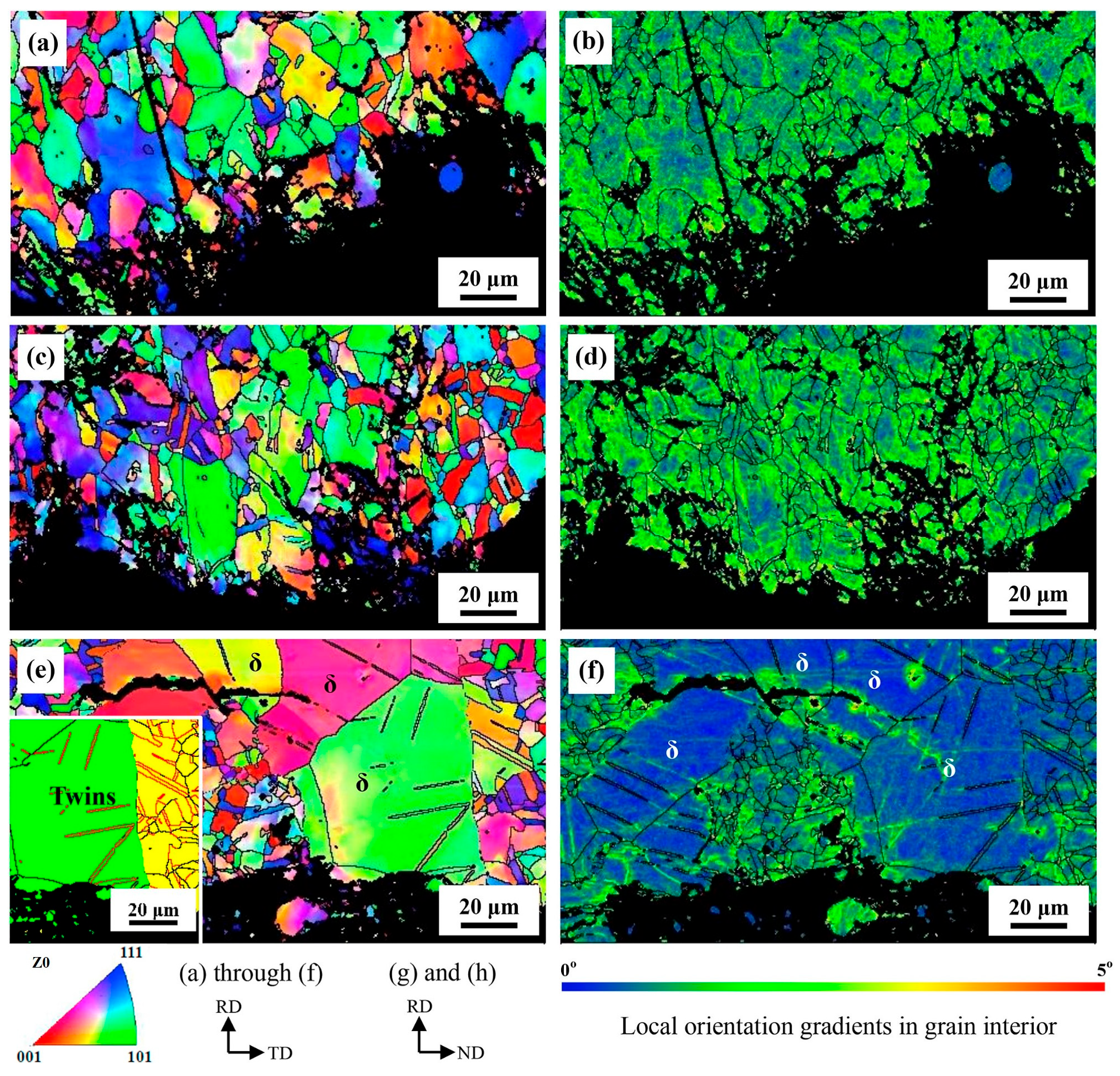

2. Deformation Mechanism of High-Manganese Steel

3. Low Temperature Brittleness of High-Manganese Steel

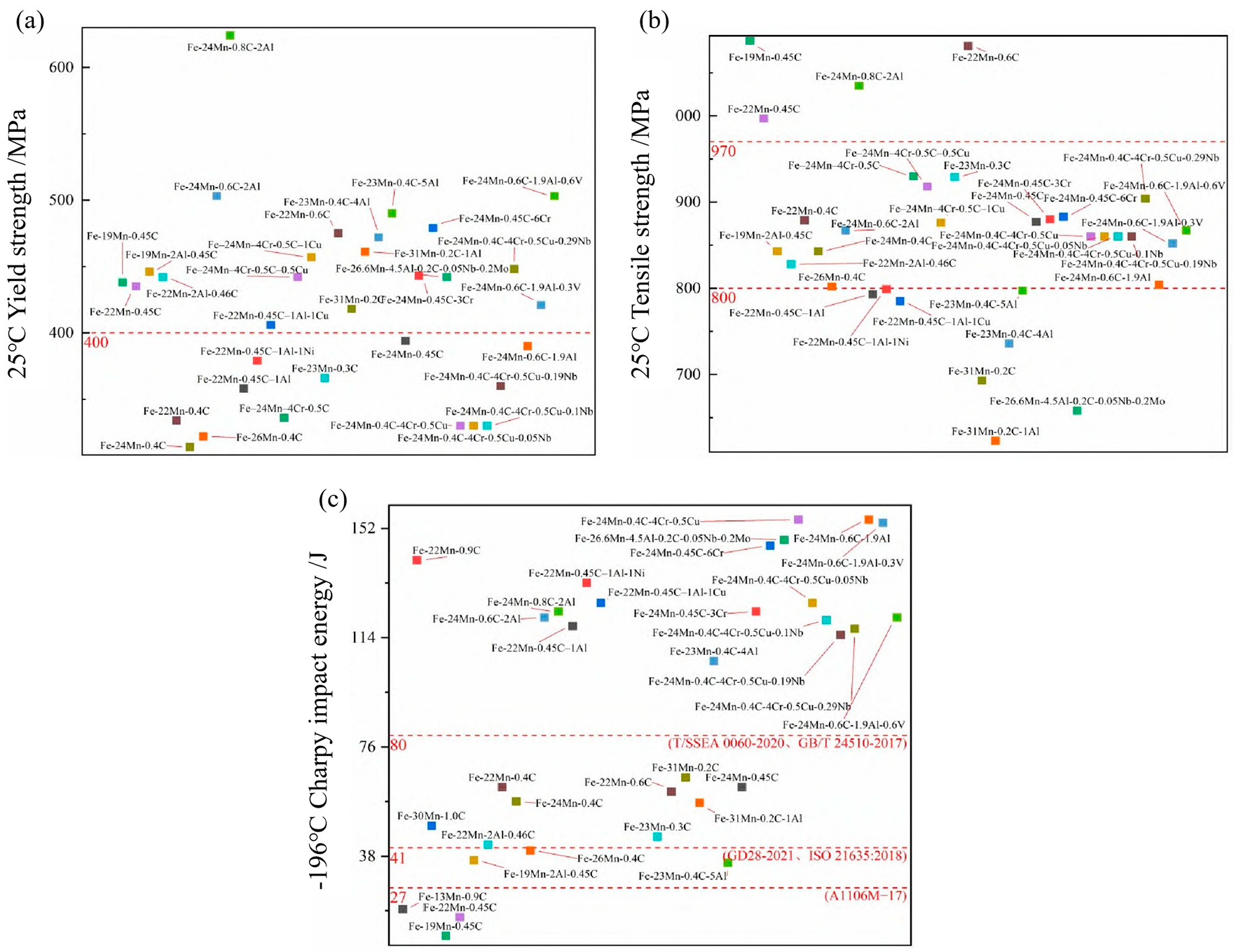

4. Effect of Alloying Elements on High-Manganese Steel

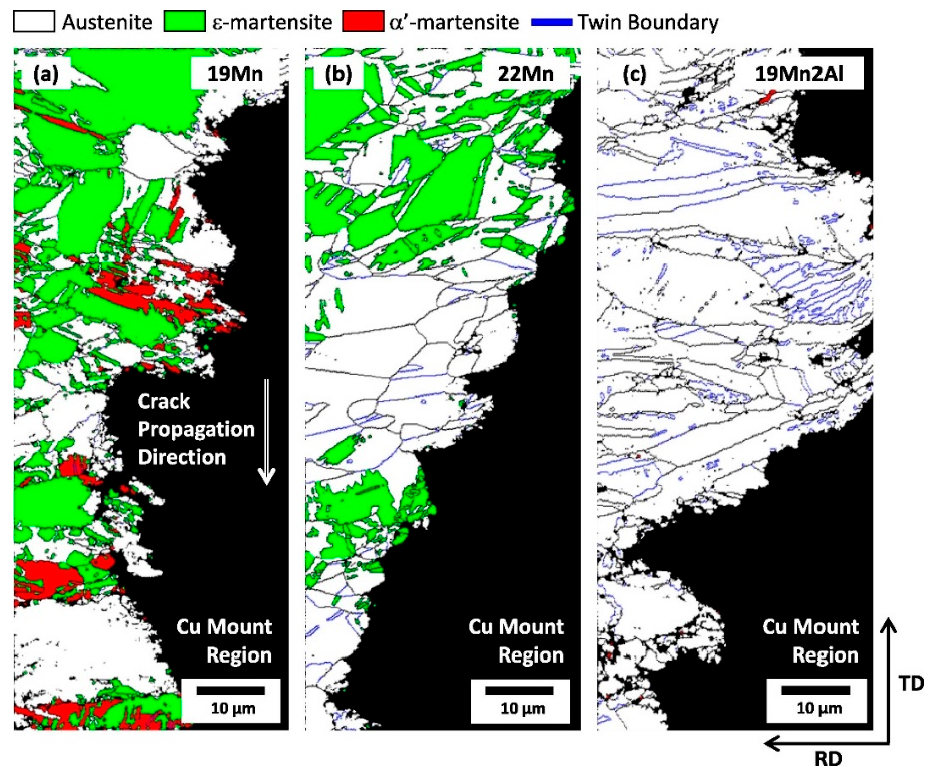

4.1. Mn

4.2. Al

4.3. Cr

4.4. C

