Abstract

This article presents a cutting-edge approach to microwave-assisted processing aimed at enhancing the efficiency of zinc extraction from materials characterized by a high degree of processing complexity. The described technique encompasses two sequential phases: phase transformation under microwave irradiation and leaching in sulfuric acid at ambient temperature. During the phase transformation, implemented through the application of microwave energy, insoluble zinc phases undergo a controlled transition. The experimental results confirm that microwave calcination at 600 °C for 5–7 min is effective for converting ZnS to ZnO without the formation of ZnO∙Fe2O3. Zinc extraction from the clinker reached 46.47% after treatment with microwave radiation at a power of 25 kW for the specified duration. Thus, this study opens up prospects for environmentally friendly zinc extraction from challenging-to-process resources.

1. Introduction

Contemporary trends in the field of zinc metallurgy reveal a persistent trend towards an increase in the global consumption of this metal, accompanied by an expansion of its applications across various industrial sectors and an increase in the cost of both zinc itself and products containing zinc. Another significant trend is the increasing share of secondary raw materials in the total volume of its processing. According to the London Metal Exchange (LME), the current price of zinc is USD 2390 per ton [1], highlighting the importance of this research.

An analysis of the current state of the zinc market indicates an escalating deficit of this metal on the global market, driven by the rate of consumption growth exceeding the production capacities of existing enterprises [2,3]. China and Australia are leading in terms of zinc reserves, with each country having approximately 30 million tons, followed by the USA with reserves of 25 million tons, and, significantly trailing behind, Canada and Peru.

Over 60% of the world’s zinc reserves are localized in sulfide–polymetallic deposits, while approximately 30% are found in stratiform deposits. The annual global production of zinc exceeds 13.5 million tons [4], with the majority (85%) produced from sulfide concentrates. At the same time, the share of non-standard and secondary raw materials, including bulk concentrates, oxidized ores, cakes, slimes, and others, remains insignificant. This is due to the lack of effective technological solutions and methods for their processing, underscoring the importance of developing new approaches in this area [5,6].

For the processing of zinc-containing technogenic raw materials, both pyrometallurgical and hydrometallurgical methods are employed [7,8,9,10]. The most common pyrometallurgical method is Waelz kiln processing (reductive volatilization roasting) at temperatures of 1100–1300 °C with the addition of coke in amounts of 35–45% by weight of the material processed. This process yields zinc vapors and clinker containing valuable components, the subsequent use of which involves sulfuric acid leaching [11]. However, estimates indicate that, in Kazakhstan, between 4.5 and 5.7 million tons of zinc industry waste has accumulated [12,13], highlighting the pressing issue of its disposal.

Pyroprocessing, despite its prevalence, has significant drawbacks, such as high energy consumption and procedural complexity, making it less preferable for processing high-silica technogenic zinc-containing materials due to their complex composition and matrix structure [14]. This often leads to such materials being stored in tailings dams instead of being processed, creating environmental and economic problems.

Given this context, the relevance of developing a new, effective technology for processing refractory zinc-containing raw materials using preliminary microwave (MW) irradiation becomes apparent [15]. This approach has the potential to not only improve the environmental situation in regions where technogenic waste is located by reducing the volume of unprocessed raw materials, but also to ensure the production of additional products in the form of non-ferrous and precious metals, thereby expanding their application areas.

One study [16] revealed significant challenges in the extraction of precious metals from zinc production clinker, suggesting effective treatment methods for this technogenic material. Another study [17] compared pyrometallurgical and hydrometallurgical methods for processing clinker, highlighting the latter as more promising and efficient. These studies emphasize the importance of an integrated approach, including magnetic separation and electro-leaching, which contributes to cost reduction and increased environmental efficiency, entirely relevant in the context of the present research.

The method we propose eliminates the use of pyrometallurgical processes, favoring electromagnetic exposure to break down the refractory matrix of the raw material. This approach not only simplifies the processing procedures, but also significantly enhances their efficiency, opening new prospects for the use of technogenic zinc-containing raw materials.

The impact of microwave (MW) radiation on complex, refractory zinc-containing raw materials leads to significant changes in their structure. The weakening of bonds between the main minerals containing valuable components and the host rock results in structural transformation, making the matrix more mobile and accessible for chemical action. Consequently, valuable components transition into more readily leachable forms, facilitating their more complete extraction into solution [18].

