On the Enhancement of Material Formability in Hybrid Wire Arc Additive Manufacturing

Abstract

1. Introduction

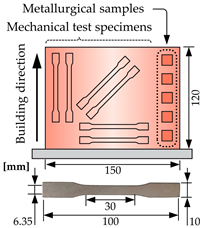

2. Materials and Methods

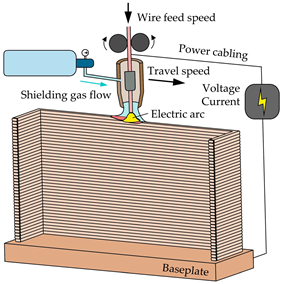

2.1. Metal Deposition by WAAM

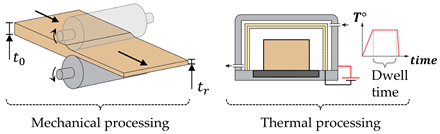

2.2. Mechanical and Thermal Processing

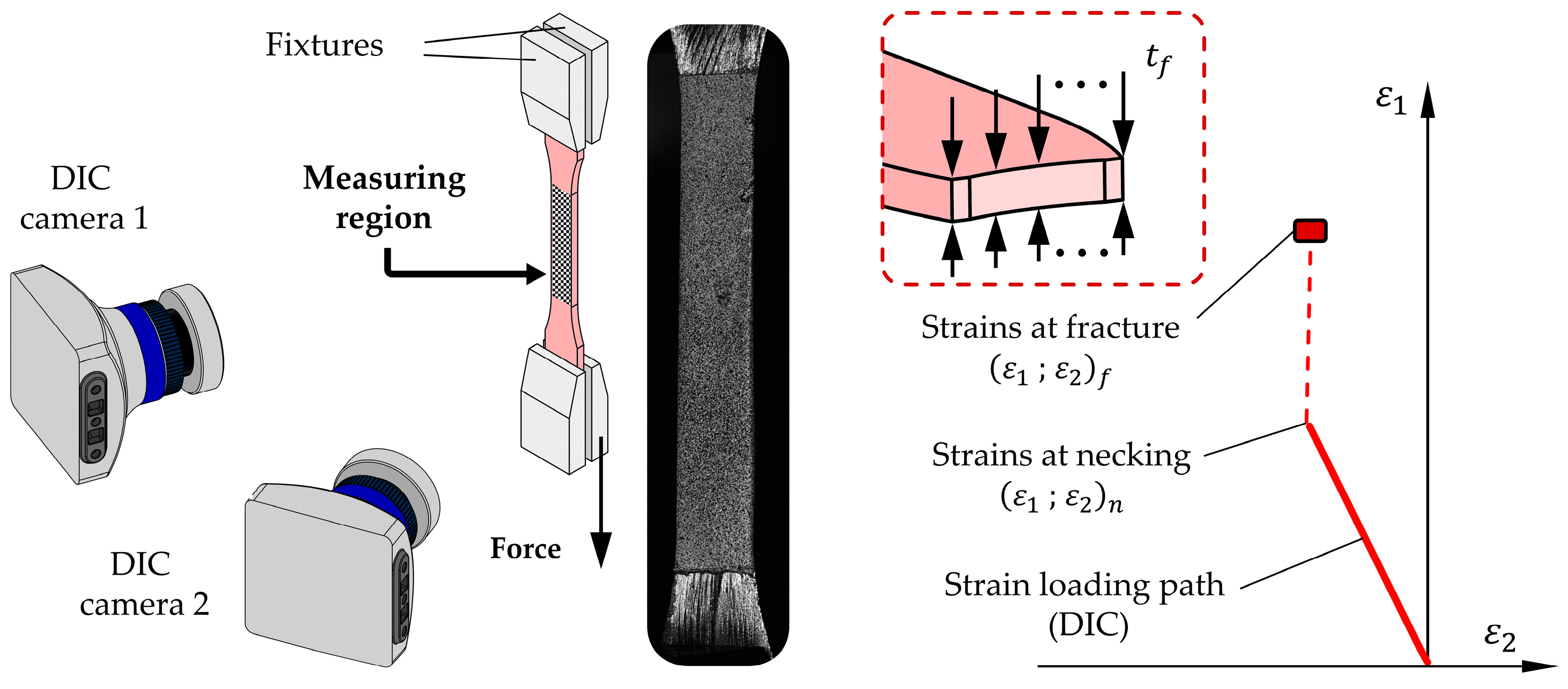

2.3. Tensile Testing

2.4. Hardness Testing, Microstruture Observations, and Fractography Analysis

3. Results and Discussion

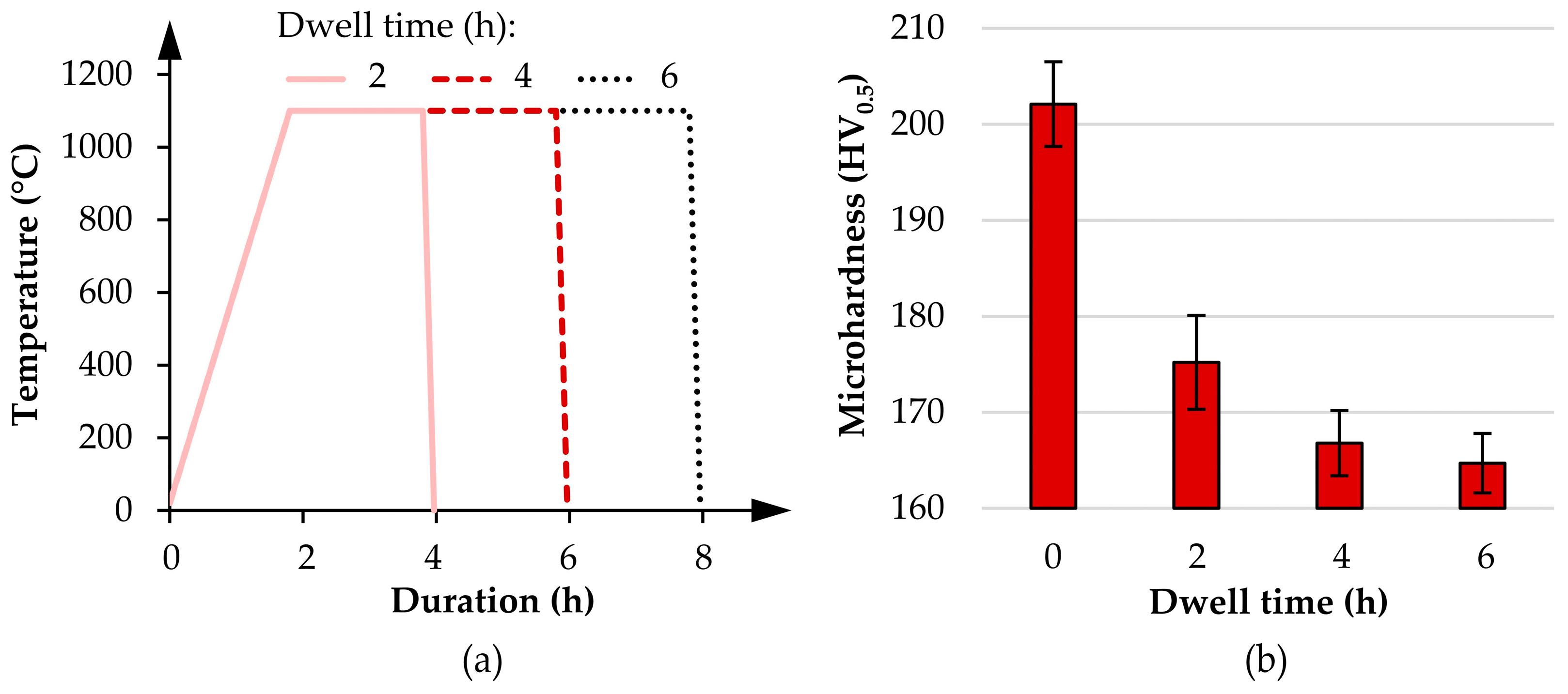

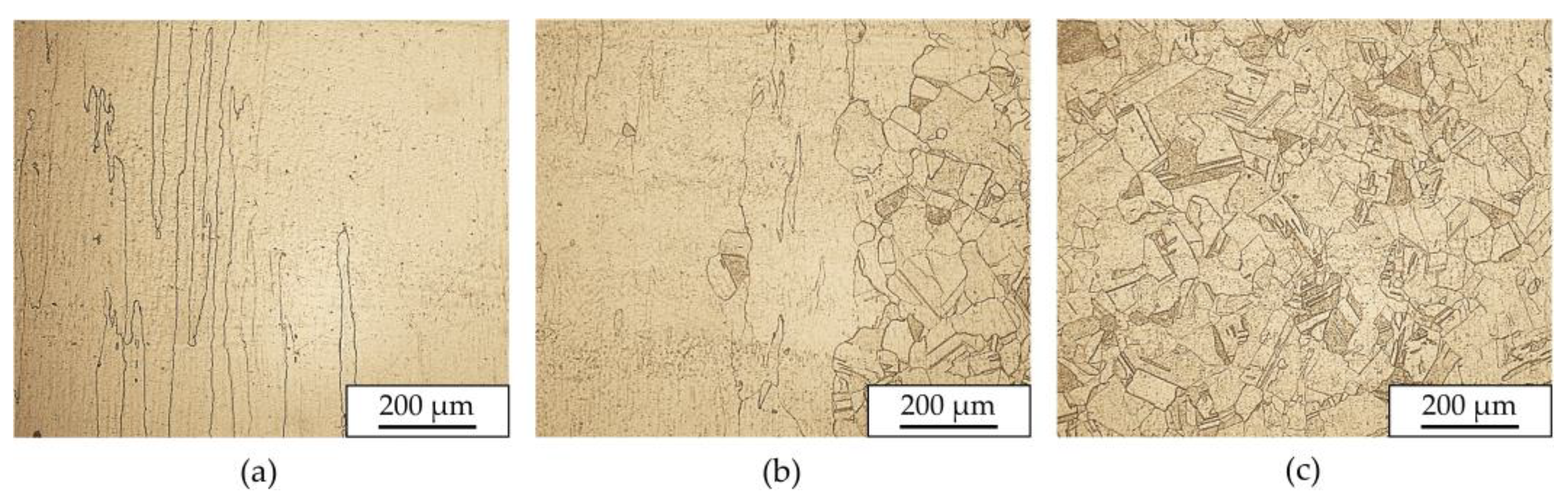

