Hybridization in Metal Wire Additive Manufacturing: A Case Study of an Impeller

Abstract

:1. Introduction

1.1. Background

1.2. Levels of Hybridization

1.3. Challenges in Manufacturing Complex Geometries

2. Materials and Methods

2.1. Materials

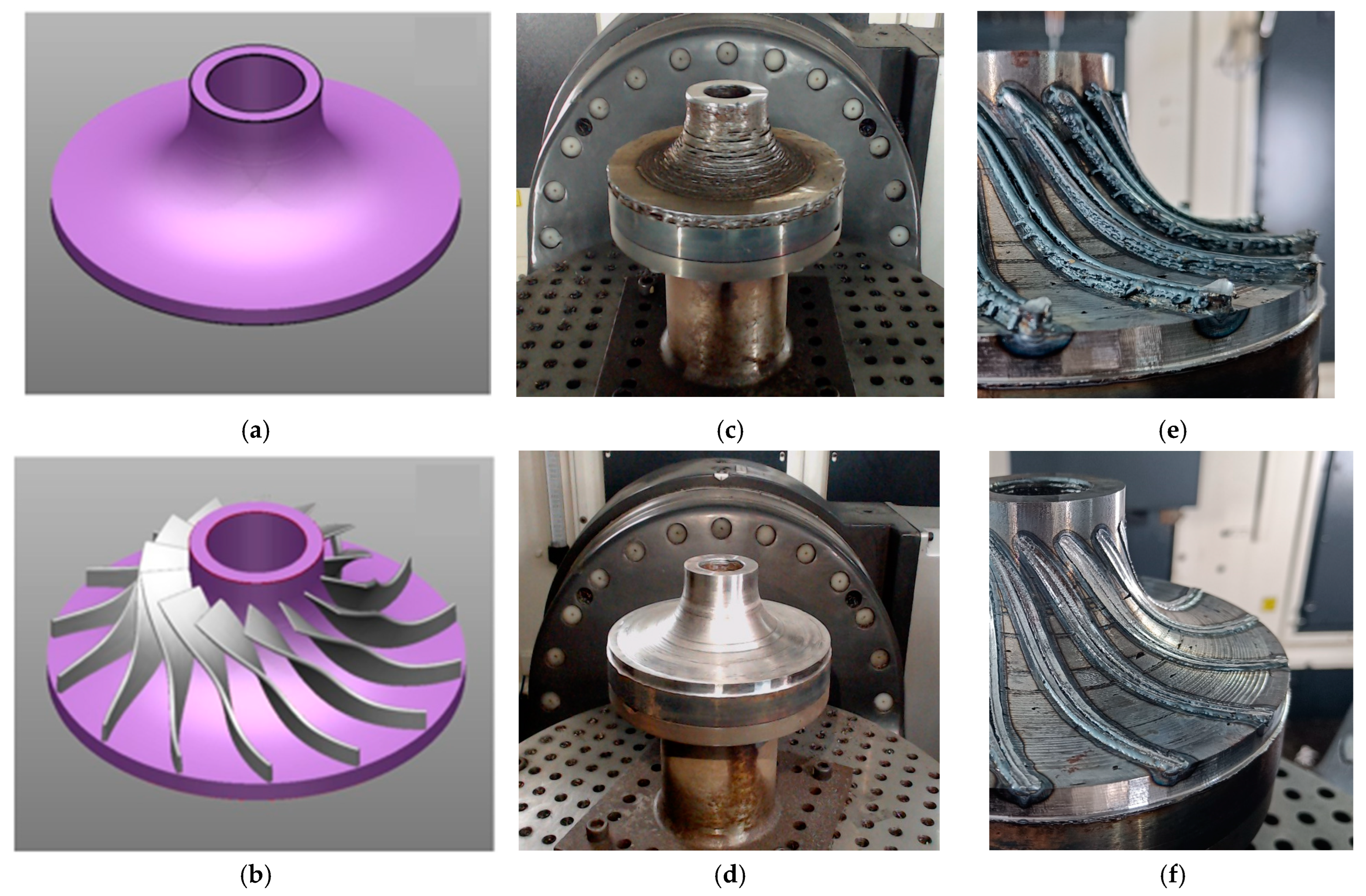

2.2. Approach for Deposition

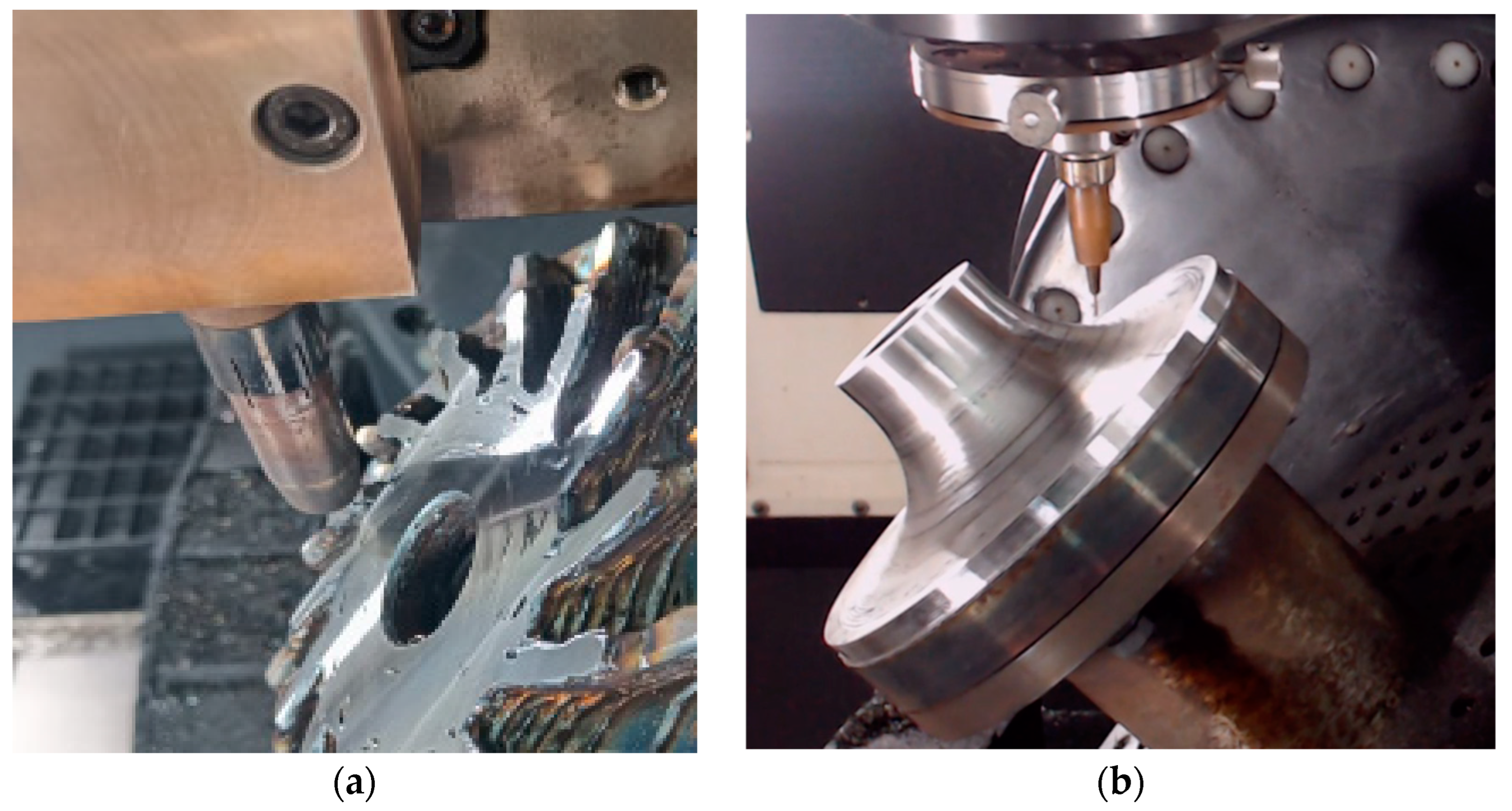

2.3. Fixture

2.4. Test Methods

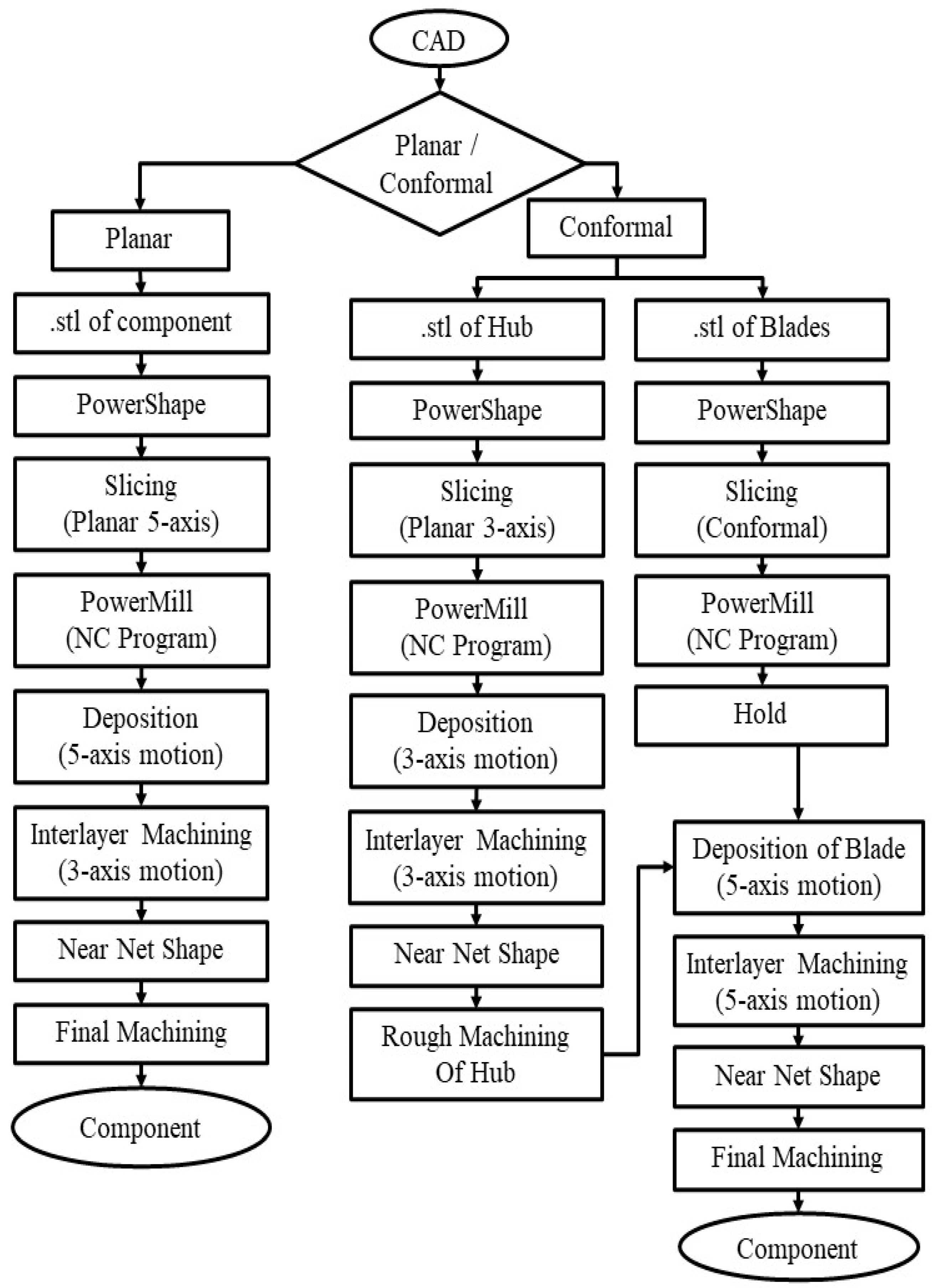

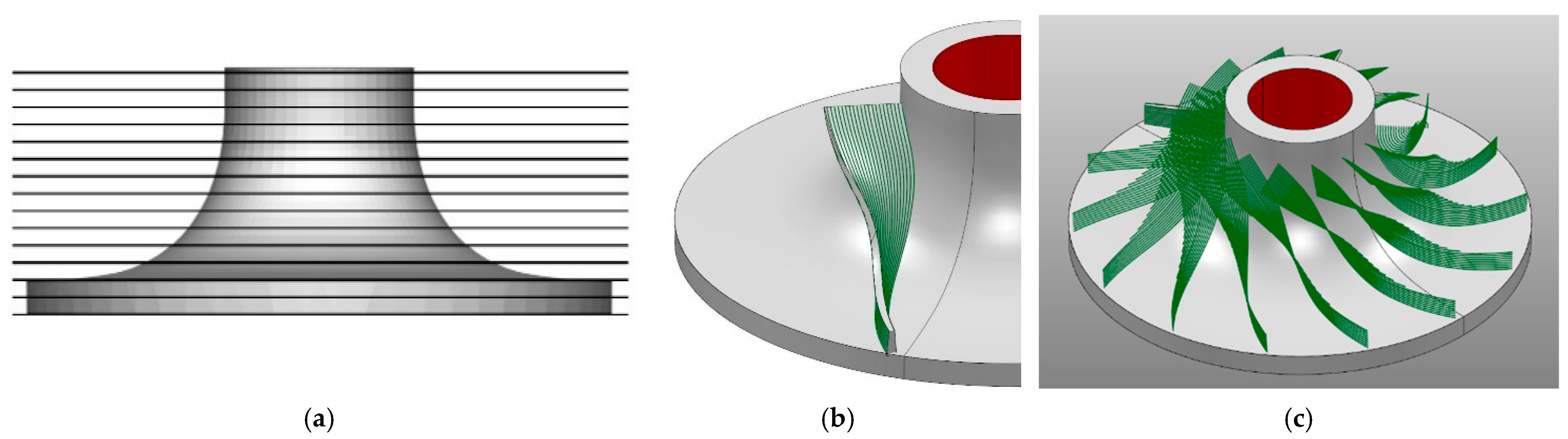

2.5. Slicing and Deposition Methodology

3. Results and Discussions

3.1. Process Hybridization

3.2. Energy Hybridization

3.3. Kinematic and Slicing Hybridization

3.4. Time and Material Wastage Comparison

