Comparative Study of Heat Transfer Simulation and Effects of Different Scrap Steel Preheating Methods

Abstract

1. Introduction

2. Establishment of the Model

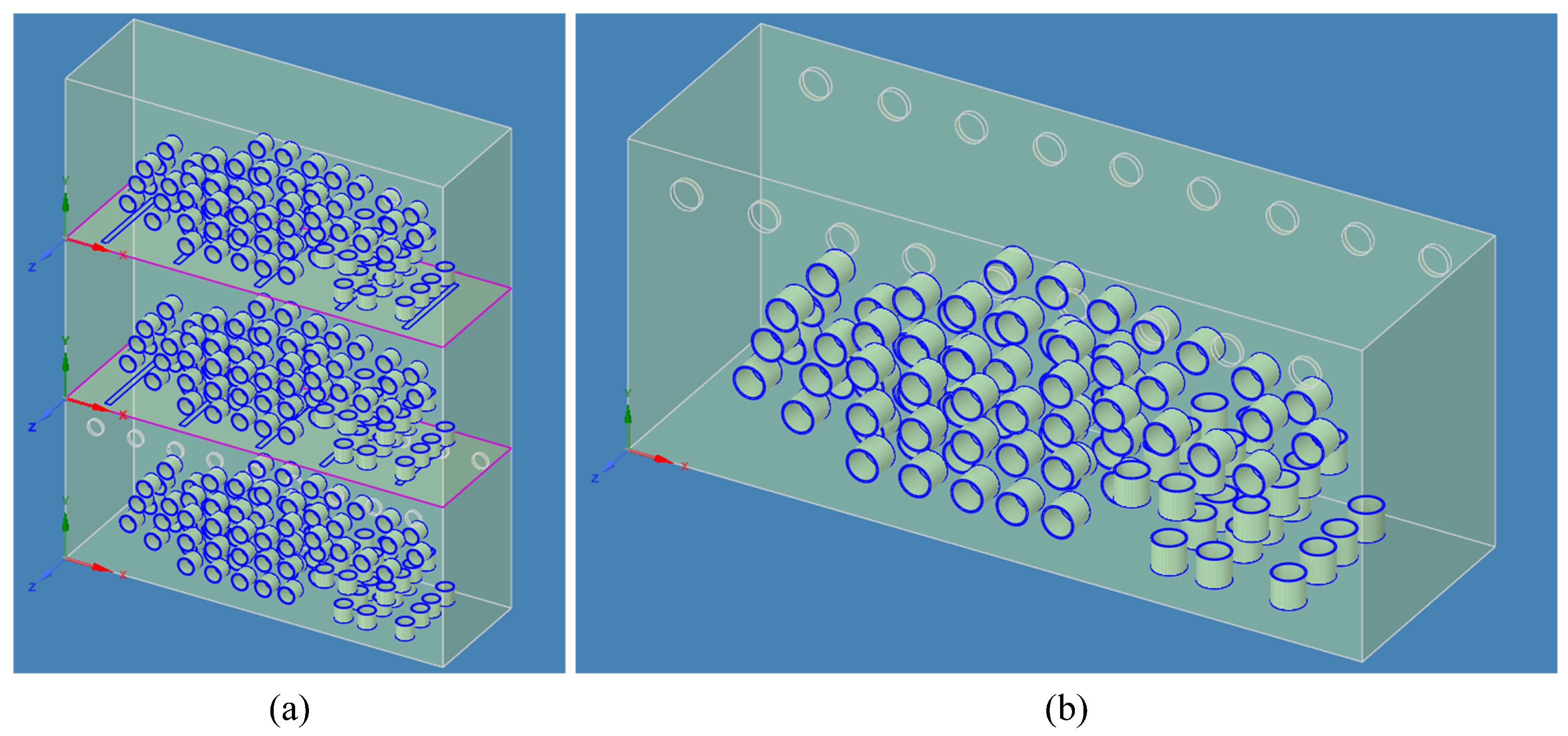

2.1. Geometric Model

2.2. Theoretical Model

2.3. Combustion Model

2.4. Model Assumptions and Initial Conditions

- The high-temperature flue gas flows smoothly as a viscous, incompressible fluid through a sleek vertical shaft;

