Effect of Laser Energy Density on the Properties of CoCrFeMnNi High-Entropy Alloy Coatings on Steel by Laser Cladding

Abstract

1. Introduction

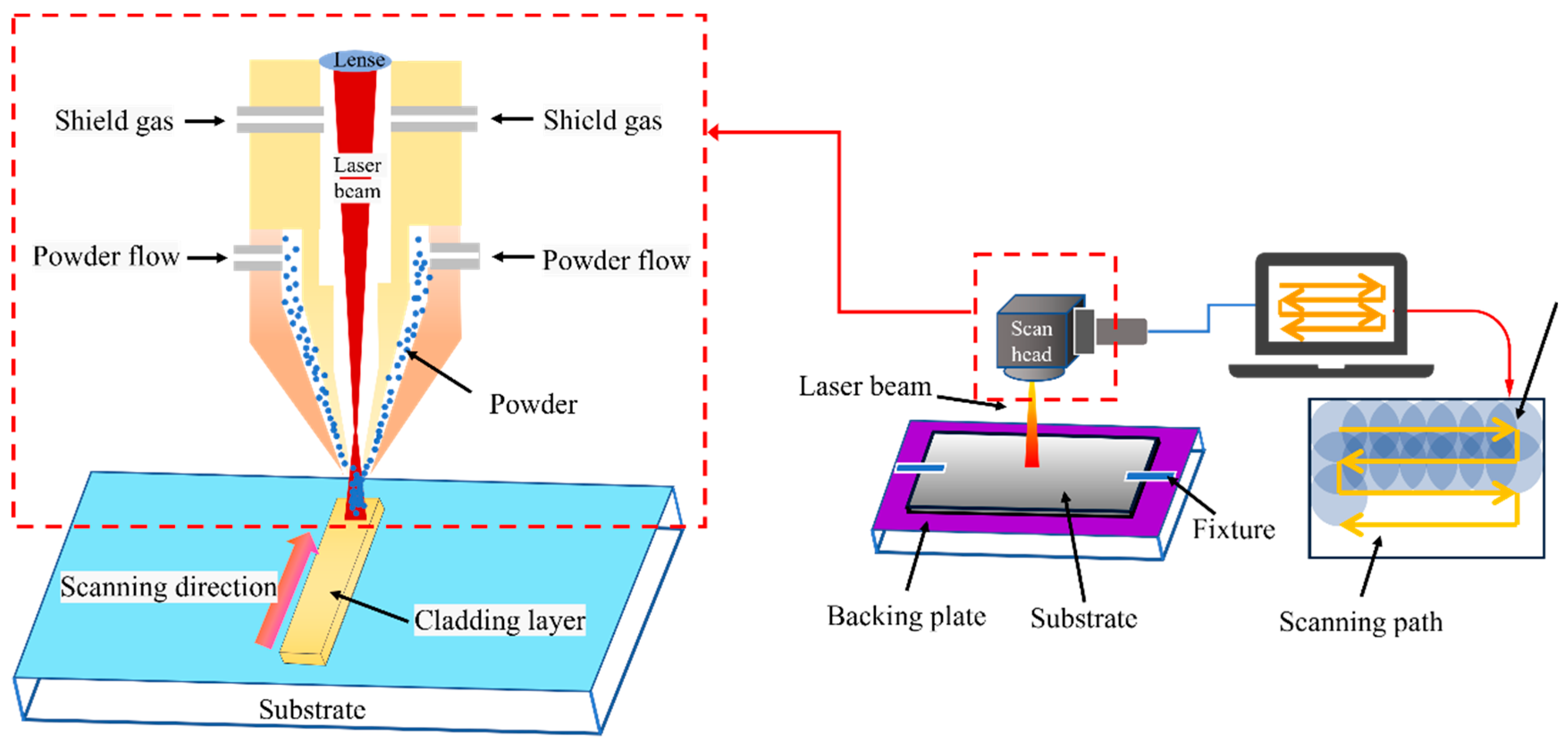

2. Experimental Procedures

2.1. Preparation of the HEA Coatings

2.2. Characterization of Microstructures

2.3. Property Tests

2.3.1. Microhardness

2.3.2. Friction and Wear Testing

2.3.3. Electrochemical Test

3. Results and Discussion

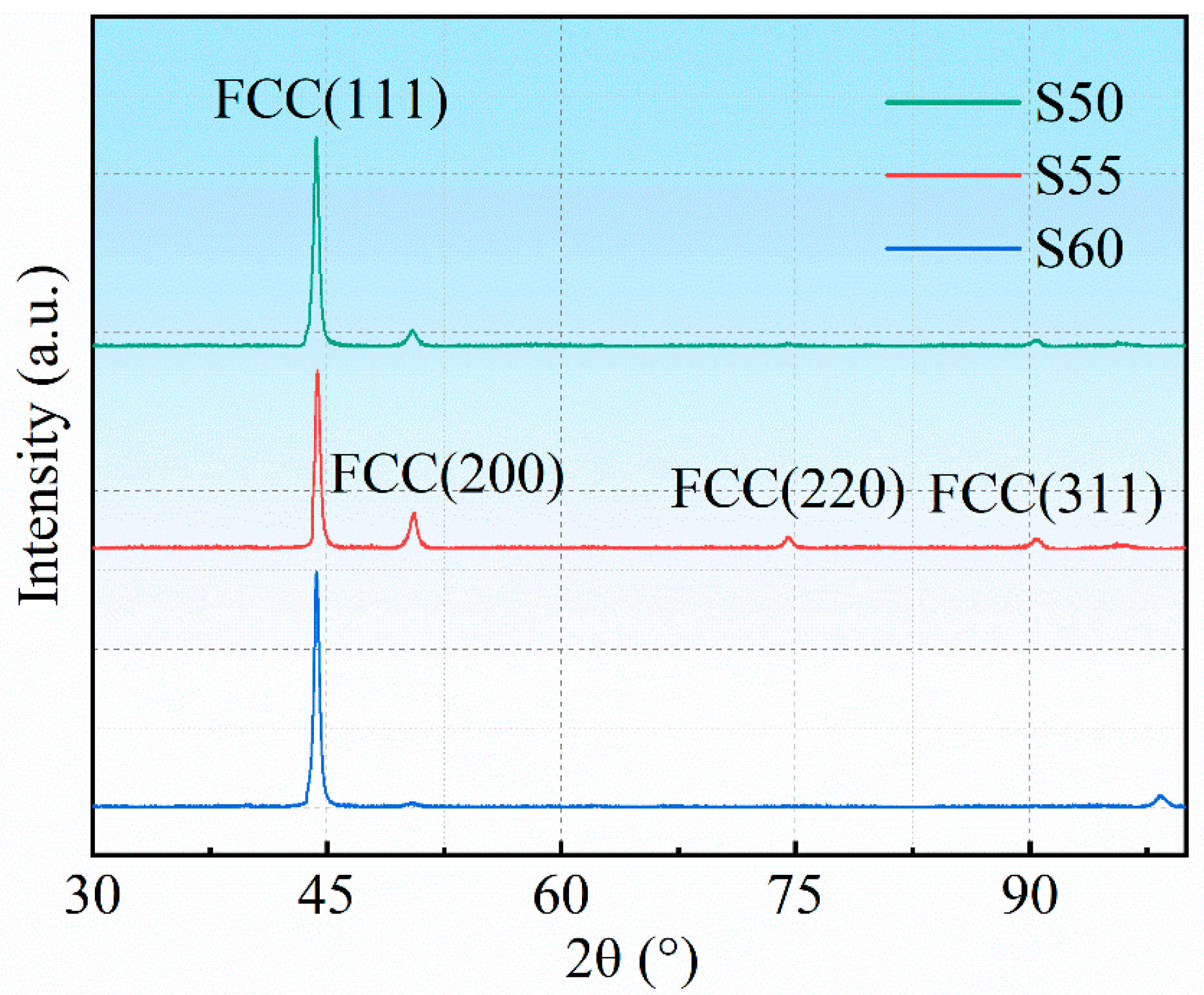

3.1. XRD Analysis

3.2. Properties Analysis

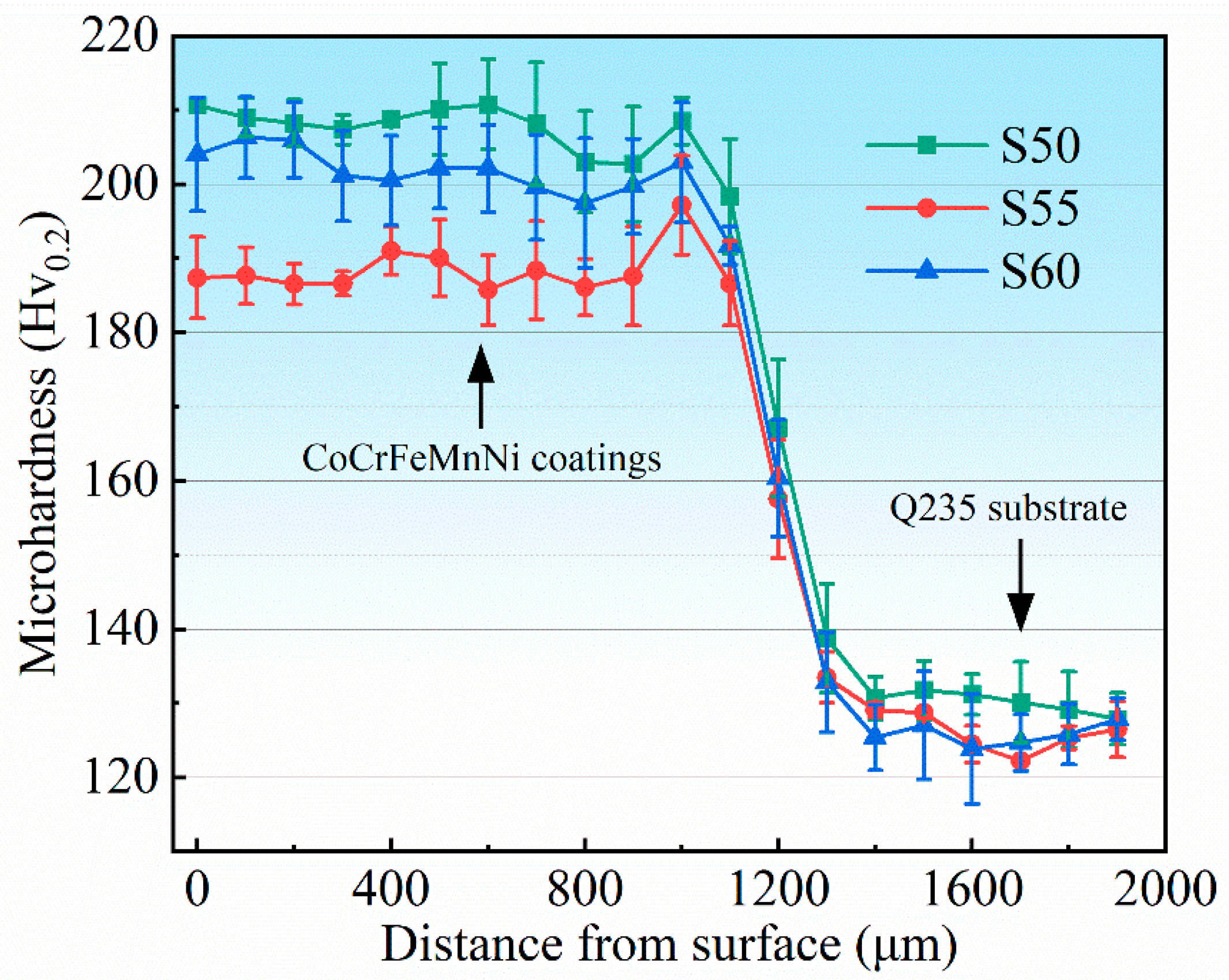

3.2.1. Hardness

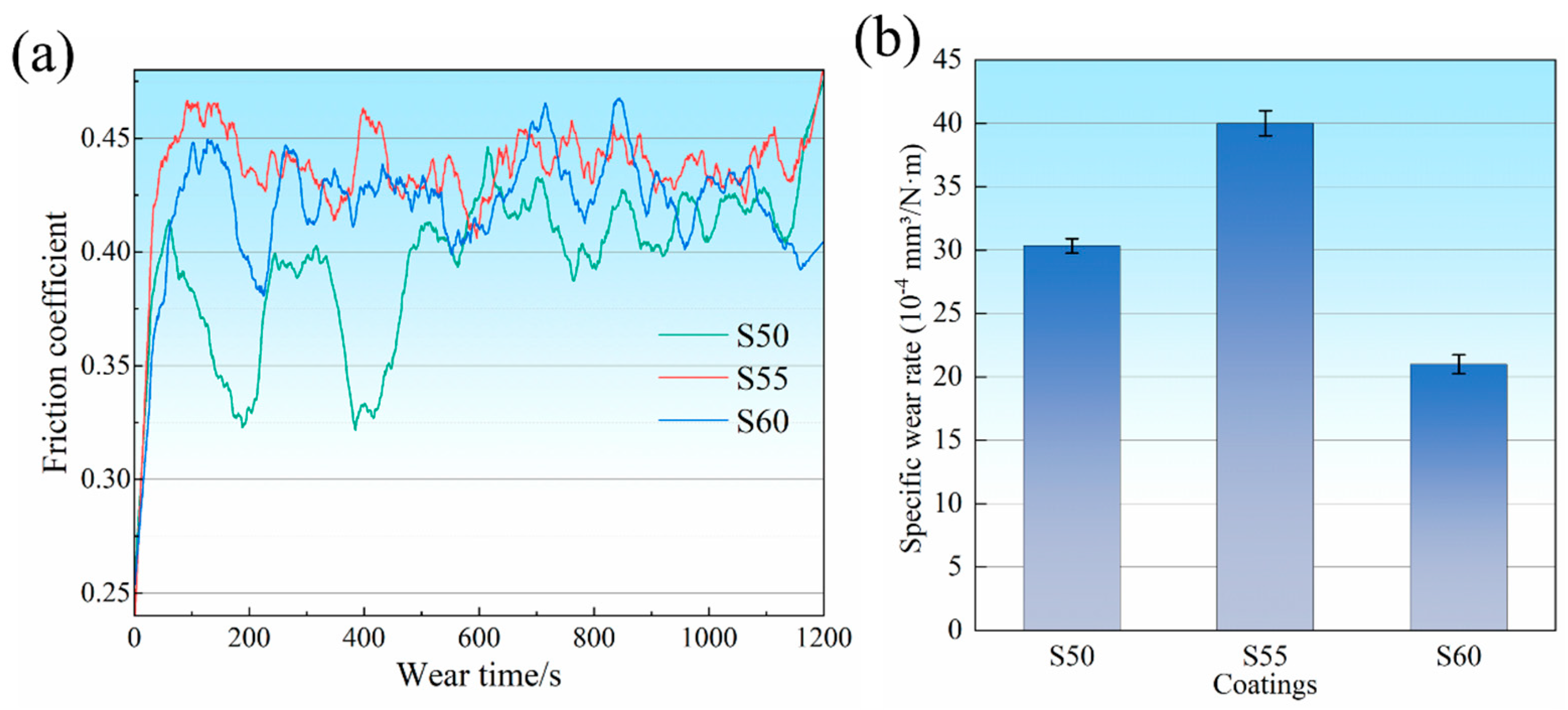

3.2.2. Wear Behavior

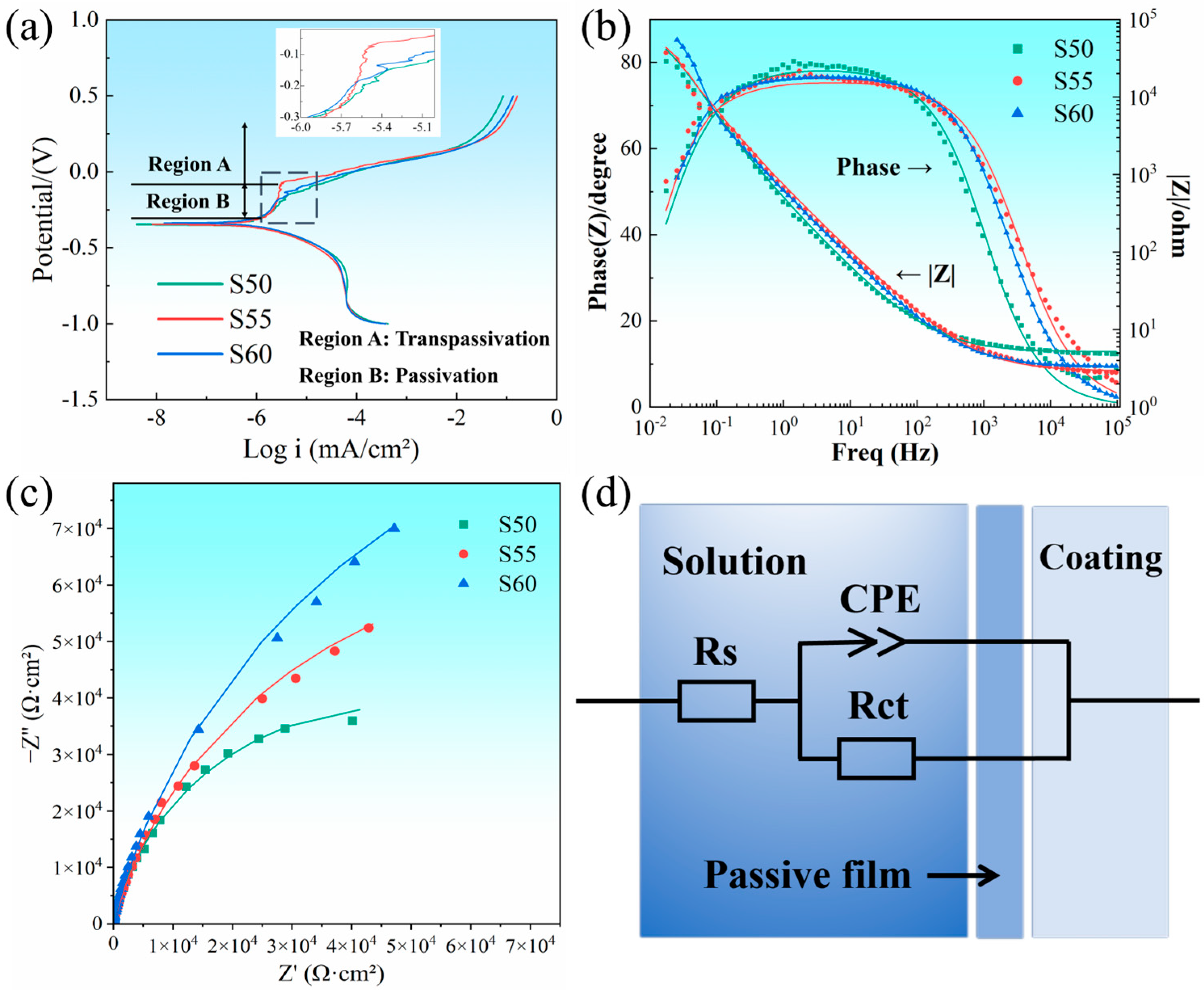

3.2.3. Electrochemical Corrosion

4. Conclusions

