Study on Grain Boundary Mechanical Behaviors of Polycrystalline γ-TiAl Using Molecular Dynamics Simulations

Abstract

1. Introduction

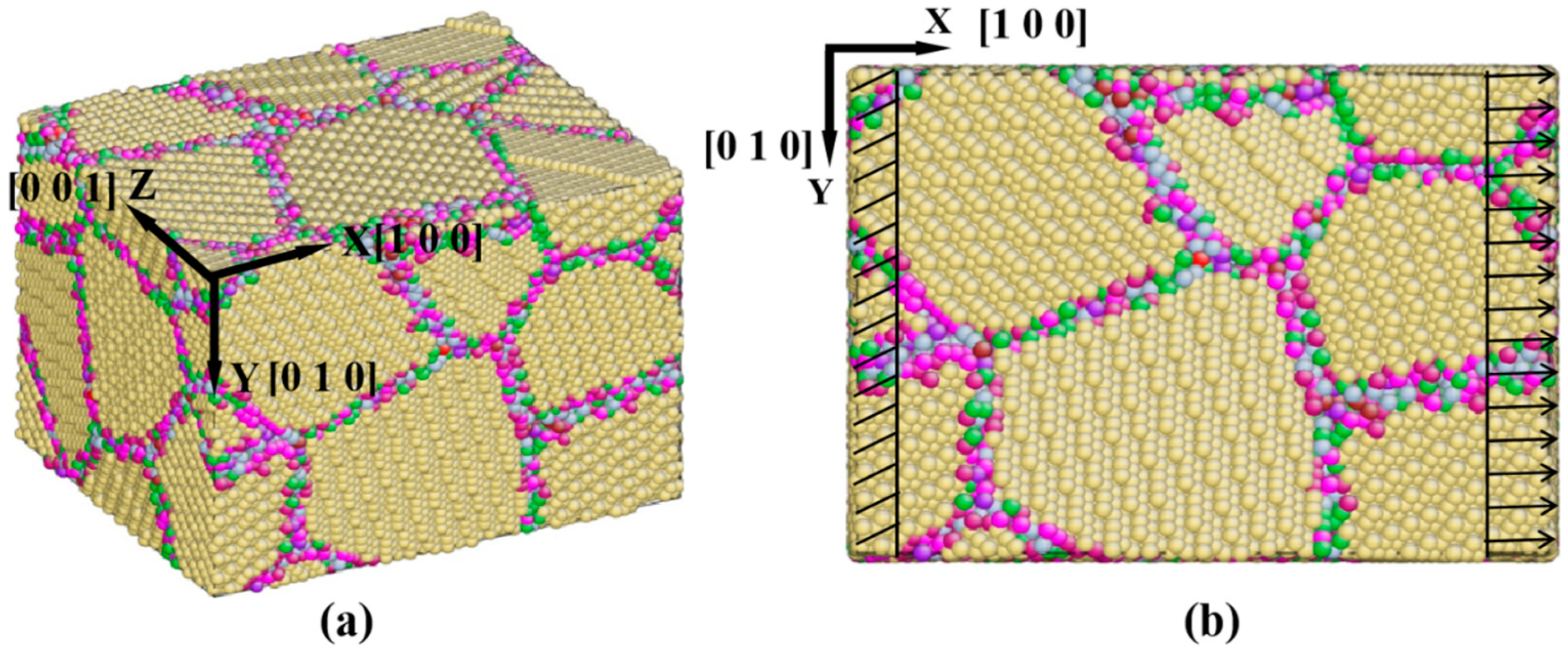

2. Modeling and Simulation

3. Results and Discussion

