Abstract

Fe–Mn–Al–C low-density steels are regarded as promising materials applied in the automotive industry to achieve the minimization of vehicular emissions and fuel consumption. This study investigates the high-temperature strength and hot ductility of Fe–22Mn–9Al–0.6C low-density steel through high-temperature tensile tests at 800–950 °C. The high-temperature strength decreases with an increasing deformation temperature. This indicates that the precipitation of B2 reduces the hot ductility during the hot deformation of steel, where the results are consistent with those during the solid-solution treatment at 800–950 °C with a holding time of 0.5 h. Furthermore, at 800 °C the γ transforms into a mixture of α + DO3 and κ-carbide precipitates. A transformation of κ + DO3→B2 occurs in the temperature range of 850–900 °C, and at this point the κ-carbide dissolves into the matrix and B2 is generated, resulting in a significant decrease in hot ductility. As the temperature increases up to 950 °C, B2 emerges and transforms into the δ phase, and the κ-carbide precipitates along the γ/γ grain boundaries. The precipitation of B2 during high-temperature treatments in Fe-Mn-Al-C low-density steels is the critical factor affecting hot ductility, leading to crack generation; therefore, it is extremely essential to prevent the temperature interval of B2 precipitation during hot deformation processes.

1. Introduction

Pressing environmental issues have led to a higher demand for lightweight automobiles []. Unfortunately, the traditional method of improving the strength of advanced high-strength steels cannot meet the requirements. In such cases, Fe–Mn–Al–C low-density steels are widely used due to their lower density and excellent combination of strength and ductility [,,,,,,,,,,,,,,,].

Some studies have reported the mechanical properties of Fe–Mn–Al–C low-density steels where the ultimate tensile strength, total elongation, and yield strength are in the ranges of 0.6–2.0 GPa, 30–100%, and 0.5–1.4 GPa, respectively [,,,,,,]. Yoo et al. [] reported that the results for the combination of strength and ductility exceeded 80 GPa·% in Fe–28Mn–9Al–0.8C low-density steel. In the study [], an optimal aging at 450 °C resulted in the subject alloy possessing a high yield strength of 1383 MPa with 32.5% elongation in Fe–9Al–28Mn–1.8C low-density steel. The excellent combination of strength and ductility in Fe–Mn–Al–C low-density steels is closely related to their microstructure, especially the secondary phases, such as κ-carbide, B2, DO3, and β-Mn, owing to the high contents of Mn, Al, and C, which provide an important strengthening effect [,,,,,].

κ-carbide forms during treatment at 500 °C to 900 °C in Fe–Mn–Al–C low-density steels, and fine intragranular κ-carbide is considered to play a positive role in improving the yield stress [,]. In addition to κ-carbide, B2 and DO3 ordered phases can also appear in Fe–Mn–Al–C low-density steels. The B2 ordered phase exhibits various morphologies in Fe–Mn–Al–C low-density steels: (1) coarse and elongated B2 bands, (2) polygonal B2 particles formed at grain boundaries, and (3) sharp-edged B2 particles within an austenite matrix [,,,,,,]. B2 precipitates from the α when the temperature reaches the ordering temperature range, and the growth of the B2 is believed to follow the classical grain growth kinetics []. In the Fe–Al phase diagram, the Al belongs to an α stabilizer. When the atomic fraction of Al is higher than 20%, the body-centered cubic (BCC) structure mutates from a disordered structure to an ordered structure, becoming a DO3 phase with a stable Fe3Al structure. The stabilized DO3 structure is transformed into a B2-structured Fe–Al phase when the temperature is higher than 530 °C []. Chao et al.’s [] study reported that DO3 + κ-carbide appeared on the austenite grain boundaries in Fe–28.6Mn–9.8Al–1.0C–0.8Si aged at 725 °C and 750 °C for 2 h, while a B2 + DO3 phase was detected after aging at 800 °C for 1 h. After aging at 840 °C for 1 h, the κ-carbide disappeared. The authors of [] suggested that a disordered BCC phase can be formed within the temperature range of 800–840 °C, and that a transformation occurs between the ordered phases during quenching at 840 °C, resulting in the formation of the B2 phase. Depending on the chemical composition and heat treatment conditions, β-Mn phases can also form in the microstructure of low-density steels. β-Mn phases with lath-shaped morphology appeared in Fe–31Mn–11Al–0.9C aged at 550 °C for 5 h [].