- The scrap used in converter steelmaking varies in size and shape. Based on actual data, scrap of different thicknesses is simplified to regular, smooth circular tubes with known average dimensions of length, thickness, and inner diameter;

- The inlet boundary flow velocity of high-temperature flue gas is uniform at the bottom of both vertical and horizontal furnaces, with all process parameters held constant, the inlet boundary flow velocity remains uniform, and all process parameters are constant without temperature variation;

- The numerical model employs velocity inlets for both gas and oxygen inputs, each set at an inlet temperature of 25 °C. The flue gas outlet of the horizontal furnace is equipped with a pressure outlet that suppresses backflow, while the triple-stage vertical preheating furnace also utilizes a pressure outlet. The model accounts for coupled heat transfer between the gas and scrap tubes. The preheating furnace operates under standard atmospheric pressure, starting at an initial temperature of 25 °C. The inlet flue gas temperature is assumed to be constant;

- The simulation does not account for heat released from organic combustion on the surface of scrap during preheating;

- The gas composition consists of CO, , , and , with mass fractions of 0.4, 0.01, 0.14, and 0.45, and a density of 0.29 kg/m3.

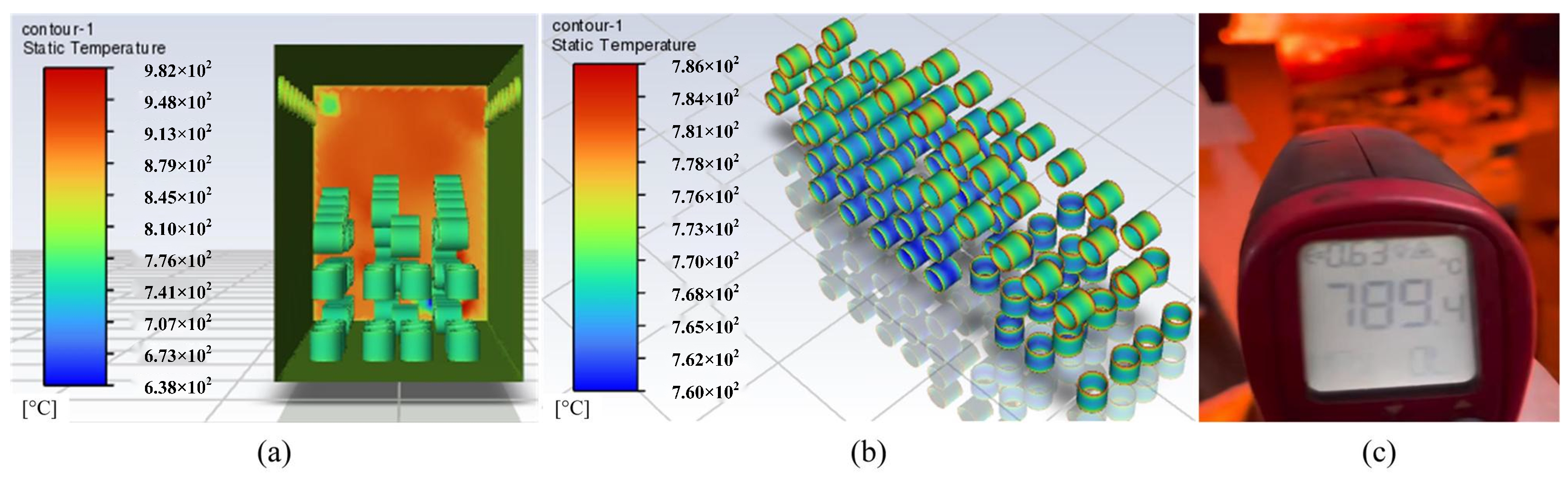

2.5. Model Results and Validation

3. Results and Discussion

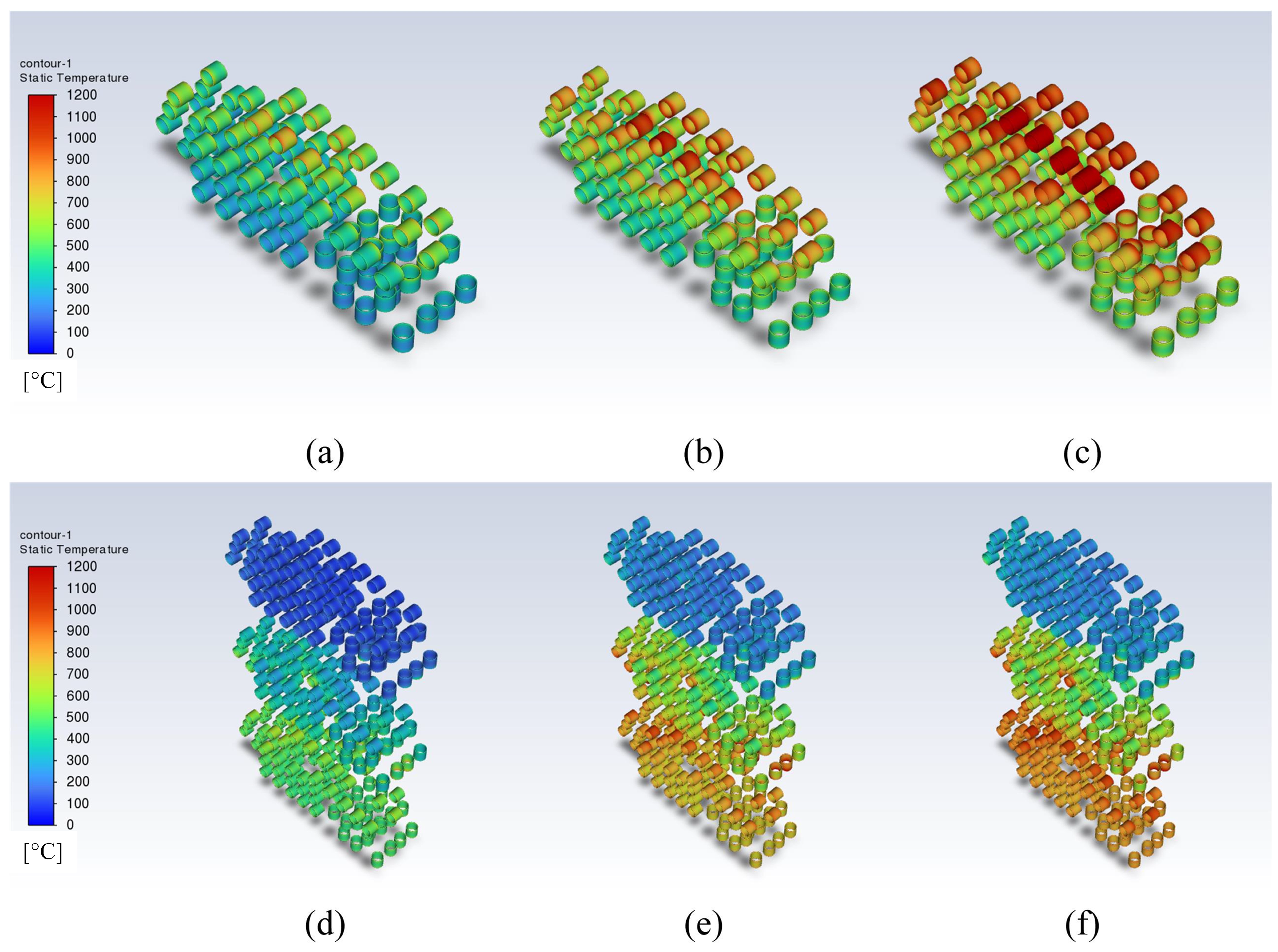

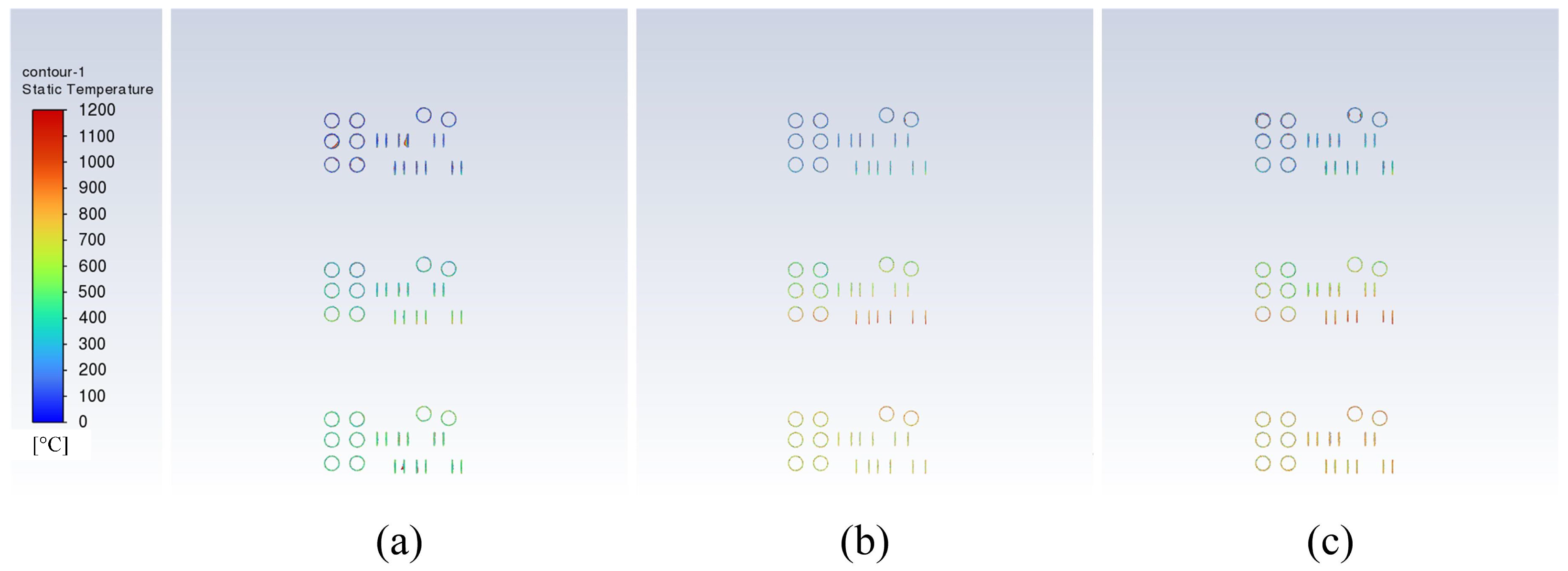

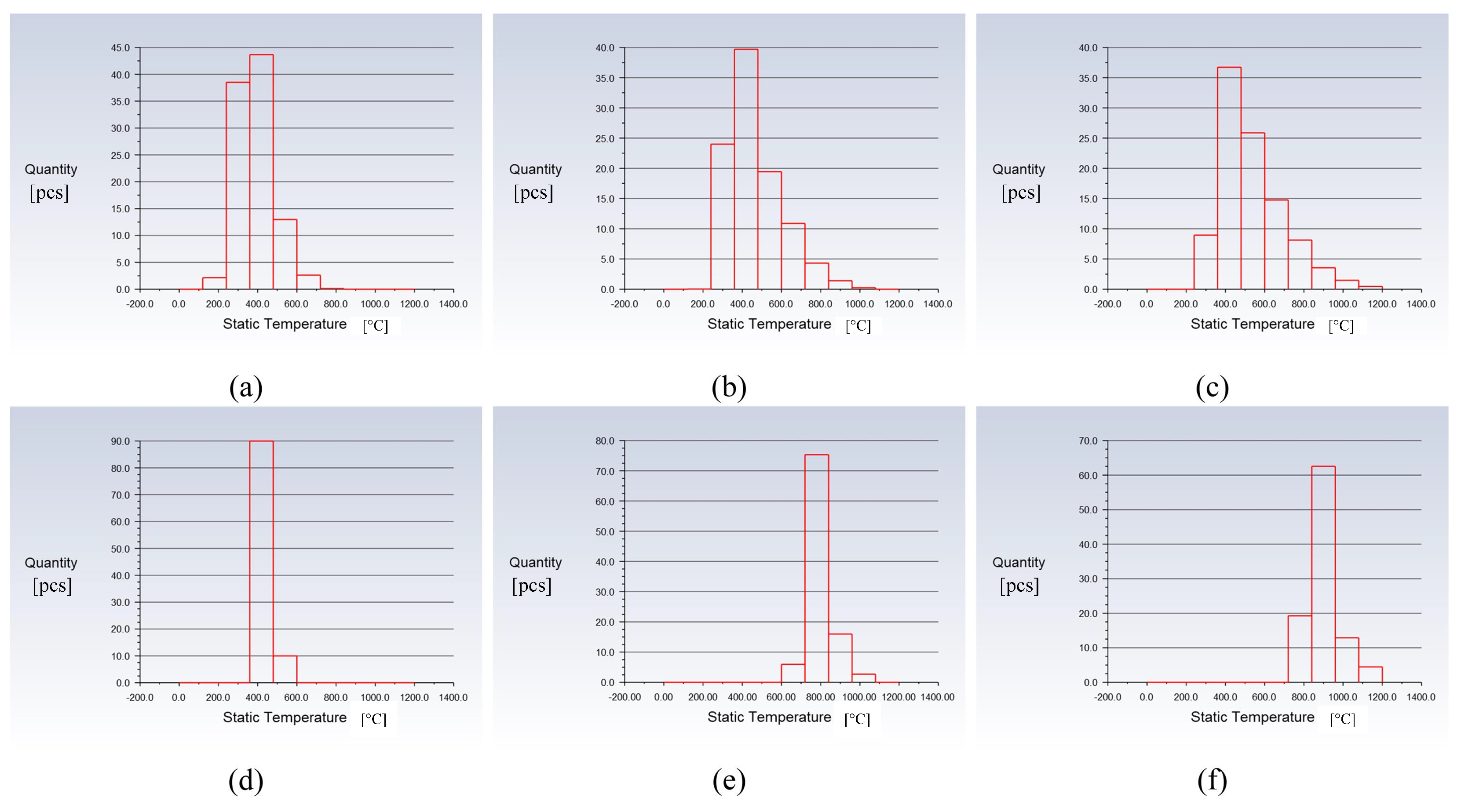

3.1. Effectiveness of Scrap Preheating at Different Preheating Times

3.2. Effects of Different Initial Gas Velocities on Scrap Preheating

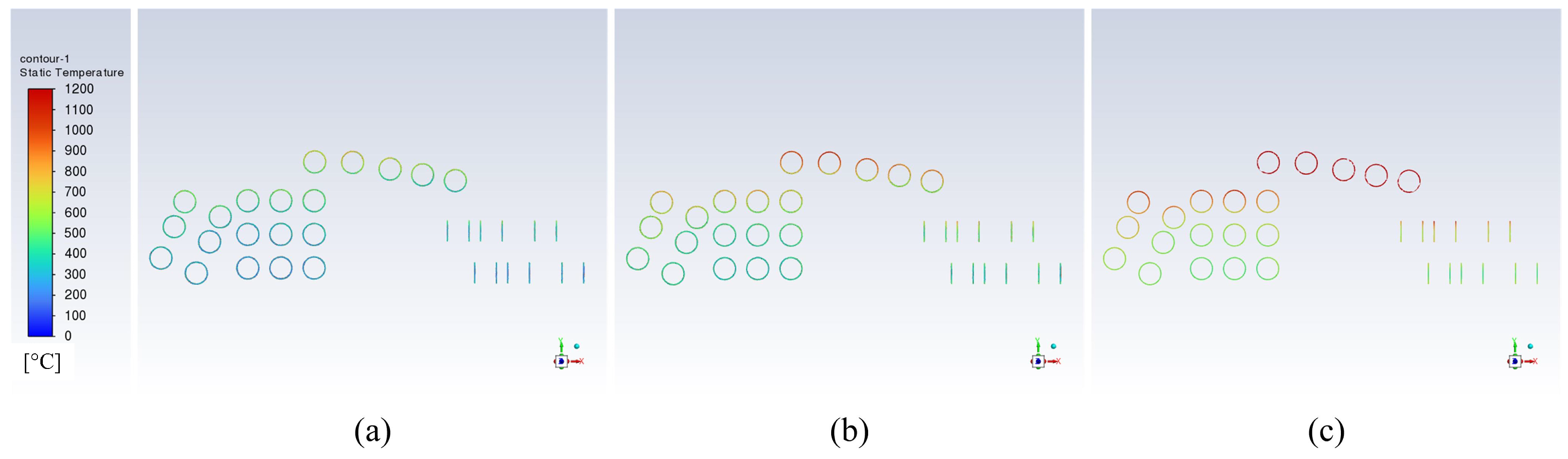

3.3. Impact of Preheating on the Core of Scrap

3.4. Energy Utilization Comparison between Vertical Furnace and Horizontal Furnace

4. Conclusions

- The preheating temperature of scrap increases with increased gas velocity; however, the rate of temperature rise decreases progressively under these conditions. In practical production environments with limited preheating time, appropriately increasing gas velocity can effectively raise the preheating temperature of scrap.