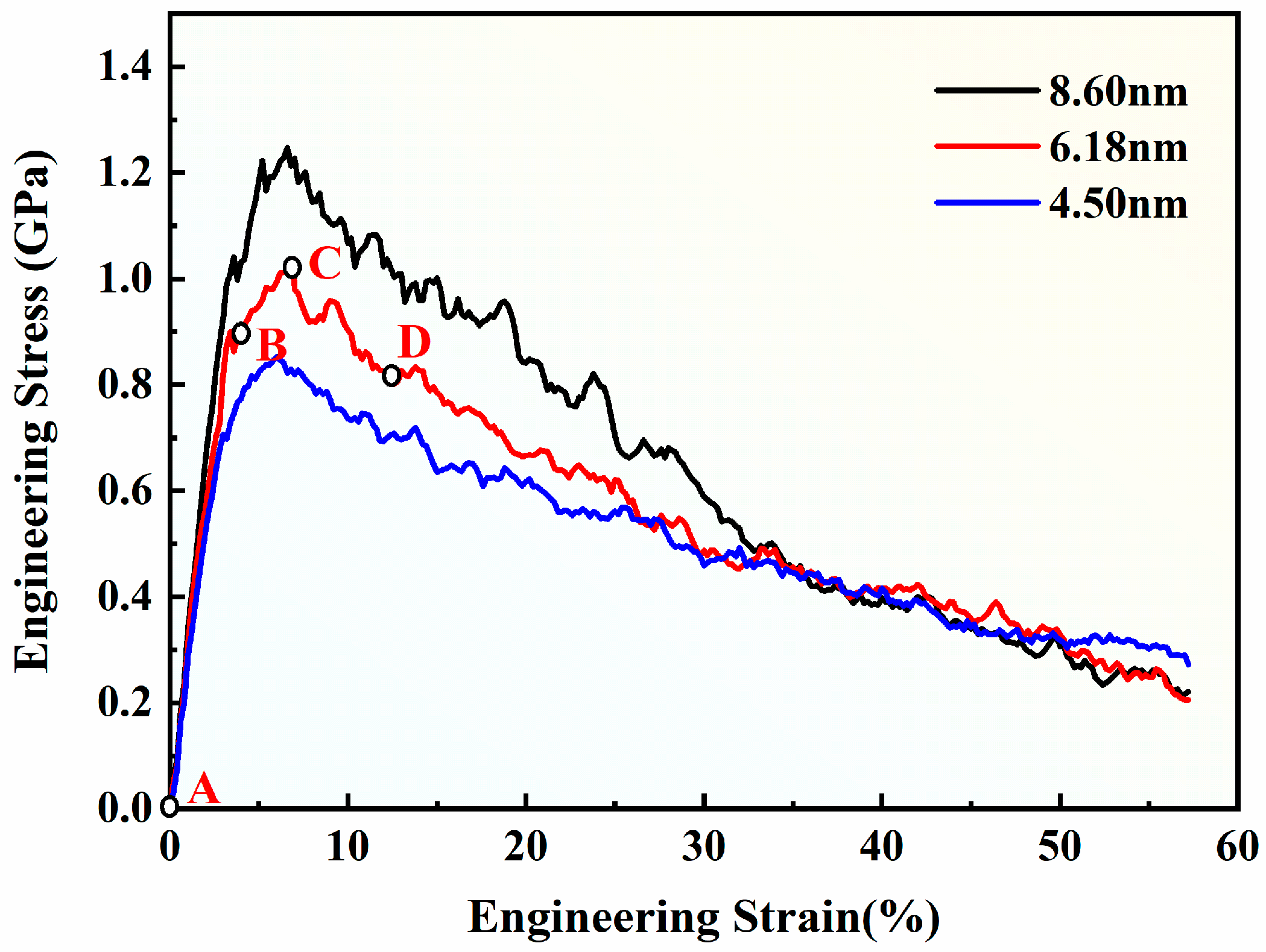

3.1. Behaviors of Stress versus Strain

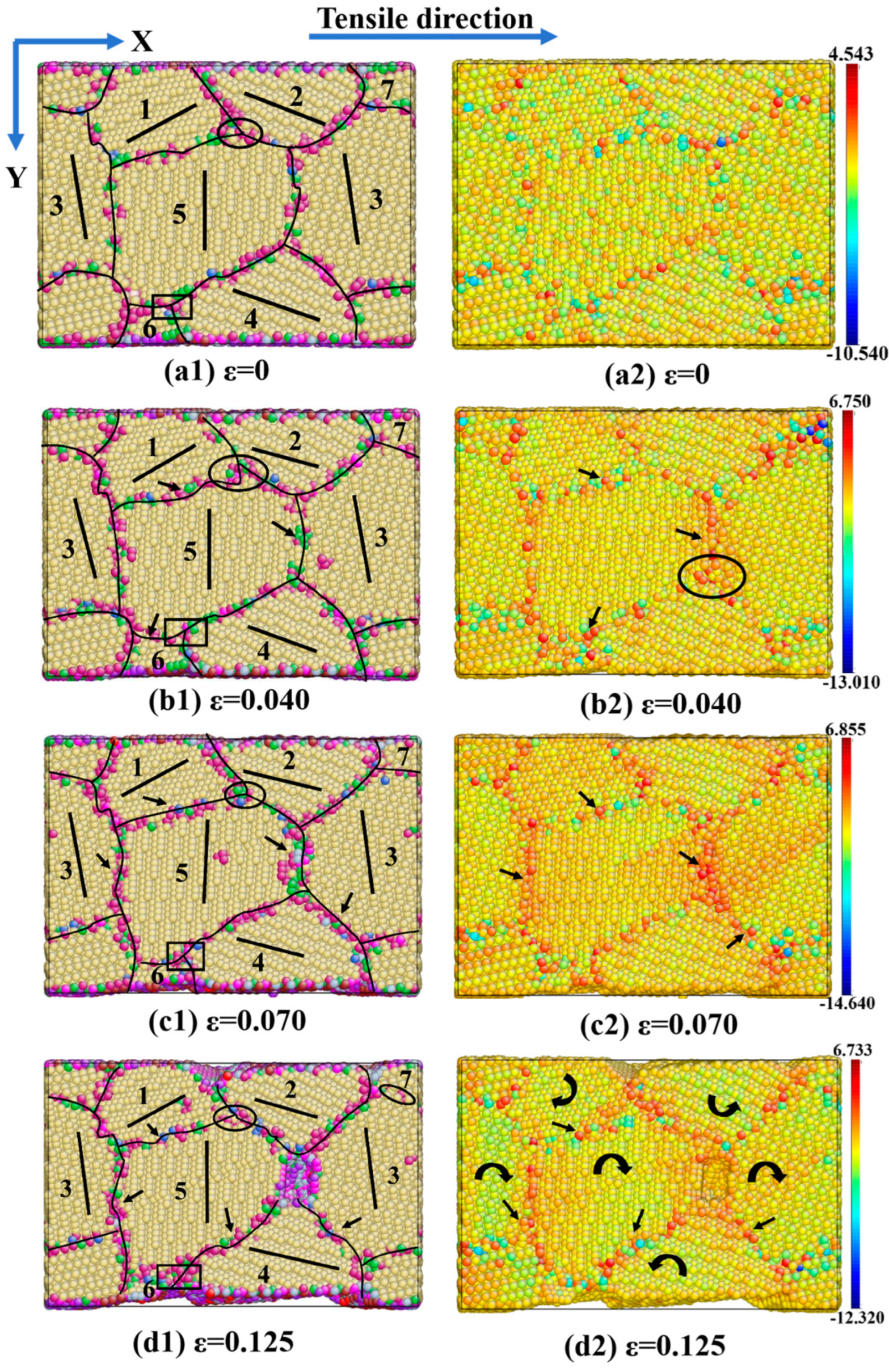

3.2. Grain Boundary Sliding and Grain Rotation

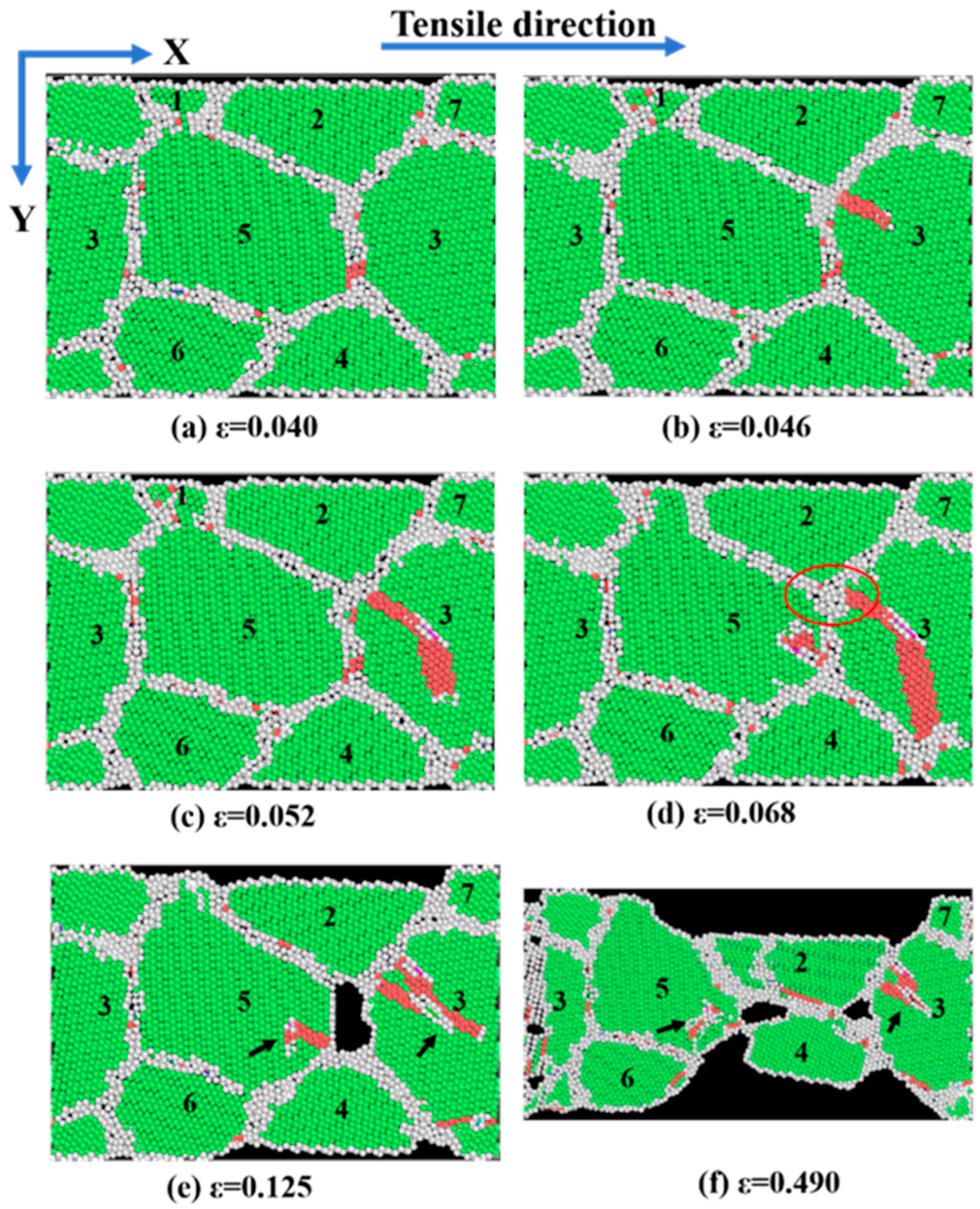

3.3. The Interaction of the Dislocation and Grain Boundary

4. Conclusions

- (1)

- From the tensile engineering stress–strain relationship of polycrystalline γ-TiAl, it is found that the peak stress of polycrystalline γ-TiAl increases with an increase in tensile strain rate (1 × 108 s−1, 5 × 108 s−1, 1 × 109 s−1). However, the peak stress decreases during the tensile process with decreasing grain size (8.60 nm, 6.18 nm, 4.50 nm), showing a visible inverse Hall-Petch relationship.