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karunakaran, K.P.; Kamal Gupta, N.; Kumar Patel, A.; Rakeshkumar, K.; Ganesan, G.; Siddhartha; Sealy, M.; Bernard, A. Multi-Station Multi-Axis Hybrid Layered Manufacturing (MSMA-HLM). Manuf. Lett. 2022, 33, 630–639. [Google Scholar] [CrossRef]

- Gupta, N.K.; Ganesan, G.; Siddhartha, S.; Karade, S.R.; Singh, S.D.; Karunakaran, K.P. A Dual-Side Deposition Technique to Mitigate Deformation in Wire Arc Additive Manufacturing. Trans. Indian Inst. Met. 2024, 77, 3425–3434. [Google Scholar] [CrossRef]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid Processes in Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2018, 140, 060801. [Google Scholar] [CrossRef]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid Additive and Subtractive Machine Tools—Research and Industrial Developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef]

- Strong, D.; Sirichakwal, I.; Manogharan, G.P.; Wakefield, T. Current State and Potential of Additive—Hybrid Manufacturing for Metal Parts. Rapid Prototyp. J. 2017, 23, 577–588. [Google Scholar] [CrossRef]

- Park, S.H.; Son, S.J.; Lee, S.B.; Yu, J.H.; Ahn, S.J.; Choi, Y.S. Surface Machining Effect on Material Behavior of Additive Manufactured SUS 316L. J. Mater. Res. Technol. 2021, 13, 38–47. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. Porosity, Surface Quality, Microhardness and Microstructure of Selective Laser Melted 316l Stainless Steel Resulting from Finish Machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Qu, S.; Yin, G.; Liang, C.; Li, P. Additive and Subtractive Hybrid Manufacturing (ASHM) of 316L Stainless Steel: Single-Track Specimens, Microstructure, and Mechanical Properties. JOM 2021, 73, 759–769. [Google Scholar] [CrossRef]

- Zhang, S.; Gong, M.; Zeng, X.; Gao, M. Residual Stress and Tensile Anisotropy of Hybrid Wire Arc Additive-Milling Subtractive Manufacturing. J. Mater. Process Technol. 2021, 293, 117077. [Google Scholar] [CrossRef]

- Chen, C.; Feng, T.; Zhang, Y.; Ren, B.; Wang, H.; Zhao, X. Improvement of Microstructure and Mechanical Properties of TC4 Titanium Alloy GTAW Based Wire Arc Additive Manufacturing by Using Interpass Milling. J. Mater. Res. Technol. 2023, 27, 1428–1445. [Google Scholar] [CrossRef]

