Examination of Novel Titanium-639 Alloy as a Means of Balancing Strength and Ductility through Molybdenum Addition Rather than Prolonged Aging Heat Treatment

Abstract

:1. Introduction

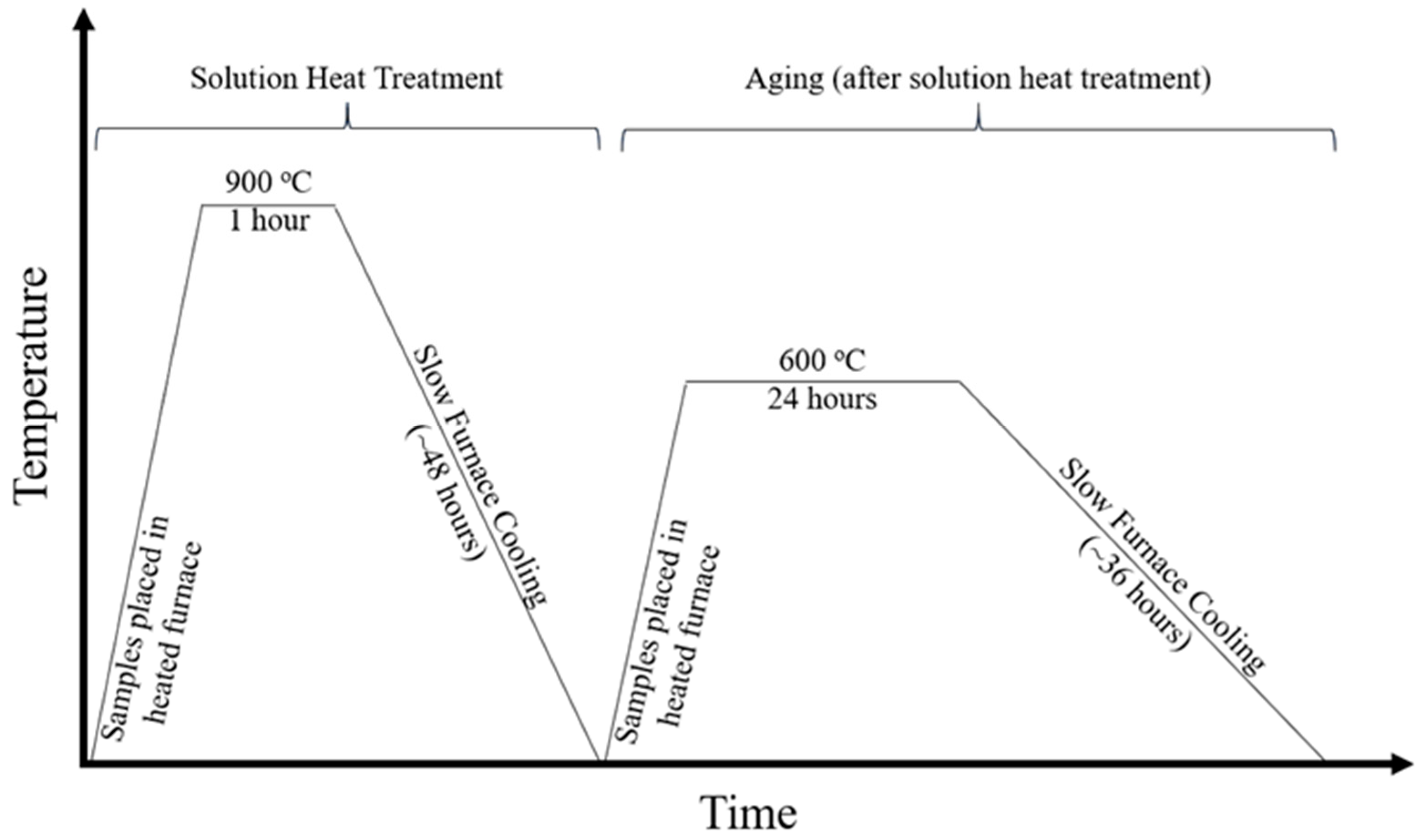

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- The depleted bimodal microstructure of solution heat-treated Ti-639 surpassed the aged microstructure of Ti-64 in both compressive strength (1561 MPa vs. 1473 MPa) and failure strain (28.2% vs. 22.9%) along the plate normal direction. This enhanced performance was attained in Ti-639 without requiring the additional prolonged aging step necessary for Ti-64.