- The CoCrFeMnNi HEA coating consists of a single FCC phase with the strongest peaks in the low-angle diffraction peaks, and the crystals are highly oriented in that direction. The increase in energy density significantly affects the microhardness, with a difference of 20 HV between the highest average hardness (S50, 210 HV) and the lowest average hardness (S55, 190 HV).

- The lowest hardness, S50, also showed better friction performance, but its friction process was unstable. Combining several indicators, S60 has the best friction resistance, and its main wear mechanism is delamination wear. A decrease in energy density enhances the hardness of the coating while decreasing the surface toughness, which inhibits the adhesive wear of the HEA coating. S55 is mainly dominated by three-body wear, and its specific friction rate is the highest. Oxidized wear generated by frictional heat was prevalent in all three coatings.

- In electrochemical tests, S60 had a slow corrosion rate, good corrosion resistance, and low corrosion tendency. Among these three parameters, only S55 experienced significant passivation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Heydartaemeh, M.; Karamoozian, M.; Potgieter, H. Application of Nano High-Entropy Alloys to Reduce Energy Consumption and Wear of Copper Oxide and High-Grade Iron Ores in Heavy Mining Industries—A Case Study. Minerals 2020, 10, 16. [Google Scholar] [CrossRef]

- Wen, X.; Cui, X.; Jin, G.; Zhang, X.; Zhang, Y.; Zhang, D.; Fang, Y. Design and characterization of FeCrCoAlMn0.5Mo0.1 high-entropy alloy coating by ultrasonic assisted laser cladding. J. Alloys Compd. 2020, 835, 155449. [Google Scholar] [CrossRef]