- (2)

- Grain boundary sliding and grain rotation occur throughout the tensile deformation process of polycrystalline γ-TiAl, with grain boundary sliding dominating the plastic deformation. The rotation angle of the border grains is larger than that of the center grains, which is caused by the combined effect of the uneven distribution of shear stress at the grain boundaries and the relative rotation of each grain.

- (3)

- During the process of tensile deformation, it is difficult to form a dislocation source inside the polycrystalline γ-TiAl grain, and the dislocation is only emitted from the grain boundary and slips into the grain interior. Dislocation slip is hindered by the grain boundary on the other side, resulting in local stress concentration at the grain boundary. The nucleation and slip of the dislocations occur after the grain boundary sliding and grain orientation rotation begin, indicating that the grain boundary sliding and grain orientation rotation in the early stage of tensile deformation play an important role in the emission of dislocations, providing conditions for orientation and shear stress.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, G.; Tang, B.; Zhao, S.; Wang, W.Y.; Chen, X.; Zhu, L.; Li, J. Evading the Strength-Ductility Trade-off at Room Temperature and Achieving Ultrahigh Plasticity at 800 °C in a TiAl Alloy. Acta Mater. 2022, 225, 117585. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Song, M.; Li, Y.; Gong, S.; Zhang, B. TiAl Alloy Fabricated Using Election Beam Selective Melting: Process, Microstructure, and Tensile Performance. Metals 2024, 14, 482. [Google Scholar] [CrossRef]

- Avdeeva, V.; Bazhina, A.; Antipov, M.; Stolin, A.; Bazhin, P. Relationship between Structure and Properties of Inter-metallic Materials Based on γ-TiAl Hardened In Situ with Ti3Al. Metals 2023, 13, 1002. [Google Scholar] [CrossRef]

- Klein, T.; Usategui, L.; Rashkova, B.; Nó, M.L.; San Juan, J.; Clemens, H.; Mayer, S. Mechanical Behavior and Related Microstructural Aspects of a Nano-Lamellar TiAl Alloy at Elevated Temperatures. Acta Mater. 2017, 128, 440–450. [Google Scholar] [CrossRef]

- Xu, R.; Li, M.; Zhao, Y. A Review of Microstructure Control and Mechanical Performance Optimization of γ-TiAl Alloys. J. Alloys Compd. 2023, 932, 167611. [Google Scholar] [CrossRef]

- He, T.; Yi, B.; Zheng, M.; Song, B.; Qu, D.; Chen, J.; Zhu, Z. Molecular Dynamics for Nanoindentation in the γ/A2 Interfacial Strengthening Mechanism of a Duplex Full Lamellar TiAl Alloy. Mater. Today Commun. 2024, 38, 107965. [Google Scholar] [CrossRef]

- Erdely, P.; Staron, P.; Maawad, E.; Schell, N.; Clemens, H.; Mayer, S. Lattice and Phase Strain Evolution during Tensile Loading of an Intermetallic, Multi-Phase γ-TiAl Based Alloy. Acta Mater. 2018, 158, 193–205. [Google Scholar] [CrossRef]

- Wiezorek, J.M.K.; Zhang, X.D.; Godfrey, A.; Hu, D.; Loretto, M.H.; Fraser, H.L. Deformation Behavior of A2-Lamellae in Fully Lamellar Ti-48Al-2Mn-2Nb at Room Temperature. Scr. Mater. 1998, 38, 811–817. [Google Scholar] [CrossRef]

- Ellard, J.J.M.; Mathabathe, M.N.; Siyasiya, C.W.; Bolokang, A.S. Low-Cycle Fatigue Behaviour of Titani-um-Aluminium-Based Intermetallic Alloys: A Short Review. Metals 2023, 13, 1491. [Google Scholar] [CrossRef]

- Pei, Y.L.; Song, M.; Ma, Y.; Gong, S.K. Effects of Heat Shock at 800 °C on Mechanical Properties of γ-TiAl Alloys. Intermetallics 2011, 19, 202–205. [Google Scholar] [CrossRef]