- The introduction of molybdenum in place of a portion of vanadium produced a marked increase in strength in Ti-639, compared to Ti-64. Molybdenum also forestalled the deterioration of bimodal microstructures during heat treatment due to its low diffusivity and tendency to aggregate at α-β interphase boundaries, as confirmed by EDS elemental mapping at the interface using TEM.

- In solution heat-treated Ti-639, colonies displayed shortened β lamellae due to recrystallized globular α grains nucleating and growing along the length of acicular β grains. EBSD results showed that the newly formed α grains followed the Burgers orientation relationship (110) ∥ (0001) with neighboring β lamellae.

- Further aging of Ti-639 caused the recrystallized α grains to continue expanding. As these α grains tried to grow across the width of the β lamellae, they split the β lamellae, further compounding the deterioration of the length of β grains. This was demonstrated through the identical crystallographic orientation of split segments which were once part of the same acicular β grain and was corroborated through TEM imaging.

- The effects of α recrystallization within colonies also extended to the existing primary α grains located at the peripheries of recrystallized colonies. Primary α grains surrounded by recrystallized colonies showed very small misorientation profiles as well as lower calculated dislocation densities, compared to primary α grains that are mostly bordered by other primary α grains.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pushp, P.; Dasharath, S.M.; Arati, C. Classification and Applications of Titanium and Its Alloys. Mater. Today Proc. 2022, 54, 537–542. [Google Scholar] [CrossRef]

- Boyer, R.R. Attributes, Characteristics, and Applications of Titanium and Its Alloys. JOM 2010, 62, 21–24. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent Advances in the Development of Aerospace Materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Xi, Z.; Fan, J.; Tang, B.; Li, J. Recent Developments in Cold Dwell Fatigue of Titanium Alloys for Aero-Engine Applications: A Review. J. Mater. Res. Technol. 2022, 20, 469–484. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable High-Entropy Dual-Phase Alloys Overcome the Strength–Ductility Trade-Off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Li, Y.; Zhu, L.; Liu, Y.; Lei, X.; Wang, G.; Wu, Y.; Mi, Z.; Liu, J.; Wang, H.; et al. Evading the Strength–Ductility Trade-off Dilemma in Steel through Gradient Hierarchical Nanotwins. Nat. Commun. 2014, 5, 3580. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xu, J. Advanced Lightweight Materials for Automobiles: A Review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Lightweight Structural Materials in Open Access: Latest Trends. Materials 2021, 14, 6577. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Cecchel, S. Materials and Technologies for Lightweighting of Structural Parts for Automotive Applications: A Review. SAE Int. J. Mater. Manuf. 2021, 14, 81–98. [Google Scholar] [CrossRef]

- Siengchin, S. A Review on Lightweight Materials for Defence Applications: Present and Future Developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Ritchie, R.O. The Conflicts between Strength and Toughness. Nat. Mater. 2011, 10, 817. [Google Scholar] [CrossRef] [PubMed]

- Venkatramani, G.; Ghosh, S.; Mills, M. A Size-Dependent Crystal Plasticity Finite-Element Model for Creep and Load Shedding in Polycrystalline Titanium Alloys. Acta Mater. 2007, 55, 3971–3986. [Google Scholar] [CrossRef]

- He, S.; Zeng, W.; Xu, J.; Zhou, D. The Texture Evolution Related to the Interactions between α and β Phases in Dual-Phase Region Annealing of a near α Titanium Alloy Pipe after Pilger Cold Rolling. J. Alloys Compd. 2022, 890, 161807. [Google Scholar] [CrossRef]