Despite the excellent combination of strength and ductility in Fe–Mn–Al–C low-density steels at room temperature due to the precipitations, the formation of the secondary phases along the grain boundaries can cause cracks and weaken the high-temperature performance [,,,]. Moon et al. [,] investigated the high-temperature tensile properties of Fe–24Mn–8Al–1C and Fe–30Mn–9Al–1C low-density steels, showing that the ductility was greatly reduced at temperatures of 600–900 °C due to the coarse κ-carbide formed in the matrix and along the austenite grain boundaries. The coarse κ-carbide strengthened the matrix but weakened the solid-solution-depleted regions adjacent to the grain boundaries, leading to high-temperature embrittlement and intergranular cracking. Lee et al. [] reported that the strength increased dramatically yet the ductility exhibited a considerable decrease in Fe–31.4Mn–11.4Al–0.89C low-density steel, which was attributed to β-Mn precipitation at the α/γ interfaces and γ/γ grain boundaries during aging at 550 °C. The decrease in the hot ductility is of great importance in limiting the hot processing of Fe–Mn–Al–C low-density steels [,]. However, there has been limited research on the effects of secondary phases’ precipitation on the hot ductility and deformation mechanisms of Fe–Mn–Al–C low-density steels [,,], particularly the action of B2 and DO3 during high-temperature deformation.

Our previous study on designed Fe–22Mn–9Al–0.6C low-density steel for automotive connecting rods found that the ends of the connecting rods exhibited cracks during the hot-forging process. To clarify the cracking of connecting rods, this study aimed to investigate the effects of secondary phases on the hot ductility of Fe–22Mn–9Al–0.6C low-density steel during high-temperature deformation. Meanwhile, the effects of the secondary phases’ precipitation on the generation of cracks are discussed, with a focus on B2.

2. Material and Experimental Methods

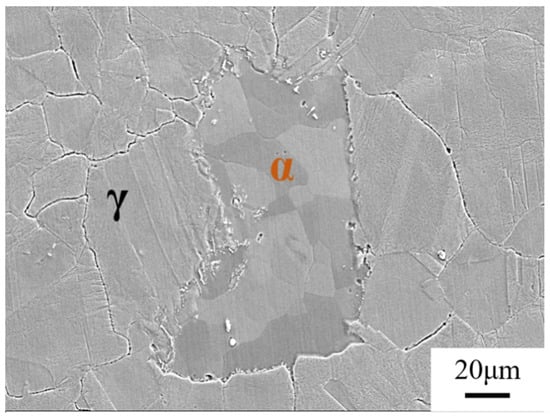

A 200 kg ingot of Fe–22Mn–9Al–0.6C steel was prepared via induction melting in an argon atmosphere, and the chemical composition was measured by titration. The ingot was soaked completely at 1100 °C for 6 h and then hot-forged into a rod of 60 mm in diameter at the temperature range of 1000 °C to 1150 °C followed by cooling to room temperature in sand. The average density of the Fe–22Mn–9Al–0.6C steel was 6.80 g/cm3, which was measured using a STARTORIU BP211D electronic analytical balance (STARTORIU Ltd., Gützenburg, Germany). Figure 1 shows an SEM image of the microstructure after hot-forging, showing that the microstructure of the hot-forged steel consists of austenite (γ) and ferrite (α).

Figure 1.

SEM image of the microstructure after hot-forging.

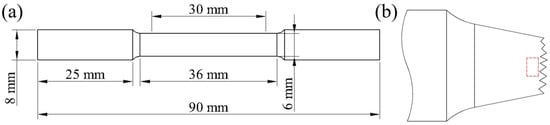

The specimens for high-temperature tension tests were cut from the hot-forged rod, machined to a diameter of 6 mm and gauge sections of 36 mm, with threads on both end sides. The size of the high-temperature tension test specimens is shown in Figure 2a. According to the standard GB/T 228-2010 [], the high-temperature tensile tests were conducted using an INSTRON 5982 high- and low-temperature tensile testing machine (INSTRON Ltd., Canton, SD, USA) at 800 °C, 850 °C, 900 °C, and 950 °C, with a strain rate of 1.6 × 10−2 s−1, and the specimens were preheated at the test temperatures for 10 min before deformation. Four tests were performed at each temperature. The specimens nearing fracture after the high-temperature tensile tests were cut to a cross-section of 10 mm × 10 mm along the longitudinal axis to explore the evolution of the secondary phases.

Figure 2.

Schematic illustrations of (a) high-temperature tension test specimens and (b) microstructure observation in the fractured specimens (red dotted box).

Additionally, another set of specimens with dimensions of 10 mm × 10 mm × 10 mm were cut from the forged rod and solid-solution treated at 800 °C, 850 °C, 900 °C, and 950 °C for 0.5 h, before being water-quenched to room temperature to determine the secondary phases’ precipitation behaviors.