5. Effect of Microalloying Elements on High-Manganese Steel

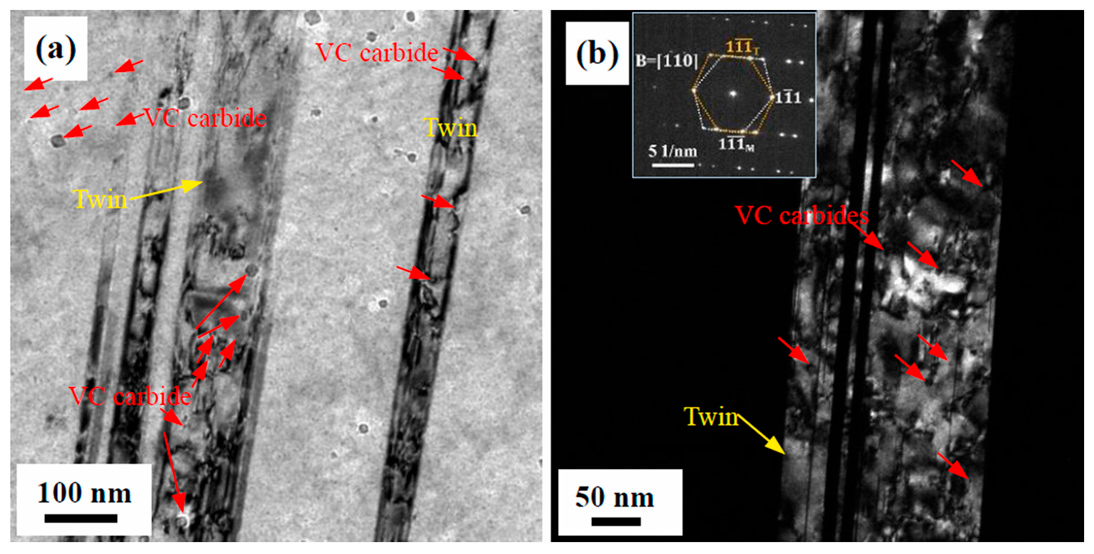

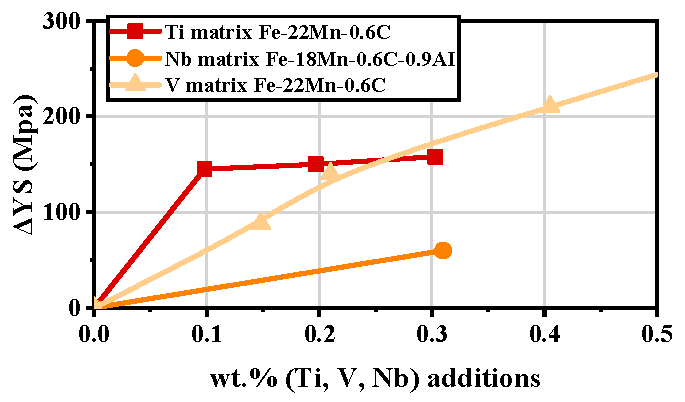

5.1. V

5.2. Nb

5.3. Ti

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, B.; Wang, T. Forecasting natural gas supply in China: Production peak and import trends. Energe Policy 2012, 49, 225–233. [Google Scholar] [CrossRef]