- Chakraborty, J.; Kumar, K.; Ranjan, R.; Chowdhury, S.G.; Singh, S.R. Thickness-Dependent Fcc–Hcp Phase Transformation in Polycrystalline Titanium Thin Films. Acta Mater. 2011, 59, 2615–2623. [Google Scholar] [CrossRef]

- Li, R.; Wang, H.; He, B.; Li, Z.; Zhu, Y.; Zheng, D.; Tian, X.; Zhang, S. Effect of α Texture on the Anisotropy of Yield Strength in Ti–6Al–2Zr–1Mo–1V Alloy Fabricated by Laser Directed Energy Deposition Technique. Mater. Sci. Eng. A 2021, 824, 141771. [Google Scholar] [CrossRef]

- Lunt, D.; Thomas, R.; Atkinson, M.D.; Smith, A.; Sandala, R.; da Fonseca, J.Q.; Preuss, M. Understanding the Role of Local Texture Variation on Slip Activity in a Two-Phase Titanium Alloy. Acta Mater. 2021, 216, 117111. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003; ISBN 3-527-30534-3. [Google Scholar]

- Sha, W.; Malinov, S. Titanium Alloys: Modelling of Microstructure, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 1-84569-586-0. [Google Scholar]

- Ding, R.; Guo, Z.X.; Wilson, A. Microstructural Evolution of a Ti–6Al–4V Alloy during Thermomechanical Processing. Mater. Sci. Eng. A 2002, 327, 233–245. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded Microstructure and Mechanical Properties of Additive Manufactured Ti–6Al–4V via Electron Beam Melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of Heat Treatments on Microstructure and Properties of Ti-6Al-4V ELI Alloy Fabricated by Electron Beam Melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef]

- Jin, N.; Yan, Z.; Wang, Y.; Cheng, H.; Zhang, H. Effects of Heat Treatment on Microstructure and Mechanical Properties of Selective Laser Melted Ti-6Al-4V Lattice Materials. Int. J. Mech. Sci. 2021, 190, 106042. [Google Scholar] [CrossRef]

- Etesami, S.A.; Fotovvati, B.; Asadi, E. Heat Treatment of Ti-6Al-4V Alloy Manufactured by Laser-Based Powder-Bed Fusion: Process, Microstructures, and Mechanical Properties Correlations. J. Alloys Compd. 2022, 895, 162618. [Google Scholar] [CrossRef]

- Hirth, J.P.; Froes, F.H. Interrelations between Fracture Toughness and Other Mechanical Properties in Titanium Alloys. Metall. Trans. A 1977, 8, 1165–1176. [Google Scholar] [CrossRef]

- Fan, W.; Peng, Y.; Wang, Y.; Qi, Y.; Feng, Z.; Tan, H.; Zhang, F.; Lin, X. Effect of Grain Boundary Widmanstätten α Colony on the Anisotropic Tensile Properties of Directed Energy Deposited Ti-6Al-4V Alloy. J. Mater. Sci. Technol. 2024, 184, 145–156. [Google Scholar] [CrossRef]

- Gao, Z.; Hu, R.; Gao, X.; Wu, Y.; Zou, H.; Li, J.; Zhou, M. Characterization of the Widmanstätten Structure in γ-TiAl Alloy Using an EBSD-FIB-TEM Combined Process. Scr. Mater. 2023, 222, 115001. [Google Scholar] [CrossRef]

- Zhang, Y.; Xin, R.; Guo, B.; Wang, K.; Liu, Q. Influence of Alternate Grain Boundary α on the Development of Widmanstätten Microstructure in TC21 Ti Alloy. Mater. Charact. 2021, 177, 111162. [Google Scholar] [CrossRef]

- Gil, F.J.; Ginebra, M.P.; Manero, J.M.; Planell, J.A. Formation of α-Widmanstätten Structure: Effects of Grain Size and Cooling Rate on the Widmanstätten Morphologies and on the Mechanical Properties in Ti6Al4V Alloy. J. Alloys Compd. 2001, 329, 142–152. [Google Scholar] [CrossRef]