The microstructure and secondary phases were identified through a combination of RIGAKU SmartLab X-ray diffraction (XRD, RIGAKU Ltd., Tokyo, Japan), ZEISS SIGMA300 scanning electron microscopy (SEM, CARL ZEISS AG Ltd., Oberkochen, Germany), and JEOL JEM-F200 transmission electron microscopy (TEM, JEOL Ltd., Tokyo, Japan). The fractured specimens and solid-solution specimens were mechanically ground and polished for the XRD measurements, and the location of the cross-section is shown in Figure 2b. The XRD measurements were performed using Cu Kα radiation with a scanning rate of 2 °/min in the scanning range of 40–100°. After the XRD measurements, the fractured specimens and solid-solution specimens were prepared for TEM and SEM observations, respectively. The thin TEM slices were cut at the fracture site of the fractured specimens to dimensions of 8 mm × 10 mm × 0.2 mm, mechanically polished to a thickness of approximately 70 μm, and then manually punched into discs with a diameter of 3 mm. The TEM discs were electrochemically etched using a LEBO TJ-100SE twin-jet electrolytic polishing machine (LEBO Ltd., Jiangsu, China) in a mixed solution of 5 vol% perchloric acid and 95 vol% methanol at −30 °C, using a voltage of 15 V. The TEM observations were performed under dark-field mode for the identification of ordered precipitates. The solid-solution specimens for the SEM observations were etched in a solution of 10% nitric acid. The SEM observations were operated at 20 KV.

3. Results

3.1. High-Temperature Tensile Properties

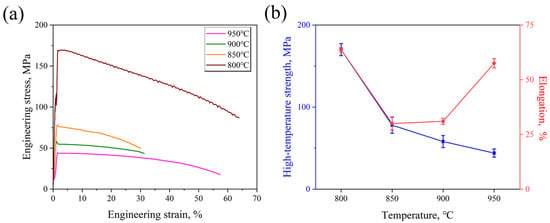

Figure 3 shows the high-temperature tensile properties of Fe–22Mn–9Al–0.6C low-density steel at the deformation temperatures of 800–950 °C. From Figure 3b, it can be seen that the high-temperature strength shows a decreasing trend from 170 MPa to 44 MPa as the deformation temperature increases. It is worth noting that the reduction in high-temperature strength at 800 °C to 850 °C is 92 MPa, which is much higher than the other deformation temperature spans. In addition, the elongation after fracture is approximately 60% at the deformation temperatures of 800 °C, 850 °C, and 900 °C, while for 850 °C and 900 °C it decreases to around half of the maximum (31% and 33%, respectively). It is believed that phase transformation occurs in the range of 850 °C to 900 °C, leading to the hot ductility worsening, which presumably causes and promotes crack generation in the forged connecting rods.

Figure 3.

High-temperature tensile properties at deformation temperatures from 800 °C to 950 °C: (a) engineering strain–stress curves; (b) tensile stress and elongation.

3.2. Precipitates after High-Temperature Tensile Tests

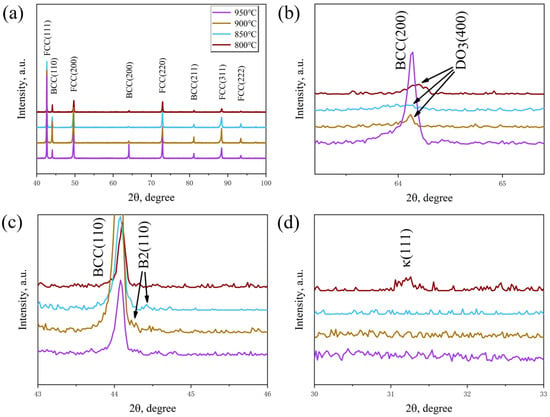

Figure 4 shows the XRD intensity profiles of the fractured specimens subjected to high-temperature tensile tests at temperatures of 800–950 °C for Fe–22Mn–9Al–0.6C steel, where (a–d) are the diffraction peaks of the matrix, DO3, B2, and κ-carbide, respectively. In Figure 4a, there are the diffraction peaks of face-centered cubic (FCC) and BCC structures, corresponding to γ and δ, respectively. Furthermore, it can be seen that the diffraction peaks of the DO3(400), B2(110), and κ-carbide(111) appear at deformation temperatures of 800–900 °C, 850–900 °C, and 800 °C in Figure 4b–d, respectively.

Figure 4.

XRD intensity profiles of the fractured specimens at deformation temperatures of 800–950 °C: (a) matrix, (b) DO3, (c) B2, and (d) κ-carbide.