- Increasing the horizontal furnace preheating time from 600 s to 1200 s results in the average surface temperature of scrap rising from 405 °C to 730 °C. Similarly, extending the vertical furnace preheating time from 600 s to 1200 s raises the surface temperature of scrap from 547 °C to 874 °C. Likewise, elevating the horizontal furnace gas velocity from 5 m/s to 9 m/s increases the surface temperature of scrap from 376 °C to 580 °C, while increasing the vertical furnace gas velocity from 5 m/s to 9 m/s boosts the surface temperature of scrap from 432 °C to 905 °C.

- In the traditional horizontal furnace heating process, measures must be taken to restrict heating duration and exhaust gas velocity to avoid localized overheating of scrap steel, which can result in melting and adherence. As a result, during a 600 s preheating cycle, the core temperature of scrap steel typically ranges between 200 °C and 500 °C, leading to suboptimal preheating efficiency. The vertical furnaces address these concerns effectively by promoting a more even temperature distribution throughout preheated scrap steel, thereby yielding superior outcomes.

- With an initial gas velocity of 9 m/s and a preheating duration of 600 s, the maximum waste heat recovery rate of the vertical furnace is 57%. The average temperature of scrap within the vertical furnace surpasses that of the horizontal furnace by 325 °C, absorbing an additional 202 MJ of heat per ton of scrap. In the horizontal preheating furnace, scrap steel exhibits a heat absorption efficiency of 35%, whereas in the vertical furnace, this efficiency increases notably to 63%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Voraberger, B.; Wimmer, G.; Dieguez Salgado, U.; Wimmer, E.; Pastucha, K.; Fleischanderl, A. Green LD (BOF) Steelmaking—Reduced CO2 Emissions via Increased Scrap Rate. Metals 2022, 12, 466. [Google Scholar] [CrossRef]

- Hao, H.; Wu, H.; Wei, F.; Xu, Z.; Xu, Y. Scrap Steel Recycling: A Carbon Emission Reduction Index for China. Sustainability 2024, 16, 4250. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H. Converter practice in China with respect to steelmaking and ferroalloys. Miner. Process. Extr. Metall. 2019, 128, 46–57. [Google Scholar] [CrossRef]

- Gao, M.; Gao, J.T.; Zhang, Y.L.; Yang, S.F. Two-dimensional temperature distribution and heat transfer during scrap melting. JOM 2020, 72, 1943–1952. [Google Scholar] [CrossRef]

- Schubert, C.; Büschgens, D.; Eickhoff, M.; Echterhof, T.; Pfeifer, H. Development of a Fast Modeling Approach for the Prediction of Scrap Preheating in Continuously Charged Metallurgical Recycling Processes. Metals 2021, 11, 1280. [Google Scholar] [CrossRef]

- Toulouevski, Y.N.; Zinurov, I.Y. Methods of realization of high-temperature scrap preheating. In Electric Arc Furnace with Flat Bath: Achievements and Prospects; Springer: Berlin/Heidelberg, Germany, 2015; pp. 69–82. [Google Scholar] [CrossRef]

- Toulouevski, Y.N.; Zinurov, I.Y. High-Temperature Heating a Scrap in a Furnace Shaft. In Fuel Arc Furnace (FAF) for Effective Scrap Melting: From EAF to FAF; Springer: Berlin/Heidelberg, Germany, 2017; pp. 79–85. [Google Scholar] [CrossRef]