- Tarik Hasib, M.; Ostergaard, H.E.; Li, X.; Kruzic, J.J. Fatigue Crack Growth Behavior of Laser Powder Bed Fusion Additive Manufactured Ti-6Al-4V: Roles of Post Heat Treatment and Build Orientation. Int. J. Fatigue 2021, 142, 105955. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The Thermomechanical Processing of Alpha/Beta Titanium Alloys. JOM 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Li, C.-L.; Wang, C.-S.; Narayana, P.L.; Hong, J.-K.; Choi, S.-W.; Kim, J.H.; Lee, S.W.; Park, C.H.; Yeom, J.-T.; Mei, Q. Formation of Equiaxed Grains in Selective Laser Melted Pure Titanium during Annealing. J. Mater. Res. Technol. 2021, 11, 301–311. [Google Scholar] [CrossRef]

- Welk, B.A.; Taylor, N.; Kloenne, Z.; Chaput, K.J.; Fox, S.; Fraser, H.L. Use of Alloying to Effect an Equiaxed Microstructure in Additive Manufacturing and Subsequent Heat Treatment of High-Strength Titanium Alloys. Metall. Mater. Trans. A 2021, 52, 5367–5380. [Google Scholar] [CrossRef]

- Yang, K.; Huang, Q.; Zhong, B.; Liu, Y.J.; He, C.; Liu, H.; Su, N.; Wang, Q.; Chen, Q. Influence of the Volume Content of α + β Colonies on the Very High Cycle Fatigue Behavior of a Titanium Alloy. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2643–2658. [Google Scholar] [CrossRef]

- Zhao, Y.; Topping, T.; Bingert, J.F.; Thornton, J.J.; Dangelewicz, A.M.; Li, Y.; Liu, W.; Zhu, Y.; Zhou, Y.; Lavernia, E.J. High Tensile Ductility and Strength in Bulk Nanostructured Nickel. Adv. Mater. 2008, 20, 3028–3033. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High Tensile Ductility in a Nanostructured Metal. Nature 2002, 419, 912. [Google Scholar] [CrossRef] [PubMed]

- Birosca, S.; Buffiere, J.Y.; Karadge, M.; Preuss, M. 3-D Observations of Short Fatigue Crack Interaction with La2mellar and Duplex Microstructures in a Two-Phase Titanium Alloy. Acta Mater. 2011, 59, 1510–1522. [Google Scholar] [CrossRef]

- Gey, N.; Bocher, P.; Uta, E.; Germain, L.; Humbert, M. Texture and Microtexture Variations in a Near-α Titanium Forged Disk of Bimodal Microstructure. Acta Mater. 2012, 60, 2647–2655. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of Processing on Microstructure and Mechanical Properties of (A+β) Titanium Alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Tang, Q.; Qi, P.; Wang, T.; Hu, J.; Yin, J.; Li, B.; Nie, Z. Formation Mechanism of Lamellar Bimodal Microstructure and Mechanical Property in the High Temperature near α Titanium Alloy. J. Alloys Compd. 2023, 938, 168289. [Google Scholar] [CrossRef]

- Brun, M.; Anoshkin, N.; Shakhanova, G. Physical Processes and Regimes of Thermomechanical Processing Controlling Development of Regulated Structure in the α + β Titanium Alloys. Mater. Sci. Eng. A 1998, 243, 77–81. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Bieler, T.R. The Effect of Alpha Platelet Thickness on Plastic Flow during Hot Working of TI–6Al–4V with a Transformed Microstructure. Acta Mater. 2001, 49, 3565–3573. [Google Scholar] [CrossRef]

- Tan, C.; Sun, Q.; Zhang, G. Role of Microstructure in Plastic Deformation and Crack Propagation Behaviour of an α/β Titanium Alloy. Vacuum 2021, 183, 109848. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S.; Tamirisakandala, S.; Srinivasan, R.; Miracle, D.B. Microstructure and Texture Evolution during β Extrusion of Boron Modified Ti–6Al–4V Alloy. Mater. Sci. Eng. A 2012, 540, 152–163. [Google Scholar] [CrossRef]