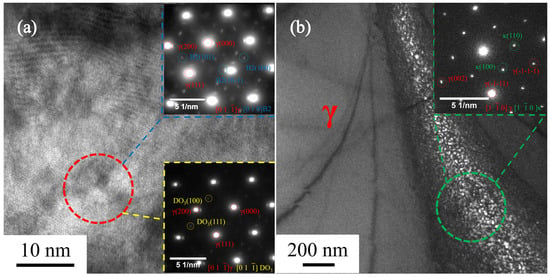

Figure 5 shows the TEM results of the microstructure near the fracture in Fe–22Mn–9Al–0.6C after high-temperature tensile tests at 900 °C and 950 °C. The incident direction of the electron beam is [01-1]. The TEM high-resolution image and selected-area diffraction (SAD, JEOL Ltd., Tokyo, Japan) patterns of the precipitates in the fractured specimen at 900 °C are shown in Figure 5a, indicating that the diffraction pattern presents the FCC structure of γ. Moreover, weak superlattice diffraction spots were detected, which were identified as B2 and DO3 after calibration. Figure 5b shows the TEM dark-field image and SAD patterns of the precipitate in the fractured specimen at 950 °C, revealing the presence of nanoscale precipitates within the γ grain boundaries, which were identified through calibration as κ-carbide. In the deformation temperature range of 900 °C to 950 °C, the transformation of secondary phases occurred, meaning that the B2 changed to κ-carbide. Combined with the XRD results, the precipitates were DO3 and κ-carbide at 800 °C; as the temperature increased to 850 °C, the κ-carbide dissolved and B2 precipitated. The presence of the B2 and DO3 remained when the deformation temperature increased to 950 °C; at higher temperatures, the DO3 and the B2 dissolved and the κ-carbide re-precipitated.

Figure 5.

TEM images and SAD patterns of the precipitates in the fractured specimens at (a) 900 °C and (b) 950 °C.

3.3. Precipitates under High Temperature

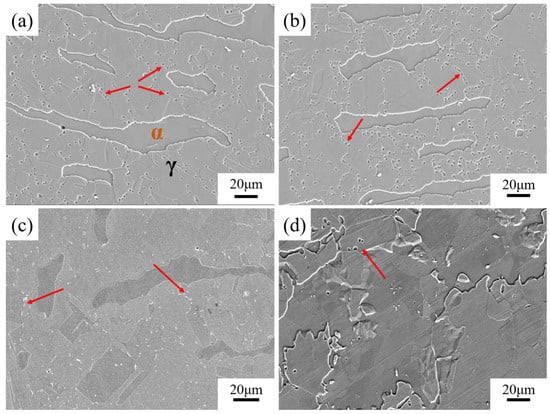

Figure 6 shows the SEM images of the microstructure in the solid-solution specimens at 800–950 °C, with a holding time of 0.5 h. It can be seen that the microstructure consists of equiaxed γ and banded α (Figure 6a–c), and all grains are equiaxed when the temperature exceeds 950 °C (Figure 6d). In addition, some discrete particles (marked by red arrows) can be observed in the microstructure at 800–950 °C.

Figure 6.

SEM images of the microstructure in solid-solution specimens at different temperatures: (a) 800 °C, (b) 850 °C, (c) 900 °C, and (d) 950 °C (red arrows indicate discrete particles).

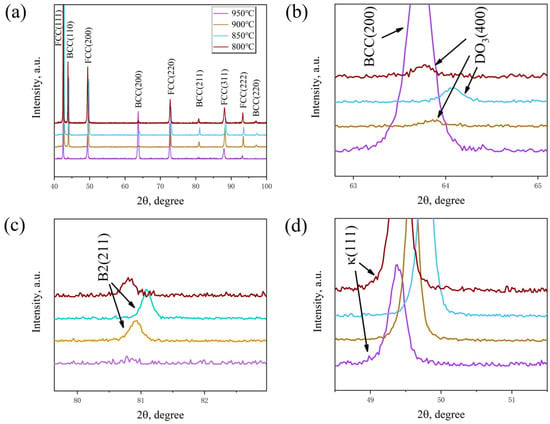

Figure 7 shows the XRD intensity profiles of the solid-solution specimens subjected to temperatures of 800–950 °C with a holding time of 0.5 h for Fe–22Mn–9Al–0.6C steel, where (a–d) are the diffraction peaks of the matrix, DO3, B2, and κ-carbide, respectively. In Figure 7a, the diffraction peaks of FCC and BCC structures can be seen, corresponding to γ and δ, respectively. In addition, it can be seen that the diffraction peaks of the DO3(400), B2(211), and κ-carbide(111) appear at the deformation temperatures of 800–900 °C, 850–900 °C, and 800 °C/950 °C in Figure 7b–d, respectively.

Figure 7.

XRD intensity profiles of the solid-solution specimens at the temperatures of 800–950 °C: (a) matrix, (b) DO3, (c) B2, and (d) κ-carbide.

4. Discussion

The reduction in high-temperature strength from 800 °C to 850 °C is much greater than for other deformation temperature intervals in Fe–22Mn–9Al–0.6C steel. From the XRD intensity profiles in Figure 4a–d, it can be seen that DO3 and κ-carbide existed in addition to γ and δ at 800 °C. At 850 °C, the κ-carbide disappeared and B2 appeared. It is well known that the interactions between κ-carbide and dislocations play an important role in the strength increase of Fe–Mn–Al–C low-density steels []. Therefore, the sudden drop in high-temperature strength at the deformation temperature of 850 °C can be attributed to the disappearance of the κ-carbide in Fe–22Mn–9Al–0.6C steel.

