Effect of Intermediate Annealing on Microstructure and Cold Rolling Hardness of AlFeMn Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

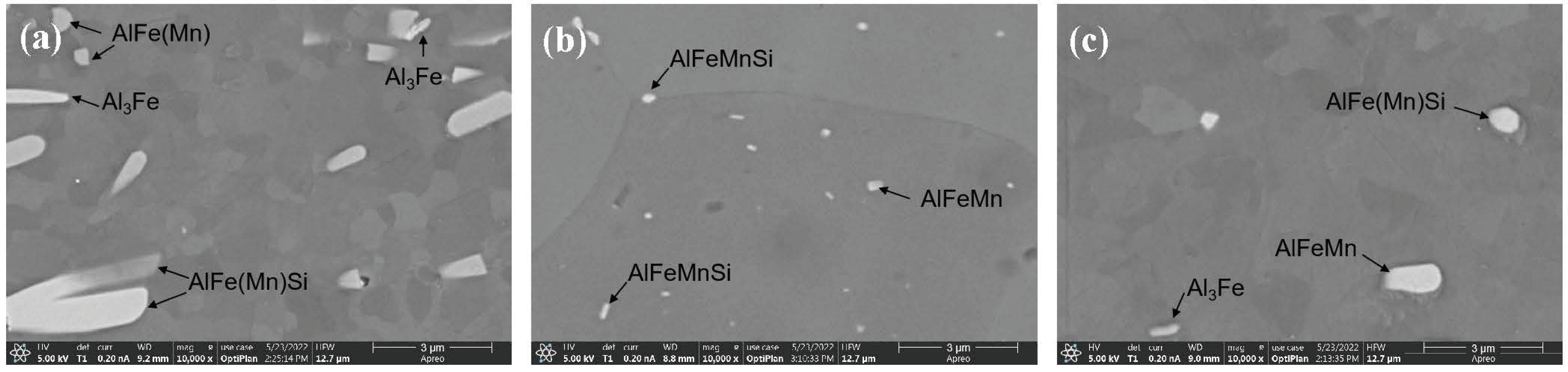

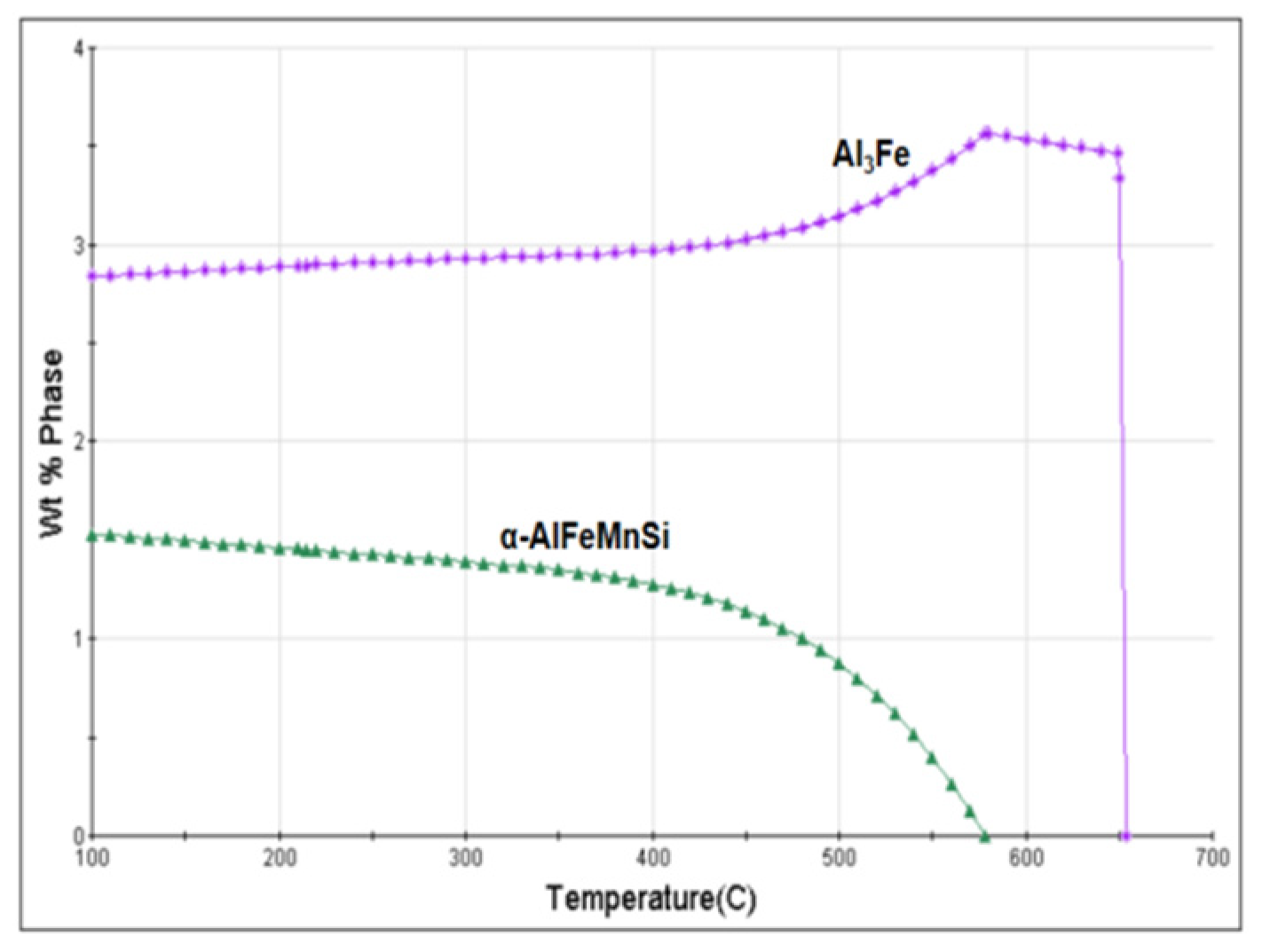

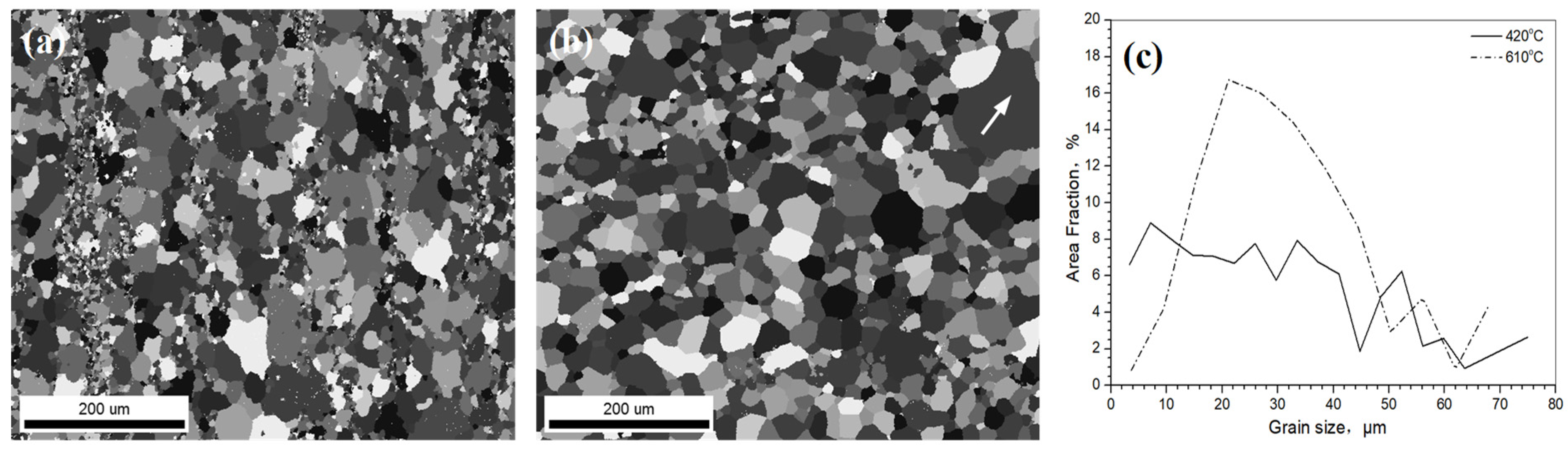

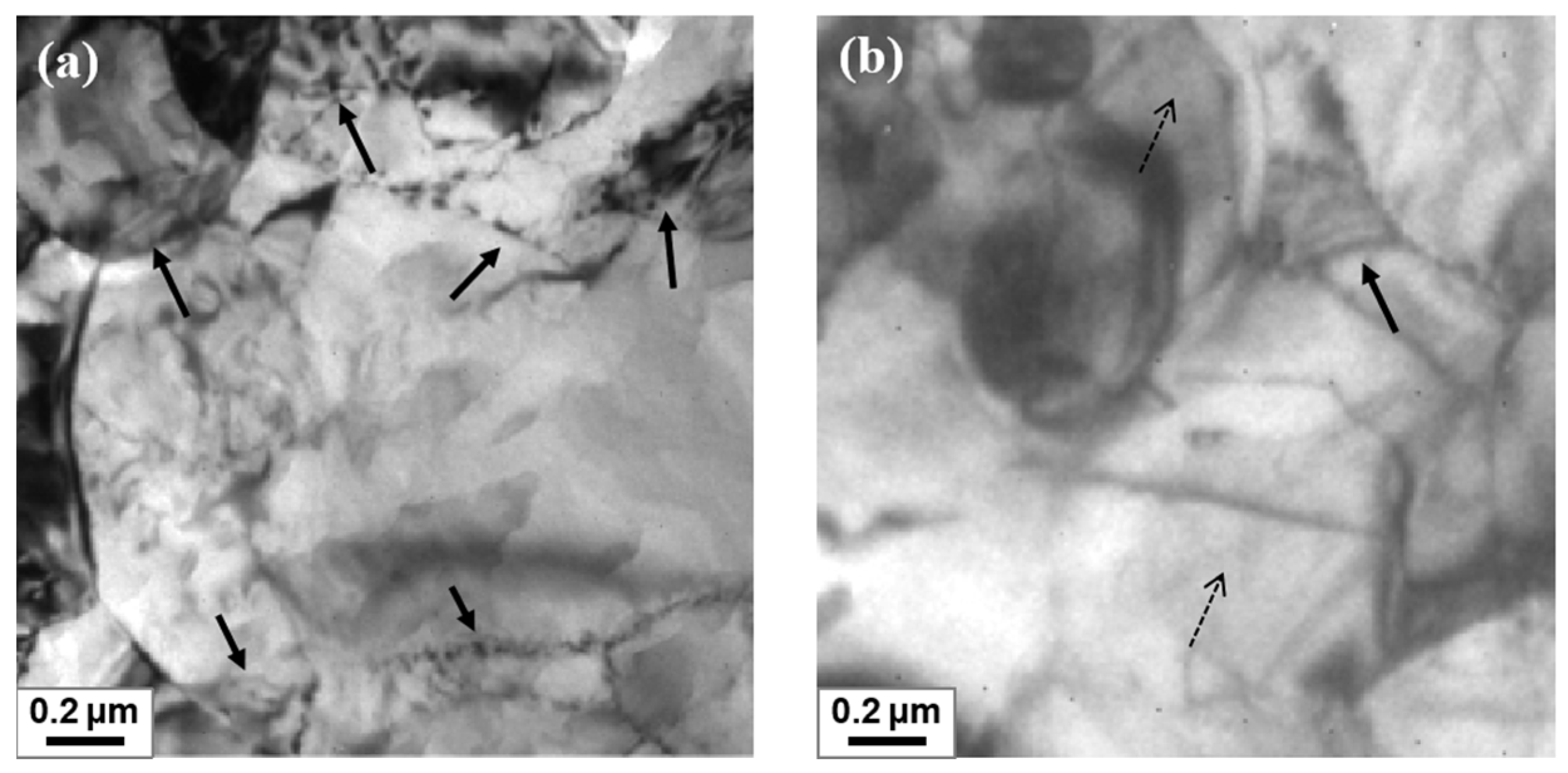

3.1. Microstructure and Texture of Intermediate Annealed Sheets

3.2. Changes in Microhardness during the Cold Rolling Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karlik, M.; Siegl, J.; Slamova, M.; Birol, Y. Study of the damage of AA 8006 twin-roll cast thin sheets during forming of heat exchanger fins. Mater. Sci. Forum 2000, 331–337, 619–624. [Google Scholar] [CrossRef]

- Chen, Z.W.; Li, S.S.; Zhao, J. Homogenization of twin-roll cast A8006 alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1280–1285. [Google Scholar] [CrossRef]

- Andreatta, F.; Lanzutti, A.; Fedrizzi, L. Corrosion behaviour of AA8xxx aluminium fins in heat exchangers. Surf. Interface Anal. 2016, 48, 789–797. [Google Scholar] [CrossRef]