- Jin, X.; Gu, X.; Quan, F.; Ran, X.; Zhang, K.; Mao, A. CoCrFeMnNi high-entropy alloy powder with excellent corrosion resistance and soft magnetic property prepared by gas atomization methodGasverdustes CoCrFeMnNi Hoch-Entropie Legierungspulver mit hervorragender Korrosionsbestandigkeit und weichmagnetischen Eigenschaften. Mater. Werkst. 2019, 50, 837–843. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Rehman, E.U.; Ullah, S.; Atif, M.; Tariq, A. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. J. Manuf. Process. 2021, 68, 225–273. [Google Scholar] [CrossRef]

- Zhou, J.; Cheng, Y.; Chen, Y.; Liang, X. Composition design and preparation process of refractory high-entropy alloys: A review. Int. J. Refract. Met. Hard Mater. 2022, 105, 105836. [Google Scholar] [CrossRef]

- Addepalli, S.N.; Joladarashi, S.; Ramesh, M.R. Elevated temperature tribological performance of non-equiatomic CoCrNiTiWx high entropy alloy coatings developed by mechanical alloying and high-velocity oxy-fuel spray. Surf. Coat. Technol. 2024, 476, 130267. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Huang, Z.; Li, Y.; Liu, Y.; Li, Q.; He, Y.; Wang, H. Tribological Behavior of High Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1428. [Google Scholar] [CrossRef]

- Aliyu, A.; Srivastava, C. Phase constitution, surface chemistry and corrosion behavior of electrodeposited MnFeCoNiCu high entropy alloy-graphene oxide composite coatings. Surf. Coat. Technol. 2022, 429, 127943. [Google Scholar] [CrossRef]