In previous studies [,,], κ-carbide was detrimental to ductility, while it increased the strength of Fe–Mn–Al–C low-density steels. In the engineering stress–strain curves of Figure 3a, the disappearance of κ-carbide does not enhance the ductility, instead causing a substantial reduction, which is well explained by the appearance of the B2 phase in Figure 4c. As the temperature increased to 850–900 °C, the κ-carbide dissolved and B2 precipitated, as shown in Figure 4c,d and Figure 7c,d. Upon further increasing the temperature to 950 °C, the B2 dissolved and the κ-carbide re-precipitated. From the TEM results in Figure 5, it can be seen that B2 and DO3 existed at the deformation temperature of 900 °C, while κ-carbide emerged at 950 °C. The decrease in the hot ductility at the deformation temperatures of 850–900 °C is believed to be the consequence of the B2 precipitation. Therefore, it is necessary to avoid the precipitation of B2 during hot deformation processes for Fe–Mn–Al–C steel. In Figure 5b, it can be seen that the size of κ-carbide is at the nanometer scale, suggesting that the lack of κ-carbide diffraction peaks may be attributed to the small size of the κ-carbide at this temperature.

In Figure 6, some discrete particles can be observed in the solid-solution specimens at 800–950 °C. Liu et al. [] reported that a mixture of α + DO3 particles preferentially forms along the austenite grain boundaries during the solid-solution treatment and is retained after quenching. According to the Fe–C phase diagram, the austenite begins to undergo an ordering transformation of γ→α when the carbon content is below 0.77% and the temperature is above Ac1, and disordered α phases form within the austenitic matrix. The formation of the α phase is closely related to the high Al content in the experimental steel, i.e., the increase in the Al content, as a ferrite stabilizer, decreases the stability of austenite under higher temperatures, thereby expanding the ferrite region and leading to the formation of a ferrite phase during the solution treatment []. These α phases combine with DO3 and are retained after quenching. In Figure 4 and Figure 7, the κ-carbide had already precipitated at 800 °C. The molecular formula for κ-carbide is (Fe, Mn)3(Fe, Al)Cx with a face-centered cubic structure. The Al and Fe (Mn) are located at the corner and face-centered positions, respectively; hence, Al–Al nearest neighbors do not exist. The DO3-type antiphase vectors a/2<100> can produce Al–Fe nearest neighbors, which are similar to those existing in the κ-carbide structure. Therefore, κ-carbide can form not only on the austenite matrix [], but also within the ordered DO3 regions [,,]. After the precipitation, the κ-carbide’s rapid quenching results in smaller-sized κ-particles, which are solubilized in the austenite matrix along with α and DO3 with a discrete particle form.

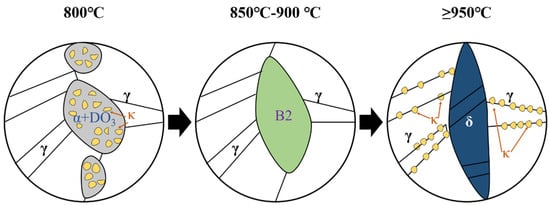

Therefore, the XRD results of both the solid-solution treatments and high-temperature tensile tests specified that two phase-transition reactions occurred at 800–950 °C. Within the temperature range of 800–850 °C, the κ-carbide formed within the α phase did not segregate internally [] and was solidly dissolved with the discrete particles. This structure can be preserved up to 850 °C, and the DO3 + κ→B2 phase transition occurs in the mixtures at 850–900 °C []. When maintained at this temperature, a significant amount of B2 is generated, and the κ-carbide dissolves. The B2 is generated from discrete particles by ordered transformation and distributed along the austenite grain boundaries, leading to a transition in the fracture mode of the steel towards brittle fracture [], which results in a significant reduction in the hot ductility of low-density steel. Moreover, in B2-type structures, unlike the DO3 structure, a/4<111> displacements produce Al-Al nearest neighbors; therefore, B2 is not favorable for the formation of κ-carbide precipitates. Therefore, aside from participating in phase transformation reactions, this could be another crucial factor contributing to the disappearance of κ-carbide between 850 °C and 900 °C. As the temperature increases, the DO3 + κ→B2 phase transition terminates. The B2 gradually decomposes and transforms into the δ phase at high temperatures (Figure 4b and Figure 7b) as the temperature increases up to 950 °C, being solidly dissolved in the γ matrix. The precipitation of κ-carbide is no longer suppressed, precipitating as nanoscale particles at the γ/γ grain boundaries. The whole phase transformation reaction can be summarized as α + DO3 + κ→B2→δ + κ in Figure 8. Thus, the occurrence of cracks in the connecting rod blanks can be attributed to the rapid cooling at the ends during the forging process, with some regions cooling to temperatures within the range of 850–900 °C, resulting in the formation of B2, which causes brittleness, poor hot ductility, and the initiation of cracking (stress concentration) during thermomechanical processes.

Figure 8.

Schematic illustration of the secondary phases’ transformations at 800–950 °C.

5. Conclusions

The hot ductility and secondary-phase transformations of Fe–22Mn–9Al–0.6C low-density steel were investigated in this study and the following conclusions are drawn:

- (1)

- The reduction in high-temperature strength at 800 °C to 850 °C is much higher than for other deformation temperature intervals, which is presumably attributable to the dissolution of κ-carbide.

