Fatigue Response of Additive-Manufactured 316L Stainless Steel

Abstract

:1. Introduction

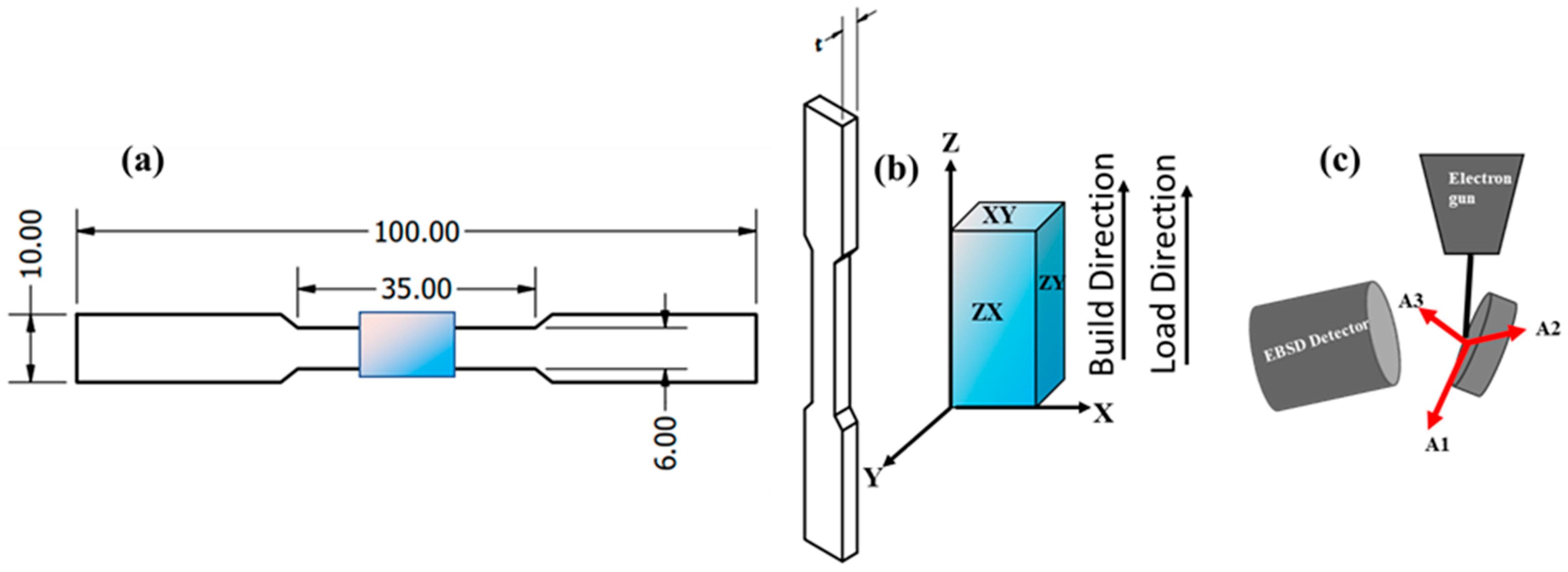

2. Materials and Methods

3. Results

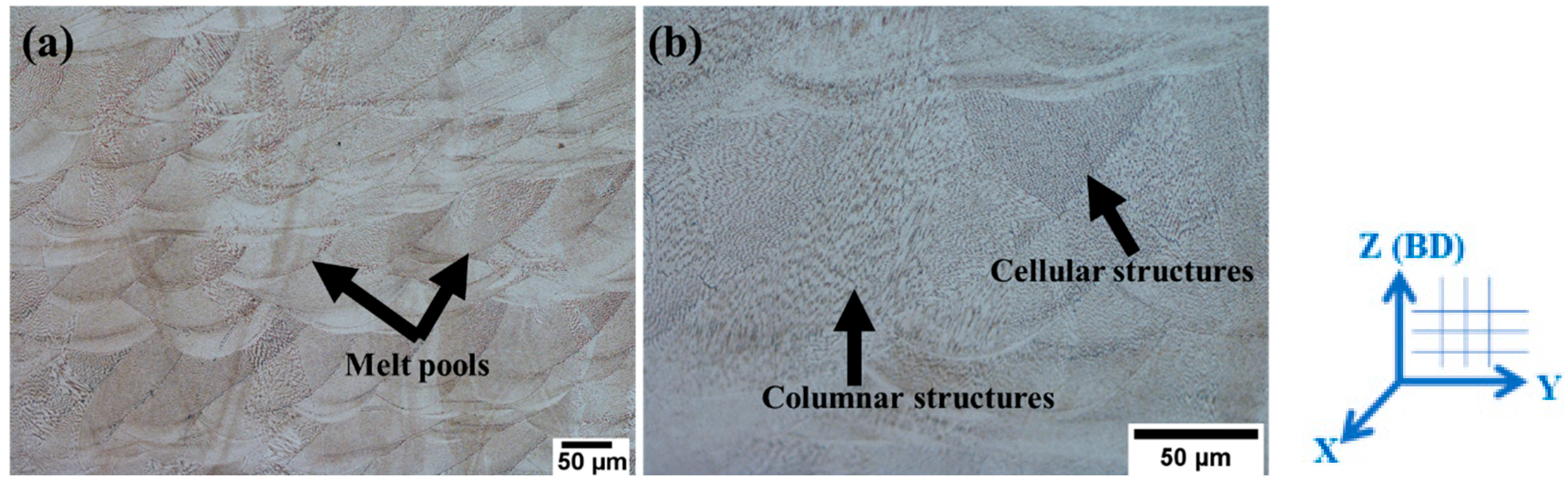

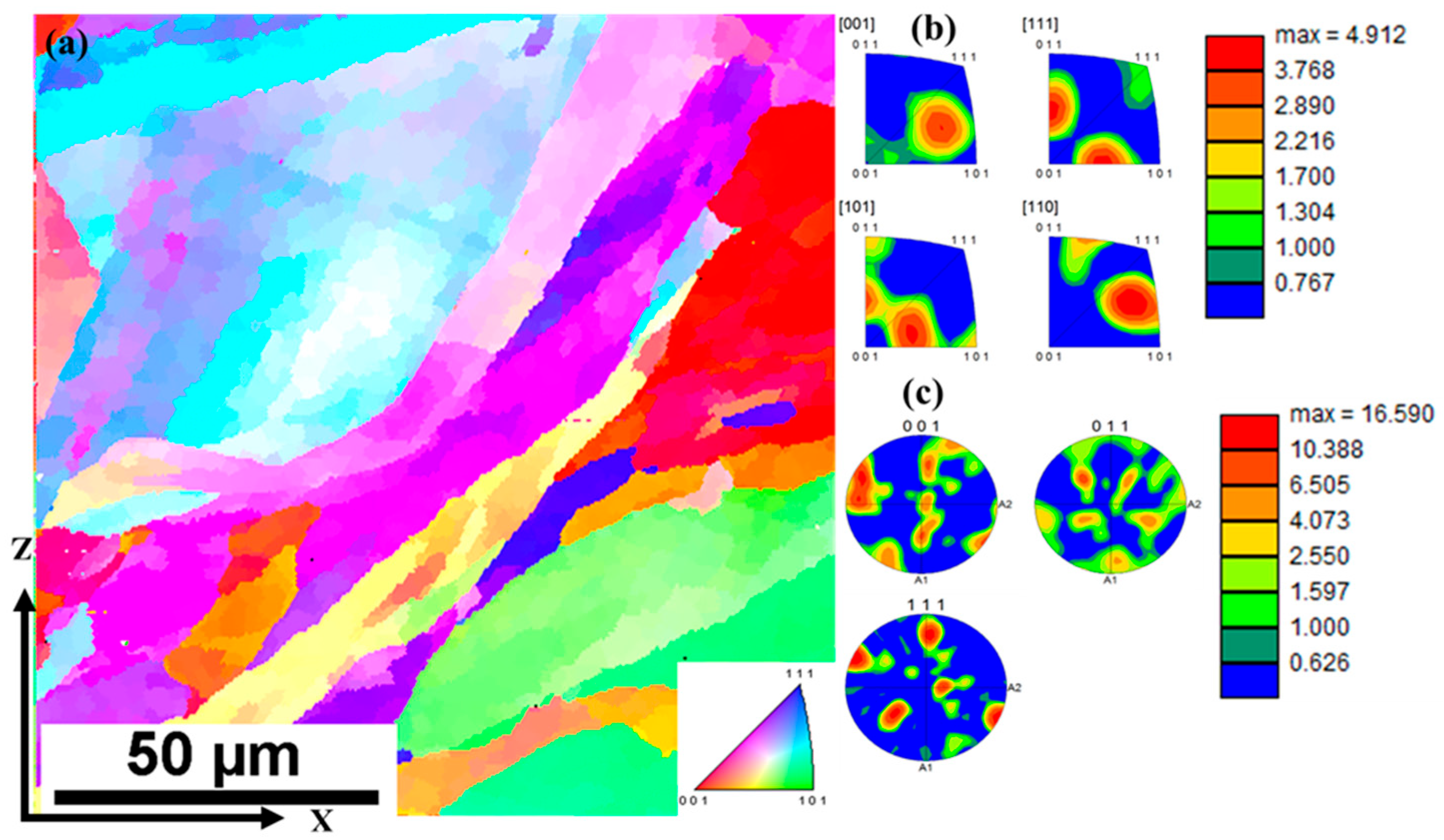

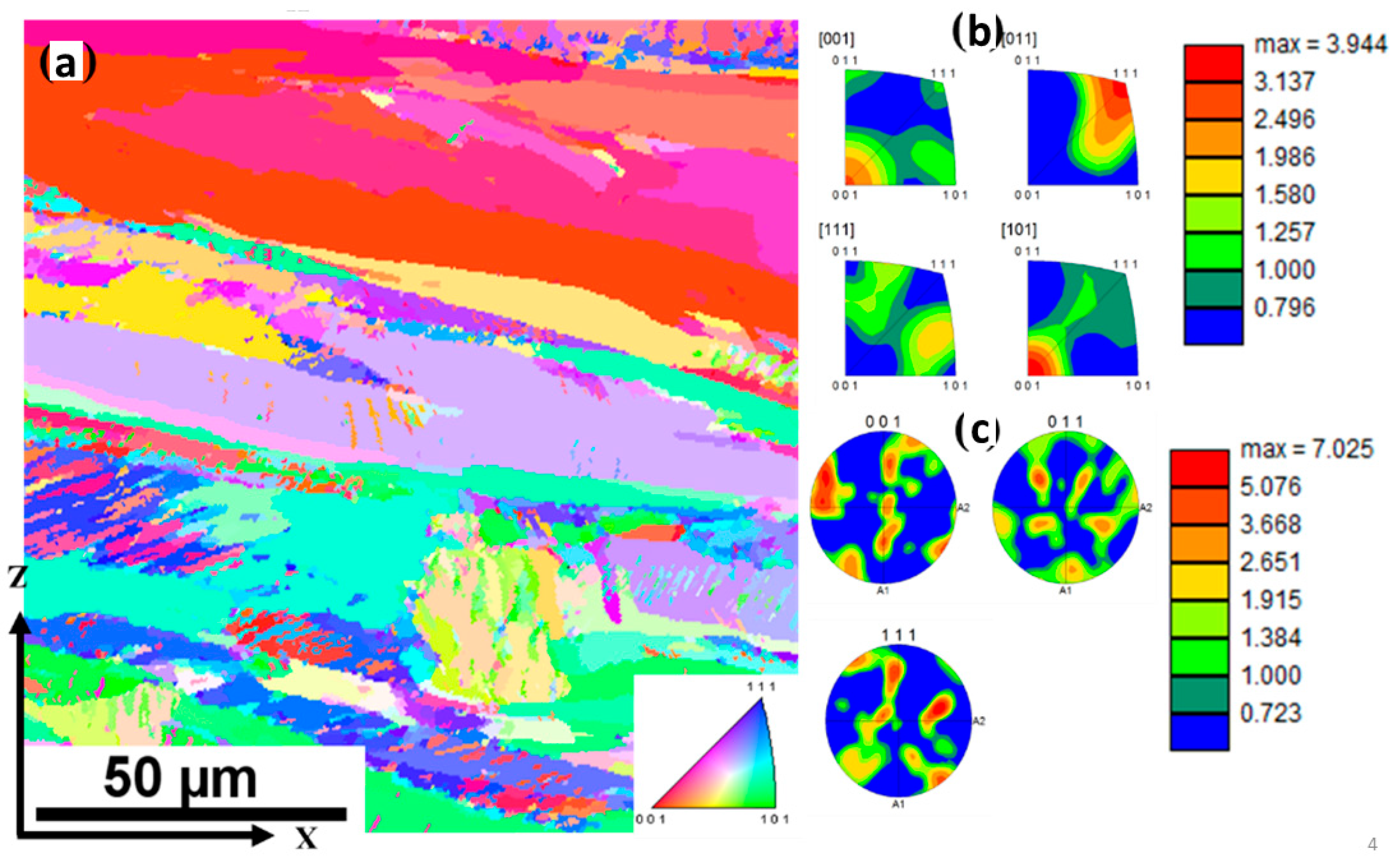

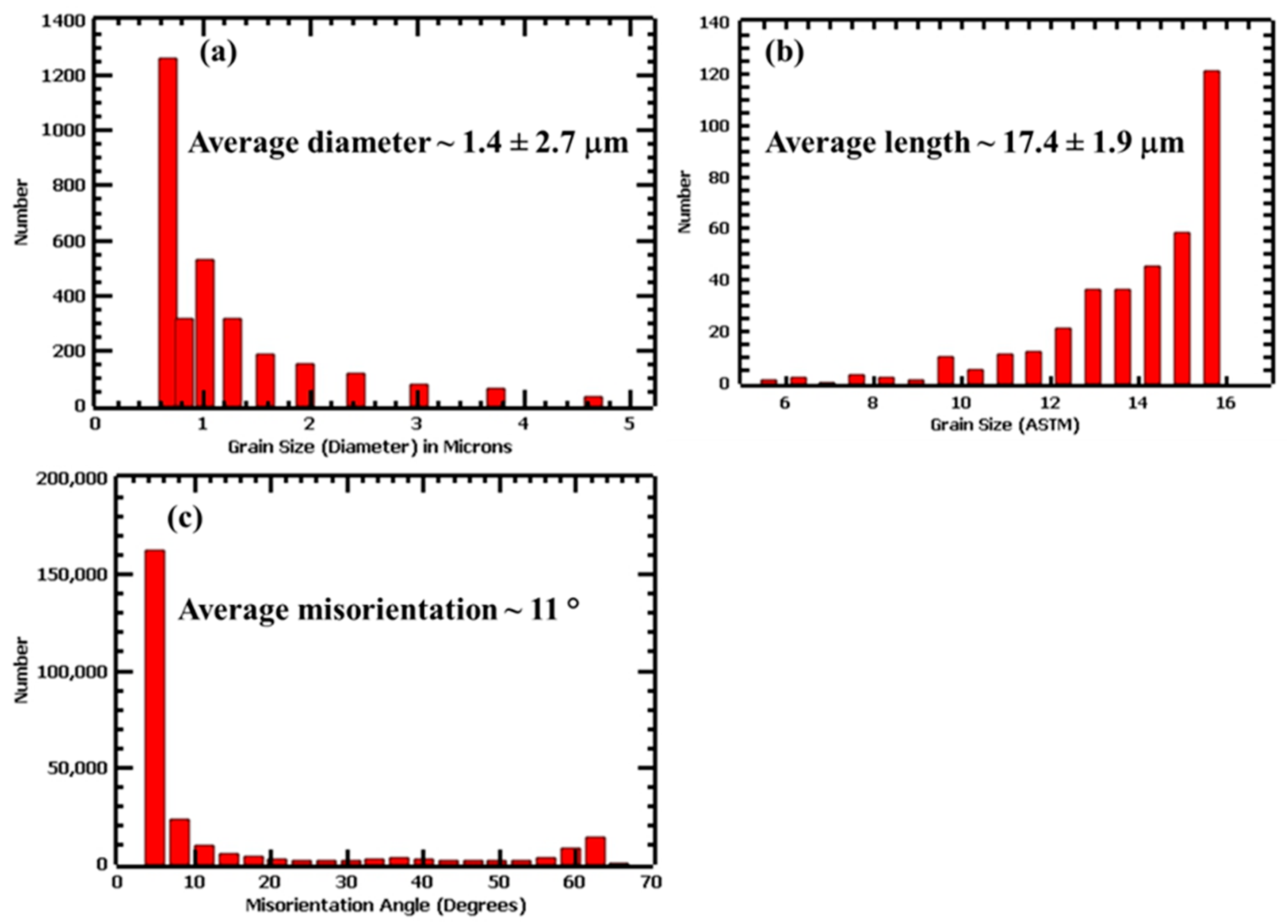