- Zou, C.; Zhao, Q.; Chen, J.; Li, J.; Yang, Z.; Sun, Q.; Lu, J.; Zhang, G. Natural gas in China: Development trend and strategic forecast. Nat. Gas Ind. B 2018, 5, 380–390. [Google Scholar] [CrossRef]

- Jia, W.; Gong, C.; Pan, K.; Yu, S. Potential changes of regional natural gas market in China amidst liberalization: A mixed complementarity equilibrium simulation in 2030. Energy 2023, 284, 129254. [Google Scholar] [CrossRef]

- Liu, Y.-Z.; Yang, C.-F.; Chai, F.; Pan, T.; Su, H. High temperature oxidation resistance of 9Ni steel. J. Iron Steel Res. Int. 2014, 21, 956–963. [Google Scholar] [CrossRef]

- Nagao, A.; Smith, C.D.; Dadfarnia, M.; Sofronis, P.; Robertson, I.M. The role of hydrogen in hydrogen embrittlement fracture of lath martensitic steel. Acta Mater. 2012, 60, 5182–5189. [Google Scholar] [CrossRef]

- Toshie, S.; Albertini, C.; Mentani, Y. Impact tensile properties of nine per cent nickel steel. J. Soc. Mater. Sci. Jpn. 1997, 46, 1286–1292. [Google Scholar] [CrossRef]

- Kinney, C.C.; Pytlewski, K.R.; Khachaturyan, A.G.; Morris, J.W. The microstructure of lath martensite in quenched 9Ni steel. Acta Mater. 2014, 69, 372–385. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, Y.; Jiang, X.; Wang, J. Research progress on materials for LNG carriers and their storage tanks. Mater. Rep. 2013, 27, 71–74. [Google Scholar]

- Xu, J. Analysis of the impact of changes in bulk material prices on the cost of LNG receiving terminal storage tank projects. China Pet. Chem. Stand. Qual. 2022, 42, 2. [Google Scholar]

- Yang, Y.; Qin, H.; Yuan, S.; Liang, G. Simulation of Rapid Tempering Process for 7% Ni Steel for LNG. J. Iron Steel Res. 2019, 31, 1080–1085. [Google Scholar]

- Wang, M.; Liu, Z.-Y.; Li, C.-G. Correlations of Ni contents, formation of reversed austenite and toughness for Ni-containing cryogenic steels. Acta Met. Sin.-Engl. 2017, 30, 238–249. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brüx, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. Isij Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Z.-Y.; Wang, G.-D. Exploring the improvement of strength and cryogenic impact toughness in hot-rolled high Mn austenitic steel for cryogenic application. J. Mater. Res. Technol. 2022, 21, 3732–3745. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, L.; Shang, X.; Li, G.; Qi, X.; Liu, P.; Li, B.; Wang, X.; Xu, X.; Shang, C. Dynamic recrystallization behavior and microstructure evolution of high-Mn austenitic steel for application in a liquefied natural gas carrier. J. Mater. Res. Technol. 2023, 27, 5479–5488. [Google Scholar] [CrossRef]

- Han, K.; Yoo, J.; Lee, B.; Han, I.; Lee, C. Effect of Ni on the hot ductility and hot cracking susceptibility of high Mn austenitic cast steel. Mater. Sci. Eng. A 2014, 618, 295–304. [Google Scholar] [CrossRef]

- Lee, J.; Sohn, S.S.; Hong, S.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn Addition on Tensile and Charpy Impact Properties in Austenitic Fe-Mn-C-Al-Based Steels for Cryogenic Applications. Met. Mater. Trans. A 2014, 45, 5419–5430. [Google Scholar] [CrossRef]

- Qi, X.; Yan, L.; Wang, C.; Zhang, P.; Li, G. Development of high manganese steel medium thick plate production technology for LNG storage tank. Steel Roll. 2023, 40, 24–29. [Google Scholar]

- Kim, B.; Lee, S.G.; Kim, D.W.; Jo, Y.H.; Bae, J.; Sohn, S.S.; Lee, S. Effects of Ni and Cu addition on cryogenic-temperature tensile and Charpy impact properties in austenitic 22Mn-0.45C-1Al steels. J. Alloys Compd. 2020, 815, 152407. [Google Scholar] [CrossRef]

- Wang, H.H.; Luo, Q.; Wan, X.L.; Li, L.; Wu, K.M.; Misra, R.D.K. Design of novel Fe-Mn-Ni cryogenic steel: Microstructure-property relationship during simulated welding. Sci. Technol. Weld. Join. 2018, 23, 125–133. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Li, W.; Khedr, M.; Liu, H.; Jin, X. Hierarchical microstructure design of a bimodal grained twinning-induced plasticity steel with excellent cryogenic mechanical properties. Acta Mater. 2018, 158, 79–94. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Lee, S.G.; Kim, B.; Jo, M.C.; Kim, K.-M.; Lee, J.; Bae, J.; Lee, B.-J.; Sohn, S.S.; Lee, S. Effects of Cr addition on Charpy impact energy in austenitic 0.45C-24Mn-(0,3,6)Cr steels. J. Mater. Sci. Technol. 2020, 50, 21–30. [Google Scholar] [CrossRef]

- Ren, J.-K.; Chen, Q.-Y.; Chen, J.; Liu, Z.-Y. Role of vanadium additions on tensile and cryogenic-temperature charpy impact properties in hot-rolled high-Mn austenitic steels. Mater. Sci. Eng. A 2021, 811, 141063. [Google Scholar] [CrossRef]

- Sun, X.; Wang, X. Microstructure and Mechanical Properties of a Hot-rolled High Manganese TWIP Steel Containing 0.3% V. Isij Int. 2020, 60, 1324–1332. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Shan, Q.; Li, Z.; Jiang, Y.; Ge, R. Influence of heat-treatment on enhancement of yield strength and hardness by Ti-V-Nb alloying in high-manganese austenitic steel. Metals 2019, 9, 299. [Google Scholar] [CrossRef]

- Zhou, Z.; Shan, Q.; Jiang, Y.; Li, Z.; Zhang, Z. Effect of nanoscale V2C precipitates on the three-body abrasive wear behavior of high-Mn austenitic steel. Wear 2019, 436, 203009. [Google Scholar] [CrossRef]