Such microwave radiation finds application across a broad spectrum of areas, including in the pre-treatment of minerals, where it aids in modifying the structural and physical properties of minerals, easing their subsequent processing. In metallurgy, this research direction justifies the use of microwave treatment for the extraction of metals from ores, enabling a reduction in energy consumption and an increase in product yield. In the field of materials science, microwave processing represents an efficient approach to the synthesis of functional materials with enhanced properties at relatively low production costs [19].

A significant advantage of microwave processing is observed in the creation of high-quality functional materials, facilitating the achievement of a high degree of homogeneity and improved mechanical and electrical properties, as well as reducing production costs. Research has shown that microwave heating can significantly accelerate synthesis processes and can optimize the morphology and structural characteristics of the resulting materials, opening new prospects for the development of technologies in the field of materials science and related disciplines [20,21,22,23,24].

Therefore, the primary objective of this study is to analyze the patterns determining changes in the phase composition and structural transformation of refractory zinc-containing raw materials under the influence of microwave radiation. Special attention is paid to studying the kinetic patterns of interaction between the key components of the raw material with acids and alkalis, which will enrich the existing database with new information about structural changes in zinc-containing raw materials after microwave treatment and will lay the groundwork for developing effective technological solutions for extracting valuable components from complex and refractory zinc-containing raw materials.

2. Materials and Methods

2.1. Materials

For the research object, refractory technogenic zinc-containing raw material—clinker—was selected. The chemical composition of the sample is represented by the major elements of Fe (25.39%), Zn (1.25%), and Cu (0.81%), as well as the content of Au (1.53 g/t) and Ag (71.81 g/t).

The results of X-ray fluorescence analysis revealed a significant amount of iron (37.53%), calcium (3.81%), silicon (4.58%), oxygen (41.644%), copper (1.04%), zinc (more than 1.2%), and others, as presented in Table 1.

Table 1.

X-ray fluorescence analysis of the clinker.

The analysis of the clinker composition allows for a deeper understanding of the chemical nature of the raw material under study, which is critically important for determining the most effective methods of its processing. The data obtained from the X-ray fluorescence analysis formed the basis for subsequent experimental studies on the effects of microwave radiation on the structural and phase transformations in the clinker.

2.2. Analysis Methods

In this article, modern analytical methods are employed to assess the phase composition of clinker and to understand the mechanisms of phase transformations. The phase composition of the samples was identified using the German X-ray diffractometer Bruker D8 Advance (Bruker, Ettlingen, Germany). The conditions were as follows: 4~90°, Cu–Kα radiation (λ = 0.15406 nm), a tube voltage of 40 kV, a tube current of 40 mA, and a continuous scanning speed of 1 degree/min. Elemental analysis was conducted using the X-ray fluorescence wavelength dispersive spectrometer Axios 1 kW (PANalytical, Almelo, The Netherlands). Subsequent processing and interpretation of the data were carried out using SuperQ5 software (Omnian 37). The surface microstructure was monitored via the electron probe microanalyzer JXA-8230 by JEOL (Jeol, Tokyo, Japan). The study was performed at an accelerating voltage of 20 kV, an electron beam current of less than 1 nA, and using aperture diaphragm No.3. Energy-dispersive spectrometric (Jeol, Tokyo, Japan) (EDS) microanalysis was carried out with an electron beam current of up to 6 nA and a dead time of up to 14%.