3.1. Thermal Processing

3.2. Mechanical and Thermal Processing

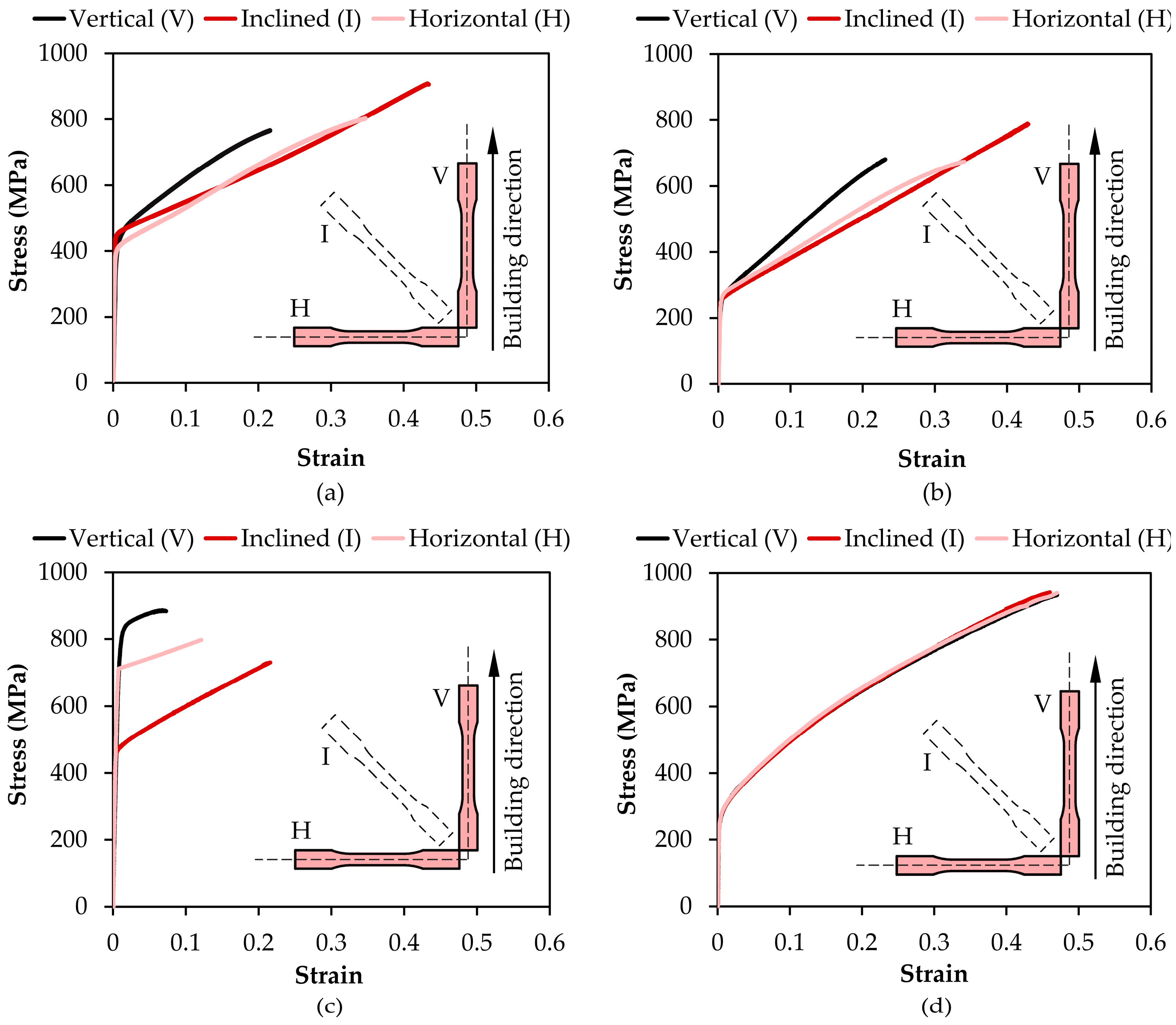

3.3. Flow Curves

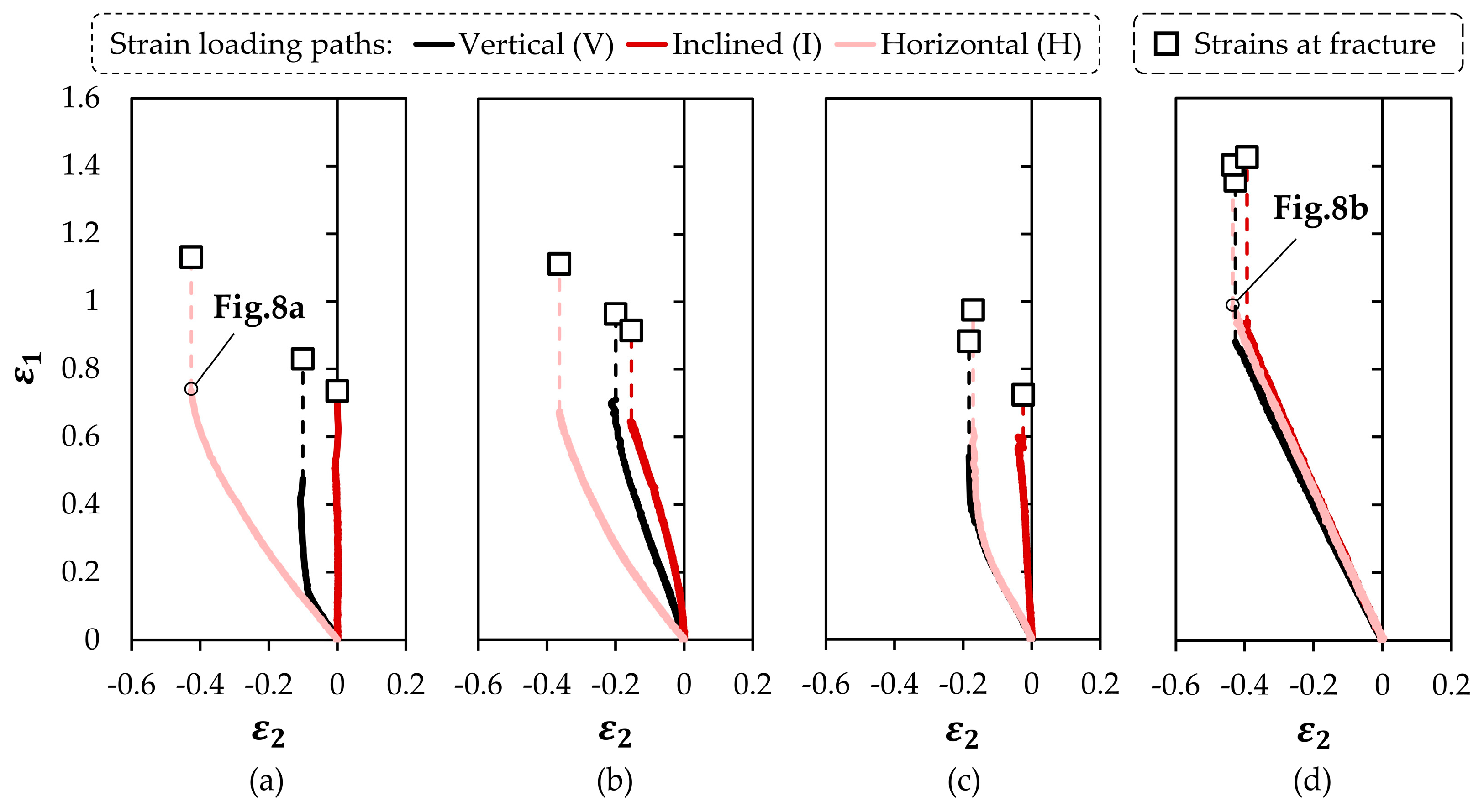

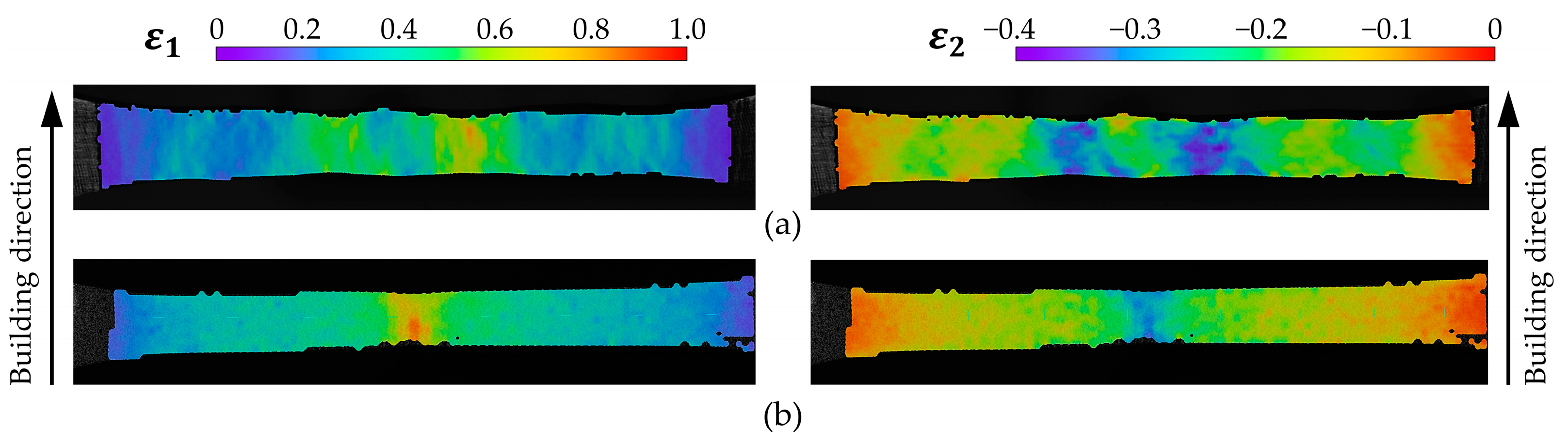

3.4. Formability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISO/ASTM 52900-21; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ASTM International: West Conshohocken, PA, USA, 2021.

- Cunningham, C.R.; Wang, J.; Dhokia, V.; Shrokani, A.; Newman, S.T. Characterisation of Austenitic 316 LSi Stainless Steel Produced by Wire Arc Additive Manufacturing with Interlayer Cooling. In Proceedings