- (2)

- The hot ductility decreases to half of the maximum, from approximately 60% to 30%, at deformation temperatures of 850–900 °C, which is presumably attributable to the formation of B2 in Fe–22Mn–9Al–0.6C low-density steel.

- (3)

- The secondary phase transformations that occur as the temperature increases from 800 °C to 950 °C are considered to be α + DO3 + κ→B2→δ + κ in the matrix.

- (4)

- The reduction in hot ductility tends to cause cracks in the alloy during the hot-forging process and may even lead to scrapping, which needs to be taken care of during hot deformation.

Author Contributions

Conceptualization, T.M. and X.W.; methodology, T.M. and H.D.; formal analysis, J.W. and Y.Z.; investigation, J.W., Y.Z., and T.M.; resources, T.M. and H.D.; data curation, T.M. and X.W.; writing—original draft, J.W. and T.M.; writing—review and editing, J.W., T.M., and X.W.; supervision, T.M. and X.W.; project administration, T.M., X.W., and H.D.; funding acquisition, T.M. All authors have read and agreed to the published version of the manuscript.

Funding

The authors were sponsored by the Natural Science Foundation of Shanghai with grant number 23ZR1421700.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

T.M. specially thanks Fort Thitipong Sangngey and Peat Wasuthorn Chaijindar for providing the most steadfast support, inspiration, and motivation that give her the strength to overcome all obstacles in her life. At the same time, T.M. thanks Ruyun Ji and Xin Wang for being with her all the way.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tang, D.; Mi, Z.; Chen, Y. Technology and research and development of advanced automobile steel abroad. Iron Steel 2005, 40, 1–4. [Google Scholar]

- Churyumov, A.Y.; Kazakova, A.A.; Pozdniakov, A.V.; Churyumova, T.A.; Prosviryakov, A.S. Investigation of hot deformation behavior and microstructure evolution of lightweight Fe–35Mn–10Al–1C steel. Metals 2022, 12, 831. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.W.; Kim, N.J. Fe-Al-Mn-C lightweight structural alloys: A review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 1–11. [Google Scholar] [CrossRef]

- Zargaran, A.; Kim, H.S.; Kwak, J.H.; Kim, N.J. Effects of Nb and C additions on the microstructure and tensile properties of lightweight ferritic Fe–8Al–5Mn alloy. Scr. Mater. 2014, 89, 37–40. [Google Scholar] [CrossRef]

- Sutou, Y.; Kamiya, N.; Umino, R.; Ohnuma, I.; Ishida, K. High-strength Fe–20Mn–Al–C-based alloys with low density. ISIJ Int. 2010, 50, 893–899. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brüx, U. Microstructures and mechanical properties of high-strength Fe–Mn–Al–C light-weight TRIPLEX steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe–Mn–Al–C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Chang, K.M.; Chao, C.G.; Liu, T.F. Excellent combination of strength and ductility in an Fe-9Al-28Mn-1.8 C alloy. Scr. Mater. 2010, 63, 162–165. [Google Scholar] [CrossRef]

- Yao, M.J.; Welsch, E.; Ponge, D.; Haghighat, S.M.H.; Sandlöbes, S.; Choi, P.; Herbig, M.; Bleskov, I.; Hickel, T.; Lipinska-Chwalek, M.; et al. Strengthening and strain hardening mechanisms in a precipitation-hardened high-Mn lightweight steel. Acta Mater. 2017, 140, 258–273. [Google Scholar] [CrossRef]

- Haase, C.; Zehnder, C.; Ingendahl, T.; Bikar, A.; Tang, F.; Hallstedt, B.; Hu, W.; Bleck, W.; Molodov, D.A. On the deformation behavior of κ-carbide-free and κ-carbide-containing high-Mn light-weight steel. Acta Mater. 2017, 122, 332–343. [Google Scholar] [CrossRef]

- Hu, J.; Li, X.Y.; Meng, Q.W.; Wang, L.Y.; Li, Y.Z.; Xu, W. Tailoring retained austenite and mechanical property improvement in Al-Si-V containing medium Mn steel via direct intercritical rolling. Mater. Sci. Eng. A 2022, 855, 143904. [Google Scholar] [CrossRef]

- Choi, K.; Seo, C.H.; Lee, H.; Kim, S.K.; Kwak, J.H.; Chin, K.G.; Park, K.T.; Kim, N.J. Effect of aging on the microstructure and deformation behavior of austenite base lightweight Fe-28Mn-9Al-0.8 C steel. Scr. Mater. 2010, 63, 1028–1031. [Google Scholar] [CrossRef]

- Frommeyer, G.; Drewes, E.J.; Engl, B. Physical and mechanical properties of iron-aluminium- (Mn, Si) lightweight steels. Metall. Res. Technol. 2000, 97, 1245–1253. [Google Scholar] [CrossRef]