- Wang, X.; Sun, X.; Song, C.; Chen, H.; Tong, S.; Han, W.; Pan, F. Evolution of microstructures and mechanical properties during solution treatment of a Ti–V–Mo-containing high-manganese cryogenic steel. Mater. Charact. 2018, 135, 287–294. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.-P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater. Sci. Eng. A 2008, 483, 184–187. [Google Scholar] [CrossRef]

- Jeong, K.; Jin, J.-E.; Jung, Y.-S.; Kang, S.; Lee, Y.-K. The effects of Si on the mechanical twinning and strain hardening of Fe–18Mn–0.6 C twinning-induced plasticity steel. Acta Mater. 2013, 61, 3399–3410. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Choi, C. Driving force for γ→ ε martensitic transformation and stacking fault energy of γ in Fe-Mn binary system. Met. Mater. Trans. A 2000, 31, 355–360. [Google Scholar] [CrossRef]

- Wang, S.-h.; Liu, Z.-y.; Wang, G.-d.; Liu, J.-L.; Liang, G.-F.; Li, Q.-l. Effects of twin-dislocation and twin-twin interactions on the strain hardening behavior of TWIP steels. J. Iron Steel Res. Int. 2010, 17, 70–74. [Google Scholar] [CrossRef]

- Liang, X.; McDermid, J.; Bouaziz, O.; Wang, X.; Embury, J.; Zurob, H. Microstructural evolution and strain hardening of Fe–24Mn and Fe–30Mn alloys during tensile deformation. Acta Mater. 2009, 57, 3978–3988. [Google Scholar] [CrossRef]

- Yang, H.; Doquet, V.; Zhang, Z. Micro-scale measurements of plastic strain field, and local contributions of slip and twinning in TWIP steels during in situ tensile tests. Mater. Sci. Eng. A 2016, 672, 7–14. [Google Scholar] [CrossRef]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L. High strength Fe–Mn–(Al, Si) TRIP/TWIP steels development—Properties—Application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- Han, Y.S.; Hong, S.H. The effect of Al on mechanical properties and microstructures of Fe-32Mn-12Cr-xAl-0.4 C cryogenic alloys. Mater. Sci. Eng. A 1997, 222, 76–83. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Van der Wegen, G.; Bronsveld, P.; De Hosson, J.T.M. A comparison between different theories predicting the stacking fault energy from extended nodes. Scr. Met. 1980, 14, 285–288. [Google Scholar] [CrossRef]

- Peng, X.; Zhu, D.; Hu, Z.; Yi, W.; Liu, H.; Wang, M. Stacking fault energy and tensile deformation behavior of high-carbon twinning-induced plasticity steels: Effect of Cu addition. Mater. Des. 2013, 45, 518–523. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

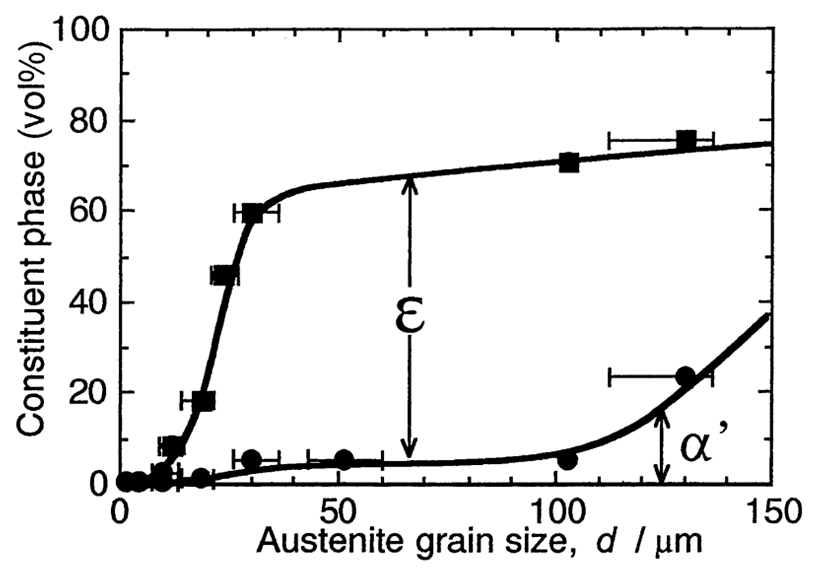

- Jun, J.-H.; Choi, C.-S. Variation of stacking fault energy with austenite grain size and its effect on the MS temperature of γ→ ε martensitic transformation in Fe–Mn alloy. Mater. Sci. Eng. A 1998, 257, 353–356. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Zaefferer, S.; Raabe, D. The effect of grain size and grain orientation on deformation twinning in a Fe-22 wt.% Mn-0.6 wt.% C TWIP steel. Mater. Sci. Eng. A 2010, 527, 3552–3560. [Google Scholar] [CrossRef]

- Lee, S.I.; Lee, S.Y.; Han, J.; Hwang, B. Deformation behavior and tensile properties of an austenitic Fe-24Mn-4Cr-0.5C high-manganese steel: Effect of grain size. Mater. Sci. Eng. A 2019, 742, 334–343. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Y.; Jiang, H.; Liao, M.; Qu, N.; Han, T.; Lai, Z.; Zhu, J. A novel FeCrNiAlTi-based high entropy alloy strengthened by refined grains. J. Alloys Compd. 2020, 823, 153729. [Google Scholar] [CrossRef]

- Dai, Y.; Mi, Z.; Tang, D.; Lu, J. Effects of aluminum, copper, and chromium alloy elements on stacking fault energy and mechanical properties of Fe-21Mn-0.4 C TWIP/TRIP steel. J. Iron Steel Res. 2011, 23, 32–36. [Google Scholar]

- Rao, P.R.; Kutumbarao, V. Developments in austenitic steels containing manganese. Int. Mater. Rev. 1989, 34, 69–92. [Google Scholar] [CrossRef]

- Xue, K.; Rong, Z.; Jing, X.; Fang, J. The improvement of low temperature toughness of high manganese austenitic steels. Adv. Cryog. Eng. Mat. 1988, 34, 501. [Google Scholar]

- Herbig, M.; Kuzmina, M.; Haase, C.; Marceau, R.K.; Gutiérrez-Urrutia, I.; Haley, D.; Molodov, D.A.; Choi, P.; Raabe, D. Grain boundary segregation in Fe–Mn–C twinning-induced plasticity steels studied by correlative electron backscatter diffraction and atom probe tomography. Acta Mater. 2015, 83, 37–47. [Google Scholar] [CrossRef]

- Chai, S. Low temperature brittleness of austenitic Fe-Mn alloys. Acta Metall. Sin. 1988, 24, 24–29. [Google Scholar]

- Chen, J.; Liu, N.; Liu, Z.Y.; Wang, G.D. Alloying design and toughness of high manganese steel for LNG storage tanks. China Metall. 33, 73–80.