- Arink, T.; Hassan, M.I. Metal scrap preheating using flue gas waste heat. Energy Procedia 2017, 105, 4788–4795. [Google Scholar] [CrossRef]

- Zhuang, S.; Zhan, D.; Wang, T.; Li, P.; Yang, Y. Influence of Oxy-Fuel Lance Parameters on the Scrap Pre-Heating Temperature in the Hot Metal Ladle. Metals 2023, 13, 847. [Google Scholar] [CrossRef]

- Zhang, L.; Fang, Q.; Zhou, W.; Wang, J.; Yu, G.; Zhang, H.; Ni, H. Numerical simulation on the melting behaviors of steel scrap in a ladle with bottom argon blowing. Chin. J. Eng. 2024, 46, 822–834. [Google Scholar] [CrossRef]

- Deng, S.; Xu, A.; Yang, G.; Wang, H. Analyses and calculation of steel scrap melting in a multifunctional hot metal ladle. Steel Res. Int. 2019, 90, 1800435. [Google Scholar] [CrossRef]

- Zhang, C.; Ding, P.; Wang, K.; Huang, J.; Zhang, J. Feasibility Study on Ladle with Scrap Add Iron. Metals 2017, 4, 186–192. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, G.; Xu, A.; Wang, C.; Zhu, R. Modelling and Simulation of the Scrap Melting in the Consteel EAF. In TMS Annual Meeting & Exhibition, Proceedings of the TMS Annual Meeting & Exhibition, Orlando, FL, USA, 3–7 March 2024; Springer Nature Switzerland: Basel, Switzerland, 2024; pp. 537–547. [Google Scholar] [CrossRef]

- Gao, M.; Yang, S.F.; Zhang, Y.L. Experimental study on mass transfer during scrap melting in the steelmaking process. Ironmak. Steelmak. 2020, 47, 1006–1014. [Google Scholar] [CrossRef]

- Gao, M.; Gao, J.T.; Zhang, Y.L.; Yang, S.F. Simulation on scrap melting behavior and carbon diffusion under natural convection. Int. J. Miner. Metall. Mater. 2021, 28, 380–389. [Google Scholar] [CrossRef]

- Zhao, A.N.; Zhang, L.Q.; Zhang, B.L.; Yang, W.O.; Ali, N.; Zhang, W.; Zhang, C.J. The Study on the Behavior of the Melting Process of Scraps in Converter. Int. J. Res. Stud. Sci. Eng. Technol. 2020, 7, 15–21. [Google Scholar]

- Zhou, X.B.; Wang, W.X.; Di, Z.X.; He, Q.L.; Yue, Q. Numerical investigation of scrap melting in high-carbon hot metal. Int. J. Chem. React. Eng. 2022, 20, 1107–1116. [Google Scholar] [CrossRef]

- Liu, M.; Ma, G.J.; Zhang, X.; Zheng, D. Numerical simulation on the melting kinetics of steel scrap in iron-carbon bath. Case Stud. Therm. Eng. 2022, 34, 101995. [Google Scholar] [CrossRef]

- Chen, Y.C.; Ryan, S.; Silaen, A.K.; Zhou, C.Q. Simulation of scrap melting process in an AC electric arc furnace: CFD model development and experimental validation. Metall. Mater. Trans. B 2022, 53, 2675–2694. [Google Scholar] [CrossRef]

- Chen, Y.C.; Luo, Q.X.; Ryan, S.; Busa, N.; Silaen, A.K.; Zhou, C.Q. Effect of coherent jet burner on scrap melting in electric arc furnace. Appl. Therm. Eng. 2022, 212, 118596. [Google Scholar] [CrossRef]

- Fan, G.Y.; Su, F.Y.; Zhao, Q.L.; Li, C.W.; Li, B. Study on Heat Transfer Process between High-Temperature Slag Particles and Scrap in Drum Based on DEM Method. Processes 2024, 12, 815. [Google Scholar] [CrossRef]

- Grasselli, A.; Reali, S.; Andersson, J.; Lehman, A.F.; Teng, L. Consteerrer™ technology: Getting the most out of the electric steelmaking process. In Proceedings of the 4th European Conference on Clean Technologies in the Steel Industry, Bergamo, Italy, 28–29 September 2018. [Google Scholar]