- Yang, H.; Tang, Z.; Wan, L.; Wei, Q.; Wu, J.; Wang, A.; Jin, X.; Li, X.; Wu, Y.; Lu, G.; et al. Achieving crack-free CuCrZr/AlSi7Mg interface by infrared-blue hybrid laser cladding with low power infrared laser. J. Alloys Compd. 2023, 931, 167572. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, Y.; Cui, H.; Song, X.; Wang, M.; Lee, K.; Gao, X.; Song, Q.; Wang, C. Addition Al and/or Ti Induced Modifications of Microstructures, Mechanical Properties, and Corrosion Properties in CoCrFeNi High-Entropy Alloy Coatings. Acta Metall. Sin. Engl. Lett. 2021, 34, 1087–1102. [Google Scholar] [CrossRef]

- Liang, Y.; Liao, Z.Y.; Zhang, L.L.; Cai, M.W.; Wei, X.S.; Shen, J. A review on coatings deposited by extreme high-speed laser cladding: Processes, materials, and properties. Opt. Laser Technol. 2023, 164, 109472. [Google Scholar] [CrossRef]

- Shu, F.; Zhang, B.; Liu, T.; Sui, S.; Liu, Y.; He, P.; Liu, B.; Xu, B. Effects of laser power on microstructure and properties of laser cladded CoCrBFeNiSi high-entropy alloy amorphous coatings. Surf. Coat. Technol. 2019, 358, 667–675. [Google Scholar] [CrossRef]

- Du, C.; Hu, L.; Ren, X.; Li, Y.; Zhang, F.; Liu, P.; Li, Y. Cracking mechanism of brittle FeCoNiCrAl HEA coating using extreme high-speed laser cladding. Surf. Coat. Technol. 2021, 424, 127617. [Google Scholar] [CrossRef]

- Du, J.L.; Xu, X.; Zhang, H.M.; Lu, M.W.; Sun, J.F.; Luo, K.Y.; Lu, J.Z. Microstructure and wear resistance of CoCrFeNiMn coatings prepared by extreme-high-speed laser cladding. Surf. Coat. Technol. 2023, 470, 129821. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, G.; Zhao, H.; Mou, H.; Xu, J.; Wang, W.; Xing, Z.; Li, Y.; Guo, W.; Wang, H. Research status and prospect of extreme high-speed laser cladding technology. Opt. Laser Technol. 2024, 168, 109800. [Google Scholar] [CrossRef]

- Xu, Q.-L.; Liu, K.-C.; Wang, K.-Y.; Lou, L.-Y.; Zhang, Y.; Li, C.-J.; Li, C.-X. TGO and Al diffusion behavior of CuAlxNiCrFe high-entropy alloys fabricated by high-speed laser cladding for TBC bond coats. Corros. Sci. 2021, 192, 109781. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, P.; Li, Z.; Zhang, J.; Liu, W. Multi-Objective optimization of laser cladding process parameters for Q345B steel. Mater. Today Commun. 2024, 39, 108679. [Google Scholar] [CrossRef]

- Dong, Z.; Feng, L.; Long, H.; Lu, B.; Zhu, J.; Yan, X.; Ma, R.; Qiu, C.; Gui, Y.; Liu, M. A multi-objective optimization of laser cladding processing parameters of AlCoCrFeNi2.1 eutectic high-entropy alloy coating. Opt. Laser Technol. 2024, 170, 110302. [Google Scholar] [CrossRef]

- Ghanbariha, M.; Farvizi, M.; Ebadzadeh, T.; Samiyan, A.A.; Kim, H.S. AlCoCrFeNi-NiTi high entropy alloy composites: Microstructure and wear performance. Mater. Today Commun. 2022, 32, 103952. [Google Scholar] [CrossRef]

- Wu, T.; Chen, Y.; Lin, B.; Yu, L.; Gui, W.; Li, J.; Wu, Y.; Zeng, D. Effects of WC on the Microstructure, Wear and Corrosion Resistance of Laser-Deposited CoCrFeNi High Entropy Alloy Coatings. Coatings 2022, 12, 985. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; He, R.; Jie, D.; Gong, Y.; Miao, X. Effect of LaB6 doping on the microstructure, microhardness and corrosion behavior of laser cladded FeCoNiCrMo coating on Ti6Al4V. Surf. Coat. Technol. 2023, 466, 129592. [Google Scholar] [CrossRef]