- Appel, F.; Lorenz, U.; Sparka, U. The Influence of Lamellar Interfaces on the Mechanical Properties of (Alpha2+gamma) Titanium Aluminides. Strength Mater. 1994, 973, 337–340. [Google Scholar]

- Meier, M.L.; Lesuer, D.R.; Mukherjee, A.K. α Grain Size and β Volume Fraction Aspects of the Superplasticity of Ti-6Al-4V. Mater. Sci. Eng. A 1991, 136, 71–78. [Google Scholar] [CrossRef]

- Jiao, S.; Tu, W.; Zhang, P.; Zhang, W.; Qin, L.; Sun, Z.; Chen, J. Atomistic Insights into the Prismatic Dislocation Loop on Al (1 0 0) during Nanoindentation Investigated by Molecular Dynamics. Comput. Mater. Sci. 2018, 143, 384–390. [Google Scholar] [CrossRef]

- Roy, A.; Devanathan, R.; Johnson, D.D.; Balasubramanian, G. Grain-Size Effects on the Deformation in Nanocrystalline Multi-Principal Element Alloy. Mater. Chem. Phys. 2022, 277, 125546. [Google Scholar] [CrossRef]

- Zhao, W.; Xu, D.; Zhao, J.; Wang, H. Molecular Dynamics Simulation of Fracture Behaviors of <110> Tilt Grain Boundaries in γ-TiAl. Trans. Nonferrous Met. Soc. China 2014, 24, 3645–3651. [Google Scholar] [CrossRef]

- Van Swygenhoven, H.; Derlet, P.M.; Frøseth, A.G. Nucleation and Propagation of Dislocations in Nanocrystalline Fcc Metals. Acta Mater. 2006, 54, 1975–1983. [Google Scholar] [CrossRef]

- Cao, H.; Yu, Z.; Zhou, B.; Li, H.; Guo, Z.; Wang, J.; Yang, W.; Feng, R. Molecular Dynamics Simulation of the Effect of Supersonic Fine Particle Bombardment on the Mechanical Behaviour of γ-TiAl Alloy: The Effect of Grain Size. Vacuum 2023, 217, 112498. [Google Scholar] [CrossRef]

- Galindo-Torres, S.A.; Pedroso, D.M. Molecular Dynamics Simulations of Complex-Shaped Particles Using Voronoi-Based Spheropolyhedra. Phys. Rev. E 2010, 81, 061303. [Google Scholar] [CrossRef]

- Zope, R.R.; Mishin, Y. Interatomic Potentials for Atomistic Simulations of the Ti-Al System. Phys. Rev. B 2003, 68, 024102. [Google Scholar] [CrossRef]

- Plimpton, S.; Crozier, P.; Thompson, A. LAMMPS-Large-Scale Atomic/Molecular Massively Parallel Simulator. J. Appl. Phys. 2015, 118, 14902. [Google Scholar] [CrossRef]

- Li, J. AtomEye: An Efficient Atomistic Configuration Viewer. Model. Simul. Mater. Sci. Eng. 2003, 11, 173. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Carlton, C.E.; Ferreira, P.J. What Is behind the Inverse Hall–Petch Effect in Nanocrystalline Materials? Acta Mater. 2007, 55, 3749–3756. [Google Scholar] [CrossRef]

- Ding, J.; Tian, Y.; Wang, L.; Huang, X.; Zheng, H.; Song, K.; Zeng, X. Micro-Mechanism of the Effect of Grain Size and Temperature on the Mechanical Properties of Polycrystalline TiAl. Comput. Mater. Sci. 2019, 158, 76–87. [Google Scholar] [CrossRef]

- Liu, X.; Yuan, F.; Wei, Y. Grain Size Effect on the Hardness of Nanocrystal Measured by the Nanosize Indenter. Appl. Surf. Sci. 2013, 279, 159–166. [Google Scholar] [CrossRef]

- Li, X.; Hu, W.; Xiao, S.; Deng, H. Comparison of Simulation of Single Crystalline and Polycrystalline Mo Nanowires under Uniaxial Tensile Strain. Chin. J. Nonferrous Met. 2009, 19, 1982–1986. [Google Scholar]

