Hot Deformation Behaviors and Dynamic Softening Mechanisms of As-Cast XM-19 Super Austenitic Stainless Steel

Abstract

1. Introduction

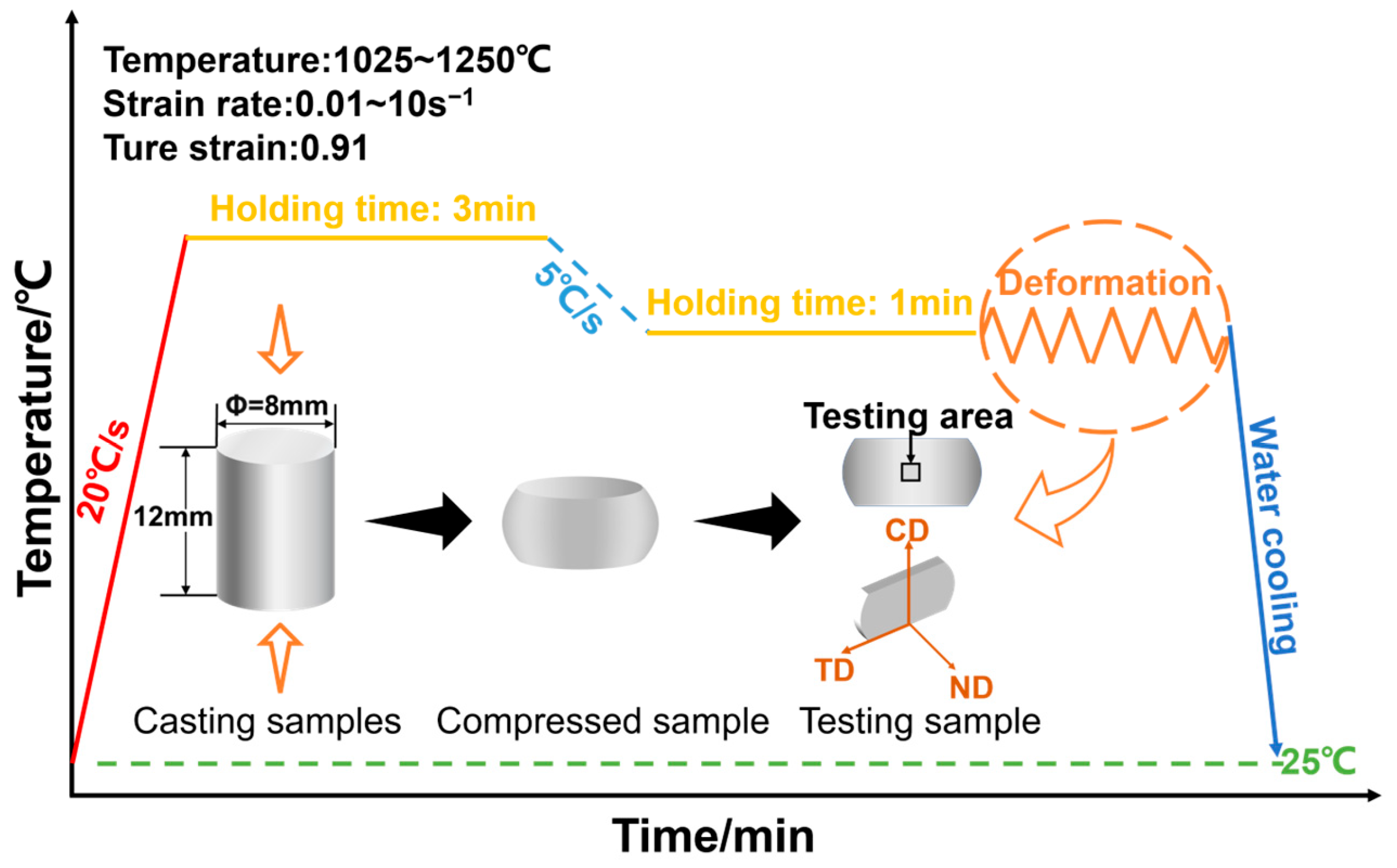

2. Materials and Methods

3. Results and Discussion

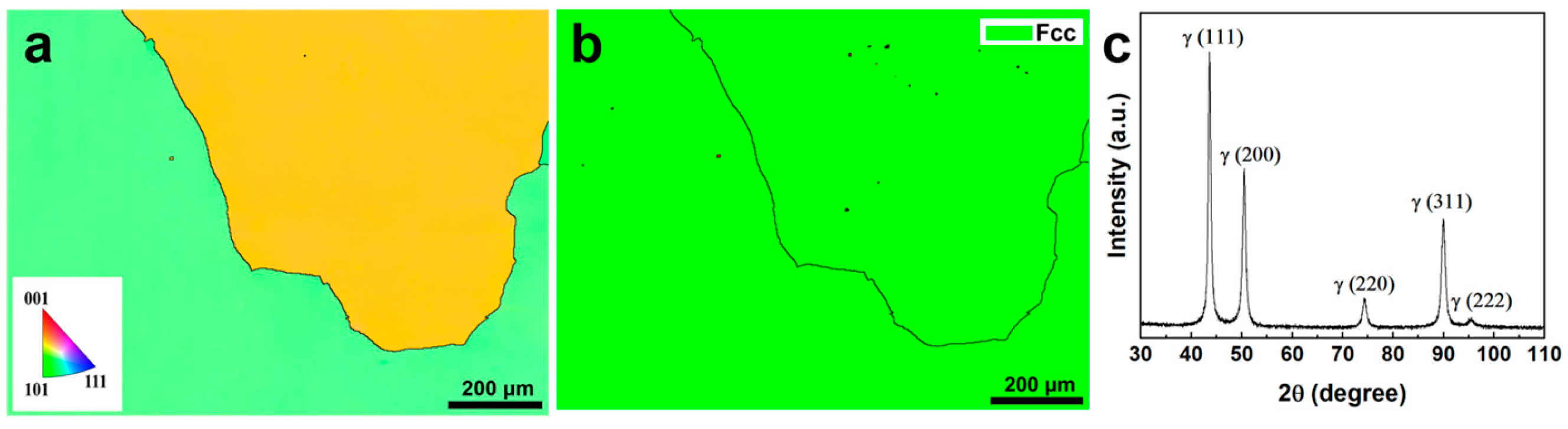

3.1. Initial Microstructure

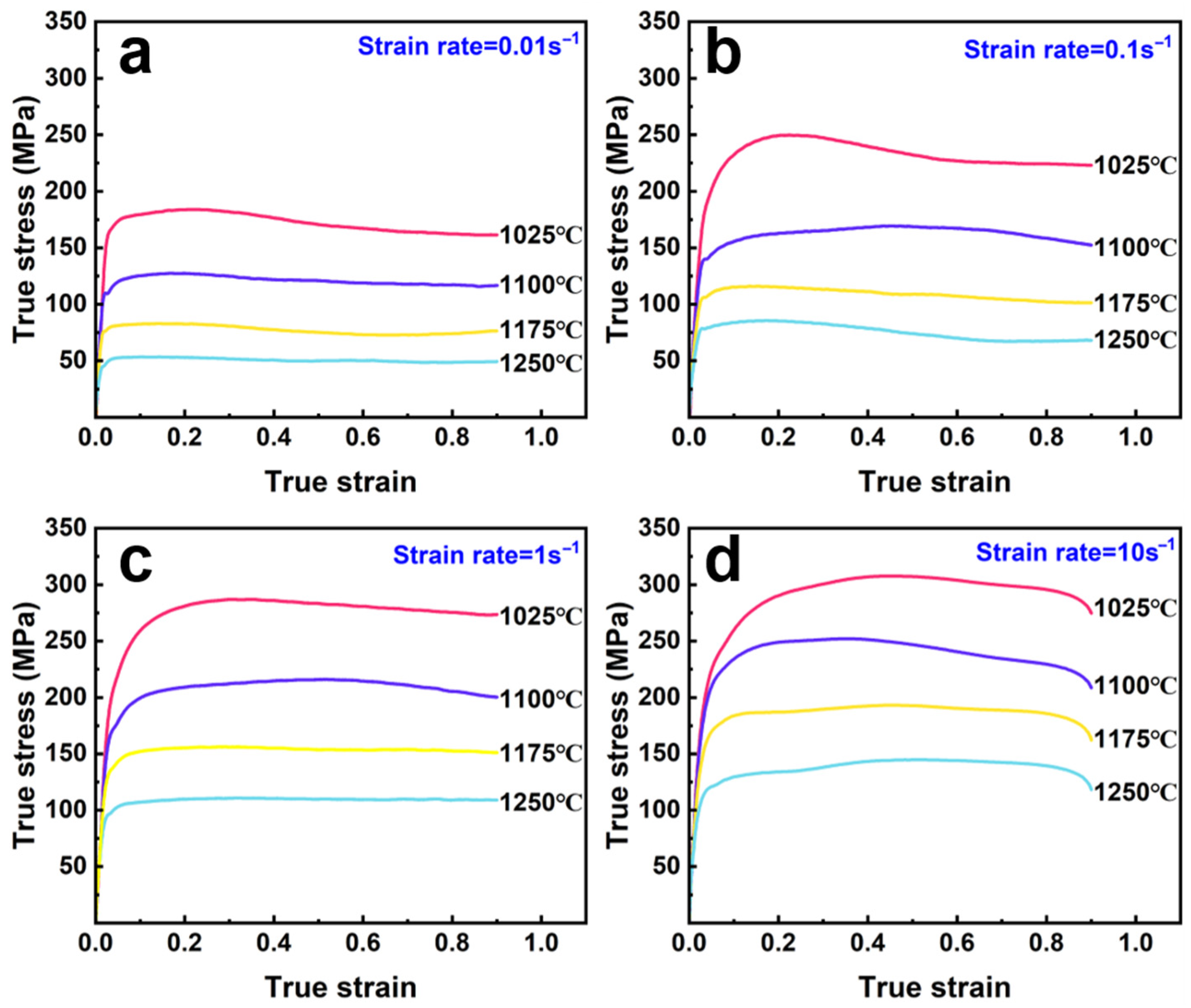

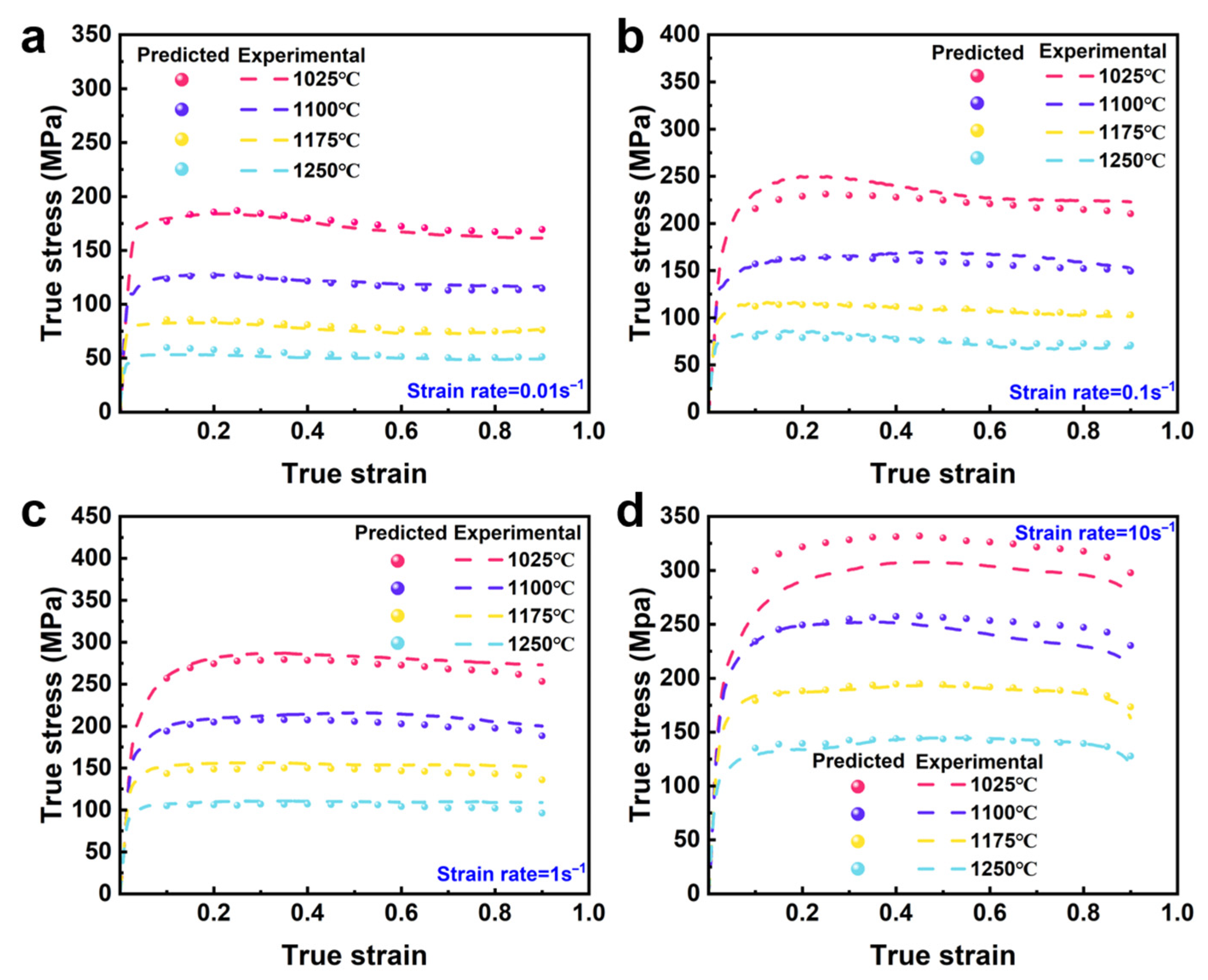

3.2. True Stress–Strain Curves and Flow Behaviors

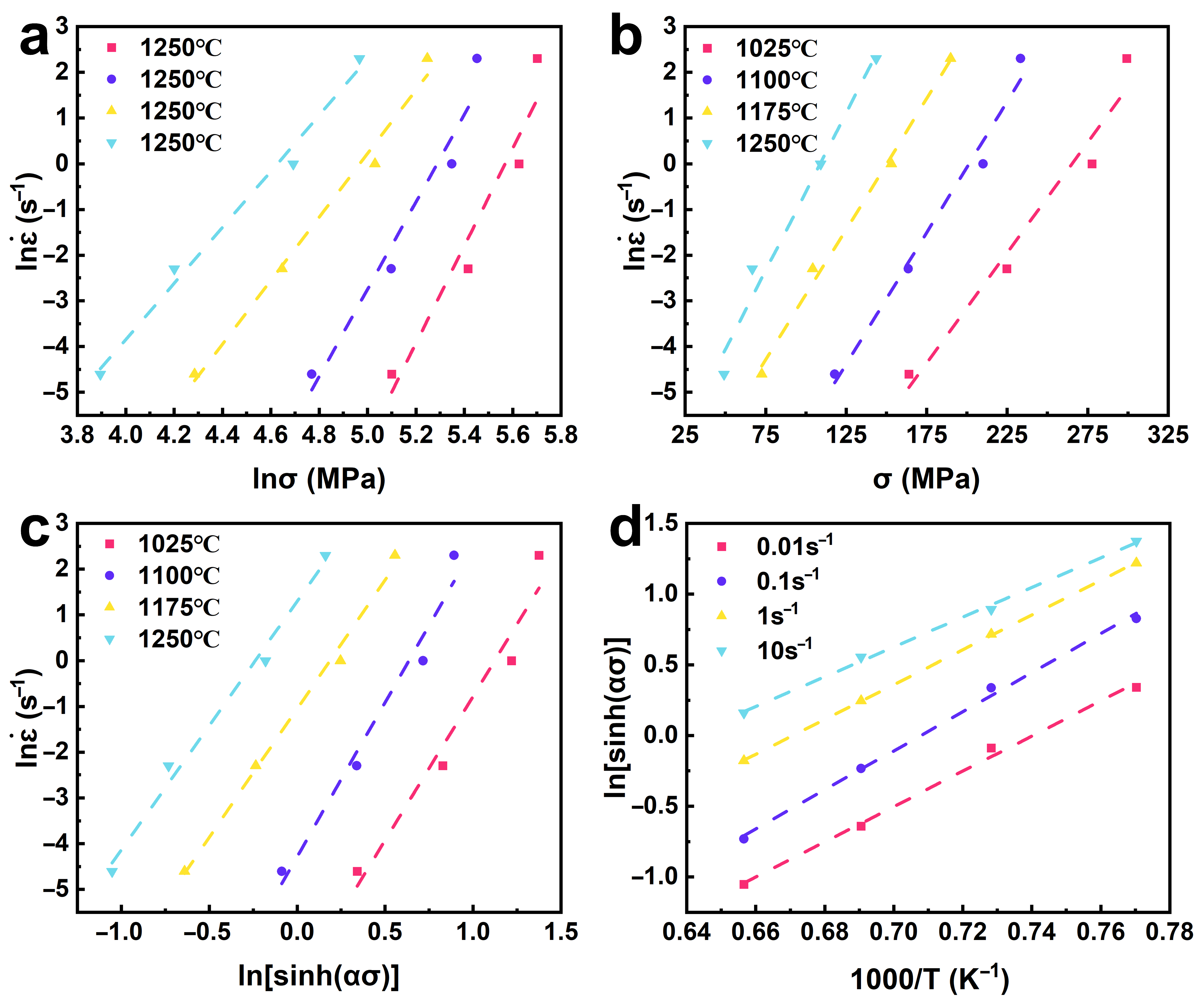

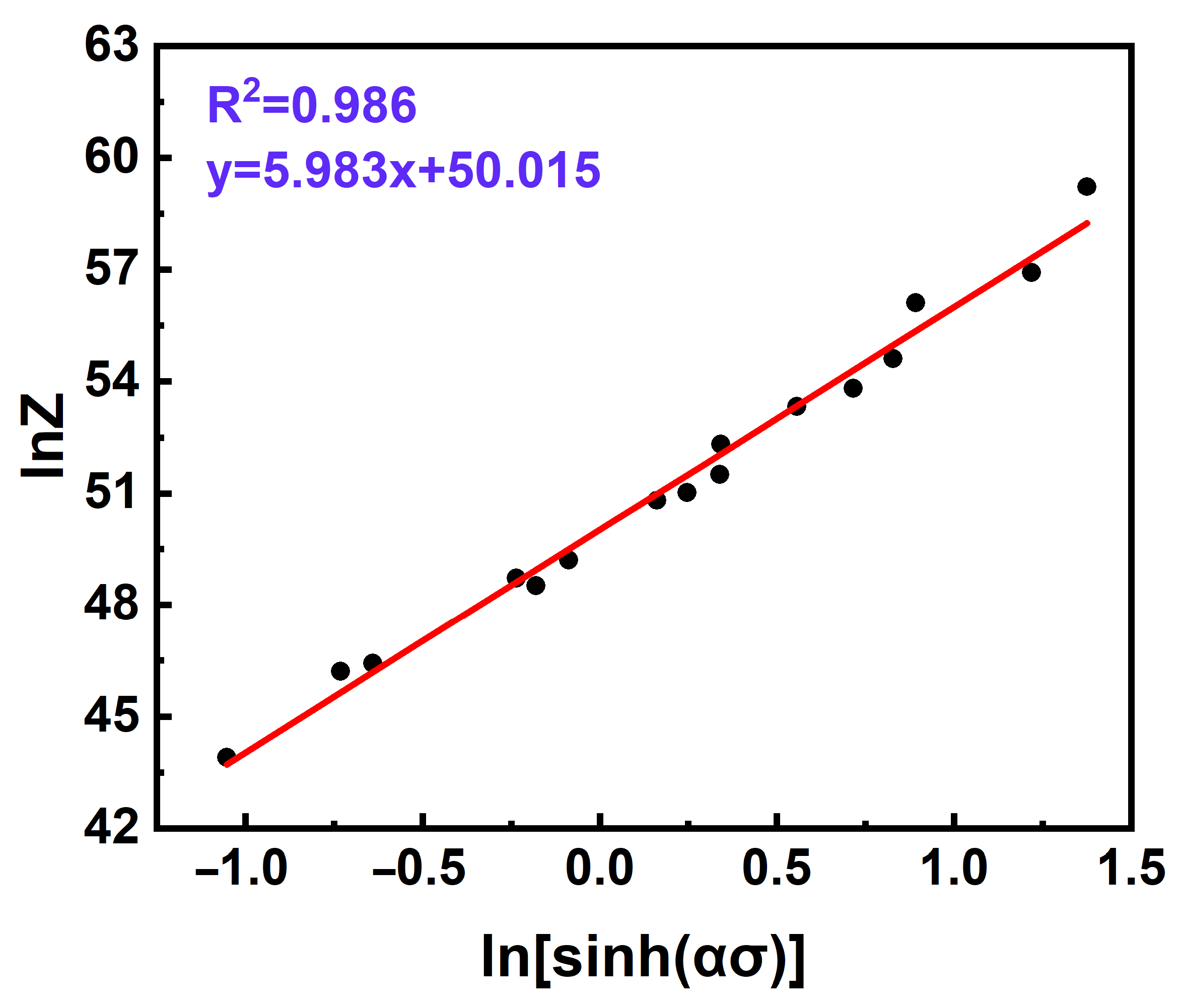

3.3. Establishment of Constitutive Model

3.4. Strain Compensation

3.5. Hot Processing Map of XM-19 SASS

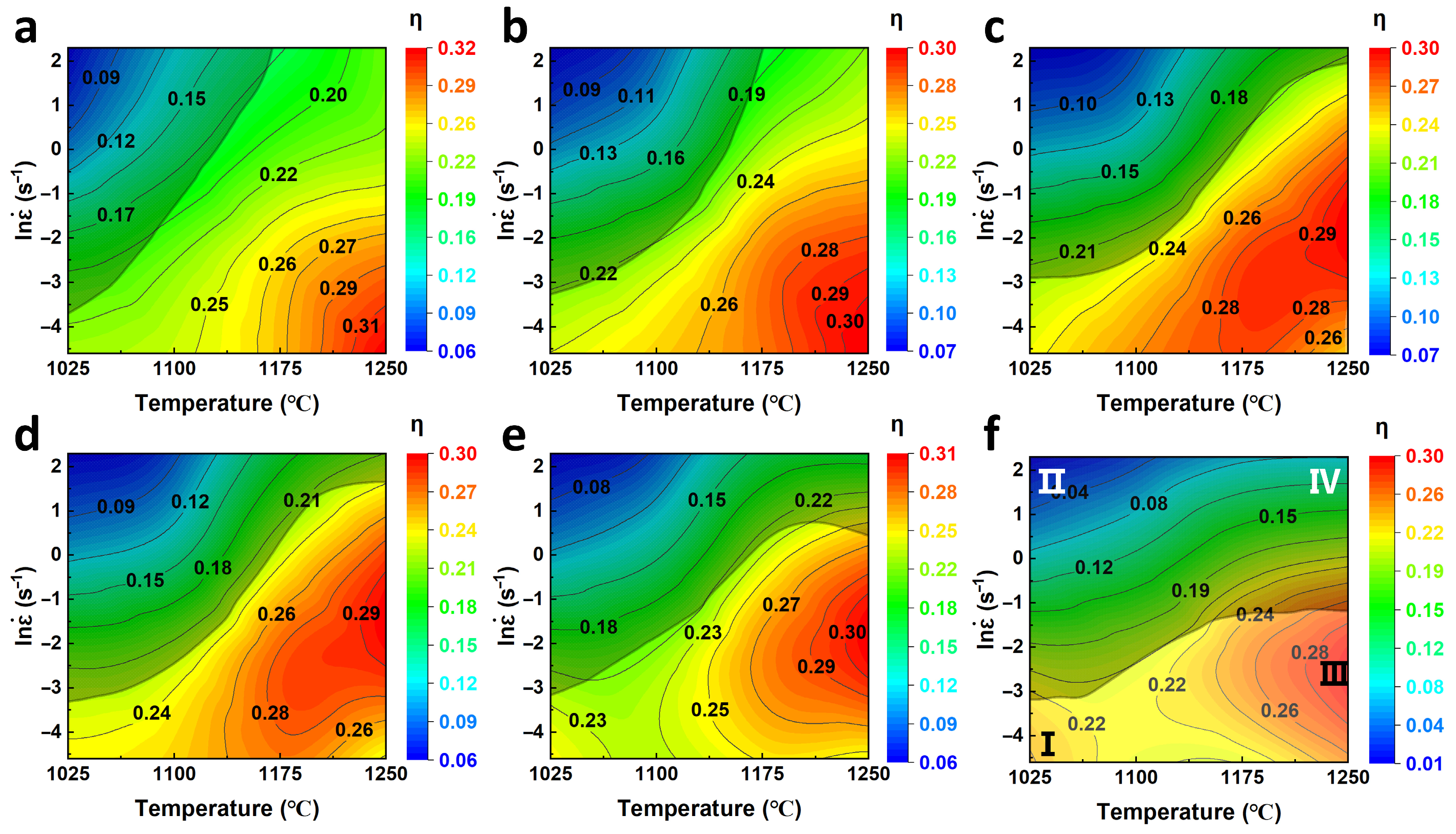