- Imandoust, A.; Zarei-Hanzaki, A.; Sabet, M.; Abedi, H.R. An analysis of the deformation characteristics of a dual phase twinning-induced plasticity steel in warm working temperature regime. Mater. Des. 2012, 40, 556–561. [Google Scholar] [CrossRef]

- Kim, Y.G.; Park, Y.S.; Han, J.K. Low temperature mechanical behavior of microalloyed and controlled-rolled Fe–Mn–Al–CX alloys. Metall. Trans. A 1985, 16, 1689–1693. [Google Scholar] [CrossRef]

- Granato, A.; Hikata, A.; Lücke, K. Recovery of damping and modulus changes following plastic deformation. Acta Metall. 1958, 6, 470–480. [Google Scholar] [CrossRef]

- Wu, Z.; Tang, Y.; Chen, W.; Lu, L.; Li, E.; Li, Z.; Ding, H. Exploring the influence of Al content on the hot deformation behavior of Fe-Mn-Al-C steels through 3D processing map. Vacuum 2019, 159, 447–455. [Google Scholar] [CrossRef]

- Song, C.; Wang, H.; Sun, Z.; Xu, J.; Chen, H.; Yin, W. A new hot-rolled lightweight steel with ultra-high strength and good ductility designed by dislocation character and transformation strain. Scr. Mater. 2022, 212, 114583. [Google Scholar] [CrossRef]

- Yoo, J.D.; Park, K.T. Microband-induced plasticity in a high Mn-Al-C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Yoo, J.D.; Hwang, S.W.; Park, K.T. Factors influencing the tensile behavior of a Fe-28Mn-9Al-0.8 C steel. Mater. Sci. Eng. A 2009, 508, 234–240. [Google Scholar] [CrossRef]

- Ha, M.C.; Koo, J.M.; Lee, J.K.; Hwang, S.W.; Park, K.T. Tensile deformation of a low density Fe–27Mn–12Al–0.8 C duplex steel in association with ordered phases at ambient temperature. Mater. Sci. Eng. A 2013, 586, 276–283. [Google Scholar] [CrossRef]

- Raabe, D.; Springer, H.; Gutiérrez-Urrutia, I.; Roters, F.; Bausch, M.; Seol, J.B.; Koyama, M.; Choi, P.P.; Tsuzaki, K. Alloy design, combinatorial synthesis, and microstructure–property relations for low-density Fe-Mn-Al-C austenitic steels. Jom 2014, 66, 1845–1856. [Google Scholar] [CrossRef]

- Liu, C.; Peng, Q.; Xue, Z. Research Situation of Fe–Mn–Al–C Low-density High-strength Steel. Mater. Rep. 2019, 33, 2572–2581. [Google Scholar]

- Lin, C.L.; Chao, C.G.; Bor, H.Y.; Liu, T.F. Relationship between microstructures and tensile properties of an Fe–30Mn–8.5 Al–2.0 C alloy. Mater. Trans. 2010, 51, 1084–1088. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, H.; Yang, M.; Jiang, P.; Yuan, F.; Wu, X. Shock and spall behaviors of a high specific strength steel: Effects of impact stress and microstructure. J. Appl. Phys. 2017, 121, 135901. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels. Scr. Mater. 2013, 68, 343–347. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, H.; Kim, N.J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 2015, 518, 77–79. [Google Scholar] [CrossRef]

- Rahnama, A.; Spooner, S.; Sridhar, S. Control of intermetallic nano-particles through annealing in duplex low density steel. Mater. Lett. 2017, 189, 13–16. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Wan, Y.; Wu, X.; Huang, Z. Research Progress of Ordered Precipitates in Low-density Steels. Mater. Rep. 2019, 32, 3979–3989. [Google Scholar]

- Park, G.; Nam, C.H.; Zargaran, A.; Kim, N.J. Effect of B2 morphology on the mechanical properties of B2-strengthened lightweight steels. Scr. Mater. 2019, 165, 68–72. [Google Scholar] [CrossRef]

- Cheng, W.C.; Cheng, C.Y.; Hsu, C.W.; Laughlin, D. Phase transformation of the L12 phase to kappa-carbide after spinodal decomposition and ordering in an Fe–C–Mn–Al austenitic steel. Mater. Sci. Eng. A 2015, 642, 128–135. [Google Scholar] [CrossRef]

- Sundman, B.; Ohnuma, I.; Dupin, N.; Kattner, U.R.; Fries, S.G. An assessment of the entire Al-Fe system including D03 ordering. Acta Mater. 2009, 57, 2896–2908. [Google Scholar] [CrossRef]

- Chao, C.Y.; Hwang, C.N.; Liu, T.F. Grain boundary precipitation behaviors in an Fe–9.8 Al–28.6 Mn–0.8 Si–1.0 C alloy. Scr. Mater. 1996, 34, 75–81. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.J.; Moon, J.; Kang, J.Y.; Lee, T.H.; Han, H.N. β-Mn formation and aging effect on the fracture behavior of high-Mn low-density steels. Scr. Mater. 2016, 124, 193–197. [Google Scholar] [CrossRef]