- Zhou, K.; Liu, B.; Yao, Y.; Zhong, K. Effects of Grain Size and Shape on Mechanical Properties of Nanocrystalline Copper Investigated by Molecular Dynamics. Mater. Sci. Eng. A 2014, 615, 92–97. [Google Scholar] [CrossRef]

- Mao, H.; Liang, Q.; Zhang, Z.; Du, Y.; Shuai, X.; Zhang, G.; Tang, S. Strain-Induced Grain Boundary Migration and Grain Rotation in Polycrystalline Metals: Atomic-and Meso-Scale Phase Field Simulations. Comput. Mater. Sci. 2023, 230, 112531. [Google Scholar] [CrossRef]

- Kumar, S.; Li, X.; Haque, A.; Gao, H. Is Stress Concentration Relevant for Nanocrystalline Metals? ACS Publ. 2011, 11, 2510–2516. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, B.Q.; Sui, M.L.; Mao, S.X. Deformation-Induced Grain Rotation and Growth in Nanocrystalline Ni. Appl. Phys. Lett. 2008, 92, 011903. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Y.; Lu, X.; Li, Z.; Sun, L.; Song, Y. Dendritic Copper-Cobalt Nanostructures/Reduced Graphene Oxide-Chitosan Modified Glassy Carbon Electrode for Glucose Sensing. Sens. Actuators B Chem. 2014, 195, 1–7. [Google Scholar] [CrossRef]

- Zhao, W.; Ding, H.; Cao, F. Microstructural Evolution during Superplastic Deformation of Ti-6Al-4V Alloy. Chin. J. Nonferrous Met. 2009, 19, 1973–1980. [Google Scholar]

- Kim, J.S.; Kim, J.H.; Lee, Y.T.; Park, C.G.; Lee, C.S. Microstructural Analysis on Boundary Sliding and Its Accommodation Mode during Superplastic Deformation of Ti-6Al-4V Alloy. Mater. Sci. Eng. A 1999, 263, 272–280. [Google Scholar] [CrossRef]

| Strain | Grain 1 | Grain 2 | Grain 3 | Grain 4 | Grain 5 |

|---|---|---|---|---|---|

| 0–0.040 (A-B) | Clockwise 2.50° | Anticlockwise 2.01° | Clockwise 0.90° | Anticlockwise 2.02° | Clockwise 0.40° |

| 0.040–0.070 (B-C) | Clockwise 2.10° | Anticlockwise 2.42° | Clockwise 0.49° | Anticlockwise 2.98° | Clockwise 0.53° |

| 0.070–0.125 (C-D) | Clockwise 3.16° | Anticlockwise 3.14° | Clockwise 0.55° | Anticlockwise 2.54° | Clockwise 0.48° |

| 0–0.125 (A-D) | Clockwise 7.76° | Anticlockwise 7.57° | Clockwise 1.94° | Anticlockwise 7.54° | Clockwise 1.41° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, W.; He, M.; Li, C.; Chen, W. Study on Grain Boundary Mechanical Behaviors of Polycrystalline γ-TiAl Using Molecular Dynamics Simulations. Metals 2024, 14, 779. https://doi.org/10.3390/met14070779

Zhao W, He M, Li C, Chen W. Study on Grain Boundary Mechanical Behaviors of Polycrystalline γ-TiAl Using Molecular Dynamics Simulations. Metals. 2024; 14(7):779. https://doi.org/10.3390/met14070779

Chicago/Turabian StyleZhao, Wenjuan, Maoqing He, Chunliang Li, and Wei Chen. 2024. "Study on Grain Boundary Mechanical Behaviors of Polycrystalline γ-TiAl Using Molecular Dynamics Simulations" Metals 14, no. 7: 779. https://doi.org/10.3390/met14070779

APA StyleZhao, W., He, M., Li, C., & Chen, W. (2024). Study on Grain Boundary Mechanical Behaviors of Polycrystalline γ-TiAl Using Molecular Dynamics Simulations. Metals, 14(7), 779. https://doi.org/10.3390/met14070779