- Zhao, P.Z.; Pan, Y.F.; Jiang, T.; Shi, X.J.; Zhang, Q. Effect of intermetallic compound content on the laser welding performance of Al-Fe alloy sheets. Mater. Sci. Forum 2014, 794–796, 401–406. [Google Scholar] [CrossRef]

- Xia, X.F.; Gu, Y.Y.; Xu, S.A. Titanium conversion coatings on the aluminum foil AA 8021 used for lithium-ion battery package. Appl. Surf. Sci. 2017, 419, 447–453. [Google Scholar] [CrossRef]

- Zhang, R.; Ding, D.Y.; Zhang, W.L.; Gao, Y.J.; Wu, Z.L.; Chen, G.Z.; Chen, R.Z.; Huang, Y.W.; Tang, J.S. Al-1.5Fe-xLa alloys for lithium-ion battery package. Metals 2018, 8, 890. [Google Scholar] [CrossRef]

- Pan, Y.F.; Shen, Y.F.; Zhao, P.Z. The microstructure and deformation behavior of Al-Fe-Mn alloys with different Fe contents during cold rolling. Metals 2018, 8, 753. [Google Scholar] [CrossRef]

- Tohma, K.; Takeuchi, Y. Work softening phenomenon in aluminum alloys. J. Jpn. Inst. Light Met. 1976, 26, 510–518. (In Japanese) [Google Scholar] [CrossRef]

- Tsumuraya, K.; Honma, K.; Watanabe, S. Work softening phenomenon in cold rolled Al-Fe alloys. J. Jpn. Inst. Light Met. 1977, 27, 599–604. (In Japanese) [Google Scholar] [CrossRef]

- Jin, Q.; Li, F.Z.; Yu, Z.M.; Liu, Z.J. Influence of uniformization on work softening of aluminium-ferro alloy. J. Harbin Univ. Sci. Technol. 1996, 1, 26–28. (In Chinese) [Google Scholar]

- Roy, R.K.; Kar, S.; Das, S. Evolution of microstructure and mechanical properties during annealing of cold-rolled AA8011 alloy. J. Alloys Compd. 2009, 468, 122–129. [Google Scholar] [CrossRef]

- Slamova, M.; KarliK, M.; Cieslar, M.; Chalupa, B.; Merle, P. Structure transformations during annealing of twin-roll cast Al-Fe-Mn-Si (AA 8006) alloy sheets. I. Effect of cold rolling and heating rate. Kov. Mater. 2002, 40, 389–400. [Google Scholar]

- Katsas, S.; Gras, C. The effect of recrystallization phenomena during annealing on the final forming properties of TRC AA8006. TMS Light Metals 2009, 1231–1234. Available online: https://www.researchgate.net/publication/269929364_The_effect_of_recrystallization_phenomena_during_annealing_on_the_final_forming_properties_of_TRC_AA8006 (accessed on 3 July 2024).

- Engler, O.; Laptyeva, G.; Wang, N. Impact of homogenization on microchemistry and recrystallization of the Al-Fe-Mn alloy AA 8006. Mater. Charact. 2013, 79, 60–75. [Google Scholar] [CrossRef]

- Birol, Y. Impact of interannealing on recrystallization during final annealing in twin-belt cast Al-Fe-Si sheet. Int. J. Mat. Res. 2012, 103, 992–997. [Google Scholar] [CrossRef]

- Birol, Y. Recrystallization of twin-roll cast Al-Fe-Si foil stock processed without homogenization. J. Alloys Compd. 2009, 488, 112–116. [Google Scholar] [CrossRef]

- Birol, Y. Response to annealing treatment of a twin-roll cast thin AlFeMnSi strip. J. Mater. Process. Technol. 2009, 209, 506–510. [Google Scholar] [CrossRef]

- Pan, Y.F.; Zhao, P.Z.; Shen, Y.F.; Shi, X.J.; Jiang, T. A study on the deformation dehaviours of Al-1.4Fe-0.2Mn alloy sheets. Mater. Sci. Forum 2016, 877, 380–386. [Google Scholar] [CrossRef]

- Yao, Z.Y.; Liu, Q.; Godfrey, A.; Liu, W. Microstructure and texture evolutions of AA1050 aluminum alloy cold rolled to high strains. Acta Metall. Sin. 2009, 45, 647–651. (In Chinese) [Google Scholar]