- Toulouevski, Y.N.; Zinurov, I.Y. Analysis of technologies and designs of the EAF as an aggregate for heating and melting of scrap. In Fuel Arc Furnace (FAF) for Effective Scrap Melting: From EAF to FAF; Springer: Berlin/Heidelberg, Germany, 2017; pp. 7–39. [Google Scholar] [CrossRef]

- Hu, H.; Yang, L.; Wei, G.; Zou, Y.; Xue, B.; Chen, F.; Wang, S.; Guo, Y. Numerical Simulation of Scrap Preheating with Flue Gas in EAF Steelmaking Process. In TMS Annual Meeting & Exhibition, Proceedings of the TMS Annual Meeting & Exhibition, Orlando, FL, USA, 3–7 March 2024; Springer Nature Switzerland: Basel, Switzerland, 2024; pp. 569–577. [Google Scholar] [CrossRef]

- Makarov, A.N. Effect of the architecture on energy efficiency of electric arc furnaces of conventional and Consteel designs. Metallurgist 2019, 62, 882–891. [Google Scholar] [CrossRef]

- Odenthal, H.-J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on Modeling and Simulation of the Electric Arc Furnace (EAF). Steel Res. Int. 2017, 89, 1700098. [Google Scholar] [CrossRef]

- Lu, S.-L.; Xiao, F.-R.; Guo, Z.-H.; Wang, L.-J.; Li, H.-Y.; Liao, B. Numerical simulation of multilayered multiple metal cast rolls in compound casting process. Appl. Therm. Eng. 2016, 93, 510–519. [Google Scholar] [CrossRef]

- Nakanishi, K.; Szekely, J. Deoxidation kinetics in a turbulent flow field. Trans. ISIJ 1975, 15, 522–530. [Google Scholar] [CrossRef]

| Time/s | The Temperature of the Scrap in the Horizontal Furnace/°C | The Temperature of the Scrap in the Vertical Furnace/°C |

|---|---|---|

| 600 | 405 | 547 |

| 900 | 513 | 806 |

| 1200 | 730 | 874 |

| Initial Velocity/m/s | The Temperature of the Scrap in the Horizontal Furnace/°C | The Temperature of the Scrap in the Vertical Furnace/°C |

|---|---|---|

| 5 | 376 | 432 |

| 7 | 509 | 801 |

| 9 | 555 | 915 |

| Time/s | The Heat Absorption of Scrap in the Horizontal Furnace/MJ | The Heat Absorption of Scrap in the Vertical Furnace/MJ |

|---|---|---|

| 600 | 2761 | 4448 |

| 900 | 3547 | 7020 |

| 1200 | 6683 | 7406 |

| Initial Velocity/m/s | The Heat Absorption of Scrap in the Horizontal Furnace/MJ | The Heat Absorption of Scrap in the Vertical Furnace/MJ |

|---|---|---|

| 5 | 2550 | 3430 |

| 7 | 3518 | 6140 |

| 9 | 3852 | 7050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, P.; Jin, Y.; Zhu, L.; Wang, C.; Zhu, R. Comparative Study of Heat Transfer Simulation and Effects of Different Scrap Steel Preheating Methods. Metals 2024, 14, 913. https://doi.org/10.3390/met14080913

Xiao P, Jin Y, Zhu L, Wang C, Zhu R. Comparative Study of Heat Transfer Simulation and Effects of Different Scrap Steel Preheating Methods. Metals. 2024; 14(8):913. https://doi.org/10.3390/met14080913

Chicago/Turabian StyleXiao, Pengcheng, Yuxin Jin, Liguang Zhu, Chao Wang, and Rong Zhu. 2024. "Comparative Study of Heat Transfer Simulation and Effects of Different Scrap Steel Preheating Methods" Metals 14, no. 8: 913. https://doi.org/10.3390/met14080913

APA StyleXiao, P., Jin, Y., Zhu, L., Wang, C., & Zhu, R. (2024). Comparative Study of Heat Transfer Simulation and Effects of Different Scrap Steel Preheating Methods. Metals, 14(8), 913. https://doi.org/10.3390/met14080913