3.5.1. Construction of Hot Processing Map

3.5.2. Analysis of Hot Processing Map

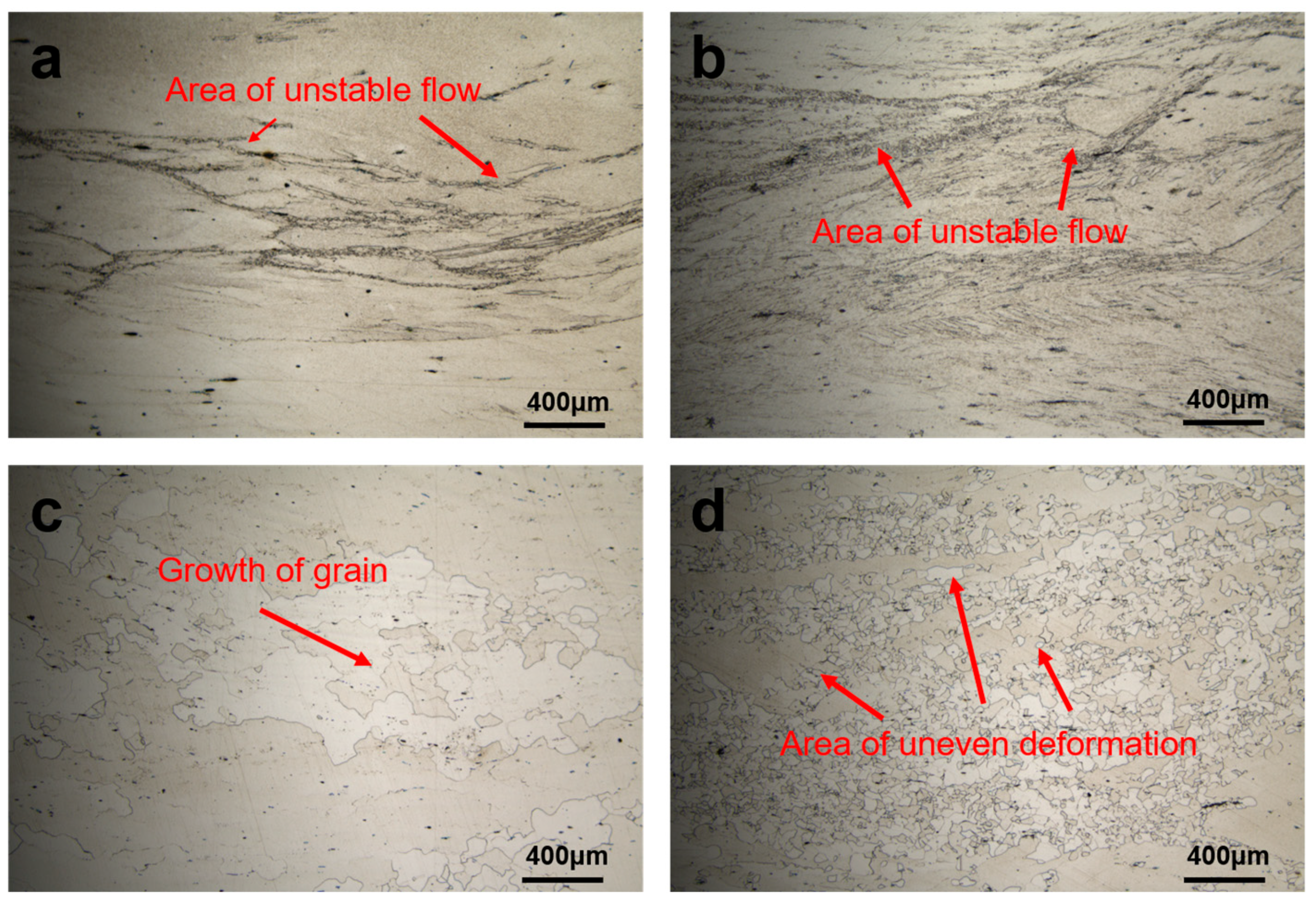

3.6. Microstructural Evolution

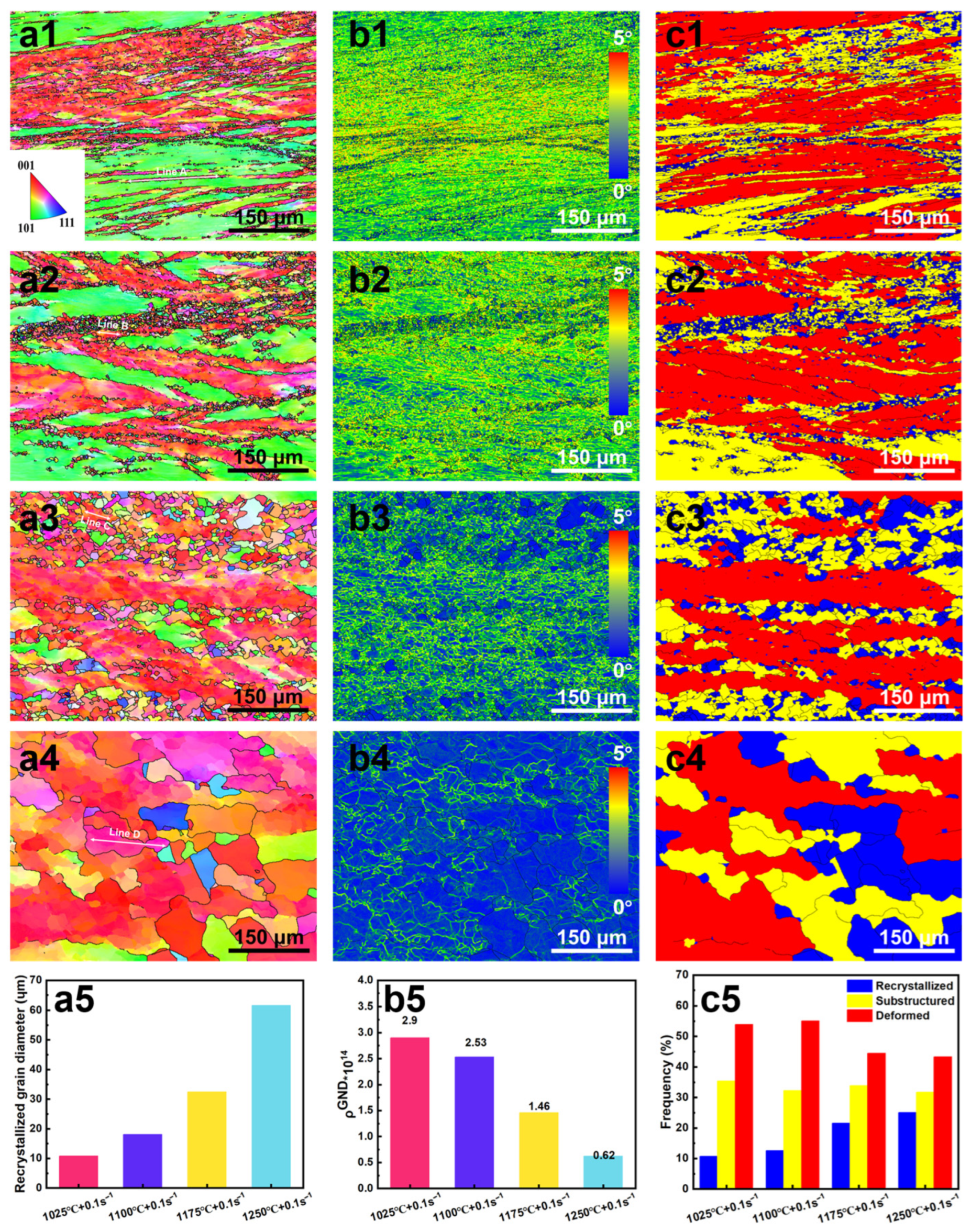

3.6.1. Effect of Deformation Temperature on Microstructure Evolution

3.6.2. Effect of Strain Rate on Microstructure Evolution

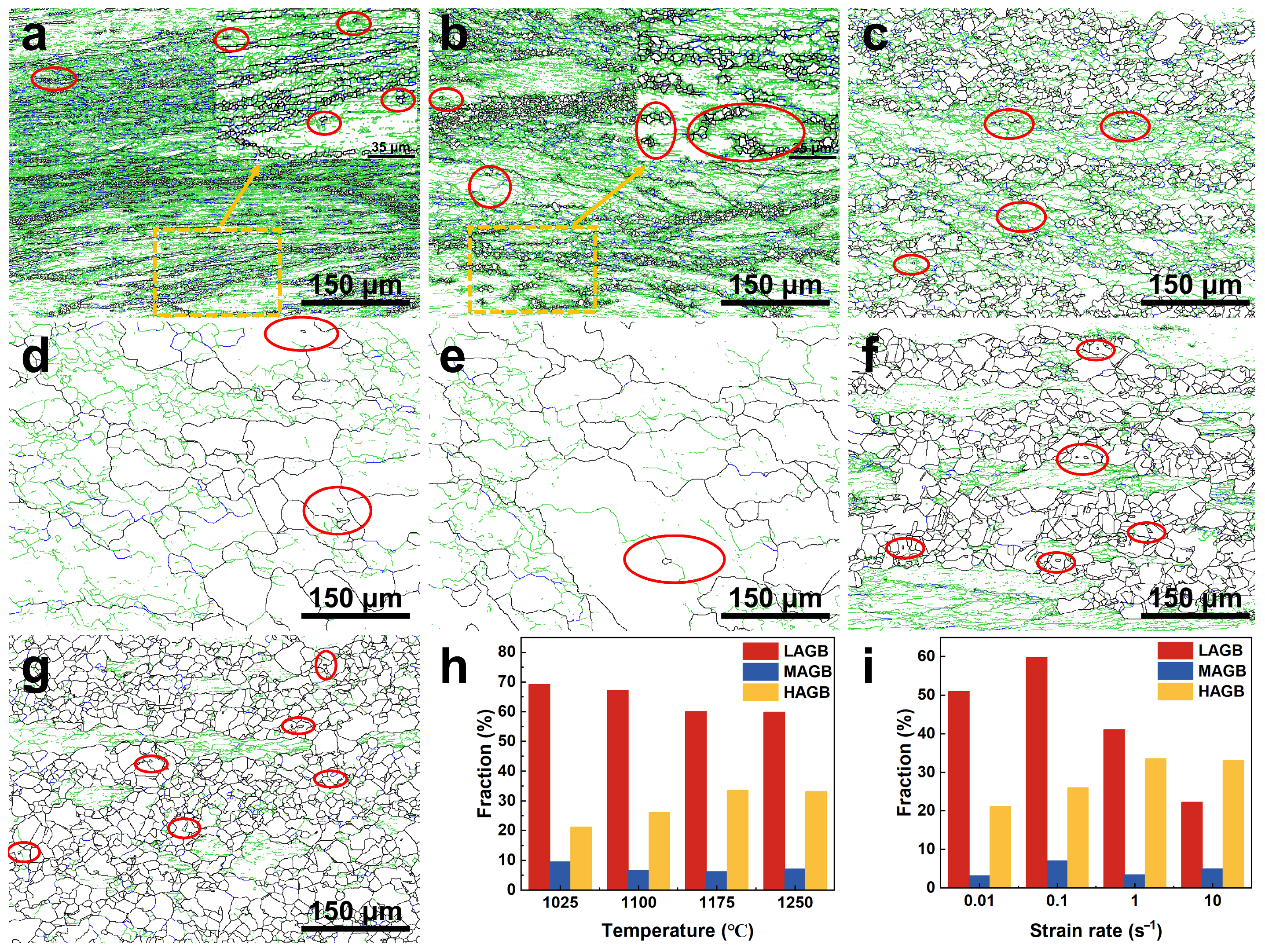

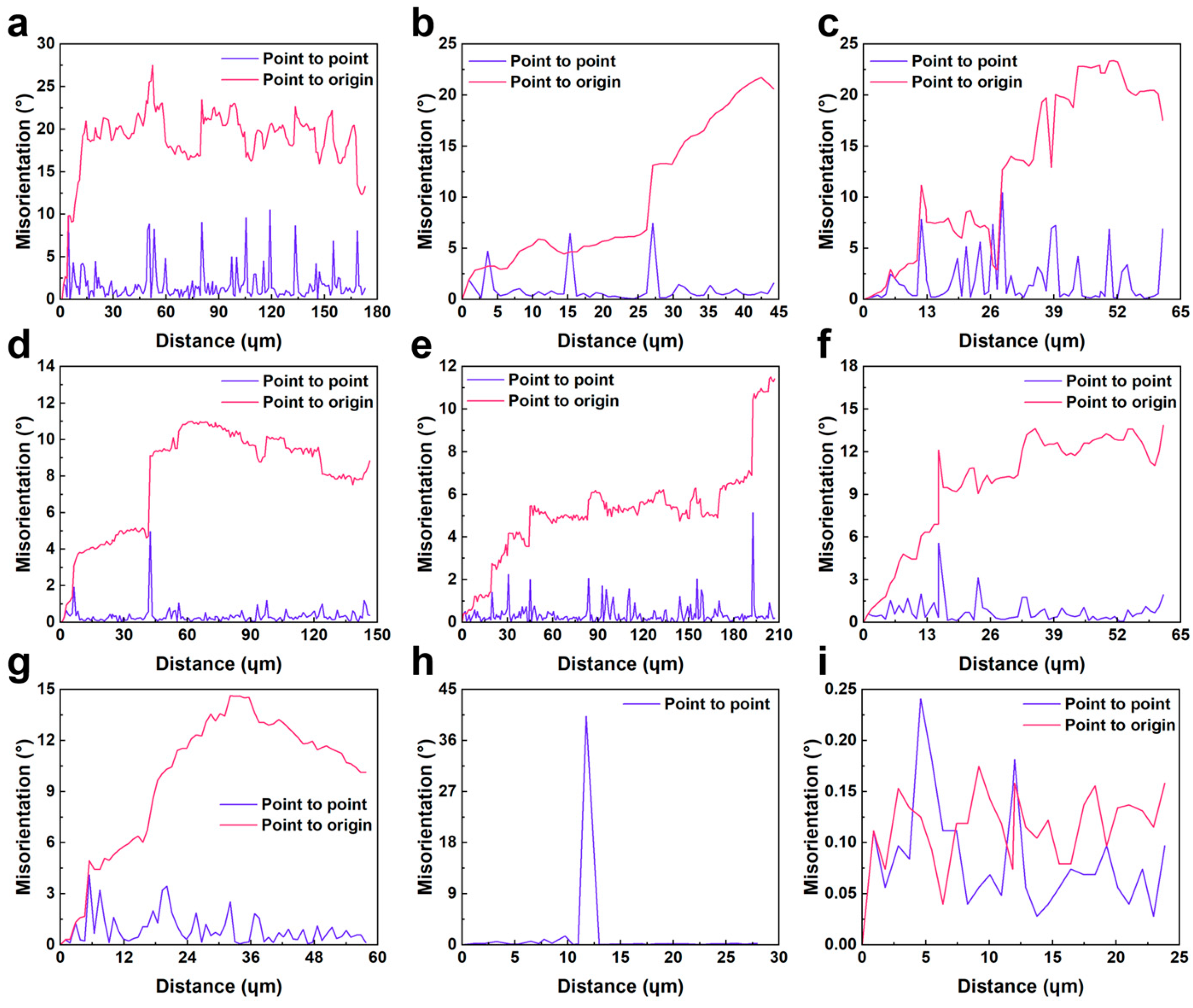

3.7. Dynamic Recrystallization Mechanism

4. Conclusions

- The thermal activation energy of XM-19 SASS at a strain of 0.7 was determined to be 614.3 kJ/mol. Based on the Arrhenius equation, a strain compensation constitutive model was developed. The resulting expression is as follows:

- 2.

- Based on the DMM theory, the hot processing map for XM-19 SASS was constructed. In the strain range of 0.4–0.9, the unstable region of XM-19 SASS gradually extended from the low-temperature and high-strain-rate region to the high-strain-rate region at various temperatures. When the true strain was 0.9, the optimal thermal deformation parameters for XM-19 SASS were a deformation temperature of 1200–1250 °C and a strain rate of 0.03–0.2 s−1.

- 3.

- Both strain rate and deformation temperature have an impact on DRX. At a strain rate of 0.1 s−1, the recrystallization fraction of XM-19 SASS increased from 11% to 25% as the deformation temperature rose from 1025 °C to 1250 °C, while at a fixed deformation temperature of 1250 °C, the recrystallization fraction surged from 20% to 78%, with the strain rate increasing from 0.01 s−1 to 10 s−1.

- 4.

- During the thermal deformation of XM-19 SASS, both DDRX and CDRX occur, with DDRX being the dominant mechanism and CDRX acting as a secondary process. The influence of CDRX decreases with increasing deformation temperature and shows dynamic variation with changes in strain rate. The cumulative misorientation within the sub-grains increases rapidly, with some grains exceeding 15°, indicating the occurrence of sub-grain rotation, which further supports the presence of CDRX.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nishimura, A.; Ono, Y.; Umezawa, O.; Kumagai, S.; Kato, Y.; Kato, T.; Yuri, T.; Komatsu, M. Study on development policy for new cryogenic structural material for superconducting magnet of fusion reactor. Nucl. Mater. Energy 2022, 30, 101125. [Google Scholar] [CrossRef]

- Kato, T.; Kato, Y.; Umezawa, O.; Ono, Y.; Yuri, T.; Nishimura, A.; Kumagai, S. Tensile Properties of 22Cr-12Ni Austenitic Stainless Steel Thick Plates and Bars at Cryogenic Temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1241, 012001. [Google Scholar] [CrossRef]

- Pokrovsky, A.; Fabritsiev, S. Effect of neutron irradiation on tensile properties of austenitic steel XM-19 for the ITER application. J. Nucl. Mater. 2011, 417, 874–877. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Hu, S.; Zhang, L.; Wang, H. Research progress and prospects on the formation mechanism of macrosegregation and shrinkage porosity in large steel ingots. Prog. Nat. Sci. 2024, 34, 470–481. [Google Scholar] [CrossRef]

- Xu, S.; He, J.; Zhang, R.; Zhang, F.; Wang, X. Hot deformation behaviors and dynamic softening mechanisms of 7Mo super-austenitic stainless steel with high stacking fault energy. J. Mater. Res. Technol. 2023, 23, 1738–1752. [Google Scholar] [CrossRef]