2.3. Experimental Procedure

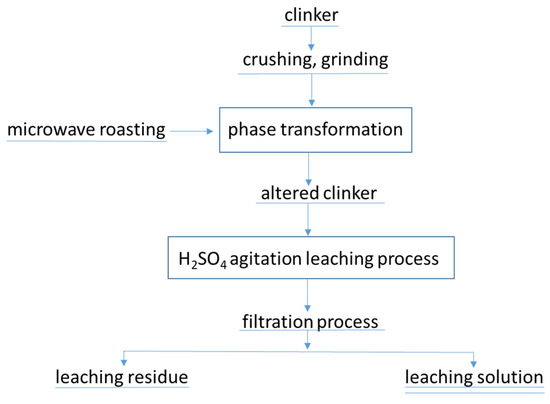

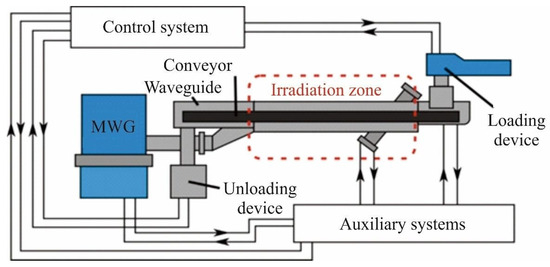

The technology for extracting zinc from clinker comprises three main stages: grinding the clinker to 90% of the –0.071 + 0 mm size fraction, microwave phase transformation, and leaching with H2SO4. The steps, depicted in Figure 1, include sample preparation; firing of the clinker in the high-temperature microwave reactor of the “ENERGY K-50” unit (Ust-Kamenogorsk, Kazakhstan) (915 MHz, 25 kW), which is advantageous for its high power, stable operation [25,26,27,28,29], and increased efficiency; and the subsequent leaching of the clinker (Figure 2). The leaching of the clinker was conducted in an H2SO4 solution with a concentration of 100 g/dm3 for 6 h at a stirring speed of 300 rpm, a solid to liquid ratio of 1:5, and a temperature of 293 K.

Figure 1.

A flow diagram of the experiment.

Figure 2.

Diagram of the “ENERGY K-50” microwave system.

3. Results and Discussion

3.1. Mineralogical Characteristics of the Clinker

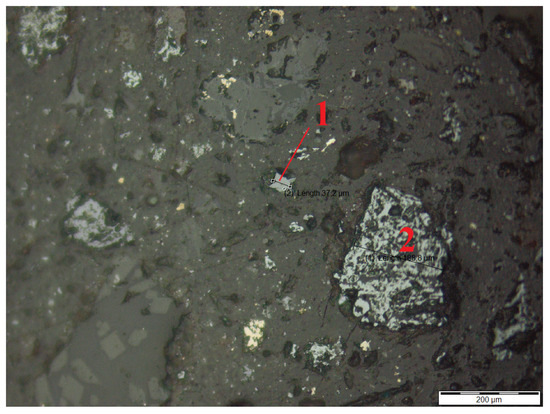

Mineralogical analysis of the clinker, conducted using an OLYMPUS BX51 microscope (Olympus, Tokyo, Japan) and presented in Figure 3, revealed the presence of several key minerals. Among them were sphalerite (ZnS), found in the form of rare, fine-dispersed anhedral grains, and chalcopyrite (CuFeS2), characterized by its syngenetic associations with pyrite (FeS2) and sphalerite, as well as the presence of hematite (Fe2O3) and carbonaceous inclusions, demonstrating significant diversity in sizes and shapes.

Figure 3.

Sphalerite (1) and hematite (2).

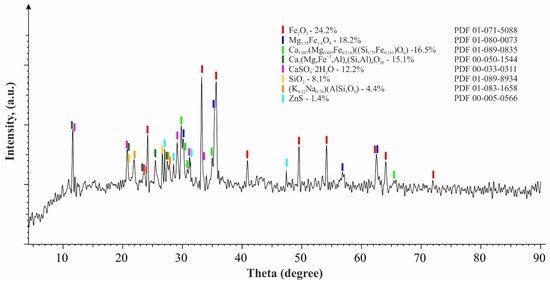

X-ray phase analysis enabled the determination that the main phase components of the clinker were hematite (24.2%), magnesium iron oxide (18.2%), and other phases, as presented in Table 2 and Figure 4.

Table 2.

Results of the X-ray phase analysis of the clinker.

Figure 4.

Diffractogram of the clinker.

3.2. Optimizing Zinc Recovery: Efficacy of Microwave-Assisted Versus Traditional Electrothermal Calcination of Clinker

The microwave phase transformation method involves the use of microwave radiation to process clinker, which predominantly consists of zinc sulfide (ZnS). Microwaves are generated by a magnetron and directed into the clinker through a waveguide, creating a “traveling wave.” This wave interacts with the material, providing dielectric heating that selectively heats the components of the clinker at the molecular level.

