On the High Elastic Modulus Mechanism of Iron Matrix Composites

Abstract

1. Introduction

2. Materials and Experimental Methods

3. Results and Discussion

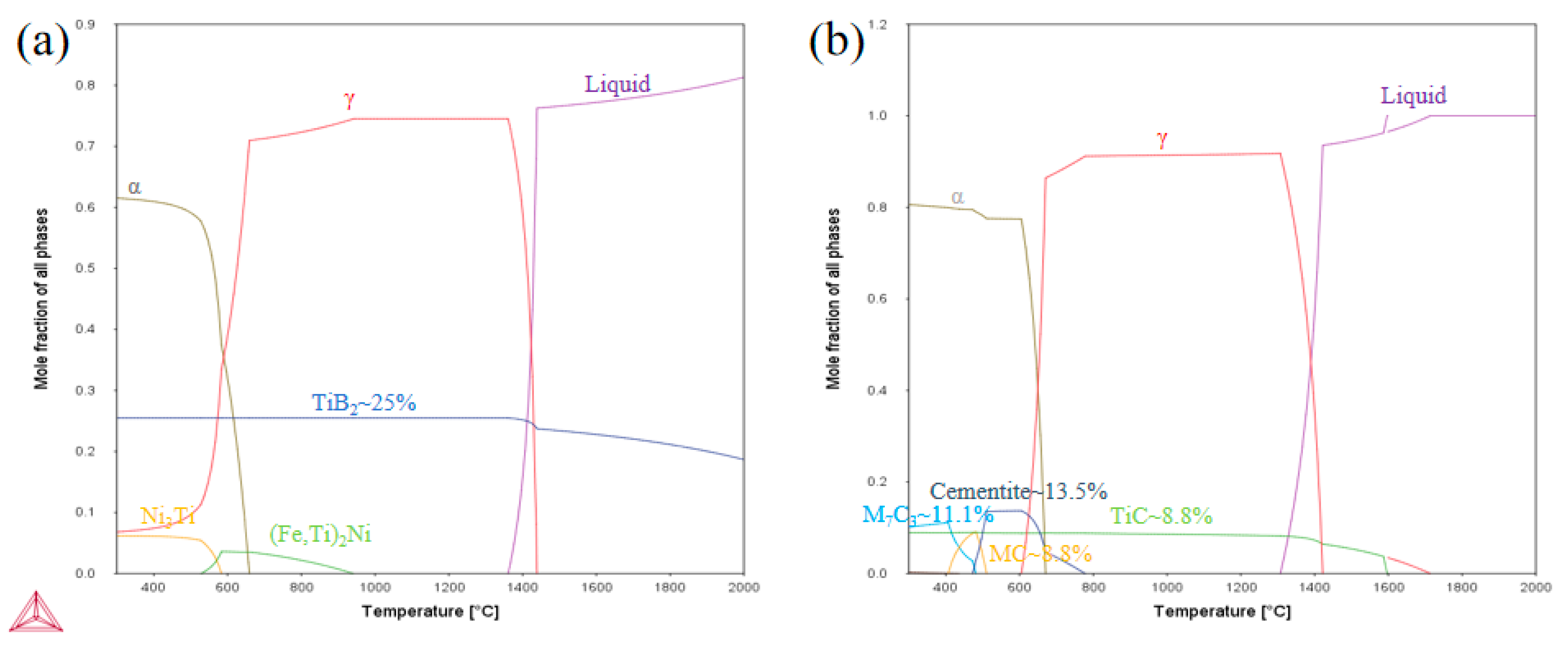

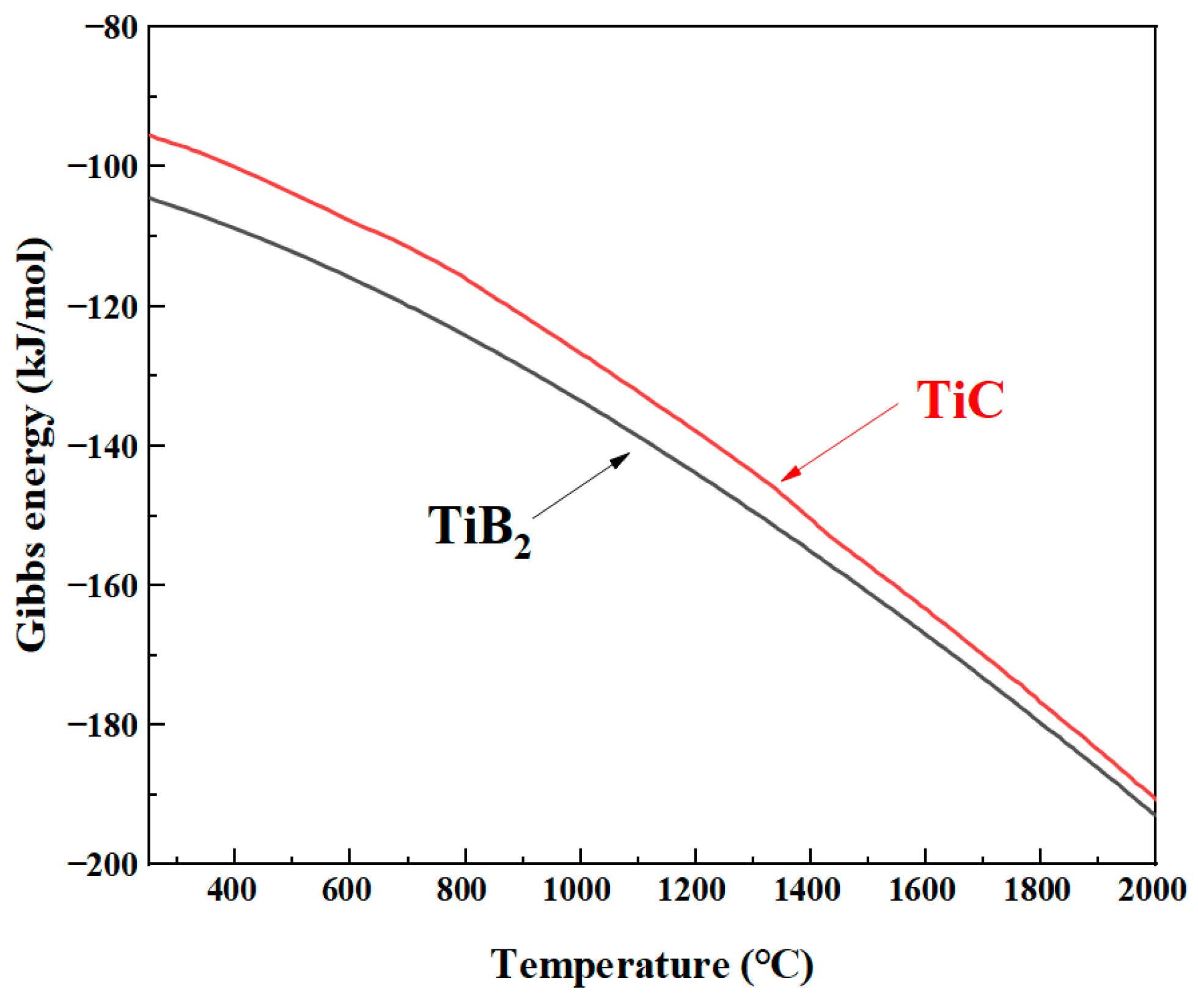

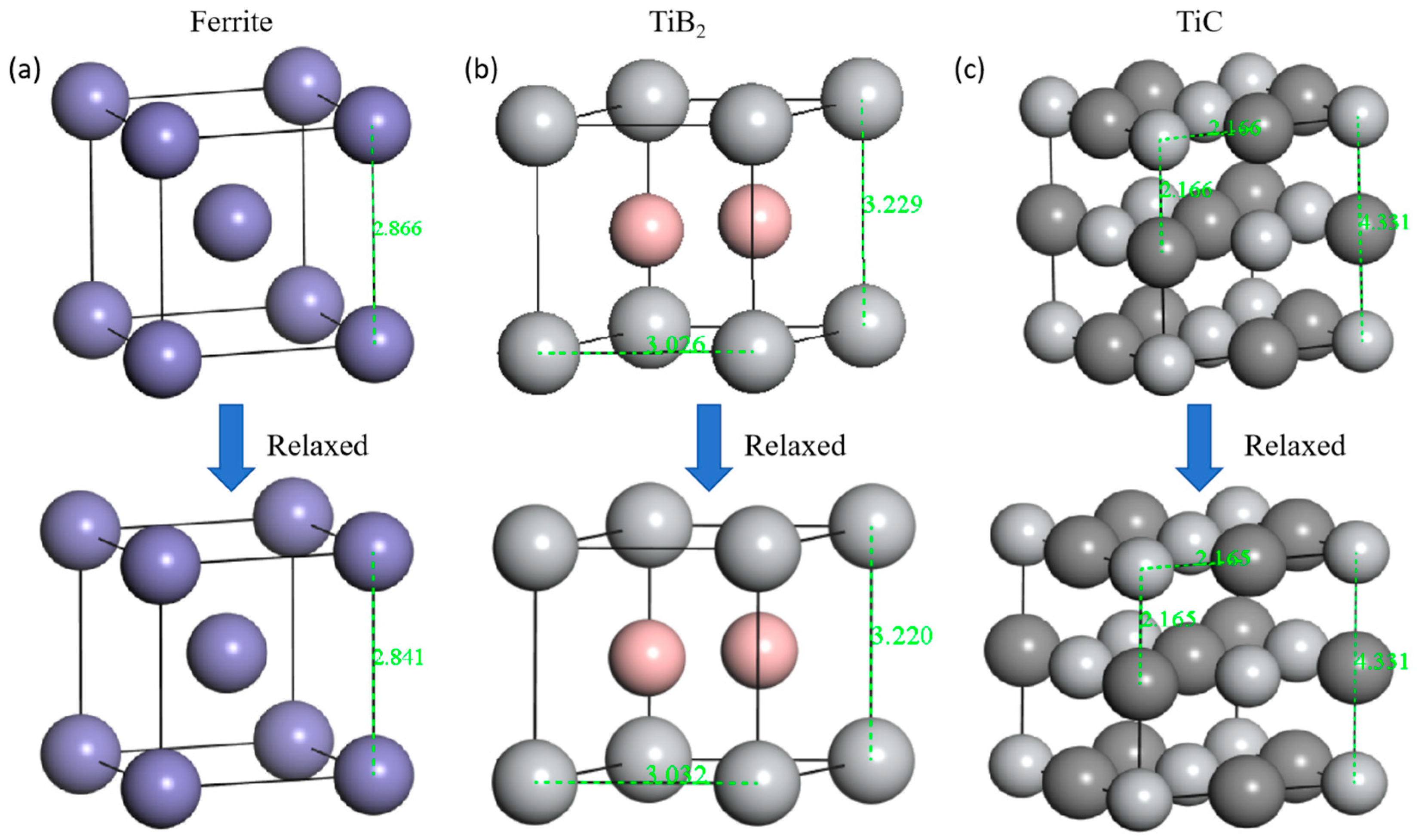

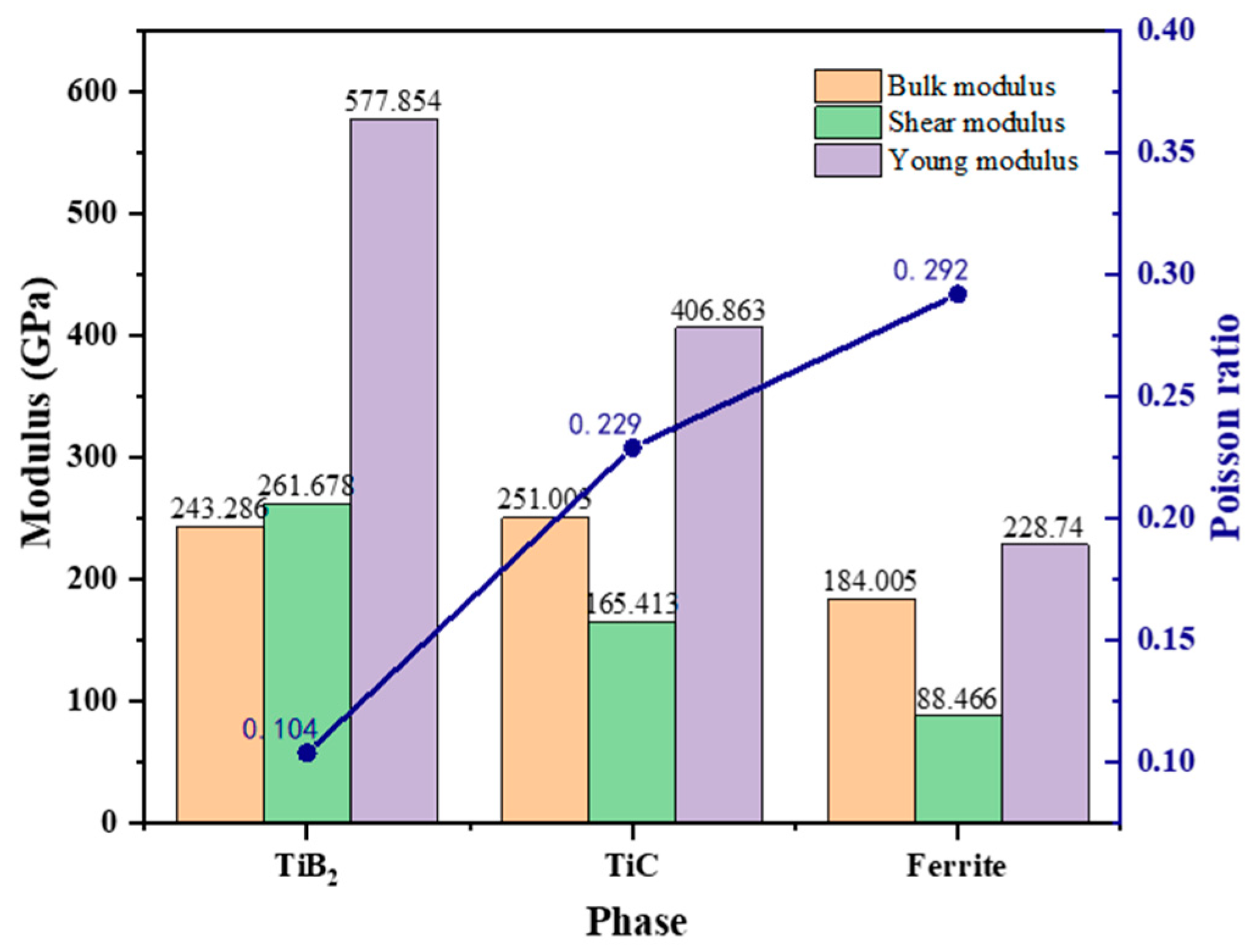

3.1. Thermodynamic Calculations and Elastic Modulus Prediction

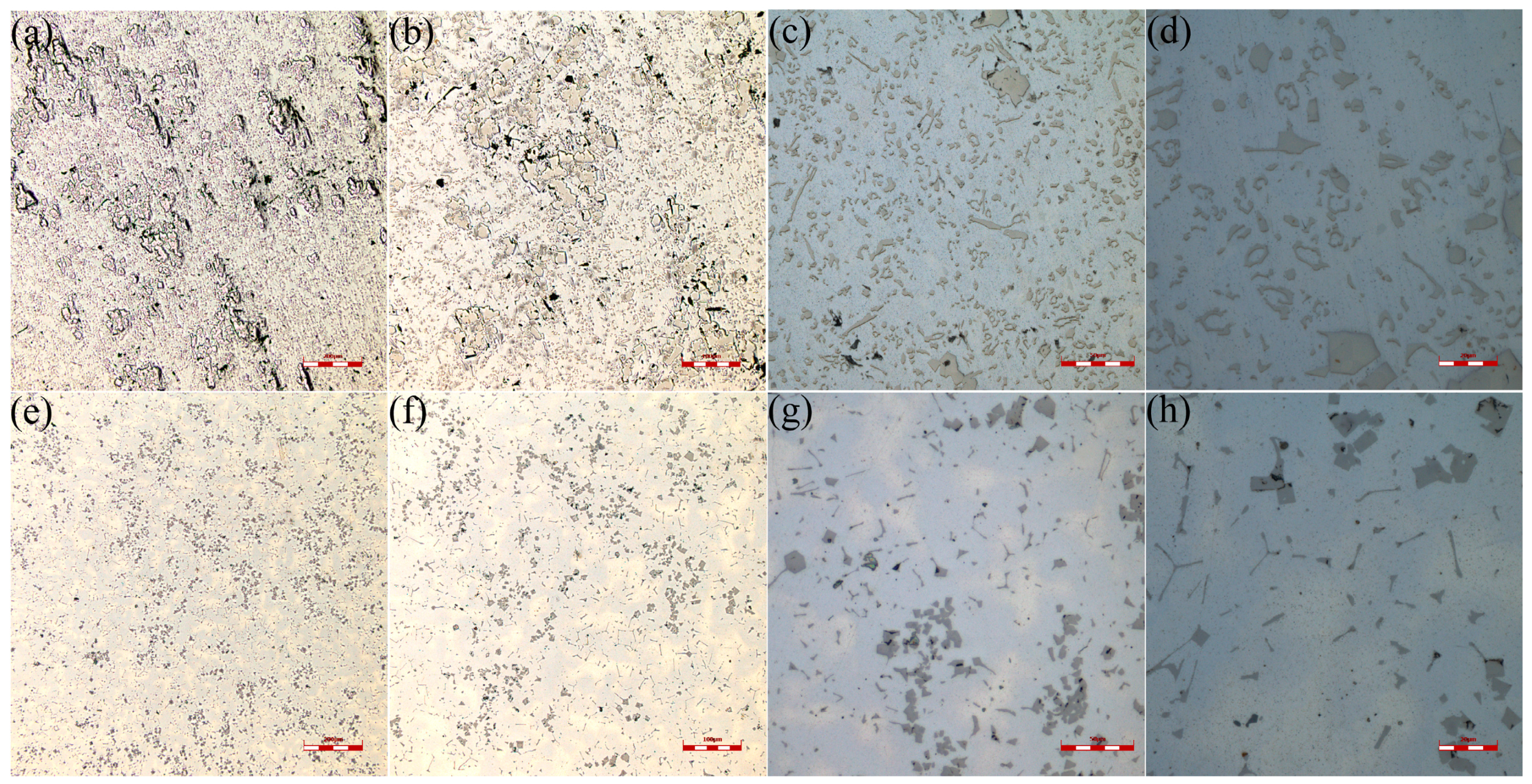

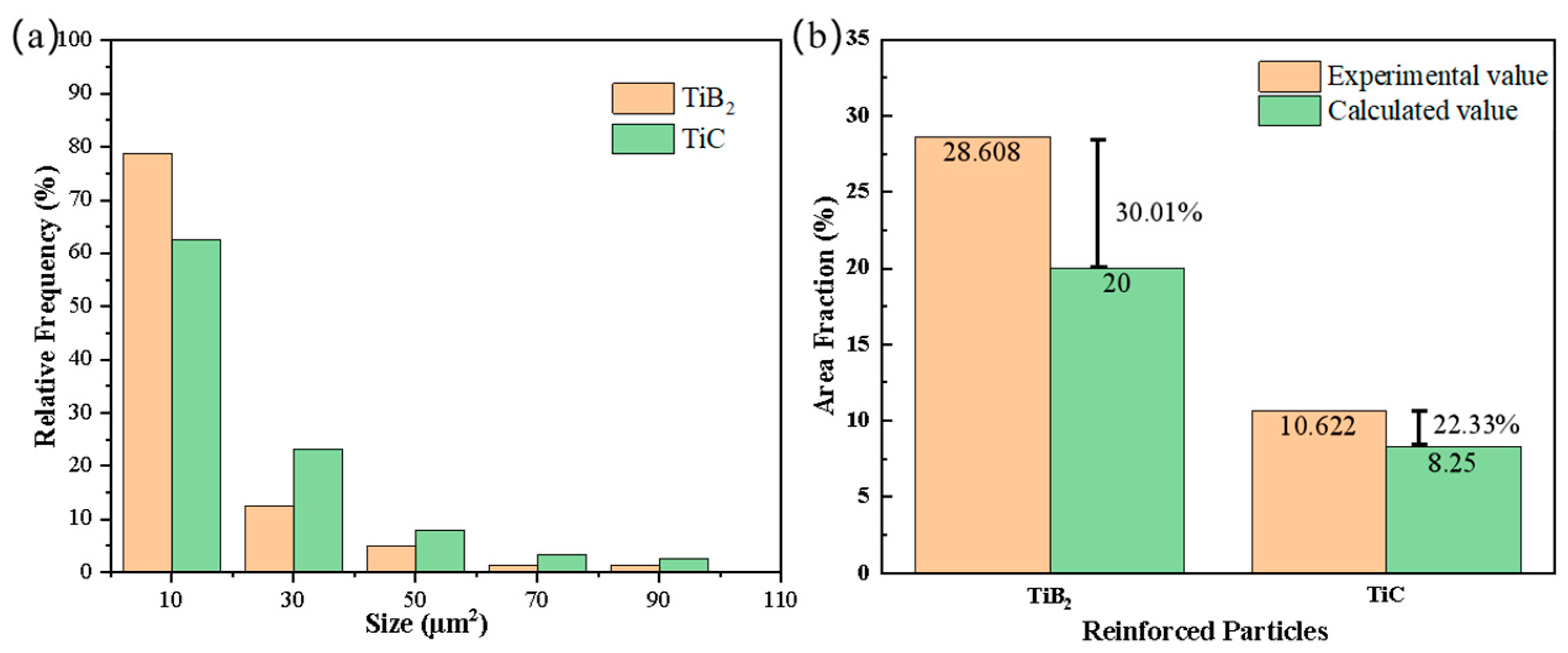

3.2. Microstructure Characterization

3.3. Elastic Modulus and Yield Strength