- Rashid, A.; Kota, A.; Boing, D.; Melkote, S.N. Effect of Interlayer Machining Interventions on the Geometric and Mechanical Properties of Wire Arc Directed Energy Deposition Parts. J. Manuf. Sci. Eng. 2024, 146, 091004. [Google Scholar] [CrossRef]

- Sadeh, S.; Mathews, R.; Zhang, R.; Sunny, S.; Marais, D.; Venter, A.M.; Li, W.; Malik, A. Interlayer Machining Effects on Microstructure and Residual Stress in Directed Energy Deposition of Stainless Steel 316L. J. Manuf. Process 2023, 94, 69–78. [Google Scholar] [CrossRef]

- Ivántabernero; Paskual, A.; Álvarez, P.; Suárez, A. Study on Arc Welding Processes for High Deposition Rate Additive Manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar] [CrossRef]

- Gupta, N.K.; Ganesan, G.; Siddhartha, S.; Karade, S.R.; Paul, A.K.; Dubey, S.; Ely, R.H.; Karunakaran, K.P. In Situ Pre-Heating in Wire Arc Additive Manufacturing: Design, Development, and Experimental Investigation on Residual Stresses and Metallurgical and Mechanical Properties. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiang, Y.; Lu, C.; Huang, J.; Pei, J.; Xing, T.; Zhao, S.; Zhu, K.; Yan, H.; Xu, Z.; et al. A Review of 5-Axis Milling Techniques for Centrifugal Impellers: Tool-Path Generation and Deformation Control. J. Manuf. Process 2024, 131, 160–186. [Google Scholar] [CrossRef]

- Fan, H.Z.; Wang, W.; Xi, G. A Novel Five-Axis Rough Machining Method for Efficient Manufacturing of Centrifugal Impeller with Free-Form Blades. Int. J. Adv. Manuf. Technol. 2013, 68, 1219–1229. [Google Scholar] [CrossRef]

- Choe, C.-M.; Yang, W.-C.; Kim, U.-H.; Ri, B.-G.; Om, M.-S. Manufacture of Centrifugal Compressor Impeller Using FDM and Investment Casting. Int. J. Adv. Manuf. Technol. 2022, 118, 173–181. [Google Scholar] [CrossRef]

- Adiaconitei, A.; Vintila, I.S.; Mihalache, R.; Paraschiv, A.; Frigioescu, T.; Vladut, M.; Pambaguian, L. A Study on Using the Additive Manufacturing Process for the Development of a Closed Pump Impeller for Mechanically Pumped Fluid Loop Systems. Materials 2021, 14, 967. [Google Scholar] [CrossRef] [PubMed]

- Gupta, N.K.; Ganesan, G.B.; Karade, S.; Mehta, A.K.; Karunakaran, K.P. Effect of Multiple Technologies on Minimizing the Residual Stresses in Additive Manufacturing. In Proceedings of the ICRS 11—The 11th International Conference of Residual Stresses, SF2M, IJL, Nancy, France, 27–30 March 2022; Volume hal-040150. [Google Scholar]

- Jacob, K.; Yadav, D.; Dixit, S.; Hohenwarter, A.; Jaya, B.N. High Pressure Torsion Processing of Maraging Steel 250: Microstructure and Mechanical Behaviour Evolution. Mater. Sci. Eng. A 2021, 802, 140665. [Google Scholar] [CrossRef]

- Farias, F.W.C.; da Cruz Payão Filho, J.; Moraes e Oliveira, V.H.P. Prediction of the Interpass Temperature of a Wire Arc Additive Manufactured Wall: FEM Simulations and Artificial Neural Network. Addit. Manuf. 2021, 48, 102387. [Google Scholar] [CrossRef]

- Paul, S.; Liu, J.; Strayer, S.T.; Zhao, Y.; Sridar, S.; Klecka, M.A.; Xiong, W.; To, A.C. A Discrete Dendrite Dynamics Model for Epitaxial Columnar Grain Growth in Metal Additive Manufacturing with Application to Inconel. Addit. Manuf. 2020, 36, 101611. [Google Scholar] [CrossRef]