- Zhang, W.; Liu, Z.; Wang, G. Deformation-induced martensite transformation and work hardening behavior of high manganese TRIP steel. Acta Metall. Sin. 2010, 46, 1230–1236. [Google Scholar] [CrossRef]

- Han, J.; Lee, S.-J.; Jung, J.-G.; Lee, Y.-K. The effects of the initial martensite microstructure on the microstructure and tensile properties of intercritically annealed Fe–9Mn–0.05 C steel. Acta Mater. 2014, 78, 369–377. [Google Scholar] [CrossRef]

- Han, J.; Nam, J.-H.; Lee, Y.-K. The mechanism of hydrogen embrittlement in intercritically annealed medium Mn TRIP steel. Acta Mater. 2016, 113, 1–10. [Google Scholar] [CrossRef]

- Koyama, M.; Lee, T.; Lee, C.S.; Tsuzaki, K. Grain refinement effect on cryogenic tensile ductility in a Fe–Mn–C twinning-induced plasticity steel. Mater. Des. 2013, 49, 234–241. [Google Scholar] [CrossRef]

- Chun, Y.S.; Park, K.-T.; Lee, C.S. Delayed static failure of twinning-induced plasticity steels. Scr. Mater. 2012, 66, 960–965. [Google Scholar] [CrossRef]

- Kim, H.; Park, J.; Jung, J.E.; Sohn, S.S.; Lee, S. Interpretation of cryogenic-temperature Charpy fracture initiation and propagation energies by microstructural evolution occurring during dynamic compressive test of austenitic Fe–(0.4, 1.0) C–18Mn steels. Mater. Sci. Eng. A 2015, 641, 340–347. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, T.-H.; Kim, S.-J. Effects of deformation-induced martensite and grain size on ductile-to-brittle transition behavior of austenitic 18Cr-10Mn-N stainless steels. Met. Mater. Int. 2010, 16, 905–911. [Google Scholar] [CrossRef]

- Tian, Y.; Bai, Y.; Chen, M.; Shibata, A.; Terada, D.; Tsuji, N. Enhanced strength and ductility in an ultrafine-grained Fe-22Mn-0.6 C austenitic steel having fully recrystallized structure. Met. Mater. Trans. A 2014, 45, 5300–5304. [Google Scholar] [CrossRef]

- Fang, X.; Yang, P.; Lu, F.; Meng, L. Dependence of Deformation Twinning on Grain Orientation and Texture Evolution of High Manganese TWIP Steels at Different Deformation Temperatures. J. Iron Steel Res. Int. 2011, 18, 7. [Google Scholar] [CrossRef]

- Moor, E.D.; Matlock, D.K.; Speer, J.G.; Merwin, M.J. Austenite stabilization through manganese enrichment. Scr. Mater. 2011, 64, 185–188. [Google Scholar] [CrossRef]

- Tomimura, K.; Takaki, S.; Tanimoto, S.; Tokunaga, Y. Optimal chemical composition in Fe-Cr-Ni alloys for ultra grain refining by reversion from deformation induced martensite. Isij Int. 1991, 31, 721–727. [Google Scholar] [CrossRef]

- Guimarães, J.; Rios, P. Martensite start temperature and the austenite grain-size. J. Mater. Sci. 2010, 45, 1074–1077. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Godfrey, A.; Kang, J.; Peng, Y.; Wang, T.; Hansen, N.; Huang, X. Cryogenic toughness in a low-cost austenitic steel. Commun. Mater. 2021, 2, 44. [Google Scholar] [CrossRef]

- Takaki, S.; Nakatsu, H.; Tokunaga, Y. Effects of austenite grain size on ε martensitic transformation in Fe-15mass% Mn alloy. Mater. Trans. JIM 1993, 34, 489–495. [Google Scholar] [CrossRef]

- Takaki, S.; Fukunaga, K.; Syarif, J.; Tsuchiyama, T. Effect of grain refinement on thermal stability of metastable austenitic steel. Mater. Trans. 2004, 45, 2245–2251. [Google Scholar] [CrossRef]

- Xu, H.; Liu, J.; Liu, H.; Liu, Y.; Li, M.; He, Y. Composition Design and Heat Treatment Welding Process Analysis of High-manganese Austenitic Cryogenic Steel. Spec. Steel 2024, 2, 8–17. [Google Scholar]

- High Manganese Austenitic Steel Plate for Low Temperature Pressure Vessels; Special Steel Enterprises Association of China: Beijing, China, 2020.

- Application Guidelines for High Manganese Austenitic Cryogenic Steels; China Classification Society: Beijing, China, 2021.

- ISO/TC 8/SC 8; Ships and Marine Technology—Specification of High Manganese Austenitic Steel used for LNG Tanks on Board Ships. ISO: Geneva, Switzerland, 2018.

- A01.11; Standard Specification for Pressure Vessel Plate, Alloy Steel, Austenitic High Manganese for Cryogenic Application. ASTM: West Conshohocken, PA, USA, 2017.

- Park, M.; Park, G.-W.; Kim, S.-h.; Choi, Y.-W.; Kim, H.C.; Kwon, S.-H.; Noh, S.; Jeon, J.B.; Kim, B.J. Tensile and Charpy impact properties of heat-treated high manganese steel at cryogenic temperatures. J. Nucl. Mater. 2022, 570, 153982. [Google Scholar] [CrossRef]

- Zhong, S.; Xu, C.; Li, Y.; Li, W.; Luo, H.; Peng, R.; Jia, X. Hierarchy modification induced exceptional cryogenic strength, ductility and toughness combinations in an asymmetrical-rolled heterogeneous-grained high manganese steel. Int. J. Plast. 2022, 154, 103316. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, X.; Xiong, M.; Li, P.; Misra, R.; Rao, D.; Wang, Y. Role of hot rolling procedure and solution treatment process on microstructure, strength and cryogenic toughness of high manganese austenitic steel. Mater. Sci. Eng. A 2021, 807, 140881. [Google Scholar]

- Chen, J.; Dong, F.-T.; Liu, Z.-Y.; Wang, G.-D. Grain size dependence of twinning behaviors and resultant cryogenic impact toughness in high manganese austenitic steel. J. Mater. Res. Technol. 2021, 10, 175–187. [Google Scholar] [CrossRef]