The heating rate of the material under the influence of microwave radiation is described by the following equation [30]:

where —is the power absorbed per unit volume; ϵ′′—is the imaginary part of the material’s dielectric permittivity, reflecting its ability to dissipate field energy; —is the electric field strength; —is the angular frequency of the microwave radiation; and —is the permittivity of free space.

By adjusting the microwave generator power, irradiation time, and wave characteristics, the heating process can be precisely controlled. This allows for the optimization of the treatment procedure to achieve desired outcomes, such as uniform heating of the material.

Table 3 showcases the parameters of experiments conducted on the “ENERGY K-50” microwave unit. During the testing, four experiments were carried out at the same microwave power (25 kW) and frequency (915 MHz), but under different temperature regimes. The duration of each experiment ranged from 5 to 7 min, with the temperatures of the experiments set at 250, 460, 600, and 700 °C, respectively.

Table 3.

Parameters of experiments on the microwave setup.

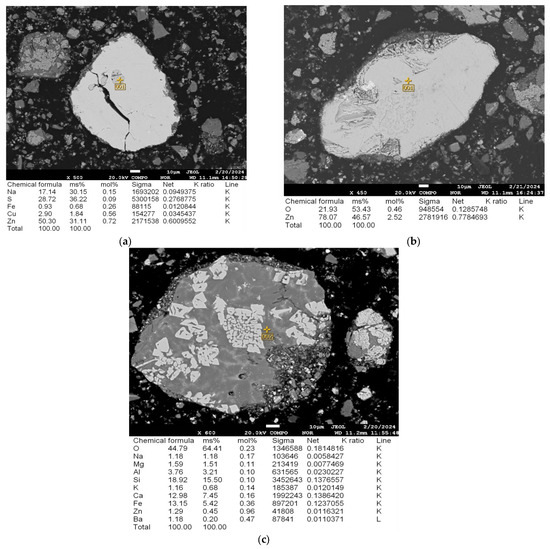

The results obtained from the experiments are illustrated by electron microscopic studies of sphalerite conducted before and after microwave radiation treatment. The use of a scanning electron microscope, JEOL JXA-8230 (Tokyo, Japan), equipped with an energy-dispersive analyzer (Figure 5, Figure 6 and Figure 7), allowed for a detailed examination of potential changes in the microstructure and phase composition of the mineral. Despite varying temperature conditions of treatment, the analysis of Figure 5a at ambient temperature and Figure 5b at 250 °C did not reveal any noticeable changes in the microstructure, phase, or chemical composition of the samples.

Figure 5.

(a) Microstructure of the original sample and energy dispersive analysis of sphalerite before microwave radiation at 25 °C; (b) microstructure and energy dispersive analysis of sphalerite after microwave radiation at 250 °C.

Figure 6.

(a) Microstructure and energy dispersive analysis of sphalerite after microwave radiation at 460 °C; (b) microstructure and energy dispersive analysis of sphalerite after microwave radiation at 600 °C; (c) microstructure and energy dispersive analysis of sphalerite after microwave radiation at 600 °C.

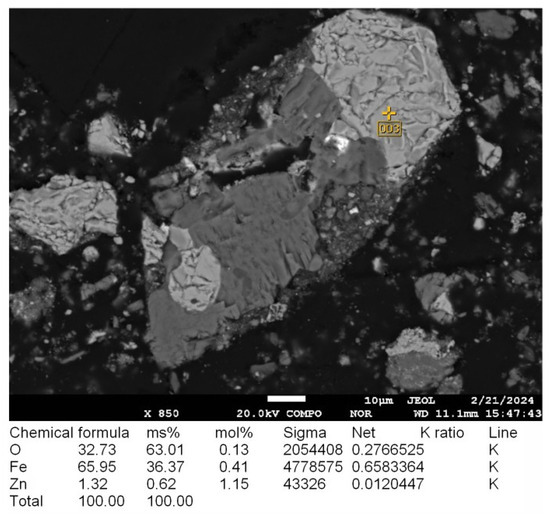

Figure 7.