- Wang, J.; Lin, X.; Wang, J.; Yang, H.; Zhou, Y.; Wang, C.; Li, Q.; Huang, W. Grain Morphology Evolution and Texture Characterization of Wire and Arc Additive Manufactured Ti-6Al-4V. J. Alloys Compd. 2018, 768, 97–113. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Londhe/Chilwant, P. Optimization of Cutting Parameters in Milling Operation to Improve Surface Finish of EN 31. Int. J. Eng. Sci. Manag. Res. 2016, 3, 1–9. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | Cr | Ni | Cu | P | Mo | S | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ER70S-6 | 0.06 | 0.94 | 1.64 | 0.02 | 0.02 | 0.02 | 0.013 | 0.005 | 0.016 | 0.004 | Remaining |

| Case Study | Part | Energy Source | Current (A) | Voltage (V) | Power (W) | Wire Feed Rate (m/min) | Travel Feed (mm/min) | Stepover (mm) |

|---|---|---|---|---|---|---|---|---|

| Planar 5-axis | Impeller | MIG | 110 | 11.4 | 1254 | 2.5 | 1000 | 2 |

| Conformal | Hub | MIG | 110 | 11.4 | 1254 | 2.5 | 1000 | 2 |

| Blades | Laser | - | - | 1500 | 1.25 | 400 | 1.5 |

| Operation | Tool Diameter (mm) | Feed Rate (mm/min) | Spindle Speed (rpm) | Depth of Cut (mm) | Stepover (mm) | |

|---|---|---|---|---|---|---|

| Roughing | Model area clearance 3-axis | Ø 16 Flat End Mill | 175 | 1150 | 1 | 12 |

| Blade area clearance 5-axis | Ø 8 Ball Nose | 800 | 2000 | 0.5 | 0.8 | |

| Finishing | Blade finishing | Ø 6 Ball Nose | 1200 | 3000 | 0.2 | 0.2 |

| Hub finishing | Ø 6 Ball Nose | 1200 | 3000 | 0.2 | 0.2 | |

| Mechanical Properties | Without Interlayer Machining | With Interlayer Machining |

|---|---|---|

| Microhardness (HV) | 152 ± 6 | 178 ± 4 |

| Ultimate tensile stress (Mpa) | 444 ± 3 | 487 ± 2 |

| Method | Strategy | Deposition | Interlayer Machining | Roughing | Finishing | Total Time | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3-Axis | 5-Axis | 3-Axis | 5-Axis | 3-Axis | 5-Axis | Blade | Hub | |||

| (measured in minutes) | ||||||||||

| Subtractive | Machining | - | - | - | - | 960 | 2212 | 140 | 224 | 3536 |

| HLM | Planar 5-axis | 61 | 194 | 90 | - | - | - | 322 | 224 | 891 |

| Conformal 5-axis | 125 | 170 | 60 | 64 | 10 | - | 140 | 224 | 792 | |

| Method | Strategy | Actual Volume of Impeller (cm3) | Volume Before Final Machining (cm3) | Change in Volume (cm3) | Material Wastage (%) |

|---|---|---|---|---|---|

| Subtractive | Machining | 428,849.49 | 1654,048.53 | 1,225,199.04 | 74.07 |

| HLM | Planar 5-axis with MIG Source | 493,068.30 | 64,218.81 | 13.02 | |

| Planar hub with MIG and conformal blades with laser | 472,953.20 | 44,103.71 | 9.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karade, S.R.; Siddhartha, S.; Gupta, N.K.; G, G.; Karunakaran, K.P.; Zeidler, H. Hybridization in Metal Wire Additive Manufacturing: A Case Study of an Impeller. Metals 2025, 15, 71. https://doi.org/10.3390/met15010071

Karade SR, Siddhartha S, Gupta NK, G G, Karunakaran KP, Zeidler H. Hybridization in Metal Wire Additive Manufacturing: A Case Study of an Impeller. Metals. 2025; 15(1):71. https://doi.org/10.3390/met15010071

Chicago/Turabian StyleKarade, Shahu R., Siddhartha Siddhartha, Neel Kamal Gupta, Ganesan G, K. P. Karunakaran, and Henning Zeidler. 2025. "Hybridization in Metal Wire Additive Manufacturing: A Case Study of an Impeller" Metals 15, no. 1: 71. https://doi.org/10.3390/met15010071

APA StyleKarade, S. R., Siddhartha, S., Gupta, N. K., G, G., Karunakaran, K. P., & Zeidler, H. (2025). Hybridization in Metal Wire Additive Manufacturing: A Case Study of an Impeller. Metals, 15(1), 71. https://doi.org/10.3390/met15010071