- Lee, D.-G.; Kim, S.; Lee, S.; Lee, C.S. Effects of Microstructural Morphology on Quasi-Static and Dynamic Deformation Behavior of Ti-6Al-4V Alloy. Metall. Mater. Trans. A 2001, 32, 315. [Google Scholar] [CrossRef]

- Lee, D.-G.; Lee, Y.H.; Lee, S.; Lee, C.S.; Hur, S.-M. Dynamic Deformation Behavior and Ballistic Impact Properties of Ti-6Al-4V Alloy Having Equiaxed and Bimodal Microstructures. Metall. Mater. Trans. A 2004, 35, 3103–3112. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural Effects on the Mechanical Behavior of B-Modified Ti–6Al–4V Alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Polmear, I.; StJohn, D.; Nie, J.-F.; Qian, M. Light Alloys: Metallurgy of the Light Metals; Butterworth-Heinemann: Oxford, UK, 2017; ISBN 0-08-099430-X. [Google Scholar]

- Balasubramanian, R.; Nagumothu, R.; Parfenov, E.; Valiev, R. Development of Nanostructured Titanium Implants for Biomedical Implants—A Short Review. Mater. Today Proc. 2021, 46, 1195–1200. [Google Scholar] [CrossRef]

- Bozoglan, A.; Dundar, S. Comparison of Osseointegration of Ti–Al6V4 and Ti–Al6Nb7 Implants: An Experimental Study. J. Oral Biol. Craniofacial Res. 2021, 11, 624–627. [Google Scholar] [CrossRef] [PubMed]

- Barber, C.C.; Burnham, M.; Ojameruaye, O.; McKee, M.D. A Systematic Review of the Use of Titanium versus Stainless Steel Implants for Fracture Fixation. OTA Int. 2021, 4, e138. [Google Scholar] [CrossRef]

- Depboylu, F.N.; Yasa, E.; Poyraz, Ö.; Minguella-Canela, J.; Korkusuz, F.; De los Santos López, M.A. Titanium Based Bone Implants Production Using Laser Powder Bed Fusion Technology. J. Mater. Res. Technol. 2022, 17, 1408–1426. [Google Scholar] [CrossRef]

- Cheng, W.W.; Chern Lin, J.H.; Ju, C.P. Bismuth Effect on Castability and Mechanical Properties of Ti–6Al–4V Alloy Cast in Copper Mold. Mater. Lett. 2003, 57, 2591–2596. [Google Scholar] [CrossRef]

- Okazaki, Y.; Rao, S.; Ito, Y.; Tateishi, T. Corrosion Resistance, Mechanical Properties, Corrosion Fatigue Strength and Cytocompatibility of New Ti Alloys without Al and V. Biomaterials 1998, 19, 1197–1215. [Google Scholar] [CrossRef]

- Weiss, I.; Froes, F.H.; Eylon, D.; Welsch, G.E. Modification of Alpha Morphology in Ti-6Al-4V by Thermomechanical Processing. Metall. Trans. A 1986, 17, 1935–1947. [Google Scholar] [CrossRef]

- Thomas, R.; Garratt, P.; Fanning, J. Titanium Alloy with Improved Properties. U.S. Patent US10119178B2, 16 November 2018. [Google Scholar]

- Timet—TIMET Home. Available online: https://www.timet.com/ (accessed on 30 January 2024).