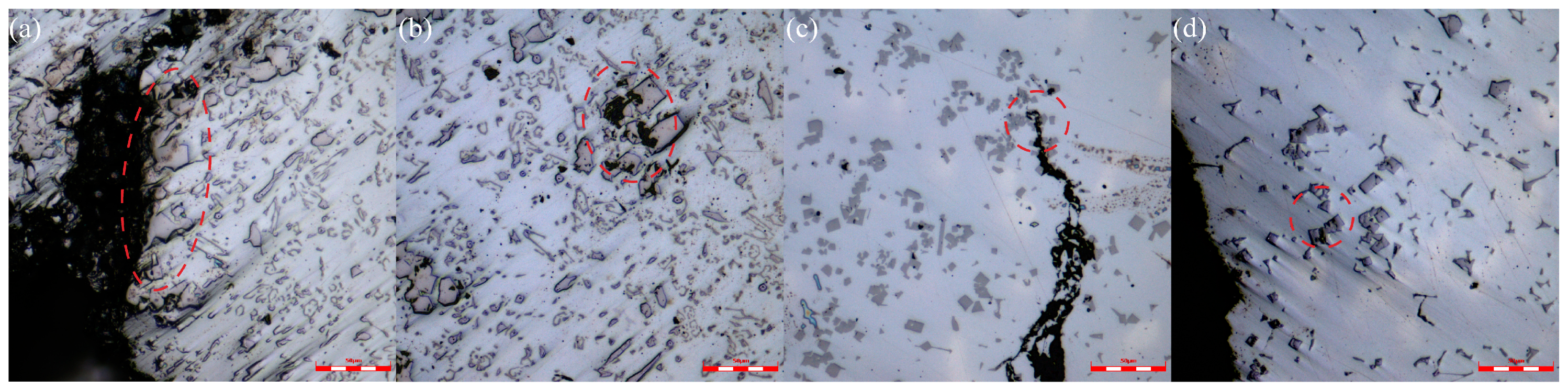

3.4. Analysis of Particle Defect

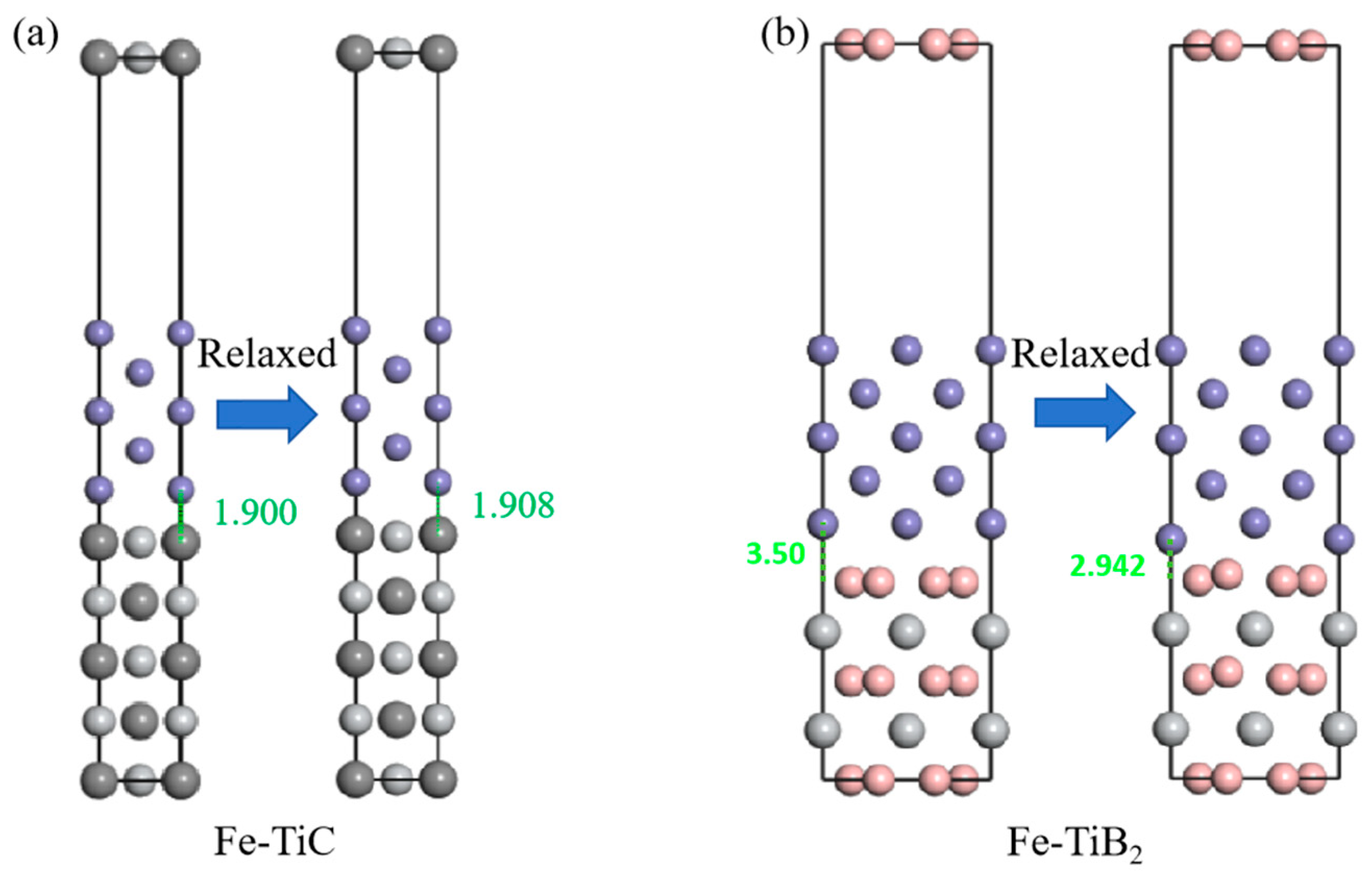

3.5. Work of Adhesion (Wad)

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bonnet, F.; Daeschler, V.; Petitgand, G. High modulus steels: New requirement of automotive market. How to take up challenge? Can. Met. Q. 2014, 53, 243–252. [Google Scholar] [CrossRef]

- Hu, Z.; Yin, H.; Li, M.; Li, J.; Zhu, H. Research and developments of ceramic-reinforced steel matrix composites—A comprehensive review. Int. J. Adv. Manuf. Technol. 