of the 2019 Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference; Austin, Austin, TX, USA, 12–14 August 2019. [Google Scholar] [CrossRef]

- Bi, X.; Li, R.; Hu, Z.; Gu, J.; Jiao, C. Microstructure and Texture of 2205 Duplex Stainless Steel Additive Parts Fabricated by the Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing (WAAM). Metals 2022, 12, 1655. [Google Scholar] [CrossRef]

- Sampaio, R.F.V.; Pragana, J.P.M.; Bragança, I.M.F.; Silva, C.M.A.; Nielsen, C.V.; Martins, P.A.F. Modelling of Wire-Arc Additive Manufacturing—A Review. Adv. Ind. Manuf. Eng. 2023, 6, 100121. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Hönnige, J.R.; Colegrove, P.A.; Ahmad, B.; Fitzpatrick, M.E.; Ganguly, S.; Lee, T.L.; Williams, S.W. Residual Stress and Texture Control in Ti-6Al-4V Wire + Arc Additively Manufactured Intersections by Stress Relief and Rolling. Mater. Des. 2018, 150, 193–205. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Waqar, S.; Garcia-Collado, A.; Gupta, M.K.; Krolczyk, G.M. A Technical Overview of Metallic Parts in Hybrid Additive Manufacturing Industry. J. Mater. Res. Technol. 2022, 18, 384–395. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sampaio, R.F.V.