- Hewitt, J.S.; Davies, P.D.; Thomas, M.J.; Garratt, P.; Bache, M.R. Titanium Alloy Developments for Aeroengine Fan Systems. Mater. Sci. Technol. 2014, 30, 1919–1924. [Google Scholar] [CrossRef]

- Boostani, A.F.; Mujahid, S.; Oppedal, A.L.; Krivanec, C.; Whittington, W.R.; Allison, P.G.; Bhattacharyya, J.J.; Agnew, S.; El Kadiri, H. Heat Treatment Strategies to Improve the Quasi-Static and Dynamic Performance of Alpha + Beta Titanium Alloys. In Proceedings of the TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings, San Antonio, TX, USA, 10–14 March 2019; Springer International Publishing: Cham, Switzerland, 2019; pp. 1383–1387. [Google Scholar]

- Mujahid, S. A Study on TIMETAL 639 Titanium Alloy and the Effects of Cyclic Rapid Heat Treatment (CRHT) on the Microstructure and Mechanical Response of Alpha Beta Titanium Alloys. Doctoral Dissertation, Mississippi State University, Mississippi State, MI, USA, 2019. [Google Scholar]

- Boostani, A.; Whittington, W.; Mujahid, S.; Agnew, S.R.; Allison, P.; Bhattacharyya, J.J.; El Kadiri, H.; Krivanec, C.; Oppedal, A. Heat Treatment of Alpha + Beta Titanium Alloys. In Proceedings of the Materials Science & Technology 2018, Columbus, OH, USA, 14–18 October 2018. [Google Scholar]

- Bocchetta, P.; Chen, L.-Y.; Tardelli, J.D.C.; Reis, A.C.d.; Almeraya-Calderón, F.; Leo, P. Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings 2021, 11, 487. [Google Scholar] [CrossRef]

- Aufa, A.N.; Hassan, M.Z.; Ismail, Z. Recent Advances in Ti-6Al-4V Additively Manufactured by Selective Laser Melting for Biomedical Implants: Prospect Development. J. Alloys Compd. 2022, 896, 163072. [Google Scholar] [CrossRef]

- Haydar, H.J.; Al-Deen, J.; AbidAli, A.K.; Mahmoud, A.A. Improved Performance of Ti6Al4V Alloy in Biomedical Applications—Review. J. Phys. Conf. Ser. 2021, 1973, 012146. [Google Scholar] [CrossRef]

- Tamayo, J.A.; Riascos, M.; Vargas, C.A.; Baena, L.M. Additive Manufacturing of Ti6Al4V Alloy via Electron Beam Melting for the Development of Implants for the Biomedical Industry. Heliyon 2021, 7, e06892. [Google Scholar] [CrossRef]

- Fernandes, C.; Taurino, I. Biodegradable Molybdenum (Mo) and Tungsten (W) Devices: One Step Closer towards Fully-Transient Biomedical Implants. Sensors 2022, 22, 3062. [Google Scholar] [CrossRef]

- Wang, Z.-Q.; Pan, Y.-W.; Wu, J.; Qi, H.-B.; Zhu, S.; Gu, Z.-J. A Bibliometric Analysis of Molybdenum-Based Nanomaterials in the Biomedical Field. Tungsten 2024, 6, 17–47. [Google Scholar] [CrossRef]

- Redlich, C.; Schauer, A.; Scheibler, J.; Poehle, G.; Barthel, P.; Maennel, A.; Adams, V.; Weissgaerber, T.; Linke, A.; Quadbeck, P. In Vitro Degradation Behavior and Biocompatibility of Bioresorbable Molybdenum. Metals 2021, 11, 761. [Google Scholar] [CrossRef]

- Centers for Disease Control and Prevention Molybdenum | Toxicological Profile | ATSDR. Available online: https://www.atsdr.cdc.gov/ToxProfiles/tp212-c1.pdf (accessed on 14 July 2024).