- Lu, J.; Hultman, L.; Holmström, E.; Antonsson, K.H.; Grehk, M.; Li, W.; Vitos, L.; Golpayegani, A. Stacking fault energies in austenitic stainless steels. Acta Mater. 2016, 111, 39–46. [Google Scholar] [CrossRef]

- Pierce, D.; Jiménez, J.; Bentley, J.; Raabe, D.; Wittig, J. The influence of stacking fault energy on the microstructural and strain-hardening evolution of Fe–Mn–Al–Si steels during tensile deformation. Acta Mater. 2015, 100, 178–190. [Google Scholar] [CrossRef]

- Ghadar, S.; Momeni, A.; Tolaminejad, B.; Soltanalinezhad, M. A comparative study on the hot deformation behavior of 410 stainless and K100 tool steels. Mater. Sci. Eng. A 2019, 760, 394–406. [Google Scholar] [CrossRef]

- Hao, X.; Sun, X.; Zhao, T.; Shen, S.; Wang, Y.; Wang, T. Effect of N on hot deformation behavior of high-Mn austenitic steel. J. Mater. Res. Technol. 2023, 27, 4345–4355. [Google Scholar] [CrossRef]

- Tian, G.; Xu, L.; Fang, H.; Li, Z.; Li, X.; Zhou, Y.; Wei, S. Deformation behavior and microstructure evolution of TZM alloy with 1.0 wt%ZrO2 under high temperature compression. Int. J. Refract. Met. Hard Mater. 2023, 117, 106382. [Google Scholar] [CrossRef]

- Zheng, X.; Yang, L.; Wei, S. Hot compression behavior and recrystallization mechanism of 1.5 wt% Ti3AlC2 ceramic-enhanced Mo alloys with two-dimensional layers. J. Mater. Res. Technol. 2023, 26, 8485–8499. [Google Scholar] [CrossRef]

- Hu, X.; Wang, Z.; Wang, L.; Chen, C.; Zhang, F.; Zhang, W. Effect of pre-deformation on hot workability of super austenitic stainless steel. J. Mater. Res. Technol. 2022, 16, 238–250. [Google Scholar] [CrossRef]

- Wang, L.; Chen, C.; Li, Z.; Wang, Z.; Lv, B.; Zhang, F. Orientation-dependent dynamic recrystallization of super austenitic stainless steels. J. Mater. Res. Technol. 2021, 15, 6769–6785. [Google Scholar] [CrossRef]

- Han, Y.; Wu, H.; Zhang, W.; Zou, D.; Liu, G.; Qiao, G. Constitutive equation and dynamic recrystallization behavior of as-cast 254SMO super-austenitic stainless steel. Mater. Des. 2015, 69, 230–240. [Google Scholar] [CrossRef]

- Kass, J.N.; Bell, W.L.; Wang, M.T.; Bobick, J. Influence of recrystallization behavior on the mechanical properties of XM-19 stainless steel (22Cr-13Ni-5Mn-2Mo-0.3N). Met. Trans. A 1979, 10, 715–725. [Google Scholar] [CrossRef]

- Hamedani, H.M.; Tolaminejad, B.; Momeni, A.; Sadeghpour, S. Hot deformation behavior and microstructural characterization of a novel high entropy steel. Mater. Sci. Eng. A 2024, 910, 146884. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Ouyang, M.; Hu, Y.; Chu, C. Hot deformation behaviors and dynamic softening mechanism of 6%Si high-silicon austenitic stainless steel. J. Mater. Res. Technol. 2023, 26, 4263–4281. [Google Scholar] [CrossRef]

- Zhong, M.; Yu, H.; Wang, Z.; Zhang, X.; Qu, J. Hot deformation behavior and process parameters optimization of GH4738 nickel-based superalloy. J. Mater. Res. Technol. 2024, 33, 7990–8001. [Google Scholar] [CrossRef]

- Zeng, X.; Huang, L.; Liu, W.; Luo, J.; Pei, L.; Song, W.; Mi, Z.; Xu, X. Hot deformation behavior and dynamic recrystallization mechanism of GH2132 superalloy. J. Alloys Compd. 2024, 1009, 176798. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Y.; Zhang, X.; Li, H.; Li, Z.; He, L. Thermal deformation behavior and microstructure evolution of Fe−8.5Mn−1.5Al light–weight medium manganese steel. J. Mater. Res. Technol. 2023, 26, 6053–6066. [Google Scholar] [CrossRef]

- Qi, X.; Chen, C.; Wang, Z.; Li, Y.; Lv, B.; Yang, Z.; Zhang, F. Study on hot workability of a novel Cr + N alloyed high-Mn austenitic steel. Mater. Charact. 2023, 203, 113071. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Stornelli, G.; Gaggiotti, M.; Mancini, S.; Napoli, G.; Rocchi, C.; Tirasso, C.; Di Schino, A. Recrystallization and Grain Growth of AISI 904L Super-Austenitic Stainless Steel: A Multivariate Regression Approach. Metals 2022, 12, 200. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Roostaei, M.; Mirzadeh, H.; Spieckermann, F.; Geranmayeh, A.R.; Mahmudi, R. Effect of sigma (σ) phase precipitation on the recrystallization kinetics of AISI 904L superaustenitic stainless steel. Vacuum 2024, 220, 112830. [Google Scholar] [CrossRef]

- Mirzaei, A.; Zarei-Hanzaki, A.; Haghdadi, N.; Marandi, A. Constitutive description of high temperature flow behavior of Sanicro-28 super-austenitic stainless steel. Mater. Sci. Eng. A 2014, 589, 76–82. [Google Scholar] [CrossRef]

- Pu, E.-X.; Zheng, W.-J.; Song, Z.-G.; Xiang, J.-Z.; Wei, X.-P. Optimization of Hot Workability in Superaustenitic Stainless Steel 654SMO. J. Iron Steel Res. Int. 2014, 21, 975–982. [Google Scholar] [CrossRef]

- Han, Y.; Liu, G.; Zou, D.; Liu, R.; Qiao, G. Deformation behavior and microstructural evolution of as-cast 904L austenitic stainless steel during hot compression. Mater. Sci. Eng. A 2013, 565, 342–350. [Google Scholar] [CrossRef]

- Pu, E.-X.; Feng, H.; Liu, M.; Zheng, W.-J.; Dong, H.; Song, Z.-G. Constitutive Modeling for Flow Behaviors of Superaustenitic Stainless Steel S32654 during Hot Deformation. J. Iron Steel Res. Int. 2016, 23, 178–184. [Google Scholar] [CrossRef]

- Xing, J.; Liu, C.; Li, A.; Wang, S.; Zhang, X.; Shi, Y. Microstructural Evolution and Stability of Coarse-Grained S31254 Super Austenitic Stainless Steel during Hot Deformation. Metals 2022, 12, 1319. [Google Scholar] [CrossRef]

- Li, X.; Ren, L.; Le, Q.; Jin, P.; Cheng, C.; Wang, T.; Wang, P.; Zhou, X.; Chen, X.; Li, D. The hot deformation behavior, microstructure evolution and texture types of as-cast Mg–Li alloy. J. Alloys Compd. 2020, 831, 154868. [Google Scholar] [CrossRef]

- Mirzadeh, H. Quantification of the strengthening effect of reinforcements during hot deformation of aluminum-based composites. Mater. Des. 2015, 65, 80–82. [Google Scholar] [CrossRef]