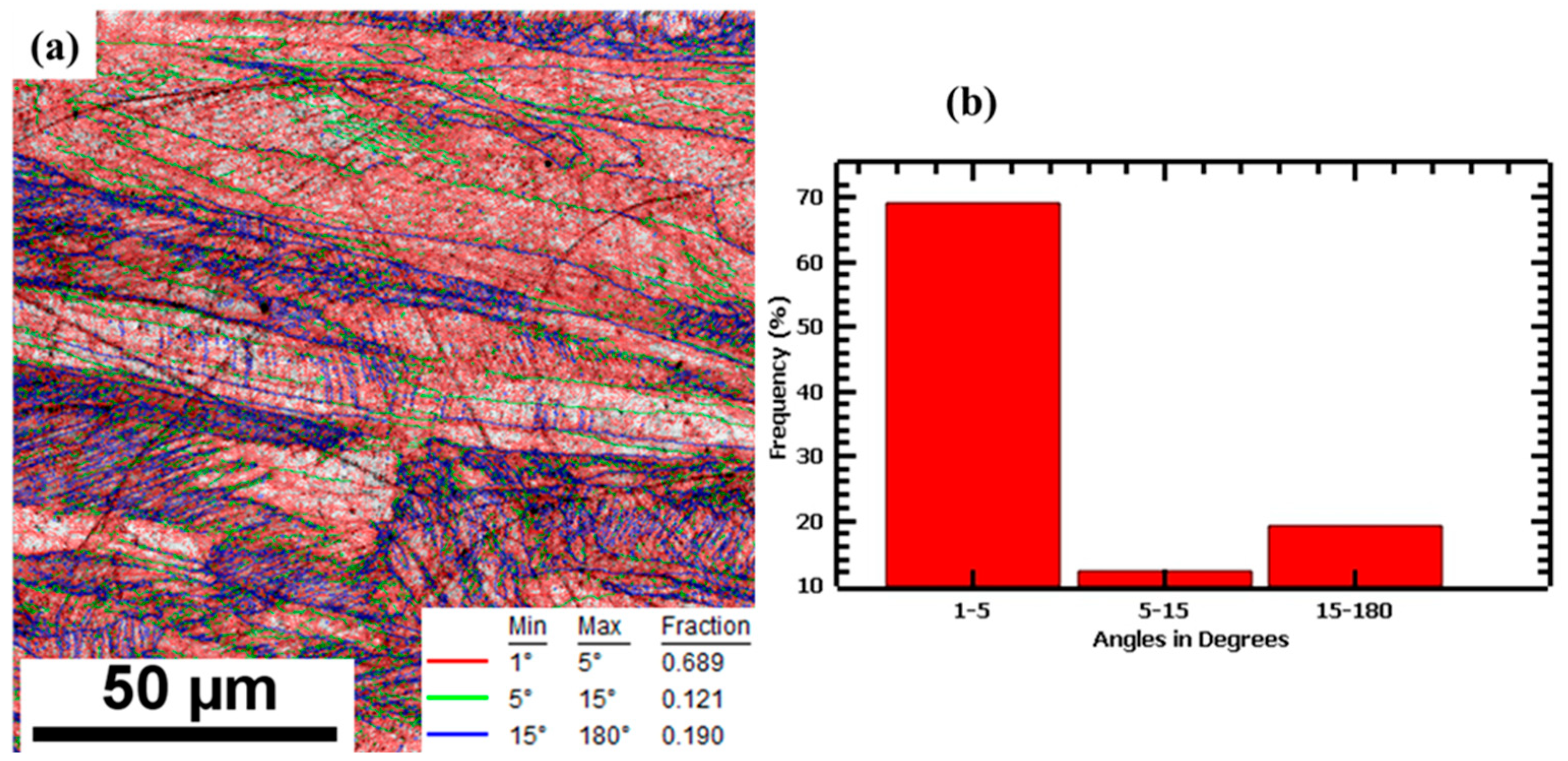

3.1. As-Built Microstructure

3.2. Mechanical Performance of LPBF 316L Stainless Steel

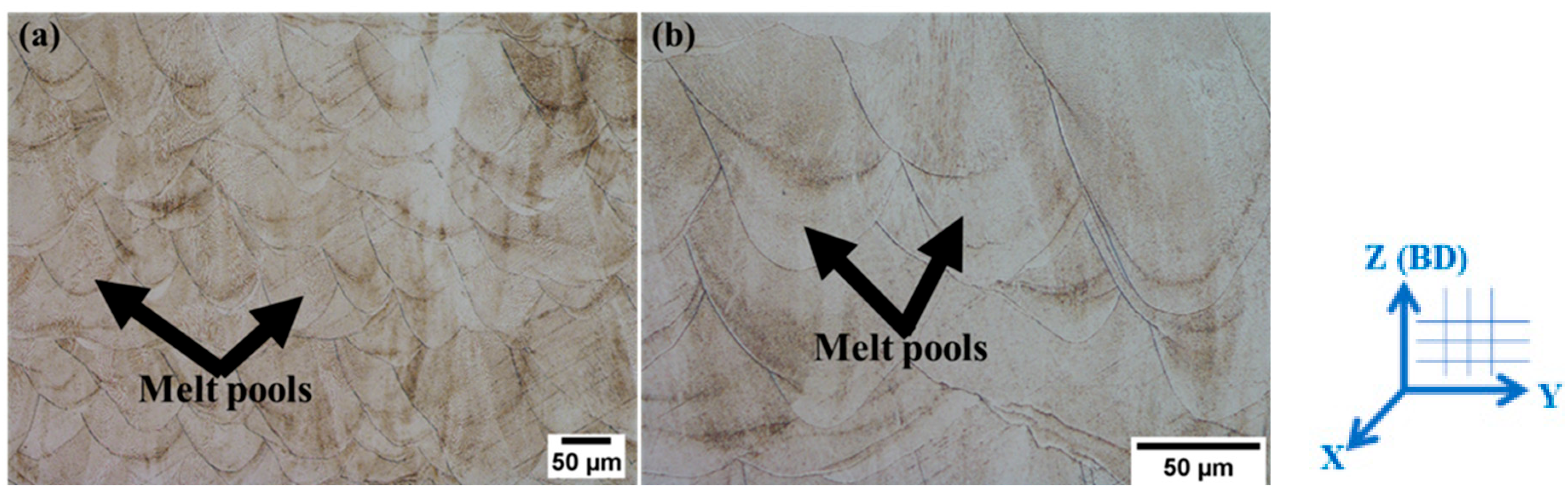

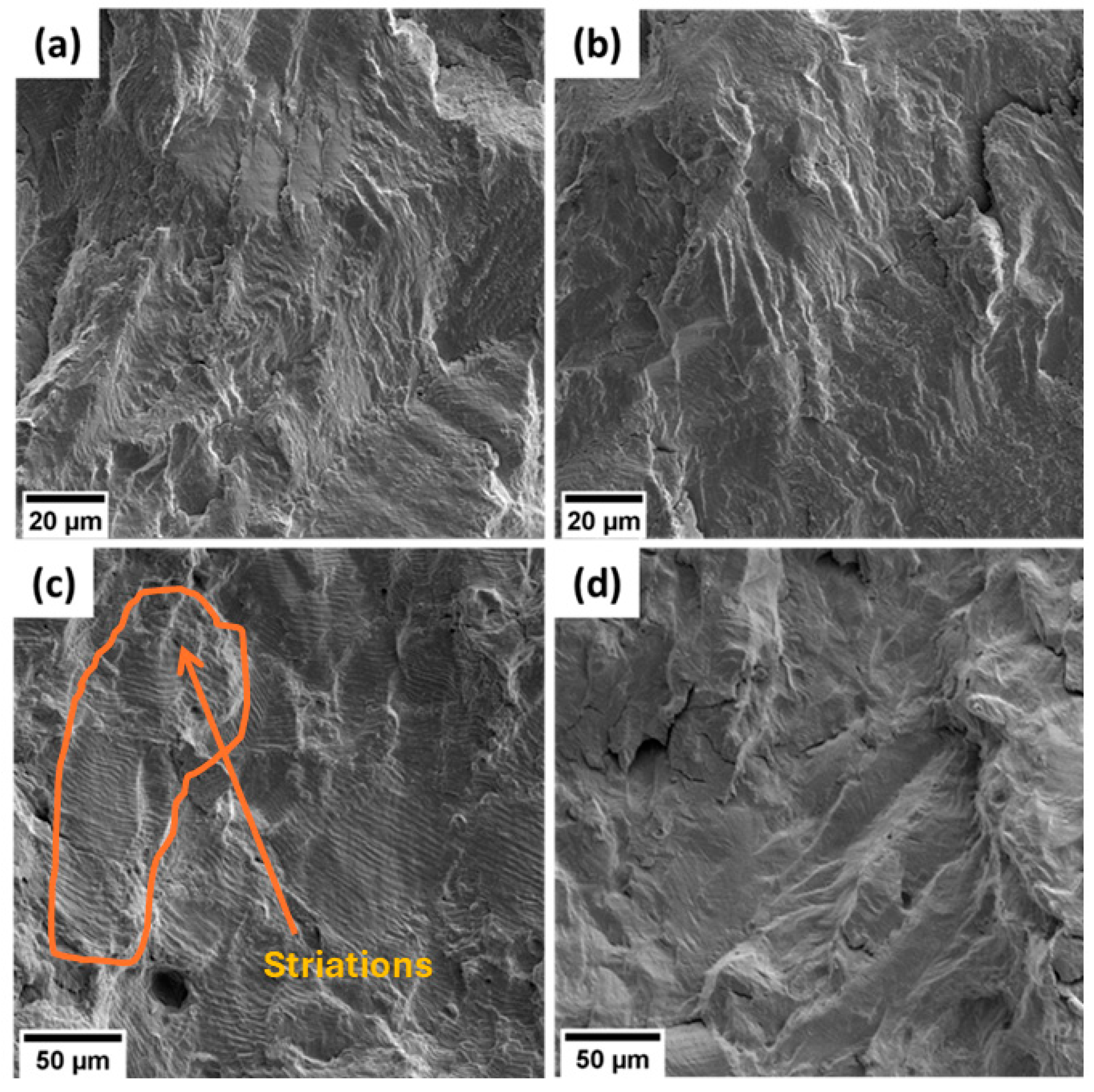

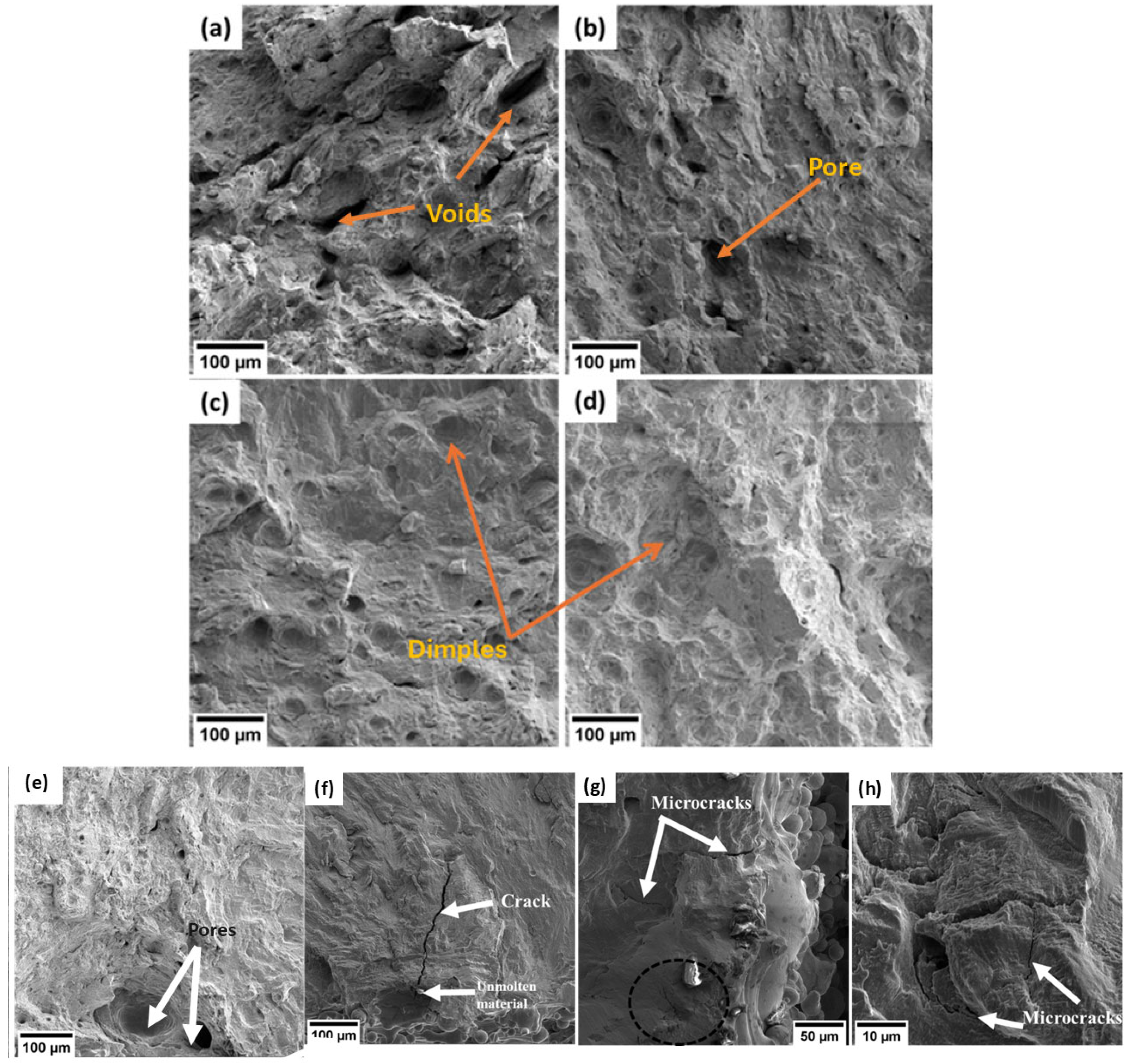

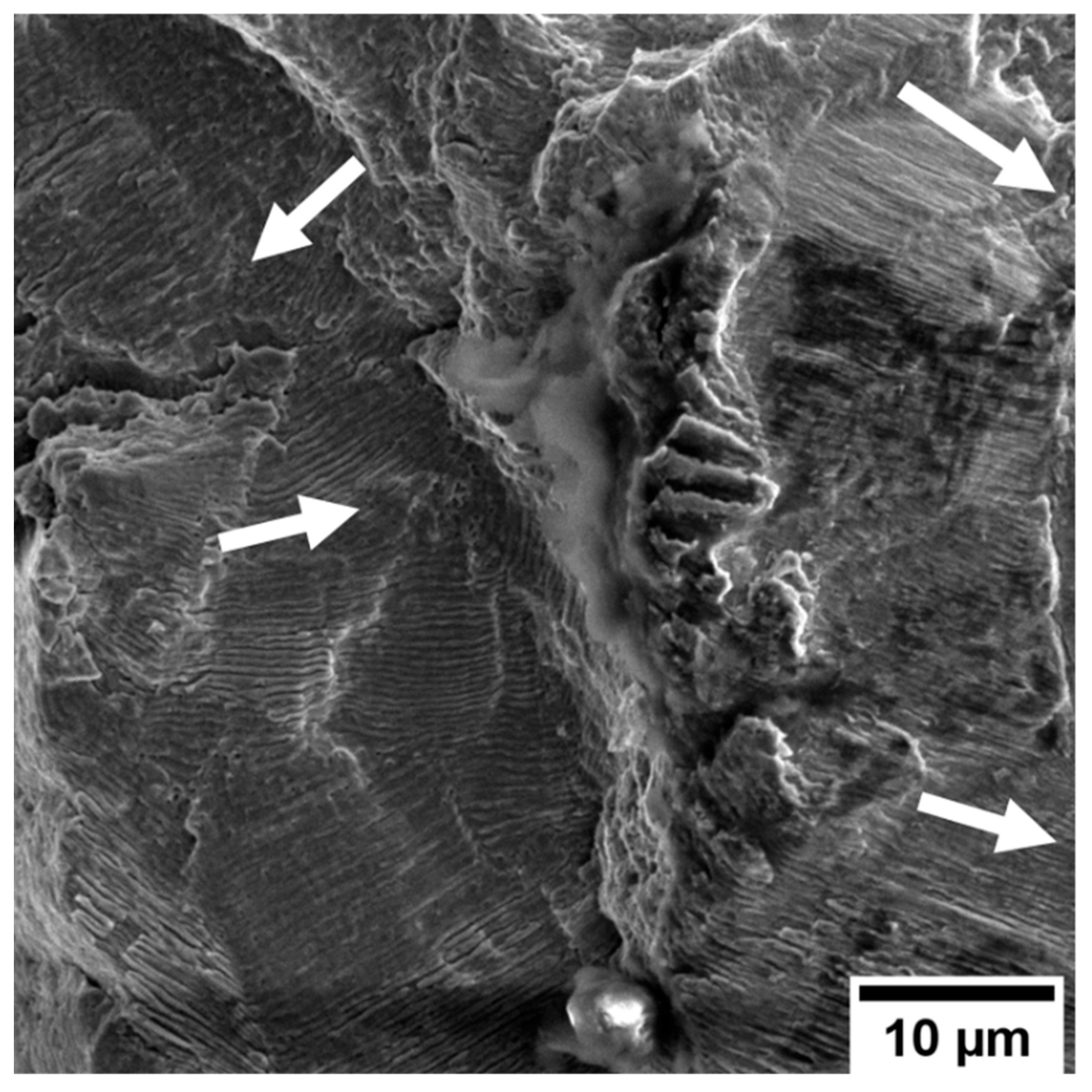