- Nieh, T.G.; Wadsworth, J. Recent Advances and Developments in Refractory Alloys. MRS Online Proc. Libr. 1993, 322, 315–327. [Google Scholar] [CrossRef]

- Snead, L.L.; Hoelzer, D.T.; Rieth, M.; Nemith, A.A.N. Chapter 13—Refractory Alloys: Vanadium, Niobium, Molybdenum, Tungsten. In Structural Alloys for Nuclear Energy Applications; Odette, G.R., Zinkle, S.J., Eds.; Elsevier: Boston, MA, USA, 2019; pp. 585–640. ISBN 978-0-12-397046-6. [Google Scholar]

- Que, Z.; Wei, Z.; Li, X.; Zhang, L.; Dong, Y.; Qin, M.; Yang, J.; Qu, X.; Li, J. Pressureless Two-Step Sintering of Ultrafine-Grained Refractory Metals: Tungsten-Rhenium and Molybdenum. J. Mater. Sci. Technol. 2022, 126, 203–214. [Google Scholar] [CrossRef]

- Yan, J.; Lin, Y.Z.; Wang, Y.; Qiu, J.; Wan, F.; Song, C. Refractory WMoNbVTa High-Entropy Alloy as a Diffusion Barrier between a Molybdenum Substrate and MoSi2 Ceramic Coating. Ceram. Int. 2022, 48, 11410–11418. [Google Scholar] [CrossRef]

- Baumler, K.J.; Alameda, L.T.; Katzbaer, R.R.; O’Boyle, S.K.; Lord, R.W.; Schaak, R.E. Introducing Porosity into Refractory Molybdenum Boride through Controlled Decomposition of a Metastable Mo–Al–B Precursor. J. Am. Chem. Soc. 2023, 145, 1423–1432. [Google Scholar] [CrossRef] [PubMed]

- 1# Molybdenum Price Today | Historical 1# Molybdenum Price Charts | SMM Metal Market. Available online: https://www.metal.com/Other-Minor-Metals/201102250481 (accessed on 14 July 2024).

- Vanadium Price Today | Historical Vanadium Price Charts | SMM Metal Market. Available online: https://www.metal.com/Other-Minor-Metals/201102250299 (accessed on 14 July 2024).

- Sander, B.; Raabe, D. Texture Inhomogeneity in a Ti–Nb-Based β-Titanium Alloy after Warm Rolling and Recrystallization. Mater. Sci. Eng. A 2008, 479, 236–247. [Google Scholar] [CrossRef]

- Guo, B.; Semiatin, S.L.; Jonas, J.J.; Yue, S. Dynamic Transformation of Ti–6Al–4V during Torsion in the Two-Phase Region. J. Mater. Sci. 2018, 53, 9305–9315. [Google Scholar] [CrossRef]

- Andersson, J.-O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, Computational Tools for Materials Science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Sente Software—Home. Available online: https://www.sentesoftware.co.uk/ (accessed on 20 March 2019).

- OIM AnalysisTM | EDAX. Available online: www.edax.com/products/ebsd/oim-analysis (accessed on 20 March 2019).

- Gong, J.; Wilkinson, A.J. Anisotropy in the Plastic Flow Properties of Single-Crystal α Titanium Determined from Micro-Cantilever Beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Hardness Conversion Chart. Available online: https://www.alliedtitanium.com/technical/hardness/Hardness%20conversion%20chart.pdf (accessed on 13 July 2024).

- Wood, J.R.; Russo, P.A.; Welter, M.F.; Crist, E.M. Thermomechanical Processing and Heat Treatment of Ti–6Al–2Sn–2Zr–2Cr–2Mo–Si for Structural Applications. Mater. Sci. Eng. A 1998, 243, 109–118. [Google Scholar] [CrossRef]

- Ankem, S.; Greene, C.A. Recent Developments in Microstructure/Property Relationships of Beta Titanium Alloys. Mater. Sci. Eng. A 1999, 263, 127–131. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Knisley, S.L.; Fagin, P.N.; Barker, D.R.; Zhang, F. Microstructure Evolution during Alpha-Beta Heat Treatment of Ti-6Al-4V. Metall. Mater. Trans. A 2003, 34, 2377–2386. [Google Scholar] [CrossRef]

- Balachandran, S.; Kumar, S.; Banerjee, D. On Recrystallization of the α and β Phases in Titanium Alloys. Acta Mater. 2017, 131, 423–434. [Google Scholar] [CrossRef]