- Guo, Y.; Zeng, Y.; Guo, Z.; Li, Z.; He, R.; Wang, G. Effect of laser energy densities on the phase composition change in laser-cladded AlCoCrNbMo high-entropy alloy coatings. Mater. Today Commun. 2023, 37, 107152. [Google Scholar] [CrossRef]

- Zhang, G.P.; Zhan, Q.Q.; Zheng, K.; Tang, J.Q.; Cai, B.; Liu, Z.X. Microstructural and electrical properties of AlN-CoCrFeMnNi cermet obtained by hot pressing. Ceram. Int. 2023, 49, 808–816. [Google Scholar] [CrossRef]

- Chen, K.; Fan, Q.; Yao, J.; Yang, L.; Xu, S.; Lei, W.; Wang, D.; Yuan, J.; Gong, H.; Cheng, X. Composition design of a novel Ti-6Mo-3.5Cr-1Zr alloy with high-strength and ultrahigh-ductility. J. Mater. Sci. Technol. 2022, 131, 276–286. [Google Scholar] [CrossRef]

- Li, X.; Yang, X.; Yi, D.; Liu, B.; Zhu, J.; Li, J.; Gao, C.; Wang, L. Effects of NbC content on microstructural evolution and mechanical properties of laser cladded Fe50Mn30Co10Cr10-xNbC composite coatings. Intermetallics 2021, 138, 107309. [Google Scholar] [CrossRef]

- Shuai, C.; Xie, J.; Jiang, X.; Peng, S.; Wang, C. Additively manufactured high entropy alloy with high wear resistance for biomedical implant. Vacuum 2024, 221, 112939. [Google Scholar] [CrossRef]

- Liu, M.; Tieu, A.K.; Lu, C.; Zhu, H.; Deng, G. A crystal plasticity study of the effect of friction on the evolution of texture and mechanical behaviour in the nano-indentation of an aluminium single crystal. Comput. Mater. Sci. 2014, 81, 30–38. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Zhang, X.; Zhang, Y.; Chen, Y.; Zhu, L.; Zhou, M. Corrosion-erosion behavior and mechanism of CuMo co-doped CoCrFeNi high-entropy alloy coating prepared by directed energy deposition. Surf. Coat. Technol. 2022, 451, 129055. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Guo, W.; Feng, K.; Zhu, K.; Zhang, Z.; Zhang, F.; Chai, L.; Guo, N.; Guo, S. Influence of laser power on microstructure and high-temperature tribological properties of CoAlTiWTa RHEA coating on Inconel 718 superalloy. Surf. Coat. Technol. 2024, 479, 130573. [Google Scholar] [CrossRef]

- Sun, H.; Xin, B.; Chen, J.; Shi, P.; Yi, G.; Wan, S.; Meng, J.; Wang, W.; Shan, Y. Effect of the high temperature phase transition on the tribological behavior of atmospheric plasma sprayed AlCoCrFeNi-Bi2O3 coating. Surf. Coat. Technol. 2024, 476, 130286. [Google Scholar] [CrossRef]

- Oke, S.R.; Bayode, A.; Falodun, O.E. Assessing wear and corrosion in oxide reinforced AlCrFeNi high entropy alloy fabricated via field assisted sintering technique. Mater. Today Commun. 2024, 38, 107734. [Google Scholar] [CrossRef]

- Ding, L.; Wang, H.; Quan, X. Effect of aging treatment on microstructure and wear resistance of CoCrFeNiTiNbB1.25 high entropy alloy coatings by laser cladding. Appl. Phys. A-Mater. Sci. Process. 2022, 128, 235. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, B.; Zhu, S.; Yu, Y.; Wang, Z.; Zhang, X.; Lu, B. Microstructural characteristics and enhanced wear resistance of nanoscale Al2O3/13 wt%TiO2-reinforced CoCrFeMnNi high entropy coatings. Surf. Coat. Technol. 2021, 412, 127019. [Google Scholar] [CrossRef]

- Vo, T.D.; Tran, B.; Tieu, A.K.; Wexler, D.; Deng, G.; Nguyen, C. Effects of oxidation on friction and wear properties of eutectic high-entropy alloy AlCoCrFeNi2.1. Tribol. Int. 2021, 160, 107017. [Google Scholar] [CrossRef]

- Li, S.; Li, H.; Zhai, Z.; Cao, X.; Liu, D.; Jiang, J. Corrosion resistance and tribological behavior of FeCoCrNi@GO/Ni high entropy alloy-based composite coatings prepared by electrodeposition. Surf. Coat. Technol. 2024, 477, 130379. [Google Scholar] [CrossRef]