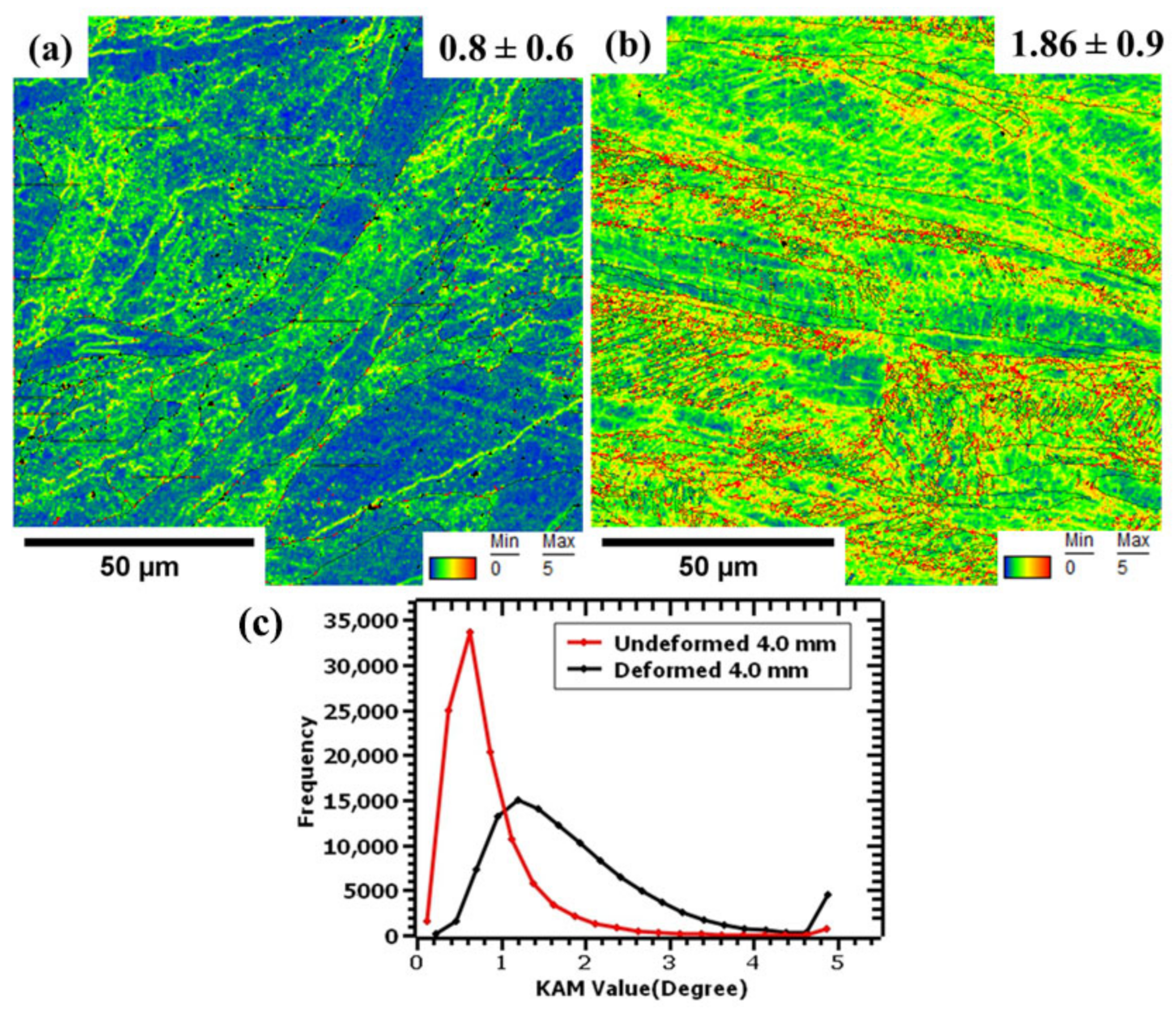

3.3. Microstructural Characterization of Fatigue-Deformed Samples

4. Conclusions

- The as-built samples showed microstructural heterogeneity, as depicted by the wide range of grain sizes. The higher magnification of the surfaces revealed the presence of cellular structures formed due to high-temperature gradients during the fabrication process.

- The unique microstructural features were observed to contribute significantly to the tensile strength of the samples. An average yield strength of 551 MPa, ultimate tensile strength of 619 MPa, and elongation to failure of 73% were obtained. The strength increased with ductility, which is usually not the case for stainless steel samples.

- The enhanced quasi-static performance of the LPBF samples was attributed to the pre-existing high-density dislocations, fine grain structures, cellular structures, and chemical micro-segregation that acted as strengthening mechanisms.

- The fatigue strength of the LPBF samples was determined to be 92.94 MPa and was observed at 30% of the UTS, where an average of 1,906,814 cycles were recorded.

- At higher stress amplitudes, the fracture areas were observed to be filled with a mixture of striations and dimples. In contrast, at lower stress amplitudes, there were reduced dimples.