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid Metal Additive Manufacturing: A State–of–the-Art Review. Adv. Ind. Manuf. Eng. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Ambrogio, G.; Gagliardi, F.; Muzzupappa, M.; Filice, L. Additive-incremental forming hybrid manufacturing technique to improve customised part performance. J. Manuf. Process. 2019, 37, 386–391. [Google Scholar] [CrossRef]

- Meiners, F.; Ihne, J.; Jürgens, P.; Hemes, S.; Mathes, M.; Sizova, I.; Bambach, M.; Hama-Saleh, R.; Weisheit, A. New Hybrid Manufacturing Routes Combining Forging and Additive Manufacturing to Efficiently Produce High Performance Components from Ti-6Al-4V. Procedia Manuf. 2020, 47, 261–267. [Google Scholar] [CrossRef]

- Merklein, M.; Schulte, R.; Papke, T. An Innovative Process Combination of Additive Manufacturing and Sheet Bulk Metal Forming for Manufacturing a Functional Hybrid Part. J. Mater. Process. Technol. 2021, 291, 117032. [Google Scholar] [CrossRef]

- López, C.; Elías-Zúñiga, A.; Jiménez, I.; Martínez-Romero, O.; Siller, H.R.; Diabb, J.M. Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process. Materials 2018, 11, 2542. [Google Scholar] [CrossRef]