Microstructure and energy dispersive analysis of sphalerite after microwave radiation at 700 °C.

The observed invariance in the microstructural integrity and elemental constituency of sphalerite after microwave irradiation exposure suggests an intrinsic resistance of this mineralogical entity to thermoradiative perturbation within the experimental thermal spectrum. This revelation accentuates the conceivable utility of microwave-mediated methodologies in the strategic manipulation of material properties at the molecular level. Concurrently, it amplifies the imperative for a more granular investigation into the parametric landscape that governs phase transition kinetics and structural reconfiguration under such conditions. Future investigative trajectories might well consider a broader parametric modulation, encompassing not only the irradiative flux and temporal extent of exposure but also the potential exploitation of wave modal alterations, with the objective of precipitating precise and predictable alterations in the material’s physicochemical constitution.

The experimental data, presented in Figure 6a–c, demonstrate significant changes in the structure of sphalerite caused by microwave treatment. The formation of cracks in sphalerite grains, noted in Figure 6a, results from thermo-induced mechanical stresses. These stresses arise due to the uneven temperature distribution within the mineral during the exposure to microwave radiation. Uneven heating leads to different degrees of thermal expansion in various parts of the mineral, causing cracks to form.

Figure 6b illustrates the phase transformation of sphalerite (ZnS) into zincite (ZnO) at temperatures above 600 °C [31,32]. This transformation occurs because of the oxidation of zinc sulfide in the air and can lead to the formation of both zinc oxide and zinc sulfate according to the following chemical reactions:

ZnS + 1.5O2 = ZnO + SO2

ZnS + 2O2 = ZnSO4

The observed oval grain of zincite with smooth contours, surrounded by intermittent rims of fine non-ore mass, confirms the phase transformation.

In contrast, Figure 6c reveals morphological and phase changes in sphalerite caused by microwave treatment. These include fragmentation and microcracks, arising from differential thermal expansion and thermal stresses. These stresses distort the mineral’s lattice, leading to morphological changes.

As illustrated in Figure 7, at temperatures above 650 °C, zinc oxide, when interacting with Fe2O3, gradually forms ferrite (ZnO·Fe2O3), which is practically insoluble in dilute acids [33].

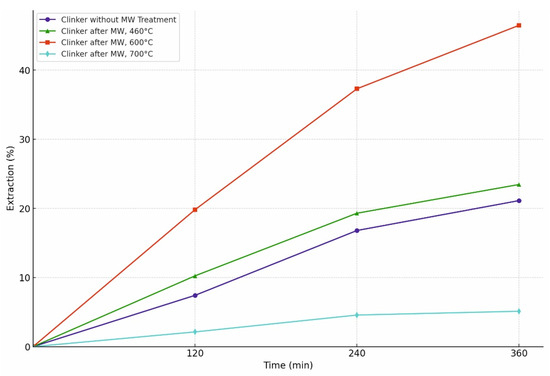

The highest zinc extraction was achieved with MW treatment of clinker at 600 °C. This process is accompanied by phase changes (Figure 8).

Figure 8.

Comparison of zinc extraction efficiency by sulfuric acid leaching.

Microwave-assisted calcination of clinker has demonstrated a superior capability to enhance the phase transformation and zinc extraction compared to traditional electrothermal methods. Utilizing an electron probe microanalyzer, it was observed that at 250 °C, the clinker remained primarily as zinc sulfide (ZnS), unchanged from its raw state, indicating that higher energy is necessary for effective transformation. Subsequent increases in microwave heating temperatures revealed significant changes: at 460 °C, thermal stresses induced microcracks in sphalerite grains, and by 600 °C, the predominant phase was zinc oxide (ZnO).

Further heating facilitated the synthesis of a chemically resistant ferrite compound (ZnO·Fe2O3) through the interaction of zinc oxide with iron (III) oxide [34]. However, the optimal temperature for maximizing zinc recovery through leaching was identified as 600 °C, where ZnO dissolves efficiently in dilute sulfuric acid [35], forming zinc sulfate (ZnSO4) as per the reaction

ZnO + H2SO4 = ZnSO4 + H2O

Comparative analysis under controlled conditions—100 g/dm3 H2SO4, 6 h of leaching, 300 rpm stirring, a solid to liquid ratio of 1:5, and a leaching temperature of 25 °C—showed that microwave treatment at 600 °C resulted in a zinc extraction efficiency of 46.47%, which was significantly higher than that from untreated clinker (21.12%) and notably more effective than both lower and higher microwave treatment temperatures or extended durations of traditional calcination, which only achieved 21.19% zinc extraction.