- Numerous defects were observed at the fractured surfaces of fatigue-tested samples, and they were determined to have reduced the fatigue strength of the stainless steel samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2020, 11, 58. [Google Scholar] [CrossRef]

- Pant, M.; Nagdeve, L.; Moona, G.; Kumar, H.; Rajput, A.; Ramkumar, J. Comprehensive Investigation of the Mechanical Properties of 316L Stainless Steel Processed via Laser Powder Bed Fusion. J. Mater. Eng. Perform. 2024, 1–14. [Google Scholar] [CrossRef]

- Hirschberg, C.; Larsen, M.S.; Bøtker, J.P.; Rantanen, J. Additive manufacturing of prototype elements with process interfaces for continuously operating manufacturing lines. Asian J. Pharm. Sci. 2018, 13, 575–583. [Google Scholar] [CrossRef]

- Chepkoech, M.; Alunda, B.O.; Otieno, L.O.; Park, S.J.; Byeon, C.C.; Lee, Y.J. Design and Fabrication of a Low-Cost Teaching Atomic Force Microscope with 3D Printed Parts. New Phys. Sae Mulli 2019, 69, 128–135. [Google Scholar] [CrossRef]

- Zhong, T.; He, K.; Li, H.; Yang, L. Mechanical properties of lightweight 316L stainless steel lattice structures fabricated by selective laser melting. Mater. Des. 2019, 181, 108076. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Grzelak, K.; Janiszewski, J.; Płatek, P.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K. Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel. Materials 2020, 13, 1449. [Google Scholar] [CrossRef]

- Seharing, A.; Azman, A.H.; Abdullah, S. A review on integration of lightweight gradient lattice structures in additive manufacturing parts. Adv. Mech. Eng. 2020, 12, 168781402091695. [Google Scholar] [CrossRef]

- Pradeep, P.I.; Kumar, V.A.; Sriranganath, A.; Singh, S.K.; Sahu, A.; Kumar, T.S.; Narayanan, P.R.; Arumugam, M.; Mohan, M. Characterization and Qualification of LPBF Additively Manufactured AISI-316L Stainless Steel Brackets for Aerospace Application. Trans. Indian Natl. Acad. Eng. 2020, 5, 603–616. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Panciroli, R.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Experimental investigation on the fatigue behavior of laser powder bed fused 316L stainless steel. CIRP J. Manuf. Sci. Technol. 2022, 38, 787–800. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Hitzler, L.; Hirsch, J.; Heine, B.; Merkel, M.; Hall, W.; Öchsner, A. On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel. Materials 2017, 10, 1136. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel. Int. J. Fatigue 2017, 94, 218–235. [Google Scholar] [CrossRef]

- Shrestha, R.; Simsiriwong, J.; Shamsaei, N. Fatigue behavior of additive manufactured 316L stainless steel parts: Effects of layer orientation and surface roughness. Addit. Manuf. 2019, 28, 23–38. [Google Scholar] [CrossRef]

- Alkindi, T.; Alyammahi, M.; Susantyoko, R.A.; Atatreh, S. The effect of varying specimens’ printing angles to the bed surface on the tensile strength of 3D-printed 17-4PH stainless-steels via metal FFF additive manufacturing. MRS Commun. 2021, 11, 310–316. [Google Scholar] [CrossRef]

- Yang, T.; Xie, D.; Yue, W.; Wang, S.; Rong, P.; Shen, L.; Zhao, J.; Wang, C. Distortion of thin-walled structure fabricated by selective laser melting based on assumption of constraining force-induced distortion. Metals 2019, 9, 1281. [Google Scholar] [CrossRef]

- Chakraborty, A.; Tangestani, R.; Batmaz, R.; Muhammad, W.; Plamondon, P.; Wessman, A.; Yuan, L.; Martin, É. In-process failure analysis of thin-wall structures made by laser powder bed fusion additive manufacturing. J. Mater. Sci. Technol. 2022, 98, 233–243. [Google Scholar] [CrossRef]

- Liang, X.; Hor, A.; Robert, C.; Salem, M.; Lin, F.; Morel, F. High cycle fatigue behavior of 316L steel fabricated by laser powder bed fusion: Effects of surface defect and loading mode. Int. J. Fatigue 2022, 160, 106843. [Google Scholar] [CrossRef]

- Zhang, J.; Zeißig, M.; Dörfert, R.; Jablonski, F.; Kienzler, R.; Schumacher, J.; Clausen, B.; Woizeschke, P.; Vollertsen, F. Influence of laser beam scanning pattern and polar angle on the fatigue behavior of additively manufactured specimens made of steel 316L. Mater. Sci. Eng. A 2023, 886, 145651. [Google Scholar] [CrossRef]

- Hamada, A.; Jaskari, M.; Gundgire, T.; Järvenpää, A. Enhancement and underlying fatigue mechanisms of laser powder bed fusion additive-manufactured 316L stainless steel. Mater. Sci. Eng. A 2023, 873, 145021. [Google Scholar] [CrossRef]

- Bian, L.; Thompson, S.M.; Shamsaei, N. Mechanical Properties and Microstructural Features of Direct Laser-Deposited Ti-6Al-4V. JOM 2015, 67, 629–638. [Google Scholar] [CrossRef]

- Hatami, S.; Ma, T.; Vuoristo, T.; Bertilsson, J.; Lyckfeldt, O. Fatigue Strength of 316 L Stainless Steel Manufactured by Selective Laser Melting. J. Mater. Eng. Perform. 2020, 29, 3183–3194. [Google Scholar] [CrossRef]

- Chepkoech, M.; Owolabi, G.; Warner, G. Investigation of Microstructures and Tensile Properties of 316L Stainless Steel Fabricated via Laser Powder Bed Fusion. Materials 2024, 17, 913. [Google Scholar] [CrossRef] [PubMed]

- Godec, M.; Zaefferer, S.; Podgornik, B.; Šinko, M.; Tchernychova, E. Quantitative multiscale correlative microstructure analysis of additive manufacturing of stainless steel 316L processed by selective laser melting. Mater. Charact. 2020, 160, 110074. [Google Scholar] [CrossRef]

- Rautio, T.; Hietala, M.; Hirvimaki, M.; Makikangas, J.; Kumpula, J.; Jarvenpaa, A. Fatigue Life and Surface Quality of Laser Powder Bed Fusion Manufactured 316L Parts by Laser Heat Treatment. In Proceedings of the 2022 7th International Conference on Business and Industrial Research (ICBIR), Bangkok, Thailand, 19–20 May 2022; pp. 187–191. [Google Scholar] [CrossRef]

- Li, J.N.; Gao, D.; Lu, Y.; Hao, Z.P.; Wang, Z.Q. Mechanical properties and microstructure evolution of additive manufactured 316L stainless steel under dynamic loading. Mater. Sci. Eng. A 2022, 855, 143896. [Google Scholar] [CrossRef]