2024, 131, 125–149. [Google Scholar] [CrossRef]

- Baron, C.; Springer, H.; Raabe, D. Combinatorial screening of the microstructure–property relationships for Fe–B–X stiff, light, strong and ductile steels. Mater. Des. 2016, 112, 131–139. [Google Scholar] [CrossRef]

- Aparicio-Fernández, R.; Springer, H.; Szczepaniak, A.; Zhang, H.; Raabe, D. In-situ metal matrix composite steels: Effect of alloying and annealing on morphology, structure and mechanical properties of TiB2 particle containing high modulus steels. Acta Mater. 2016, 107, 38–48. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, K.; Xie, H.; Dai, L.; Zhao, G. Precipitation of ceramic particles in Fe-TiB2 and Fe-Ni-TiB2 cast steels during the sub-rapid solidification process. J. Alloy Compd. 2023, 943, 169148. [Google Scholar] [CrossRef]

- Zheng, S.; Rementeria, R.; Kan, W.; Xu, M.; Huang, J.; Huang, Y.; Pan, X.; Apelian, D.; Liang, Y.; Lin, J.; et al. Nanoparticle enabled high performance high modulus steels. Scr. Mater. 2021, 201, 113954. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Kim, N.; Kim, Y.; Cho, S.; Lee, S.-K.; Jo, I. Microstructure and mechanical properties of lightweight TiC-steel composite prepared by liquid pressing infiltration process. Mater. Charact. 2020, 162, 110202. [Google Scholar] [CrossRef]

- Tu, X.; Xiao, L.; Zhao, X.; Cai, Z.; Zhao, Z.; Zeng, D.; Wang, S.; Xiao, Y. Microstructure and nanoindentation creep behavior of TiC reinforced steel matrix composite after stabilizing heat treatments. Ceram. Int. 2022, 48, 24733–24744. [Google Scholar] [CrossRef]

- Parashivamurthy, K.I.; Mallikarjuna, C. Effect of Manganese on the Microstructure and TiC Precipitation in Hypoeutectoid Steel. Mater. Manuf. Process. 2013, 28, 1161–1165. [Google Scholar] [CrossRef]

- Chang, F.; Li, C.-D.; Yang, H.-Y.; Qiu, F.; Shu, S.-L.; Chen, L.-Y.; Jiang, Q.-C. Hot-work die steel with superior mechanical properties at room and high temperatures prepared via a combined approach of composition design and nanoparticle modification. J. Mater. Res. Technol. 2023, 25, 1748–1760. [Google Scholar] [CrossRef]