- Zhang, J.; Li, G.; Wang, H.; Wan, X.; Hu, M.; Meng, Q. Microstructure, non-metallic inclusions and impact toughness of high-Mn cryogenic steel weld metal. Sci. Technol. Weld. Join. 2022, 27, 553–563. [Google Scholar] [CrossRef]

- Fan, X.; Li, Y.; Qi, Y.; Cai, X.; Wang, Z.; Ma, C. Mechanical properties of cryogenic high manganese steel joints filled with nickel-based materials by SMAW and SAW. Mater. Lett. 2021, 304, 130596. [Google Scholar] [CrossRef]

- Choi, M.; Lee, J.; Nam, H.; Kang, N.; Kim, M.; Cho, D. Tensile and microstructural characteristics of Fe-24Mn steel welds for cryogenic applications. Met. Mater. Int. 2020, 26, 240–247. [Google Scholar] [CrossRef]

- Nickel Alloy Steel Plates for Low Temperature Pressure Vessels; Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- Bhattacharya, A.; Biswal, S.; Barik, R.K.; Mahato, B.; Ghosh, M.; Mitra, R.; Chakrabarti, D. Comparative interplay of C and Mn on austenite stabilization and low temperature impact toughness of low C medium Mn steels. Mater. Charact. 2024, 208, 113658. [Google Scholar] [CrossRef]

- Zhu, R.; Lu, Y.; Li, S.; Zhang, F. Valence electron structure and essential characteristics of high manganese steel. Chin. Sci. Bull. 1996, 41, 1336–1338. [Google Scholar]

- Li, S.; Lu, Y.; Zhu, R.; Chao, Z. A brief discussion on the work hardening mechanism of high manganese steel. Ordnance Mater. Sci. Eng. 1999, 22, 61–65. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, R.; Li, S.; Chao, Z.; Wang, S. Valence electron structure analysis of austenite structure and properties of manganese steel. J. Iron Steel Res. 1999, 11, 51–53. [Google Scholar]

- Shin, J.-H.; Jang, J.H.; Kim, S.-D.; Park, S.-J.; Lee, J. Dynamic strain aging in Fe-Mn-Al-C lightweight steel. Philos. Mag. Lett. 2020, 100, 355–364. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, F.; Chen, C.; Ma, H.; Yang, Z.; Zhang, F.; Tang, T. Effect of Mn content and strain rate on mechanical properties of high-C high-Mn austenitic steel. Mater. Sci. Eng. A 2022, 851, 143653. [Google Scholar] [CrossRef]

- Qian, L.; Guo, P.; Zhang, F.; Meng, J.; Zhang, M. Abnormal room temperature serrated flow and strain rate dependence of critical strain of a Fe–Mn–C twin-induced plasticity steel. Mater. Sci. Eng. A 2013, 561, 266–269. [Google Scholar] [CrossRef]

- Qian, L.; Guo, P.; Meng, J.; Zhang, F. Unusual grain-size and strain-rate effects on the serrated flow in FeMnC twin-induced plasticity steels. J. Mater. Sci. 2013, 48, 1669–1674. [Google Scholar] [CrossRef]

- Limmer, K.; Medvedeva, J.E.; Van Aken, D.C.; Medvedeva, N. Ab initio simulation of alloying effect on stacking fault energy in fcc Fe. Comput. Mater. Sci. 2015, 99, 253–255. [Google Scholar] [CrossRef]

- Kim, H.; Ha, Y.; Kwon, K.H.; Kang, M.; Kim, N.J.; Lee, S. Interpretation of cryogenic-temperature Charpy impact toughness by microstructural evolution of dynamically compressed specimens in austenitic 0.4 C–(22–26) Mn steels. Acta Mater. 2015, 87, 332–343. [Google Scholar] [CrossRef]

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Mater. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.-J.; Moon, J.; Kang, J.-Y.; Lee, T.-H.; Han, H.N. β-Mn formation and aging effect on the fracture behavior of high-Mn low-density steels. Scr. Mater. 2016, 124, 193–197. [Google Scholar] [CrossRef]

- Tjong, S.C. Electron microscope observations of phase decompositions in an austenitic Fe-8.7Al-29.7Mn-1.04C alloy. Mater. Charact. 1990, 24, 275–292. [Google Scholar] [CrossRef]

- Horiuchi, T.; Ogawa, R.; Shimada, M. Cryogenic Fe-Mn Austenitic Steels; Advances in Cryogenic Engineering Materials; Springer: Boston, MA, USA, 1986. [Google Scholar]

- Strum, M.; Morris, J.W. Influence of post-anneal cooling treatments on suppression of cryogenic intergranular fracture in experimental Ni-free high-Mn austenitic steels. In Proceedings of the Cryogenic Engineering Conference, St. Charles, IL, USA, 14 June 1987. [Google Scholar]

- Matsui, H.; Kimura, H. The Influence of Oxygen and Sulfur on the Intergranular Brittleness of Iron. Jpn. Inst. Met. 1983, 47, 294. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and prediction of flow behavior in high-manganese twinning induced plasticity steels: Part I. Mechanism maps and work-hardening behavior. Met. Mater. Trans. A 2012, 43, 1688–1704. [Google Scholar] [CrossRef]

- Morris, J.W. Structural Alloys for High Field Superconducting Magnets. In Advances in Cryogenic Engineering Materials; Springer: Boston, MA, USA, 1986. [Google Scholar]

- Xue, K.; Sun, D.; Wang, B.; Shen, J.; Wang, W. Methods to improve the low temperature toughness of high manganese austenitic ultra-low temperature steel. J. Mech. Eng. 1998, 34, 6. [Google Scholar]

- Kusakin, P.; Belyakov, A.; Molodov, D.A.; Kaibyshev, R. On the effect of chemical composition on yield strength of TWIP steels. Mater. Sci. Eng. A 2017, 687, 82–84. [Google Scholar] [CrossRef]

- Cooman, J.B.C.D. Temperature dependence of the flow stress of Fe–18Mn–0.6C–xAl twinning-induced plasticity steel. Acta Mater. 2013, 61, 6724–6735. [Google Scholar]

- Yang, W.; Wan, C. The influence of aluminium content to the stacking fault energy in Fe-Mn-Al-C alloy system. J. Mater. Sci. 1990, 25, 1821–1823. [Google Scholar] [CrossRef]

- Chen, J.; Ren, J.-K.; Liu, Z.-Y. Deformation microstructures as well as strengthening and toughening mechanisms of low-density high Mn steels for cryogenic applications. J. Mater. Res. Technol. 2021, 13, 947–961. [Google Scholar] [CrossRef]