These findings underscore the efficiency of microwave calcination at 600 °C, which not only enhances the physicochemical transformation of minerals within the clinker, but also doubles the zinc extraction rate compared to conventional methods, attributing to the specific non-thermal effects of microwave energy [36]. This method presents a promising alternative for the metallurgical processing of zinc-bearing materials, offering substantial improvements in energy efficiency and extraction outcomes [37].

4. Conclusions

In this study, effective zinc extraction from clinker is achieved using microwave (MW) radiation. The extraction process consists of two procedures: phase transformation using MW radiation and leaching with H2SO4. Results from the electron probe microanalysis indicate that MW radiation can facilitate the transformation of the refractory zinc phase sphalerite (ZnS) into zincite (ZnO) and inhibit the formation of ferrite (ZnO·Fe2O3). Under the specified conditions (microwave calcination at 600 °C for 5–7 min, H2SO4 concentration of 100 g/dm3, leaching time of 6 h, stirring speed of 300 rpm, solid to liquid ratio of 1:5, and temperature of 293 K), zinc leaching can reach 46.47%. This work demonstrates the significant potential of using environmentally friendly methods for extracting zinc from non-traditional sources, contributing to the improvement of the environmental situation in areas with an accumulation of technogenic waste, enriching the assortment of extracted non-ferrous and precious metals, and adapting the developed technologies for processing various types of raw materials.

Author Contributions

Conceptualization, B.K. and Z.B.; methodology, A.B., T.S. and K.S.; software, B.K., T.S. and K.S.; validation, B.K. and A.B.; formal analysis, A.B.; investigation, A.B. and B.K.; resources, B.K. and K.S.; data curation, Z.B. and A.B.; writing—original draft preparation, Z.B.; writing—review and editing, Z.B., B.K. and A.B.; visualization, T.S.; supervision, Z.B.; project administration, B.K. and Z.B.; funding acquisition, B.K. and Z.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AR 19675985).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Information Agency INSIDER. Observed Growth in Zinc Prices on the London Metal Exchange (LME) Market Overview. Available online: https://metallicheckiy-portal.ru/index-cen-lme (accessed on 31 March 2024).

- Kaplunov, D.R. Rationale for the role and significance of geotechnological modules in the design of combined development of ore deposits. In Combined Geotechnology: Comprehensive Development and Preservation of the Earth’s Subsoil; Magnitogorsk State Technical University: Magnitogorsk, Russia, 2011; pp. 12–22. [Google Scholar]

- Annually, Kazakhstan Produces 300 Thousand Tons of Zinc and 150 Thousand Tons of Lead. Available online: https://dknews.kz/ru/ekonomika/105991-v-kazahstane-ezhegodno-proizvoditsya-300-tysyach-tonn (accessed on 18 June 2020).

- Review of Price Dynamics for Key Products in the Mining and Metallurgical Sector. Available online: https://home.kpmg/content/dam/kpmg/ru/pdf/2019/10/ru-ru-metals-and-mining-prices-report-3q-2019.pdf (accessed on 22 December 2023).

- Esezobor, D.E.; Balogun, S.A. Zinc accumulation during recycling of iron oxide wastes in the blast furnace. Ironmak. Steelmak. 2006, 33, 419–425. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2020; U.S. Geological Survey: Reston, VA, USA, 2020; p. 200. [Google Scholar] [CrossRef]

- Yang, C.; Sun, B. Modeling, Optimization, and Control of Zinc Hydrometallurgical Purification Process. In Emerging Methodologies and Applications in Modelling; Identification and Control; Academic Press: Cambridge, MA, USA, 2021; pp. 213–221. [Google Scholar] [CrossRef]

- Klein, S.E.; Kozlov, P.A.; Naboychenko, S.S. Extraction of Zinc from Ore Raw Materials; Ural State Mining University: Yekaterinburg, Russia, 2009; p. 492. [Google Scholar]

- Akhtamov, F.E.; Nishonov, B.U. On the issue of processing zinc cakes. Theory Technol. Metall. Prod. 2016, 1, 69–72. Available online: https://cyberleninka.ru/article/n/k-voprosu-pererabotki-tsinkovyh-kekov (accessed on 22 December 2023).