- Lartigue-Korinek, S.; Walls, M.; Haneche, N.; Cha, L.; Mazerolles, L.; Bonnet, F. Interfaces and defects in a successfully hot-rolled steel-based composite Fe–TiB2. Acta Mater. 2015, 98, 297–305. [Google Scholar] [CrossRef]

- Dong, W.; Yang, X.; Wang, K.; Liu, B. Research and prospect of particle reinforced iron matrix composites. Int. J. Adv. Manuf. Technol. 2023, 128, 3723–3744. [Google Scholar] [CrossRef]

- Sahoo, S.; Jha, B.B.; Mandal, A. Powder metallurgy processed TiB2-reinforced steel matrix composites: A review. Mater. Sci. Technol. 2021, 37, 1153–1173. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, B.; Wang, G.; Sun, L.; Zheng, Q.; Liu, Z.; Gao, Y. Revealing the novel fracture mechanism of the interfaces of TiB2/Fe composite from a first principles investigation. Acta Mater. 2018, 156, 228–244. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, P.; Zhou, Y.; Guo, J.; Ren, X.; Yang, Y.; Yang, Q. First-principles study on ferrite/TiC heterogeneous nucleation interface. J. Alloy Compd. 2012, 556, 160–166. [Google Scholar] [CrossRef]

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: Philadelphia, PA, USA, 2024.

- Bohnenkamp, U.; Sandström, R. Evaluation of the elastic modulus of steels. Steel Res. 2000, 71, 94–99. [Google Scholar] [CrossRef]

- Anal, A.; Bandyopadhyay, T.; Das, K. Synthesis and characterization of TiB2-reinforced iron-based composites. J. Mech. Work. Technol. 2006, 172, 70–76. [Google Scholar] [CrossRef]

- Wang, M. The investigation of dependences of mechanical and electronic properties of TiB2on pressure using the first-principles method. Phys. Scr. 2014, 89, 115702. [Google Scholar] [CrossRef]

- Ledbetter, H.; Tanaka, T. Elastic-Stiffness Coefficients of Titanium Diboride. J. Res. Natl. Inst. Stand. Technol. 2009, 114, 333–339. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Zeng, Q.; Guan, K.; Li, K.; Ren, H.; Liu, S.; Cheng, L. Structural, elastic and electronic properties of transition metal carbides TMC (TM=Ti, Zr, Hf and Ta) from first-principles calculations. Solid State Commun. 2011, 151, 602–606. [Google Scholar] [CrossRef]

- Gilman, J.J.; Roberts, B.W. Elastic Constants of TiC and TiB2. J. Appl. Phys. 1961, 32, 1405. [Google Scholar] [CrossRef]

- Feng, K.; Yang, Y.; Shen, B.; Guo, L. In situ synthesis of TiC/Fe composites by reaction casting. Mater. Des. 2005, 26, 37–40. [Google Scholar] [CrossRef]

- Springer, H.; Fernandez, R.A.; Duarte, M.; Kostka, A.; Raabe, D. Microstructure refinement for high modulus in-situ metal matrix composite steels via controlled solidification of the system Fe–TiB2. Acta Mater. 2015, 96, 47–56. [Google Scholar] [CrossRef]

- Wang, B.; Yi, H.; Wang, G.; Long, Z.; Huang, M. Three-dimensional morphology reconstruction of TiB2 in in situ generated iron-based composites. J. Met. 2019, 55, 133–140. [Google Scholar]

- Lord, J.D.; Morrell, R.M. Comparison of static and dynamic methods for measuring stiffness of high modulus steels and metal composites. Can. Met. Q. 2014, 53, 292–299. [Google Scholar] [CrossRef]

- Wang, X.; Leng, H.; Han, B.; Wang, X.; Hu, B.; Luo, H. Solidified microstructures and elastic modulus of hypo-eutectic and hyper-eutectic TiB2-reinforced high-modulus steel. Acta Mater. 2019, 176, 84–95. [Google Scholar] [CrossRef]

- Wang, K.-Y.; Ke, Y.-J.; Wang, J.-S.; Liu, X.-G.; Zhang, W.-W.; Guo, Y.; Sasaki, G. Systematic investigation of the microstructure evolution and dynamic recrystallization mechanisms of as-cast Fe–TiB2 composites under different hot deformation parameters. J. Mater. Res. Technol. 2023, 27, 2833–2846. [Google Scholar] [CrossRef]

- Chen, R. Effect of particle morphology on fatigue crack propagation mechanism of TiB2-reinforced steel matrix composites. Eng. Fract. Mech. 2022, 274, 108752. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Zhang, W.-N.; Li, Y.-W.; Wang, G.-D.; Liu, H.-T. Heterogeneous nucleation of M2B-type borides (M = Cr, Fe) attached to TiB2 and Ti(C,N) particles in as-cast high borated steel. Mater. Charact. 2020, 169, 110588. [Google Scholar] [CrossRef]

- Li, B.; Xu, K.; Chen, R.; Li, Y.; Wang, X.; Jiang, C.; Huang, M. On the fatigue crack propagation mechanism of a TiB2-reinforced high-modulus steel. Compos. Part B Eng. 2020, 190, 107960. [Google Scholar] [CrossRef]