- Zhang, M.; Tian, G.; Yan, H.; Guo, R.; Niu, B. Anticorrosive superhydrophobic high-entropy alloy coating on 3D iron foam for efficient oil/water separation. Surf. Coat. Technol. 2023, 468, 129756. [Google Scholar] [CrossRef]

- Lou, B.-S.; Rahmadtulloh, I.; Wang, C.-J.; Wang, W.-H.; Lee, J.-W. Tribocorrosion behaviors of VNbMoTaWCr high entropy alloy coatings. Surf. Coat. Technol. 2024, 476, 130250. [Google Scholar] [CrossRef]

- Huang, K.; Chen, L.; Lin, X.; Huang, H.; Tang, S.; Du, F. Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding. Entropy 2018, 20, 915. [Google Scholar] [CrossRef]

- Thanhhung, N.; Ly, X.; Huang, M.; Qin, Y.; Yang, S. Fabrication and Characterization of AlxFeMnNiCrCu0.5 (x = 0.0; 0.5; 1.0) High-Entropy Alloy Coatings by Laser Cladding. J. Therm. Spray Technol. 2022, 31, 980–990. [Google Scholar] [CrossRef]

| Materials | Elements (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Co | Cr | Fe | Mn | Ni | C | Si | S | |

| Q235 | - | - | Bal. | ≤1.4 | - | 0.14~0.22 | ≤0.35 | ≤0.050 |

| CoCrFeMnNi | 21.0 | 18.5 | 19.9 | 19.6 | 20.9 | - | - | - |

| Sample | Laser Power (W) | The Laser Energy Density (J/mm2) | Scanning Speed (mm/s) | Focal Distance (mm) | Laser Beam Spot Diameter (mm) | Overlap Ratio (%) | Powder Feeding Rate (g/min) |

|---|---|---|---|---|---|---|---|

| S50 | 3200 | 50 | 16 | 150 | 4 | 40 | 12 |

| S55 | 3500 | 55 | 16 | 150 | 4 | 40 | 12 |

| S60 | 3800 | 60 | 16 | 150 | 4 | 40 | 12 |

| Elements | O | Fe | Cr | C | Ni | Co | Mn | Si |

|---|---|---|---|---|---|---|---|---|

| S50 | 24.3 | 19.8 | 14.2 | 4.2 | 12.8 | 12.1 | 12.2 | 0.4 |

| 22.5 | 14.6 | 12.1 | 8.0 | 11.3 | 10.6 | 11.3 | 9.6 | |

| S55 | 21.1 | 18.7 | 15.3 | 3.6 | 13.8 | 14.2 | 13.1 | 0.2 |

| 13.3 | 6.2 | 3.8 | 50.3 | 2.1 | 3.7 | 2.8 | 17.8 | |

| S60 | 21.8 | 17.8 | 15.3 | 6.7 | 14.1 | 13.1 | 11.1 | 0.1 |

| 3.2 | 9.3 | 5.2 | 49.4 | 5.0 | 4.1 | 2.4 | 21.4 |

| Sample | Ecorr (V) | Icorr (A/cm2) |

|---|---|---|

| S50 | −0.334 | 1.128 × 10−6 |

| S55 | −0.345 | 1.152 × 10−6 |

| S60 | −0.334 | 9.953 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, C.; Zhang, Q.; Sun, S.; Ni, H.; Liu, Y.; Wang, X.; Wan, X.; Wang, H. Effect of Laser Energy Density on the Properties of CoCrFeMnNi High-Entropy Alloy Coatings on Steel by Laser Cladding. Metals 2024, 14, 997. https://doi.org/10.3390/met14090997

Ding C, Zhang Q, Sun S, Ni H, Liu Y, Wang X, Wan X, Wang H. Effect of Laser Energy Density on the Properties of CoCrFeMnNi High-Entropy Alloy Coatings on Steel by Laser Cladding. Metals. 2024; 14(9):997. https://doi.org/10.3390/met14090997

Chicago/Turabian StyleDing, Chenchen, Qi Zhang, Siyu Sun, Hongjun Ni, Yu Liu, Xiao Wang, Xiaofeng Wan, and Hui Wang. 2024. "Effect of Laser Energy Density on the Properties of CoCrFeMnNi High-Entropy Alloy Coatings on Steel by Laser Cladding" Metals 14, no. 9: 997. https://doi.org/10.3390/met14090997

APA StyleDing, C., Zhang, Q., Sun, S., Ni, H., Liu, Y., Wang, X., Wan, X., & Wang, H. (2024). Effect of Laser Energy Density on the Properties of CoCrFeMnNi High-Entropy Alloy Coatings on Steel by Laser Cladding. Metals, 14(9), 997. https://doi.org/10.3390/met14090997