- Saboori, A.; Abdi, A.; Fatemi, S.A.; Marchese, G.; Biamino, S.; Mirzadeh, H. Hot deformation behavior and flow stress modeling of Ti–6Al–4V alloy produced via electron beam melting additive manufacturing technology in single β-phase field. Mater. Sci. Eng. A 2020, 792, 139822. [Google Scholar] [CrossRef]

- Langdon, T.G. Identifying creep mechanisms in plastic flow. Int. J. Mater. Res. 2005, 96, 522–531. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, L.; Guo, M.; Li, Z.; Xu, Z.; Ye, J.; Wei, S. Microstructure evolution of W-1.0 m-ZrO2 alloy during high temperature deformation. J. Alloys Compd. 2022, 921, 166153. [Google Scholar] [CrossRef]

- Maheshwari, A.K. Prediction of flow stress for hot deformation processing. Comput. Mater. Sci. 2013, 69, 350–358. [Google Scholar] [CrossRef]

- Dolzhenko, P.; Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Peculiarities of DRX in a Highly-Alloyed Austenitic Stainless Steel. Materials 2021, 14, 4004. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, L.; Shang, X.; Li, G.; Qi, X.; Liu, P.; Li, B.; Wang, X.; Xu, X.; Shang, C. Dynamic recrystallization behavior and microstructure evolution of high-Mn austenitic steel for application in a liquefied natural gas carrier. J. Mater. Res. Technol. 2023, 27, 5479–5488. [Google Scholar] [CrossRef]

- Zhao, G.; Tian, Y.; Li, H.; Ma, L.; Li, Y.; Li, J. Microstructure evolution and dynamic recrystallization mechanisms of 316L stainless steel during hot deformation. Arch. Civ. Mech. Eng. 2024, 24, 35. [Google Scholar] [CrossRef]

- Sheng, S.; Qiao, Y.; Zhai, R.; Sun, M.; Xu, B. Processing map and dynamic recrystallization behaviours of 316LN-Mn austenitic stainless steel. Int. J. Miner. Met. Mater. 2024, 30, 2386–2396. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Behera, A.N.; Sarkar, A.; Kapoor, R.; Ray, R.K.; Suwas, S. Hot deformation behaviour of Mo-TZM and understanding the restoration processes involved. Acta Mater. 2019, 164, 153–164. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H.; Zhang, J.; Zhang, J.; Ma, T.; Misra, R. An electron backscattered diffraction study on the dynamic recrystallization behavior of a nickel–chromium alloy (800H) during hot deformation. Mater. Sci. Eng. A 2013, 585, 71–85. [Google Scholar] [CrossRef]

- Han, Y.; Zou, D.; Chen, Z.; Fan, G.; Zhang, W. Investigation on hot deformation behavior of 00Cr23Ni4N duplex stainless steel under medium–high strain rates. Mater. Charact. 2011, 62, 198–203. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Hornbuckle, B.; Luckenbaugh, T.; Fudger, S.; Roberts, A.; Jannotti, P.; Byun, T.; Hoelzer, D.; Solanki, K.; Darling, K. Role of geometric dynamic recrystallization in nanocrystalline alloys. Materialia 2023, 30, 101807. [Google Scholar] [CrossRef]

- Wang, X.; Wang, D.; Jin, J.; Li, J. Effects of strain rates and twins evolution on dynamic recrystallization mechanisms of austenite stainless steel. Mater. Sci. Eng. A 2019, 761, 138044. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Zhou, H.; Lu, Z.; Zhao, C.; Yang, X. Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation. Mater. Des. 2015, 80, 51–62. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | V | Al | N | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.034 | 0.49 | 5.02 | 22.32 | 11.62 | 2.56 | 0.14 | 0.001 | 0.395 | Bal. |

| Flow Stress (MPa) at Different Temperature (°C) | |||||

|---|---|---|---|---|---|

| 1025 °C | 1100 °C | 1175 °C | 1250 °C | ||

| 0.7 | 0.01 | 164.03 | 117.91 | 72.60 | 49.18 |

| 0.1 | 224.87 | 163.67 | 104.19 | 66.74 | |

| 1 | 277.67 | 210.18 | 153.06 | 109.23 | |

| 10 | 299.26 | 233.43 | 190 | 143.6 | |

| Reference | Alloy | Temperature Range (°C) | Strain Rate Range (s−1) | Activation Energy, Q (kJ/mol) |

|---|---|---|---|---|

| Present Work | XM-19 SASS | 1025–1250 | 0.01–10 | 614.3 |

| [25] | Sanicro-28 SASS | 800–1100 | 0.001–0.1 | 509 |

| [26] | 654SMO SASS | 950–1200 | 0.001–10 | 494 |

| [5] | 7Mo SASS | 1000–1200 | 0.001–10 | 558.9 |

| [12] | 7Mo-0.37N-RE SASS | 900–1200 | 0.01–10 | 622–712 |

| [27] | 904L SASS | 1000–1150 | 0.01–10 | 459.12 |

| [14] | 254SMO SASS | 900–1200 | 0.01–10 | 577.845 |

| [28] | S32654 SASS | 900–1250 | 0.001–10 | 486 |

| [29] | S31254 SASS | 950–1250 | 0.001–10 | 542.91 |

| α (MPa) | Q (kJ·mol−1) | n | lnA (s−1) | ||||

|---|---|---|---|---|---|---|---|

| A0 | 9.4841 | B0 | 1180.6 | C0 | 12.529 | D0 | 96.439 |

| A1 | −63.201 | B1 | 12,735 | C1 | −116.43 | D1 | −1040.6 |

| A2 | 619.26 | B2 | 132,010 | C2 | 1043.2 | D2 | 10,737 |

| A3 | −3211.7 | B3 | −697,670 | C3 | −5089.3 | D3 | −56,586 |

| A4 | 9642.5 | B4 | 2,089,300 | C4 | 14,471 | D4 | 169,190 |

| A5 | −17,348 | B5 | −375,600 | C5 | −24,829 | D5 | −301,490 |

| A6 | 18,502 | B6 | 3,934,700 | C6 | 25,426 | D6 | 318,420 |

| A7 | −10,809 | B7 | −278,200 | C7 | −14,352 | D7 | −184,480 |

| A8 | 2671.2 | B8 | 558,520 | C8 | 3446 | D8 | 45,270 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Zhou, Y.; Xu, L.; Sun, Y. Hot Deformation Behaviors and Dynamic Softening Mechanisms of As-Cast XM-19 Super Austenitic Stainless Steel. Metals 2025, 15, 334. https://doi.org/10.3390/met15030334

Cao L, Zhou Y, Xu L, Sun Y. Hot Deformation Behaviors and Dynamic Softening Mechanisms of As-Cast XM-19 Super Austenitic Stainless Steel. Metals. 2025; 15(3):334. https://doi.org/10.3390/met15030334

Chicago/Turabian StyleCao, Lujun, Yucheng Zhou, Liujie Xu, and Yuanhang Sun. 2025. "Hot Deformation Behaviors and Dynamic Softening Mechanisms of As-Cast XM-19 Super Austenitic Stainless Steel" Metals 15, no. 3: 334. https://doi.org/10.3390/met15030334

APA StyleCao, L., Zhou, Y., Xu, L., & Sun, Y. (2025). Hot Deformation Behaviors and Dynamic Softening Mechanisms of As-Cast XM-19 Super Austenitic Stainless Steel. Metals, 15(3), 334. https://doi.org/10.3390/met15030334