- Savaedi, Z.; Motallebi, R.; Mirzadeh, H. A review of hot deformation behavior and constitutive models to predict flow stress of high-entropy alloys. J. Alloys Compd. 2022, 903, 163964. [Google Scholar] [CrossRef]

- Moon, J.; Jo, H.H.; Park, S.J.; Kim, S.D.; Lee, T.H.; Lee, C.H.; Lee, M.G.; Hong, H.U.; Suh, D.W.; Raabe, D. Ti-bearing lightweight steel with large high temperature ductility via thermally stable multi-phase microstructure. Mater. Sci. Eng. A 2021, 808, 140954. [Google Scholar] [CrossRef]

- Moon, J.; Park, S.J.; Lee, C.H.; Hong, H.U.; Lee, B.H.; Kim, S.D. Influence of microstructure evolution on hot ductility behavior of austenitic Fe-Mn-Al-C lightweight steels during hot tensile deformation. Mater. Sci. Eng. A 2023, 868, 144786. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.J.; Lee, J.; Moon, J.; Kang, J.Y.; Kim, D.I.; Suh, J.Y.; Han, H.N. Effect of aging treatment on microstructure and intrinsic mechanical behavior of Fe–31.4 Mn–11.4 Al–0.89 C lightweight steel. J. Alloys Compd. 2016, 656, 805–811. [Google Scholar] [CrossRef]

- Renault, C.; Churyumov, A.Y.; Pozdniakov, A.V.; Churyumova, T.A. Microstructure and hot deformation behavior of FeMnAlCMo steel. J. Mater. Res. Technol. 2020, 9, 4440–4449. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P. Hot ductility behaviour of high-Mn TWIP steels. Mater. Sci. Eng. A 2011, 528, 1819–1827. [Google Scholar] [CrossRef]

- GB/T 228.1-202x; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. Standardization Administration of China (SAC). State Administration for Market Regulation (SAMR): Beijing, China, 2019.

- Kim, C.W.; Kwon, S.I.; Lee, B.H.; Moon, J.O.; Park, S.J.; Lee, J.H.; Hong, H.U. Atomistic study of nano-sized κ-carbide formation and its interaction with dislocations in a cast Si added FeMnAlC lightweight steel. Mater. Sci. Eng. A 2016, 673, 108–113. [Google Scholar] [CrossRef]

- Brüx, U.; Frommeye, R.G.; Jimenez, J. Light-weight steels based on iron-aluminium-influence of micro alloying elements (B, Ti, Nb) on microstructures, textures and mechanical properties. Steel Res. 2002, 73, 543–548. [Google Scholar] [CrossRef]

- Rana, R.; Liu, C.; Ray, R.K. Low-density low-carbon Fe-Al ferritic steels. Scr. Mater. 2013, 68, 354–359. [Google Scholar] [CrossRef]

- Herrmann, J.; Inden, G.; Sauthoff, G. Deformation behaviour of iron-rich iron-aluminum alloys at low temperatures. Acta Mater. 2003, 51, 2847–2857. [Google Scholar] [CrossRef]

- Liu, T.F.; Chou, J.S.; Wu, C.C. Effect of Si addition on the microstructure of an Fe–8.0 AI–29.0 Mn–0.90 C alloy. Metall. Trans. A 1990, 21, 1891–1899. [Google Scholar] [CrossRef]

- Cheng, W.C. Phase transformations of an Fe–0.85 C–17.9 Mn–7.1 Al austenitic steel after quenching and annealing. Jom 2014, 66, 1809–1820. [Google Scholar] [CrossRef]

- Choo, W.K.; Han, K.H. Phase constitution and lattice parameter relationships in rapidly solidified (Fe 0.65 Mn 0.35) 0.83 Al 0.17–xC and Fe 3 Al–xC pseudo-binary alloys. Metall. Trans. A 1985, 16, 5–10. [Google Scholar] [CrossRef]

- Choo, W.K.; Kim, D.G. Lattice modulation and formation of lamellar duplex ferrite/cubic carbide microstructure in rapidly solidified Fe-Ni-Al-C alloys. Metall. Mater. Trans. A 1987, 18, 759–766. [Google Scholar] [CrossRef]

- Han, K.H.; Yoon, J.C.; Choo, W.K. TEM evidence of modulated structure in Fe– Mn– Al–C austenitic alloys. Scr. Metall. 1986, 20, 33–36. [Google Scholar] [CrossRef]

- Acselrad, O.; Kalashnikov, I.S.; Silva, E.M.; Khadyev, M.S.; Simao, R.A. Diagram of phase transformations in the austenite of hardened alloy Fe–28% Mn–8.5% Al–1% C–1.25% Si as a result of aging due to isothermal heating. Met. Sci. Heat Treat. 2006, 48, 543–553. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).