- Naboychenko, S.S.; Karelov, S.V.; Mamayachenkov, S.V.; Yakornov, S.A. Complex processing of zinc-containing technogenic wastes of Ural copper smelting enterprises. Min. J. 1997, 11–12, 250–255. [Google Scholar]

- Kozlov, P.A. Extraction of a range of non-ferrous and rare metals from industrial waste: Physico-chemical basis and technical solutions. Tsvetnye Met. 2020, 5, 28–36. [Google Scholar] [CrossRef]

- Kolesnikov, A.; Fediuk, R.; Kolesnikova, O.G.; Zhanikulov, N.N.; Zhakipbayev, B.; Kuraev, R.M.; Akhmetova, E.; Shal, A. Processing of Waste from Enrichment with the Production of Cement Clinker and the Extraction of Zinc. Materials 2022, 15, 324. [Google Scholar] [CrossRef]

- Yessengaziyev, A.; Kenzhaliyev, B.; Berkinbayeva, A.; Sharipov, R.; Suleimenov, E. Electrochemical Extraction of Pb and Zn from a Collective Concentrate Using a Sulfur-Graphite Electrode as a Cathode. J. Chem. Technol. Metall. 2017, 52, 975–980. [Google Scholar]

- Beisembaev, B.B.; Kenzhaliyev, B.K.; Gorkun, V.I.; Govyadovskaya, O.U.; Ignatyev, M.M. Deep Processing of Lead-Zinc Ores and Intermediary Products with Receiving of Products with Increased Marketability. Almaty 2002, 3, 220. [Google Scholar]

- Singh, C.; Khanna, V.; Singh, S. Sustainability of Microwave Heating in Materials Processing Technologies. Materials Today: Proceedings. 2022. Available online: https://www.sciencedirect.com/science/article/pii/S2214785322048398 (accessed on 25 July 2022).

- Toshkodirova, R.E.; Abdurakhmonov, S. Processing of Clinker—Technogenic Waste of Zinc Production. Univers. Tech. Sci. 2020, 11, 78–81. [Google Scholar] [CrossRef]

- Lobanov, V.G.; Kolmachikhina, O.B.; Polygalov, S.E.; Khabibulina, R.E.; Sokolov, L.V. Features of the Presence of Precious Metals in the Zinc Production Clinker. Russ. J. Non-Ferr. Met. 2022, 63, 594–598. [Google Scholar] [CrossRef]

- Li, J.; Niu, H.; Peng, J.; Zhang, S.; Zhang, L.; Wei, X.; Fan, X.; Huang, M. Present Situation and Prospect about Comprehensive Utilization of Zinc Kiln Slags. Multipurp. Util. Miner. Resour. 2008, 6, 44–48. [Google Scholar] [CrossRef]

- Ramesh, S.; Teng, W.D.; Sopyan, I.; Bang, L.T.; Sarhan, A.A.D. Comparison between microwave and conventional sintering on the properties and microstructural evolution of tetragonal zirconia. Ceram. Int. 2018, 44, 8922–8927. [Google Scholar] [CrossRef]

- Kamariah, N.; Kalebic, D.; Xanthopoulos, P.; Blannin, R.; Araujo, F.P.; Koelewijn, S.F.; Spooren, J. Conventional versus microwave-assisted roasting of sulfidic tailings: Mineralogical transformation and metal leaching behavior. Miner. Eng. 2022, 183, 107587. [Google Scholar] [CrossRef]

- Soni, A.; Smith, J.; Thompson, A.; Brightwell, G. Microwave-induced thermal sterilization-A review on history, technical progress, advantages, and challenges as compared to conventional methods. Trends Food Sci. Technol. 2020, 97, 433–442. [Google Scholar] [CrossRef]