- Chawla, N.; Andres, C.; Davis, L.C.; Jones, J.W.; Allison, J.E. The interactive role of inclusions and SiC reinforcement on the high-cycle fatigue resistance of particle reinforced metal matrix composites. Met. Mater. Trans. A 2000, 31, 951–957. [Google Scholar] [CrossRef]

- Tekmen, C.; Ozdemir, I.; Cocen, U.; Onel, K. The mechanical response of Al–Si–Mg/SiCp composite: Influence of porosity. Mater. Sci. Eng. A 2003, 360, 365–371. [Google Scholar] [CrossRef]

- Bindumadhavan, P.; Wah, H.K.; Prabhakar, O. Assessment of particle–matrix debonding in particulate metal matrix composites using ultrasonic velocity measurements. Mater. Sci. Eng. A 2002, 323, 42–51. [Google Scholar] [CrossRef]

- Kumar, A.; Jha, P.K.; Mahapatra, M.M. Abrasive Wear Behavior of In Situ TiC Reinforced with Al-4.5%Cu Matrix. J. Mater. Eng. Perform. 2014, 23, 743–752. [Google Scholar] [CrossRef]

- Hadjem-Hamouche, Z.; Derrien, K.; Héripré, E.; Chevalier, J.-P. In-situ experimental and numerical studies of the damage evolution and fracture in a Fe-TiB2 composite. Mater. Sci. Eng. A 2018, 724, 594–605. [Google Scholar] [CrossRef]

- Zhang, H.; Springer, H.; Aparicio-Fernández, R.; Raabe, D. Improving the mechanical properties of Fe—TiB2 high modulus steels through controlled solidification processes. Acta Mater. 2016, 118, 187–195. [Google Scholar] [CrossRef]

| Composite | Ti | B | Ni | Mn | C | Cr | Fe |

|---|---|---|---|---|---|---|---|

| Fe/TiB2 | 10.10 | 3.86 | 10.00 | 2.00 | - | - | Bal. |

| Fe/TiC | 4.00 | - | 0.005 | 6.00 | 1.80 | 0.15 | Bal. |

| Phase | Species | C11 | C12 | C13 | C33 | C44 | C66 | B | G | E |

|---|---|---|---|---|---|---|---|---|---|---|

| TiB2 | Present | 638.7 | 52.6 | 89.3 | 449.8 | 258.3 | 293.1 | 243.3 | 261.7 | 577.9 |

| Cal. [19] | 653.0 | 64.0 | 101.0 | 455.0 | 260.0 | 294.5 | 253.0 | 260.0 | 580.0 | |

| Exp. [20] | 654.4 | 49.0 | 95.3 | 458.1 | 262.3 | 302.7 | 247.5 | 264.3 | 584.7 | |

| TiC | Present | 487.0 | 132.9 | 157.7 | 251.0 | 165.4 | 406.9 | |||

| Cal. [21] | 507.1 | 121.3 | 171.5 | 249.9 | 180.1 | 435.0 | ||||

| Exp. [22] | 500.0 | 113.0 | 175.0 | 242.0 | 182.0 | 437.0 | ||||

| Ferrite | Present | 265.6 | 143.2 | 106.6 | 184.0 | 88.5 | 228.7 | |||

| Exp. [23] | 243.1 | 138.1 | 121.9 | 173.1 | 94.1 | 239.0 |

| Composite | Test Methods | Elastic Modulus (GPa) | Yield Strength (MPa) |

|---|---|---|---|

| Fe/TiB2 | dynamic method | 210 | - |

| Static method (tension method) | 226 | 630 | |

| Static method (compression method) | - | 897 | |

| Fe/TiC | dynamic method | 177 | - |

| Static method (tension method) | 183 | 320 | |

| Static method (compression method) | - | 314 |

| System | Adhesion Work Wad (J/m2) | Interface Distance d0 (Å) |

|---|---|---|

| Fe/TiB2 | 3.922 | 1.375 |

| Fe/TiC | 1.768 | 1.908 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, Q.; Fang, X.; Yang, X.; Wang, M.; Tang, X.; Wu, Y.; Mi, Z. On the High Elastic Modulus Mechanism of Iron Matrix Composites. Metals 2025, 15, 129. https://doi.org/10.3390/met15020129

Liu H, Zhang Q, Fang X, Yang X, Wang M, Tang X, Wu Y, Mi Z. On the High Elastic Modulus Mechanism of Iron Matrix Composites. Metals. 2025; 15(2):129. https://doi.org/10.3390/met15020129

Chicago/Turabian StyleLiu, Hangrui, Qi Zhang, Xing Fang, Xiaoyu Yang, Mai Wang, Xiqing Tang, Yanxin Wu, and Zhenli Mi. 2025. "On the High Elastic Modulus Mechanism of Iron Matrix Composites" Metals 15, no. 2: 129. https://doi.org/10.3390/met15020129

APA StyleLiu, H., Zhang, Q., Fang, X., Yang, X., Wang, M., Tang, X., Wu, Y., & Mi, Z. (2025). On the High Elastic Modulus Mechanism of Iron Matrix Composites. Metals, 15(2), 129. https://doi.org/10.3390/met15020129