- Bambach, M.; Sviridov, A.; Weisheit, A.; Schleifenbaum, J. Case Studies on Local Reinforcement of Sheet Metal Components by Laser Additive Manufacturing. Metals 2017, 7, 113. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A Review of the Wire Arc Additive Manufacturing of Metals: Properties, Defects and Quality Improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Gornyakov, V.; Sun, Y.; Ding, J.; Williams, S. Modelling and Optimising Hybrid Process of Wire Arc Additive Manufacturing and High-Pressure Rolling. Mater. Des. 2022, 223, 111121. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Bai, J.; Zhai, Y.; Ma, P. The Strengthening Effect of Inter-Layer Cold Working and Post-Deposition Heat Treatment on the Additively Manufactured Al–6.3Cu Alloy. Mater. Sci. Eng. A 2016, 651, 18–26. [Google Scholar] [CrossRef]

- Silva, C.M.A.; Pragana, J.P.M.; Bragança, I.M.F.; Martins, P.A.F. Mechanical and thermal processing of wire-arc additively deposited stainless steel. CIRP Ann. 2024, in press. [Google Scholar] [CrossRef]

- Pragana, J.P.; Bragança, I.M.; Reis, L.; Silva, C.M.; Martins, P.A. Formability of Wire-Arc Deposited AISI 316L Sheets for Hybrid Additive Manufacturing Applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 2839–2850. [Google Scholar] [CrossRef]

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- Atkins, A.G. Fracture in Forming. J. Mater. Process. Technol. 1996, 56, 609–618. [Google Scholar] [CrossRef]

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Lee, S.H. CMT-Based Wire Arc Additive Manufacturing Using 316L Stainless Steel: Effect of Heat Accumulation on the Multi-Layer Deposits. Metals 2020, 10, 278. [Google Scholar] [CrossRef]

- Elmer, J.W.; Fisher, K.; Gibbs, G.; Sengthay, J.; Urabe, D. Post-Build Thermomechanical Processing of Wire Arc Additively Manufactured Stainless Steel for Improved Mechanical Properties and Reduction of Crystallographic Texture. Addit. Manuf. 2022, 50, 102573. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Paul, S.K.; Manikandan, G.; Verma, R.K. Prediction of Entire Forming Limit Diagram from Simple Tensile Material Properties. J. Strain Anal. Eng. Des. 2013, 48, 386–394. [Google Scholar] [CrossRef]

| Element | Fe | Cr | Ni | Mo | Mn | Si | N | C |

|---|---|---|---|---|---|---|---|---|

| % wt | Bal. | 18.2 | 12.0 | 2.6 | 1.7 | 0.4 | 0.04 | 0.01 |

| Processing Parameters | Schematic Representation | |

|---|---|---|

| Voltage: | Current: |  |

| 16.5 V | 100 A | |

| Wire feed speed: | ||

| 6 m/min | ||

| Travel speed: | ||

| 600 mm/min | ||

| Shielding gas flow rate: | ||

| 10 L/min | ||

| Stick-out length: | ||

| 10 mm | ||

| Processing Conditions | Samples and Test Specimens | ||

|---|---|---|---|

| As-built | Mechanical | Thermal |  |

Dwell time = 0 h | Dwell time = 2 h; 4 h; 6 h (annealing at 1100 °C) | ||

| |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pragana, J.P.M.; Brito, B.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. On the Enhancement of Material Formability in Hybrid Wire Arc Additive Manufacturing. Metals 2024, 14, 716. https://doi.org/10.3390/met14060716

Pragana JPM, Brito B, Bragança IMF, Silva CMA, Martins PAF. On the Enhancement of Material Formability in Hybrid Wire Arc Additive Manufacturing. Metals. 2024; 14(6):716. https://doi.org/10.3390/met14060716

Chicago/Turabian StylePragana, João P. M., Beatriz Brito, Ivo M. F. Bragança, Carlos M. A. Silva, and Paulo A. F. Martins. 2024. "On the Enhancement of Material Formability in Hybrid Wire Arc Additive Manufacturing" Metals 14, no. 6: 716. https://doi.org/10.3390/met14060716

APA StylePragana, J. P. M., Brito, B., Bragança, I. M. F., Silva, C. M. A., & Martins, P. A. F. (2024). On the Enhancement of Material Formability in Hybrid Wire Arc Additive Manufacturing. Metals, 14(6), 716. https://doi.org/10.3390/met14060716