- Wang, Z.T.; Tian, R.Z. Aluminum Alloy and Its Processing Handbook, 2nd ed.; Central South University Press: Changsha, China, 2000. (In Chinese) [Google Scholar]

- Zhang, X.M.; Wu, W.X.; Liu, S.D.; Jian, X.; Tang, J.G. Precipitation and recrystallization of AA3003 aluminium alloy during annealing. J. Cent. South Univ. (Sci. Technol.) 2006, 37, 1–5. (In Chinese) [Google Scholar]

- Zhang, D.F. Investigation on Textures and Microstructures of 3l04 Aluminium Alloy during Processes of Deformation and Recrystallization; Northeastern University: Shenyang, China, 2004. (In Chinese) [Google Scholar]

- Merchant, H.D.; Morris, J.G. Annealing response of 3000 and 5000 series aluminum alloys. Metall. Trans. A 1990, 21A, 2643–2654. [Google Scholar] [CrossRef]

- Engler, O. On the origin of the R orientation in the recrystallization textures of aluminum alloys. Metall. Mater. Trans. A 1999, 30, 1517–1527. [Google Scholar] [CrossRef]

- Engler, O. On the influence of dispersoids on the particle stimulated nucleation of recrystallization in an Al-Fe-Si model alloy. Mater. Sci. Forum 1998, 273–275, 483–488. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, A.; Kumar, A.; Chouhan, R.N.; Khatirkar, R.K. Microstructure and texture development during deformation and recrystallisation in strip cast AA8011 aluminum alloy. J. Alloys Compd. 2018, 742, 369–382. [Google Scholar] [CrossRef]

- Hirsch, J.R.; Lücke, K. The application of quantitative texture analysis for investigating continuous and discontinuous recrystallization processes of Al-0.01Fe. Acta Metall. 1985, 33, 1927–1938. [Google Scholar] [CrossRef]

- Engler, O.; Lücke, K. Mechanisms of recrystallization texture formation in aluminium alloys. Scripta Metall. Mater. 1992, 27, 1527–1532. [Google Scholar] [CrossRef]

- Muggerud, A.M.F.; Mortsell, E.A.; Li, Y.J.; Holmestad, R. Dispersoid strengthening in AA3xxx alloys with varying Mn and Si content during annealing at low temperatures. Mater. Sci. Eng. A 2013, 567, 21–28. [Google Scholar] [CrossRef]

| Fe | Si | Mn | Ti | Al |

|---|---|---|---|---|

| 1.4 | 0.09 | 0.21 | 0.015 | Bal. |

| Texture | Miller Index | Texture Content | Texture | Miller Index | Texture Content | ||

|---|---|---|---|---|---|---|---|

| 420 °C | 610 °C | 420 °C | 610 °C | ||||

| R | {124}<211> | 16.15 | 10 | Brass | {011}<211> | 6.5 | 3.3 |

| Q | {013}<231> | 7.9 | 6.1 | S | {123}<634> | 9.55 | 7.8 |

| Cube | {001}<100> | 2.5 | 8.9 | Copper | {112}<111> | 7.45 | 3.8 |

| CubeND | {001}<310> | 6.35 | 14.2 | Goss | {011}<100> | 2.1 | 3.9 |

| CubeRD | {013}<100> | 5.35 | 8.3 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Shen, Y.; Cao, L. Effect of Intermediate Annealing on Microstructure and Cold Rolling Hardness of AlFeMn Alloy. Metals 2024, 14, 785. https://doi.org/10.3390/met14070785

Pan Y, Shen Y, Cao L. Effect of Intermediate Annealing on Microstructure and Cold Rolling Hardness of AlFeMn Alloy. Metals. 2024; 14(7):785. https://doi.org/10.3390/met14070785

Chicago/Turabian StylePan, Yanfeng, Yifu Shen, and Lingyong Cao. 2024. "Effect of Intermediate Annealing on Microstructure and Cold Rolling Hardness of AlFeMn Alloy" Metals 14, no. 7: 785. https://doi.org/10.3390/met14070785

APA StylePan, Y., Shen, Y., & Cao, L. (2024). Effect of Intermediate Annealing on Microstructure and Cold Rolling Hardness of AlFeMn Alloy. Metals, 14(7), 785. https://doi.org/10.3390/met14070785