- Kalebic, D.; Dehaen, W.; Spooren, J. Additive-Free Aqueous Extraction of Copper and Zinc from Sulfidic Tailings Using Fast Microwave-Assisted Pre-and Post-Treatments. Ind. Eng. Chem. Res. 2022, 61, 13303–13313. [Google Scholar] [CrossRef]

- Wei, W.; Shao, Z.; Zhang, Y.; Qiao, R.; Gao, J. Fundamentals and applications of microwave energy in rock and concrete processing—A review. Appl. Therm. Eng. 2019, 157, 113751. [Google Scholar] [CrossRef]

- Feng, D.; Bai, L.; Xie, H.; Tong, X. Study on separation of low-grade zinc oxide ore with sulfurization-amination flotation. Physicochem. Probl. Miner. Process. 2019, 55, 1082–1090. [Google Scholar]

- Hamidi, A.; Nazari, P.; Shakibania, S.; Rashchi, F. Microwave irradiation for the recovery enhancement of fly ash components: Thermodynamic and kinetic aspects. Chem. Eng. Process. 2023, 191, 109472. [Google Scholar] [CrossRef]

- Kumar, P.; Ingle, A.; Jhavar, S. Parametric review of microwave-based materials processing and its applications. J. Mater. Res. Technol. 2019, 8, 3306–3326. [Google Scholar] [CrossRef]

- Ma, A.; Zheng, X.; Gao, L.; Li, K.; Omran, M.; Chen, G. Enhanced Leaching of Zinc from Zinc-Containing Metallurgical Residues via Microwave Calcium Activation Pretreatment. Metals 2021, 11, 1922. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Zhang, L.; Yang, K. Application of the Microwave and Ultrasonic Combined Technique in the Extraction of Refractory Complex Zinc Ore. Superalloys 2023, 13, 356. [Google Scholar] [CrossRef]

- Erans, M.; Durán-Jimenez, G.; Rodríguez, J.M.; Stevens, L.; Dodds, C. Microwave Thermal Pre-treatment and Calcination of Biomineralised Sorbents for Calcium Looping. J. CO2 Util. 2024, 83, 102794. [Google Scholar] [CrossRef]

- Okress, O. (Ed.) Title in English: Microwave Power Engineering; Mir: Moscow, Russia, 1971; p. 272. [Google Scholar]

- Karimi, S.; Rashchi, F.; Ghahreman, A. The Evaluation of Sphalerite Surface Formed During Oxidative Leaching in Acidic Ferric Sulfate Media. J. Sustain. Metall. 2021, 7, 1304–1313. [Google Scholar] [CrossRef]

- Li, Y.; Tan, W.; Wu, Y. Phase transition between sphalerite and wurtzite in ZnS optical ceramic materials. J. Eur. Ceram. Soc. 2020, 40, 2130–2140. [Google Scholar] [CrossRef]

- Junwei, H.; Liu, W.; Zhang, T.; Xue, K.; Li, W.; Fen, J.; Qin, W. Mechanism study on the sulfidation of ZnO with sulfur and iron oxide at high temperature. Sci. Rep. 2017, 7, 42536. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-K.; Yang, C.-Y. A study on the preparation of zinc ferrite. Scand. J. Metall. 2001, 30, 238–241. [Google Scholar]

- Xin, C.; Xia, H.; Jiang, G.; Zhang, Q.; Zhang, L.; Xu, Y. Studies on Recovery of Valuable Metals by Leaching Lead–Zinc Smelting Waste with Sulfuric Acid. Minerals 2022, 12, 1200. [Google Scholar] [CrossRef]

- Li, H.X.; Li, B.W.; Deng, L.B.; Xu, P.F.; Du, Y.S.; Ouyang, S.L.; Liu, Z.X. Evidence for non-thermal microwave effect in processing of tailing-based glass-ceramics. J. Eur. Ceram. Soc. 2019, 39, 1389–1396. [Google Scholar] [CrossRef]

- Li, H.; Shi, S.; Lin, B.; Lu, J.; Lu, Y.; Ye, Q.; Wang, Z.; Hong, Y.; Zhu, X. A fully coupled electromagnetic, heat transfer and multiphase porous media model for microwave heating of coal. Fuel Process. Technol. 2019, 189, 49–61. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).