- Mi, Z.; Wang, D.; Jiang, H. Effect of Al on delayed fracture properties of Fe-18Mn-0.6 C steel. Trans. Mater. Heat Treat. 2015, 36, 129–135. [Google Scholar]

- Tani, T.; Nagumo, M. Fracture process of a low carbon low alloy steel relevant to charpy toughness at ductile-brittle fracture transition region. Met. Mater. Trans. A 1995, 26, 391–399. [Google Scholar] [CrossRef]

- Zuidema, B.; Subramanyam, D.; Leslie, W. The effect of aluminum on the work hardening and wear resistance of Hadfield manganese steel. Met. Trans. A 1987, 18, 1629–1639. [Google Scholar] [CrossRef]

- Hamada, A.; Karjalainen, L.; Somani, M. The influence of aluminum on hot deformation behavior and tensile properties of high-Mn TWIP steels. Mater. Sci. Eng. A 2007, 467, 114–124. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, F.; Wang, F.; Liu, H.; Yu, B. Effect of N+ Cr alloying on the microstructures and tensile properties of Hadfield steel. Mater. Sci. Eng. A 2017, 679, 95–103. [Google Scholar] [CrossRef]

- Sun, H.; Giron-Palomares, B.; Qu, W.; Chen, G.; Wang, H. Effects of Cr addition and cold pre-deformation on the mechanical properties, damping capacity, and corrosion behavior of Fe–17% Mn alloys. J. Alloys Compd. 2019, 803, 250–259. [Google Scholar] [CrossRef]

- Yuan, X.; Zhao, Y.; Li, X.; Chen, L. Effect of Cr on mechanical properties and corrosion behaviors of Fe-Mn-C-Al-Cr-N TWIP steels. J. Mater. Sci. Technol. 2017, 33, 1555–1560. [Google Scholar] [CrossRef]

- Deb, S.; Panigrahi, S.; Weiss, M. The effect of annealing treatment on the evolution of the microstructure, the mechanical properties and the texture of nano SiC reinforced aluminium matrix alloys with ultrafine grained structure. Mater. Charact. 2019, 154, 80–93. [Google Scholar] [CrossRef]

- Wang, L.J.; Sheng, L.Y.; Hong, C.M. Influence of grain boundary carbides on mechanical properties of high nitrogen austenitic stainless steel. Mater. Des. 2012, 37, 349–355. [Google Scholar] [CrossRef]

- Kwon, K.; Yi, I.-C.; Ha, Y.; Um, K.-K.; Choi, J.-K.; Hono, K.; Oh-Ishi, K.; Kim, N.J. Origin of intergranular fracture in martensitic 8Mn steel at cryogenic temperatures. Scr. Mater. 2013, 69, 420–423. [Google Scholar] [CrossRef]

- Chen, J.; Ren, J.-K.; Liu, Z.-Y.; Wang, G.-D. Interpretation of significant decrease in cryogenic-temperature Charpy impact toughness in a high manganese steel. Mater. Sci. Eng. A 2018, 737, 158–165. [Google Scholar] [CrossRef]

- Mahato, B.; Sahu, T.; Shee, S.K.; Sahu, P.; Karjalainen, L.P. Simultaneous twinning nucleation mechanisms in an Fe–Mn–Si–Al twinning induced plasticity steel. Acta Mater. 2017, 132, 264–275. [Google Scholar] [CrossRef]

- Byun, T.S. On the stress dependence of partial dislocation separation and deformation microstructure in austenitic stainless steels—ScienceDirect. Acta Mater. 2003, 51, 3063–3071. [Google Scholar] [CrossRef]

- Wang, Y.; Lan, P.; Li, Y.; Zhang, J. Effect of alloying elements on mechanical behavior of Fe-Mn-C series TWIP steel. J. Mater. Eng. 2015, 43, 30–38. [Google Scholar]

- Choi, W.S.; De Cooman, B.C.; Sandlöbes, S.; Raabe, D. Size and orientation effects in partial dislocation-mediated deformation of twinning-induced plasticity steel micro-pillars. Acta Mater. 2015, 98, 391–404. [Google Scholar] [CrossRef]

- Koyama, M.; Shimomura, Y.; Chiba, A.; Akiyama, E.; Tsuzaki, K. Room-temperature blue brittleness of Fe-Mn-C austenitic steels. Scr. Mater. 2017, 141, 20–23. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.-K.; Mao, D.-S.; Gao, Y.; Chen, J.; Liu, Z.-Y. High carbon alloyed design of a hot-rolled high-Mn austenitic steel with excellent mechanical properties for cryogenic application. Mater. Sci. Eng. A 2021, 827, 141959. [Google Scholar] [CrossRef]

- Yen, H.-W.; Huang, M.; Scott, C.P.; Yang, J.-R. Interactions between deformation-induced defects and carbides in a vanadium-containing TWIP steel. Scr. Mater. 2012, 66, 1018–1023. [Google Scholar] [CrossRef]

- Gavriljuk, V.; Shanina, B.; Berns, H. Ab initio development of a high-strength corrosion-resistant austenitic steel. Acta Mater. 2008, 56, 5071–5082. [Google Scholar] [CrossRef]

- Gavriljuk, V.; Shanina, B.; Berns, H. A physical concept for alloying steels with carbon+ nitrogen. Mater. Sci. Eng. A 2008, 481, 707–712. [Google Scholar] [CrossRef]

- Gavriljuk, V. Influence of interstitial carbon, nitrogen, and hydrogen on the plasticity and brittleness of steel. Steel Transl. 2015, 45, 747–753. [Google Scholar] [CrossRef]

- Kang, J.; Zhang, F. Deformation, fracture, and wear behaviours of C+ N enhancing alloying austenitic steels. Mater. Sci. Eng. A 2012, 558, 623–631. [Google Scholar] [CrossRef]

- Yong, Q.; Wu, B.; Sun, Z.; Wang, G. Theoretical calculation of the chemical composition and solid solubility of binary microalloy carbonitrides. J. Iron Steel Res. Int. 1989, 1, 47–52. [Google Scholar]

- Yong, Q.; Yan, S.; Pei, H.; Tian, J.; Yang, W. Basic data of physical metallurgy of vanadium in steel. J. Iron Steel Res. 1998, 10, 4. [Google Scholar]

- Scott, C.; Remy, B.; Collet, J.-L.; Cael, A.; Bao, C.; Danoix, F.; Malard, B.; Curfs, C. Precipitation strengthening in high manganese austenitic TWIP steels. Int. J. Mater. Res. 2011, 102, 538–549. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Zhang, W. Effect of VC precipitated particles on work hardening behavior of TWIP steel. Acta Metall. Sin. 2012, 48, 1067–1073. [Google Scholar] [CrossRef]