- Kumar, D.; Shankar, G.; Prashanth, K.G.; Suwas, S. Control of texture and microstructure in additive manufacturing of stainless steel 316 L. J. Alloys Compd. 2024, 976, 173040. [Google Scholar] [CrossRef]

- Sun, Z.; Tsai, S.P.; Konijnenberg, P.; Wang, J.Y.; Zaefferer, S. A large-volume 3D EBSD study on additively manufactured 316L stainless steel. Scr. Mater. 2024, 238, 115723. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Neumann, R.S.; Skrotzki, B.; Evans, A. Mechanical anisotropy of additively manufactured stainless steel 316L: An experimental and numerical study. Mater. Sci. Eng. A 2021, 799, 140154. [Google Scholar] [CrossRef]

- Dixit, S.; Liu, S.; Murdoch, H.A.; Smith, P.M. Investigating build orientation-induced mechanical anisotropy in additive manufacturing 316L stainless steel. Mater. Sci. Eng. A 2023, 880, 145308. [Google Scholar] [CrossRef]

- Mohammad, K.A.; Zainudin, E.S.; Salit, M.S.; Zahari, N.I.; Ali, A. Experimental determination of the fatigue behavior of austenitic 316L stainless steel under fatigue and creep-fatigue tests at high temperature. Int. J. Met. Steel Res. Technol. 2013, 1, 1–11. Available online: http://acascipub.com/Journals.php (accessed on 25 August 2024).

- Omoniyi, P.O.; Mahamood, R.M.; Arthur, N.; Pityana, S.; Skhosane, S.; Okamoto, Y.; Shinonaga, T.; Maina, M.R.; Jen, T.C.; Akinlabi, E.T. Joint integrity evaluation of laser beam welded additive manufactured Ti6Al4V sheets. Sci. Rep. 2022, 12, 4062. [Google Scholar] [CrossRef]

- Ceschini, L.; Minak, G. Fatigue behaviour of low temperature carburised AISI 316L austenitic stainless steel. Surf. Coat. Technol. 2008, 202, 1778–1784. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Matı, F.; Herrera, I.; Berrı, J.A.; Dixit, S.; Bhat, D. On the fatigue behavior of an AISI 316L stainless steel coated with a PVD TiN deposit. Surf. Coat. Technol. 2004, 182, 276–286. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, S.; Huang, Y.; Fan, C.; Peng, Z.; Gao, Z. Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM). Materials 2021, 14, 7544. [Google Scholar] [CrossRef] [PubMed]

- Afkhami, S.; Dabiri, M.; Alavi, S.H.; Björk, T.; Salminen, A. Fatigue characteristics of steels manufactured by selective laser melting. Int. J. Fatigue 2019, 122, 72–83. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Lamb, K.; Koube, K.; Kacher, J.; Sloop, T.; Thadhani, N.; Babu, S.S. Anisotropic spall failure of additively manufactured 316L stainless steel. Addit. Manuf. 2023, 66, 103464. [Google Scholar] [CrossRef]

- Elangeswaran, C.; Cutolo, A.; Muralidharan, G.K.; Vanmeensel, K.; Van Hooreweder, B. Microstructural analysis and fatigue crack initiation modelling of additively manufactured 316L after different heat treatments. Mater. Des. 2020, 194, 108962. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Wei, J.; Hardacre, D.; Li, H. Predictive models for fatigue property of laser powder bed fusion stainless steel 316L. Mater. Des. 2018, 145, 42–54. [Google Scholar] [CrossRef]

- Mughrabi, H. Damage Mechanisms and Fatigue Lives: From the Low to the Very High Cycle Regime. Procedia Eng. 2013, 55, 636–644. [Google Scholar] [CrossRef]

- Sun, G.; Wang, C.; Wei, X.; Shang, D.; Chen, S. Study on small fatigue crack initiation and growth for friction stir welded joints. Mater. Sci. Eng. A 2019, 739, 71–85. [Google Scholar] [CrossRef]

- Mineur, M.; Villechaise, P.; Mendez, J. Influence of the crystalline texture on the fatigue behavior of a 316L austenitic stainless steel. Mater. Sci. Eng. A 2000, 286, 257–268. [Google Scholar] [CrossRef]

- Dowling, N.E. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue, 4th ed.; Pearson Education Inc.: London, UK, 2013. [Google Scholar]

- Zhang, Z.F.; Wang, Z.G. Dependence of intergranular fatigue cracking on the interactions of persistent slip bands with grain boundaries. Acta Mater. 2003, 51, 347–364. [Google Scholar] [CrossRef]

- Wang, G.; Ouyang, H.; Fan, C.; Guo, Q.; Li, Z.; Yan, W.; Li, Z. The origin of high-density dislocations in additively manufactured metals. Mater. Res. Lett. 2020, 8, 283–290. [Google Scholar] [CrossRef]

| Machine | Parameters | Scanning Strategy | |||

|---|---|---|---|---|---|

| Renishaw AM250 | Laser Power | Exposure time | Layer Thickness | Hatch Distance | Stripes |

| 180 W | 86 μs | 40 μm | 85 μm | ||

| Element wt. % | Fe | Cr | Ni | Mo | Mn | Si | N | O | P | C | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 316L stainless steel Powder | Bal. | 18.2 | 10.2 | 2.57 | 1.1 | 0.8 | 0.07 | 0.02 | 0.009 | 0.013 | 0.001 |

| Sample | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation to Failure (%) | Rockwell Hardness (HRB) |

|---|---|---|---|---|

| 4.0 mm | 551.21 ± 2.43 | 619.58 ± 3.23 | 73.66 ± 3.02 | 93 ± 1.5 |

| ASTM A240/A240M-20a | 170 | 485 | 40 | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chepkoech, M.; Omoniyi, P.; Owolabi, G. Fatigue Response of Additive-Manufactured 316L Stainless Steel. Metals 2024, 14, 988. https://doi.org/10.3390/met14090988

Chepkoech M, Omoniyi P, Owolabi G. Fatigue Response of Additive-Manufactured 316L Stainless Steel. Metals. 2024; 14(9):988. https://doi.org/10.3390/met14090988

Chicago/Turabian StyleChepkoech, Melody, Peter Omoniyi, and Gbadebo Owolabi. 2024. "Fatigue Response of Additive-Manufactured 316L Stainless Steel" Metals 14, no. 9: 988. https://doi.org/10.3390/met14090988

APA StyleChepkoech, M., Omoniyi, P., & Owolabi, G. (2024). Fatigue Response of Additive-Manufactured 316L Stainless Steel. Metals, 14(9), 988. https://doi.org/10.3390/met14090988