- Rollett, A.; Alvi, M.; Brahme, A.; Fridy, J.; Weiland, H.; Suni, J.; Cheong, S. Texture-Dependent Recrystallization in Aluminum 1050. In Proceedings of the 9th International Conference on Aluminium Alloys, Brisbane, Australia, 2–5 August 2004; Institute of Materials Engineering Australasia Ltd.: Brisbane, Australia, 2004; Volume 28, pp. 1173–1178. [Google Scholar]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. About Quantitative EBSD Analysis of Deformation and Recovery Substructures in Pure Tantalum. IOP Conf. Ser. Mater. Sci. Eng. 2015, 89, 012038. [Google Scholar] [CrossRef]

- Wood, R.M. The Lattice Constants of High Purity Alpha Titanium. Proc. Phys. Soc. 1962, 80, 783–786. [Google Scholar] [CrossRef]

| Alloy | Processing Condition | Microstructure (EBSD) | Quasi-Static Compression (True Stress–True Strain) | Vickers Microhardness | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Avg. Grain Size (μm) | Phase Fraction | Yield Stress (MPa) | Peak Stress (MPa) | Strain at Peak Stress (%) | Avg. Value | Converted Tensile Strength (MPa) [84] | |||||

| ND | RD | ND | RD | ND | RD | ||||||

| Ti-639 | As received | 10.2 | 94% α–6% β | 1107 | 1126 | 1498 | 1529 | 33.9 | 16.4 | 349.2 | 1119 |

| SHT | 9.8 | 95% α–5% β | 1173 | 1226 | 1561 | 1558 | 28.2 | 11.5 | 343.0 | 1102 | |

| SHT + Aged | 8.6 | 96% α–4% β | 1186 | 1267 | 1519 | 1571 | 25.2 | 11.8 | 380.0 | 1215 | |

| Ti-64 | As received | 8.2 | 98% α–2% β | 1009 | 975 | 1402 | 1396 | 27.1 | 23.8 | 336.3 | 1077 |

| SHT | 8.5 | 97% α–3% β | 1195 | 1074 | 1550 | 1438 | 15.5 | 19.2 | 325.7 | 1043 | |

| SHT + Aged | 9.5 | 97% α–3% β | 1082 | 1237 | 1473 | 1580 | 22.9 | 16.6 | 342.7 | 1096 | |

| Grain | Avg. Misorientation (deg) | Length of Line Scan (μm) | Dislocation Density (m−2) |

|---|---|---|---|

| a | 0.83 | 13.1 | 7.5 × 1012 |

| b | 0.58 | 11.8 | 5.8 × 1012 |

| c | 14.9 | 19.2 | 9.2 × 1013 |

| d | 18.5 | 22.4 | 9.8 × 1013 |

| e | 8.7 | 22.6 | 4.6 × 1013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mujahid, S.; Boostani, A.F.; Paudel, Y.; Oppedal, A.; Paliwal, B.; Rhee, H.; El Kadiri, H. Examination of Novel Titanium-639 Alloy as a Means of Balancing Strength and Ductility through Molybdenum Addition Rather than Prolonged Aging Heat Treatment. Metals 2024, 14, 828. https://doi.org/10.3390/met14070828

Mujahid S, Boostani AF, Paudel Y, Oppedal A, Paliwal B, Rhee H, El Kadiri H. Examination of Novel Titanium-639 Alloy as a Means of Balancing Strength and Ductility through Molybdenum Addition Rather than Prolonged Aging Heat Treatment. Metals. 2024; 14(7):828. https://doi.org/10.3390/met14070828

Chicago/Turabian StyleMujahid, Shiraz, Alireza Fadavi Boostani, YubRaj Paudel, Andrew Oppedal, Bhasker Paliwal, Hongjoo Rhee, and Haitham El Kadiri. 2024. "Examination of Novel Titanium-639 Alloy as a Means of Balancing Strength and Ductility through Molybdenum Addition Rather than Prolonged Aging Heat Treatment" Metals 14, no. 7: 828. https://doi.org/10.3390/met14070828