- Mejía, I.; Reyes-Calderón, F.; Cabrera, J. Modeling the hot flow behavior of a Fe–22Mn–0.41 C–1.6 Al–1.4 Si TWIP steel microalloyed with Ti, V and Nb. Mater. Sci. Eng. A 2015, 644, 374–385. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Yu, Q.; Sun, Y.; Li, Z.; Wei, X.; Liu, X. The role of trace amounts of solid solution Nb in steel. Iron Steel 2006, 41, 59–62. [Google Scholar]

- Huang, B.; Wang, X.; Rong, Y.; Wang, L.; Jin, L. Mechanical behavior and martensitic transformation of an Fe–Mn–Si–Al–Nb alloy. Mater. Sci. Eng. A 2006, 438, 306–311. [Google Scholar] [CrossRef]

- Kwon, E.P.; Kim, D.Y.; Park, H.K. Deformation twinning in Nb-microalloyed Fe-Mn-C-Al twinning-induced plasticity steel. J. Mater. Eng. Perform. 2017, 26, 4500–4507. [Google Scholar] [CrossRef]

- Cao, J.-L.; Zhao, A.-M.; Liu, J.-X.; He, J.-G.; Ding, R. Effect of Nb on microstructure and mechanical properties in non-magnetic high manganese steel. J. Iron Steel Res. Int. 2014, 21, 600–605. [Google Scholar] [CrossRef]

- Chen, J.; Ren, J.-K.; Liu, Z.-Y.; Wang, G.-D. The essential role of niobium in high manganese austenitic steel for application in liquefied natural gas tanks. Mater. Sci. Eng. A 2020, 772, 138733. [Google Scholar] [CrossRef]

- Salas-Reyes, A.; Mejía, I.; Bedolla-Jacuinde, A.; Boulaajaj, A.; Calvo, J.; Cabrera, J. Hot ductility behavior of high-Mn austenitic Fe–22Mn–1.5 Al–1.5 Si–0.45 C TWIP steels microalloyed with Ti and V. Mater. Sci. Eng. A 2014, 611, 77–89. [Google Scholar] [CrossRef]

- Han, K.; Yoo, J.; Lee, B.; Han, I.; Lee, C. Hot ductility and hot cracking susceptibility of Ti-modified austenitic high Mn steel weld HAZ. Mater. Chem. Phys. 2016, 184, 118–129. [Google Scholar] [CrossRef]

- Wu, J.; Jin, X.; Long, M.; Chen, D.; Liu, T.; Duan, H. Causes and improvements of low-temperature impact toughness fluctuations of titanium-containing microalloy steel. China Metall. 2017, 27, 59–65. [Google Scholar]

- Liu, T.; Long, M.-J.; Chen, D.-F.; Duan, H.-M.; Gui, L.-T.; Yu, S.; Cao, J.-S.; Chen, H.-B.; Fan, H.-L. Effect of coarse TiN inclusions and microstructure on impact toughness fluctuation in Ti micro-alloyed steel. J. Iron Steel Res. Int. 2018, 25, 1043–1053. [Google Scholar] [CrossRef]

- Duan, H.-J.; Zhang, Y.; Ren, Y.; Zhang, L.-F. Distribution of TiN inclusions in Ti-stabilized ultra-pure ferrite stainless steel slab. J. Iron Steel Res. Int. 2019, 26, 962–972. [Google Scholar] [CrossRef]

- Jin, Y.; Du, S. Precipitation behaviour and control of TiN inclusions in rail steels. Ironmak. Steelmak. 2018, 45, 224–229. [Google Scholar] [CrossRef]

- Yan, W.; Shan, Y.; Yang, K. Effect of TiN inclusions on the impact toughness of low-carbon microalloyed steels. Met. Mater. Trans. A 2006, 37, 2147–2158. [Google Scholar] [CrossRef]

| Standard No. | Standards Organizations | C | Si | Mn | P | S | Cr | Cu | B | N |

|---|---|---|---|---|---|---|---|---|---|---|

| T/SSEA 0060―2020 | Special Steel Enterprises Association of China | 0.35–0.55 | 0.10–0.50 | 22.50–25.50 | ≤0.012 | ≤0.005 | 3.00–4.00 | 0.30–0.70 | ≤0.005 | ≤0.050 |

| GD28―2021 | China Classification Society | 0.35–0.55 | 0.10–0.50 | 22.50–25.50 | ≤0.030 | ≤0.010 | 3.00–4.00 | 0.30–0.70 | ≤0.005 | ≤0.050 |

| ISO 21635:2018 | ISO International Standards Organization | 0.35–0.55 | 0.10–0.50 | 22.50–25.50 | ≤0.030 | ≤0.010 | 3.00–4.00 | 0.30–0.70 | ≤0.005 | ≤0.050 |

| A1106M―17 | American Society for Testing and Materials | 0.35–0.55 | 0.10–0.50 | 22.50–25.50 | ≤0.030 | ≤0.010 | 3.00–4.00 | 0.30–0.70 | ≤0.005 | ≤0.050 |

| Microalloying Element | Strengthening Coefficient for Microalloying Additions <0.1 wt.% |

|---|---|

| Nb | 187 MPa/wt.% |

| V | >530 MPa/wt.% |

| Ti | 1380 MPa/wt.% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, J.; Zhang, D.; Pang, Q. Optimization of Mechanical Properties of High-Manganese Steel for LNG Storage Tanks: A Comprehensive Review of Alloying Element Effects. Metals 2024, 14, 677. https://doi.org/10.3390/met14060677

Li Y, Li J, Zhang D, Pang Q. Optimization of Mechanical Properties of High-Manganese Steel for LNG Storage Tanks: A Comprehensive Review of Alloying Element Effects. Metals. 2024; 14(6):677. https://doi.org/10.3390/met14060677

Chicago/Turabian StyleLi, Yuchen, Jiguang Li, Dazheng Zhang, and Qihang Pang. 2024. "Optimization of Mechanical Properties of High-Manganese Steel for LNG Storage Tanks: A Comprehensive Review of Alloying Element Effects" Metals 14, no. 6: 677. https://doi.org/10.3390/met14060677

APA StyleLi, Y., Li, J., Zhang, D., & Pang, Q. (2024). Optimization of Mechanical Properties of High-Manganese Steel for LNG Storage Tanks: A Comprehensive Review of Alloying Element Effects. Metals, 14(6), 677. https://doi.org/10.3390/met14060677